Cashmere blending method for reducing card neps with design and color

The technology of tuft and tufting is applied in the field of tufting to reduce the tufted tufts, which can solve the problems of increasing labor, consuming labor cost and time cost, reducing yarn quality and production rate, etc., so as to improve work efficiency, Improve production efficiency, ensure the effect of internal quality and appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes a preferred embodiment of the present invention with reference to the accompanying drawings to make its technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

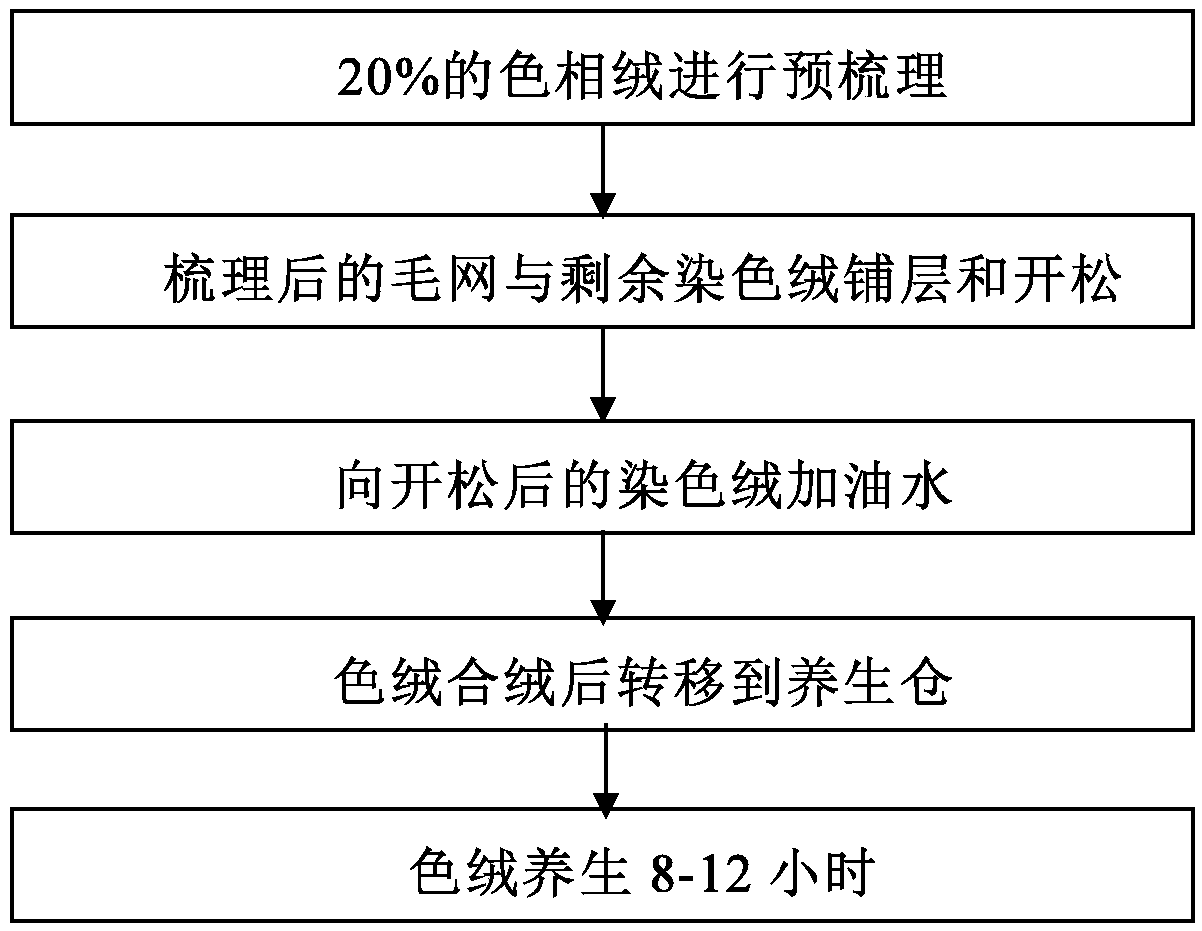

[0025] Such as figure 1 A preferred embodiment of the present invention is shown in the flow chart of a method for reducing interlocking colored hair grains. This method mainly includes the following four processes: pre-combing the hue velvet, combing the hue velvet and remaining dyed velvet Laying and opening, add oil and water to the dyed fleece after carding, laying and loosening, and transfer the hue fleece to the health care warehouse after the dyed fleece is combined. Specifically, the hue fleece with a dyed fleece ratio of less than 20% is pre-combed and combed. It is a wool net shape, and then the combed h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com