Preparation process of octafluoropropane

A preparation process and octafluoropropane technology, applied in the field of preparation technology of octafluoropropane, can solve the problems of increasing the amount of three wastes, increasing the reaction equipment, etc., so as to reduce the generation of short-chain perfluoroalkane by-products, the reaction is sufficient, and the fracture is reduced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

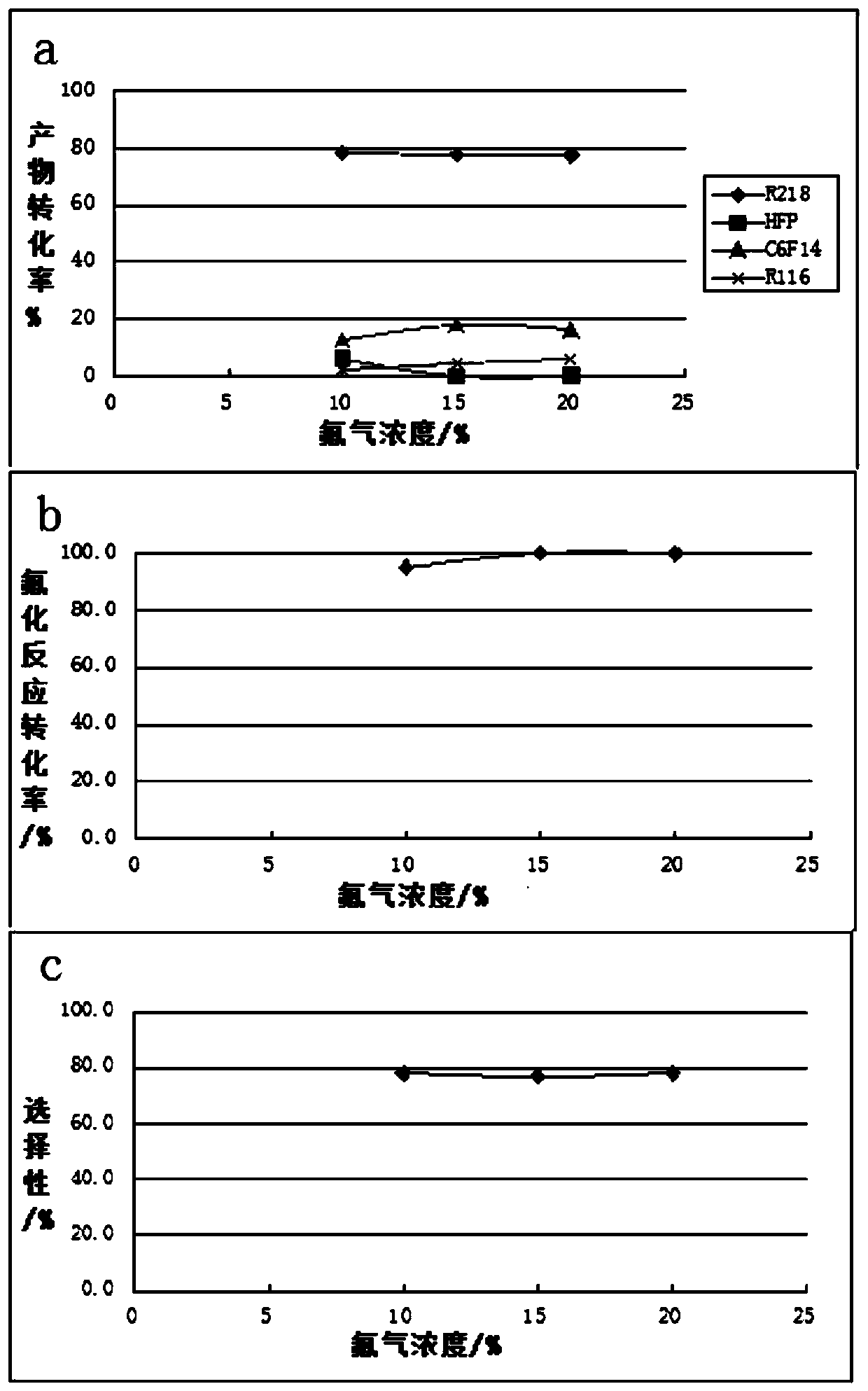

[0047] Embodiment 1: the impact of fluorine gas concentration on product components

[0048] The operating conditions are as follows: the reaction temperature is 35-55°C, the pressure is 0 MPa, and the molar ratio of fluorine gas to HFP is about 1.25:1. Reaction product composition, reaction conversion and selectivity results such as image 3 shown. Among them, R218 in Figure 3(a) is octafluoropropane, R116 is perfluoroethane, and HFP is hexafluoropropylene.

[0049] From image 3 According to the experimental results, under a certain material ratio, the reaction conversion rate is not greatly affected by the concentration of fluorine gas. When the concentration of fluorine gas is 15% and 20%, the conversion rate reaches or approaches 100%, while when the concentration of fluorine gas is 10%, the conversion rate is about 95%. The possible reason is that when the concentration of fluorine gas is too low, the content of nitrogen gas is too high, which leads to insufficient c...

Embodiment 2

[0050] Embodiment 2: the influence of reaction mass ratio on fluorination reaction

[0051] 20% fluorine-nitrogen mixed gas and 99.9% HFP are used to react at a temperature of 2-30° C. and a pressure of nearly 0.0 MPa. The molar ratio of fluorine gas to HFP is respectively 0.6:1, 0.7:1, 0.8:1, 0.9:1, 1.0:1, 1.1:1, 1.2:1, 1.4:1, 2.0:1, 2.4:1 and 3.7: 1. The experimental results such as product composition, reaction conversion rate and selectivity are as follows: Figure 4 shown.

[0052] It can be seen from the experimental results that the material ratio has an influence on the reaction conversion rate and R218 selectivity. The reaction conversion rate increases with the increase of the molar ratio of fluorine gas to HFP. This phenomenon is particularly obvious when the molar ratio of fluorine gas to HFP is in the range of 0.5-1.2, that is, the reaction conversion rate increases obviously with the increase of the molar ratio of fluorine gas to HFP. When the molar ratio of...

Embodiment 3

[0055] Embodiment 3: the influence of reaction temperature on fluorination reaction

[0056] 20% fluorine-nitrogen mixed gas and 99.9% HFP are used, the molar ratio of fluorine gas to HFP is about 1.2:1, and the reaction is carried out at a pressure of nearly 0.0 MPa. The reaction temperatures are respectively 2°C, 4°C, 40°C, 60°C, 70°C, 130°C, 135°C and 140°C. The experimental results such as product composition, reaction conversion rate and selectivity are as follows: Figure 5 shown.

[0057] It can be seen from the experimental results that the reaction temperature has little effect on the conversion rate of HFP fluorination reaction and the selectivity of R218 within the range of 0-100 °C. When the temperature is higher than 100°C, the reaction conversion remains at about 100%, but the selectivity of R218 decreases, mainly because the amount of R116 increases rapidly with the increase of temperature, that is, more carbon chain breaks occur Case. We believe that when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com