Coated natural kraft and manufacturing method thereof

A technology of coated kraft liner and kraft liner, which is applied in the field of papermaking, can solve the problems that the quality of coated white-faced kraft liner cannot be effectively improved, the quality of coated kraft liner is difficult to be effectively improved, and the combination method is difficult to achieve. Conducive to sustainable use, beautiful appearance, good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

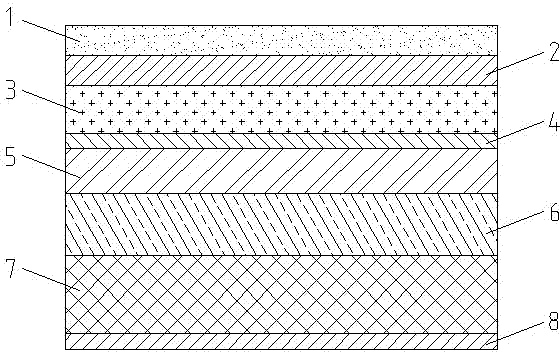

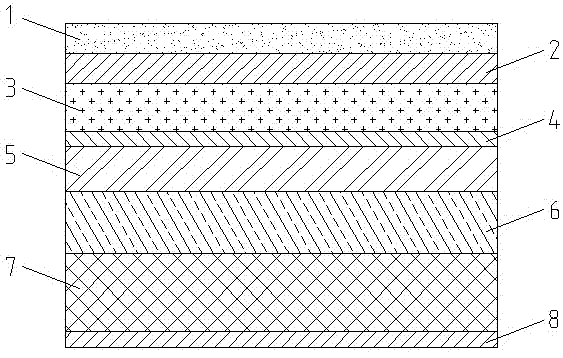

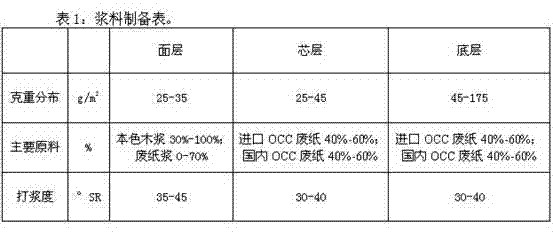

[0019] see figure 1 , the natural color coated kraft cardboard in this embodiment is composed of natural color kraft cardboard, a surface sizing layer and a surface coating layer, wherein the natural color kraft cardboard is composed of a bottom layer 7, a core layer 6 and a surface layer 5, and the core layer The lower surface of 6 is fixed on the upper surface of the bottom layer 7 , and the lower surface of the surface layer 5 is fixed on the upper surface of the core layer 6 . The bottom layer 7 in this embodiment is composed of OCC waste paper pulp, and the core layer 6 is composed of waste paper. The surface layer 5 in this embodiment is composed of uncolored wood pulp and waste paper pulp. Both the uncolored wood pulp and the waste paper pulp are calculated on an absolute dry basis. The weight percentage of the uncolored wood pulp is 30%-90%, and the balance is waste paper pulp, that is, Said that in the surface layer 5, the percentage by weight of dry wood pulp is 30%-9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com