Patents

Literature

30 results about "Octafluoropropane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

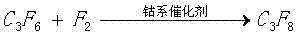

Octafluoropropane (C₃F₈) is a fluorocarbon non-flammable greenhouse gas that can be produced either by electrochemical fluorination or by the Fowler process using cobalt fluoride.

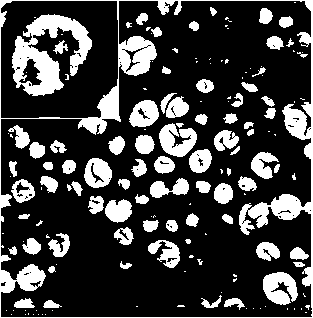

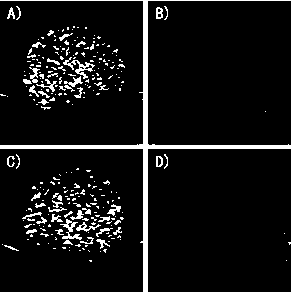

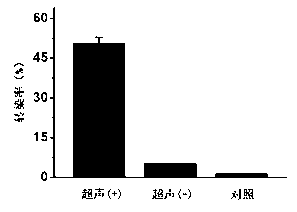

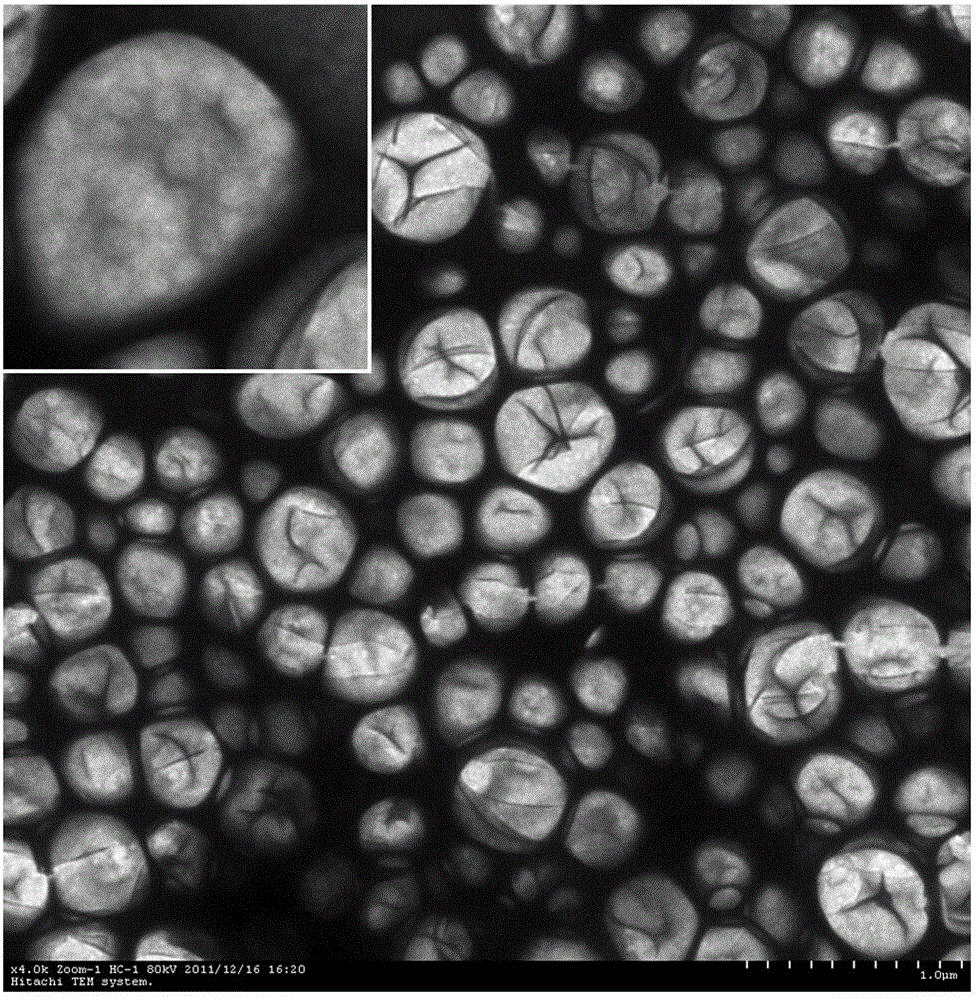

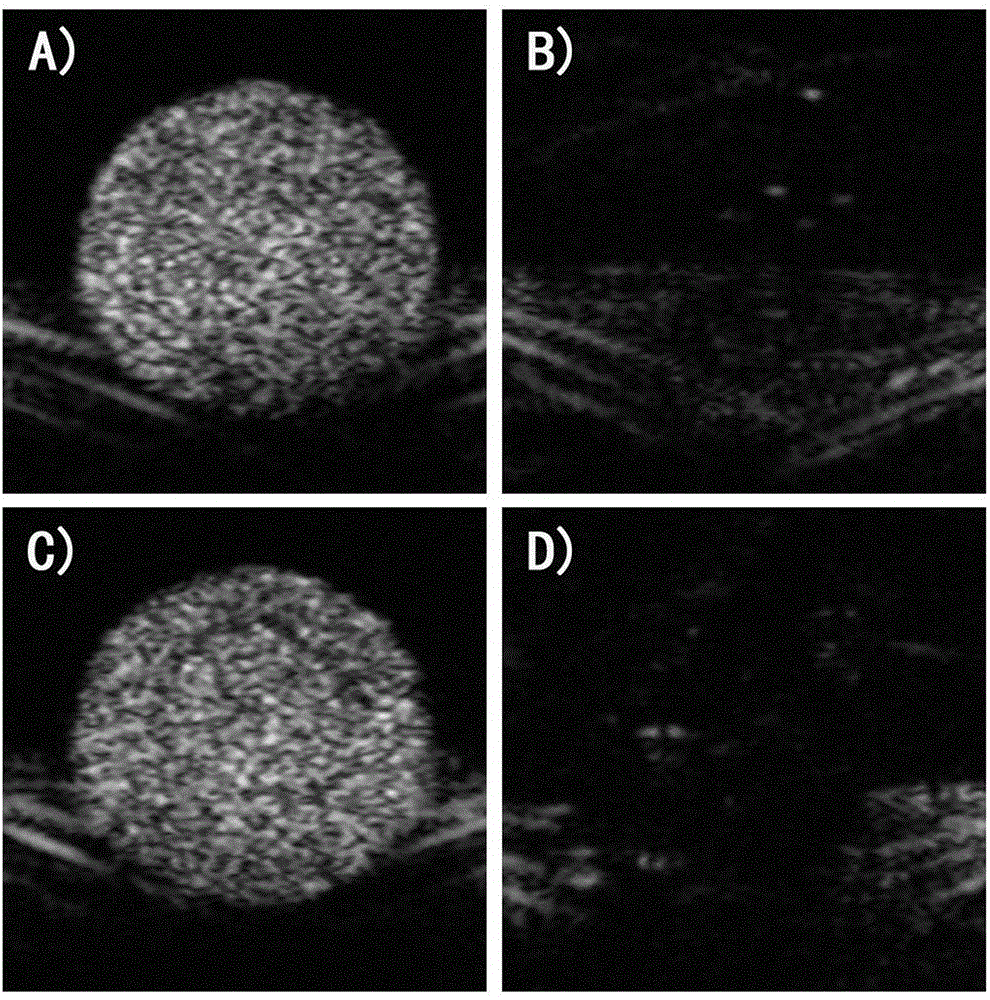

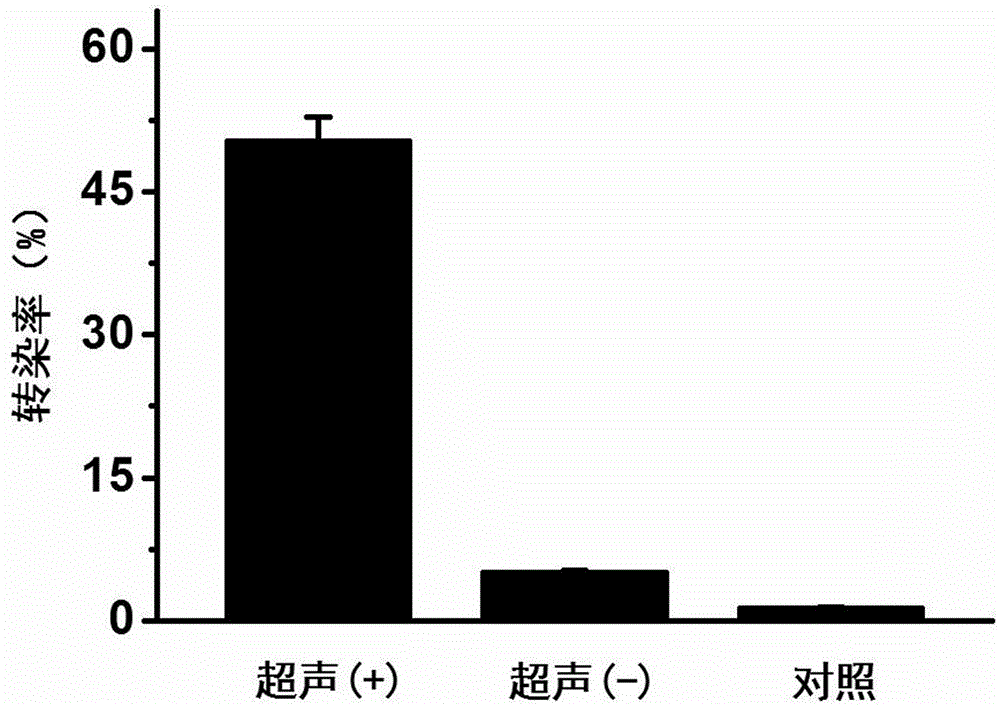

Load small interfering RNA nanoscale lipid microbubble ultrasonic contrast agent and preparation method

InactiveCN103100093AAchieve targeted releaseRealize integrationGenetic material ingredientsEchographic/ultrasound-imaging preparationsUltrasound contrast mediaPolyethylene glycol

The invention discloses a load small interfering RNA (siRNA) nanoscale lipid microbubble ultrasonic contrast agent and a preparation method. The load siRNA lipid microbubble is formed by preparing DPPC (Dipalmitoyl Phosphatidyl Choline), DSPE (1, 2-distearoyl-sn-glycero-3-phosphoethanolamine) and DPPA (Diphenyl Phosphoryl Azide) into microbubbles (containing octafluoropropane) according to the weight part ratio of 18:1:1 and then assembling together with PEG-PLL (Polyethylene Glycol-Polylysne)-coated siRNA nanomicelle. The load siRNA nanoscale lipid is nanosclae, has an obvious ultrasonic contrast effect, and can generate obvious siRNA cell transfection efficiency under low-frequency ultrasonic irradiation, thereby further hopefully having important research values and application prospects in the fields of ultrasonic diagnosis and gene treatment.

Owner:THE THIRD AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

Production and use of octafluoropropane

InactiveUS20030157800A1Easy to separateAvoid easy removalPreparation by halogen halide additionPreparation by halogen replacementOctafluoropropaneGas phase

Octafluoropropane is produced by a process comprising a step (1) of reacting hexafluoropropene with hydrogen fluoride in a gas phase at a temperature of from 150 to 450° C. in the presence of a fluorination catalyst to obtain 2H-heptafluoropropane and a step (2) of reacting 2H-heptafluoropropane obtained in step (1) with fluorine gas in a gas phase at a temperature of from 250 to 500° C. in the absence of a catalyst to obtain octafluoropropane. High-purity octafluoropropane is obtained which can be used in a process for producing a semiconductor device.

Owner:SHOWA DENKO KK

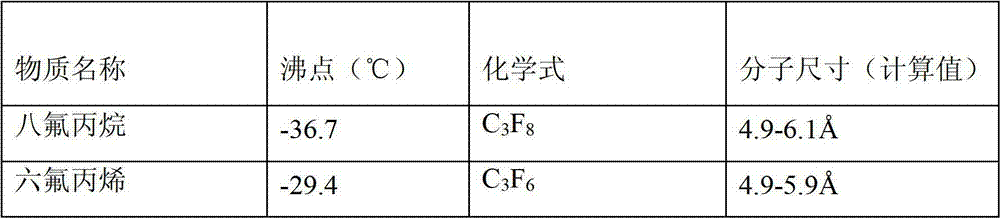

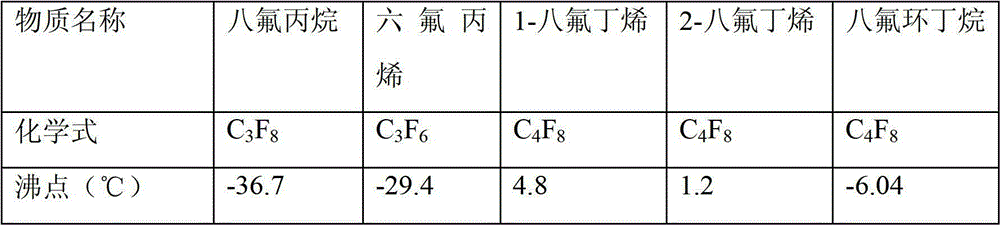

Adsorbent for purifying perfluorocarbon, process for producing same, high purity octafluoropropane and octafluorocyclobutane, and use thereof

To provide a purification adsorbent capable of effectively removing impurities contained in a perfluorocarbon and obtaining a perfluorocarbon reduced in the impurity content to 1 ppm by mass or less; a process for producing the adsorbent; high-purity octafluoropropane or octafluorocyclobutane; processes for purifying and for producing the octafluoropropane or octafluorocyclobutane; and uses thereof. Purification is performed using a purification adsorbent produced by a method comprising (1) washing an original coal with an acid and then with water, (2) deoxidizing and / or dehydrating the original coal, (3) re-carbonizing the original coal at a temperature of from 500 to 700° C. and (4) activating the original coal at a temperature of from 700 to 900° C. in a mixed gas stream containing an inert gas, carbon dioxide and water vapor.

Owner:SHOWA DENKO KK

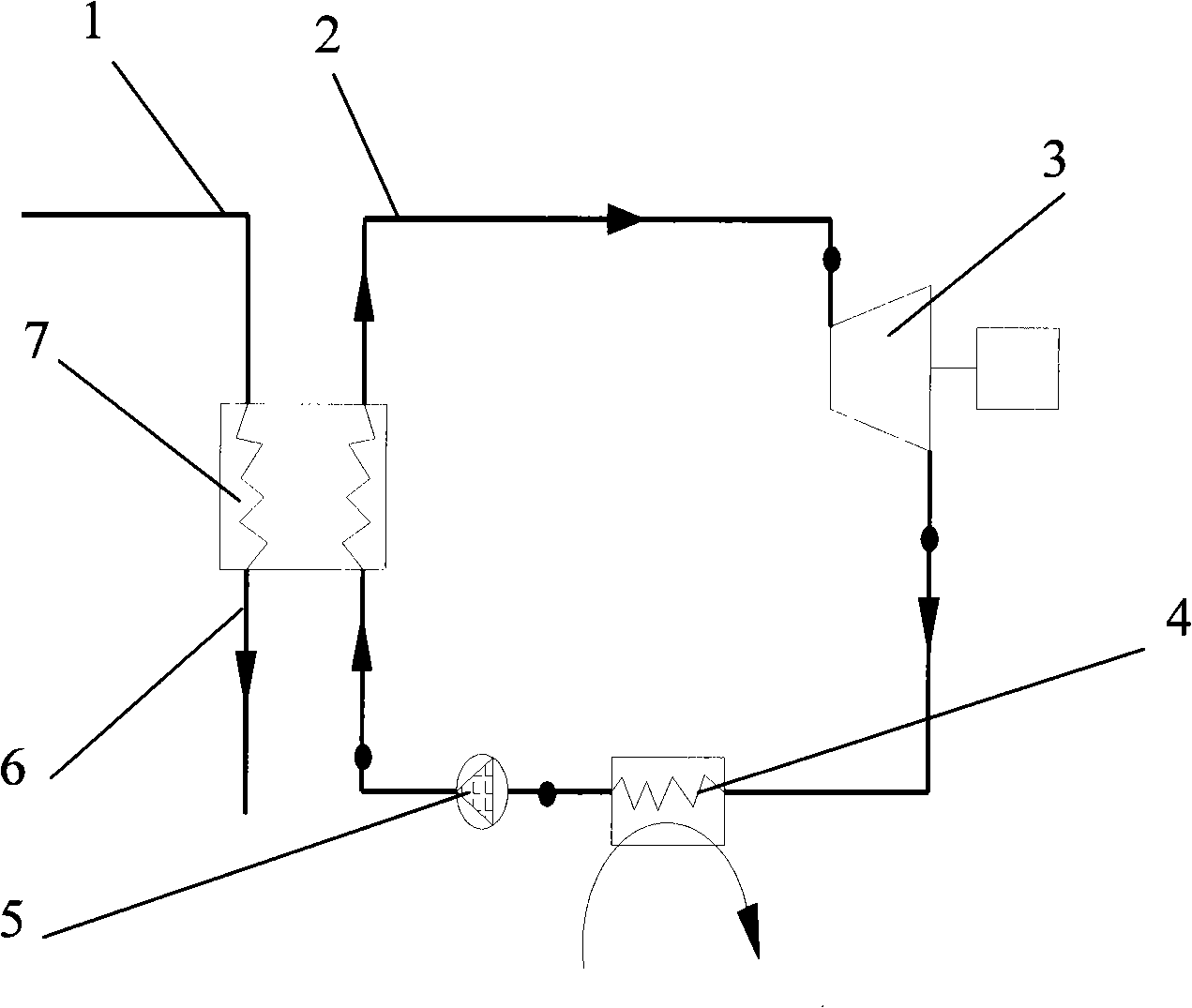

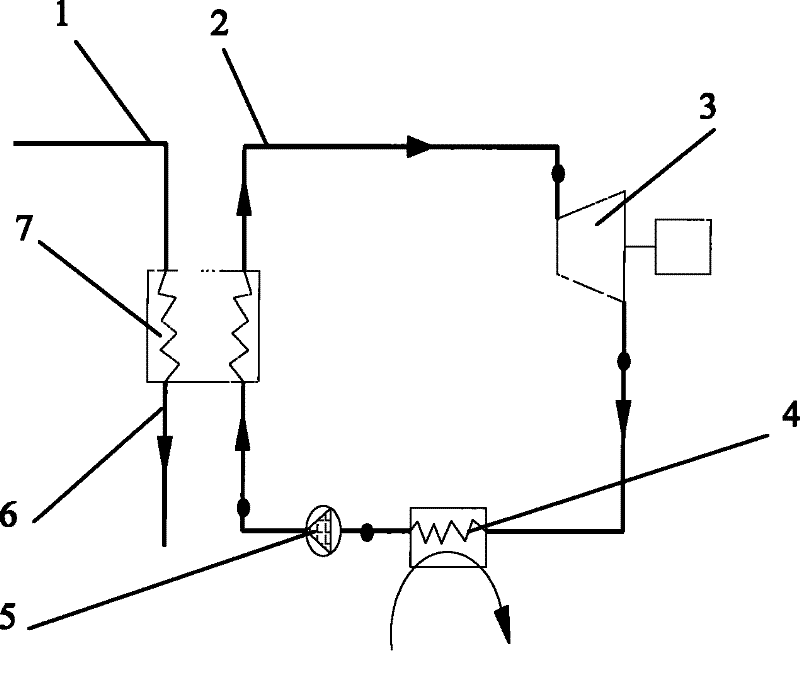

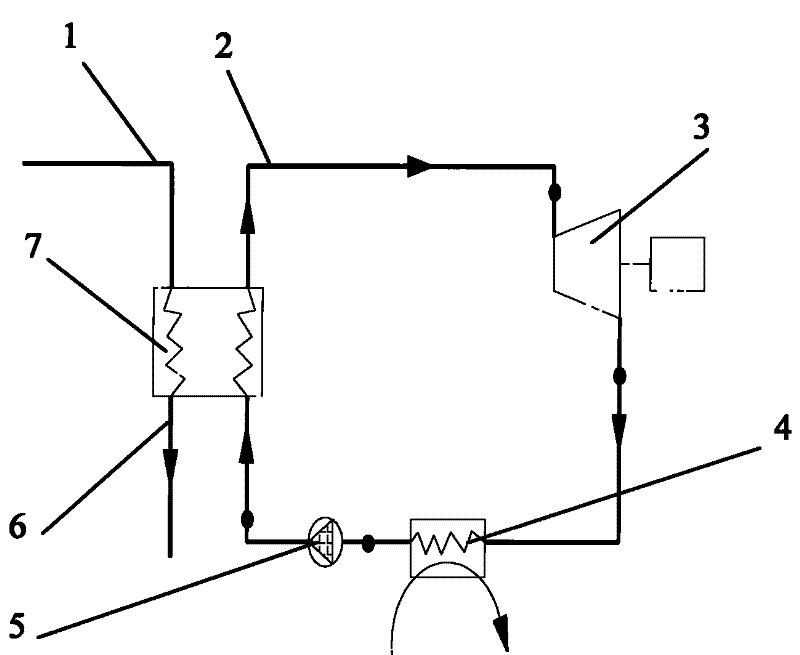

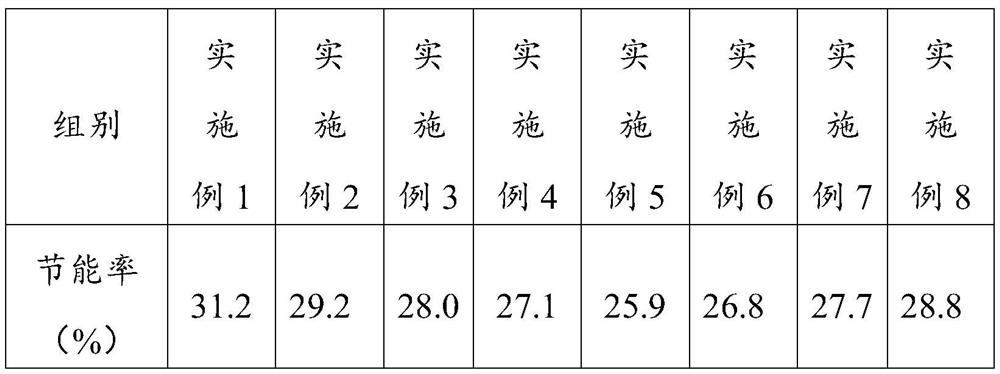

Method for supercritical Rankine cycle recycling low-temperature waste heat power

InactiveCN101298843AImprove overall utilizationReduce heat pollutionEnergy industrySteam engine plantsThermal energyResource utilization

The present invention relates to a method of recovering low temperature energy power, especially aiming at the low temperature waste heat discharged in metallurgical industry, generation by solar energy temperature difference and resource utilization in bi-circular terrestrial heat generation, belonging to the technical field of resource and environment. The circular working substance of the present invention adopts duality mixed working substance configured by propane and octafluoropropane, directly heats to the supercritical state from the outlet of the compressing pump under the supercritical pressure, enters into the organic turbine to apply work, expands to the steam of the condensed pressure ensured by the condensing temperature, then condenses to liquid to the inlet of the compressing pump to be circularly used. The method is able to recover the available energy in the low temperature energy at a large extent and cause the final discharging temperature of the low temperature heat stream (or remaining heat stream) to reduce in the range permitted by the environment.

Owner:KUNMING UNIV OF SCI & TECH

Process for purifying octafluoropropane

InactiveUS7041264B2Easy to useDispersed particle separationSulfide/polysulfide preparationPurification methodsSorbent

Owner:SHOWA DENKO KK

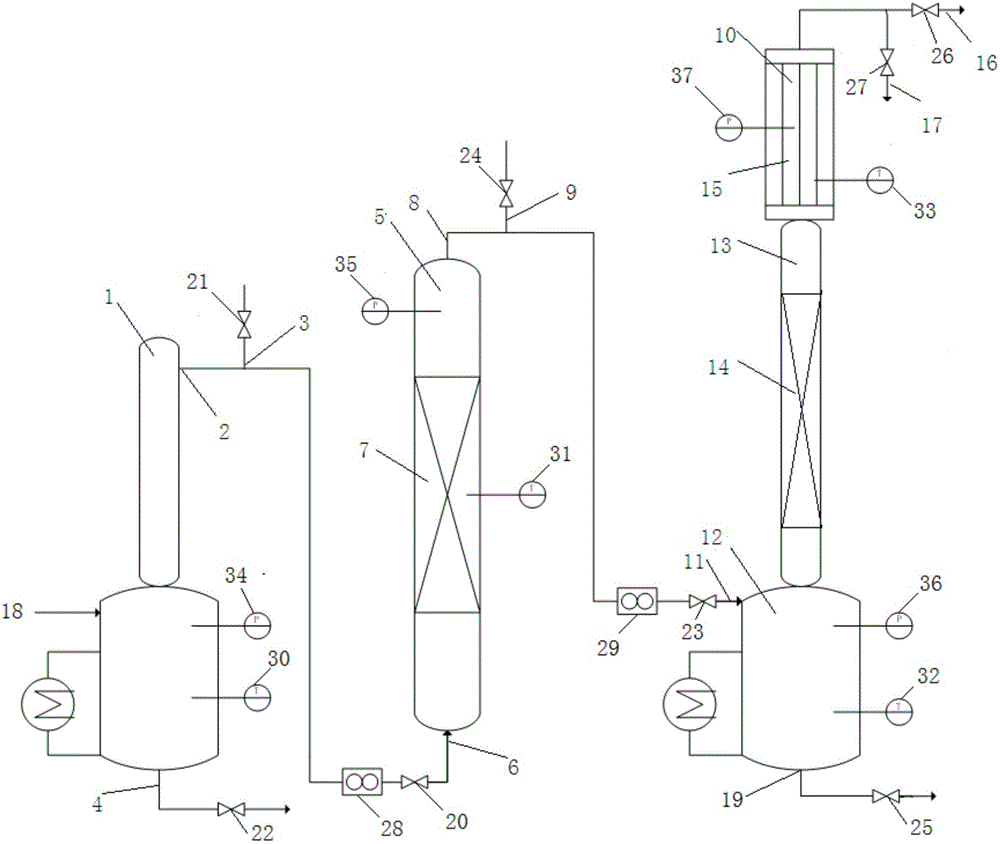

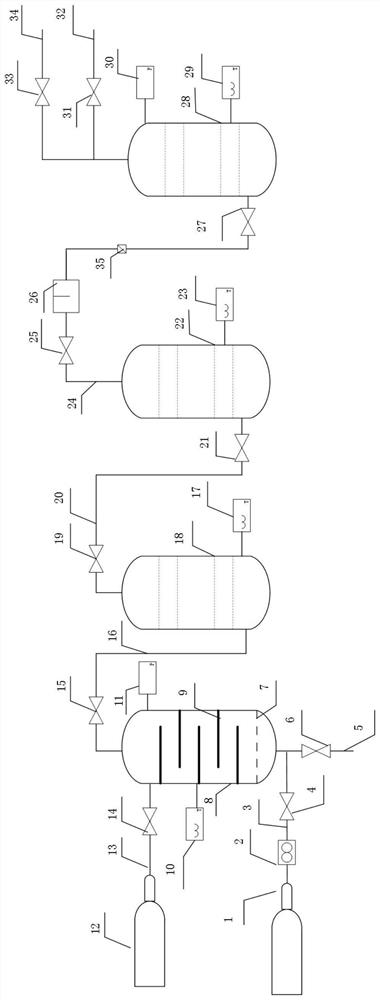

Octafluoropropane purifying method and purifying apparatus thereof

ActiveCN106380372AReduce consumptionImprove economyHalogenated hydrocarbon separation/purificationPurification methodsSorbent

The invention relates to an octafluoropropane purifying method and a purifying apparatus thereof, which belong to the field of fine chemical engineering. The purifying method employs a cold trap for light-discharge and heavy-removal processing of an octafluoropropane crude product, the light components and heavy components impurity content are greatly reduced; an adsorbent is used for adsorption, H2O content is reduced, a part of a fluorocarbon compound is absorbed; a rectification technology is employed, the high-boiling point and low-boiling point impurity can be removed by controlling the rectification parameters, the H2O content is less than 1 ppm, the content of the organic fluorocarbon compound is less than 1 ppm, the total impurity content is less than 10 ppm, cold amount and heat consumed during the rectification process are reduced, economic performance is good, and the octafluoropropane with purity of greater than 99.999% can be obtained after being purified. The purifying apparatus mainly comprises the cold trap, an adsorption tower and a rectifying tower, and is adapted to usage of the purifying method.

Owner:PERIC SPECIAL GASES CO LTD

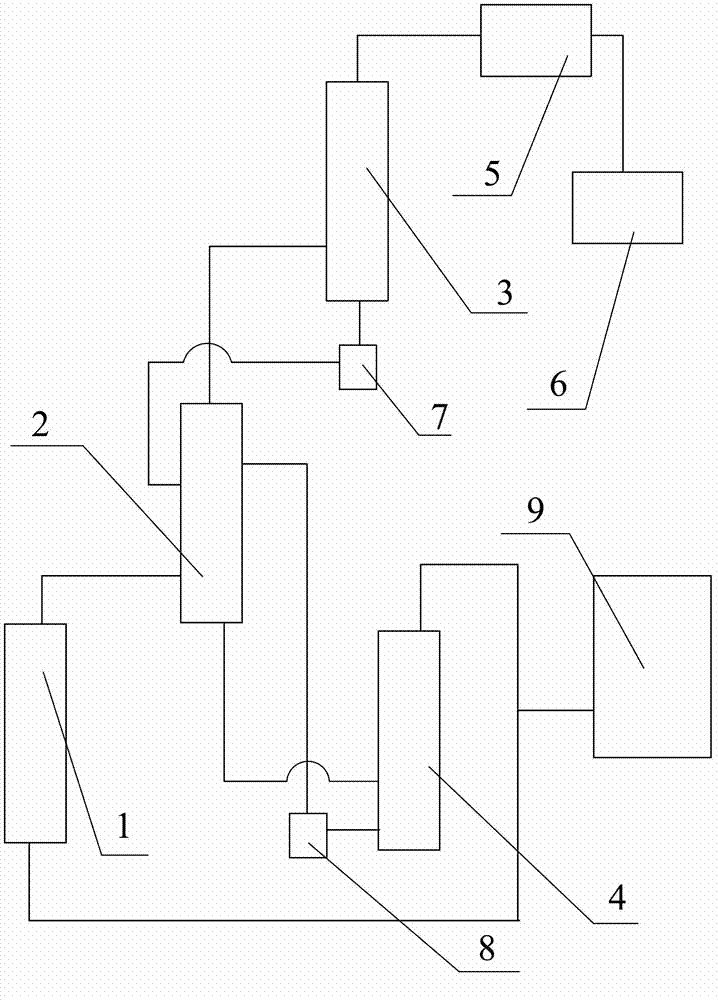

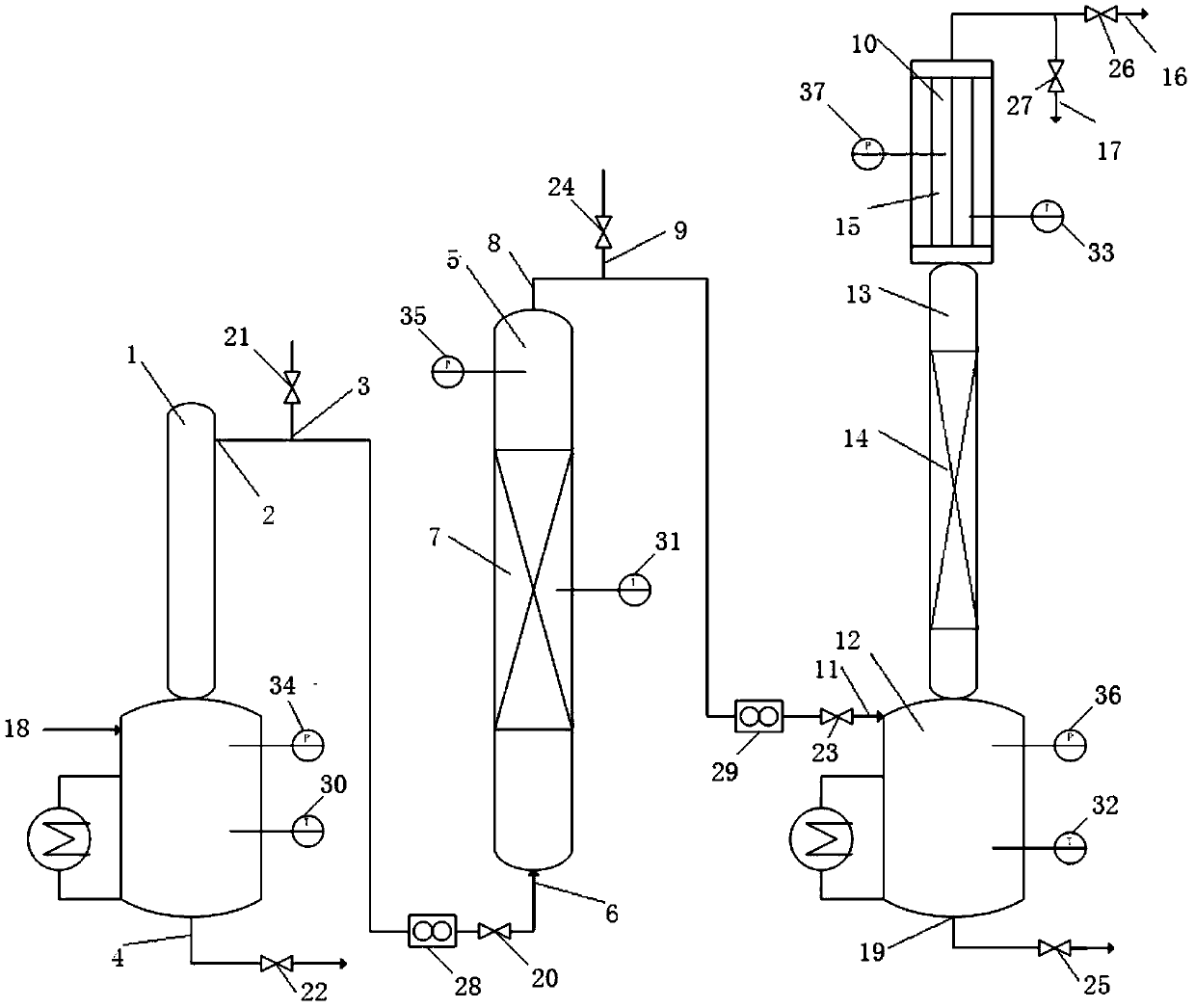

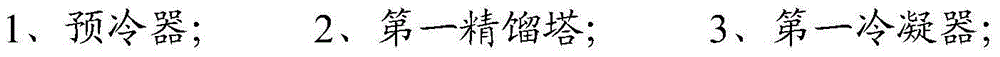

Method for recovering octafluoropropane from hexafluoropropylene production process

ActiveCN102766016AAvoid pollutionEasy to operateHalogenated hydrocarbon preparationOctafluoropropaneHexafluoropropylene

The invention relates to a method for recovering octafluoropropane from the hexafluoropropylene production process and belongs to the filed of chemical product recycling. The method is characterized in that material gas enters a light component removal column, azeotrope of octafluoropropane and hexafluoropropylene in the material gas in the light component removal column is separated from other components, and octafluoropropane and hexafluoropropylene in the material gas are gathered at the column top; the material gas containing octafluoropropane and hexafluoropropylene at the column top of the light component removal column enters an extraction column for extracting, and extracting agents are used for absorbing hexafluoropropylene; column kettle materials in the extraction column enter a resolving column for resolving, high-purity hexafluoropropylene material gas obtained at the column top of the resolving column enters a hexafluoropropylene rectifying column for rectifying; and materials at the column top of the extraction column enter an octafluoropropane rectifying column for rectifying, and octafluoropropane gas is obtained at the column top of the octafluoropropane rectifying column. According to the method, a conventional rectifying device is combined with an extraction rectifying device and the extracting agents can be recycled, so that the whole production process is simple to operate, and purity of the recovered octafluoropropane is no lower than 99.999%.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

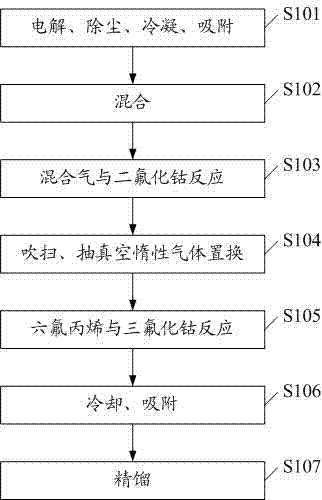

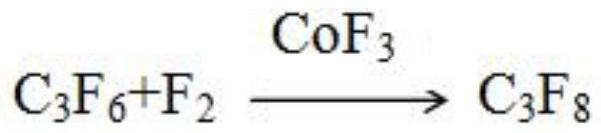

Preparation method of perfluoropropane

InactiveCN103497086AReduce corrosionExtend your lifePreparation by halogen additionElectrolysisHexafluoropropylene

The invention discloses a preparation method of perfluoropropane. The preparation method sequentially comprises the following steps: (1) electrolyzing potassium bifluoride to obtain a mixed fluorine gas, and sequentially carrying out dust extraction, condensation and adsorption treatments on the mixed fluorine gas to purify the mixed fluorine gas to raw material fluoride; (2) pressurizing the raw material fluoride and uniformly mixing the raw material fluoride with an inert gas to obtain a mixed gas; (3) introducing the mixed gas into a reactor filled with cobaltous fluoride to react to obtain cobaltic oxide; (4) carrying out purging and vacuumizing replacement treatments on the reactor and related pipelines and pipe fittings after the reaction; (5) introducing hexafluoropropylene into the reactor to react with the cobaltic oxide to obtain perfluoropropane containing impurities; (6) cooling and adsorbing the perfluoropropane; and (7) introducing the perfluoropropane into a rectifying column through a compressor to be rectified. By adopting the preparation method disclosed by the invention, the corrosion of impurities on the reactor can be reduced, such unfavorable side reactions as hexafluoropropylene pyrolysis, self polymerization, addition, and the like, are inhibited, and perfluoropropane with high purity is prepared.

Owner:FOSHAN HUATE GASES +1

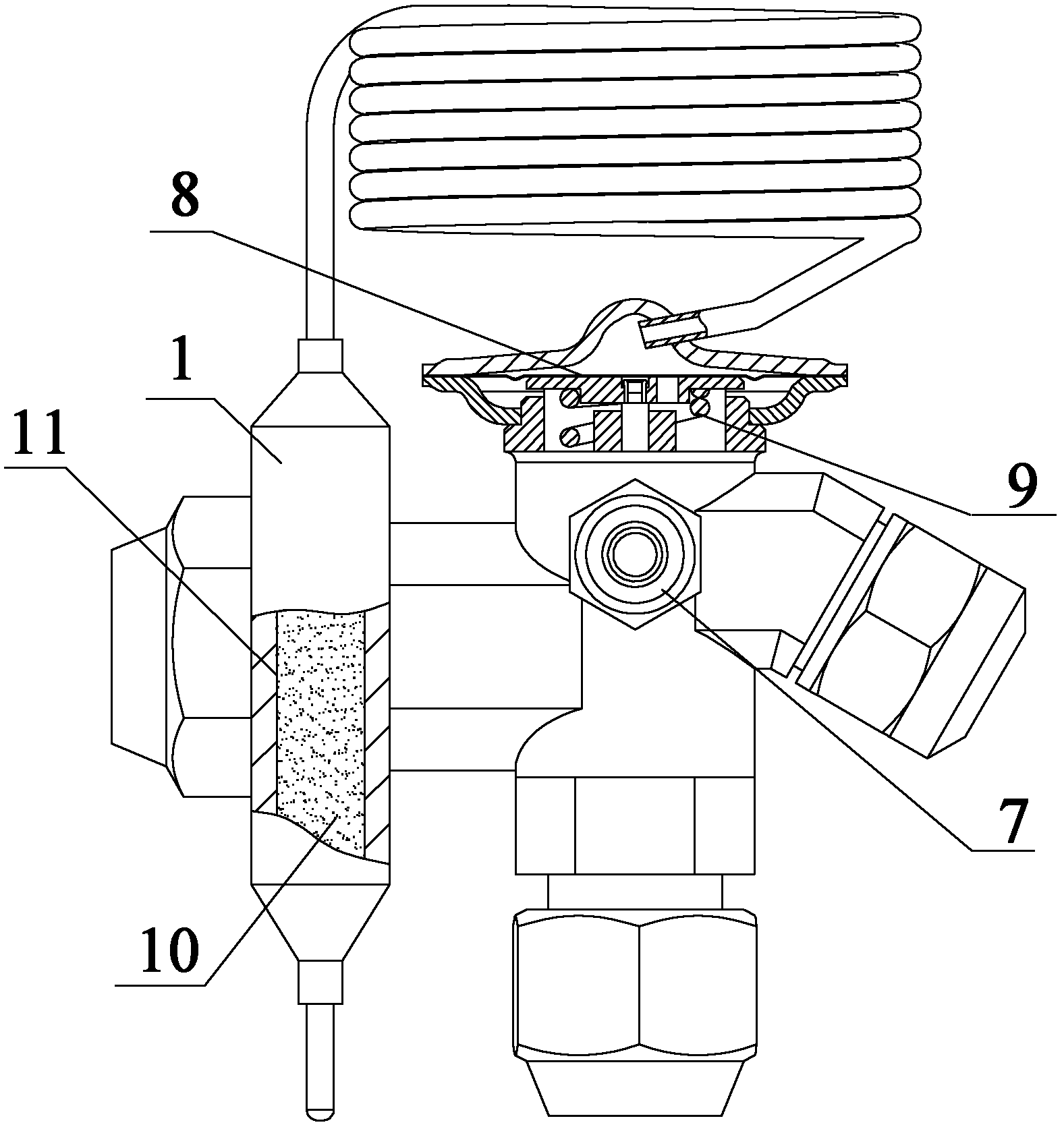

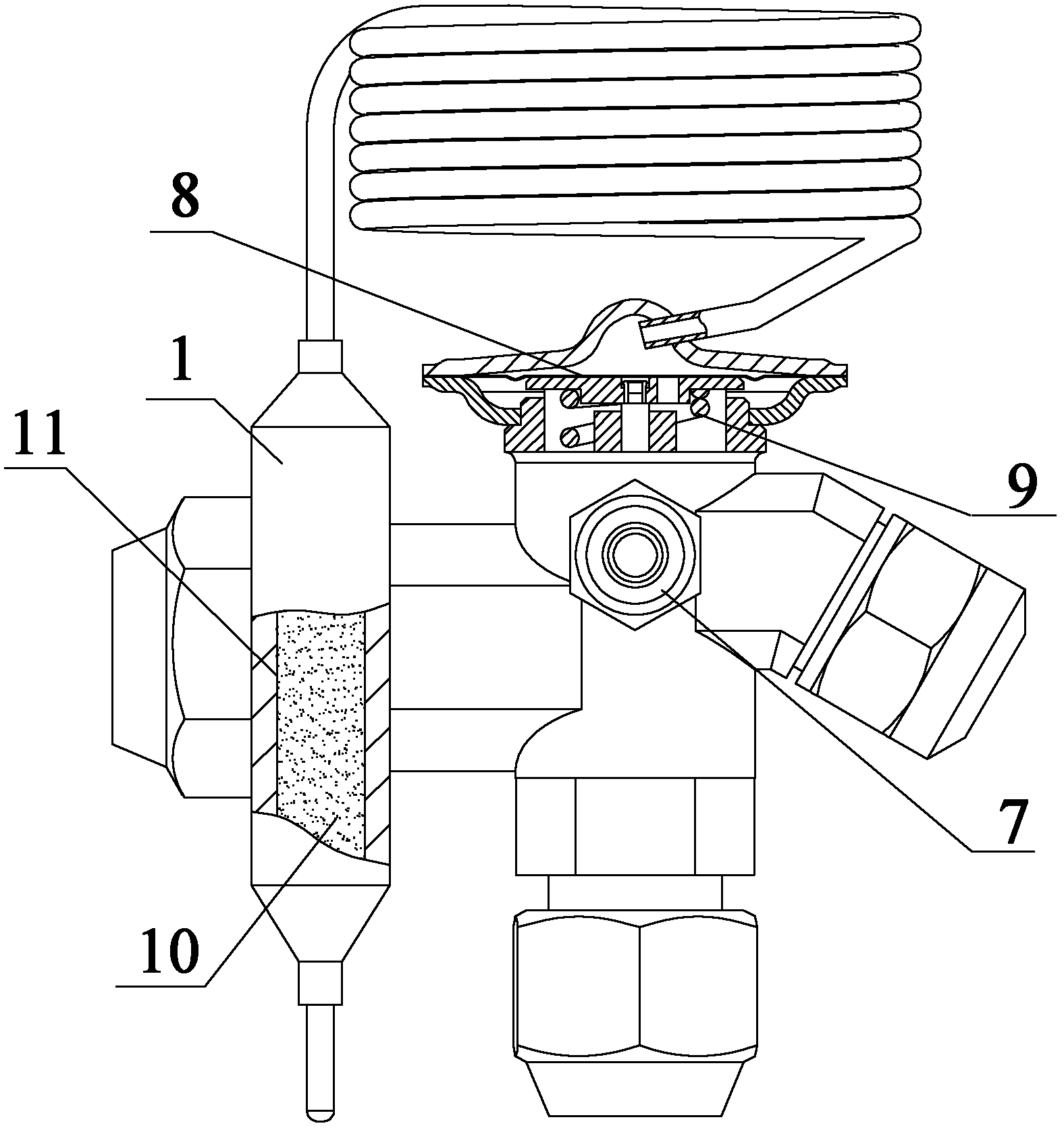

Temperature-sensing element

InactiveCN102252128AImprove consistencyImprove energy efficiencyOperating means/releasing devices for valvesFluid circulation arrangementTemperature controlOctafluoropropane

The invention discloses a temperature sensing element comprising a thermometer bulb and an inner cavity arranged in the thermometer bulb. A temperature-sensing working medium is filled in the inner cavity and consists of chlorotetrafluoroethane and octafluoropropane. By utilizing a thermostatic expansion valve in the temperature-sensing element disclosed by the invention, the control deviation of the superheat degree can be ensured to be smaller than 0.9 DEG C, the consistency of the control on the superheat degree of an evaporator is excellent, the temperature control precision and the operating stability of a system under cooling and heating conditions are favorably ensured and the overall energy efficiency of an R134a refrigerating system is increased.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

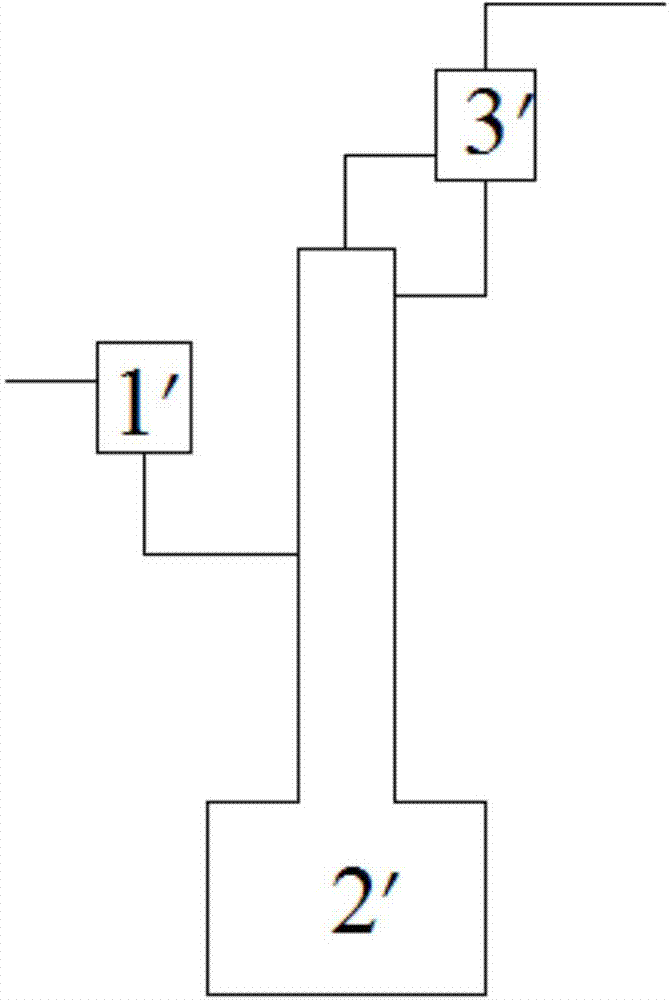

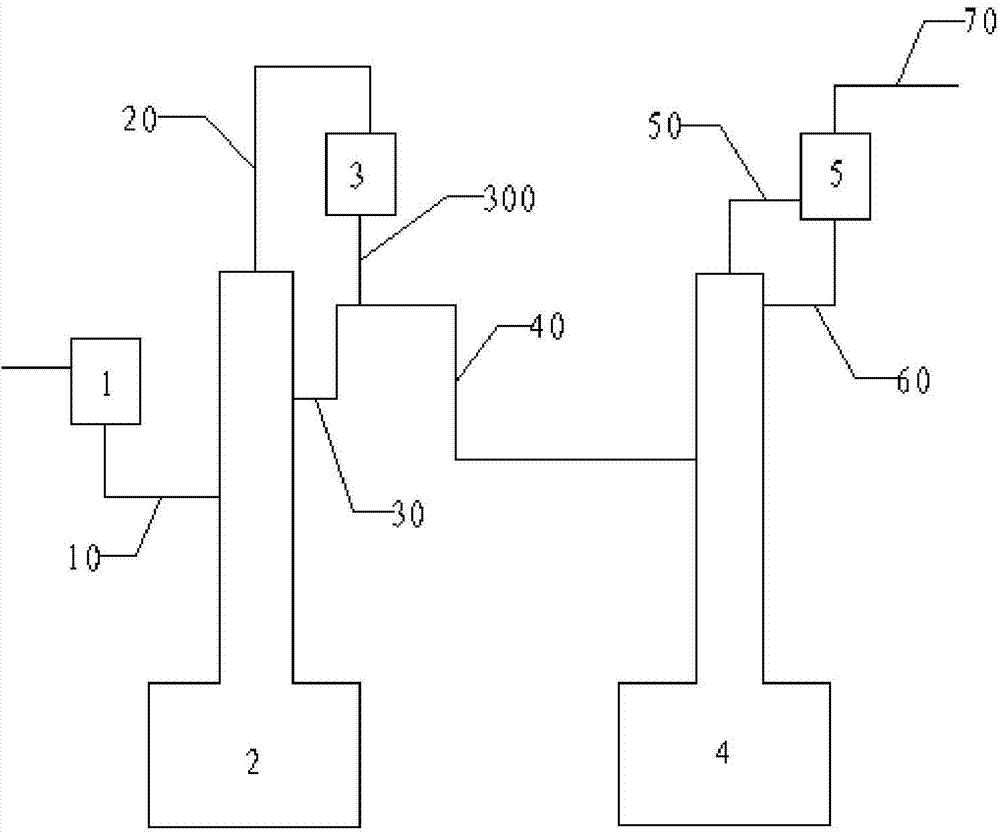

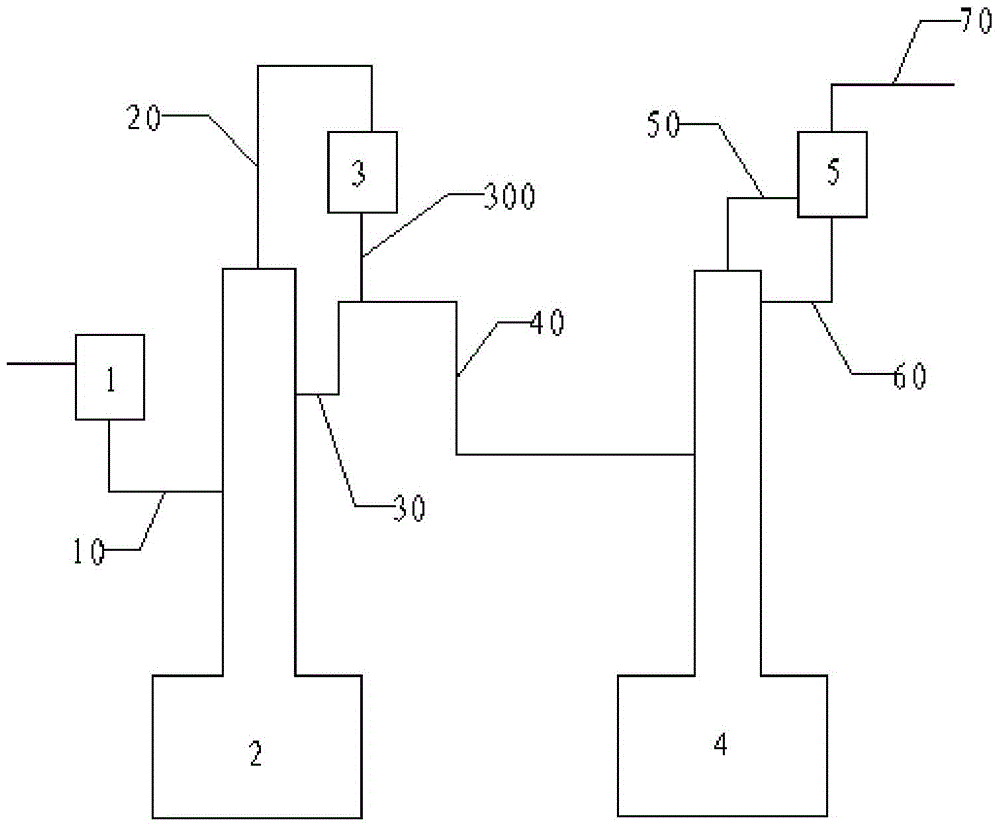

Rectification device and rectification process used for electronic grade sulfur hexafluoride production

ActiveCN103754834AEfficient removalLow costSulfur and halogen compoundsHexafluoroethaneSulfur hexafluoride

The invention relates to a rectification device and a rectification process used for electronic grade sulfur hexafluoride production. Specifically, a rough sulfur hexafluoride gas is pressurized and then sent into a precooler to be converted from gas to liquid under high pressure and low temperature conditions, then gasification, condensation and reflux are carried out in a first rectifying tower and a first condenser to remove high-boiling residue, and then by means of gasification, condensation and reflux in a second rectifying tower and a second condenser, the sulfur hexafluoride is condensed into a liquid state for collection, while low-boiling residue maintains a gas state and escapes from the second condenser. The rectification device and the rectification process provided by the invention can effectively remove high-boiling residue and low-boiling residue impurities from the rough sulfur hexafluoride gas, especially the hexafluoroethane and octafluoropropane impurity gases with a very close boiling point to sulfur hexafluoride under high pressure and low temperature states required by the rectification process. The obtained sulfur hexafluoride fully meets the technical requirements of electronic grade sulfur hexafluoride, also the equipment cost is low, and the production process is simple.

Owner:FUJIAN YONGJING TECH CO LTD

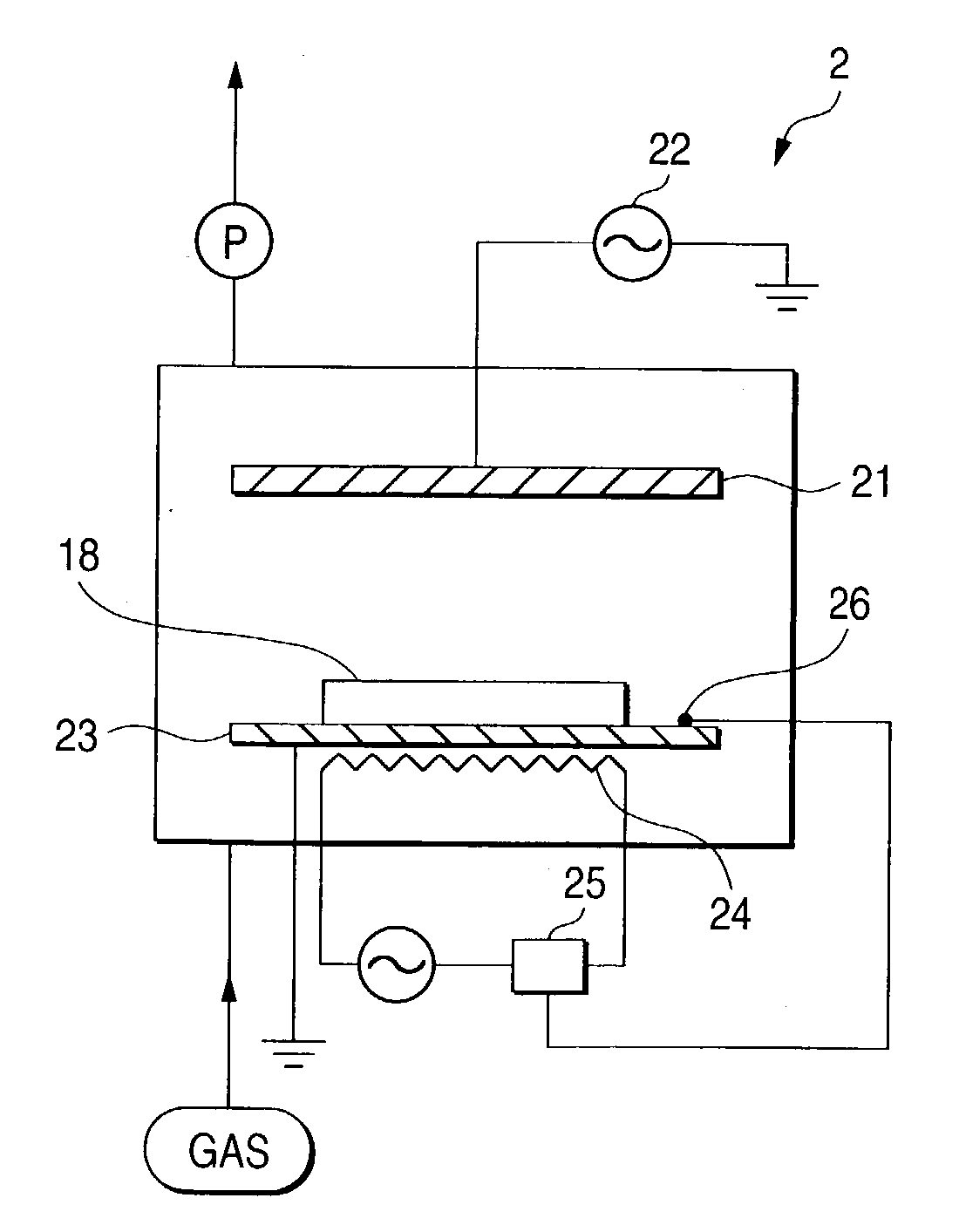

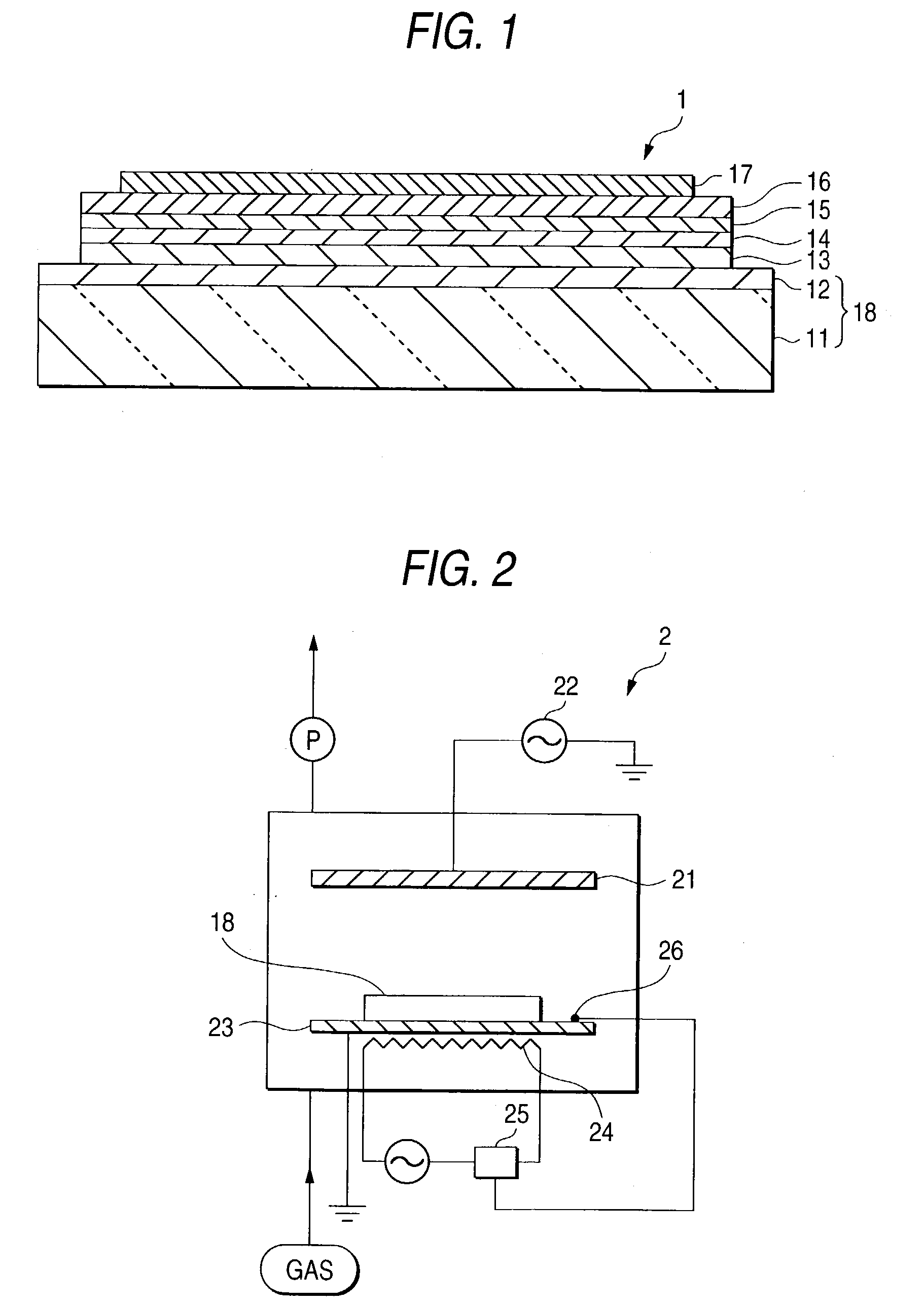

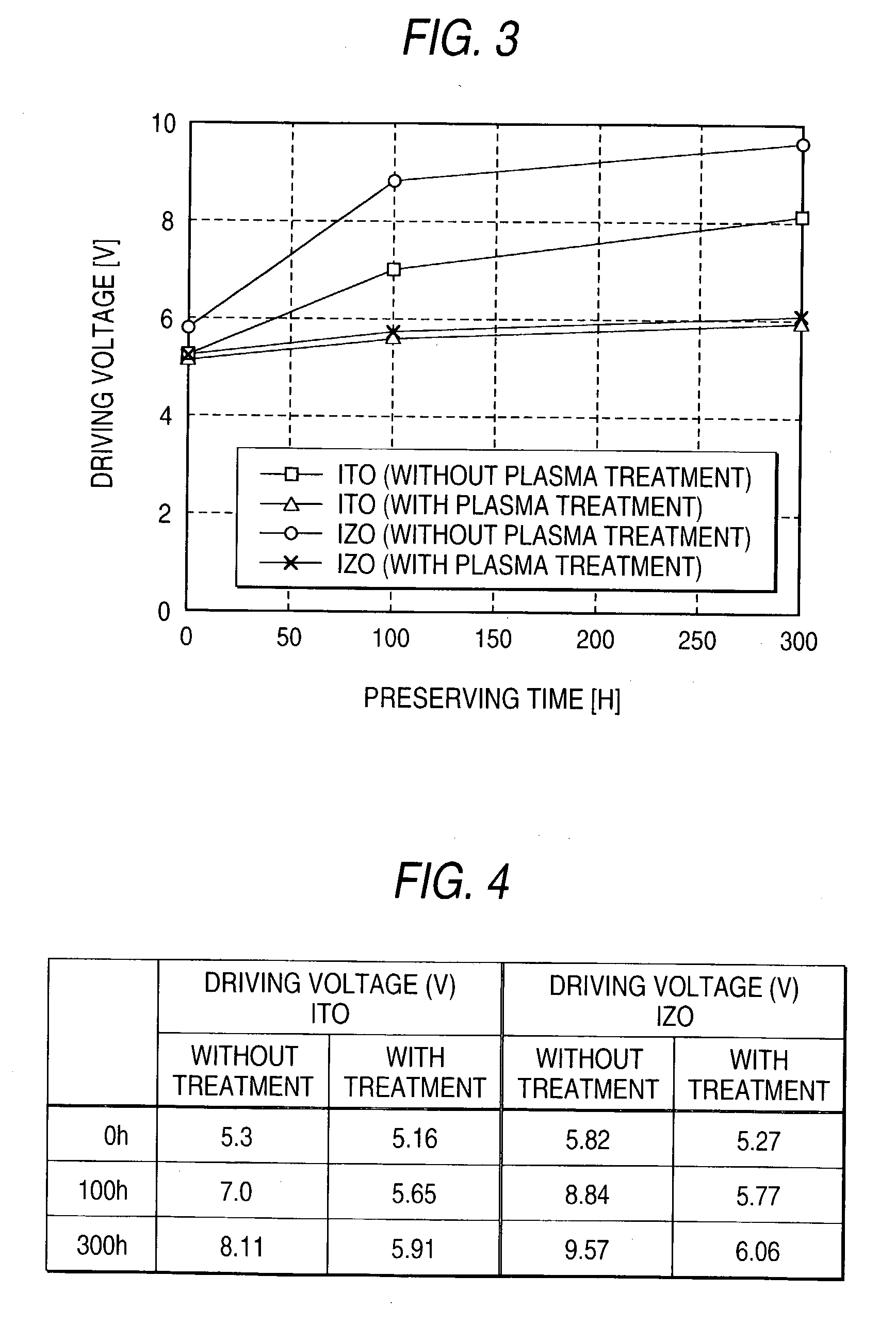

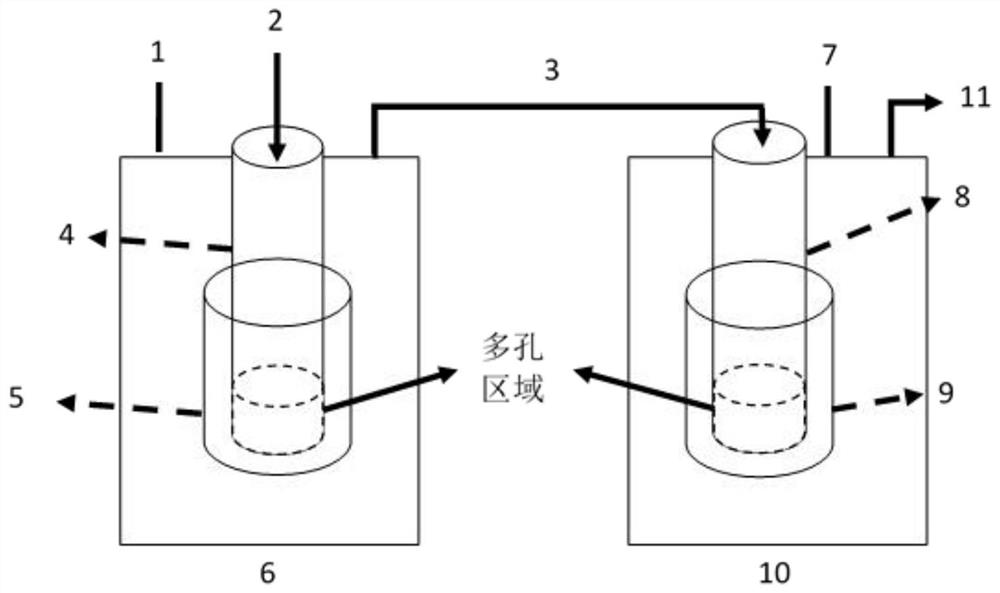

Manufacturing method of organic electroluminescent element

InactiveUS20030211233A1Low heat resistanceAvoid etchingElectroluminescent light sourcesSolid-state devicesHexafluoroethaneOctafluorocyclobutane

An electrode-equipped substrate includes a substrate portion of synthetic resin and a transparent electrode. The electrode-equipped substrate is subjected to heat treatment at a temperature of 200° C. or less as well as plasma treatment before organic layers are deposited. The plasma treatment is carried out within atmosphere of (A) a mixed gas of oxygen and any one of nitrogen, argon, helium, neon and xenon, with an oxygen density of 5% or less; (B) a mixed gas of oxygen and any one of carbon tetrafluoride, hexafluoroethane, octafluoropropane and octafluorocyclobutane; or (C) a sole gas of nitrogen, argon, helium, neon, xenon, carbon monoxide, carbon dioxide, nitrogen monoxide or nitrous oxide.

Owner:PIONEER CORP

Production and use of octafluoropropane

InactiveUS6720464B2Easy to separateAvoid easy removalPreparation by halogen halide additionPreparation by halogen replacementGas phaseOctafluoropropane

Octafluoropropane is produced by a process comprising a step (1) of reacting hexafluoropropene with hydrogen fluoride in a gas phase at a temperature of from 150 to 450° C. in the presence of a fluorination catalyst to obtain 2H-heptafluoropropane and a step (2) of reacting 2H-heptafluoropropane obtained in step (1) with fluorine gas in a gas phase at a temperature of from 250 to 500° C. in the absence of a catalyst to obtain octafluoropropane. High-purity octafluoropropane is obtained which can be used in a process for producing a semiconductor device.

Owner:SHOWA DENKO KK

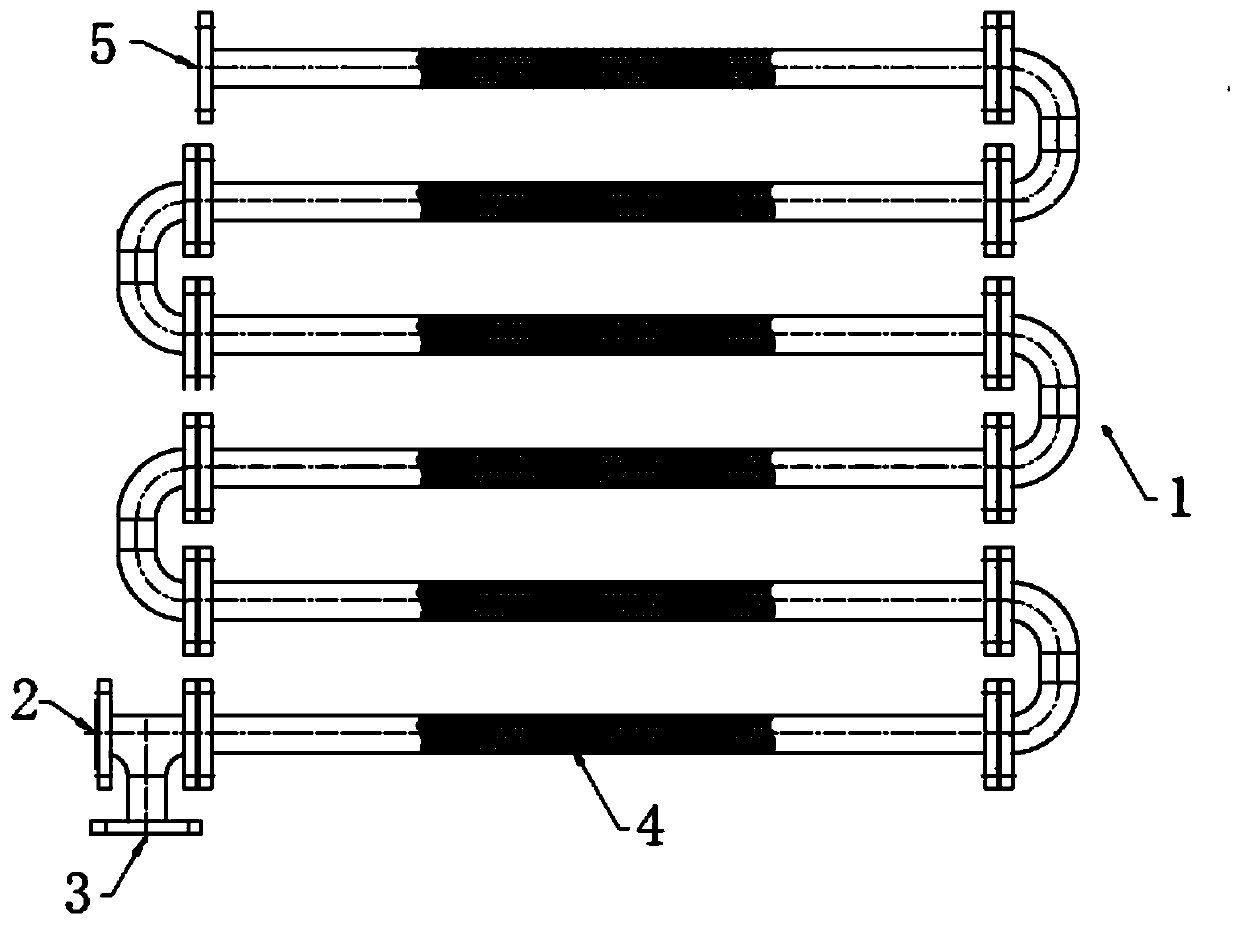

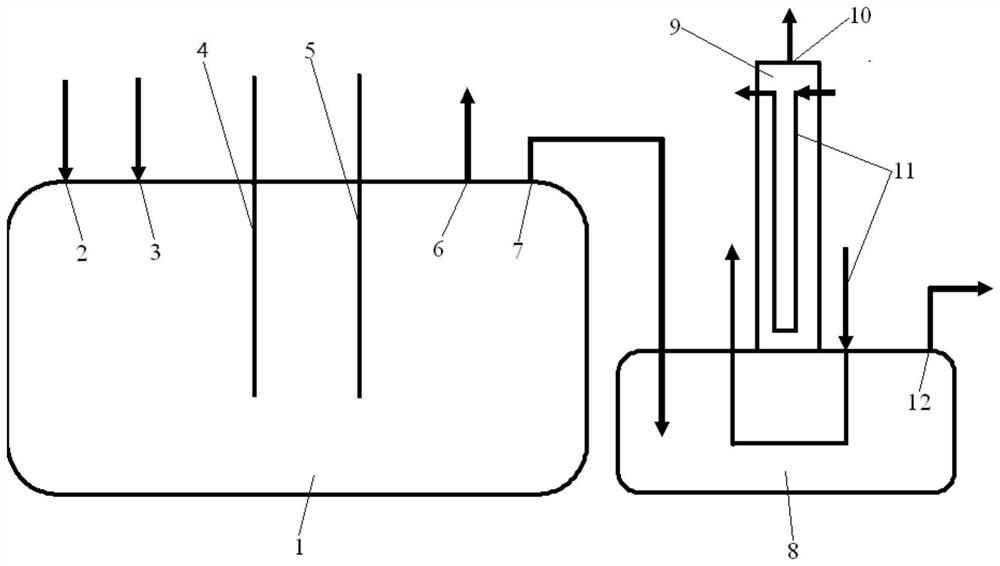

Multi-stage tubular electrolysis device for preparing octafluoropropane and preparation method

ActiveCN112831798AGuaranteed conversionHigh yieldCellsElectrolytic organic productionElectrolytic agentOctafluoropropane

The invention discloses a multi-stage tubular electrolysis device for preparing octafluoropropane by adopting an electrolysis method and a preparation method. The device comprises more than two electrolytic baths, local porous anodes, cathodes, liquid inlets, gas pipelines and gas outlets, wherein the electrolytic baths provide a closed electrolytic environment and store electrolytes; the anodes provide gas raw material channels and the fluorine element for reaction; the cathodes form an electronic loop; an electrolyte is added into the electrolytic baths through the liquid inlets; the electrolytic baths are connected through the gas pipelines, electrolysis gas of the previous electrolytic cell is cooled, and a gas channel is provided; and the octafluoropropane crude product gas is mainly discharged through the gas outlets. The device and the method have the advantages of simple production process, high octafluoropropane yield and the like.

Owner:PERIC SPECIAL GASES CO LTD

Process for purifying octafluoropropane, process for preparing the same, and use thereof

InactiveUS20040047785A1Easy to useDispersed particle separationHalogen/halogen-acidsPurification methodsOctafluoropropane

A process for purifying octafluoropropane according to the present invention comprises the step of contacting a crude octafluoropropane containing impurities with an impurity decomposing agent under elevated temperature and then with an adsorbent to substantially remove the impurities from the crude octafluoropropane. According to the purification process or preparation process of octafluoropropane of the present invention, the impurities such as chlorine compounds can be substantially removed and a high-purity octafluoropropane can be easily obtained. The octafluoropropane obtained by the purification process of the present invention is substantially free of impurities and therefore, can be used as an etching or cleaning gas for use in the production process of a semiconductor device and the like.

Owner:SHOWA DENKO KK

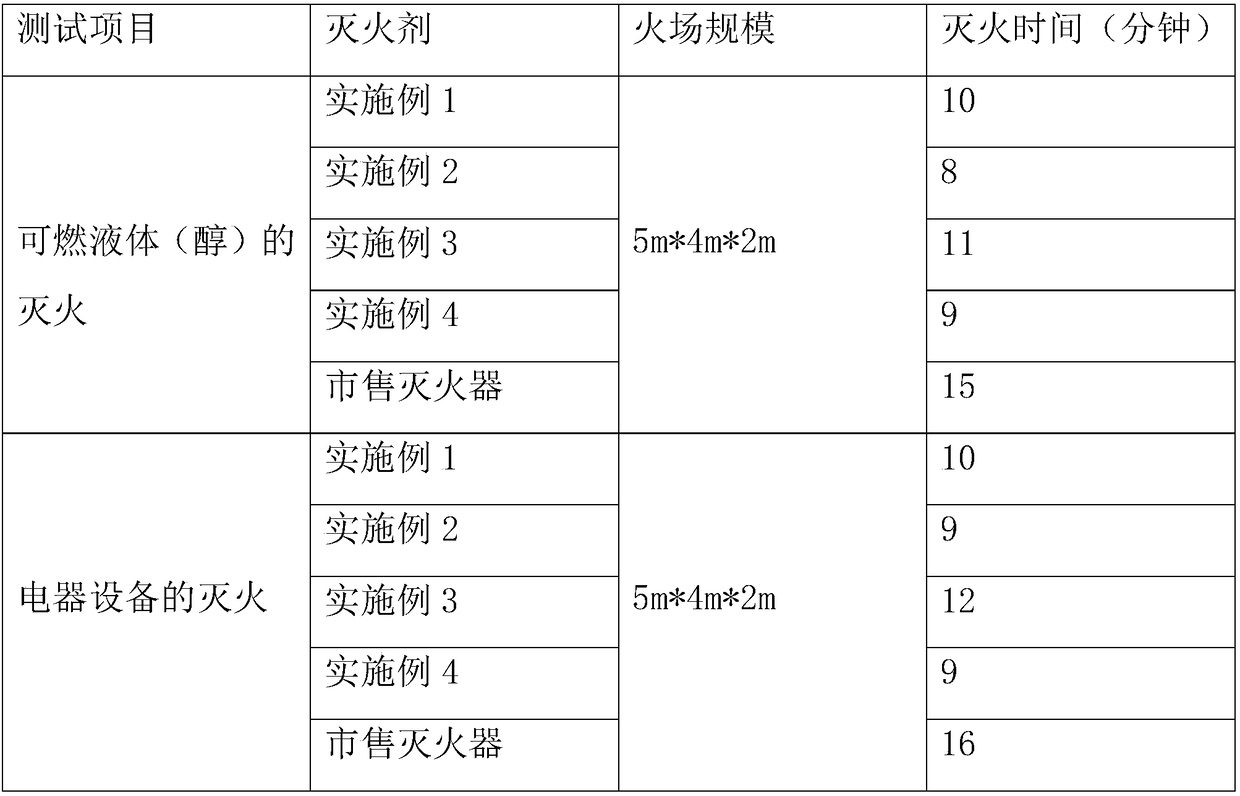

Novel CFA gaseous extinguishing agent and extinguishing system thereof

InactiveCN108905037AImprove fire extinguishing effectIsolated contactFire extinguisherHexafluoroethaneHydrogen

The invention relates to the field of firefighting extinguishing materials, in particular to a novel CFA gaseous extinguishing agent and an extinguishing system thereof. The novel CFA gaseous extinguishing agent consists of 20 to 30 parts by weight of trifluoromethane, 10 to 20 parts of hexafluoroethane, 4 to 8 parts of octafluoropropane, 3 to 5 parts of nitrogen, 4 to 8 parts of sodium hydrogen carbonate powder, 2 to 5 parts of argon, 3 to 6 parts of heptafluoropropane and 1 to 2 parts of absorbent. The invention aims at overcoming the technical defects of the existing aqueous film forming foam extinguishing agent and providing the environment-friendly foam extinguishing agent. The novel CFA gaseous extinguishing agent has the characteristics that the extinguishing agent is good in foam forming effect, long in adhesion time and small in environmental pollution; and the CFA is used as the extinguishing agent, by adding the nitrogen and argon, a great amount of gas can be produced whenin use to effectively insulate the contact of the oxygen and an inflamer, the extinguishing capability of the extinguishing agent can effectively improved, the extinguishing time is shortened, and theenvironmental friendliness can be improved.

Owner:EASTEX XIAMEN FIRETEC

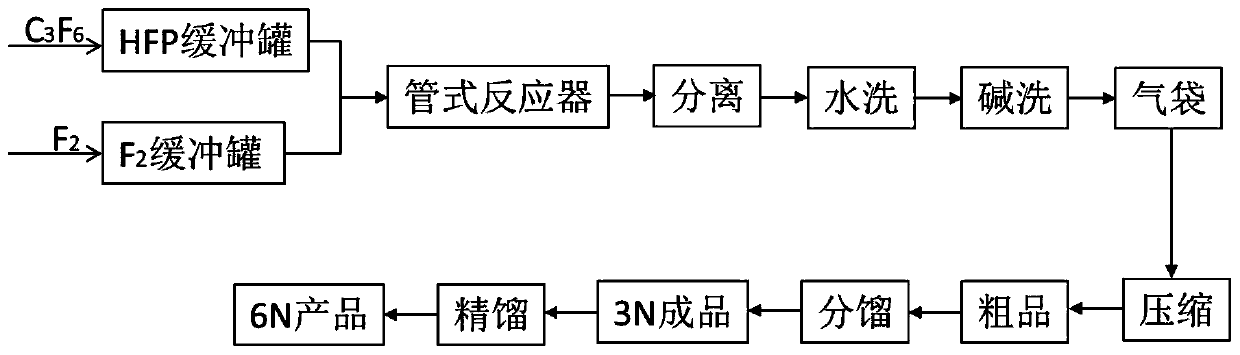

Preparation process of octafluoropropane

InactiveCN110372470AGood dispersionWell mixedFlow mixersTransportation and packagingHexafluoropropyleneGas phase

The invention discloses a preparation process of octafluoropropane. The preparation process includes a fluorination reaction section, in the fluorination reaction section, hexafluoropropylene and fluorine nitrogen mixed gases enter a tubular reactor in the form of a parallel flow, and a continuous flow gas-phase reaction is carried out under a certain temperature and pressure to generate the octafluoropropane, and at least one static mixer is installed in the tubular reactor. The preparation process has the advantages of simple process, high reaction efficiency, less by-products and high product purity.

Owner:FUJIAN DEER TECH CORP

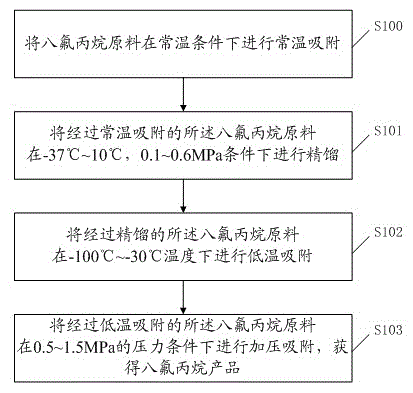

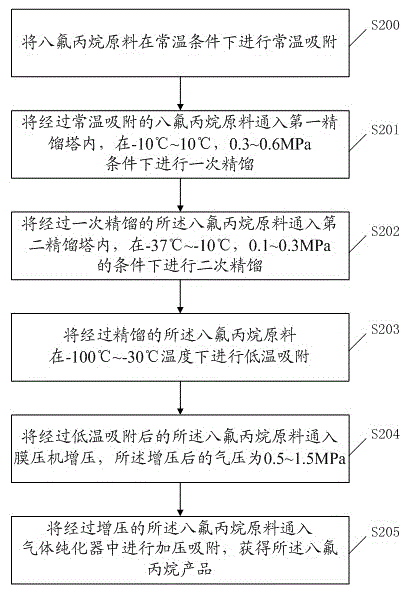

A kind of octafluoropropane purification method

ActiveCN103664502BHigh purityHigh selectivityHalogenated hydrocarbon separation/purificationPurification methodsDistillation

The invention discloses an octafluoropropane purifying method. The octafluoropropane purifying method comprises the following steps: carrying out normal-temperature adsorption on an octafluoropropane material under a normal-temperature condition; carrying out distillation on the octafluoropropane material adsorbed at the normal temperature under conditions with the temperature of -37 DEG C-10 DEG C and pressure of 0.1 MPa-0.6 MPa; carrying out low-temperature adsorption on the distilled octafluoropropane material at the temperature ranging from-100 DEG C to -30 DEG C; carrying out pressurized adsorption on the low-temperature adsorbed octafluoropropane material under the pressure condition of 0.5 MPa-1.5 MPa to obtain an octafluoropropane product. The octafluoropropane purifying method disclosed by the invention is adopted, so that not only most of fluorine-chlorine-carbon compound-containing impurities are removed, but also a problem that removing depth for carbon dioxide and carbon in the prior art is not enough is solved, thus energy consumption is lowered, adsorption effect of an adsorbent is strengthened and the purity of the octafluoropropane product is over 99.999%.

Owner:FOSHAN HUATE GASES +1

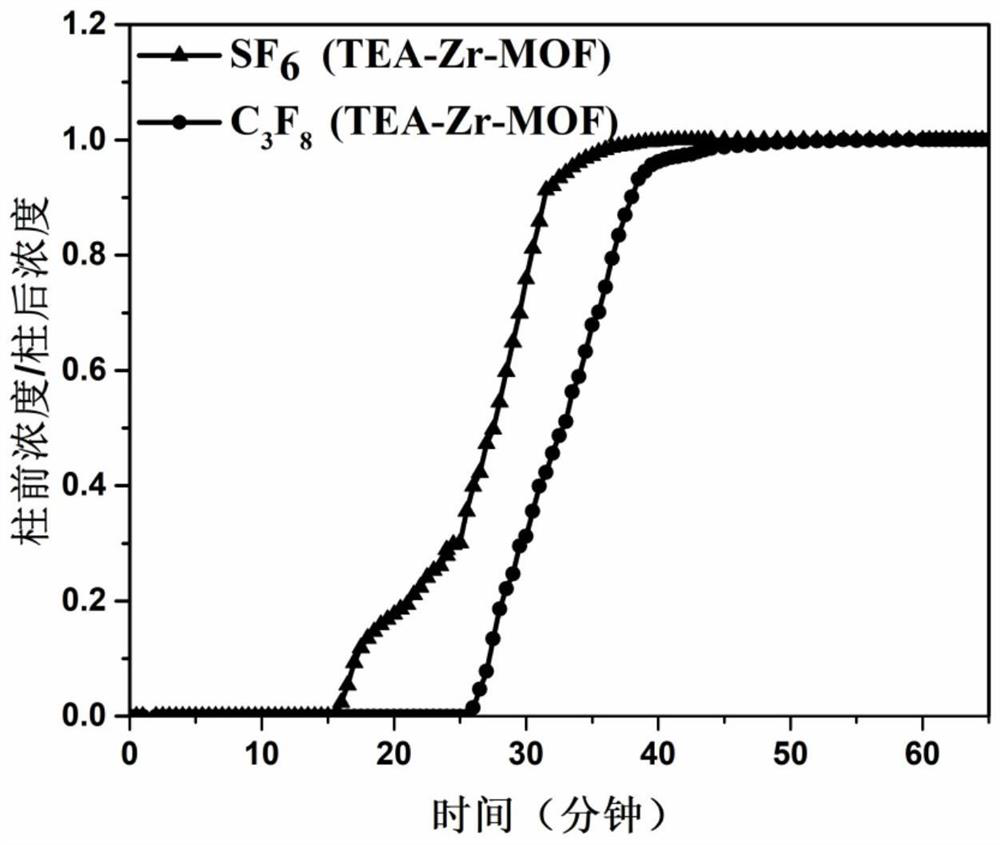

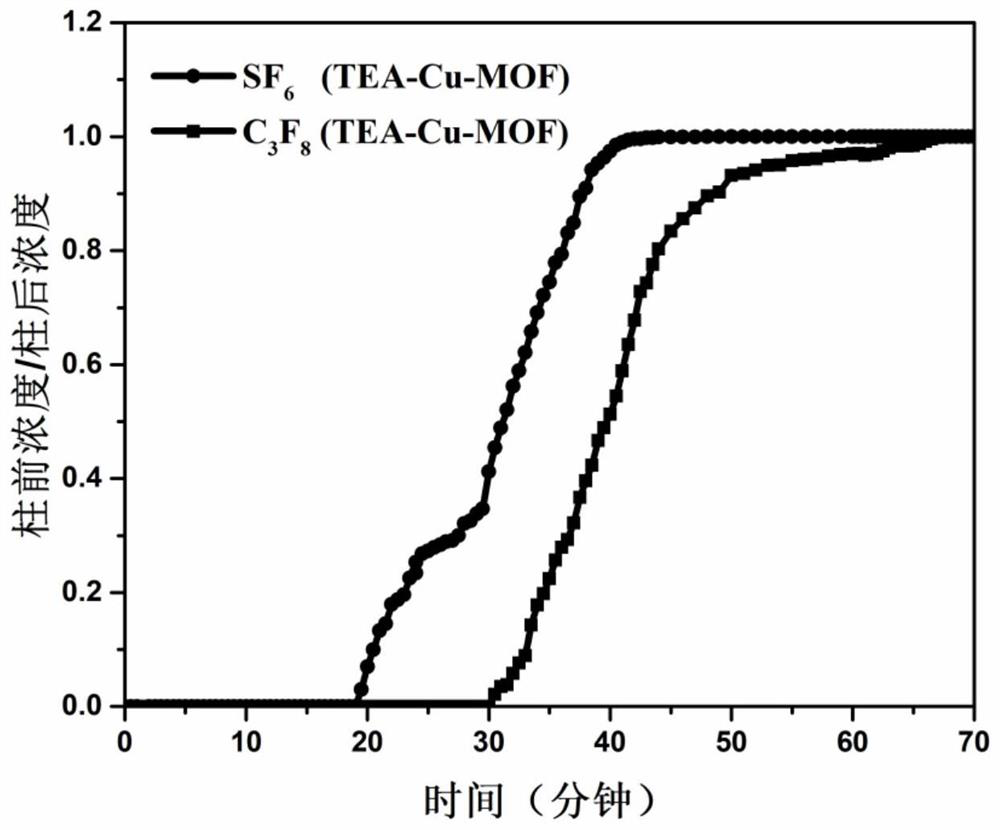

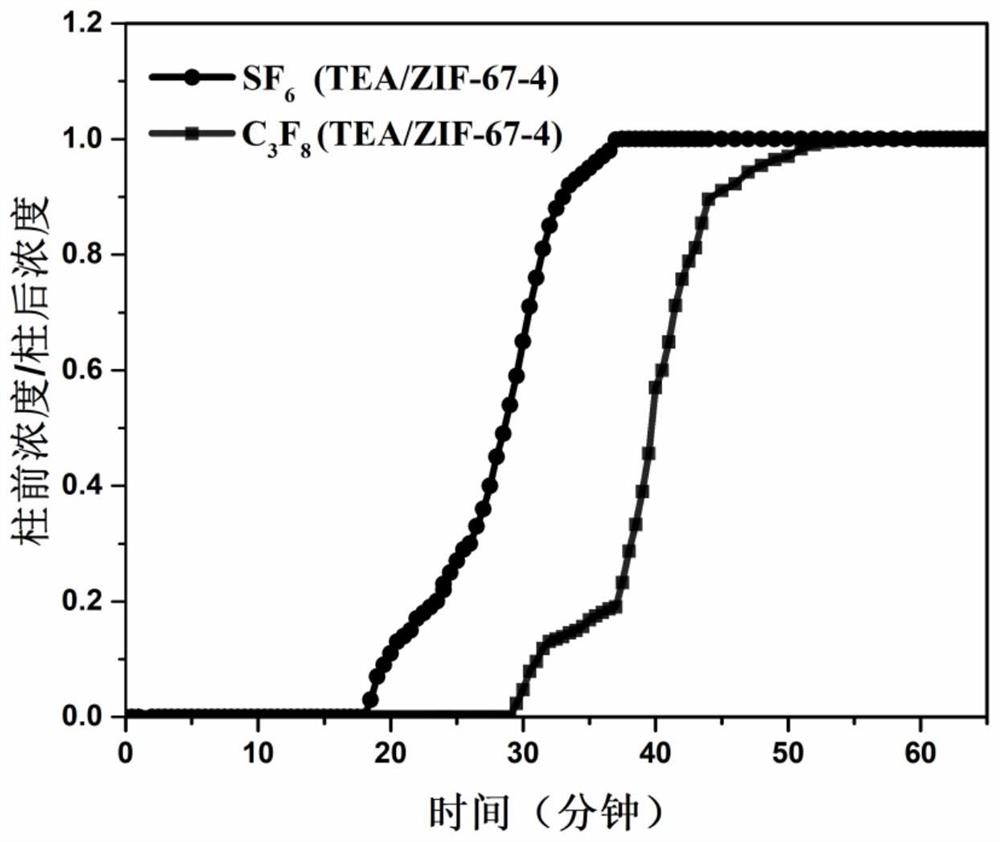

Method for adsorbing and separating octafluoropropane in sulfur hexafluoride by using metal-organic framework material

PendingCN114471468AEasy to separateAdjustable structureGas treatmentOther chemical processesOctafluoropropaneSulfur hexafluoride

The invention discloses a method for adsorbing and separating octafluoropropane in sulfur hexafluoride by using a metal-organic framework material, which comprises the following steps: adsorbing and separating mixed gas containing octafluoropropane and sulfur hexafluoride through an adsorption column filled with the metal-organic framework material, and controlling the adsorption and separation temperature to be 15-60 DEG C; the metal-organic framework material is a metal-organic framework material which is formed by metal ions and organic ligands through coordination and has a micropore and ultra-micropore structure. The metal ions are Zr < 4 + >, Cu < 2 + >, Zn < 2 + >, Co < 2 + >, Mn < 2 + > or Ni < 2 + >; the organic ligand is one or more of terephthalic acid, trimesic acid and dimethylimidazole. The dynamic adsorption capacity of C3F8 of the metal-organic framework material can reach 4.31 mmol / g, and is obviously superior to that of the existing adsorption material.

Owner:ANHUI XINLT POWER TECH CONSULTING +1

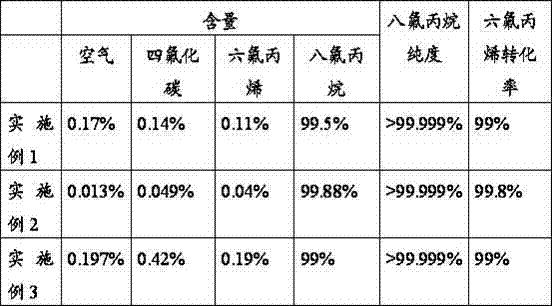

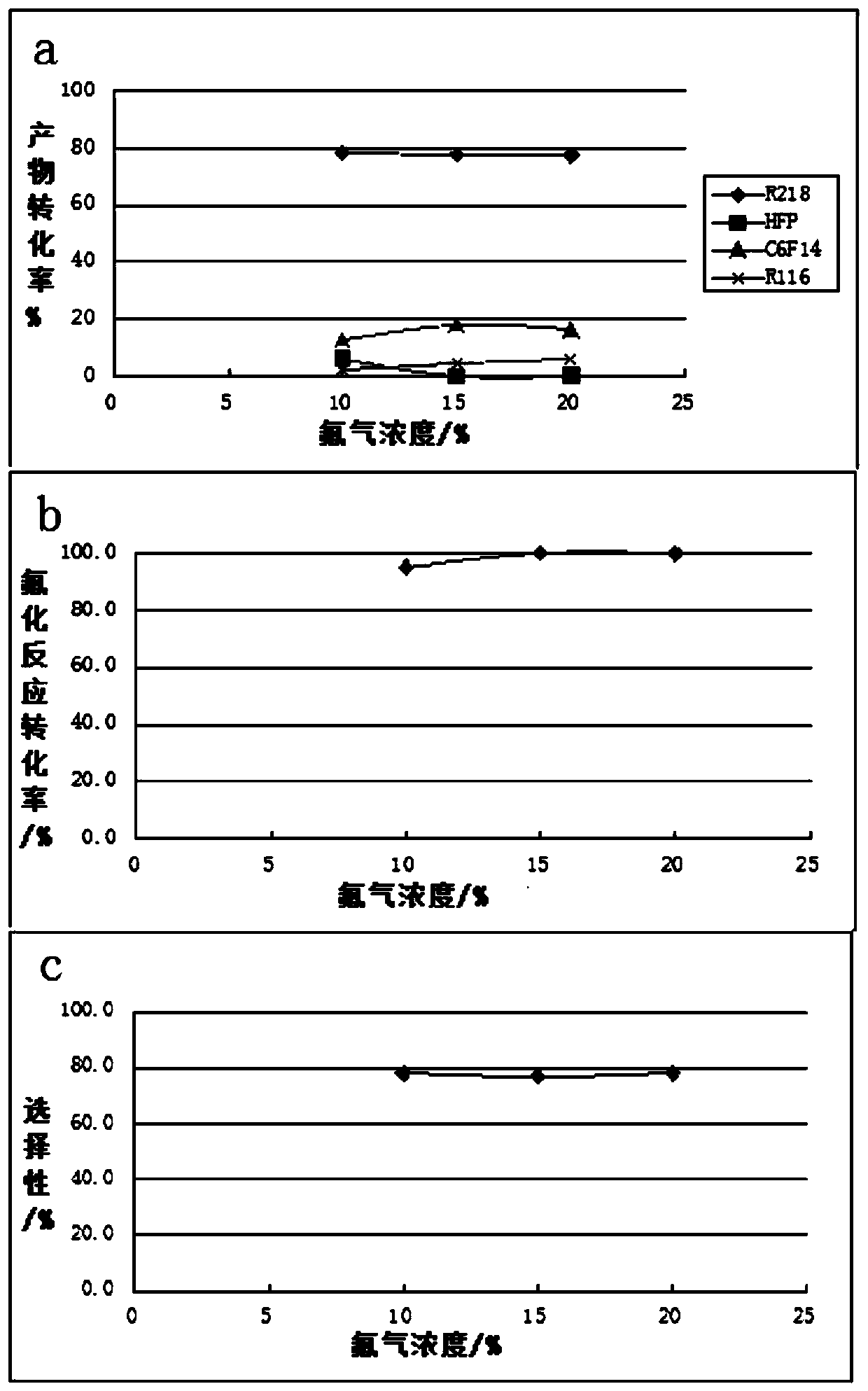

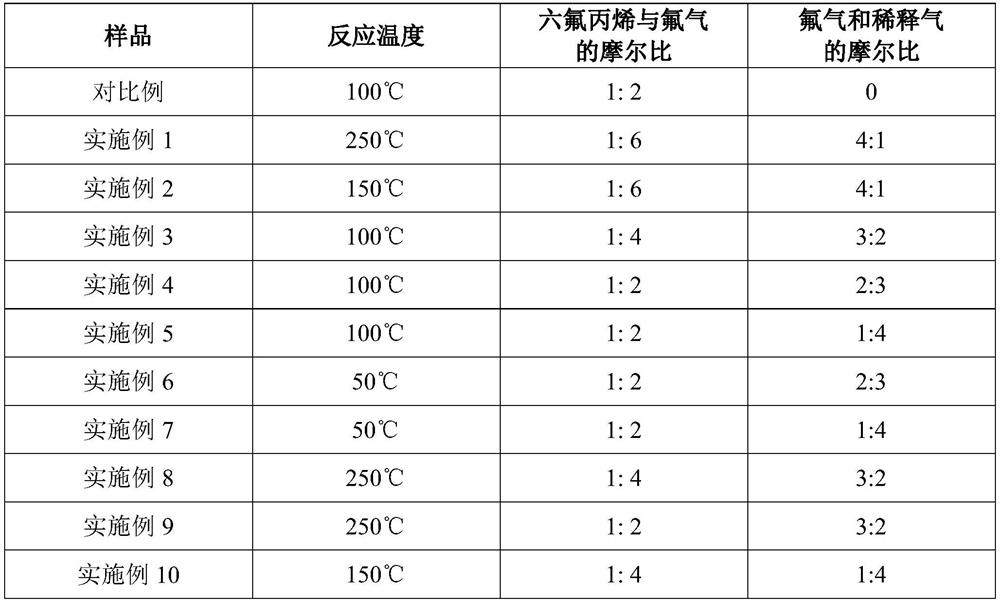

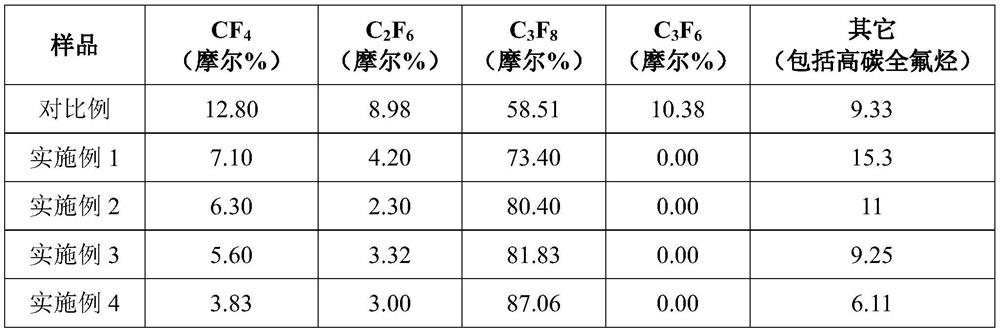

A method for preparing high-purity octafluoropropane

ActiveCN107098790BRealize industrial productionFacilitate addition reactionPreparation by halogen additionPtru catalystHexafluoropropylene

The invention relates to a method for preparing high-purity octafluoropropane, comprising the steps of: setting the reaction temperature to 50-250°C in a reactor, using cobalt trifluoride as a catalyst, hexafluoropropylene and fluorine as reaction gases, The reaction prepares octafluoropropane; the molar ratio of the hexafluoropropylene to the fluorine gas is 1:2-6. In this preparation method, cobalt trifluoride is used as a catalyst to realize continuous reaction, which promotes the addition reaction of hexafluoropropylene and fluorine gas, the conversion rate of hexafluoropropylene is almost 100%, and the yield of octafluoropropane can reach More than 90%, the selectivity of the reaction is good, and the content of by-products is small. The obtained crude product can prepare high-purity octafluoropropane after subsequent purification treatment, which is a low-cost, high-efficiency octafluoropropane production method that can realize industrial production.

Owner:FOSHAN HUATE GASES +1

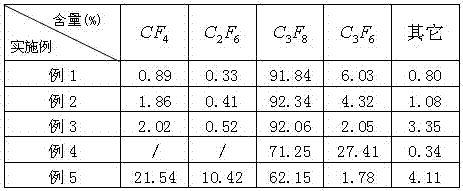

Preparation method of perfluoropropane

InactiveCN107540515AHigh yieldAvoid violent reactionsPreparation by halogen additionHydrogen fluorideOctafluoropropane

The invention discloses a preparation method of perfluoropropane. The preparation method comprises following steps: S1, hexafluoropropene and diluted fluorine gas are uniformly mixed at a certain molar ratio so as to obtain a mixed raw material gas; S2, the mixed raw material gas is delivered into a fixed bed reactor containing a cobalt catalyst at an appropriate temperature under appropriate pressure conditions for reaction so as to obtain a mixed gas containing perfluoropropane; S3, the mixed gas containing perfluoropropane is delivered into an alkaline washing tower and an absorber successively for treatment so as to remove a trace of fluorine gas, hydrogen fluoride, and water, and obtain crude perfluoropropane; and S4, the crude perfluoropropane is delivered into a rectification systemfor further refining so as to obtain high purity perfluoropropane. The beneficial effects are that: hexafluoropropene is taken as a preparation raw material, perfluoropropane is prepared via additionreaction of hexafluoropropene with diluted fluorine gas under the action of the cobalt catalyst, the raw material conversion rate is high, yield is high, selectivity is high, the preparation method is simple, production cost is low, operation is convenient, reaction temperature is low, and energy consumption is low.

Owner:SHANGHAI HELI IND GAS CO LTD

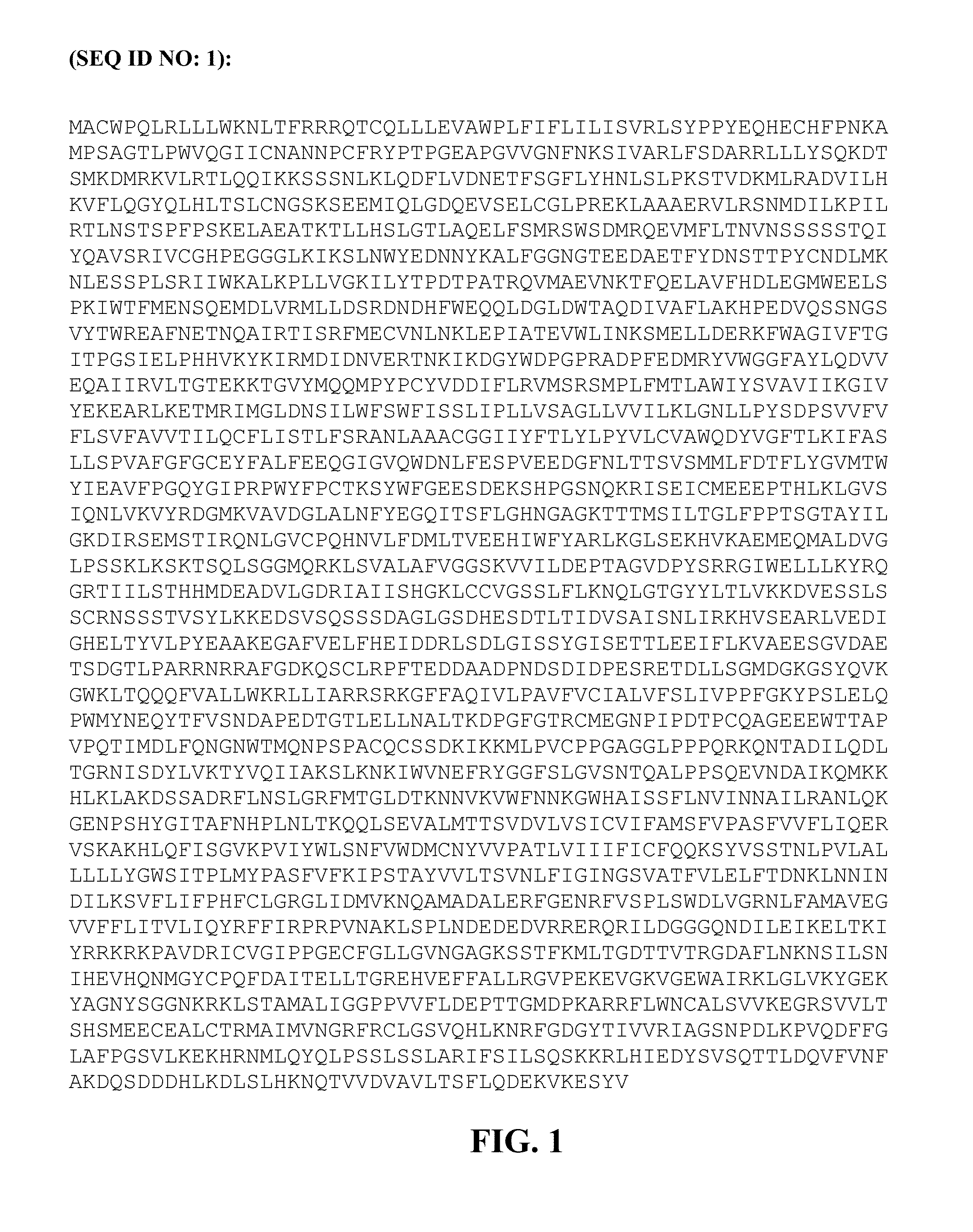

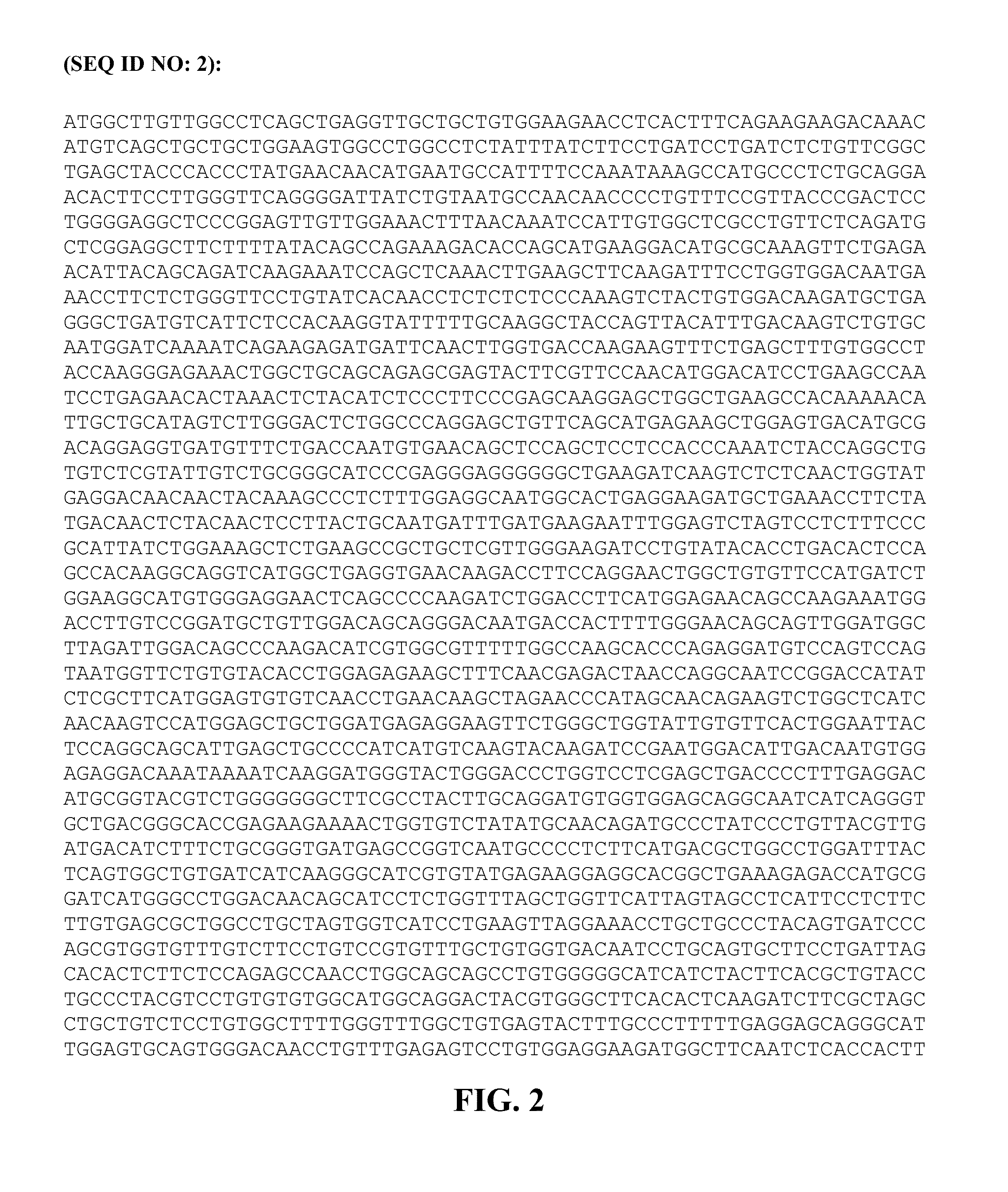

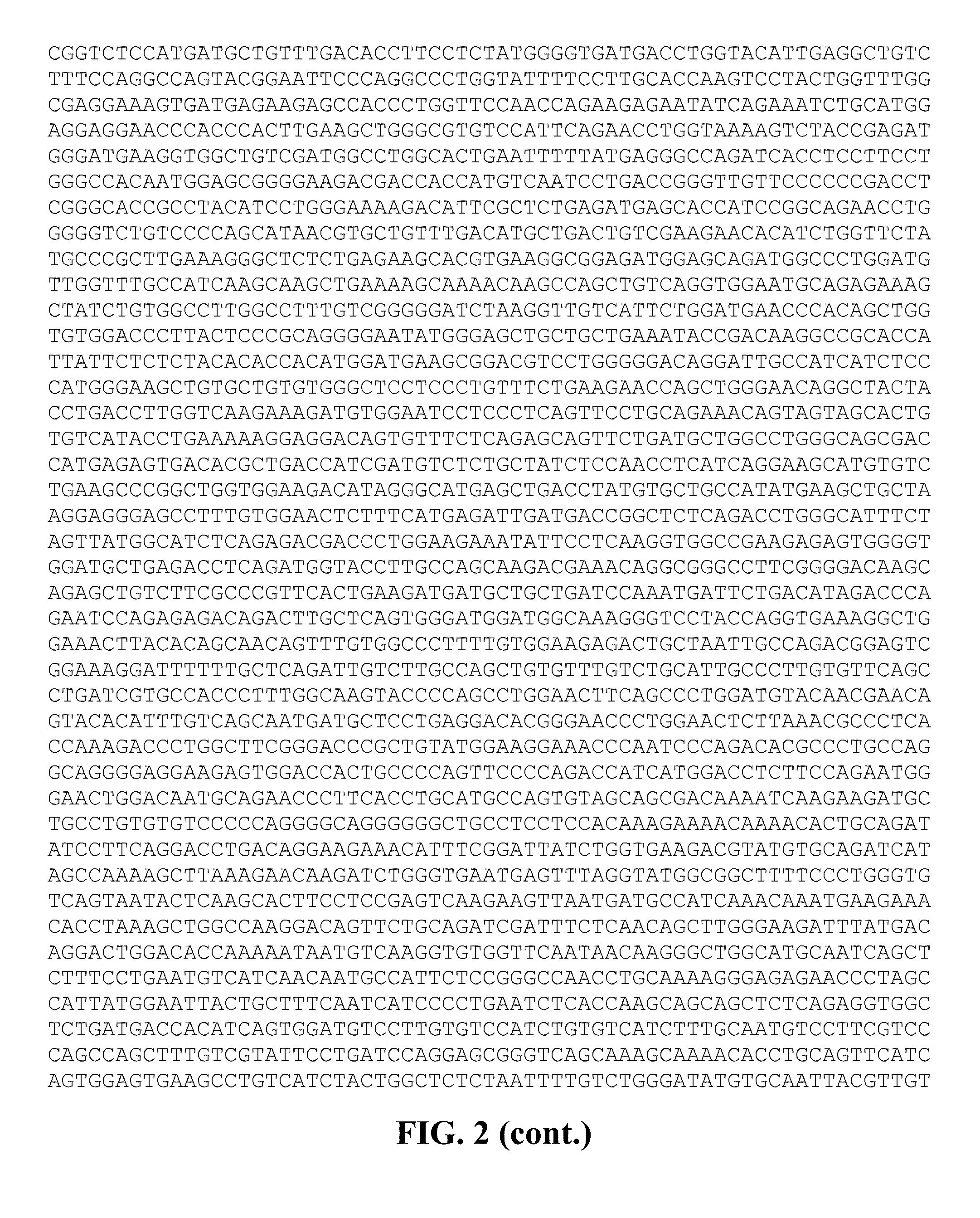

Sonochemical induction of ABCA1 expression and compositions therefor

The present invention provides compositions useful for transfecting cells (e.g., liver cells) to express ABCA1. The compositions described herein comprise a pharmaceutically acceptable aqueous carrier containing sonochemically-active microspheres together with a plasmid DNA construct encoding an active form of ABCA1 and at least one promoter for the expression thereof. Preferably, the sonochemically-active microspheres comprise, consist essentially of, or consist of gas bubbles (e.g., a fluorocarbon gas, such as octafluoropropane) encapsulated within protein-containing or lipid-containing shells (e.g., human serum albumin shells). The microspheres are disruptable by exposure to ultrasonic acoustic energy to release the encapsulated gas.

Owner:SONOGENE

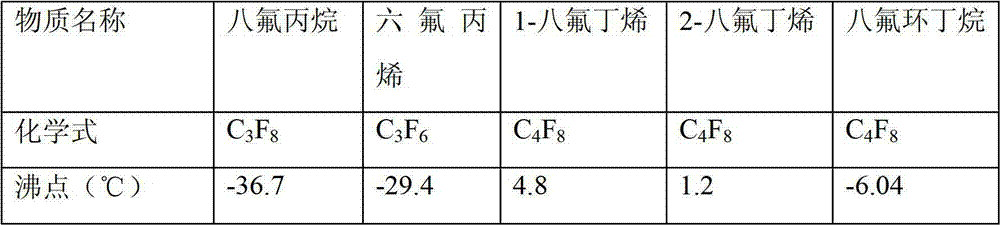

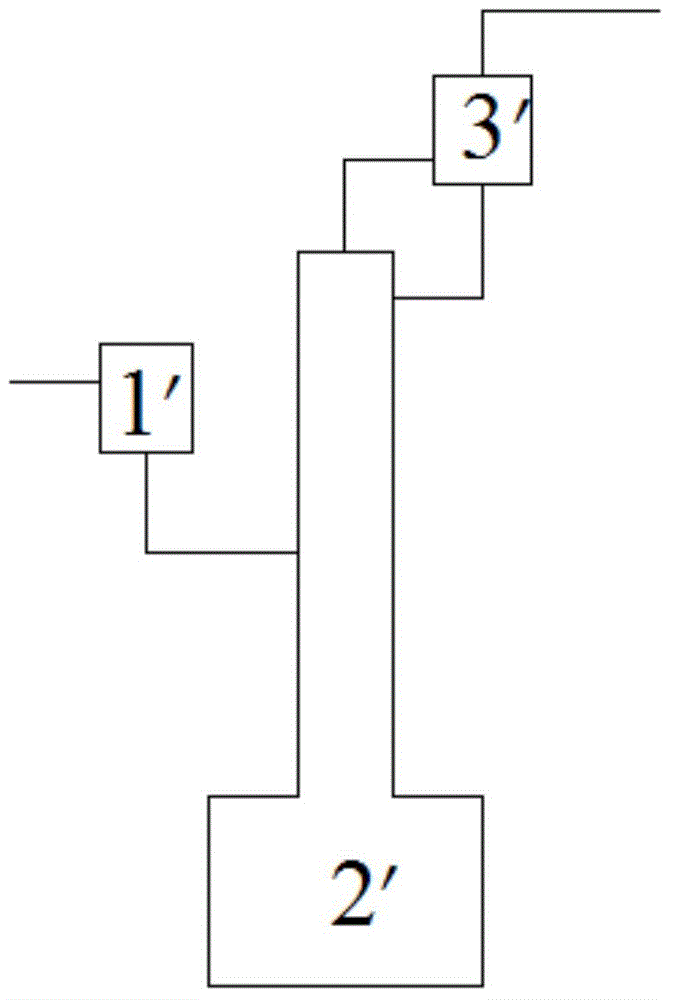

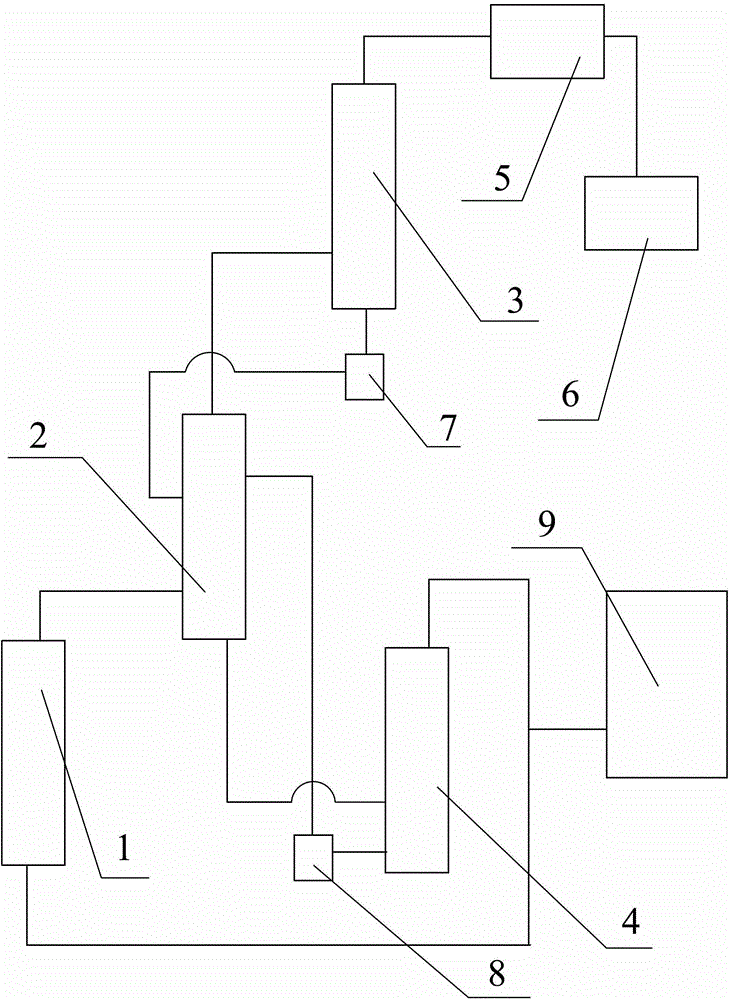

Device for removing hexafluorocyclopropane impurity in octafluoropropane and removal method of hexafluorocyclopropane impurity

ActiveCN114436763AReduce difficultyEasy to operateChemical industryHalogenated hydrocarbon preparationOctafluoropropanePhysical chemistry

The invention discloses a device for removing hexafluorocyclopropane impurities in octafluoropropane, the device comprises an addition tower, a deacidification tower, a drying tower and a purification tower which are arranged in sequence, the upper end inlet of the addition tower is connected with a high-purity hydrogen chloride gas steel cylinder, and the lower end inlet of the addition tower is connected with a crude product octafluoropropane raw material steel cylinder; the invention also provides a removal method using the device, which comprises the following steps: heating the addition tower, replacing the whole device with inert gas, vacuumizing the addition tower, and introducing hydrogen chloride gas and crude octafluoropropane gas to react in the addition tower to obtain mixed gas; introducing the mixed gas into a deacidification tower to remove acidic gas to obtain deacidified gas; and introducing the deacidified gas into a drying tower to remove moisture, and then sequentially introducing the deacidified gas into a filter, a dust remover and a purification tower to obtain the high-quality octafluoropropane. The method is simple in technological process and easy and convenient to operate, high-purity industrial octafluoropropane is finally obtained, and industrial production is easy to achieve.

Owner:PERIC SPECIAL GASES CO LTD

A purification method and purification device for octafluoropropane

ActiveCN106380372BReduce consumptionImprove economyHalogenated hydrocarbon separation/purificationPurification methodsBoiling point

The invention relates to an octafluoropropane purifying method and a purifying apparatus thereof, which belong to the field of fine chemical engineering. The purifying method employs a cold trap for light-discharge and heavy-removal processing of an octafluoropropane crude product, the light components and heavy components impurity content are greatly reduced; an adsorbent is used for adsorption, H2O content is reduced, a part of a fluorocarbon compound is absorbed; a rectification technology is employed, the high-boiling point and low-boiling point impurity can be removed by controlling the rectification parameters, the H2O content is less than 1 ppm, the content of the organic fluorocarbon compound is less than 1 ppm, the total impurity content is less than 10 ppm, cold amount and heat consumed during the rectification process are reduced, economic performance is good, and the octafluoropropane with purity of greater than 99.999% can be obtained after being purified. The purifying apparatus mainly comprises the cold trap, an adsorption tower and a rectifying tower, and is adapted to usage of the purifying method.

Owner:PERIC SPECIAL GASES CO LTD

Method and device for preparing octafluoropropane through electrolysis

The invention relates to a method for preparing octafluoropropane through electrolysis, and belongs to the technical field of fine chemical engineering. The method comprises the following steps: mixing HF and alkali metal fluoride to obtain a molten salt electrolyte, and adding the molten salt electrolyte into an electrolytic bath for electrolytic water removal; adding the raw materials into an electrolytic bath, controlling the electrolytic voltage to be 4V-10V and the electrolytic temperature to be -10 DEG C to 20 DEG C, and collecting an electrolytic product to obtain an octafluoropropane crude product when the electrolytic product is detected to contain octafluoropropane; cooling the octafluoropropane crude product at the temperature of 70 DEG C below zero to 50 DEG C below zero, and collecting a liquid phase; and finally, heating and gasifying the liquid phase to obtain the octafluoropropane. According to the method, high-yield and high-purity preparation of the octafluoropropane can be realized.

Owner:PERIC SPECIAL GASES CO LTD

Rectification device and rectification process used for electronic grade sulfur hexafluoride production

The invention relates to a rectification device and a rectification process used for electronic grade sulfur hexafluoride production. Specifically, a rough sulfur hexafluoride gas is pressurized and then sent into a precooler to be converted from gas to liquid under high pressure and low temperature conditions, then gasification, condensation and reflux are carried out in a first rectifying tower and a first condenser to remove high-boiling residue, and then by means of gasification, condensation and reflux in a second rectifying tower and a second condenser, the sulfur hexafluoride is condensed into a liquid state for collection, while low-boiling residue maintains a gas state and escapes from the second condenser. The rectification device and the rectification process provided by the invention can effectively remove high-boiling residue and low-boiling residue impurities from the rough sulfur hexafluoride gas, especially the hexafluoroethane and octafluoropropane impurity gases with a very close boiling point to sulfur hexafluoride under high pressure and low temperature states required by the rectification process. The obtained sulfur hexafluoride fully meets the technical requirements of electronic grade sulfur hexafluoride, also the equipment cost is low, and the production process is simple.

Owner:FUJIAN YONGJING TECH CO LTD

Method for recovering octafluoropropane from hexafluoropropylene production process

ActiveCN102766016BAvoid pollutionEasy to operateHalogenated hydrocarbon preparationHexafluoropropyleneOctafluoropropane

The invention relates to a method for recovering octafluoropropane from the hexafluoropropylene production process and belongs to the filed of chemical product recycling. The method is characterized in that material gas enters a light component removal column, azeotrope of octafluoropropane and hexafluoropropylene in the material gas in the light component removal column is separated from other components, and octafluoropropane and hexafluoropropylene in the material gas are gathered at the column top; the material gas containing octafluoropropane and hexafluoropropylene at the column top of the light component removal column enters an extraction column for extracting, and extracting agents are used for absorbing hexafluoropropylene; column kettle materials in the extraction column enter a resolving column for resolving, high-purity hexafluoropropylene material gas obtained at the column top of the resolving column enters a hexafluoropropylene rectifying column for rectifying; and materials at the column top of the extraction column enter an octafluoropropane rectifying column for rectifying, and octafluoropropane gas is obtained at the column top of the octafluoropropane rectifying column. According to the method, a conventional rectifying device is combined with an extraction rectifying device and the extracting agents can be recycled, so that the whole production process is simple to operate, and purity of the recovered octafluoropropane is no lower than 99.999%.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for supercritical Rankine cycle recycling low-temperature waste heat power

InactiveCN101298843BImprove overall utilizationReduce heat pollutionEnergy industrySteam engine plantsThermal energyResource utilization

The present invention relates to a method of recovering low temperature energy power, especially aiming at the low temperature waste heat discharged in metallurgical industry, generation by solar energy temperature difference and resource utilization in bi-circular terrestrial heat generation, belonging to the technical field of resource and environment. The circular working substance of the present invention adopts duality mixed working substance configured by propane and octafluoropropane, directly heats to the supercritical state from the outlet of the compressing pump under the supercritical pressure, enters into the organic turbine to apply work, expands to the steam of the condensed pressure ensured by the condensing temperature, then condenses to liquid to the inlet of the compressing pump to be circularly used. The method is able to recover the available energy in the low temperature energy at a large extent and cause the final discharging temperature of the low temperature heat stream (or remaining heat stream) to reduce in the range permitted by the environment.

Owner:KUNMING UNIV OF SCI & TECH

Load small interfering RNA nanoscale lipid microbubble ultrasonic contrast agent and preparation method

InactiveCN103100093BSmall particle sizeAchieving targeted aggregationGenetic material ingredientsEchographic/ultrasound-imaging preparationsUltrasound contrast mediaPolyethylene glycol

Owner:THE THIRD AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

Refrigerant replacing r-32 and its preparation method and application

ActiveCN110791255BHigh self-ignition pointEasy to installHeat-exchange elementsDifluoroethyneOctafluoropropane

The invention belongs to the technical field of household and commercial small split air-conditioning refrigerants, and in particular relates to a refrigerant replacing R-32 and its preparation method and application. The refrigerant replacing R-32 includes the following components in parts by weight: 8-25 parts of isobutane; 20-45 parts of octafluoropropane; 30-60 parts of difluoroethane; 10-25 parts of trifluoroiodomethane . The refrigerant substituting R-32 provided by the invention not only has a very low GWP, but also is energy-saving and environment-friendly.

Owner:湖北瑞能华辉能源管理有限公司

Modified alumina adsorbent for adsorbing and removing benzene from chemical wastewater

InactiveCN108114691ALarge adsorption capacityImprove removal efficiencyOther chemical processesWater contaminantsBenzeneOctafluoropropane

The invention discloses a modified alumina adsorbent for adsorbing and removing benzene in chemical wastewater. Alumina is modified through mixed liquid prepared from Cu(NO3)2, Zn(NO3)2, Co(NO3)2, Mg(NO3)2 and Pb(NO3)2 after being cleaned to be prepared into a substance C; the substance C is modified through mixed liquid prepared from 3,5-dichloro-2-cyanopyridine, 4-hydroxyisoquinoline, 3,6-dimethylpyridazine, 3-acetylpyridazine, 2,3-difluoropyridine, 3-bromo-4-fluorobenzoic acid, 2-fluorobenzaldehyde, 3,4-difluoroanisole, 2-bromo-4-chloro-5-fluoropyridine, octafluoropropane and 3,6-dimethylpyridazine to prepare a substance, namely the modified alumina adsorbent for adsorbing and removing benzene from chemical wastewater.

Owner:BEIJING YIQINGYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com