Breaking and separation integrated comprehensive recovery system of chrysotile tailings

A kind of chrysotile and sorting technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high energy consumption, complicated process and long cycle of dehydration and drying, so as to improve product value, reduce production cost, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

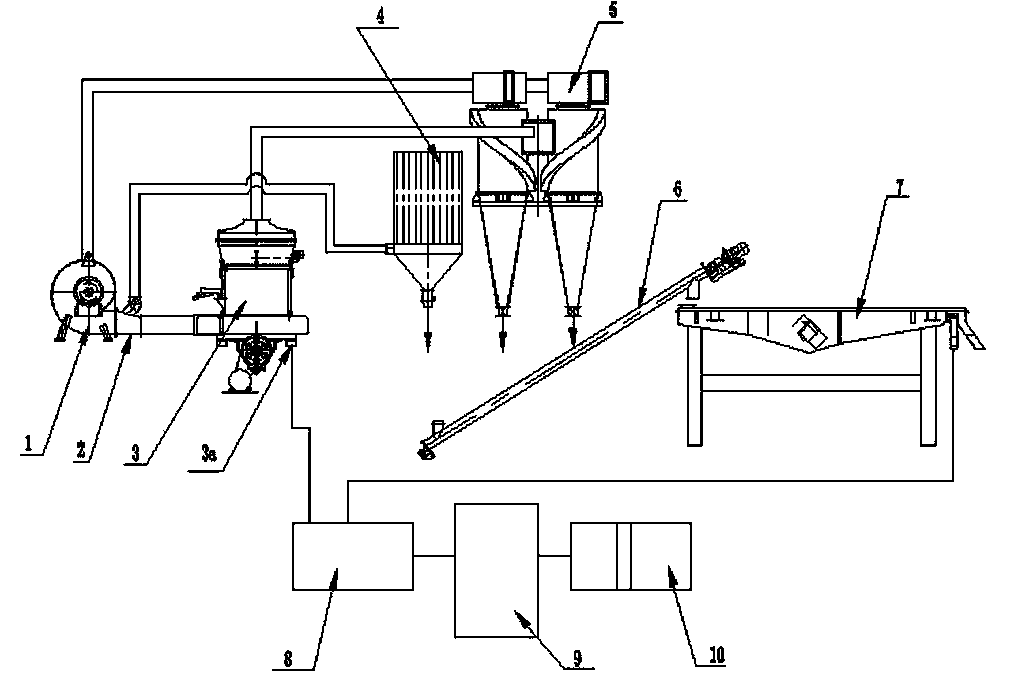

[0011] The following examples will be combined with figure 1 , figure 2 The present invention will be further explained.

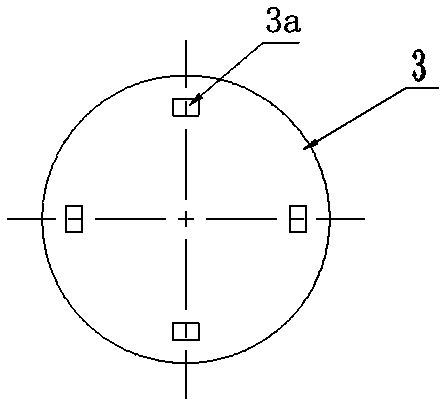

[0012] An integrated comprehensive recovery system for chrysotile asbestos tailings crushing and sorting, including fan 1, three-way valve 2, grinding host 3, dust collector 4, cyclone collector 5, screw conveyor 6, plane gyratory screen 7 , Weak magnetic separator 8, ball mill 9, Wet weak magnetic separator 10. Fan 1 is connected to the main grinding machine 3 and dust collector 4 through the three-way valve 2 respectively. The bottom of the main grinding machine 3 is provided with 4~ 8 sand discharge outlets, figure 2 Shown in the figure are four sand discharge outlets 3a; the outlet of the grinding host is connected to the cyclone collector 5 through a pipe, the inlet of the screw conveyor 6 is connected with the outlet of the cyclone collector 5, and the screw conveyor 6 The outlet is conveyed to the plane gyratory screen 7 to realize the recovery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com