Method for supercritical Rankine cycle recycling low-temperature waste heat power

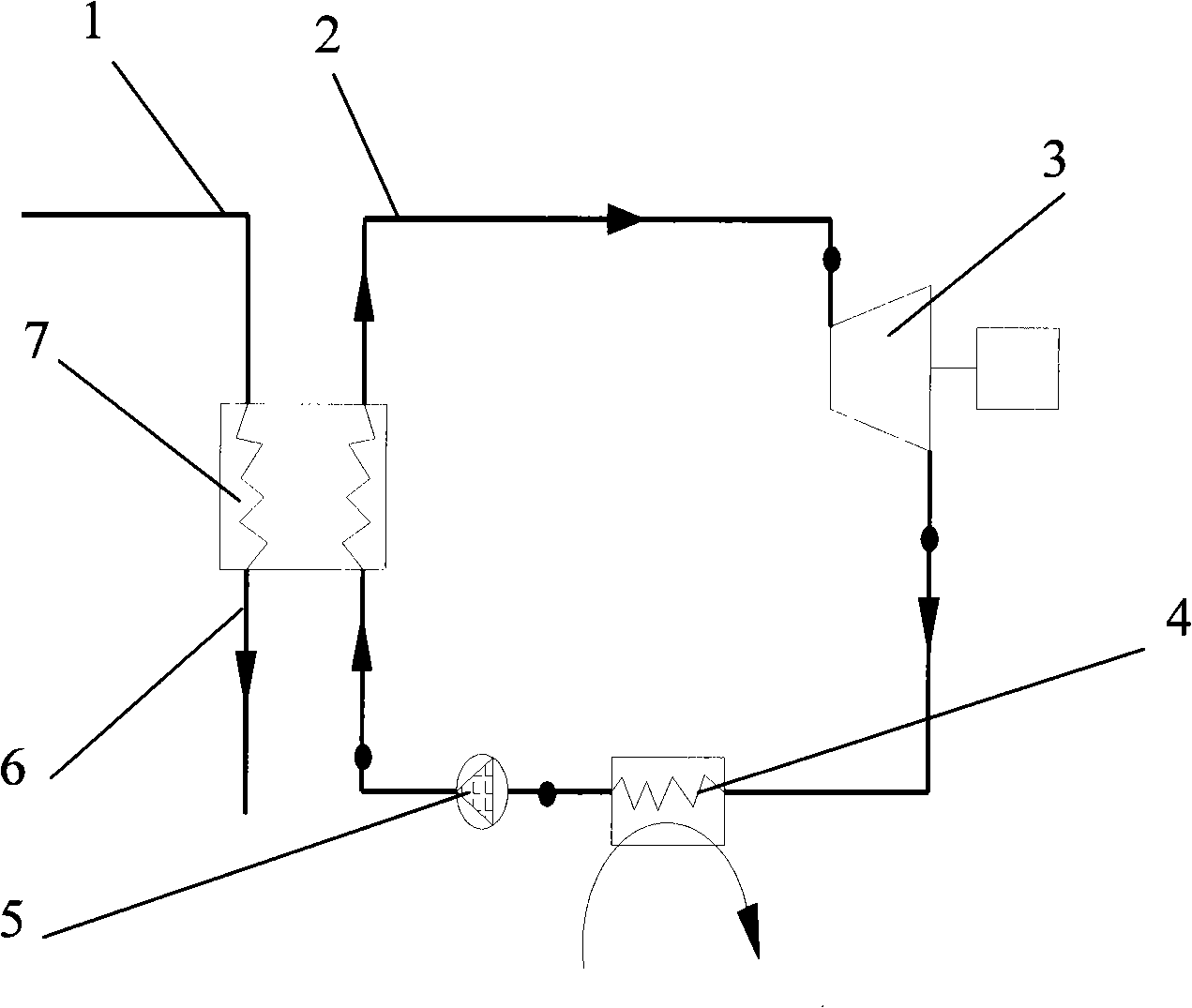

A low-temperature waste heat and Rankine cycle technology, applied in the field of resources and environment, can solve the problems of unsatisfactory energy conversion efficiency and complex composition, and achieve the effects of improving the total utilization rate, increasing the total utilization rate, and expanding the temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The displacement of 100°C hot water discharged by a smelter is 100t / h. Under the condition that the condensation temperature is set at 35°C, when the original R11 working fluid is used, the power output of 356Kw can be obtained, and the final discharge temperature of waste heat is 65°C; And adopt the technical solution of the present invention, promptly the proportioning of R290+R218 mixed working medium is 30% R290, when the evaporation pressure is 3.2Mpa, carry out the supercritical Rankine cycle of mixed working medium, then can obtain the power output of 509Kw, waste heat The final discharge temperature is 50°C, and the output power increases by 30.05%.

Embodiment 2

[0018] The outlet water temperature of a geothermal power generation production well is 95°C, and a 500Kw power station is built. Under the condition that the condensation temperature is set at 35°C, when R245fa is used as the working fluid, the groundwater extraction flow rate is 642.3t / h, and the geothermal flow is finally The discharge (or recharge) temperature is 88 DEG C; and adopt the technical scheme of the present invention, namely the proportioning of R290+R218 mixed working medium is 20% R290, when the evaporation pressure is 3.15Mpa, carry out the supercritical Lang of mixed working medium If the cycle is used, the groundwater extraction flow will be reduced to 136.4t / h, the final discharge (or recharge) temperature of the geothermal flow will be 62°C, and the groundwater extraction will drop by about 80%, which can greatly reduce the cost and initial investment of groundwater extraction.

Embodiment 3

[0020] The flue gas emission of a 350°C blast furnace in a smelter has been measured to be about 40,000kg / h. A 500Kw waste heat power station was originally built using F85. When the inlet temperature of the condenser is 25°C and the outlet temperature is 31.7°C, the evaporation pressure in the boiler is 49.2ata, 500Kw of power generation can be obtained, and the final exhaust temperature of the flue gas is 161°C; now the technical solution of the present invention is adopted, that is, the ratio of R290+R218 mixed working fluid is 10% R290, and the evaporation pressure is 4.0Mpa When the supercritical Rankine cycle of the mixed working fluid is carried out, the power generation power of 604KW can be obtained, the final discharge temperature of the flue gas is 118°C, the power generation power can be increased by 20%, and the final discharge temperature of the flue gas can be reduced by 43°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com