Method for preparing ultrahigh-purity gas through low temperature separation, and low temperature separation system

A separation system and pure gas technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of relatively high purity requirements of raw material gas, low separation efficiency of towers, and small product output, etc., to achieve Low operating pressure, reduced investment cost, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

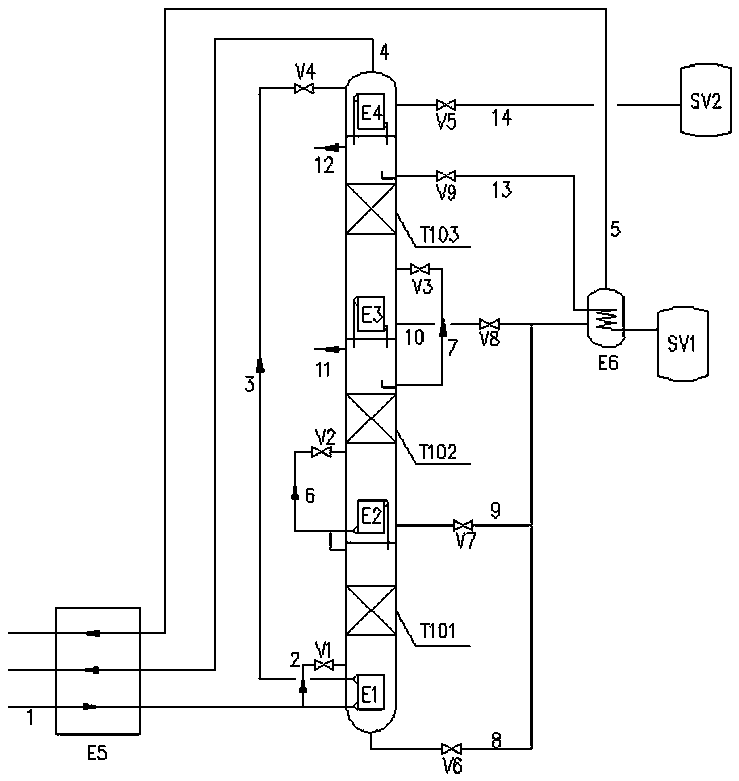

Image

Examples

Embodiment 1

[0033] Example 1: Preparation of ultra-high-purity nitrogen.

[0034] Impurities such as oxygen, argon, neon, helium, hydrogen, and carbon monoxide usually exist in nitrogen, among which neon, helium, and hydrogen are light component impurities. Most of the traditional nitrogen purification methods use the adsorption method. Since the purity of the product depends on the ability and activation degree of the adsorbent, it is not only difficult to select the adsorbent, but also the adsorption purification effect is not good, and the energy consumption is high. It is difficult to achieve ultra-high purity for the electronics industry. Nitrogen requires a purity of 6.0N grade (99.9999%) or higher.

[0035] Applying the method and equipment for producing ultra-high-purity gas by low-temperature separation of the present invention can simultaneously remove light components and heavy-component impurities in nitrogen, and can easily obtain ultra-high-purity nitrogen products above 6.0...

Embodiment 2

[0040] The preparation of embodiment 2 ultra-high purity carbon tetrafluoride

[0041] At present, there are mainly four methods for producing carbon tetrafluoride on an industrial scale, and the method of producing carbon tetrafluoride by fluorocarbon synthesis has become the most industrially produced carbon tetrafluoride because of its advantages such as easy availability of raw materials and controllable process. common method. Carbon tetrafluoride is directly synthesized from amorphous carbon and fluorine gas. Impurities in carbon tetrafluoride after alkali washing include nitrogen, oxygen, carbon monoxide, hexafluoroethane, octafluoropropane, etc., among which nitrogen, oxygen, and carbon monoxide are light groups Sub-impurities. Commonly used methods for the purification of carbon tetrafluoride include adsorption, membrane separation, and cryogenic distillation.

[0042] Applying the method and equipment for separating and purifying gas at low temperature of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com