Production process of low weight middle partition paper

A production process, low quantitative technology, applied in the paper, papermaking, paper machine and other directions, can solve the problem of not adapting to the needs of the packaging market, high quantitative, to achieve sustainable development, stable product quality, and increased use area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

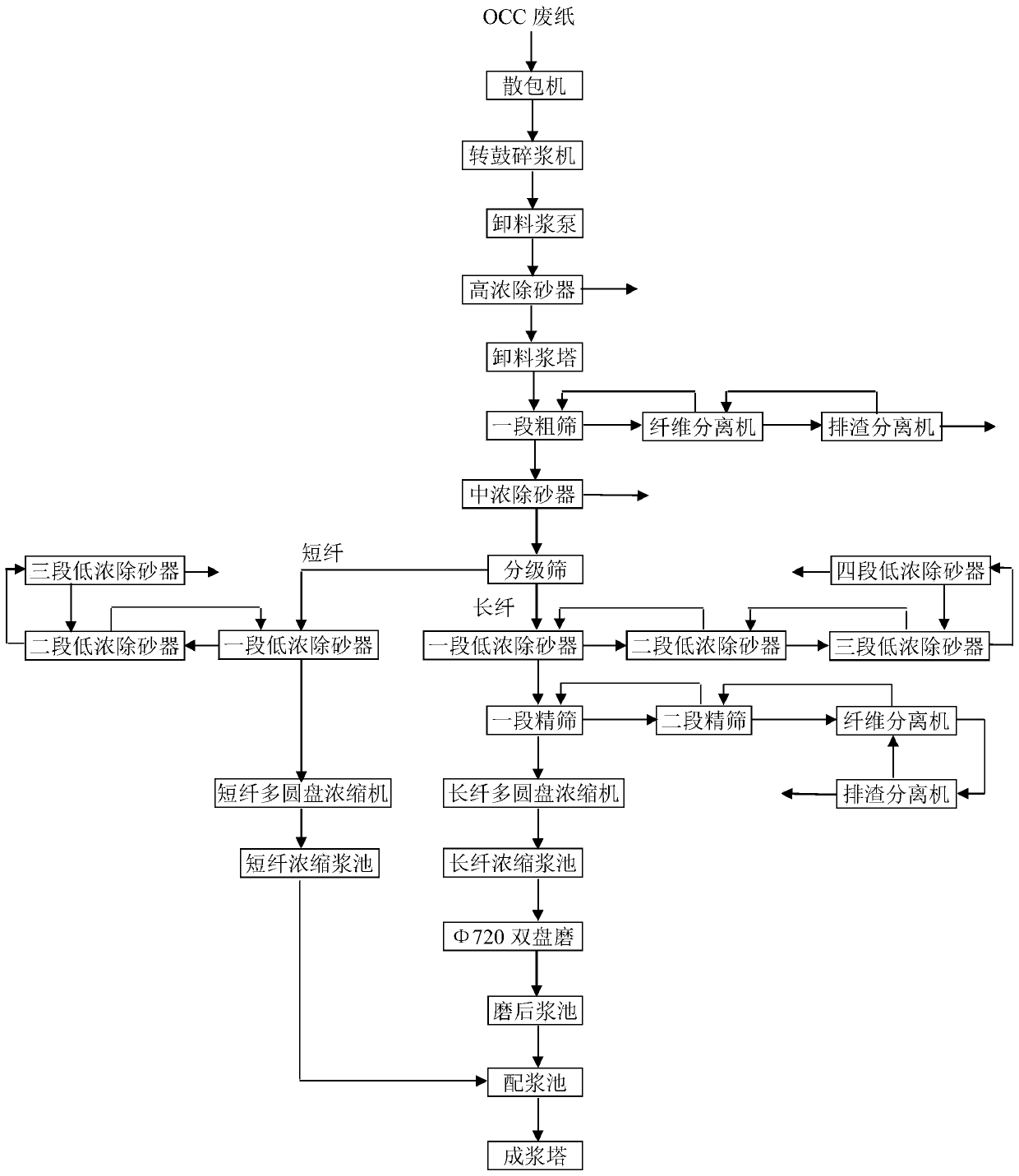

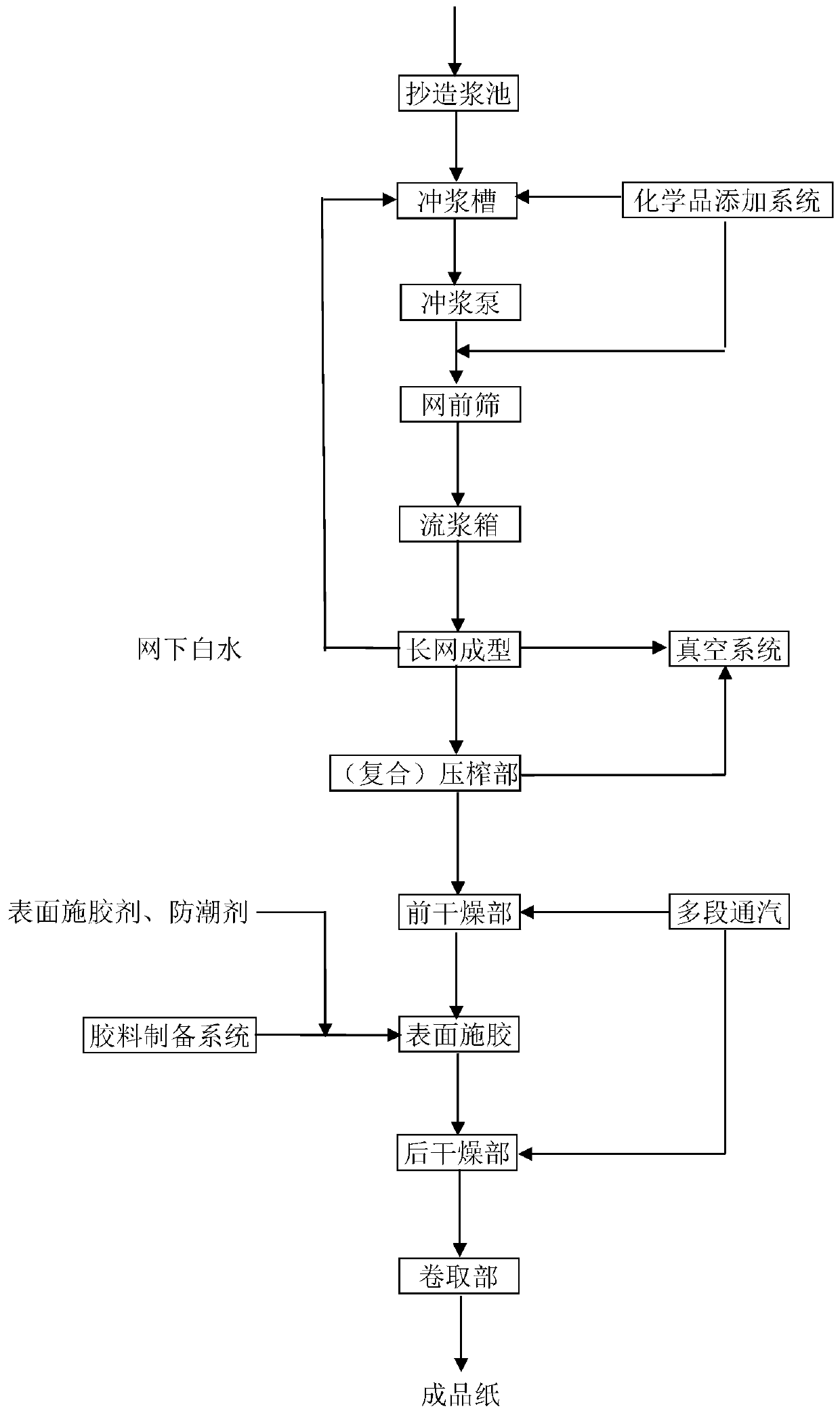

[0094] Another specific embodiment of a production process of a low-weight intermediate paper, comprising the following steps:

[0095]1. Ingredients. According to the fiber quality and impurity content, different grades of OCC waste paper are matched according to the ratio of raw materials determined by the products produced. Under the premise of product cost control, the effect of improving the physical strength index of the product is achieved by using imported waste paper raw materials containing high-quality wood pulp fibers, and the matching amount reaches 10-30%. The imported waste paper includes AOCC (American waste paper), EOCC (European waste paper), HOCC (Hong Kong waste paper) and the like. The specific ratio of waste paper is EOCC (European waste paper) 20%: LOCC (domestic waste paper) 80%.

[0096] 2. Disintegrate. Add the mixed waste paper into the white water, and under the mechanical and hydraulic action, the waste paper will be turned into coarse pulp thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com