Refiner

A technology of a refiner and a grinding disc, which is applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., which can solve problems such as high power consumption and excessive material loss, and reduce power consumption and material loss , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

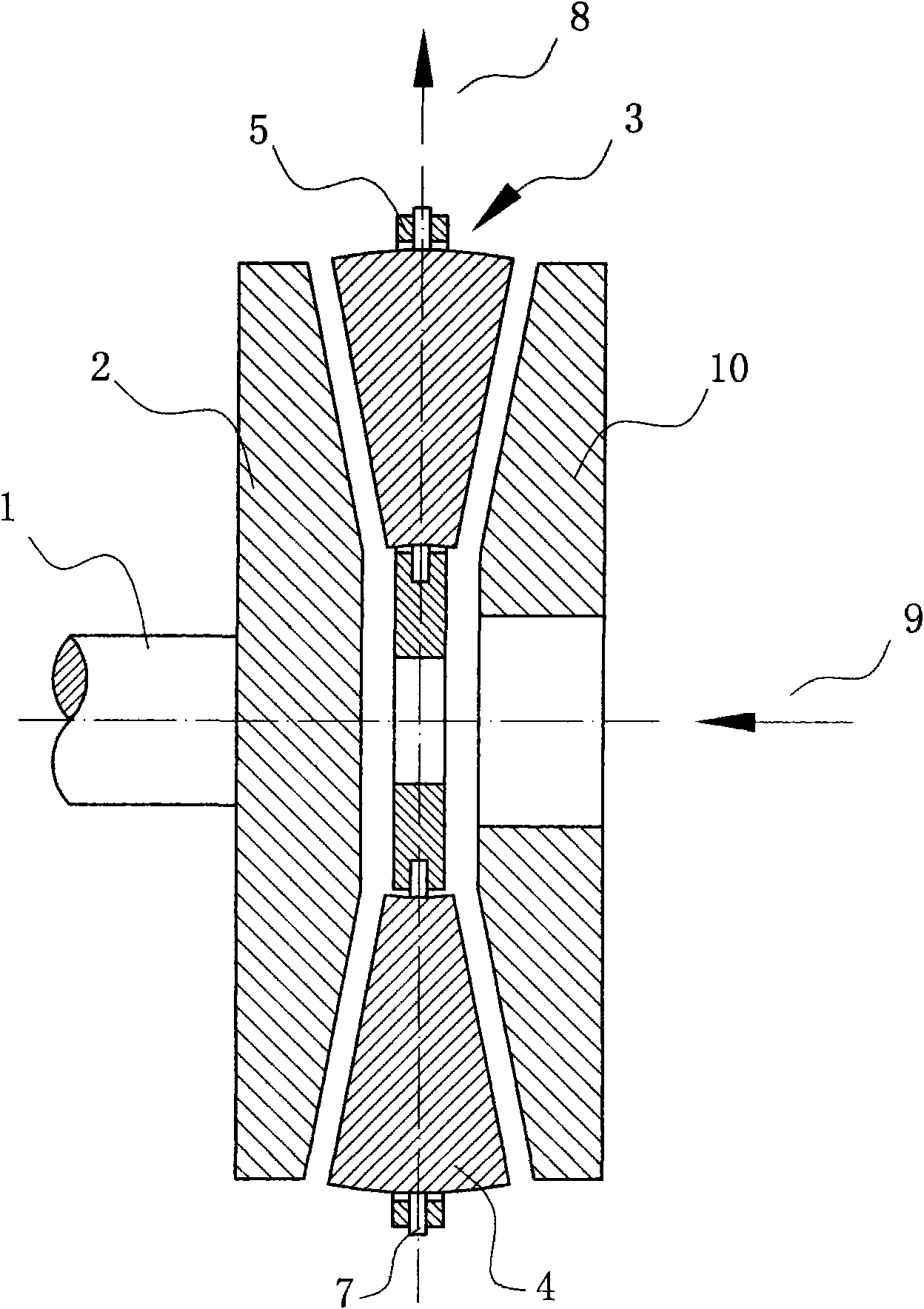

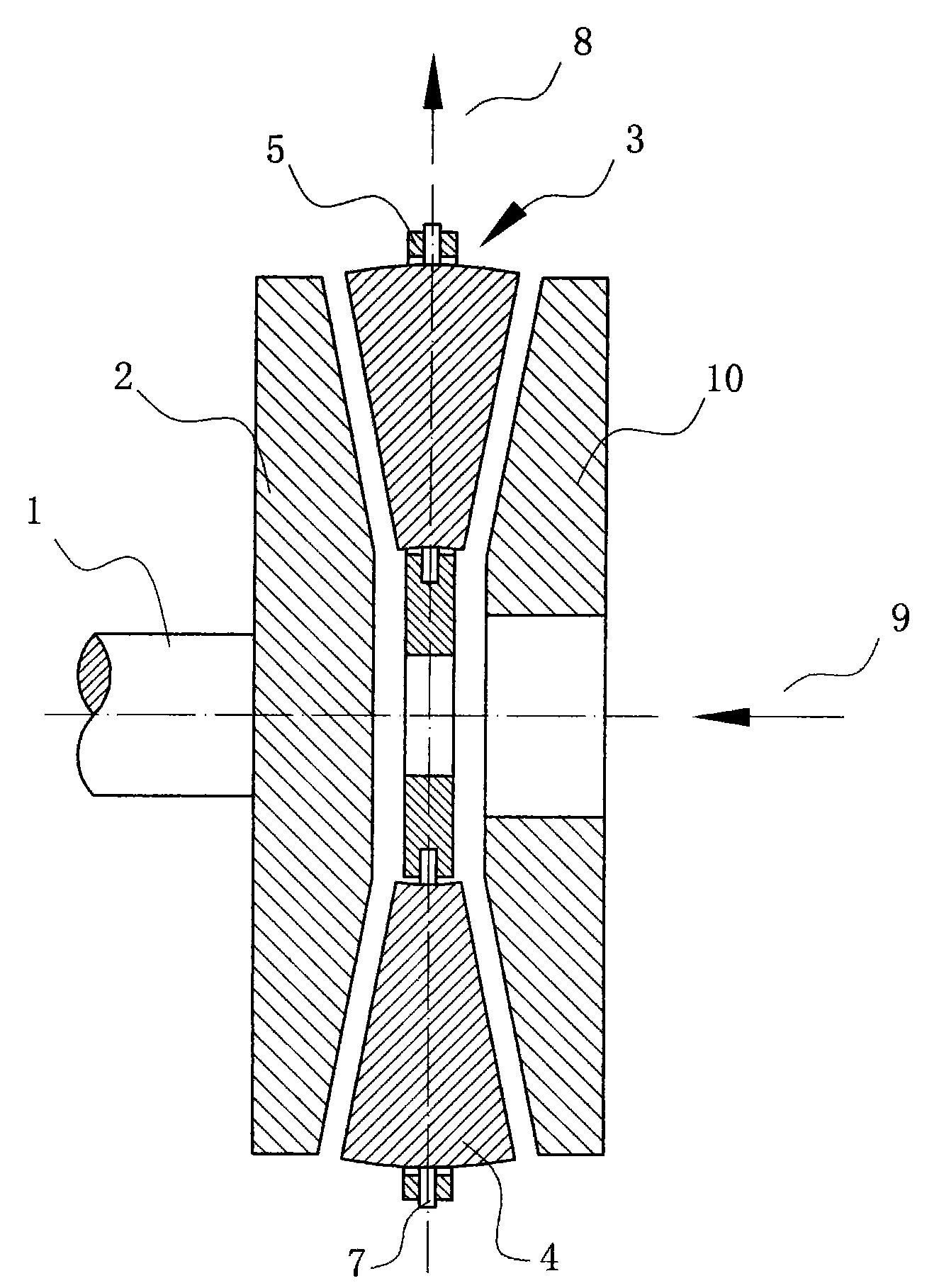

[0016] like figure 1 , figure 2 As shown, well-known components such as the body and the pressurizing device are omitted in the figure. The refiner of this embodiment comprises a first grinding disc 2 and a second grinding disc 10 which rotate relatively. In this embodiment, the first grinding disc 2 is a moving grinding disc driven by the shaft 1 to rotate, the second grinding disc 10 is a static grinding disc, and the second grinding disc 10 is a static grinding disc. The center of the grinding disc 10 is provided with a feed inlet 9, and the refiner of the present embodiment also includes:

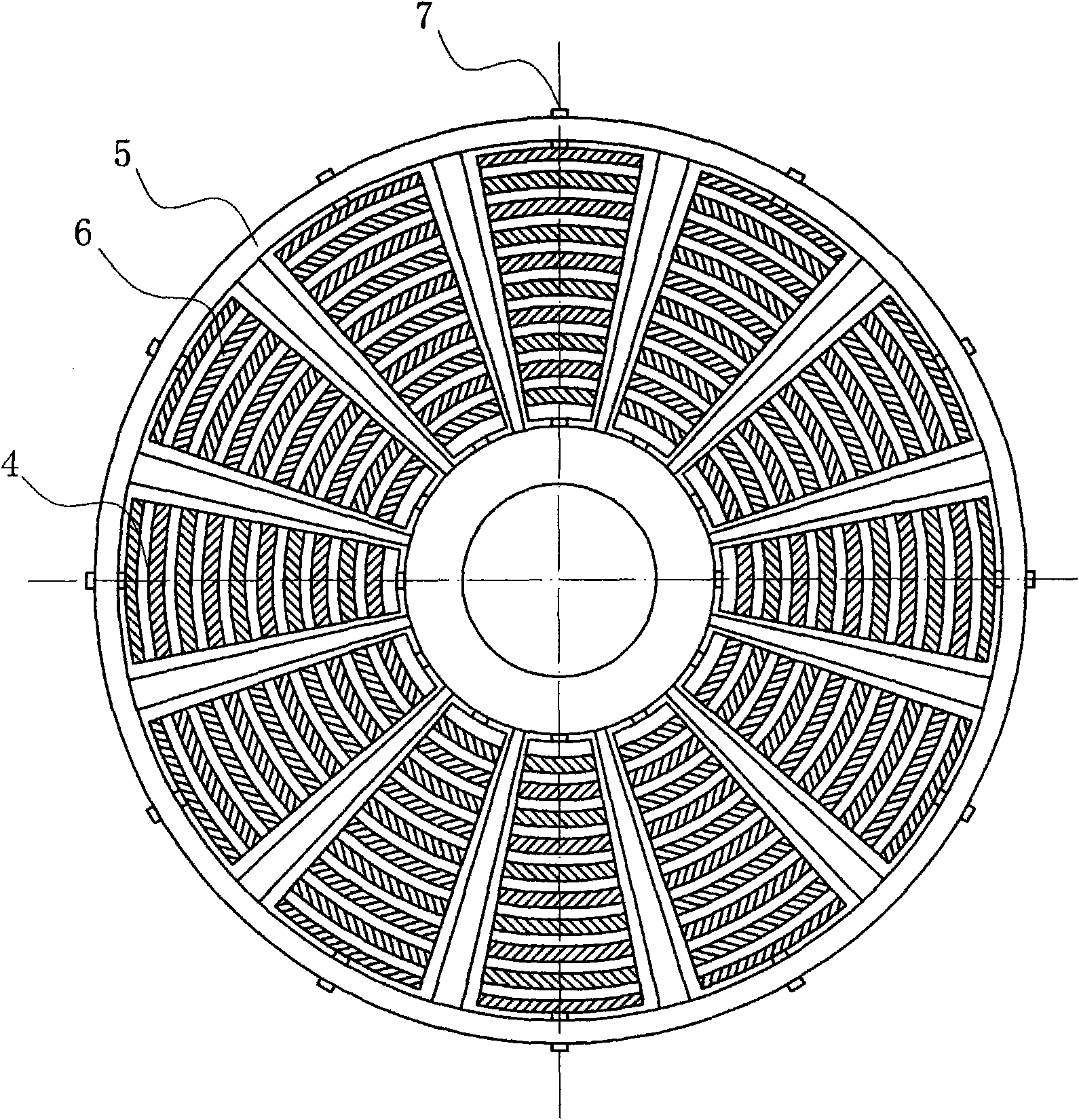

[0017] The middle grinding disc 3 is installed between the first grinding disc 2 and the second grinding disc 10, and includes a grinding disc frame 5, on which twelve tapered rollers 4 are installed along the circumference of the intermediate grinding disc 3, the cone The small ends of the rollers 4 are inward; the tapered rollers 4 are uniformly distributed on the disc frame 5 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com