Device for removing hexafluorocyclopropane impurity in octafluoropropane and removal method of hexafluorocyclopropane impurity

A technology for hexafluorocyclopropane and octafluoropropane, which is applied in the field of devices for removing hexafluorocyclopropane impurities in octafluoropropane, can solve problems such as difficulty in removing hexafluorocyclopropane, and achieves high conversion efficiency, simple and clear technological process, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

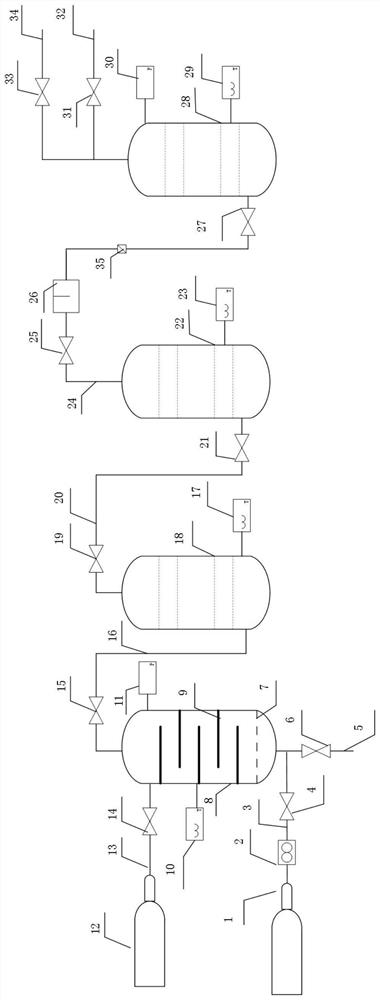

[0027] The device for removing hexafluorocyclopropane impurities in octafluoropropane in this embodiment includes an addition tower 8 connected by pipelines, an acid removal tower 18, a drying tower 22 and a purification tower 28, the addition tower 8 The upper end inlet is connected with the high-purity hydrogen chloride gas cylinder 12, the lower end inlet of the addition tower 8 is connected with the crude product octafluoropropane raw material steel cylinder 1, and the drying tower 22 top is connected with a drying tower gas outlet pipeline 24, and the drying tower 22 top is The gas outlet line 24 of the drying tower is connected to the inlet of the purification tower 28, and the gas outlet line 24 of the drying tower is provided with a dust collector 26 and a filter 35 in sequence; , the gas baffles 9 are provided with a heating system with an automatic temperature control device.

[0028] In this embodiment, the outer wall of the crude octafluoropropane raw material cyli...

Embodiment 2

[0034] This embodiment is a method for removing hexafluorocyclopropane impurities in octafluoropropane using the device for removing hexafluorocyclopropane impurities in octafluoropropane in Example 1, including the following steps:

[0035] S1, first open the gas baffle plate 9 to heat the addition tower 8, and then use nitrogen gas with a mass purity of 99.999% to replace the whole device for 3 times. The replacement temperature of the whole device is 60 ° C. After the replacement treatment, the whole The water content of the device is 0.5ppm, then the addition tower 8 is evacuated to a pressure of -0.095MPa, the high-purity hydrogen chloride gas cylinder 12 and the hydrogen chloride gas discharge valve 14 are opened, and the mass is fed through the high-purity hydrogen chloride gas discharge pipeline 13. The hydrogen chloride gas with a purity of 99.999% makes the pressure of the adding tower 8 0.6 MPa, then opens the crude product octafluoropropane raw material steel cylind...

Embodiment 3

[0041] This embodiment is a method for removing hexafluorocyclopropane impurities in octafluoropropane using the device for removing hexafluorocyclopropane impurities in octafluoropropane in Example 1, including the following steps:

[0042] S1, first open the gas baffle 9 to heat the addition tower 8, and then use helium gas with a mass purity of 99.999% to replace the whole device 5 times. The replacement temperature of the whole device is 150 ° C. After the replacement treatment The water content of the whole device is 0.4ppm, then the addition tower 8 is evacuated to a pressure of -0.098MPa, the high-purity hydrogen chloride gas cylinder 12 and the hydrogen chloride gas discharge valve 14 are opened, and the high-purity hydrogen chloride gas discharge pipeline 13 is passed into Hydrogen chloride gas with a mass purity of 99.999% makes the pressure of the addition tower 8 2 MPa, then opens the crude product octafluoropropane raw material steel cylinder 1, feed valve 4 and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com