A purification method and purification device for octafluoropropane

A technology of octafluoropropane and purification method, which is applied in chemical instruments and methods, disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc. It can solve the problems of difficult purification, small adsorption capacity, and difficult removal, and achieve the reduction of impurity content, The effect of improving product yield and prolonging the required time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

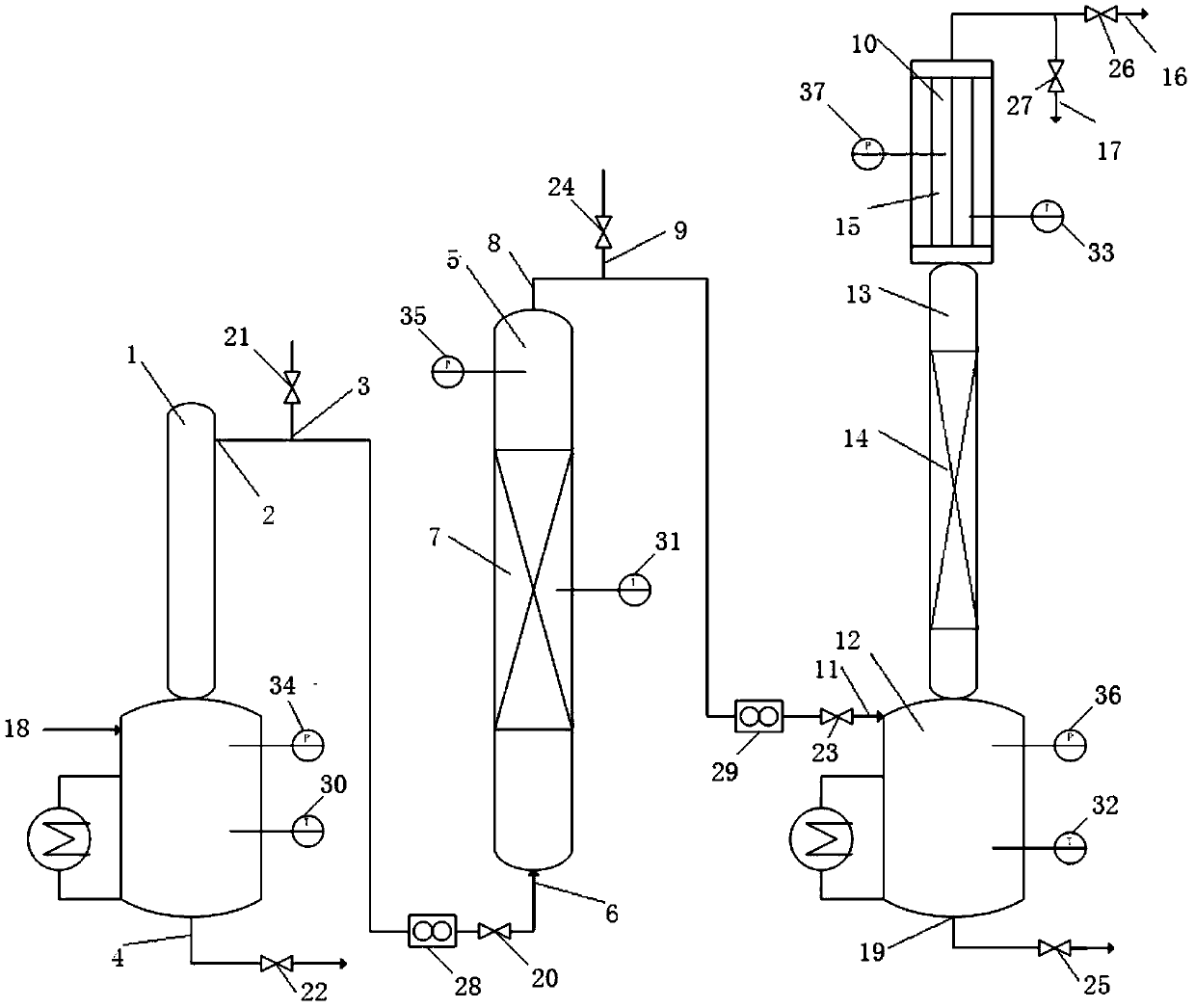

[0054] The rectification tower 10 is a packed rectification tower, the packing 14 is a stainless steel θ ring with a diameter of 1 mm, the rectification tower 10 is made of nickel, and the height is 15 m, and the diameter of the rectification column 13 is 50 mm.

[0055] A purification method for octafluoropropane, the steps of the purification method are as follows:

[0056] (1) Introduce crude octafluoropropane gas into cold trap 1 at a temperature of -100°C, heat it up at a rate of 1°C / min, and perform light-removal treatment at -90°C to -40°C to reduce light component impurities with low boiling points Vaporization discharge. When the temperature rises to greater than -40°C and less than or equal to -20°C, the treated crude octafluoropropane gas is introduced into the bottom of the adsorption tower 5. When the temperature rises to greater than -20°C, the flow to the bottom of the adsorption tower 5 is stopped. In, the higher boiling point heavy component impurities left in the ...

Embodiment 2

[0064] The rectification tower 10 is a packed rectification tower, and the packing 14 is a nickel Pall ring with a diameter of 5 mm. The rectification tower 10 is made of stainless steel and has a height of 8 m. The diameter of the rectification column 13 is 500 mm.

[0065] A purification method for octafluoropropane, the steps of the purification method are as follows:

[0066] (1) Introduce crude octafluoropropane gas into cold trap 1 at a temperature of -91°C, heat it up at a rate of 2°C / min, and perform light-removal treatment at -90°C to -40°C to reduce light component impurities with low boiling points Vaporization discharge. When the temperature rises to greater than -40°C and less than or equal to -20°C, the treated crude octafluoropropane gas is introduced into the bottom of the adsorption tower 5. When the temperature rises to greater than -20°C, the flow to the bottom of the adsorption tower 5 is stopped. In, the higher boiling point heavy component impurities left in t...

Embodiment 3

[0074] The rectification tower 10 is a packed rectification tower, the packing 14 is a polytetrafluoroethylene Pall ring with a diameter of 100 mm, the rectification tower 10 is made of Monel alloy with a height of 5 m, and the diameter of the rectification column 13 is 300 mm.

[0075] A purification method for octafluoropropane, the steps of the purification method are as follows:

[0076] (1) Introduce crude octafluoropropane gas into cold trap 1 at a temperature of -100°C, heat it up at a rate of 1.5°C / min, and perform light-removal treatment at -90°C to -40°C to reduce light component impurities with low boiling points Vaporization discharge. When the temperature rises to greater than -40°C and less than or equal to -20°C, the treated crude octafluoropropane gas is introduced into the bottom of the adsorption tower 5. When the temperature rises to greater than -20°C, the flow to the bottom of the adsorption tower 5 is stopped. In, the higher boiling point heavy component impur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com