Patents

Literature

42results about How to "Protection length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical device applications of nanostructured surfaces

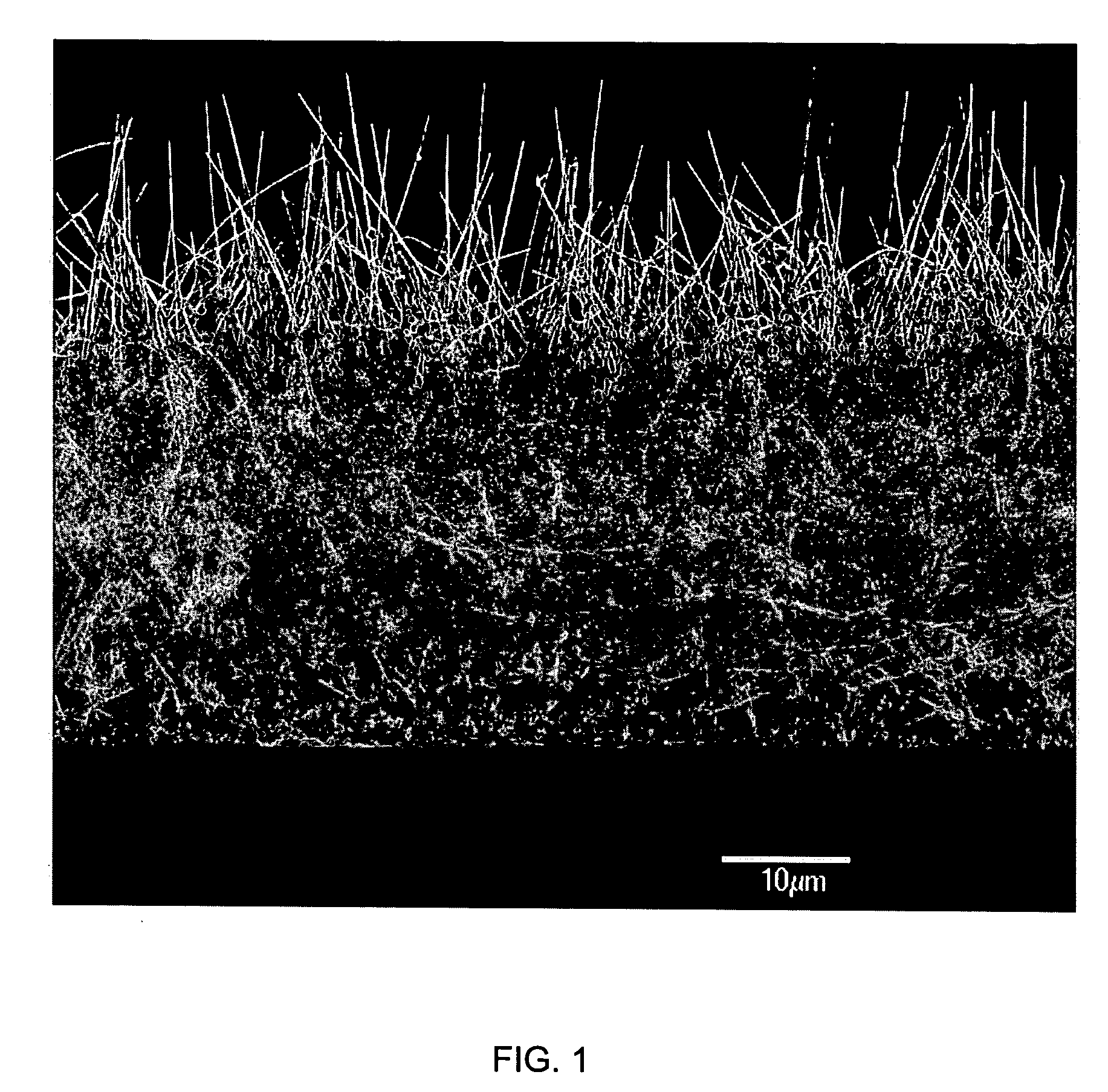

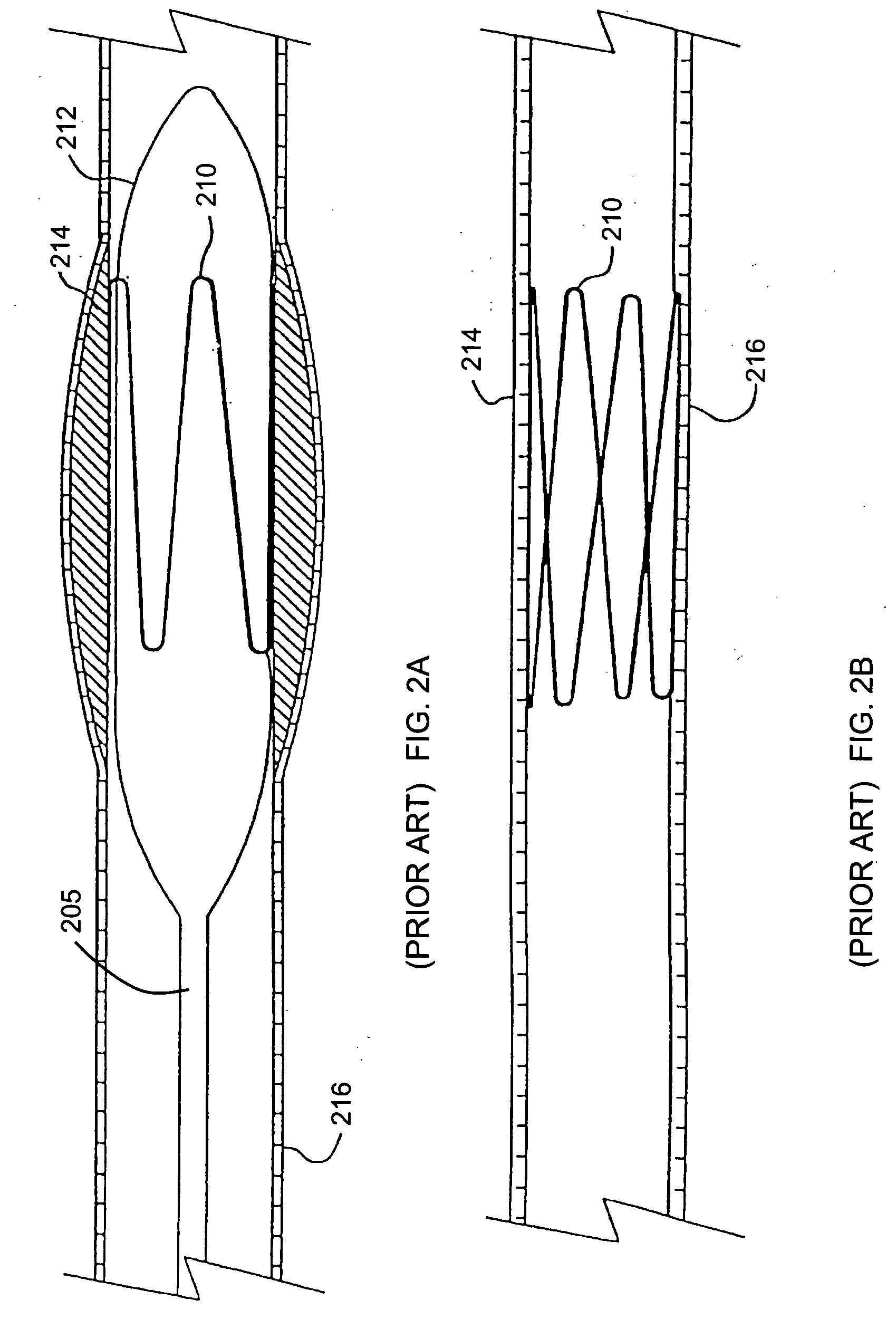

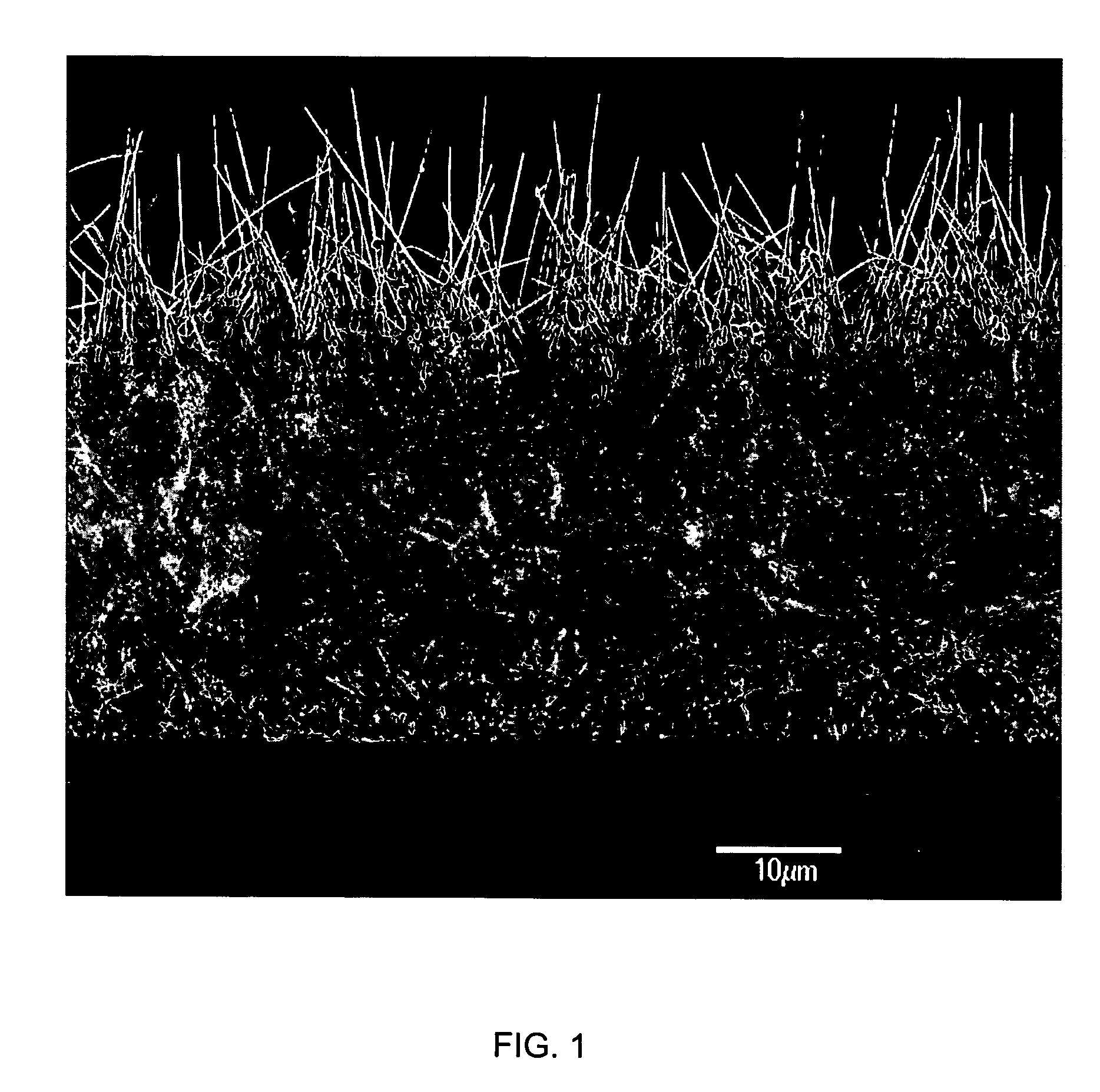

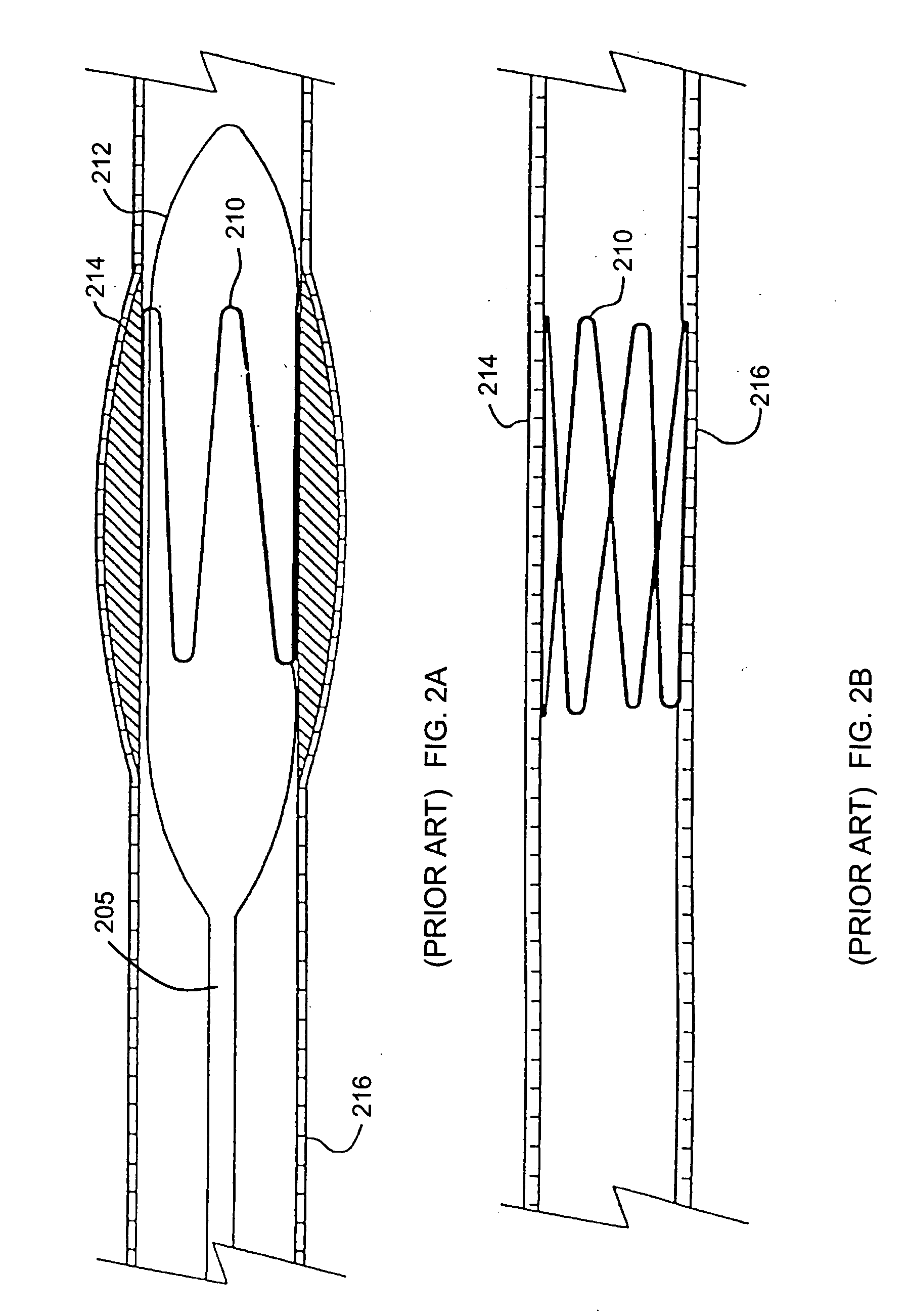

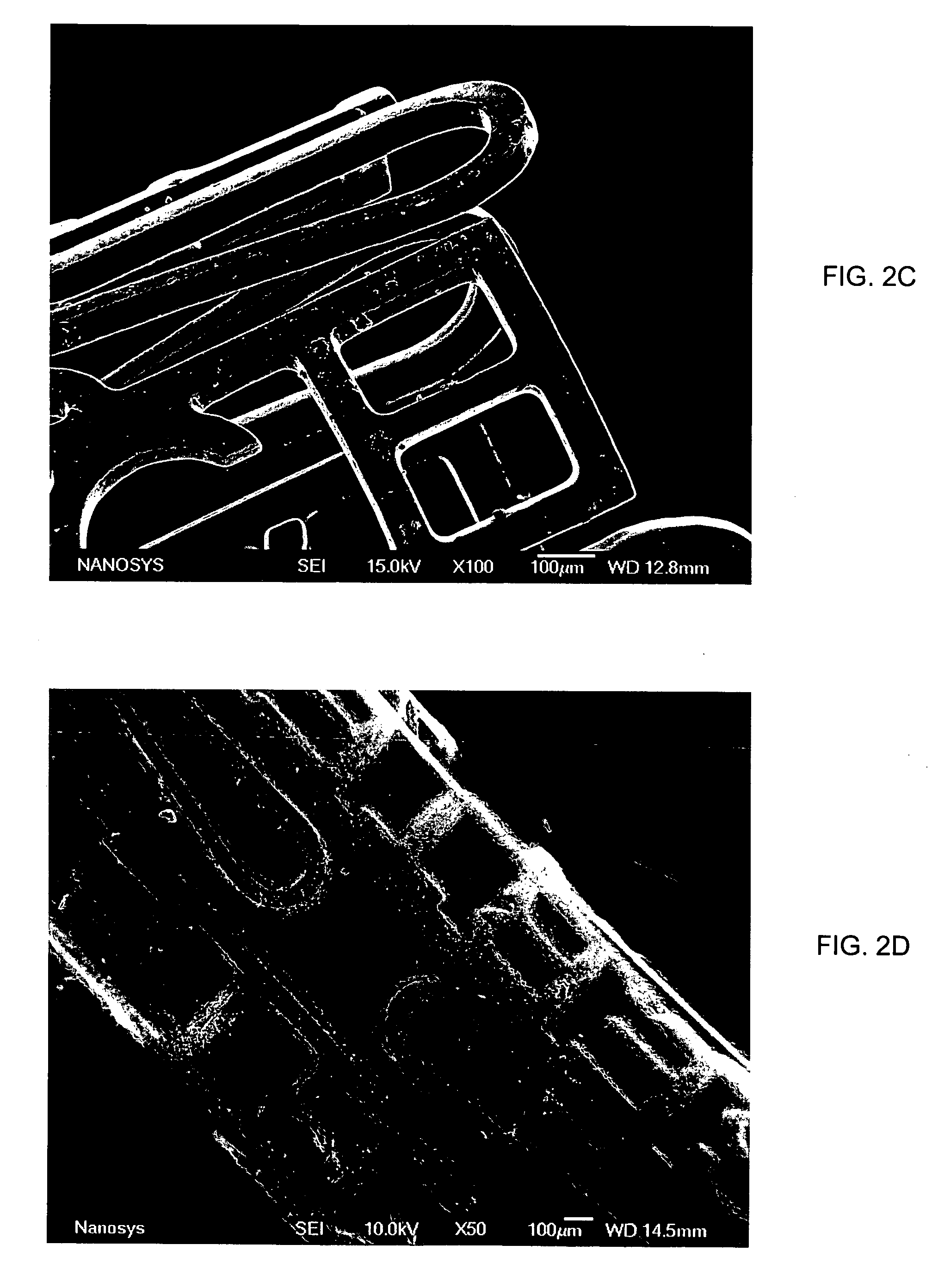

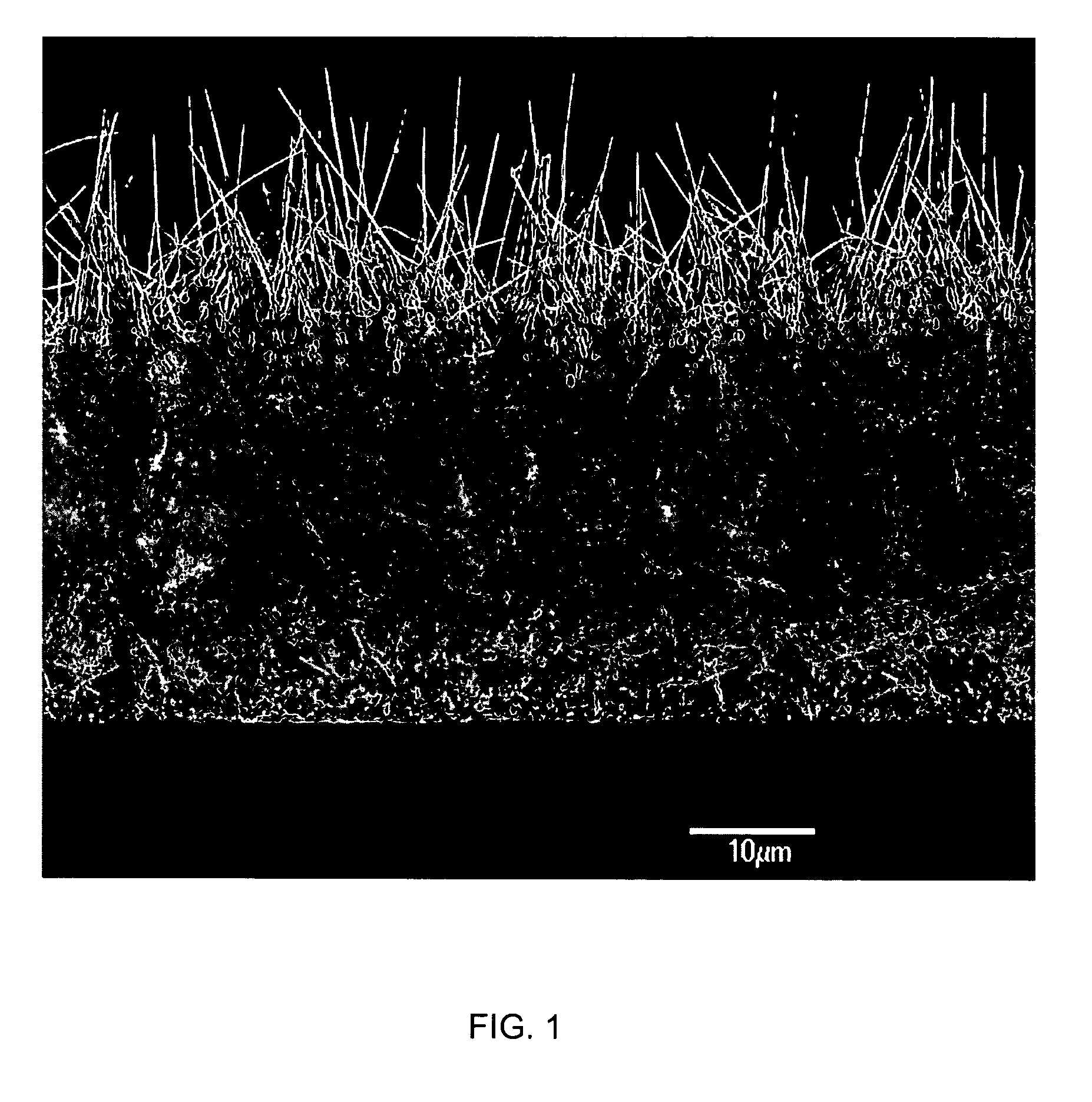

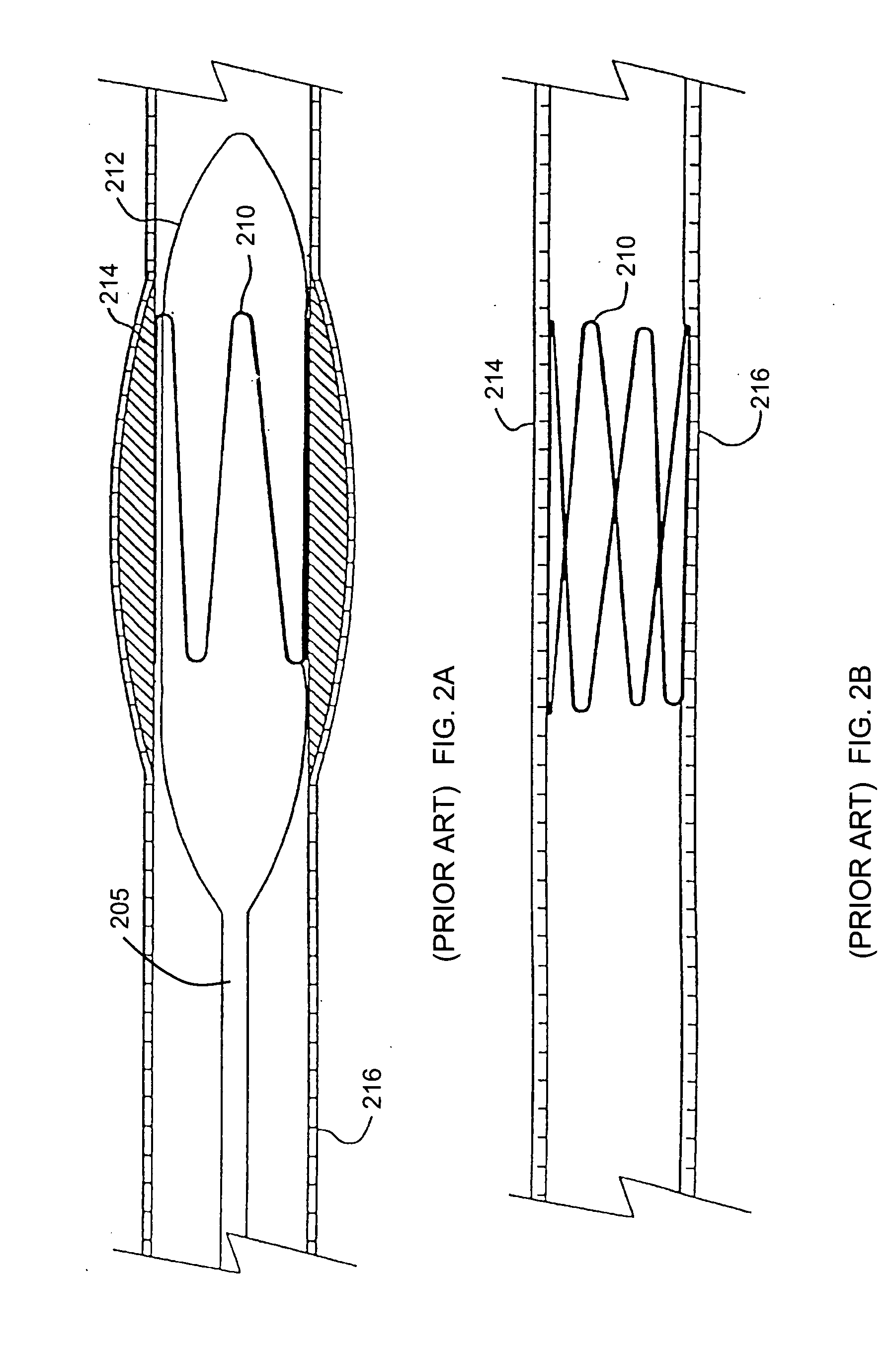

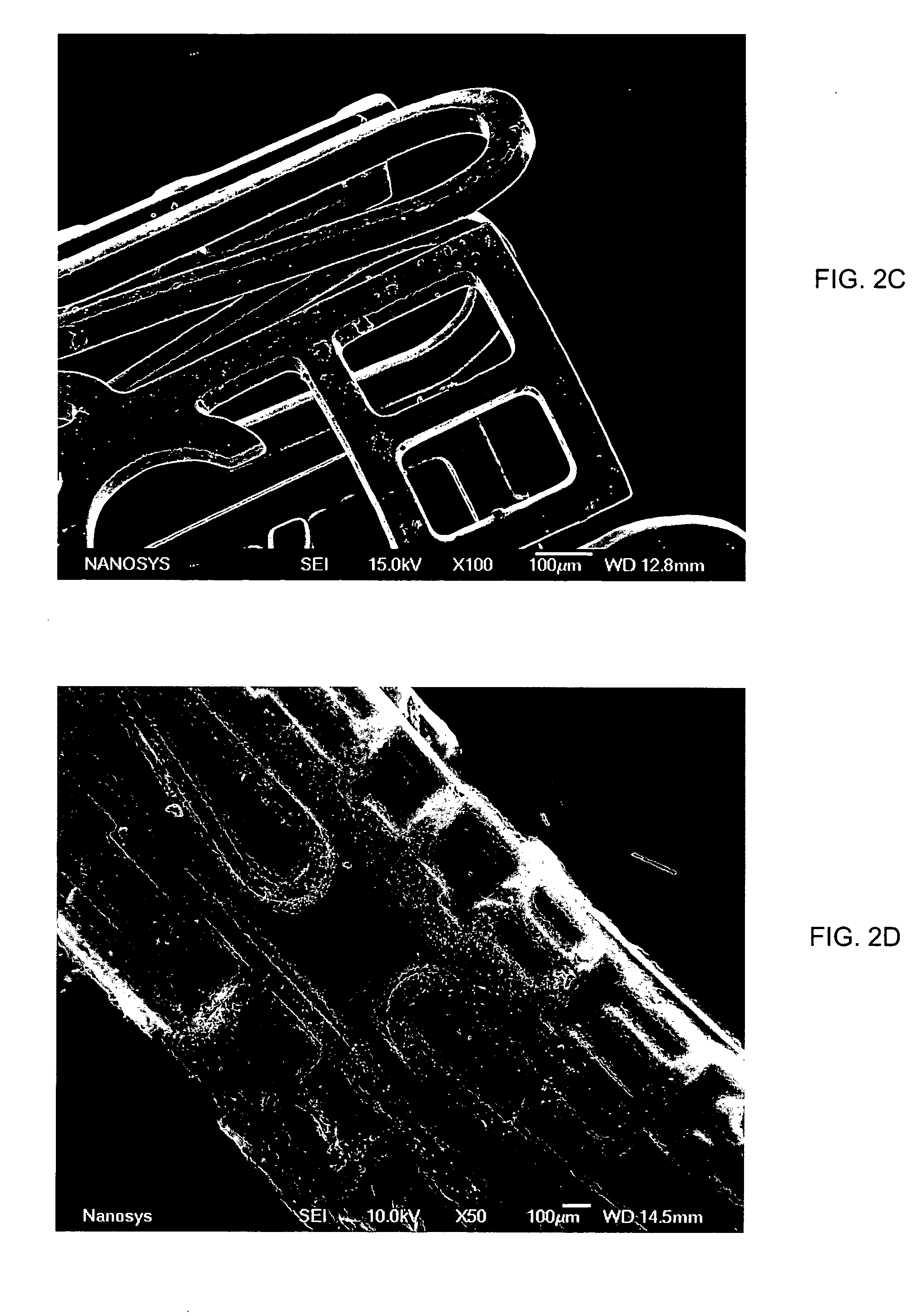

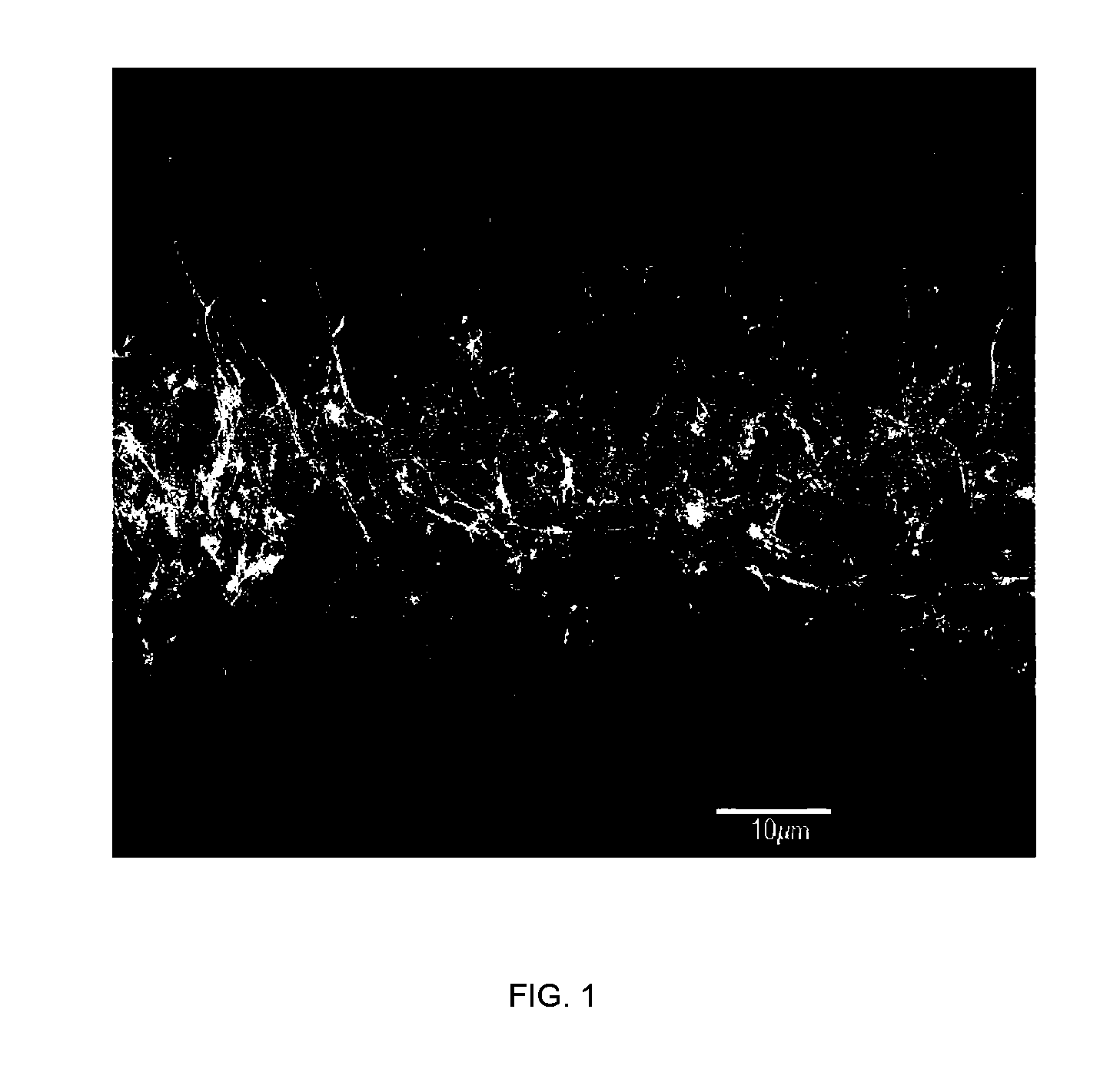

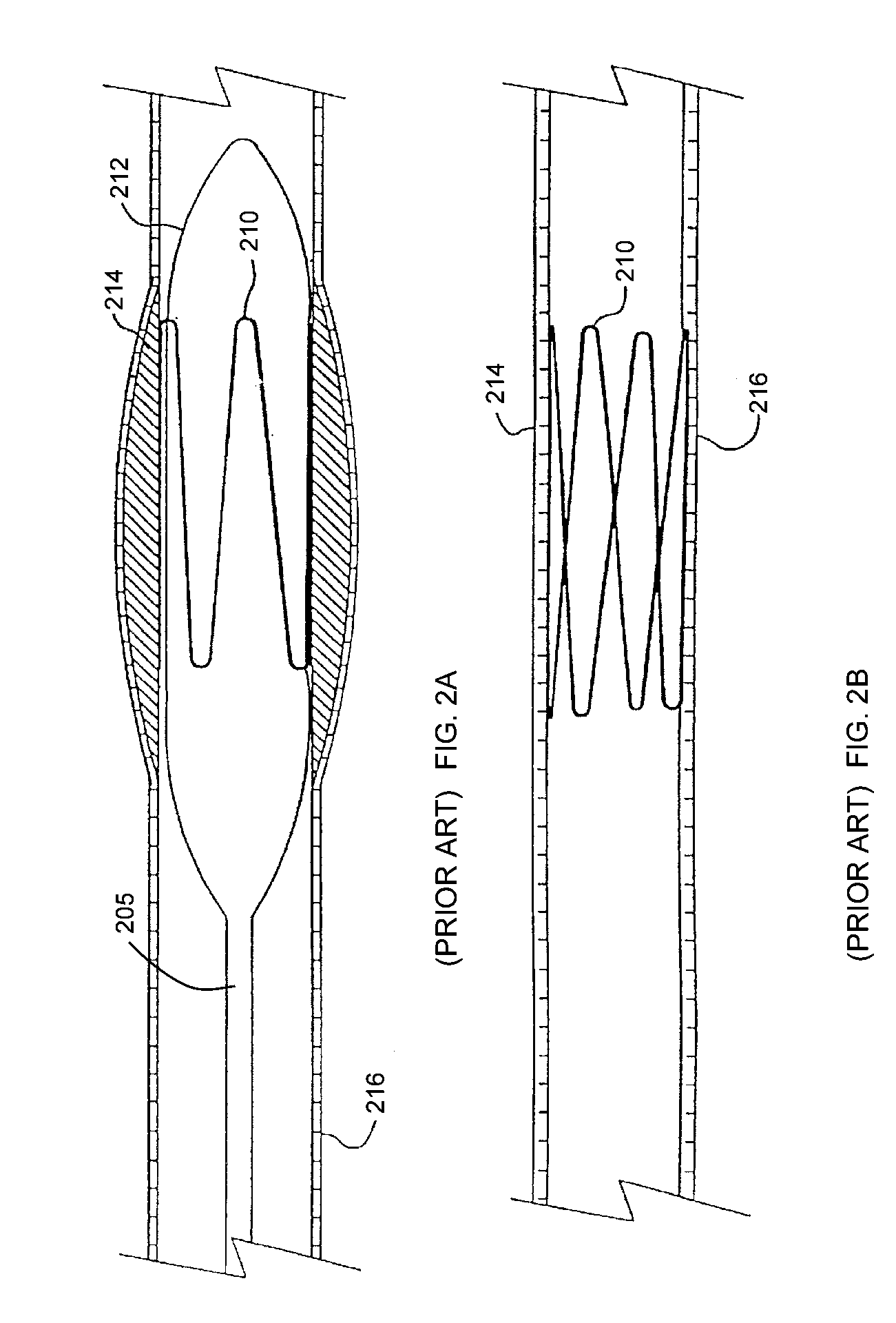

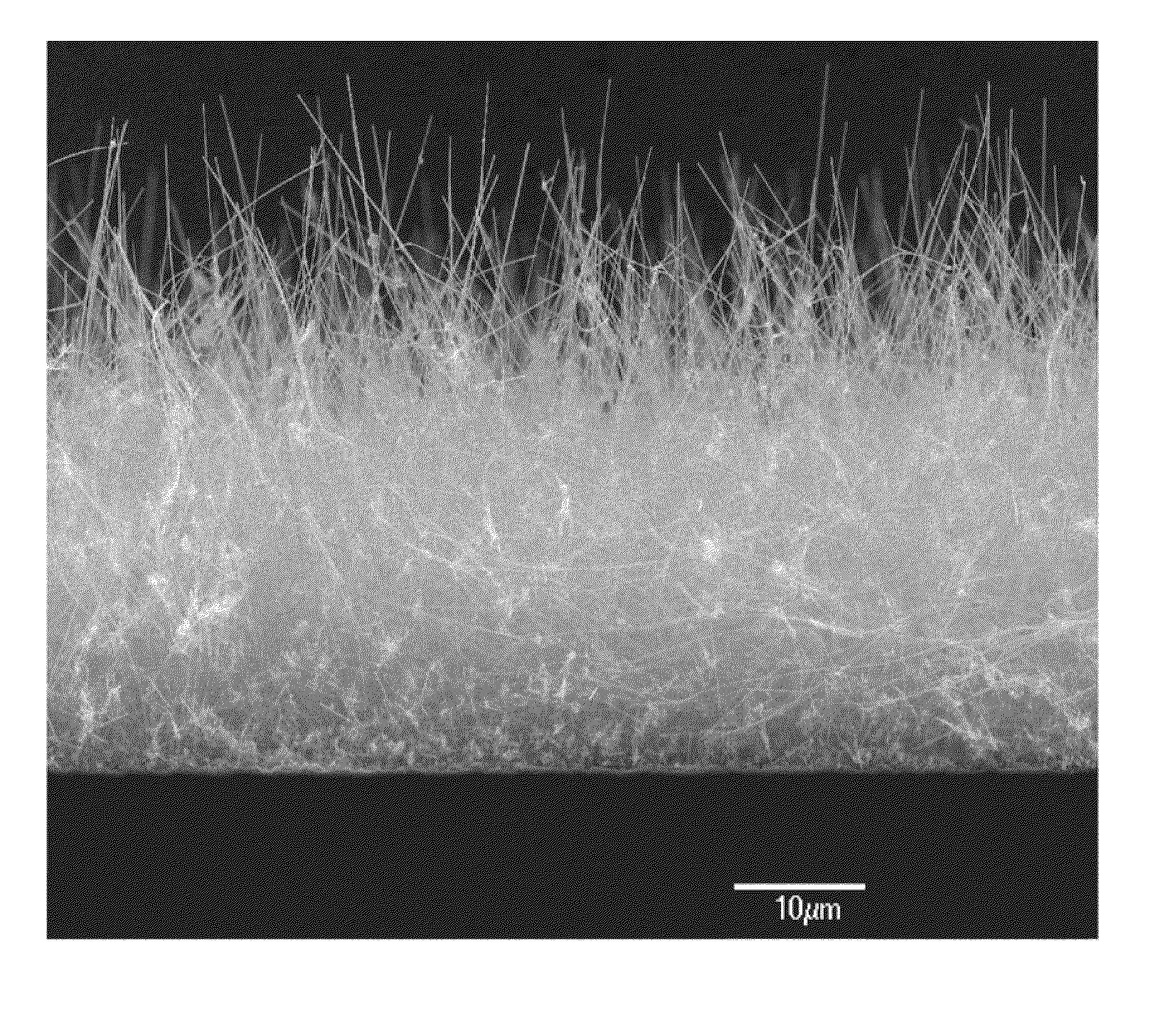

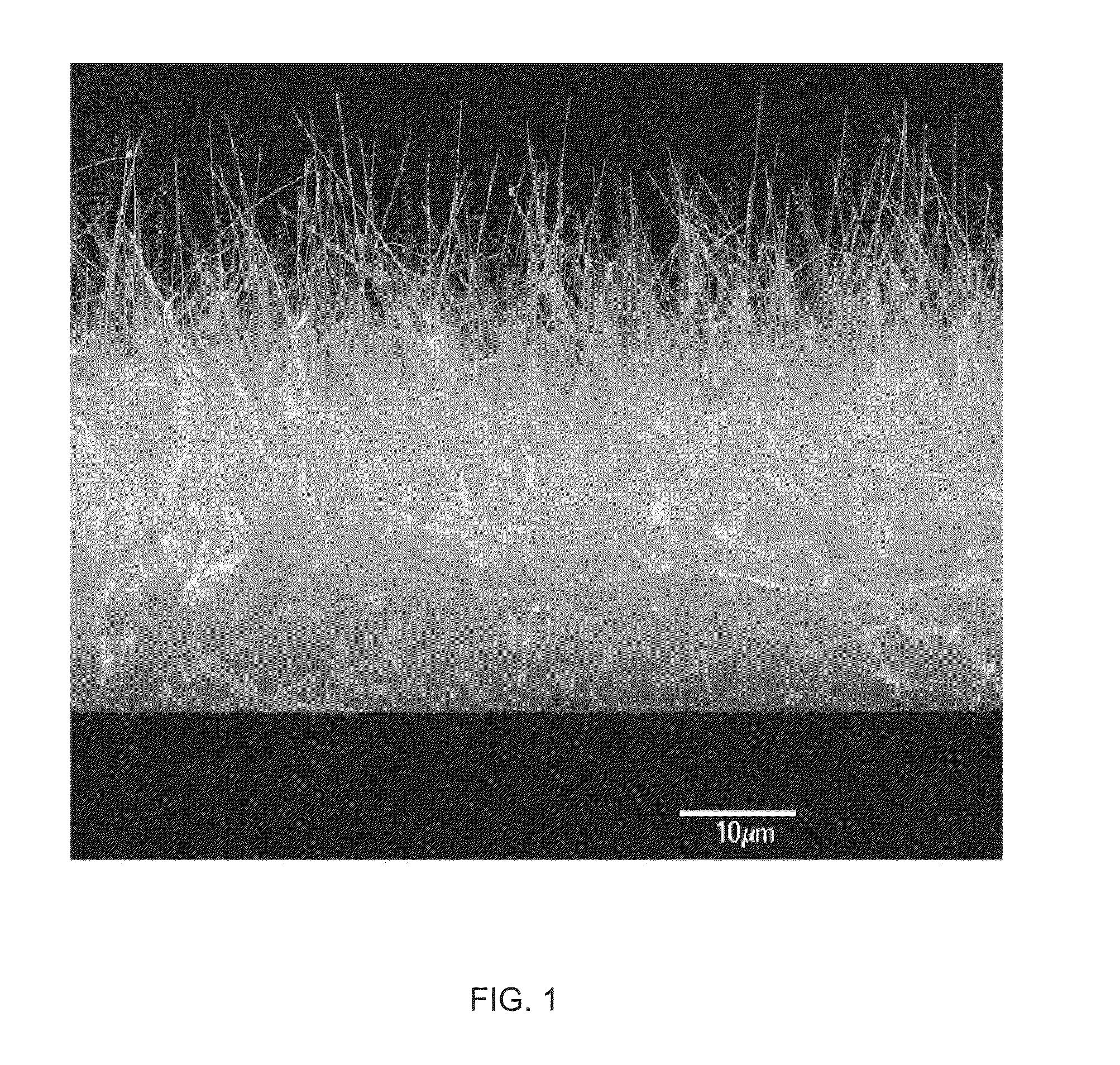

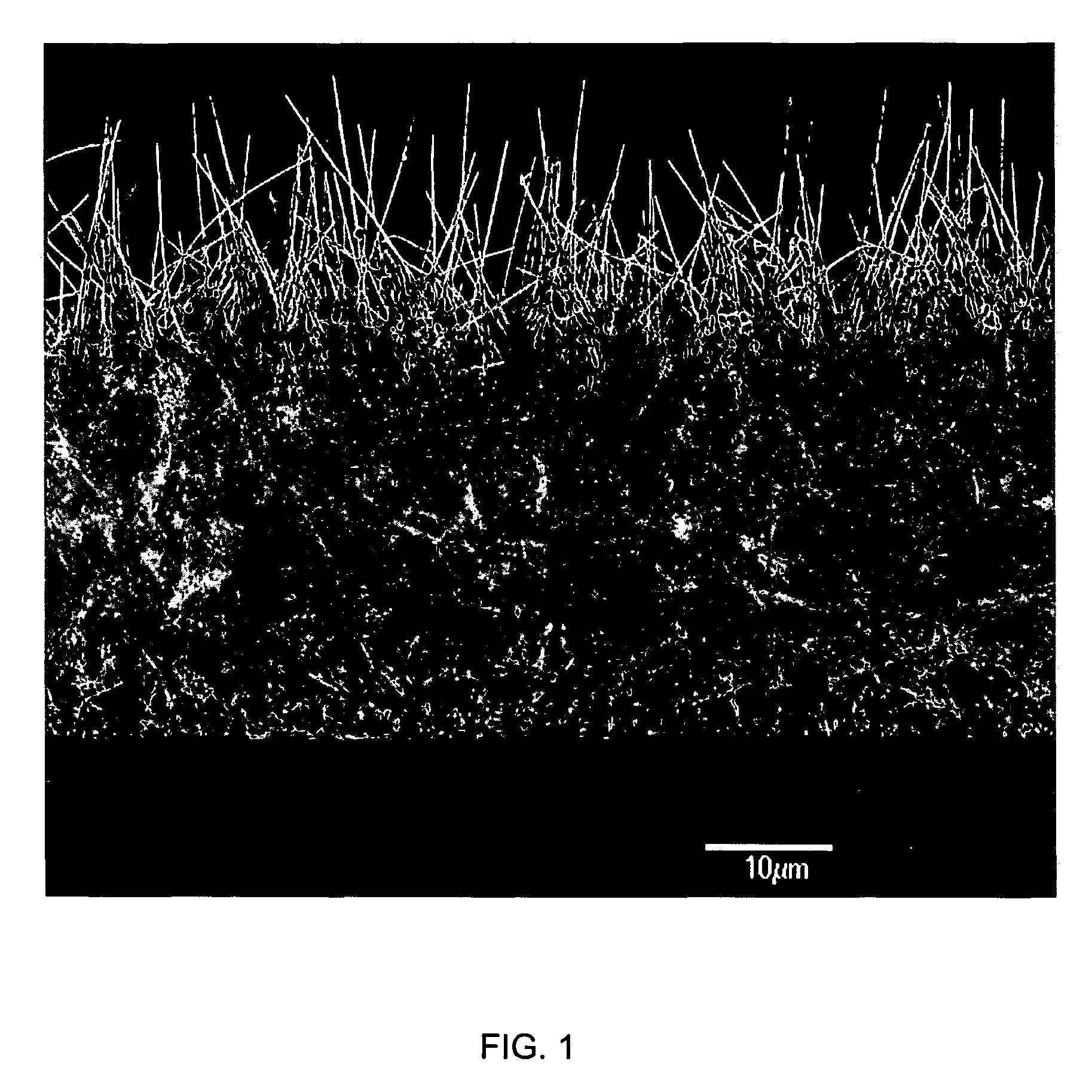

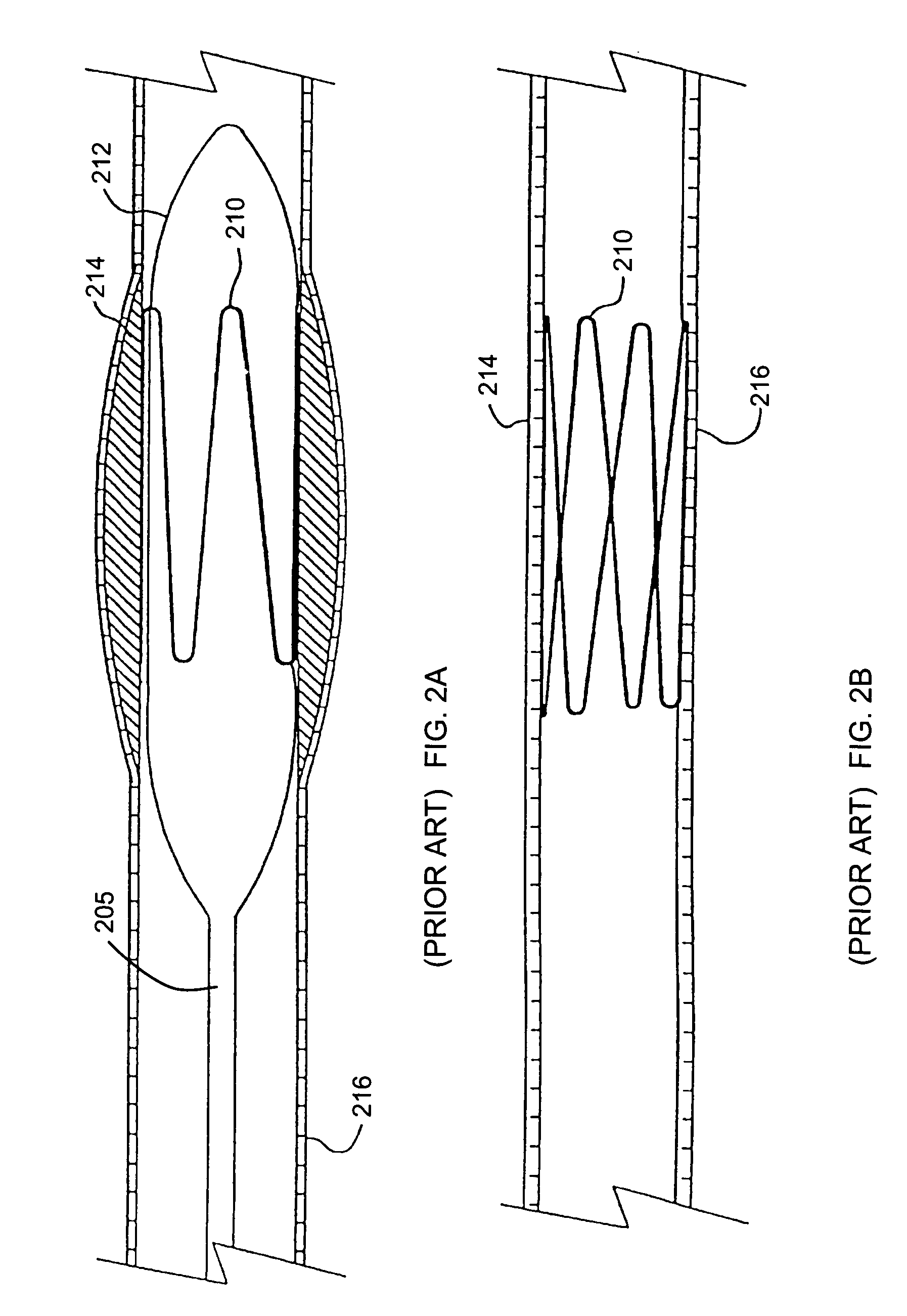

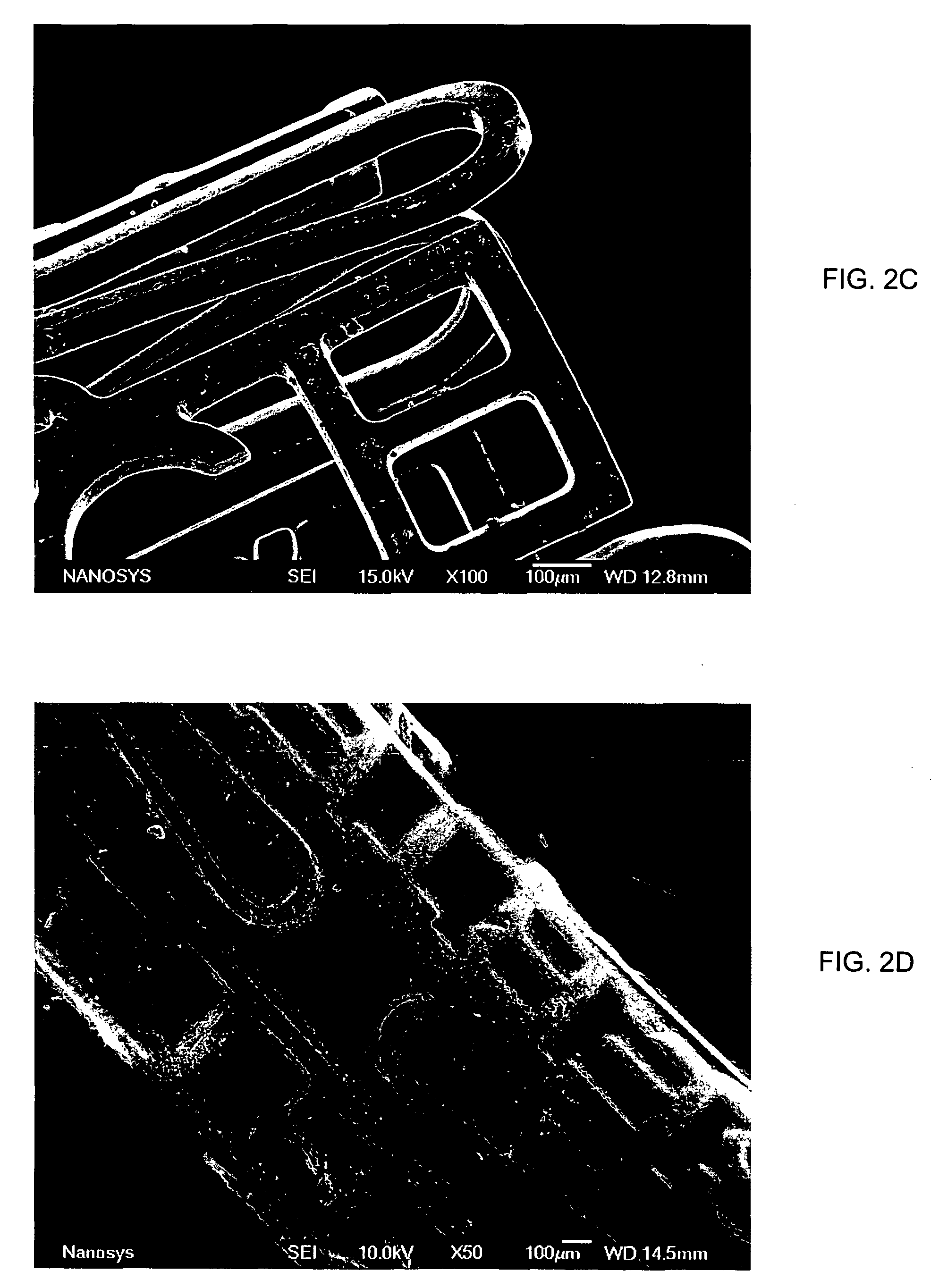

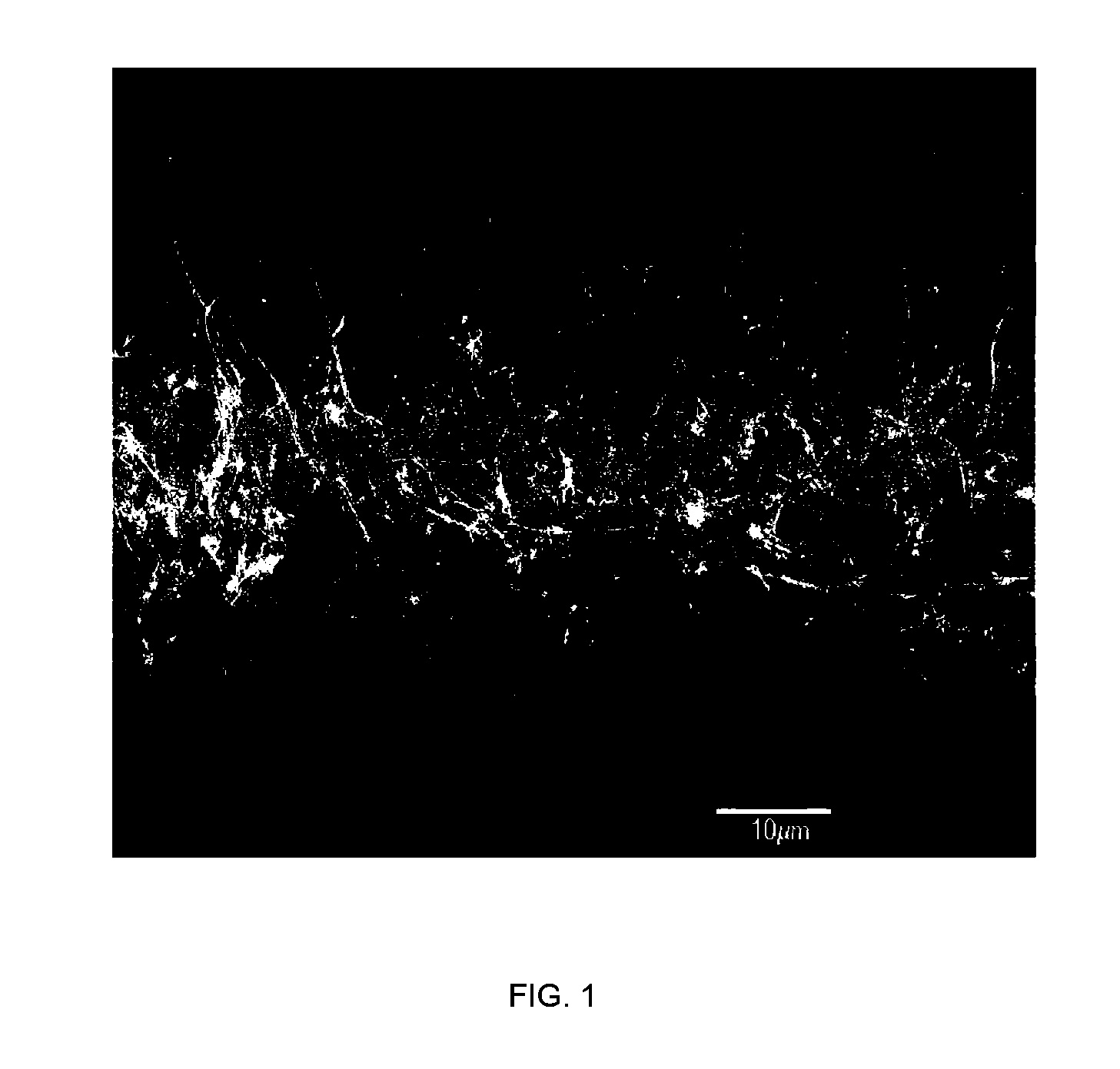

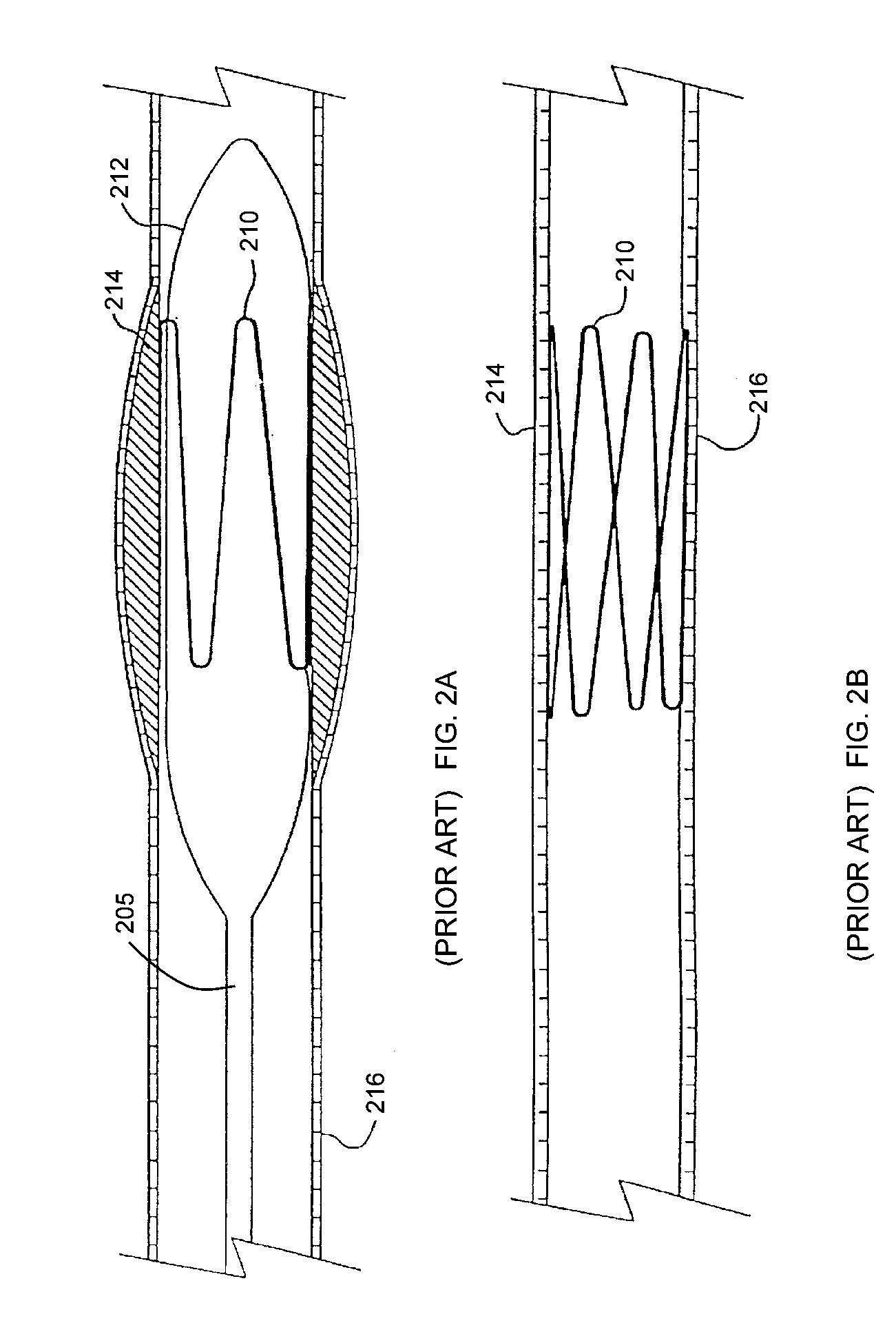

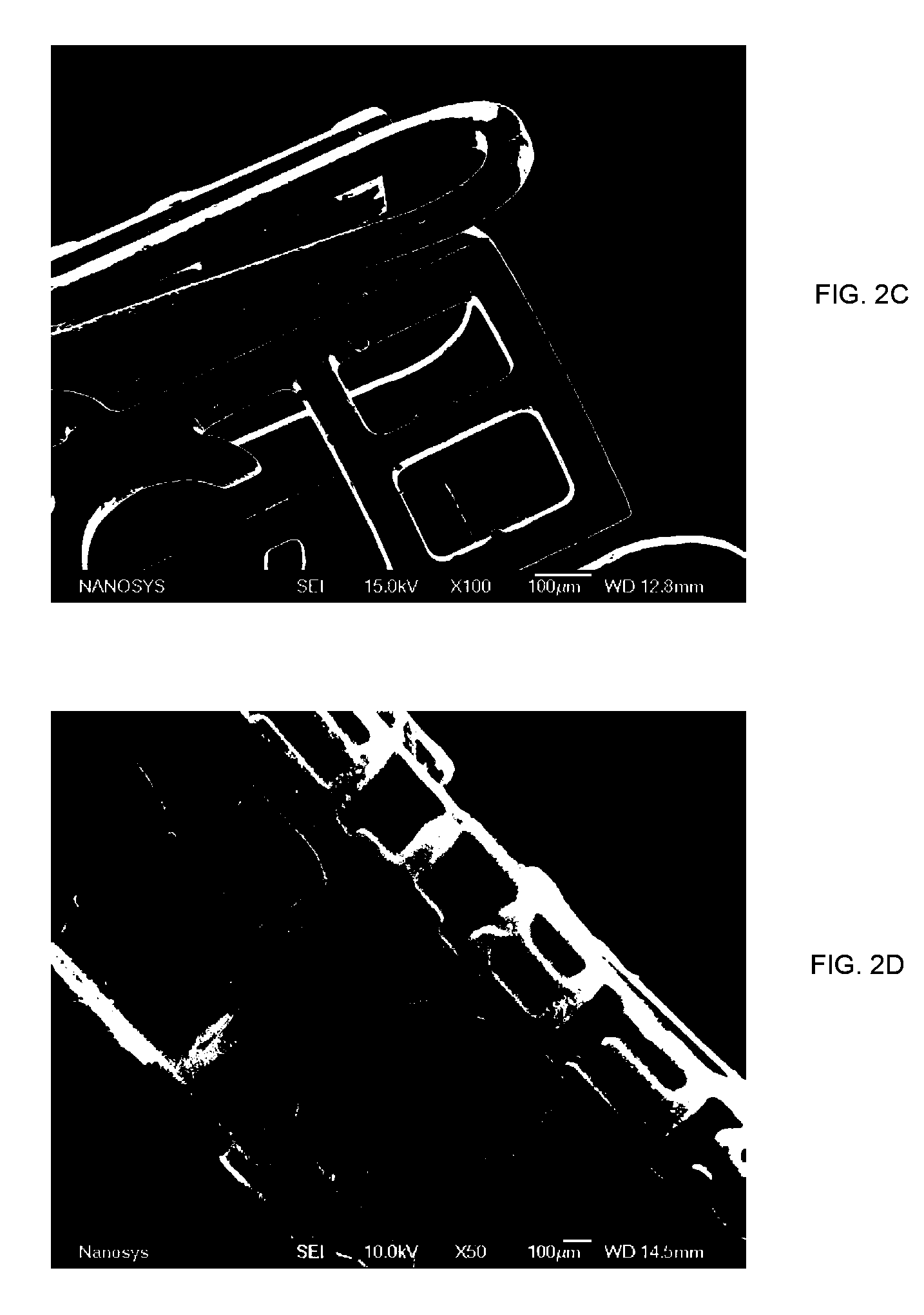

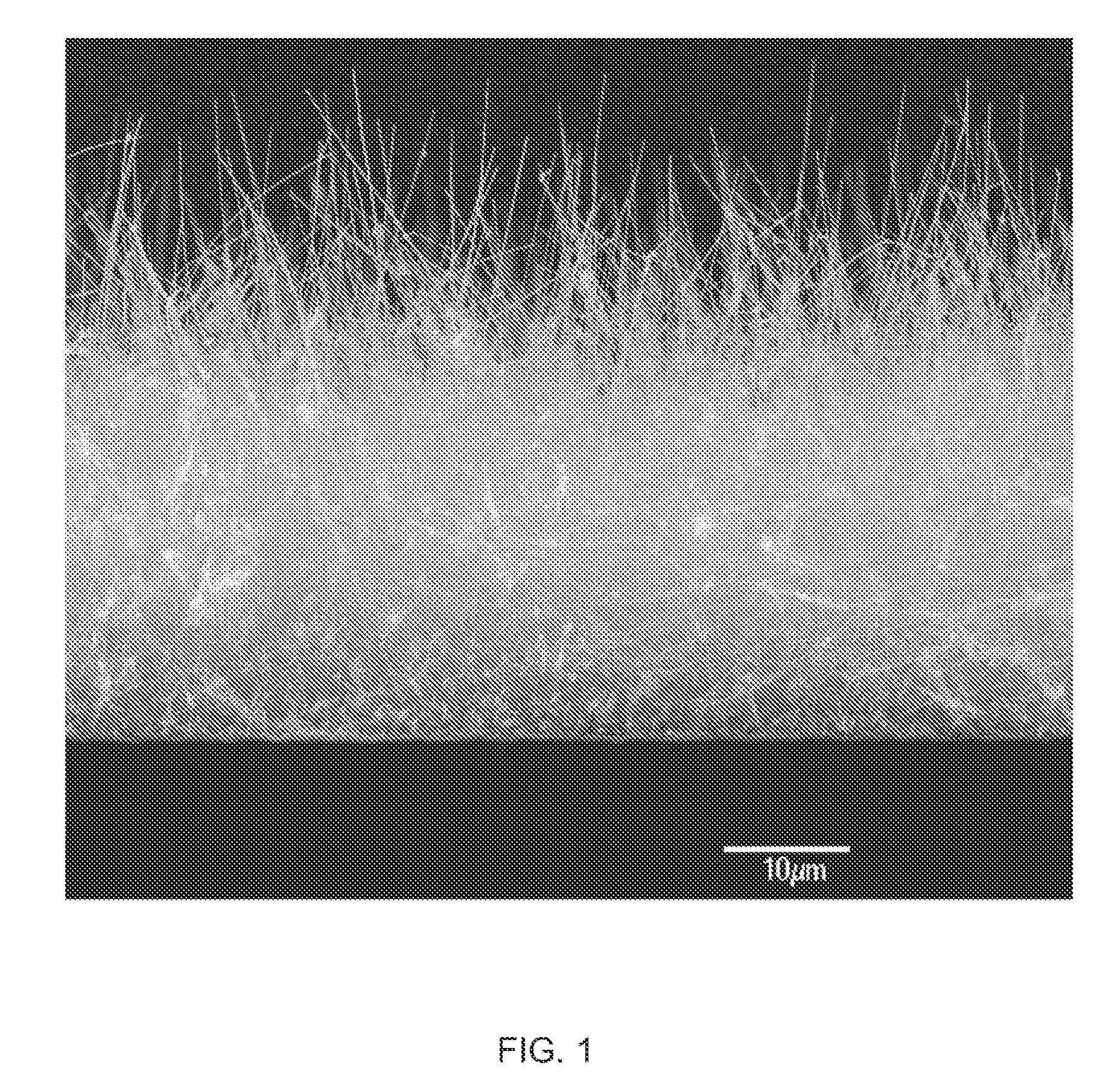

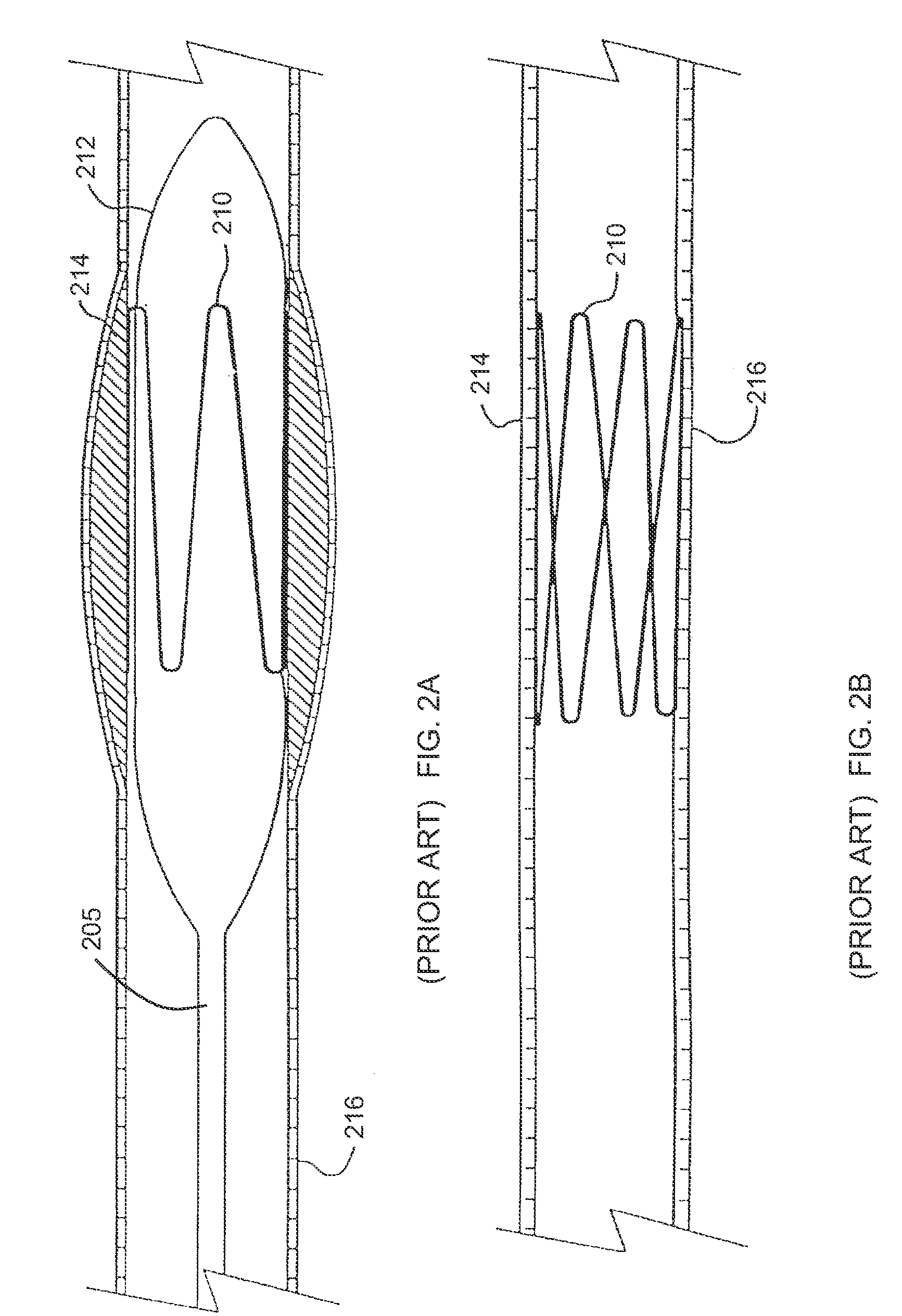

InactiveUS20050038498A1Fine surfacePrevent/reduce bio-foulingAntibacterial agentsMaterial nanotechnologyFiberNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices.

Owner:NANOSYS INC

Medical device applications of nanostructured surfaces

InactiveUS20060204738A1Improve adhesionIncrease frictionBiocideMaterial nanotechnologyOsteoblastNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, methods for enhancing cellular functions on a surface of a medical device implant are disclosed which generally comprise providing a medical device implant comprising a plurality of nanofibers (e.g., nanowires) thereon and exposing the medical device implant to cells such as osteoblasts.

Owner:GLO TECH LLC

Medical device applications of nanostructured surfaces

InactiveUS20050221072A1Fine surfacePrevent/reduce bio-foulingNanomedicinePharmaceutical delivery mechanismMedicineOsteoblast

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, methods for enhancing cellular functions on a surface of a medical device implant are disclosed which generally comprise providing a medical device implant comprising a plurality of nanofibers (e.g., nanowires) thereon and exposing the medical device implant to cells such as osteoblasts.

Owner:NANOSYS INC

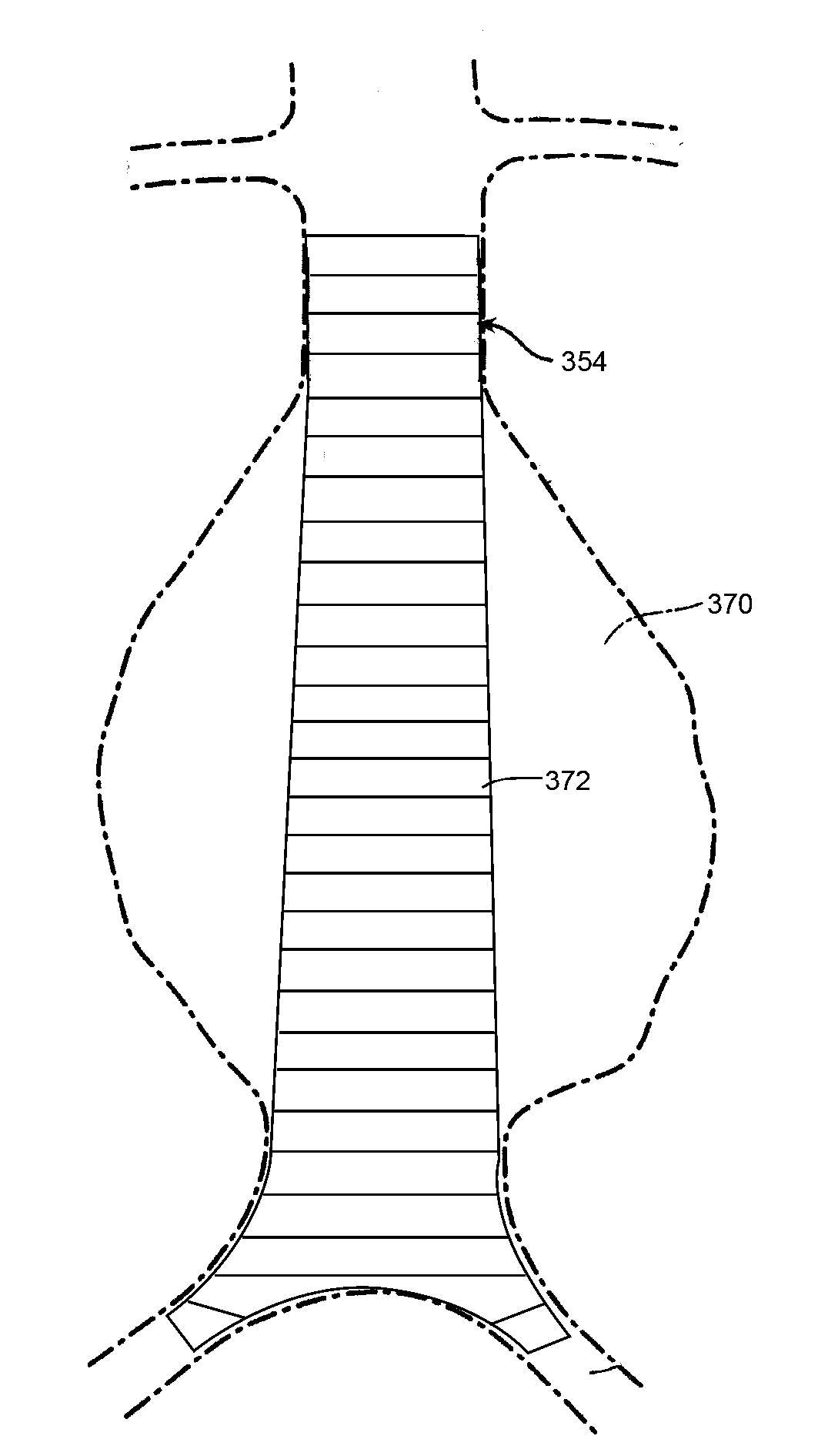

Medical Device Applications of Nanostructured Surfaces

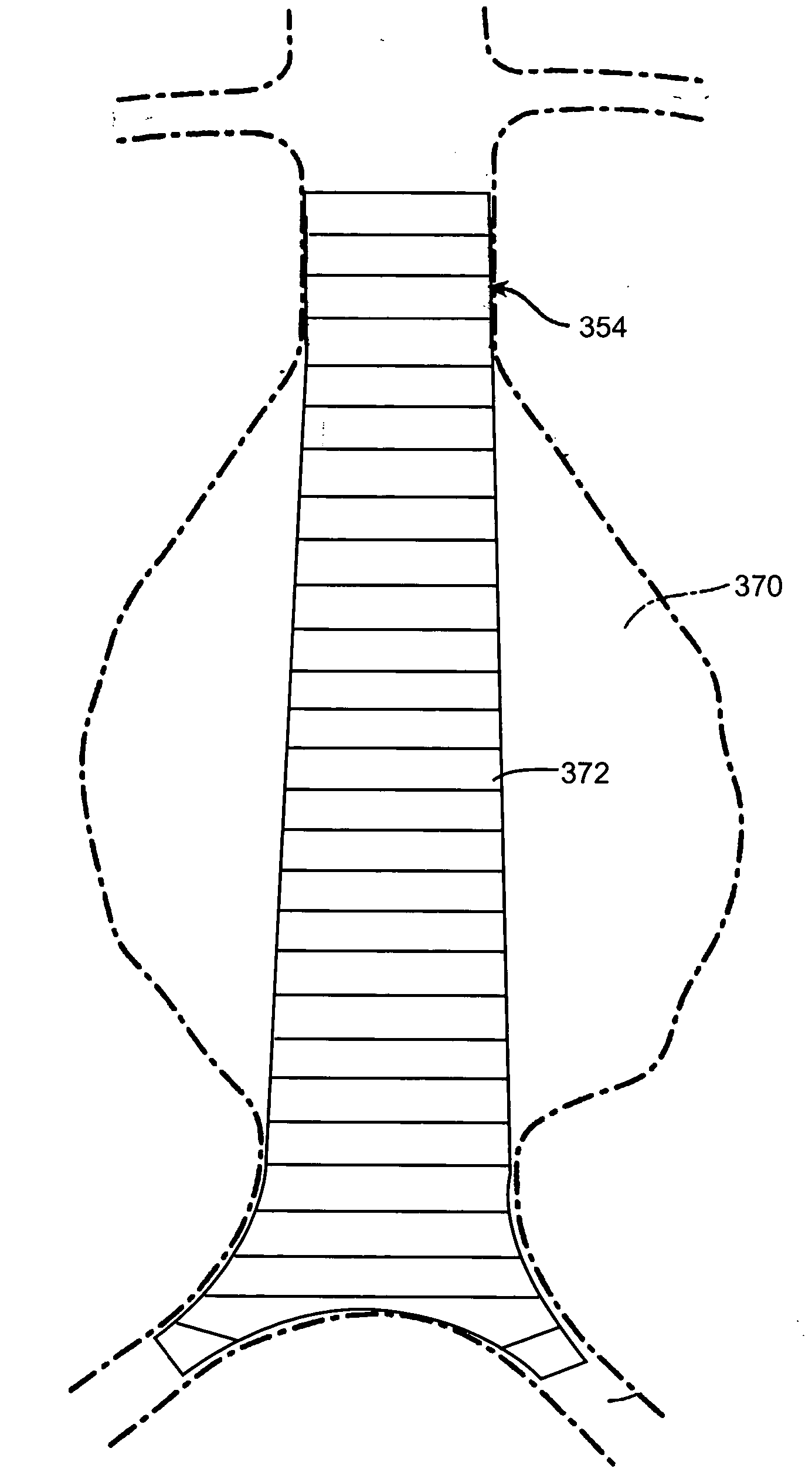

ActiveUS20070282247A1Increase heightPrevent/reduce bio-foulingNanotechElectrotherapyMedicineNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, a method of administering a composition to a patient is disclosed which comprises providing a composition-eluting device, said composition-eluting device comprising at least a first surface and a plurality of nanostructures attached to the first surface, and introducing the composition-eluting device into the body of the patient.

Owner:RGT UNIV OF CALIFORNIA +1

Medical Device Applications of Nanostructured Surfaces

InactiveUS20110201984A1Improve adhesionIncrease frictionMaterial nanotechnologyInternal electrodesFiberOsteoblast

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, methods for enhancing cellular functions on a surface of a medical device implant are disclosed which generally comprise providing a medical device implant comprising a plurality of nanofibers (e.g., nanowires) thereon and exposing the medical device implant to cells such as osteoblasts.

Owner:NANOSYS INC

Medical device applications of nanostructured surfaces

Owner:GLO TECH LLC

Medical device applications of nanostructured surfaces

ActiveUS7803574B2Improve adhesionIncrease frictionElectrotherapyNanostructure manufactureFiberNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, a method of administering a composition to a patient is disclosed which comprises providing a composition-eluting device, said composition-eluting device comprising at least a first surface and a plurality of nanostructures attached to the first surface, and introducing the composition-eluting device into the body of the patient.

Owner:RGT UNIV OF CALIFORNIA +1

Medical Device Applications of Nanostructured Surfaces

InactiveUS20090162643A1Fine surfacePrevent/reduce bio-foulingAntibacterial agentsMaterial nanotechnologyFiberNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices.

Owner:NANOSYS INC

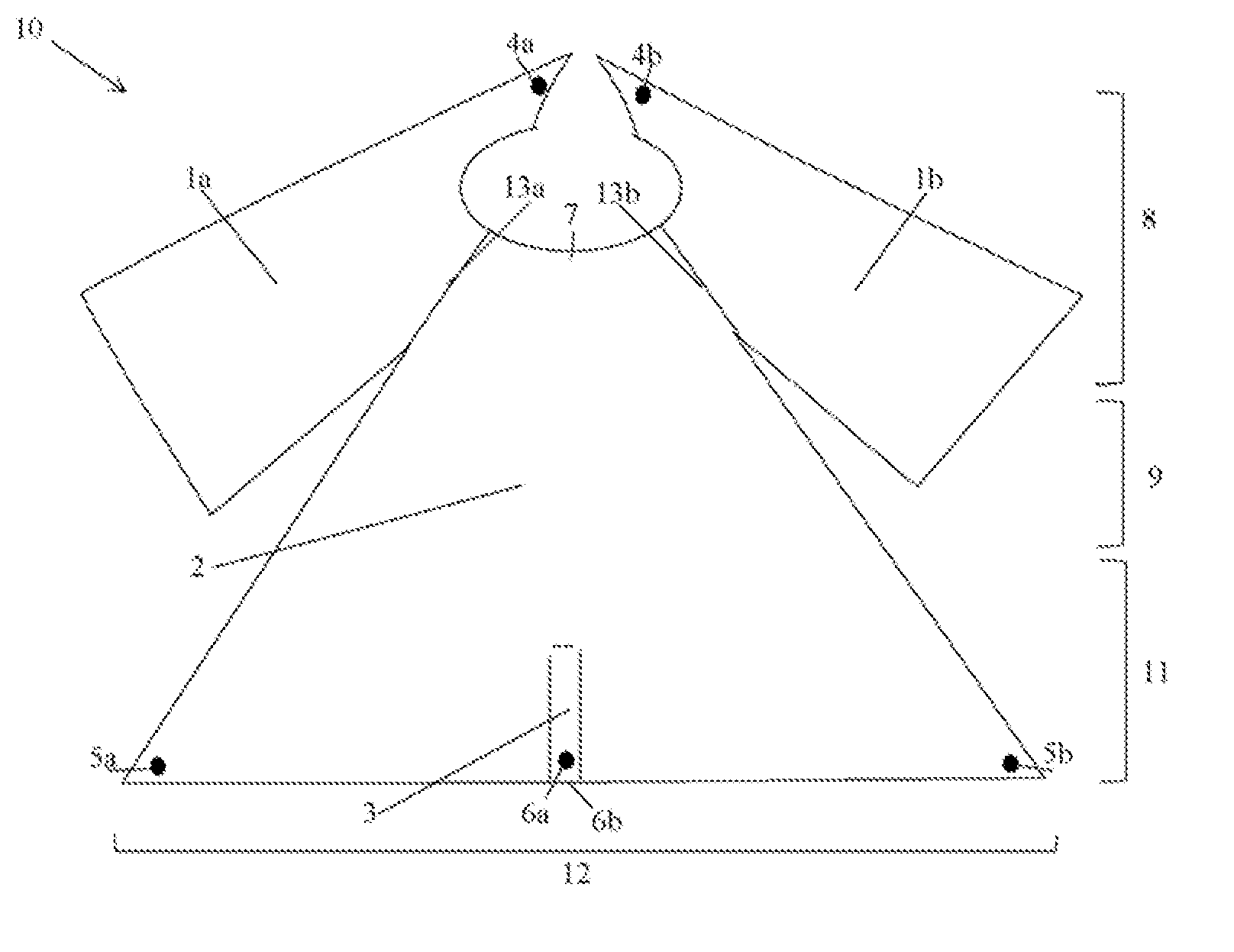

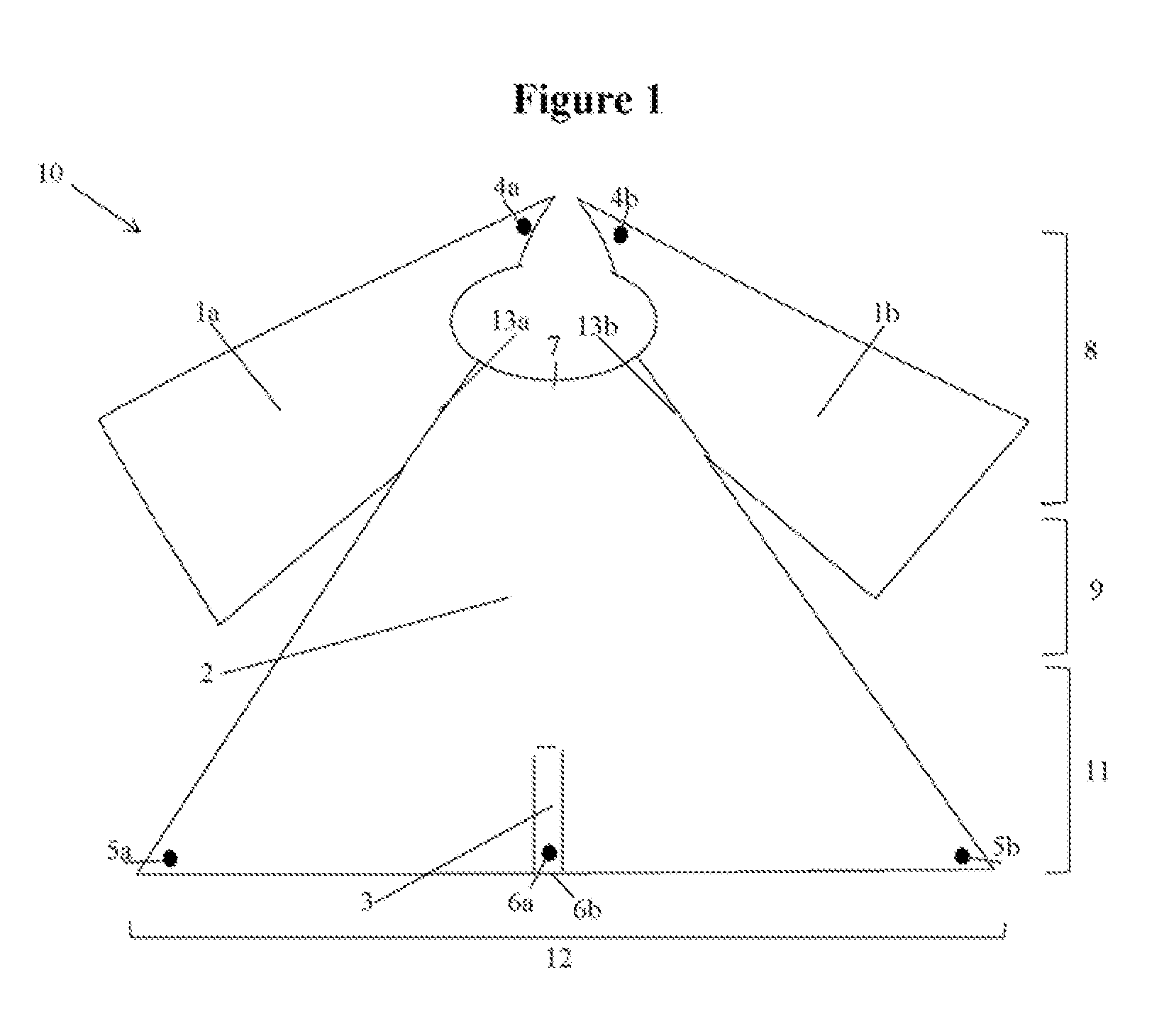

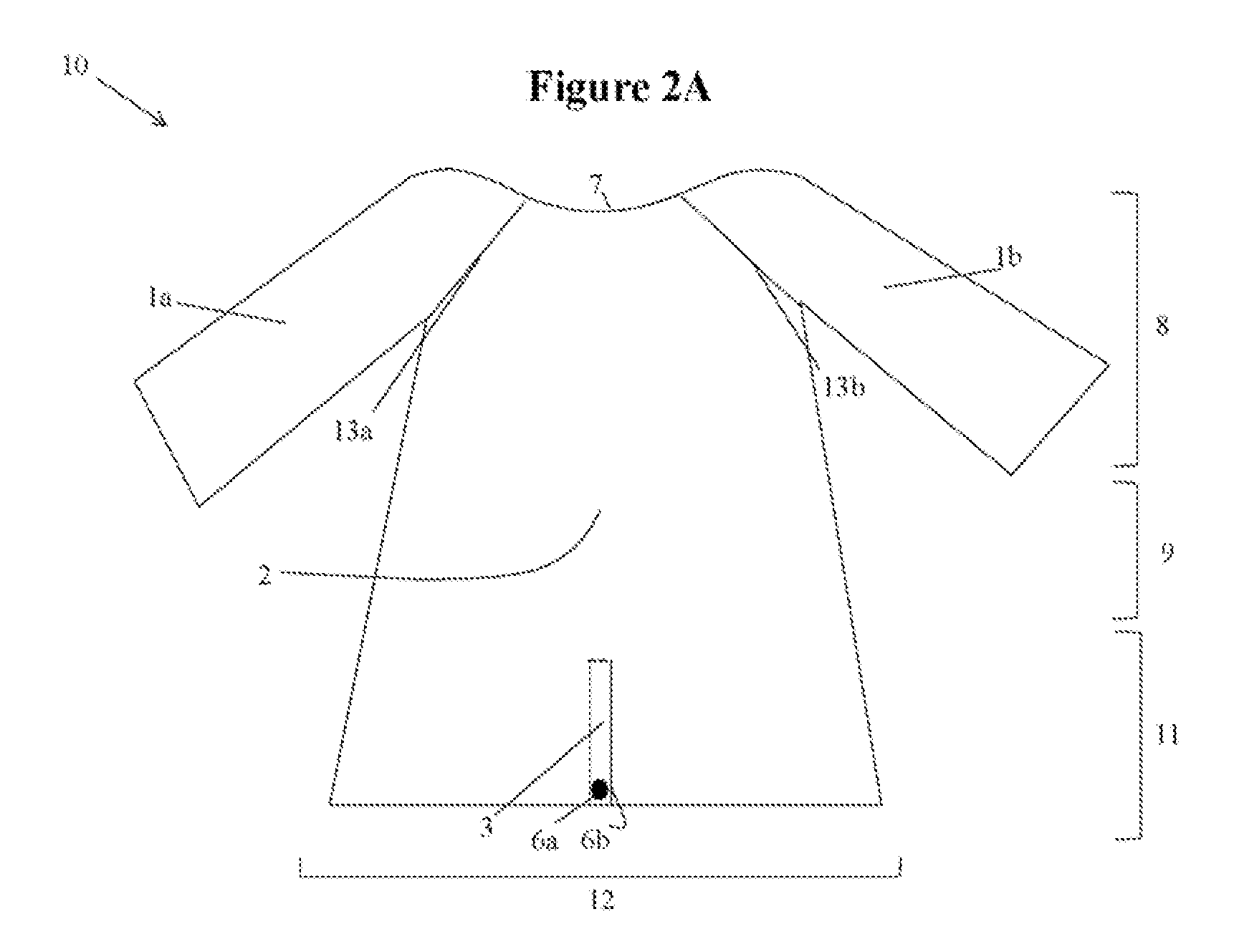

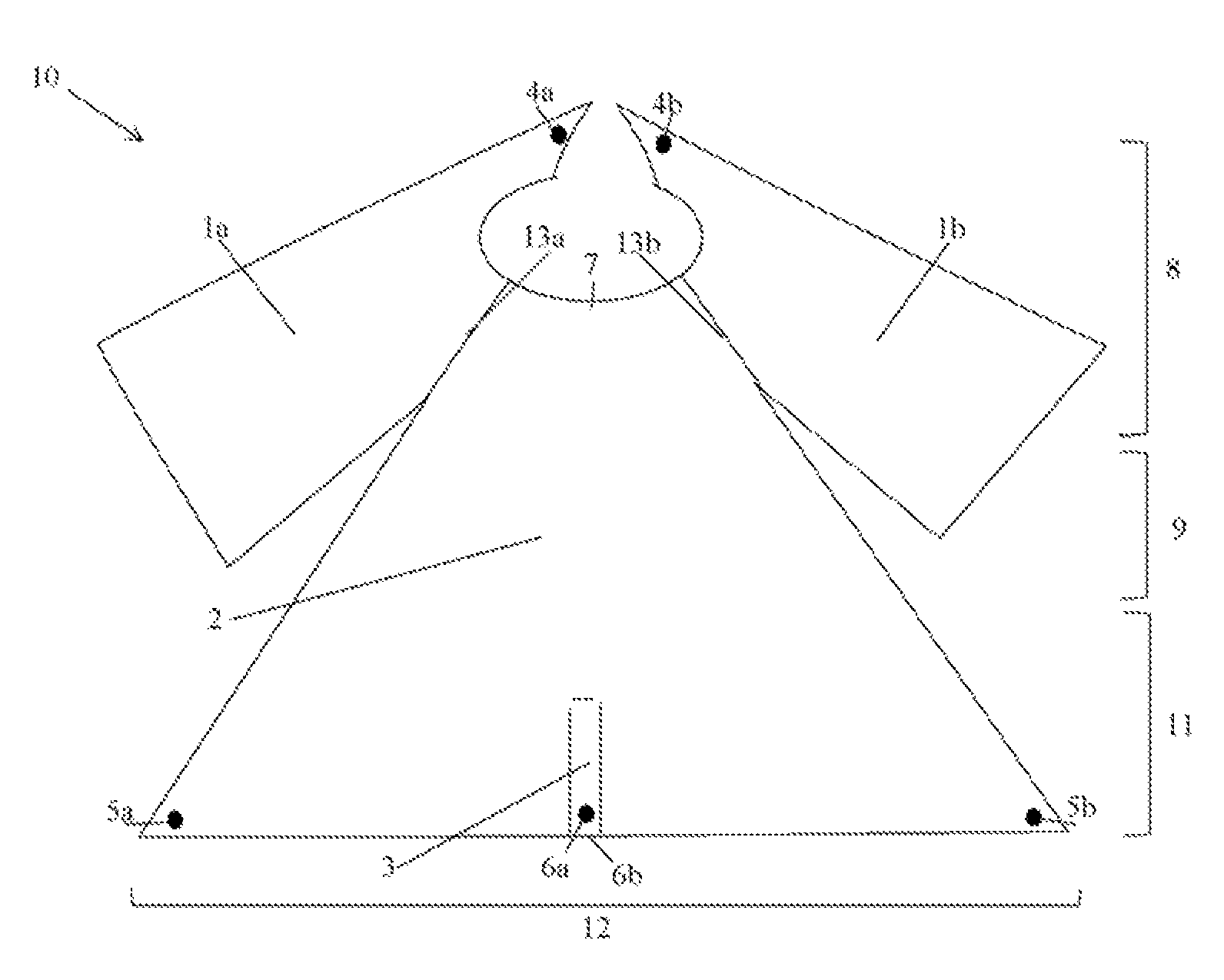

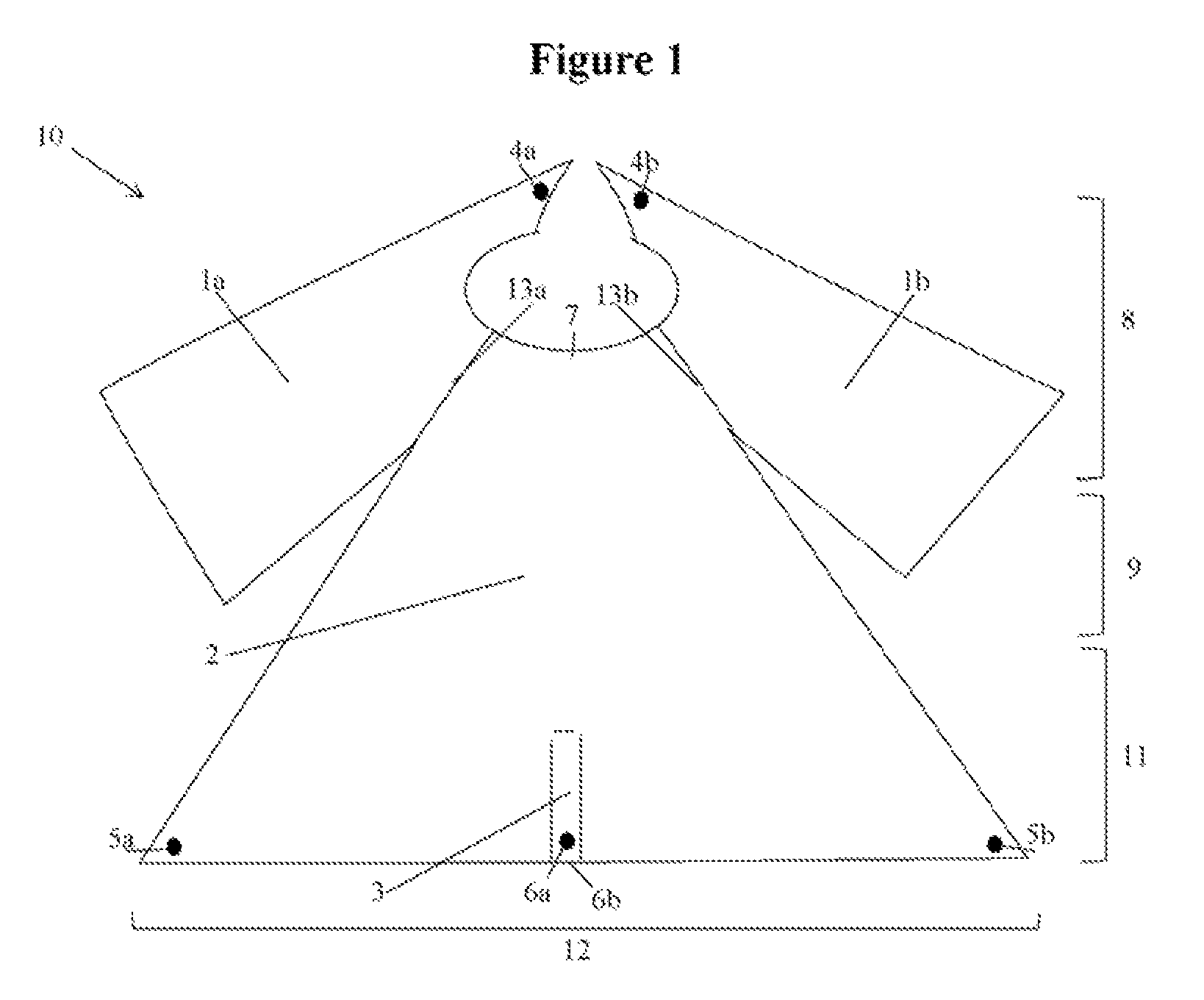

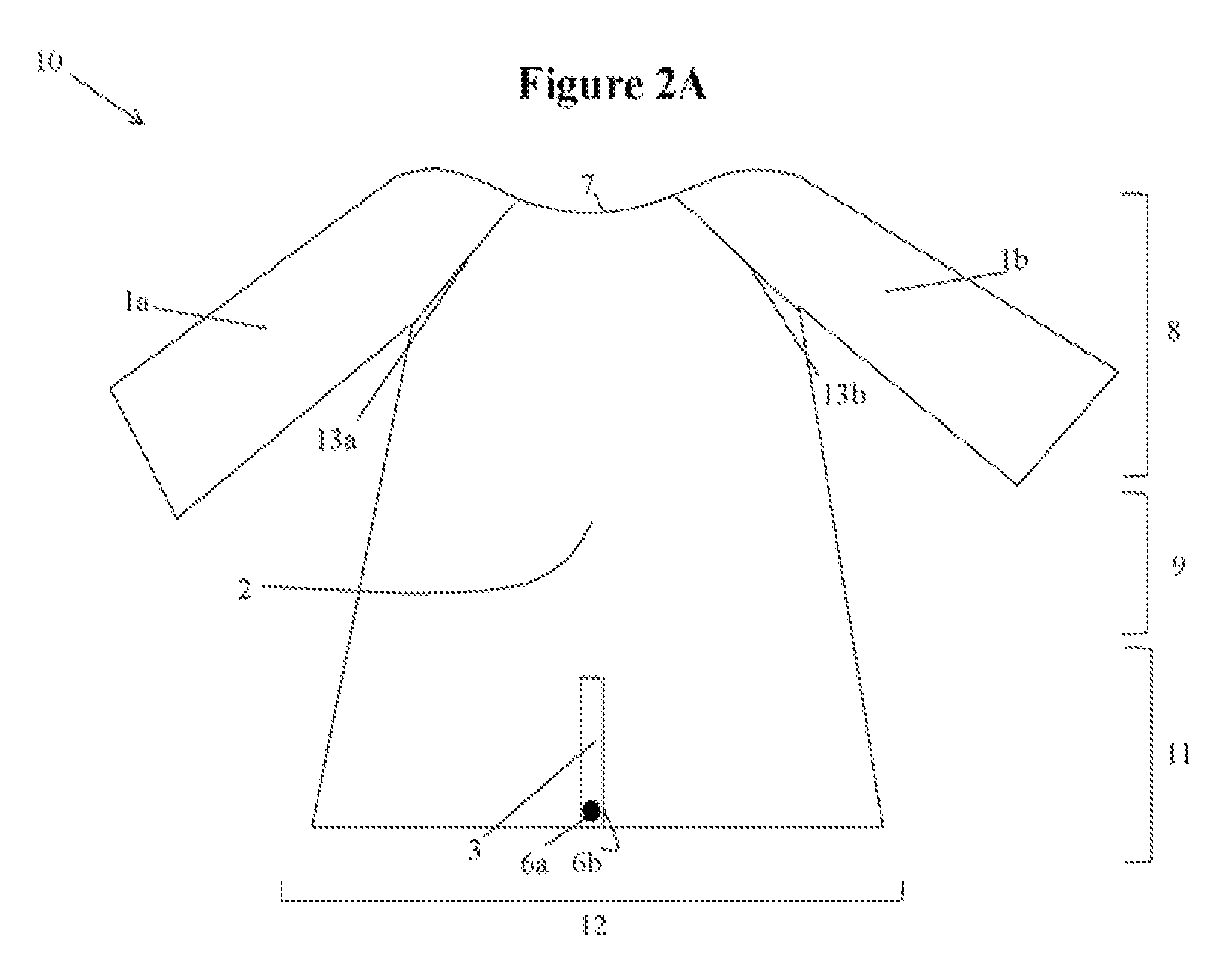

Protective Bib

InactiveUS20080092263A1Easy to wearProtection lengthBaby linensProtective garmentEngineeringSitting Positions

Protective garments that can keep the front of the wearer's clothes clean and dry are provided. The bibs include a substantially overlapping slit formed in the center of a lower section of a front panel. The bibs with the slit are easy to put on and provide substantial coverage of -frontal position of a wearer. The bibs can be used during eating, drinking, sitting, playing, crawling, etc. In some examples, the open back can enable the bib to be easily slipped on an already seated person without the need to stand. One or more bibs provide the ability to fasten the apron around each leg separately resulting in mobility and coverage, as well as the ability to use in seating where there is a vertical obstruction between the legs.

Owner:GOOD MICHELE ANNETTE

Protective bib

Protective garments that can keep the front of the wearer's clothes clean and dry are provided. The bibs include a substantially overlapping slit formed in the center of a lower section of a front panel. The bibs with the slit are easy to put on and provide substantial coverage of frontal position of a wearer. The bibs can be used during eating, drinking, sitting, playing, crawling, etc. In some examples, the open back can enable the bib to be easily slipped on an already seated person without the need to stand. One or more bibs provide the ability to fasten the apron around each leg separately resulting in mobility and coverage, as well as the ability to use in seating where there is a vertical obstruction between the legs.

Owner:GOOD MICHELE ANNETTE

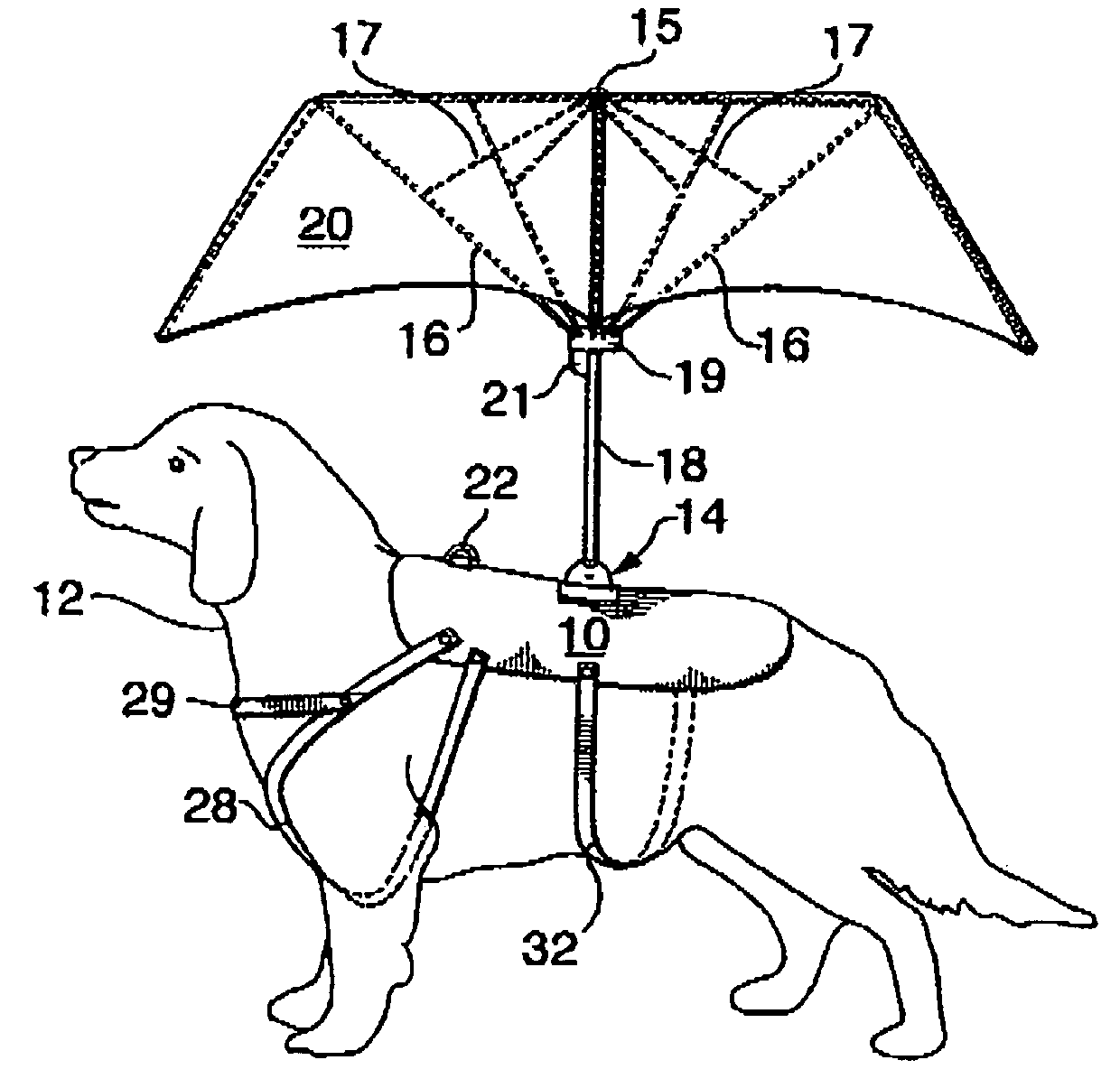

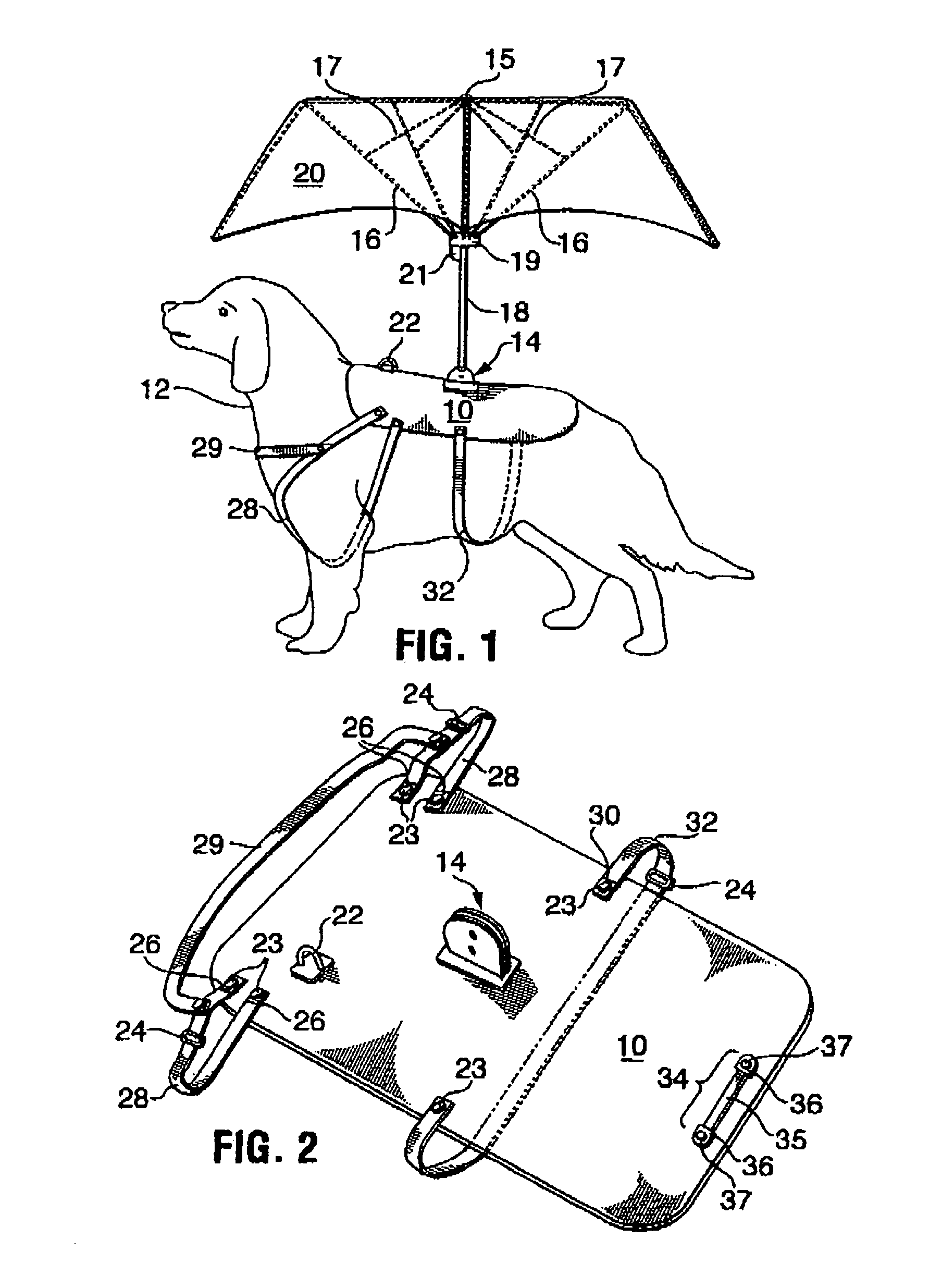

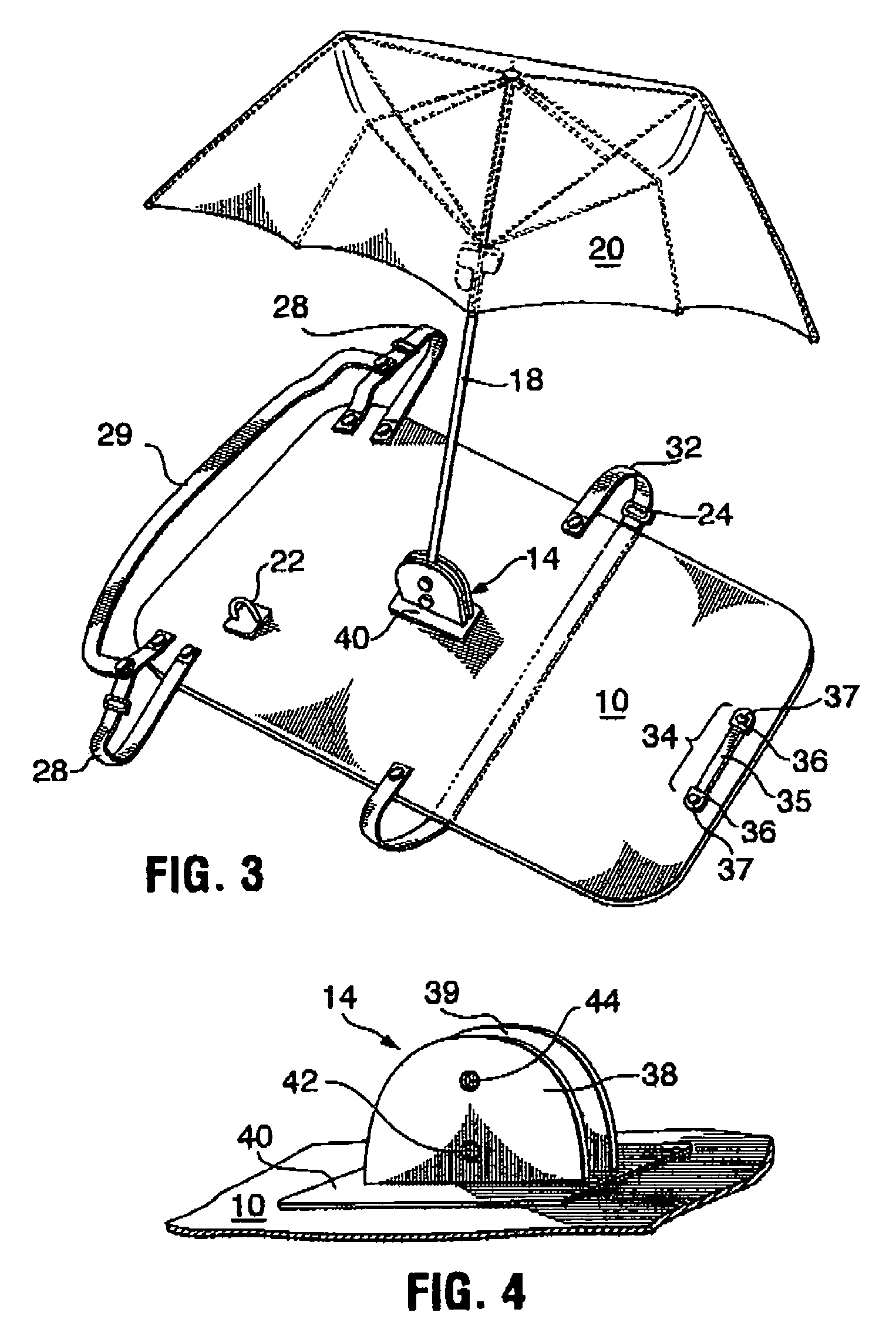

Animal umbrella

ActiveUS7021246B2Reduce disadvantagesProtection lengthUmbrellasOther apparatusEngineeringMechanical engineering

An animal umbrella is disclosed. The animal umbrella comprises a saddle, straps connected to the saddle for detachably attaching the saddle to the animal, a collapsible canopy, a shaft with first and second ends, connected at the first end to the canopy, and connected at the second end to the saddle in a pivotable manner, and a position lock to releasably secure the shaft in a vertical position. The shaft can be pivoted between a substantially vertical position and a substantially horizontal position, so that in a vertical position the canopy is open and held vertically, and in a horizontal position the canopy is closed and lies horizontally along the animal's back.

Owner:SEYMOUR LOU H

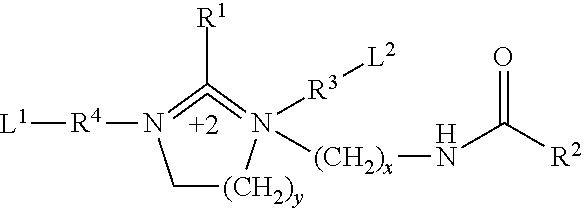

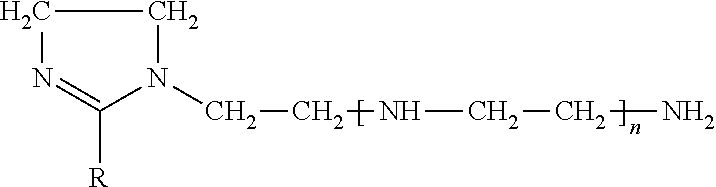

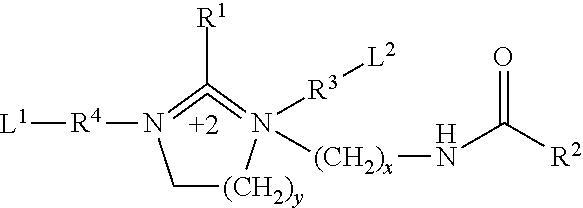

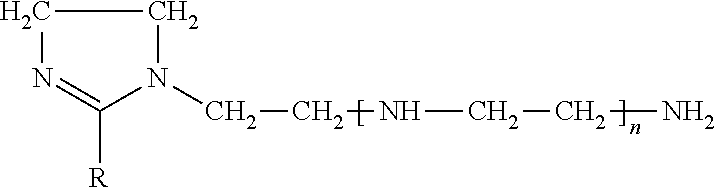

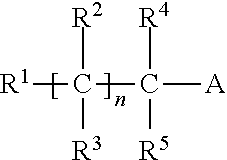

Liquid Inhibitor Composition And A Method For Its Preparation And Application As A Heavy Brine Corrosion Control

ActiveUS20170342310A1Reduce rateImprove integrityDrilling compositionBorehole/well accessoriesPhosphateSulfur

A composition useful as corrosion inhibitor formulation for application in heavy brine systems, comprising at least one imidazoline; at least one sulfur synergist; at least one phosphate ester. In a preferred embodiment, the composition comprises additionally formulation bonding surfactant; and / or at least one solvent system.

Owner:CLARIANT INT LTD

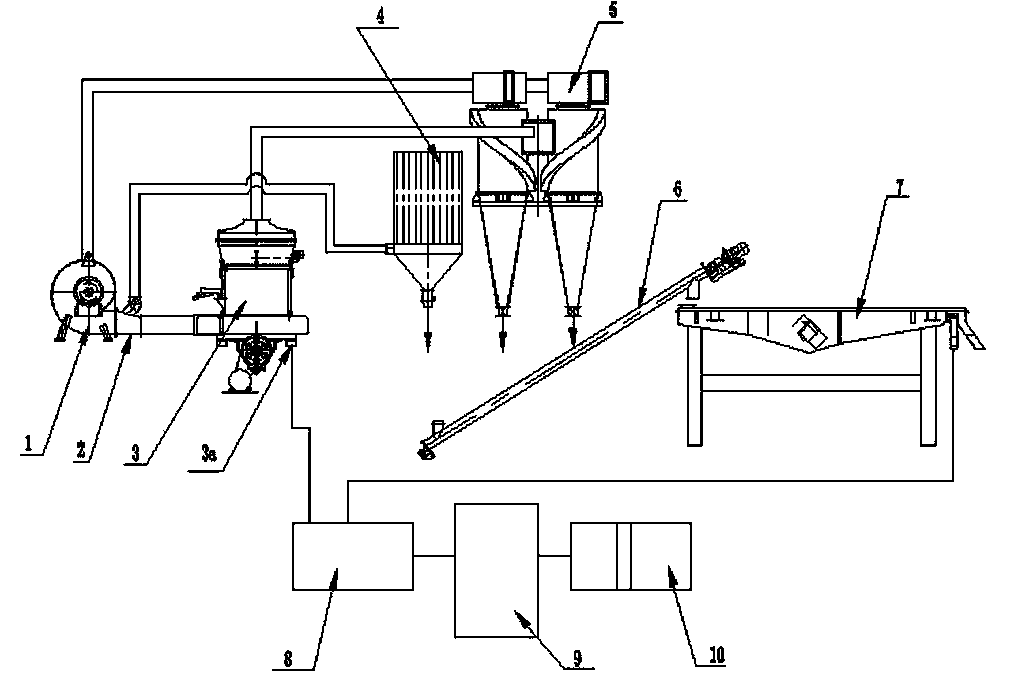

Breaking and separation integrated comprehensive recovery method of chrysotile tailings

InactiveCN103433137AReduce the delivery linkReduce lossesMagnetic separationGrain treatmentsRecovery methodMagnetic separator

The invention provides a breaking and separation integrated comprehensive recovery method of chrysotile tailings, which is characterized by comprising the steps of putting the dried chrysotile tailings in breaking and separation integrated equipment consisting of a pulverizer and a cyclone powder collector, achieving pulverizing and separation by adding 4-8 sand discharge ports on a pulverizing disc of the pulverizer, separating a chrysotile mixed material containing dust and tailing waste, conveying the chrysotile mixed material to a plane revolving screen or a plane shaking screen for classification and dedusting, removing fine sand and the dust, obtaining chrysotile products of different levels, roughing the tailing waste, the fine sand and the dust with a weak magnetic separator, obtaining magnetic middlings and tailings, and conveying the magnetic middlings into a ball mill for milling, and a wet weak magnetic separator for concentrating to obtain magnetite concentrates and tailings. According to the method, two production processes, grinding & asbestos fiber opening, and separation, of the chrysotile tailings are organically combined into a whole, effects of energy conservation and consumption reduction are achieved, and the chrysotile products of different levels and the magnetite concentrates are obtained simultaneously.

Owner:十堰源禹工贸有限公司

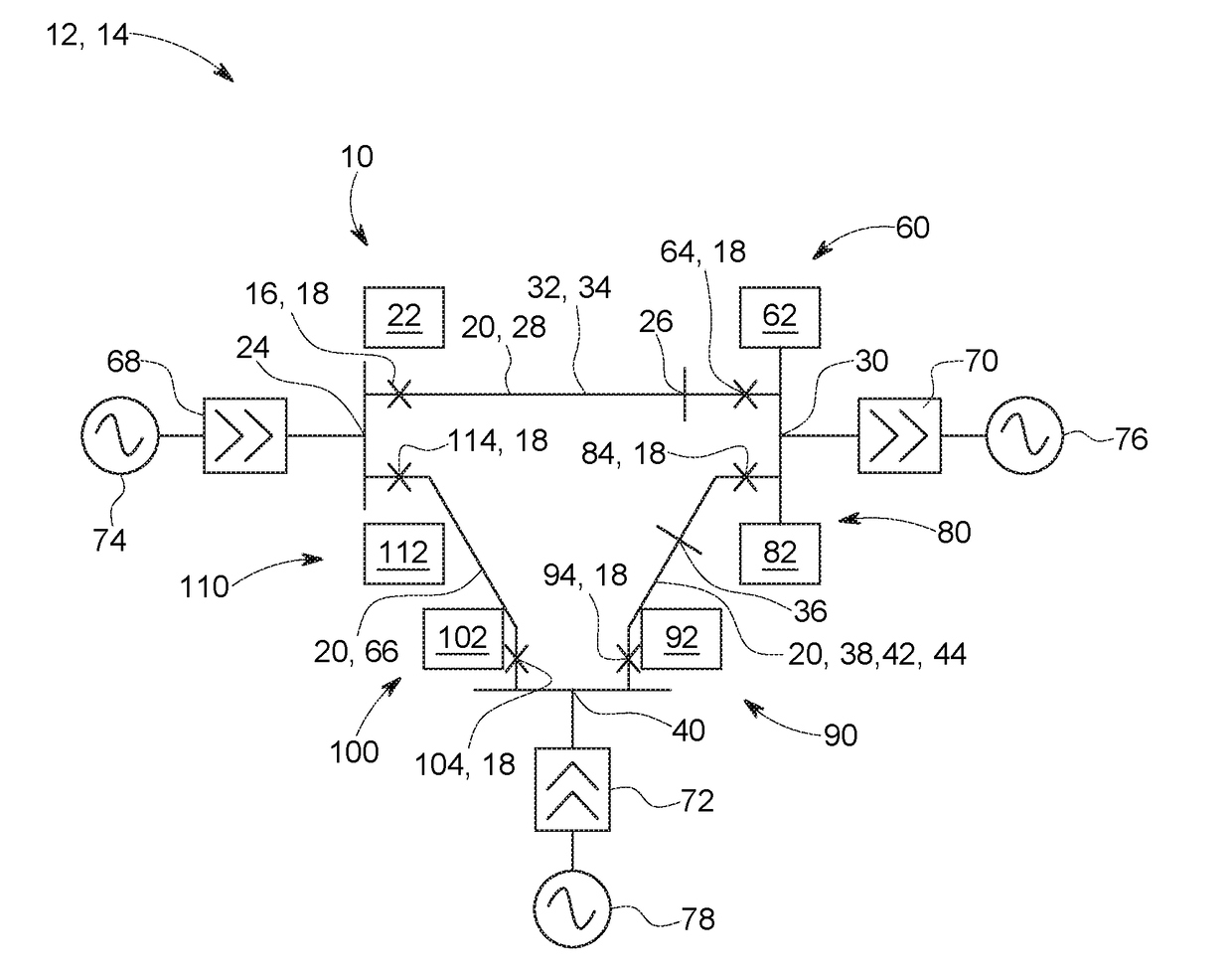

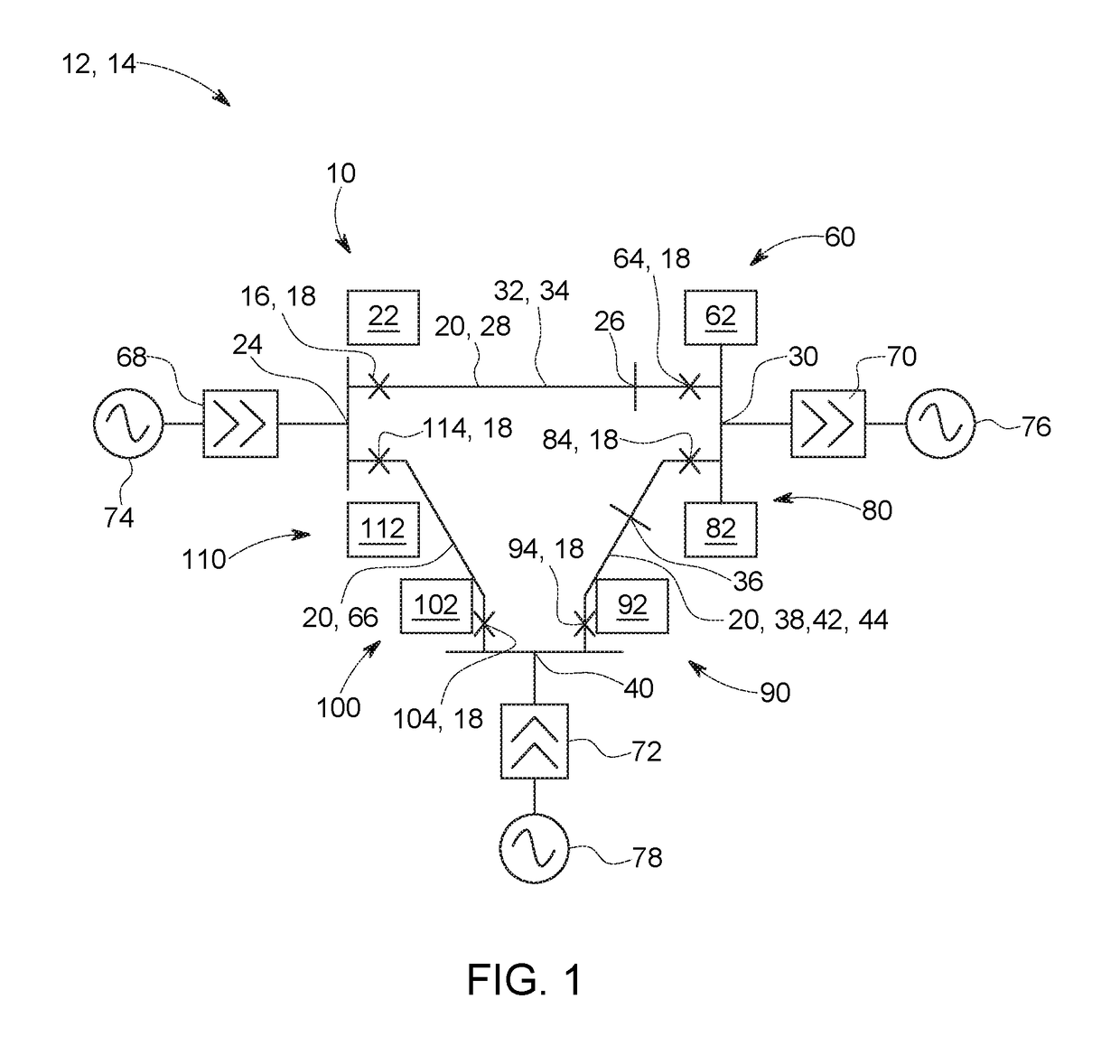

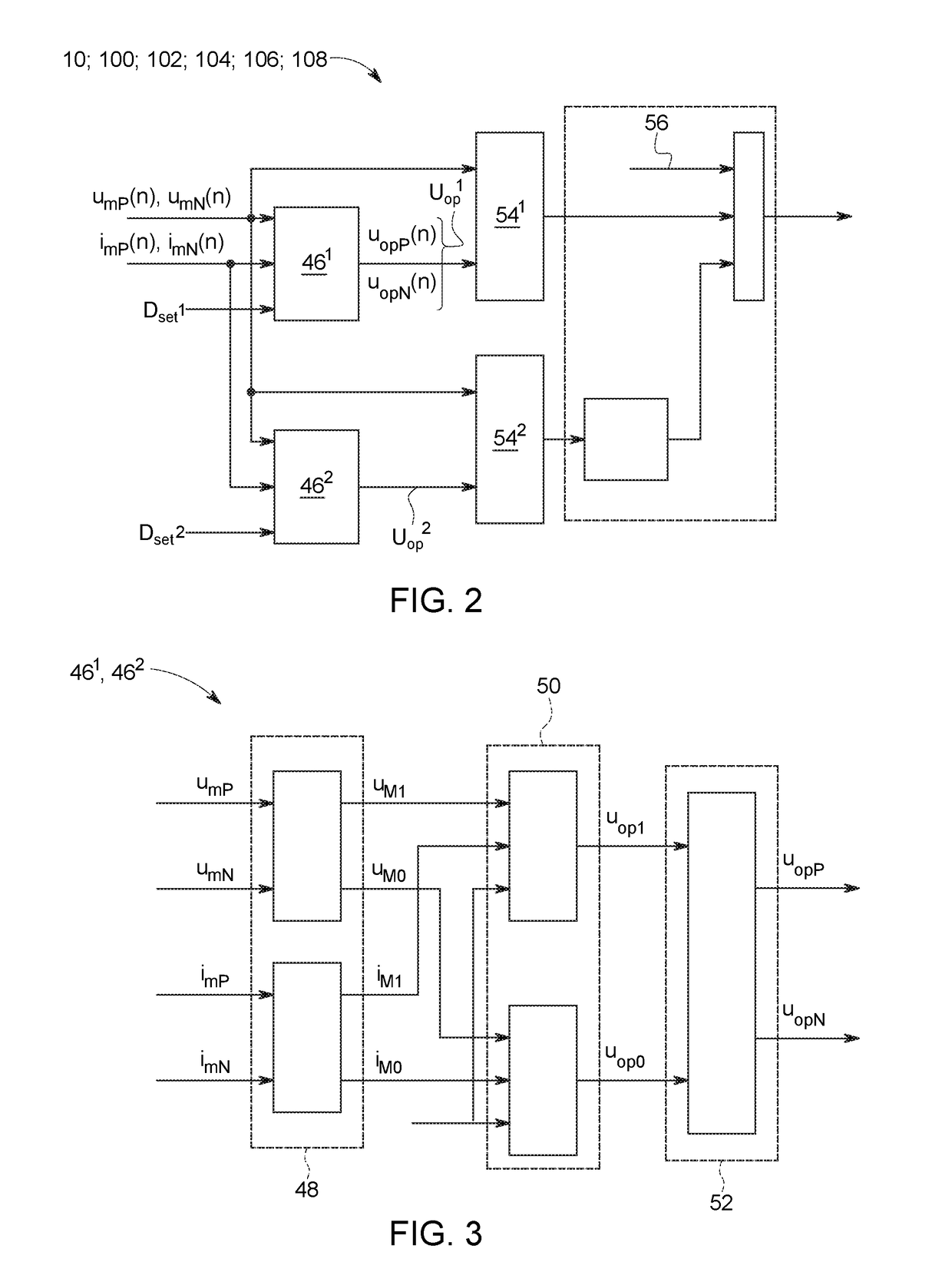

Improvements in or relating to direct current distance protection schemes

ActiveUS20180294644A1Function increaseProtection lengthCurrent/voltage measurementEmergency protection detectionPower flowPower grid

A DC distance protection scheme for protecting a DC power transmission medium within the DC electrical power network. The DC distance protection scheme includes a protection device that is coupled in use to a DC power transmission medium. The protection device is operable to protect the DC power transmission medium from an electrical fault. The DC distance protection scheme also includes a measurement apparatus to selectively measure the current and voltage of the DC power transmission medium. In addition the DC distance protection scheme also includes a controller that is programmed to calculate an operating voltage of the DC power transmission medium using the measured current and voltage; perform a transient comparison between the calculated operating voltage and the measured voltage; and operate the protection device to protect the DC power transmission medium if the transient comparison meets a predefined criterion.

Owner:GENERAL ELECTRIC TECH GMBH

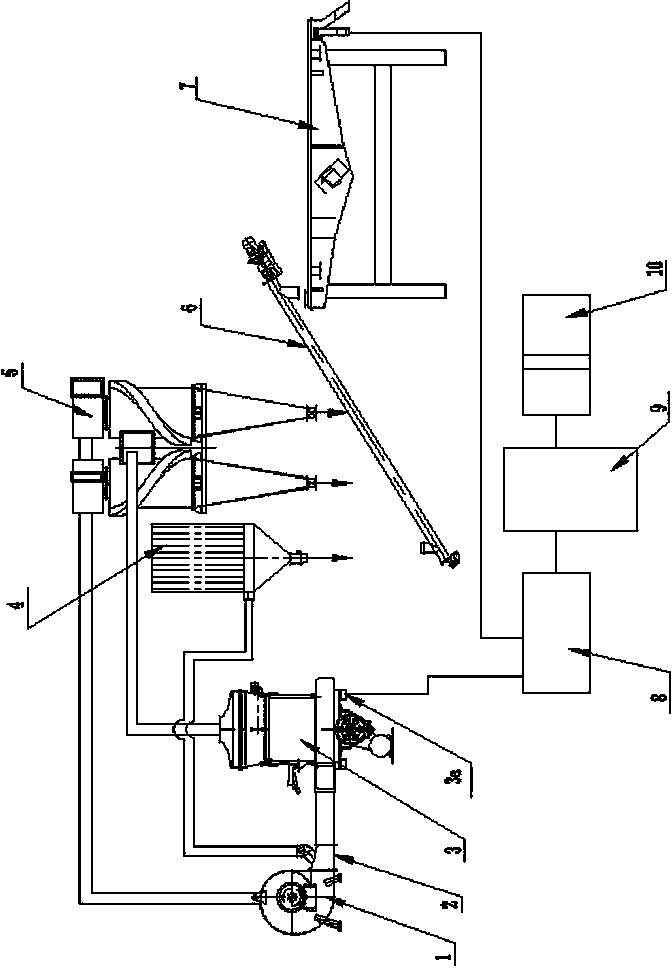

Breaking and separation integrated comprehensive recovery system of chrysotile tailings

InactiveCN103433138AReduce lossesProtection lengthMagnetic separationGrain treatmentsMagnetiteMagnetic separator

The invention provides a breaking and separation integrated comprehensive recovery system of chrysotile tailings, which is characterized in that a fan is connected with a pulverizing host and a duster respectively by a three-way valve; 4-8 sand discharge ports are annularly formed at the bottom of the pulverizing host; an outlet of the pulverizing host is connected with a cyclone collector by a pipeline; an inlet of a screw conveyer is connected with an outlet of the cyclone collector; an outlet of the screw conveyer is conveyed to a plane revolving screen or a plane shaking screen to achieve recovery of chrysotile; integrated functions of breaking and separation are achieved; a weak magnetic separator, a ball mill and a wet weak magnetic separator are connected sequentially to form a magnetic separating system of magnetite; and the magnetic separating system is used for magnetic separating of the magnetite from dust. According to the recovery system, the sand discharge ports in the pulverizing host separate tailing waste, two production processes of grinding & asbestos fiber opening and separation are organically combined into a whole, the production cost is lowered, the energy conservation and consumption reduction are achieved, and the magnetic separating system weakly separates the magnetite to produce iron ore concentrates.

Owner:十堰源禹工贸有限公司

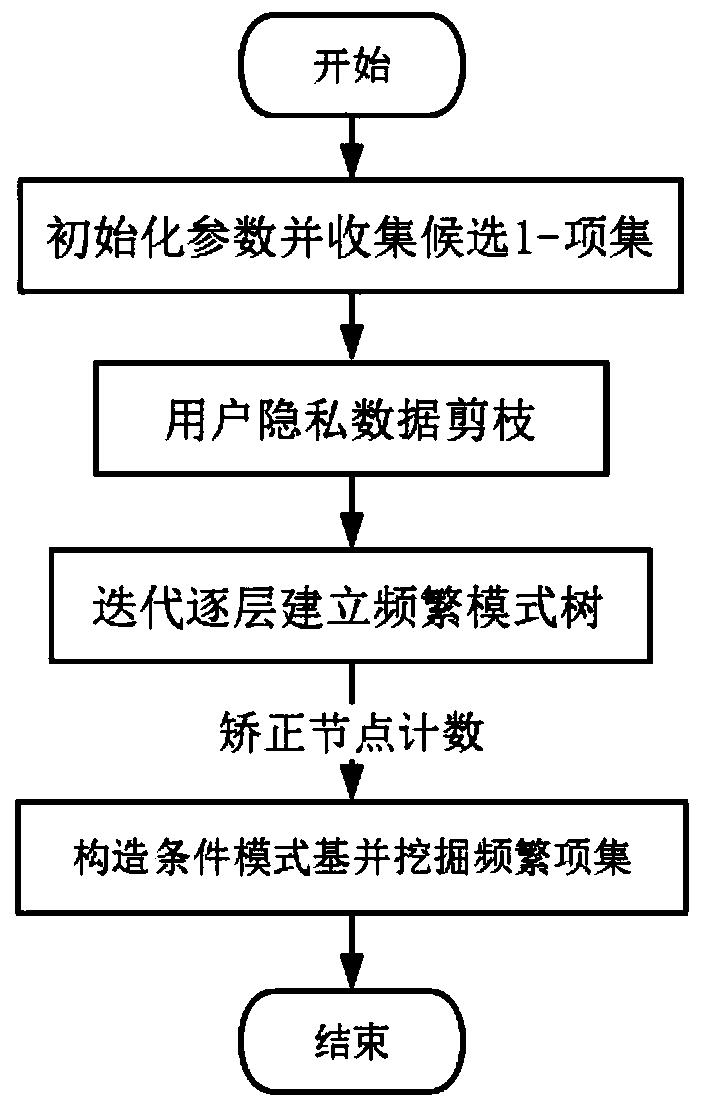

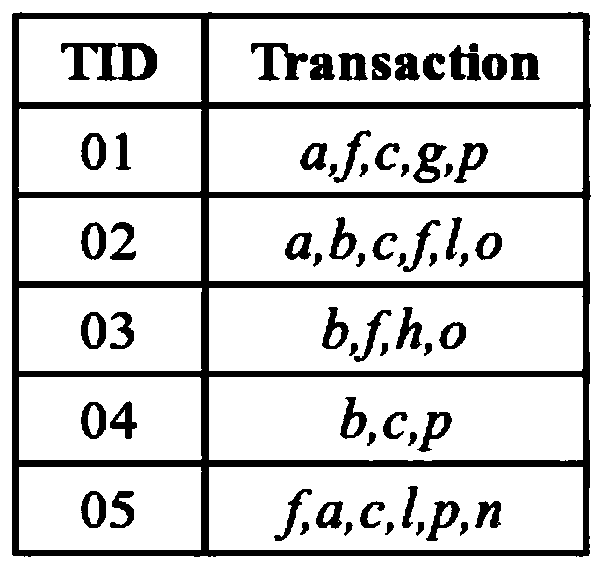

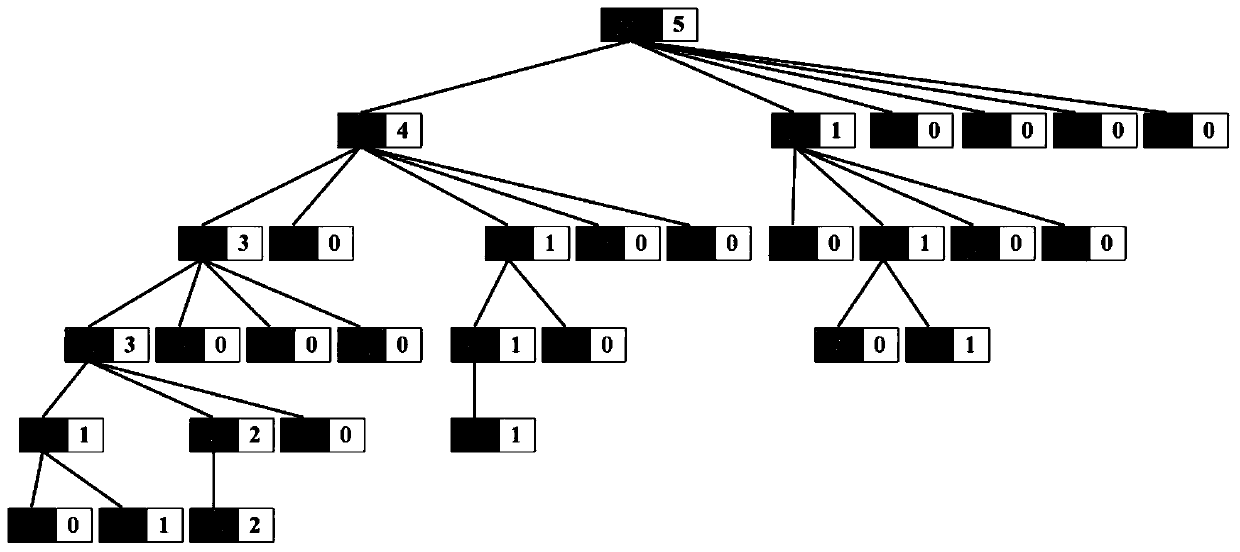

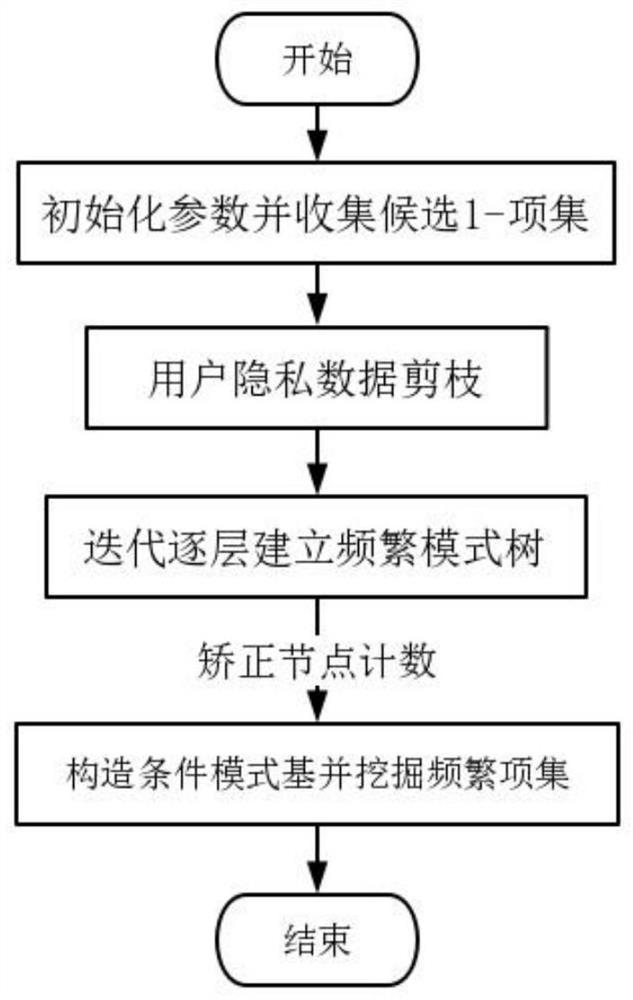

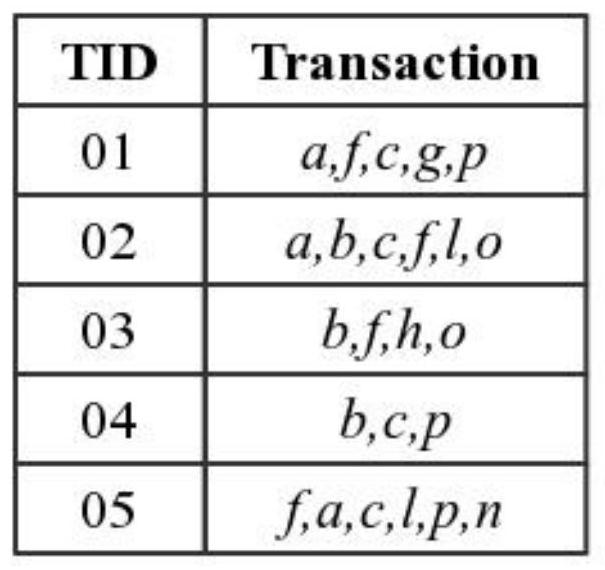

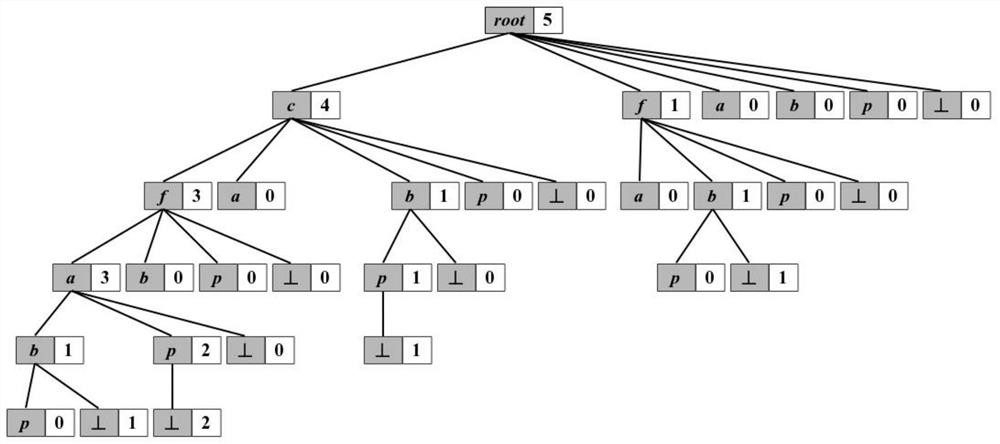

Localized differential privacy protection frequent item set mining method based on frequent pattern tree

ActiveCN110471957AImprove privacy protectionReduce overheadDigital data information retrievalDigital data protectionThird partyPrivacy protection

The invention discloses a localized differential privacy protection frequent item set mining method based on a frequent pattern tree, which is applied to a scene formed by an untrusted third-party data aggregator A and n users, and comprises the following steps of: S1, an initialization stage; S2, a data pruning stage; S3, a tree building stage; S4, a data mining stage. According to the method, under the condition that the third-party data aggregator A does not hold any user privacy record information, all frequent item sets meeting a given support degree threshold value and corresponding support degrees can be estimated, so that it is guaranteed that a third party can mine useful association rules according to an obtained result, and support is provided for possible decisions.

Owner:ANHUI UNIVERSITY

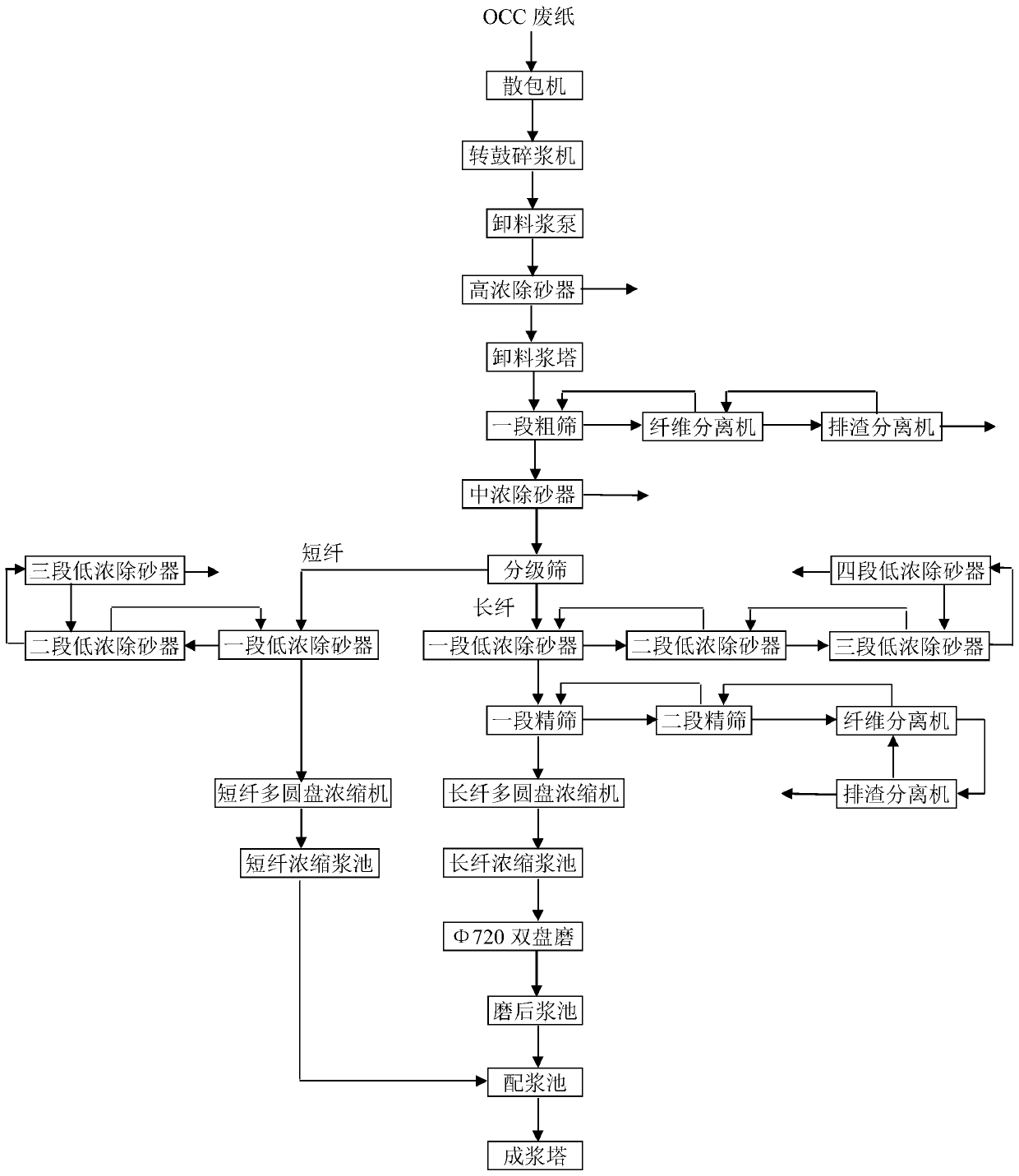

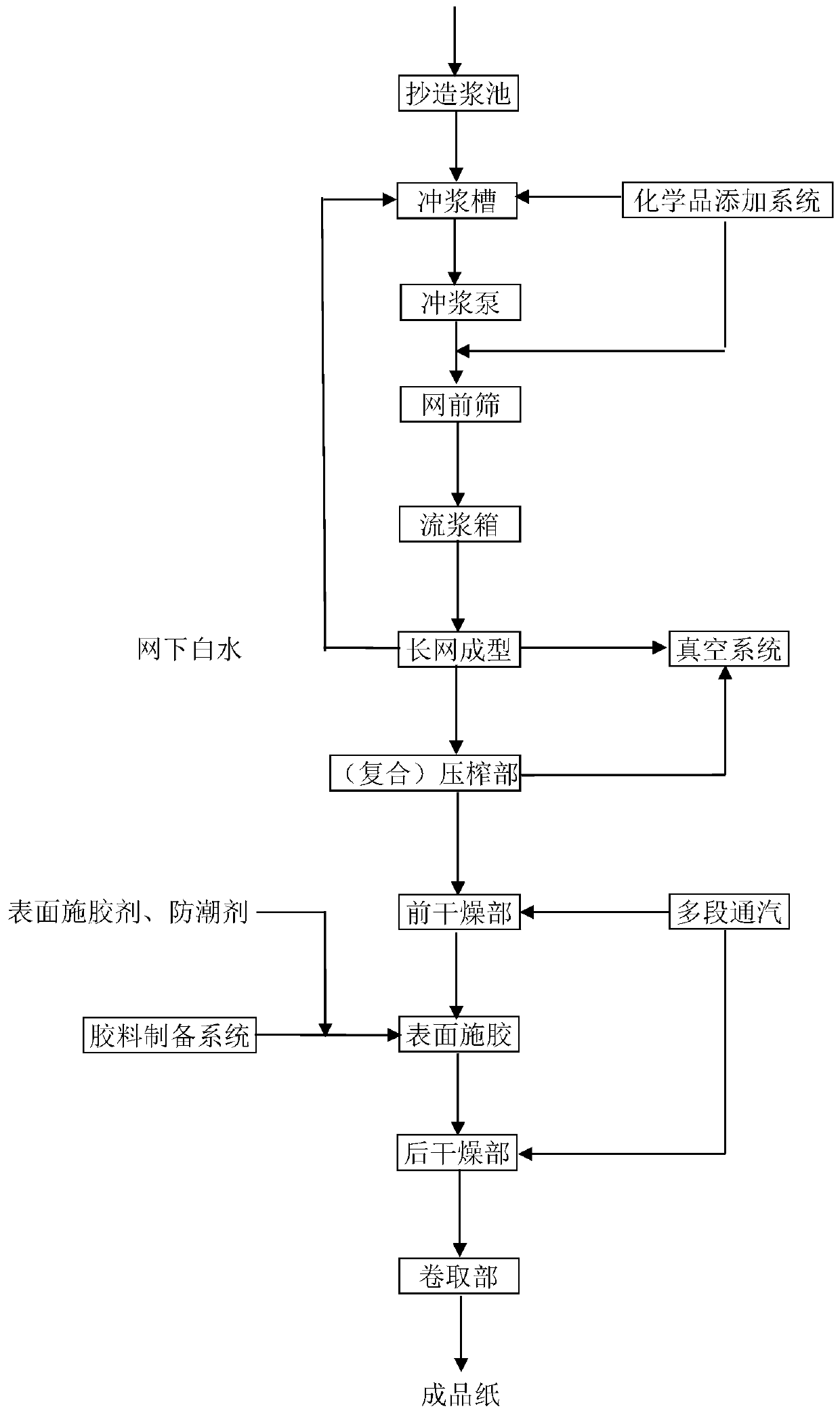

Production process of low weight middle partition paper

InactiveCN111364268AIncrease the usable areaReduce adverse effectsNon-fibrous pulp additionPulp beating methodsSizingEnvironmental geology

The invention provides a production process of low weight middle partition paper. The production process comprises the following steps: burdening, disintegrating, screening and purifying, concentrating, pulping, pulp preparing, flowing, forming, compound squeezing, drying, surface sizing, and coiling. In the burdening step, based on fiber quality and impurity content, OCC waste paper of differentgrades is matched according to the determined raw material ratio of a product; wherein the OCC waste paper comprises domestic waste paper and imported waste paper accounting for 10-30% of the total weight, and the imported waste paper comprises American waste paper, European waste paper and Hong Kong waste paper. Main physical indexes of the low weight middle partition paper produced by the production process are as follows: quantifying (60-65) + / -3g / m<2>; the tightness is greater than or equal to 0.50 g / cm<3>; the transverse ring crush index is greater than or equal to 3.0 Nm / g; the longitudinal breaking length is larger than or equal to 3.5 km, the water content is 7.5%-10.0%, and the water absorption is smaller than or equal to 50 g / m<2>. On the premise that the strength index of the product meets the use purpose, the quantification of the middle partition paper product is reduced as much as possible, under the condition of the same weight, the use area of the product is remarkablyincreased, and therefore development of low-carbon economy can be promoted.

Owner:中山永发纸业有限公司

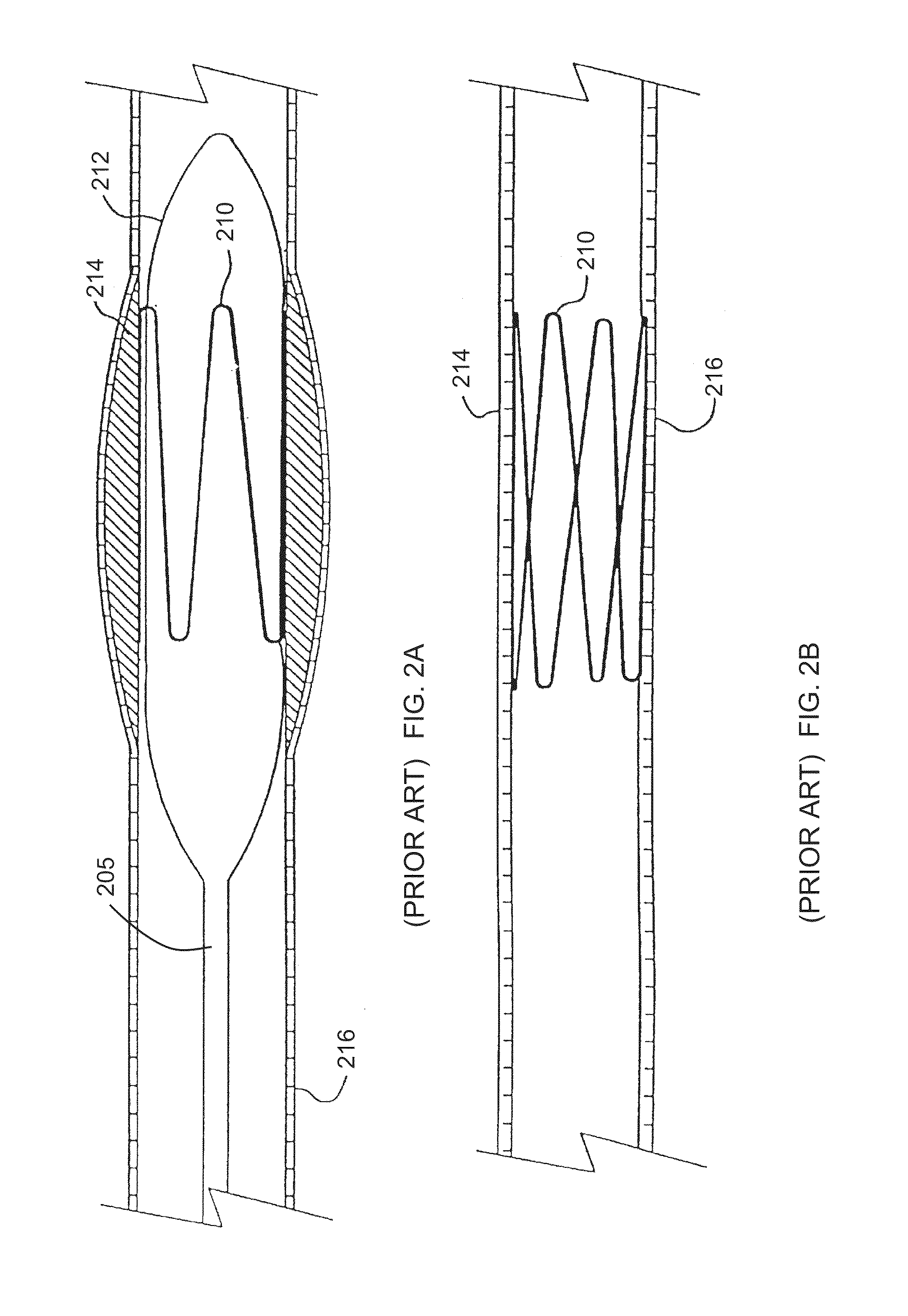

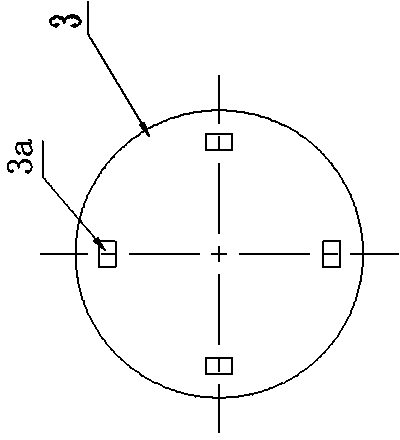

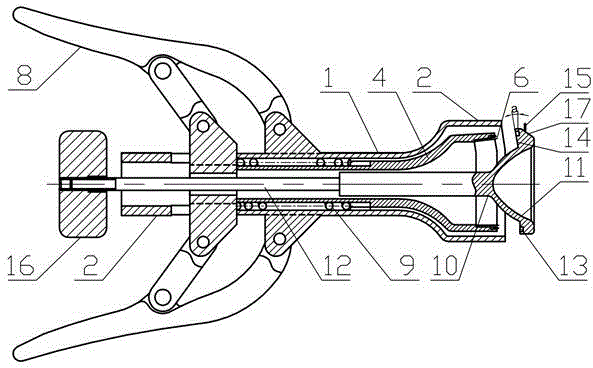

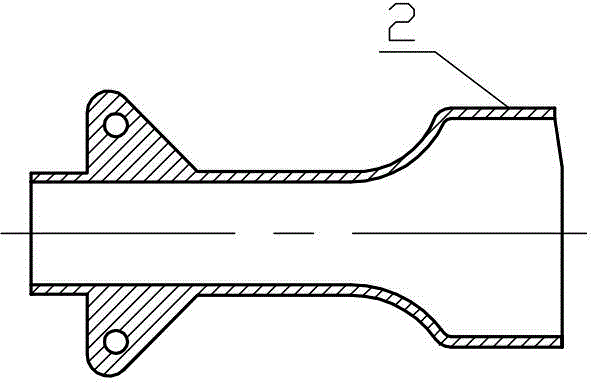

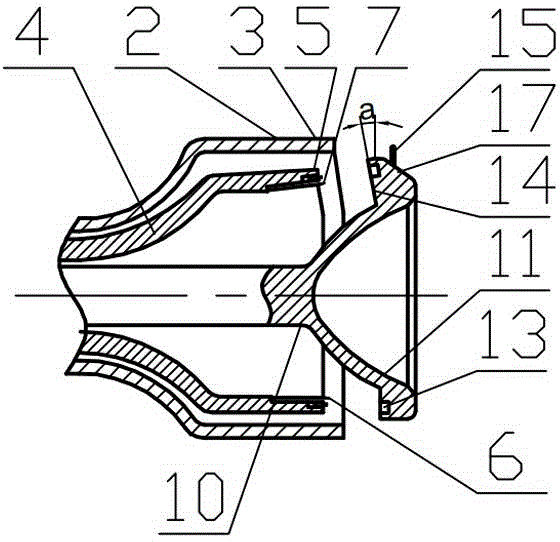

Stitching instrument for male penis prepuce circumcision

A stitching instrument for male penis prepuce circumcision comprises an upper stitching instrument body and a lower stitching instrument body. The upper stitching instrument body is composed of a stitching cutting part and a handle, the stitching cutting part is designed to be in a regular round tube shape, and a frenulum protecting part protruding outwards to the tube wall is arranged on one section of the round tube wall, and namely is the frenulum protecting part of the upper stitching instrument body. With the glans penis being the center, the frenulum part of the frenulum protecting part protrudes outwards and is of a V-shaped or U-shaped protruding structure, the frenulum incision face and the prepuce incision face are on the same plane, and the frenulum protecting part is matched with the lower stitching instrument body. Frenulum protecting parts are arranged on prepuce incision stitching positions respectively in a matched mode, in this way, the stitching instrument can incise the redundant prepuce in parallel with the coronary sulcus, the lower stitching instrument body keeps the prepuce frenulum at the proper position through a positioning needle, and the upper stitching instrument body is connected with a lower stapler to incise the redundant prepuce under the action of the handle, so that clinical requirements are met; the stitching instrument is easy to operate, convenient to use and capable of really achieving accurate operation, relieving pains of a patient and reducing doctor-patient disputes.

Owner:张首府

Liquid inhibitor composition and a method for its preparation and application as a heavy brine corrosion control

ActiveUS10611951B2Reduce rateImprove integrityDrilling compositionBorehole/well accessoriesPhosphoric Acid EstersPhosphate

A composition useful as corrosion inhibitor formulation for application in heavy brine systems, comprising at least one imidazoline; at least one sulfur synergist; at least one phosphate ester. In a preferred embodiment, the composition comprises additionally formulation bonding surfactant; and / or at least one solvent system.

Owner:CLARIANT INT LTD

Special paper for paper diapers and production process thereof

ActiveCN108914679AGood fiber lengthWith fiber strengthNatural cellulose pulp/paperSpecial paperPerformance indexPulp and paper industry

The invention discloses special paper for paper diapers and a production process thereof, the special paper is prepared from native coniferous wood pulp. The fix quantify of the special paper for thepaper diapers is 50g / m<2>, the beating degree is 28 to 38-degree SR; the transverse tensile index of the finished paper is equal to or greater than 50N-m / g, the longitudinal tensile index of the finished paper is equal to or greater than 100N.m / g, and the longitudinal wet tensile strength of the finished paper is equal to or greater than 150N / m, the tear index of the finished paper is equal to orgreater than 8mN.m<2> / g, the burst index of the finished paper is equal to or greater than 5kPa.m<2> / g and folding resistance of the finished paper is equal to or greater than 1000 times. The specialpaper for the paper diaper is close to non-woven fabric used by current paper diapers manufacturers in performance indexes, and can replace a surface coating layer of the paper diapers. In addition, the special paper for the paper diapers can absorb and remove odor and harmful gases in the paper diapers so as to make the paper diapers safer, sanitary and comfortable.

Owner:山东爱舒乐卫生用品有限责任公司

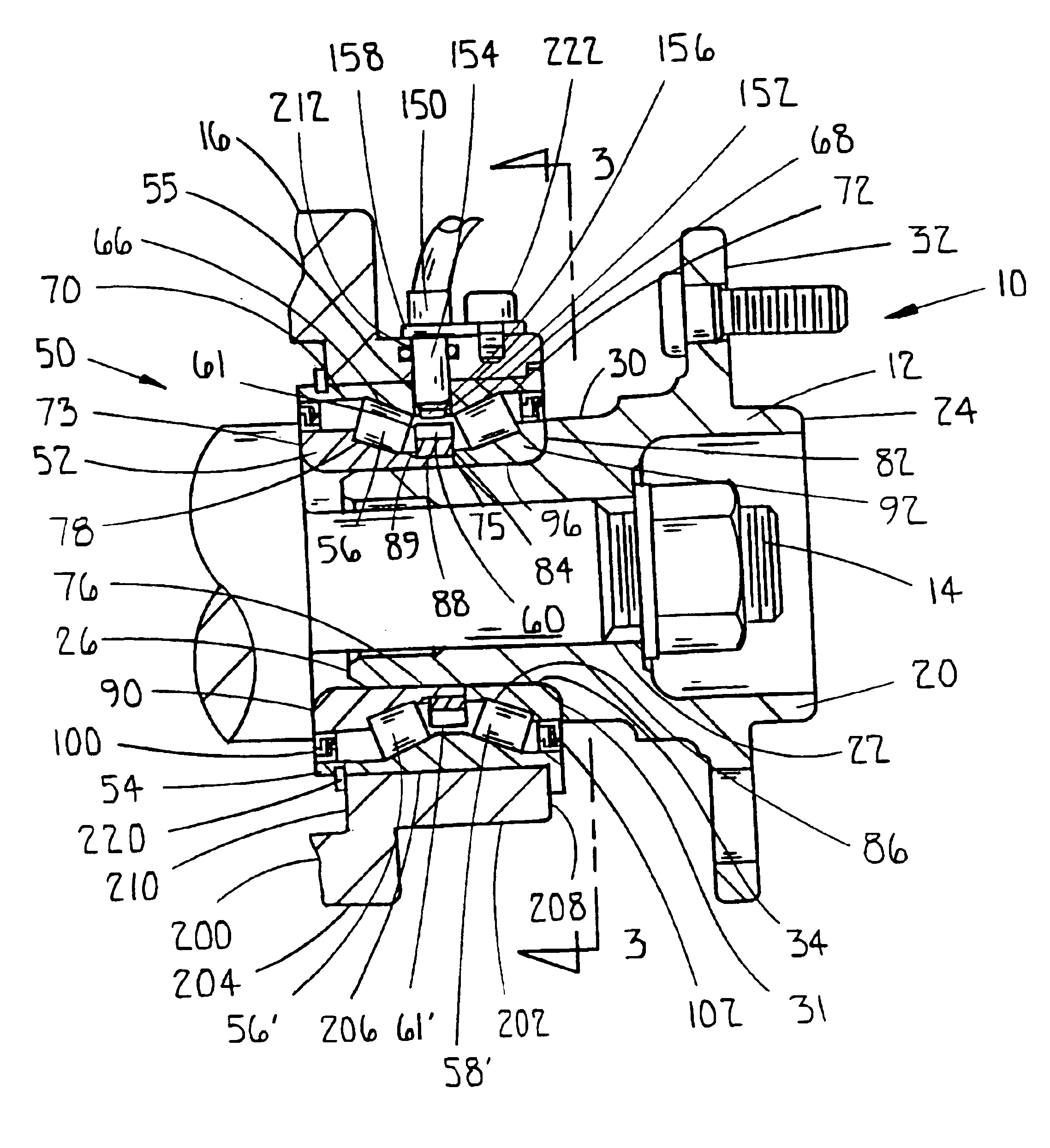

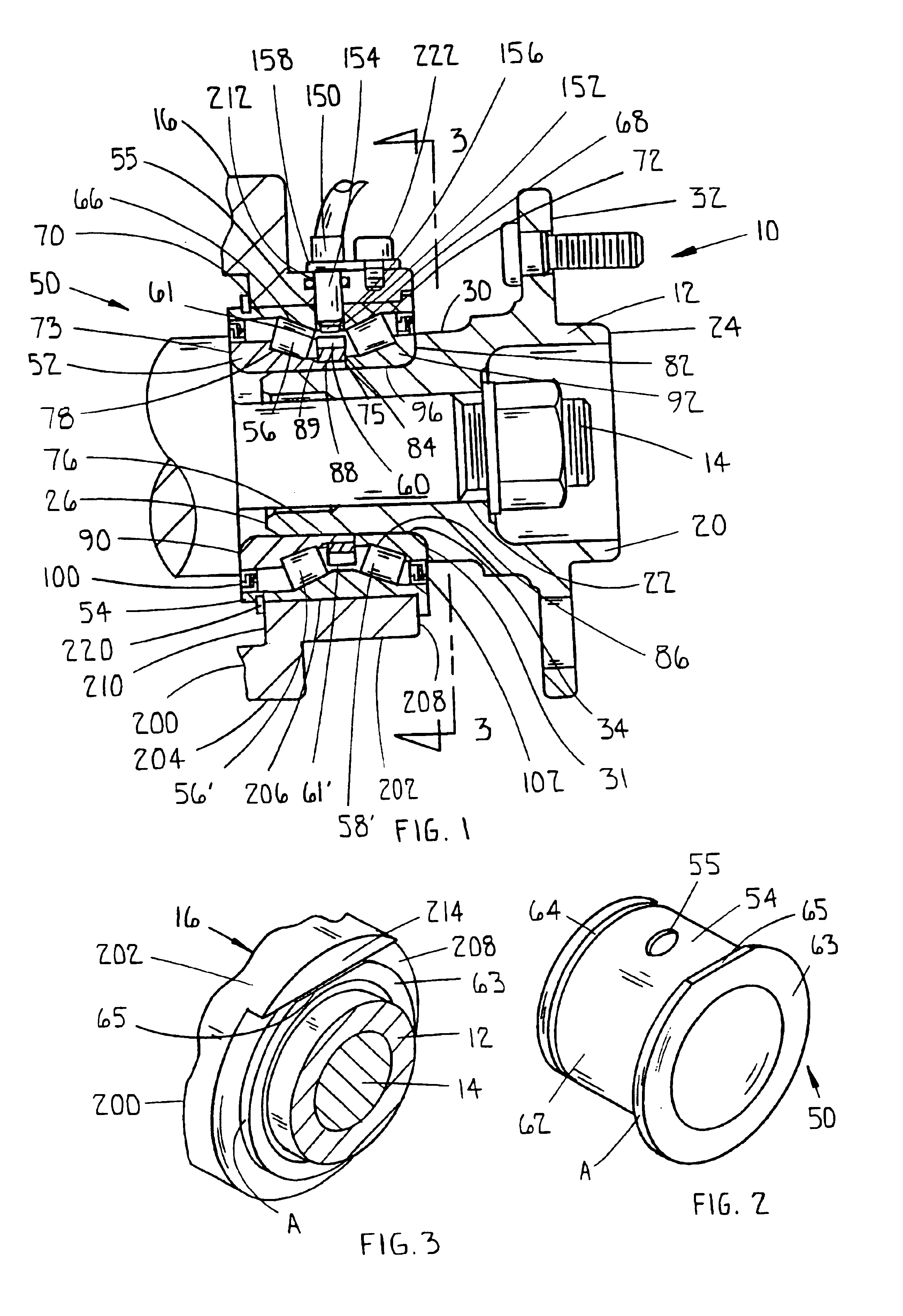

Bearing assembly for a vehicle

A corner module for use in a motor vehicle having a bearing pack through which a wheel hub for the motor vehicle is connected with a support member. The bearing pack includes an inner race and an outer race for retaining first and second roller elements such that a wheel attached to the hub may rotate with respect to the support member. The bearing pack is characterized by an exciter ring that is located between the first and second roller elements and the outer race is characterized by an opening that is in radial alignment with the exciter ring. A sensor that is fixed to the support member has a functional length and a sensing area that extends through the radial opening in the outer race and into the bearing pack to a position adjacent the exciter ring such that the functional length and sensing area is protected from exposure to contamination that may be present in the environment. The sensing area is activated by movement of the exciter ring to provide an electronic control unit with a signal relating to the rotation of the wheel and used in the control of an anti-skid brake system.

Owner:ROBERT BOSCH CORP

Improved APMP pulping method

InactiveCN101319470AReduce the binding forceHigh strengthPulping with inorganic basesContinuous pulping processFiberChemical reaction

The invention discloses an improved APMP pulping method. As a chemical reaction step is carried out before a defibering step and is a contact reaction between a wood chip and liquid medicine in a wood chip reaction bin, the wood chip first has chemical reaction with the liquid medicine in the reaction bin before defibering, thus after the wood chip has chemical reaction with the liquid medicine, the binding force among fibers is remarkably weakened and the fiber length in a defibering process can be effectively protected, which is favorable for raising the strength of paper pulp. Meanwhile, energy needed in the defibering process is also remarkably reduced, thereby saving a great amount of energy.

Owner:李昊

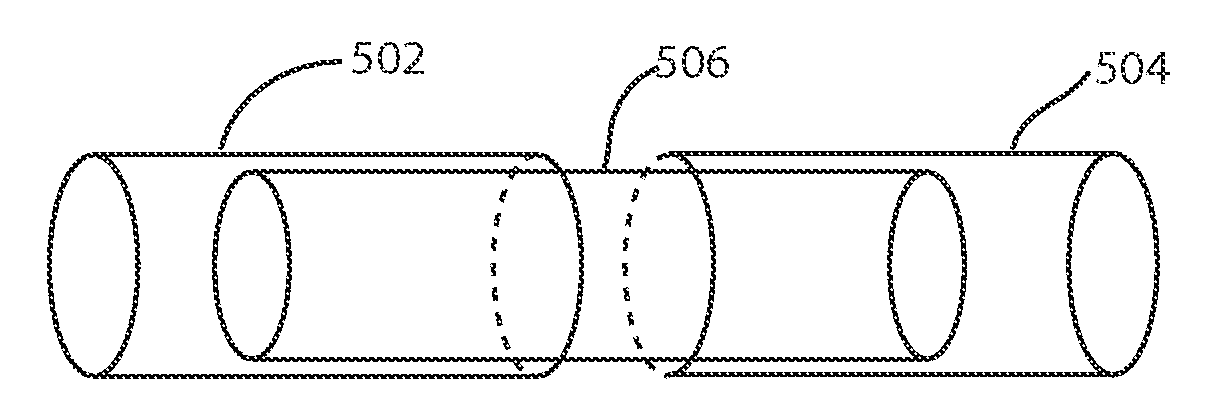

Flexible clad protection system

ActiveUS10008840B2Stay flexibleProtection lengthElectrical apparatusLoad-engaging elementsEngineeringImpact resistance

Embodiments disclosed herein relate to a protection device and / or system that may include a thimble capable of being placed over a transmission line, such as an electrical power cord, to provide protection in the form of cut resistance, abrasion resistance, and / or impact resistance. In some embodiments, a plurality of thimbles can be placed over the transmission line to form an overlapping arrangement to protect a desired length of the transmission line. While each thimble may be rigid, semi-rigid, and / or flexible, the arrangement can maintain flexibility to allow for many degrees of movement of the electrical power cord even as it is cladded in the protection system.

Owner:CRANE 1 SERVICES INC

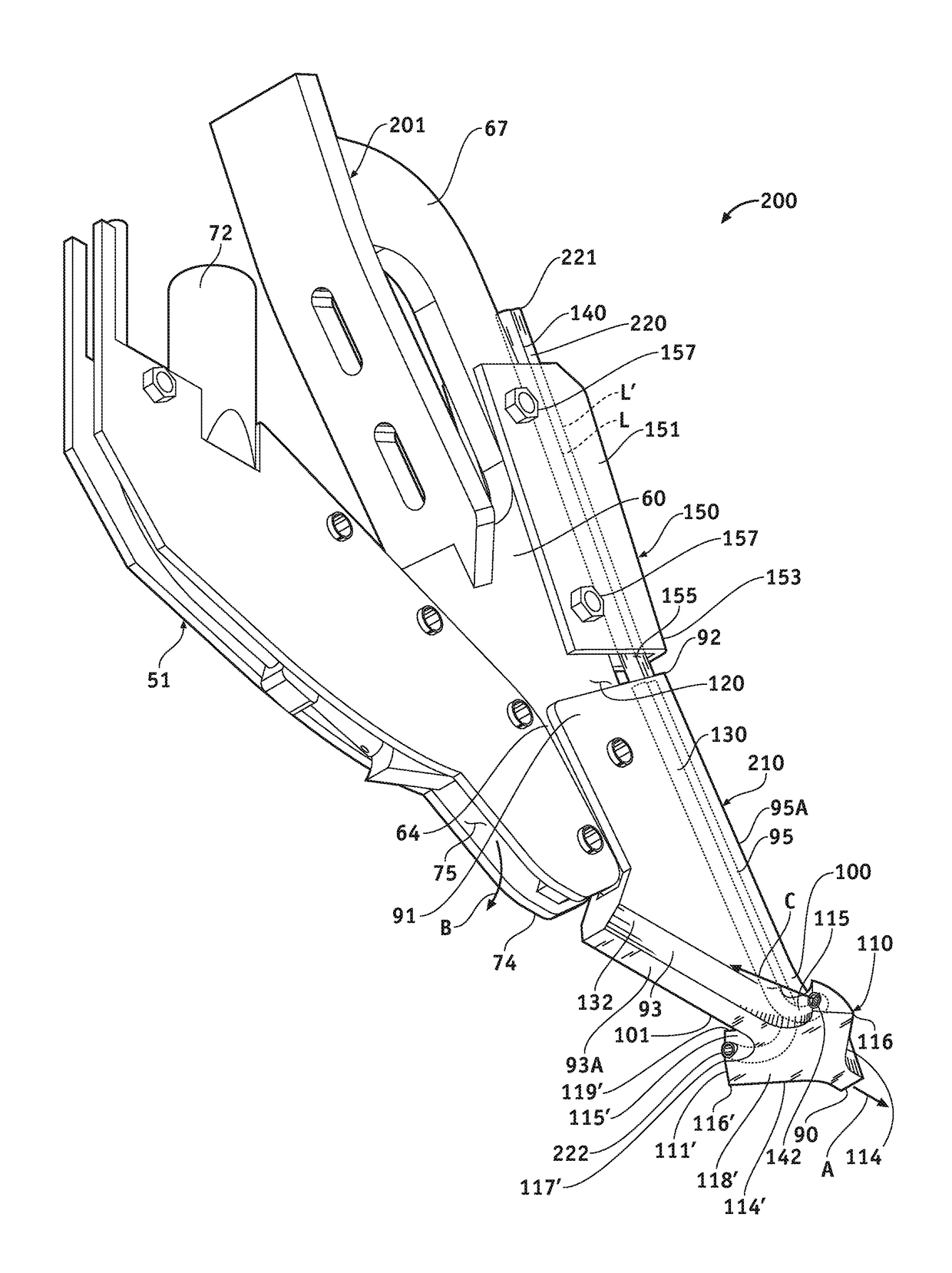

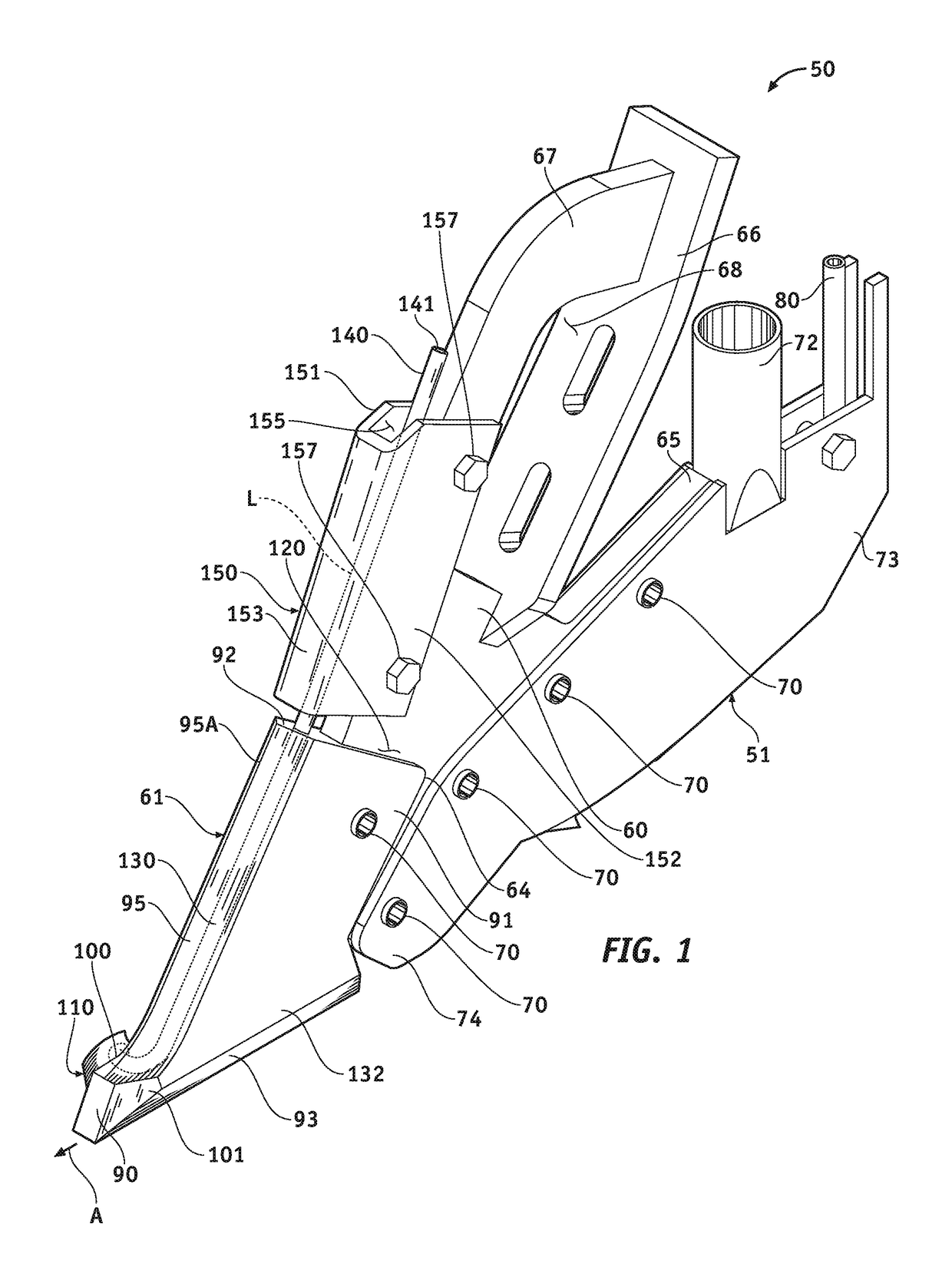

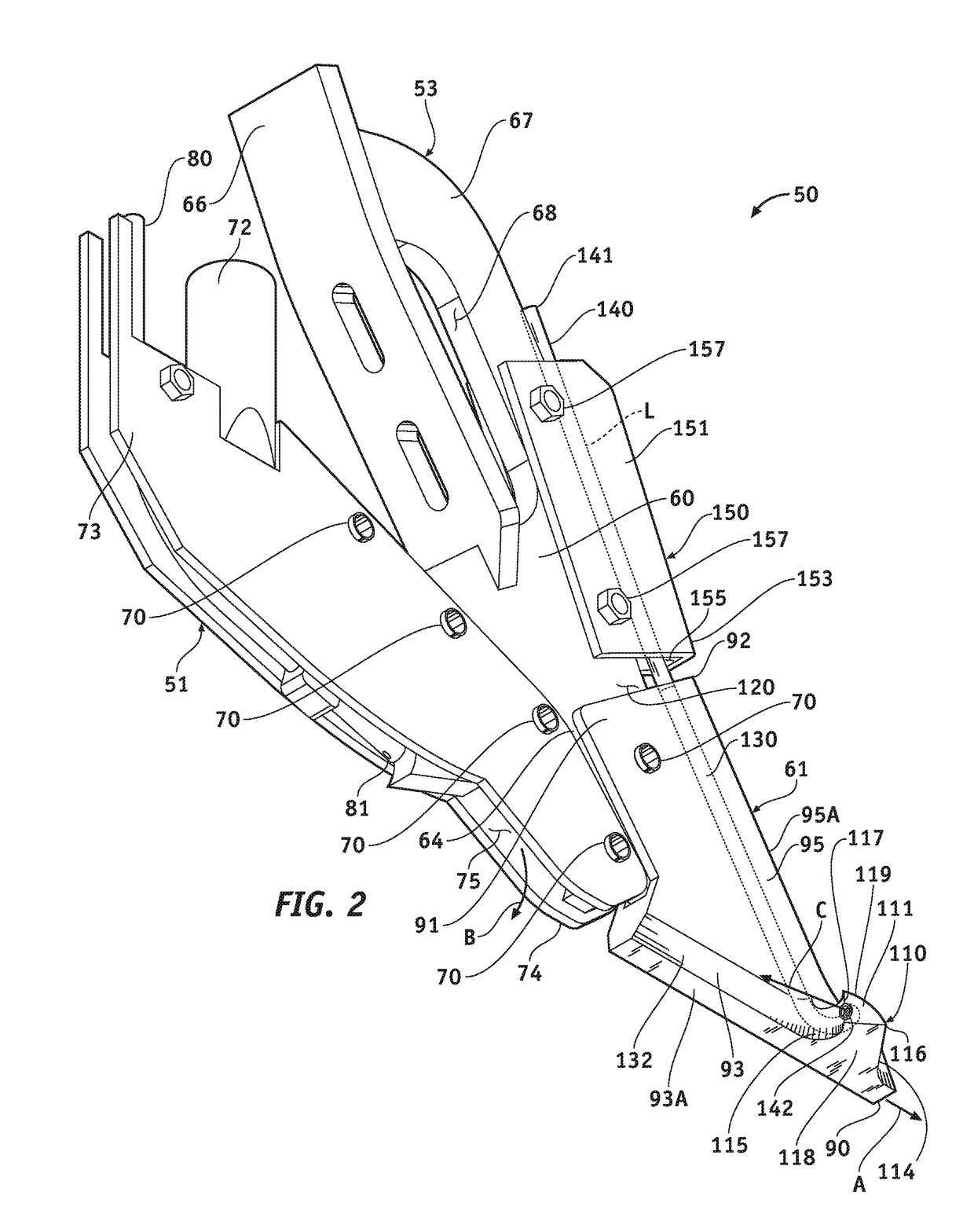

Cutting heads and agricultural seeder implements formed therewith

A soil cutting head for a mount of an agricultural implement includes a head having a leading extremity for cutting into soil ahead of the mount, and a fertilizer tube extending through the head to a discharge end for discharging a stream of fertilizer into the soil from the head.

Owner:KILE RONALD J

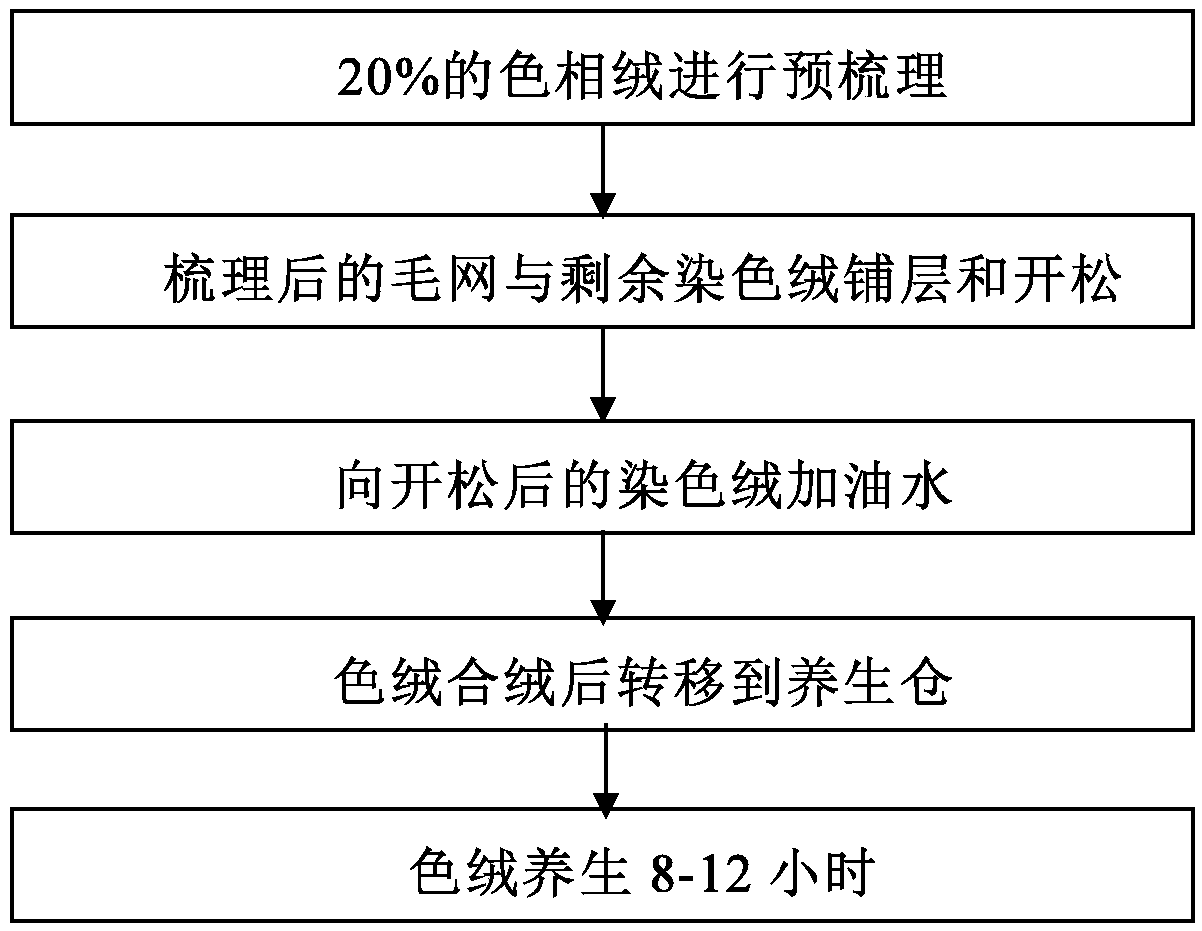

Cashmere blending method for reducing card neps with design and color

The invention discloses a cashmere blending method for reducing card neps with design and color, and relates to the field of cashmere blending of cashmere industries. The method is characterized by comprising the following steps that step one, pre-carding is carried out on 20% of hue cashmere; step two, laying-up and opening are carried out on carded hue cashmere and remaining dyed cashmere; stepthree, oil water is added; and step four, bin transferring is carried out for maintenance. The cashmere blending method for reducing the card neps with the design and color has the advantages that (1)laying-up once and opening twice are carried out on the carded hue cashmere and other hue cashmere, a preliminary blending process is omitted, the frequency of opening is reduced, thereby protectingthe length of a cashmere fiber, reducing the time and labor, and improving the production efficiency; (2) the card neps of the pre-carded fiber are obviously reduced during spinning, spun yarns have no card nep, no card nep picking link exists during knitting production, thereby improving the working efficiency and ensuring the inherent quality and appearance quality of cashmere products; (3) during all production processes from spinning to knitting, energy conservation and consumption reduction are achieved, and the production efficiency is improved.

Owner:NINGXIA RONGCHANG CASHMERE IND GROUP

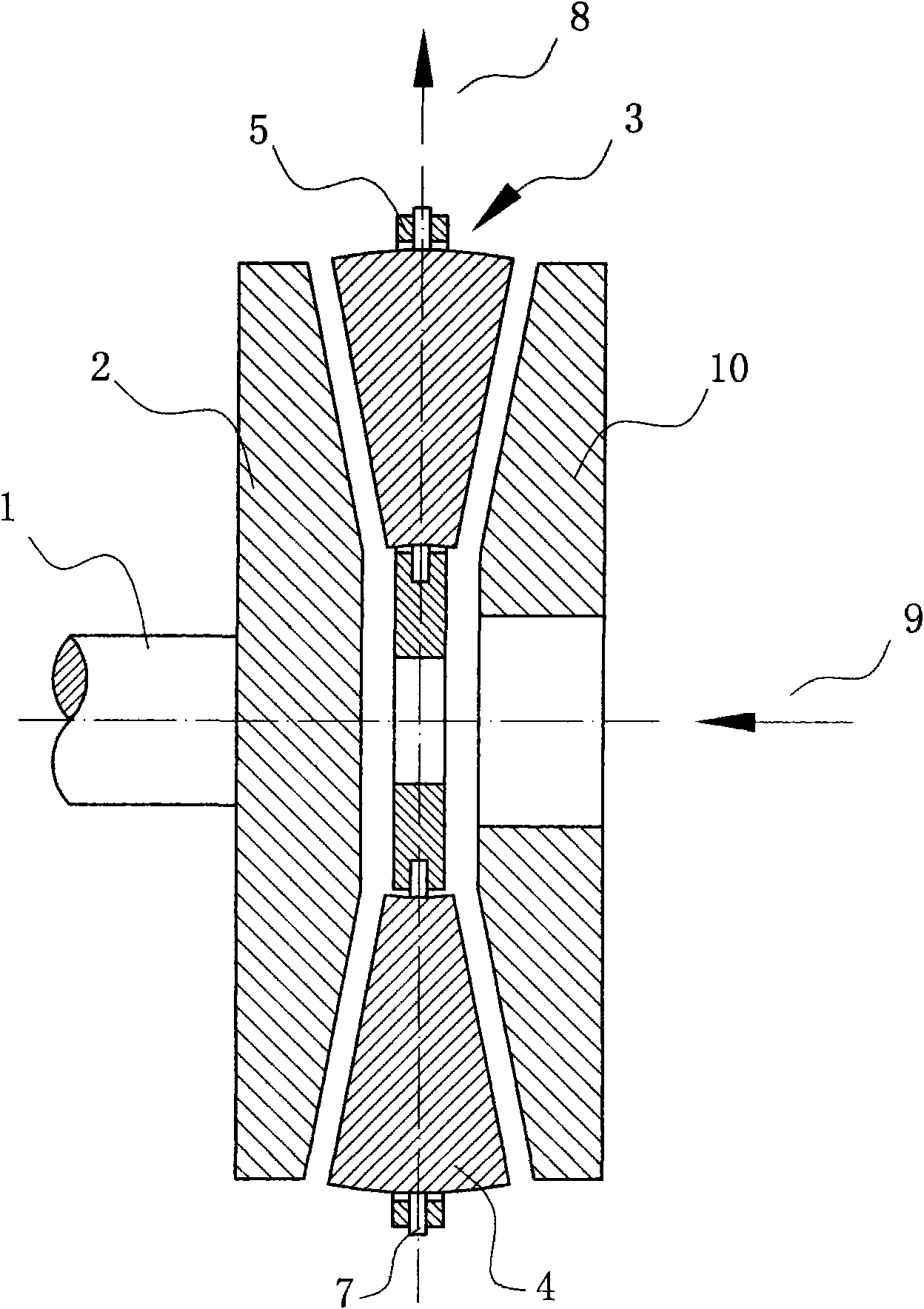

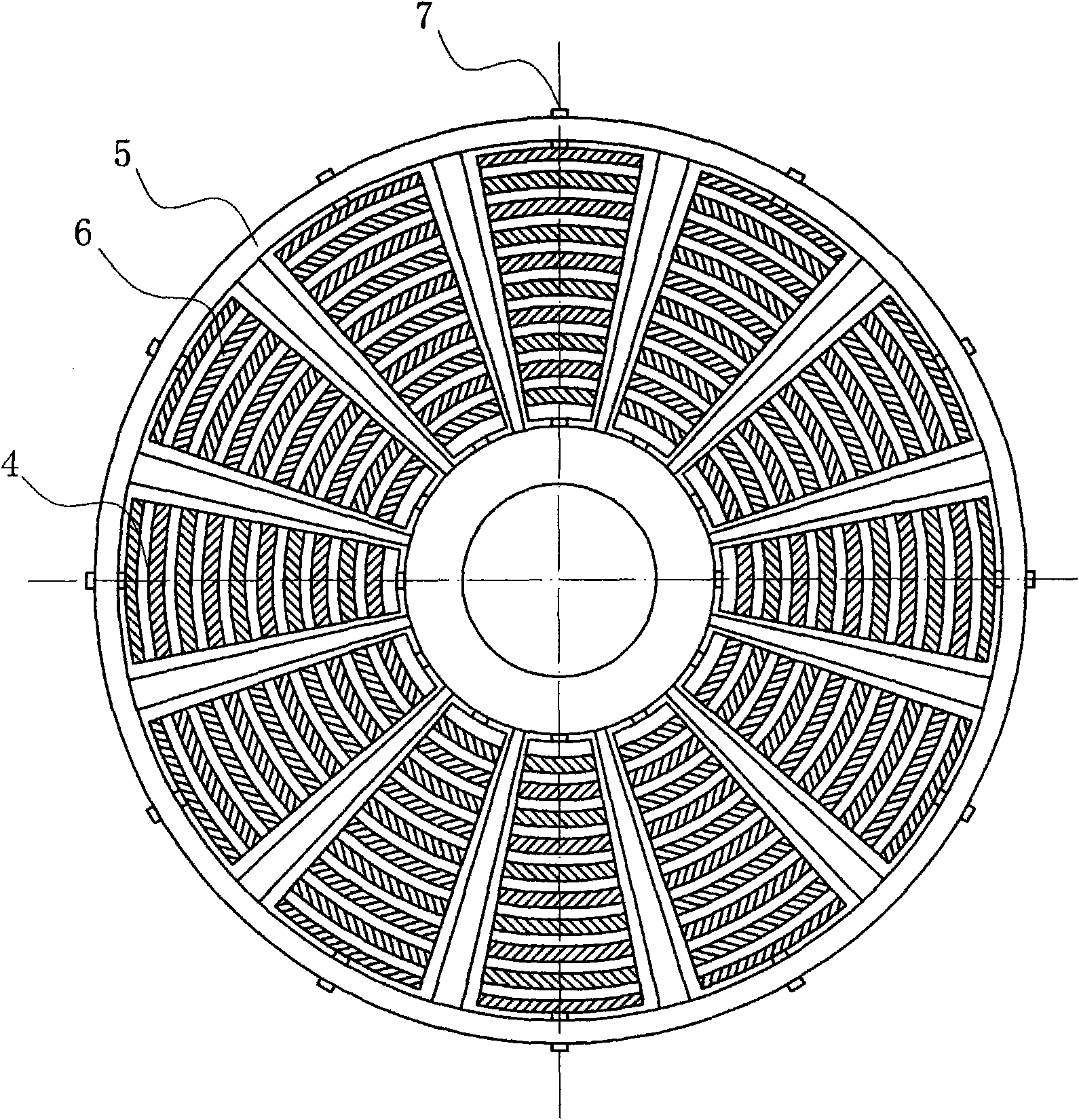

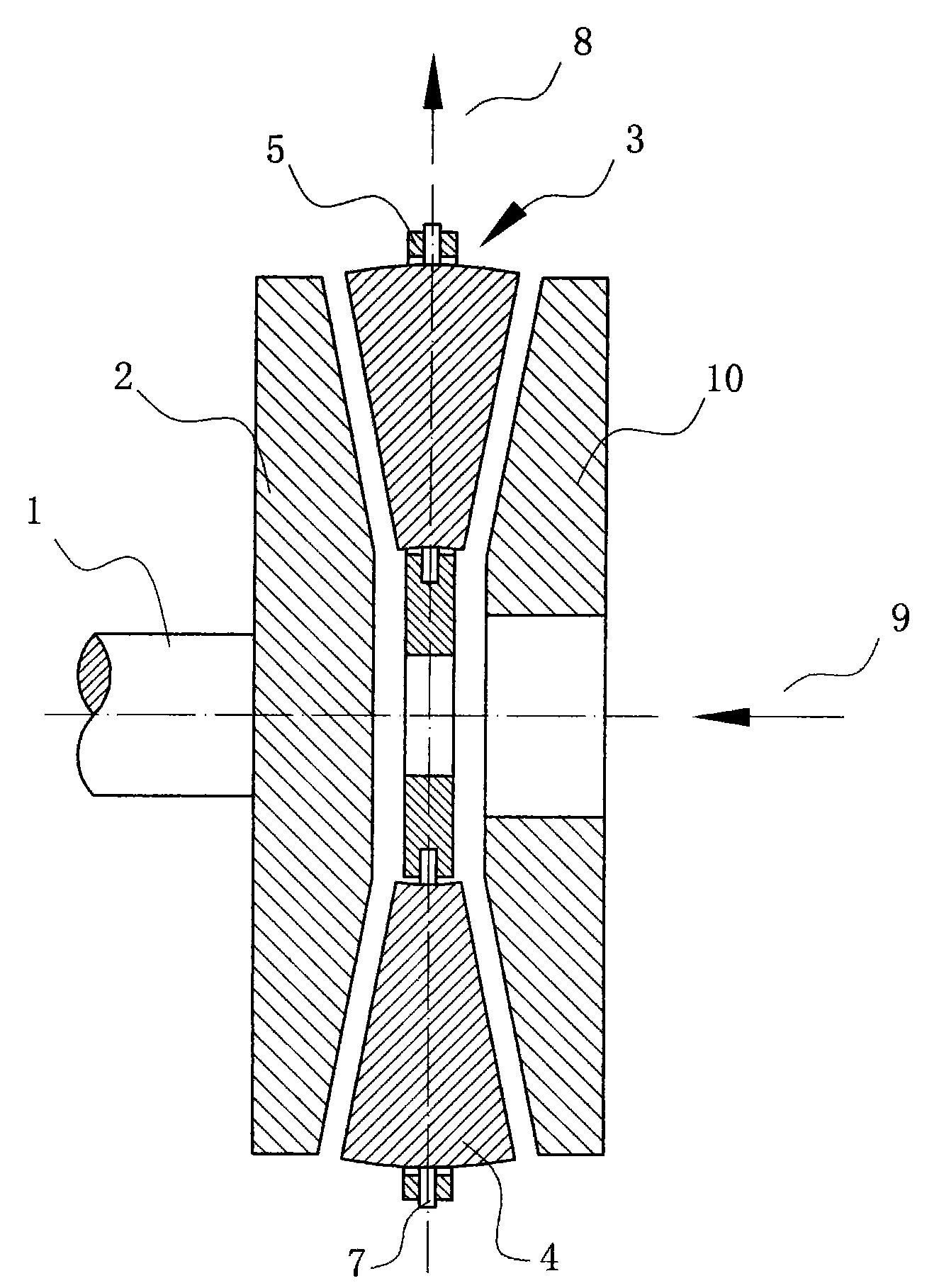

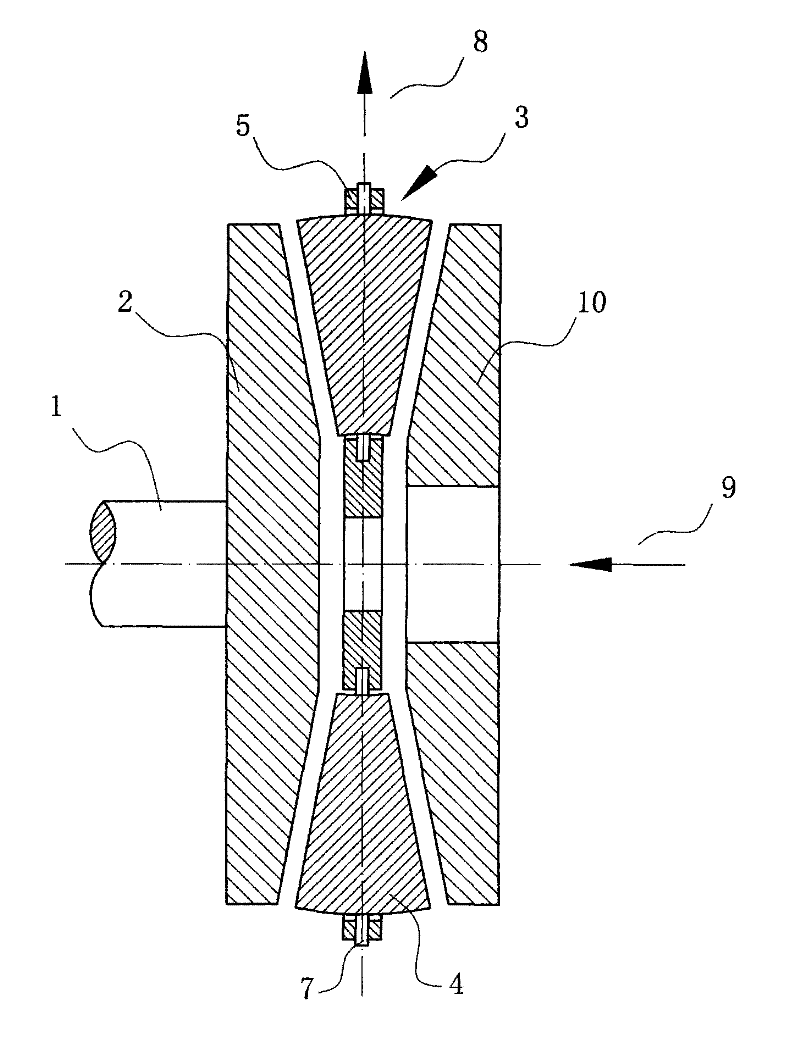

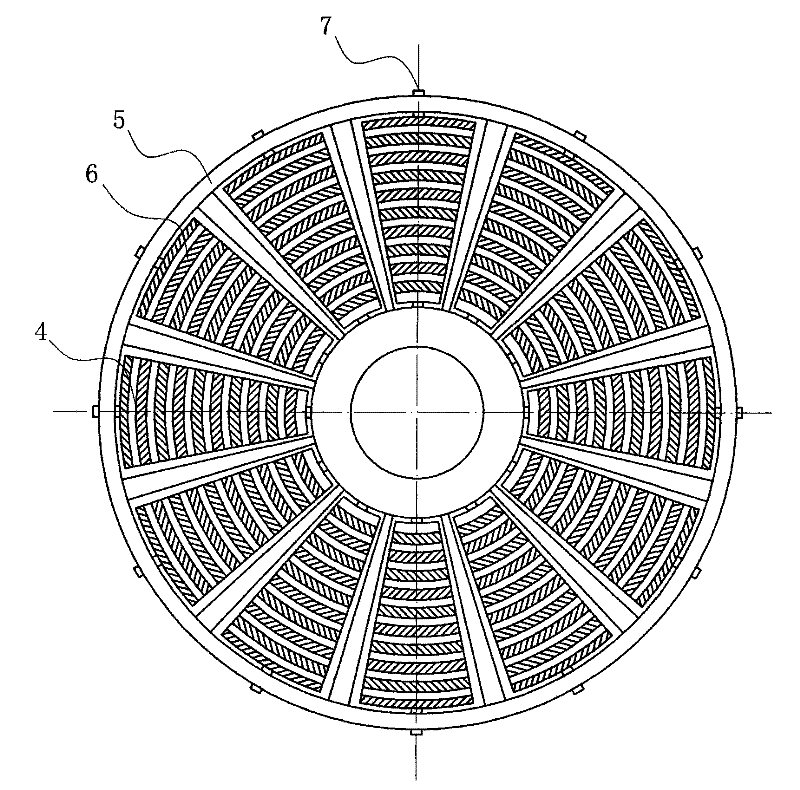

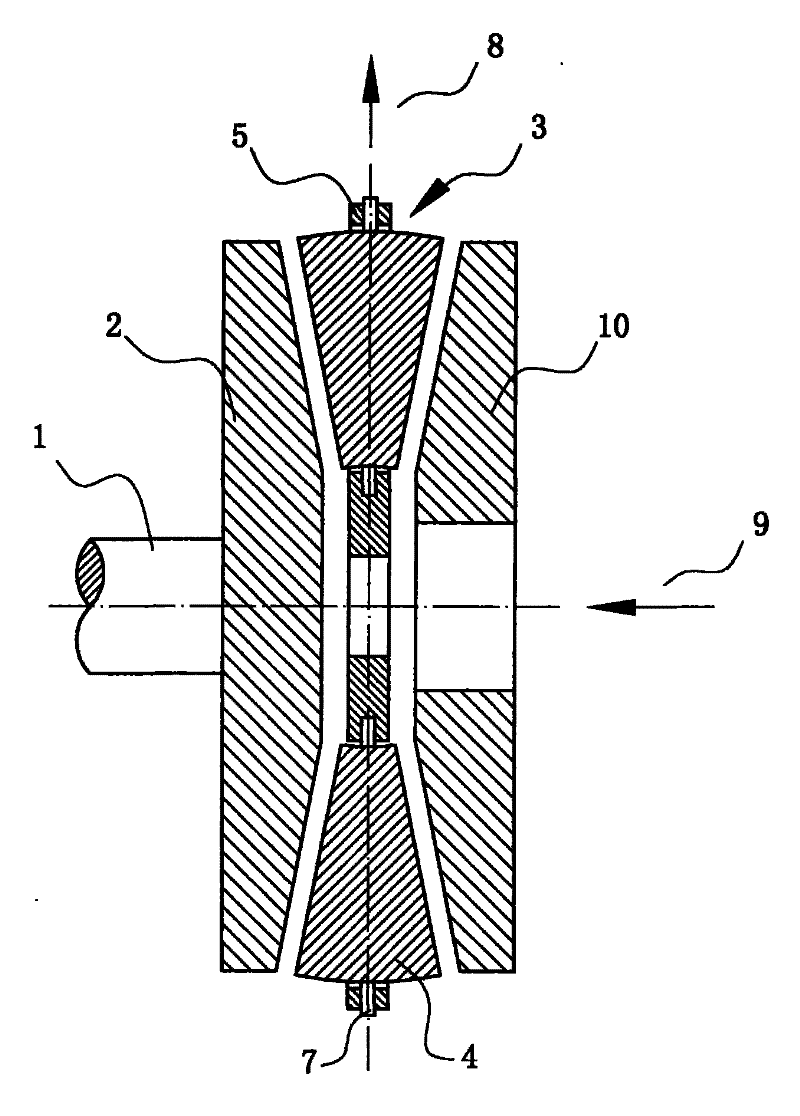

Refiner

InactiveCN101851874AReduce lossGrind evenly and neatlyPulp beating/refining methodsMaterial consumptionEngineering

The invention discloses a refiner, which comprises a first millstone, a second millstone and a middle millstone which rotate relative to each other, wherein the middle millstone is installed between the first millstone and the second millstone, cone rolls are installed on the racks of the millstones along the circumferential direction of the middle millstone, the small ends of the cone rolls are inwards; when the first millstone and the second millstone rotate relative to each other under the traction of a crankshaft, cone rolls on the middle millstone are driven to rotate, thus the cone rolls perform rolling operation on the contact work surface of the millstones; on one hand, power consumption can be significantly reduced, material consumption can be reduced, service life can be prolonged, and work efficiency is improved; on the other hand, due to the numerous cone rolls, once the cone rolls roll at a high speed to operate, a material can be pressed and crushed again and again successively by the cone rolls rotating at the high speed as long as entering the refiner, therefore, the mainly refining method of the invention is milling, the material is easy to be evenly and neatly milled, thus the fiber strength is protected and the performance of the refiner is significantly enhanced as compared with the existing grinder.

Owner:冯秀娟

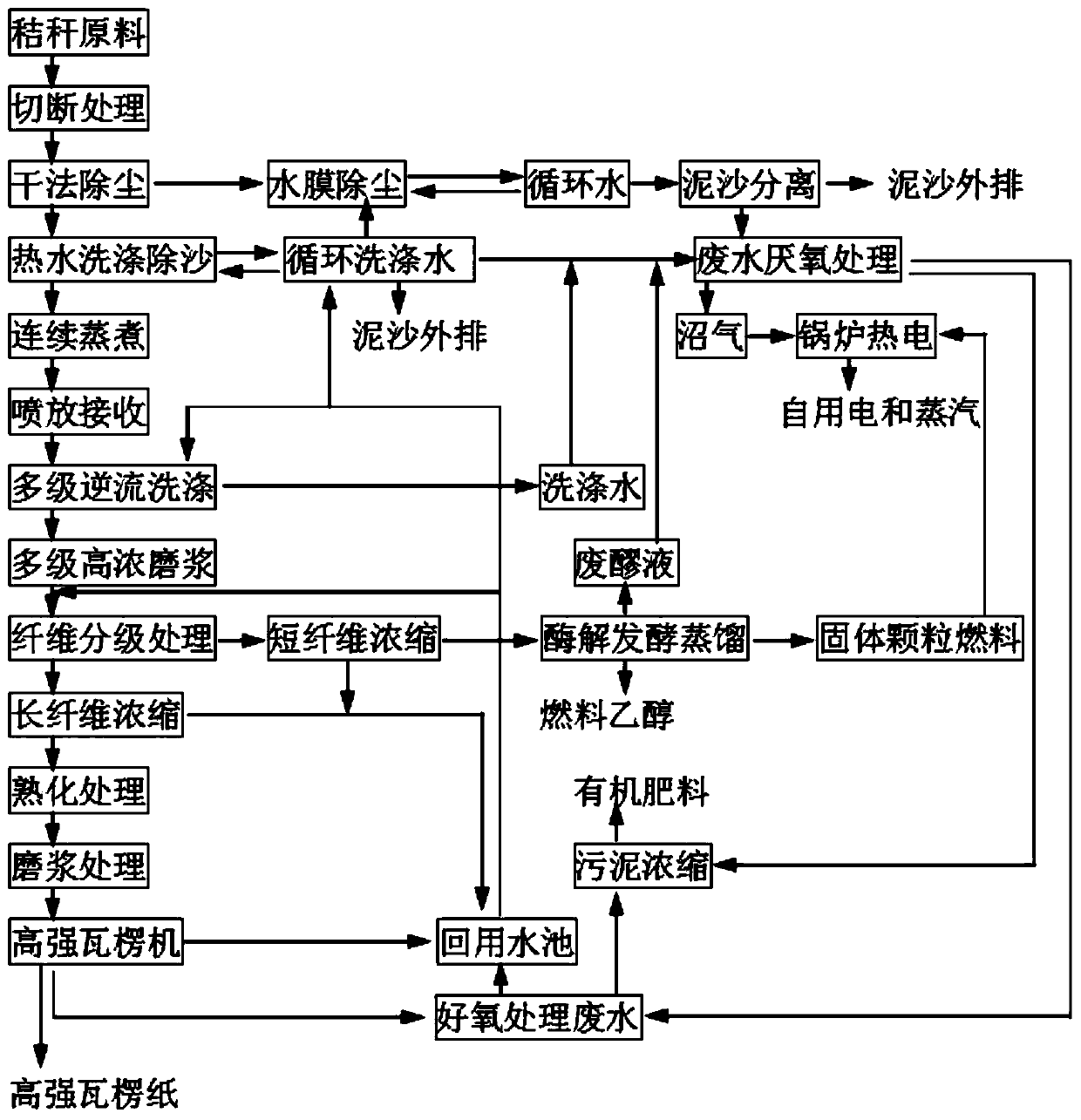

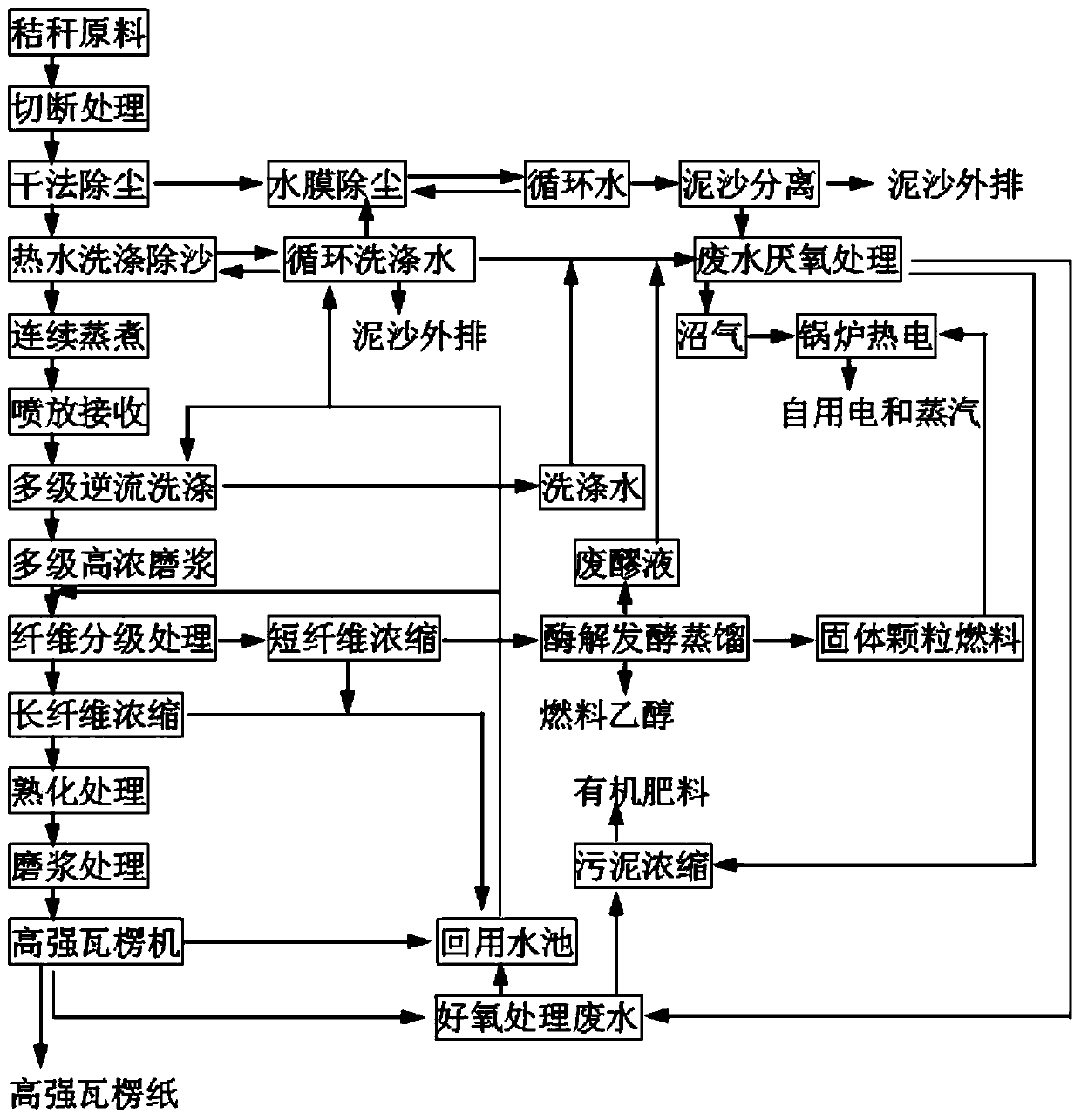

Straw comprehensive utilization method

InactiveCN109989285AImprove COD valueImprove water filtration performanceBioreactor/fermenter combinationsBiological substance pretreatmentsFiberHigh concentration

The invention relates to a straw comprehensive utilization method, and belongs to the technical field of biomass raw material comprehensive utilization. The method mainly comprises the following key steps: straw cutting treatment, dry-process dedusting, hot-water washing for sand removing, continuous cooking, spraying and receiving, multi-stage countercurrent washing, multi-stage high-concentration pulp grinding, fiber classification treatment, long-fiber concentration, long-fiber curing treatment, long-fiber pulp grinding and production of corrugated paper through long fibers, short-fiber concentration, and enzymolysis, fermentation and distillation of short fibers for production of fuel ethanol and solid granular fuel. The method has the beneficial effects that high-value comprehensive utilization of all components of the straw material is realized, chemicals are not added, a water system is closed and circulated, and the zero discharge of wastewater is realized; the specific surfacearea of a fine fiber component is large, and the enzymolysis efficiency is high; corrugated paper produced by the long fiber component is high in strength and good in quality; when the fine fiber component is used for an enzymolysis system, not only is the enzymolysis property of the material improved, but also the cost of enzymolysis sugar is greatly reduced, so that the development of a biomasscomprehensive utilization technology is promoted.

Owner:吴学军 +5

Localized Differential Privacy Preserving Frequent Itemset Mining Method Based on Frequent Pattern Tree

ActiveCN110471957BImprove privacy protectionReduce overheadDigital data information retrievalDigital data protectionThird partyDifferential privacy

Owner:ANHUI UNIVERSITY

APMP novel pulping method

InactiveCN101333776ASave resourcesWeakened bindingPulping with inorganic basesContinuous pulping processBinding forceContact reaction

The invention discloses a novel method for APMP pulping. The first chemical reaction step is conducted before steps of wood chip washing and fluffing, and the chemical reaction step means the contact reaction in a wood chip reaction bin between wood chips and a medical solution in the reaction bin; the chemical reaction step is conducted prior to the wood chip washing step, so the residual reaction in the chemical reaction step can be directly used as a solution for wood chip washing, thereby greatly saving mass resources; the chemical reaction step which is conducted prior to the fluffing step makes the wood chips react chemically with the medical solution in the reaction bin before fluffing, thereby the binding force among fibers is decreased greatly after the reaction between the wood chips and the medical solution, and lengths of fibers are protected effectively in the fluffing process. The method is favorable for improving the intensity of paper pulp as well as obviously reducing the energy required in the fluffing process, leading to greatly saved energy.

Owner:李昊

Refiner

The present invention discloses a refiner which comprises a first grinding disc, a second grinding disc and an intermediate grinding disc that rotate relatively. The intermediate grinding disc is installed between the first grinding disc and the second grinding disc. Tapered rollers are installed along the peripheral direction of the intermediate grinding disc on the grinding disc frame of the grinding disc. The small ends of the tapered rollers are inward. When the first grinding disc and the second grinding disc are dragged by a crankshaft to rotate relatively, the tapered rollers on the intermediate grinding disc must be driven to rotate. Thus the tapered rollers rotate and operate on the contact working surfaces of the grinding discs. On one hand, the refiner of the invention has the advantages of greatly reduced power consumption, reduced material damage, prolonged service lifetime and increased operating efficiency; and on the other hand, as many tapered rollers are provided, when the tapered rollers rotate and operate with a high speed, the material is crushed repeatedly by the tapered rollers which operate in high speed one after another once enters the refiner. Therefore the main grinding mode of the invention is grinding. The material is easily grinded uniformly and regularly. The length of the fiber is protected and the performance of the refiner according to the invention is remarkably reinforced compared with the prior grinder.

Owner:SHENZHEN DEWEI INTELLIGENT MFG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com