Refiner

A technology of a refiner and a grinding disc, which is applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc. It can solve the problems of high power consumption and excessive material loss, so as to reduce power consumption and material loss , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

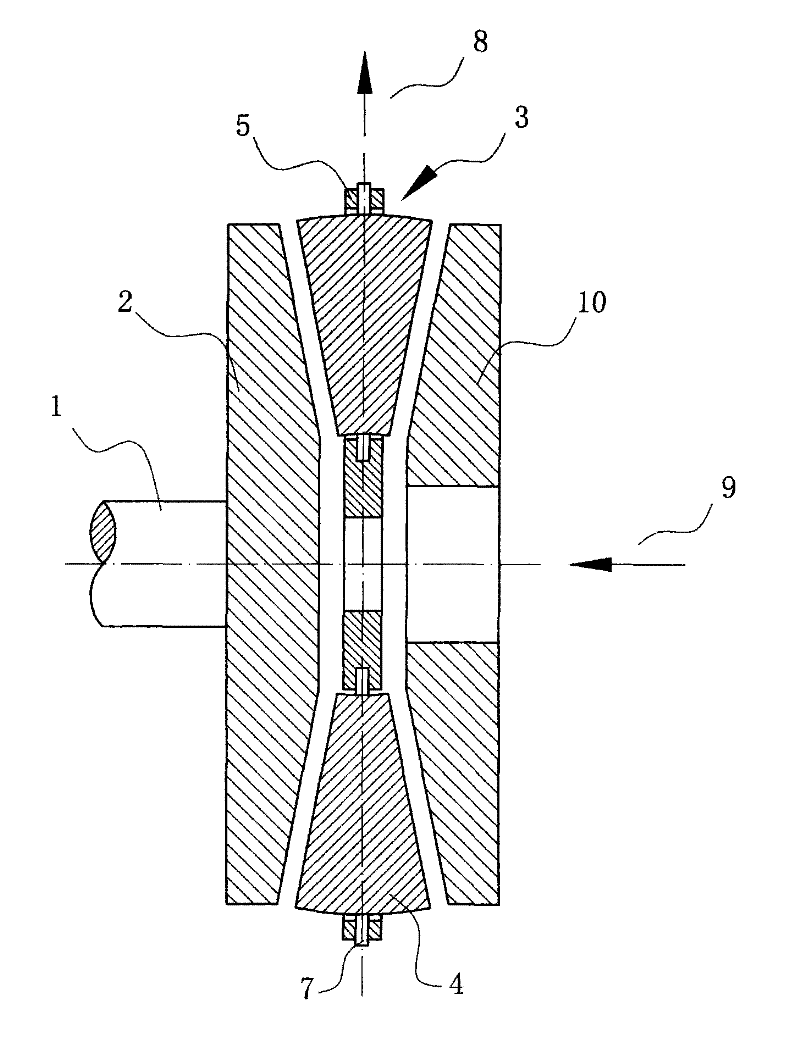

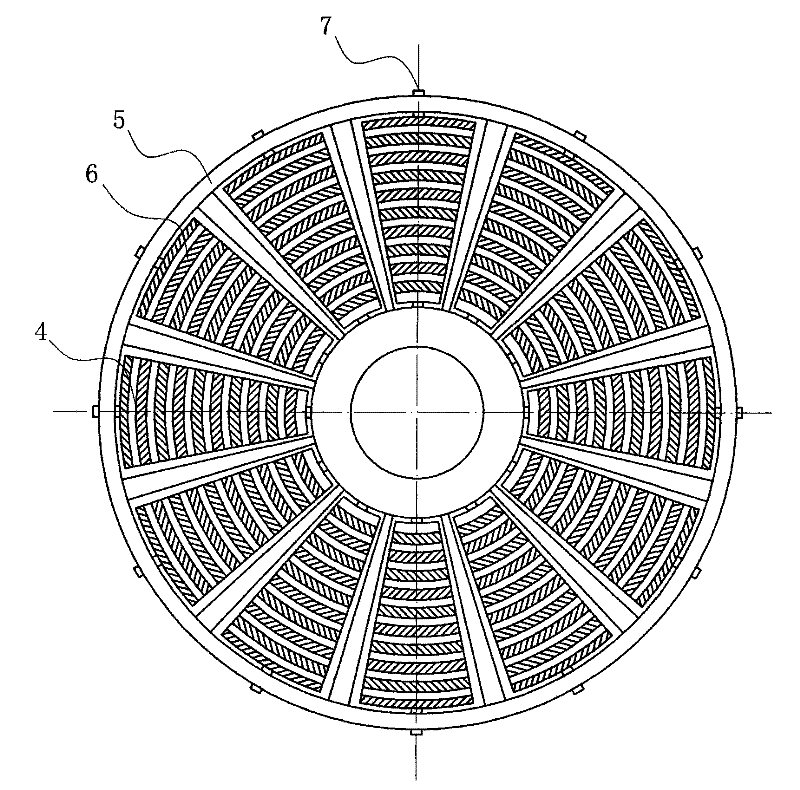

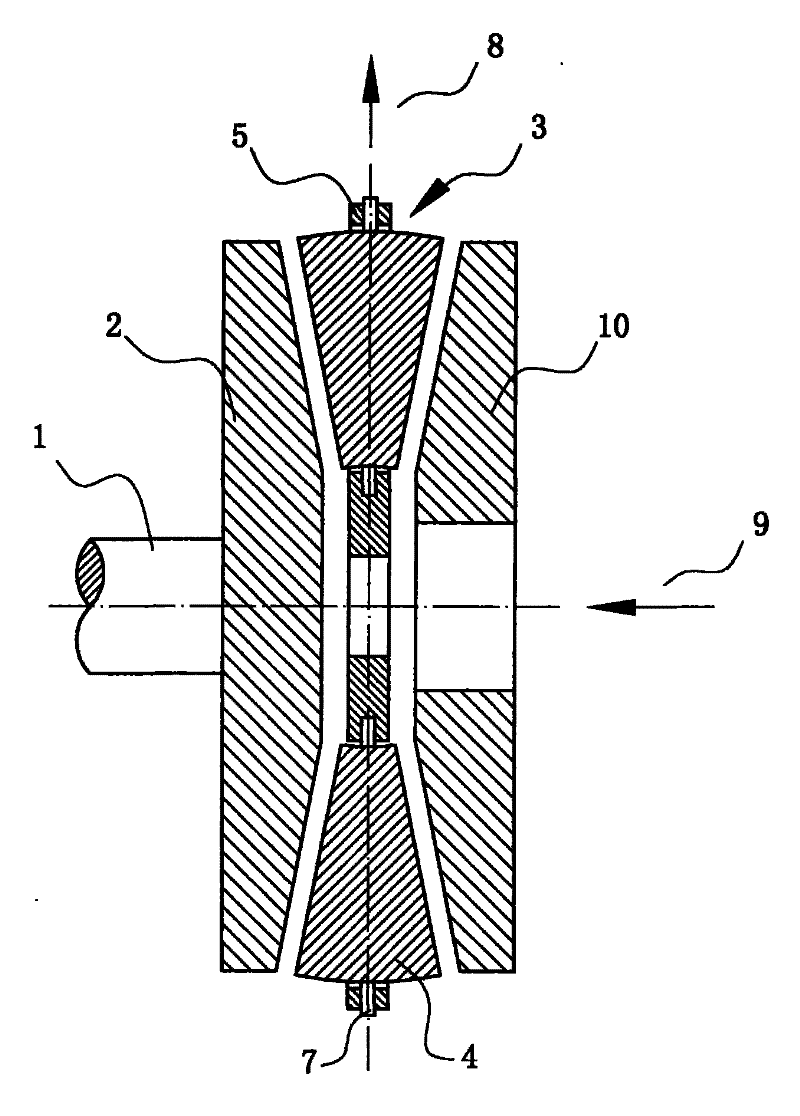

[0016] Such as figure 1 , figure 2 As shown, well-known components such as the body and the pressurizing device are omitted in the figure. The refiner of this embodiment comprises a first grinding disc 2 and a second grinding disc 10 which rotate relatively. In this embodiment, the first grinding disc 2 is a moving grinding disc driven by the shaft 1 to rotate, the second grinding disc 10 is a static grinding disc, and the second grinding disc 10 is a static grinding disc. The center of the grinding disc 10 is provided with a feed inlet 9, and the refiner of the present embodiment also includes:

[0017] The middle grinding disc 3 is installed between the first grinding disc 2 and the second grinding disc 10, and includes a grinding disc frame 5, on which twelve tapered rollers 4 are installed along the circumference of the intermediate grinding disc 3, the cone The small ends of the rollers 4 are inward; the tapered rollers 4 are uniformly distributed on the disc frame 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com