Patents

Literature

43 results about "Electrochemical fluorination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

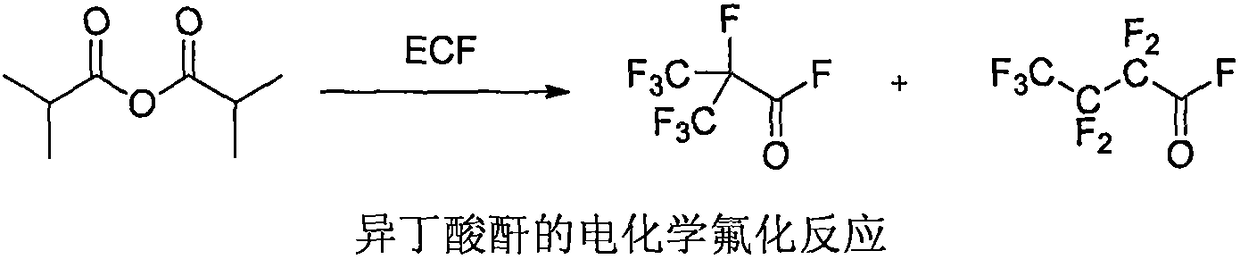

Electrochemical fluorination (ECF), or electrofluorination, is a foundational organofluorine chemistry method for the preparation of fluorocarbon-based organofluorine compounds. The general approach represents an application of electrosynthesis. The fluorinated chemical compounds produced by ECF are useful because of their distinctive solvation properties and the relative inertness of carbon–fluorine bonds. Two ECF synthesis routes are commercialized and commonly applied: the Simons process and the Phillips Petroleum process. It is also possible to electrofluorinate in various organic media. Prior to the development of these methods, fluorination with fluorine, a dangerous oxidant, was a dangerous and wasteful process. Also, ECF can be cost-effective but it may also result in low yields.

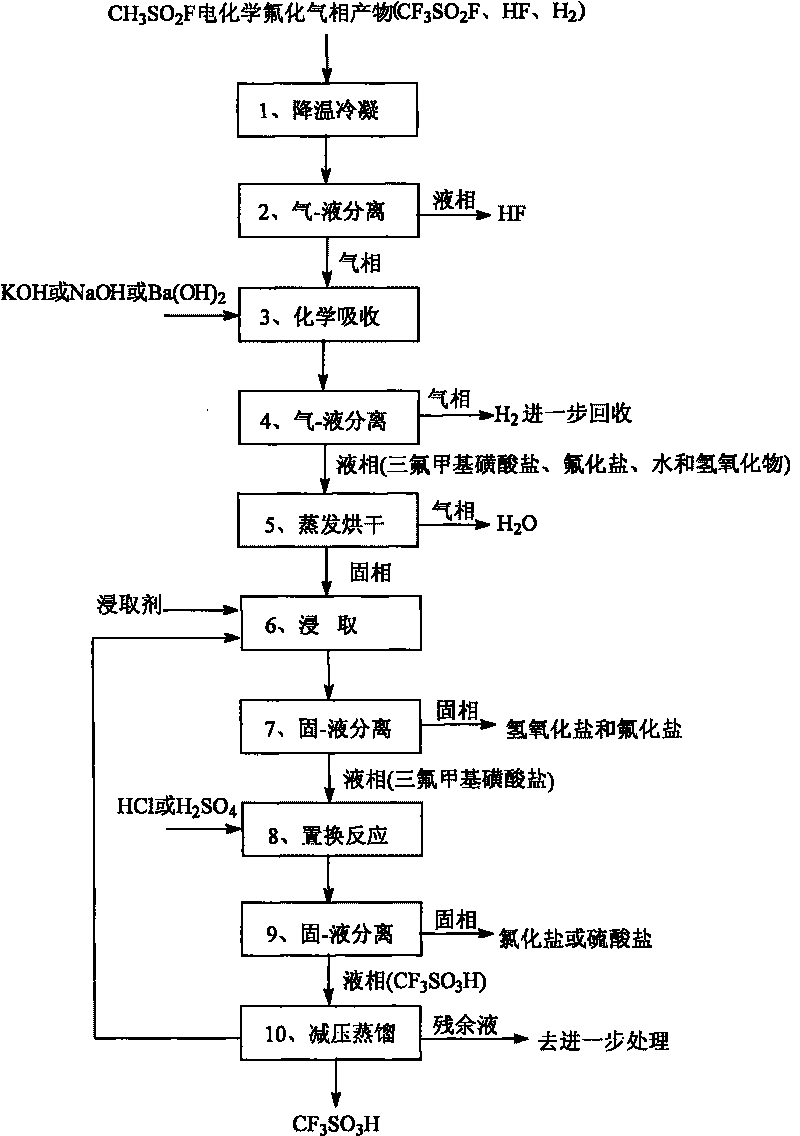

Process for preparing high-purity trifluoromethyl sulphonic acid

ActiveCN101402591AFast hydrolysisAdequate responseElectrolysis componentsOrganic compound preparationAlkaline earth metalDistillation

The invention relates to a process method for preparing high-purity trifluoromethane sulfonic acid. The process method comprises the following steps: firstly, hydrolyzing trifluoromethane sulfuryl fluoride gas prepared by an electrochemical fluorination method in alkaline metal or alkaline-earth metal hydroxide solution, recrystallizing the generated trifluoromethane sulphonate in a solvent to purify, and then reacting the trifluoromethane sulphonate with 100 percent of sulfuric acid in the presence of silicon dioxide to obtain an initial product of the trifluoromethane sulfonic acid, and finally purifying the trifluoromethane sulfonic acid through reduced pressure distillation. The process method not only effectively improves the hydrolysis speed of the trifluoromethane sulfuryl fluoride gas, leads the trifluoromethane sulfuryl fluoride gas to react more completely, and improves the yield, but also effectively reduces the content of F<-> in the trifluoromethane sulfonic acid product, and improves the purity of the product.

Owner:PERIC SPECIAL GASES CO LTD

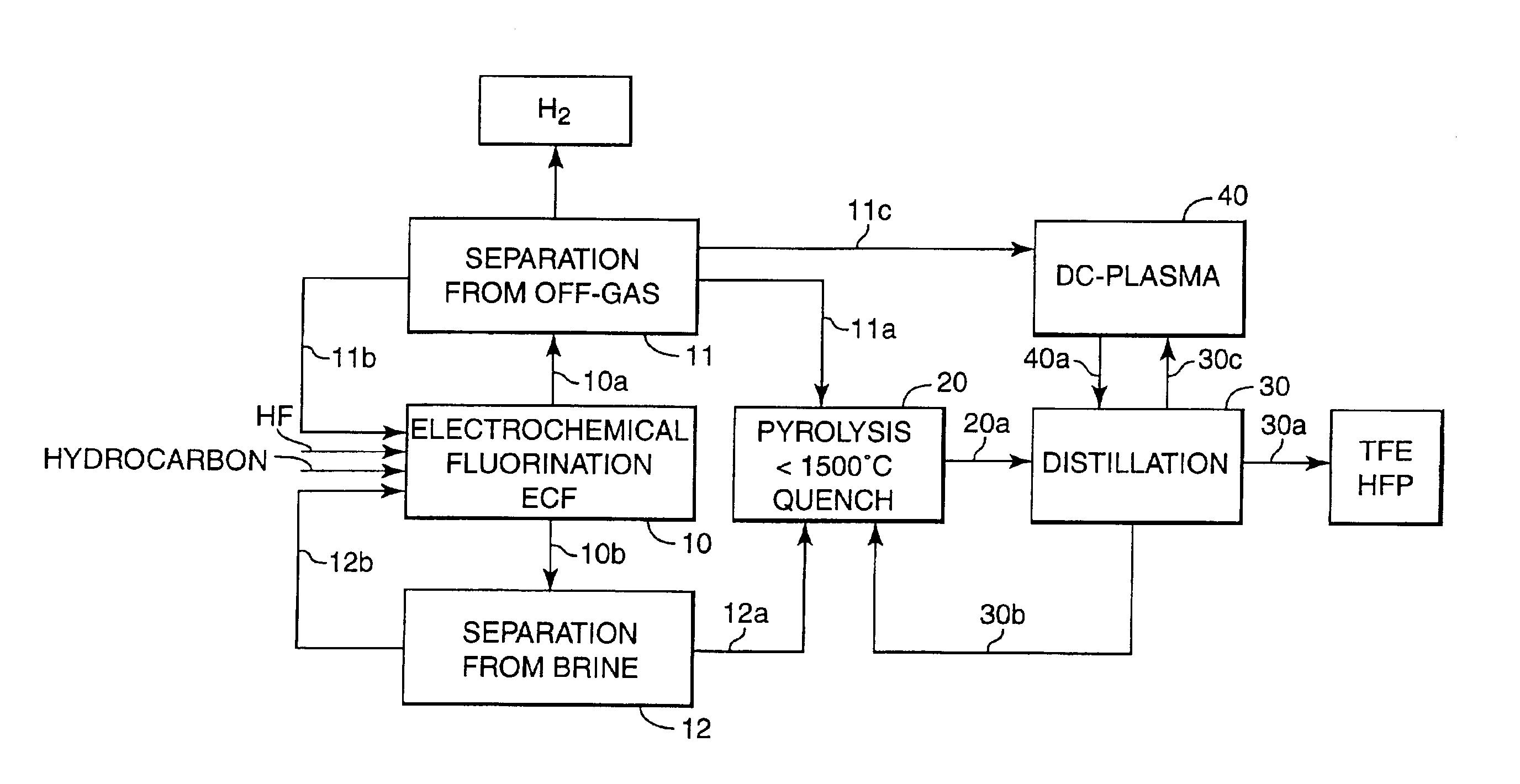

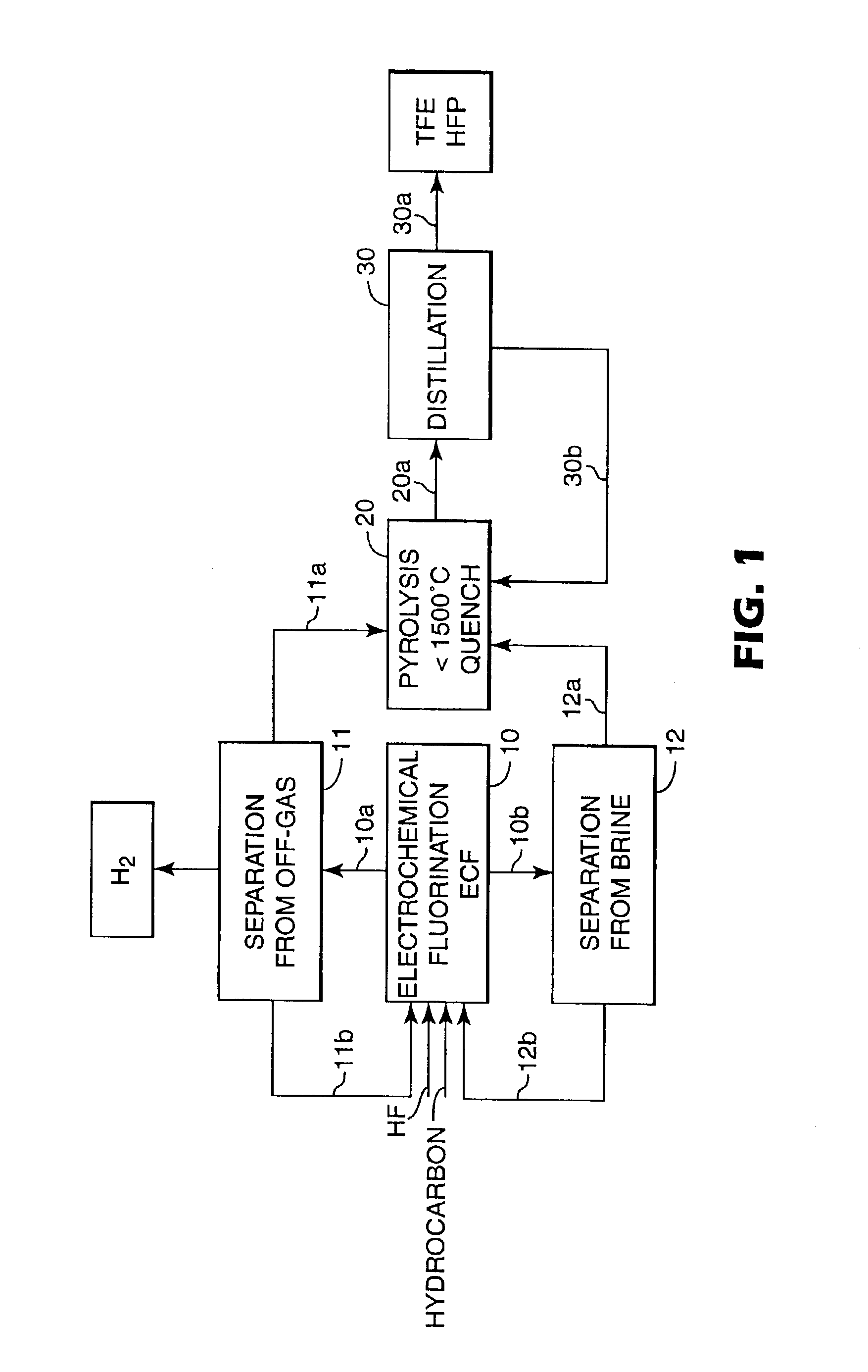

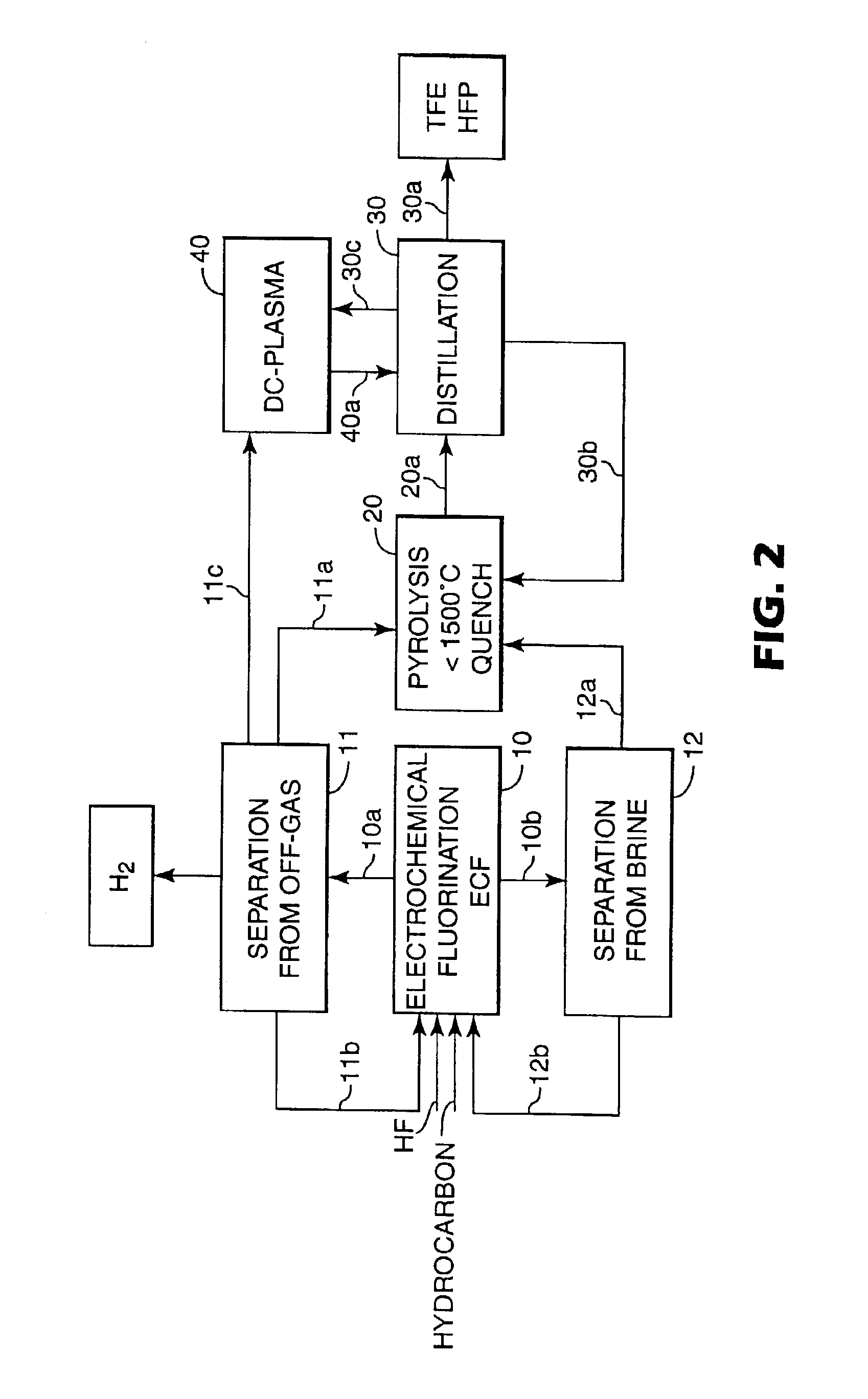

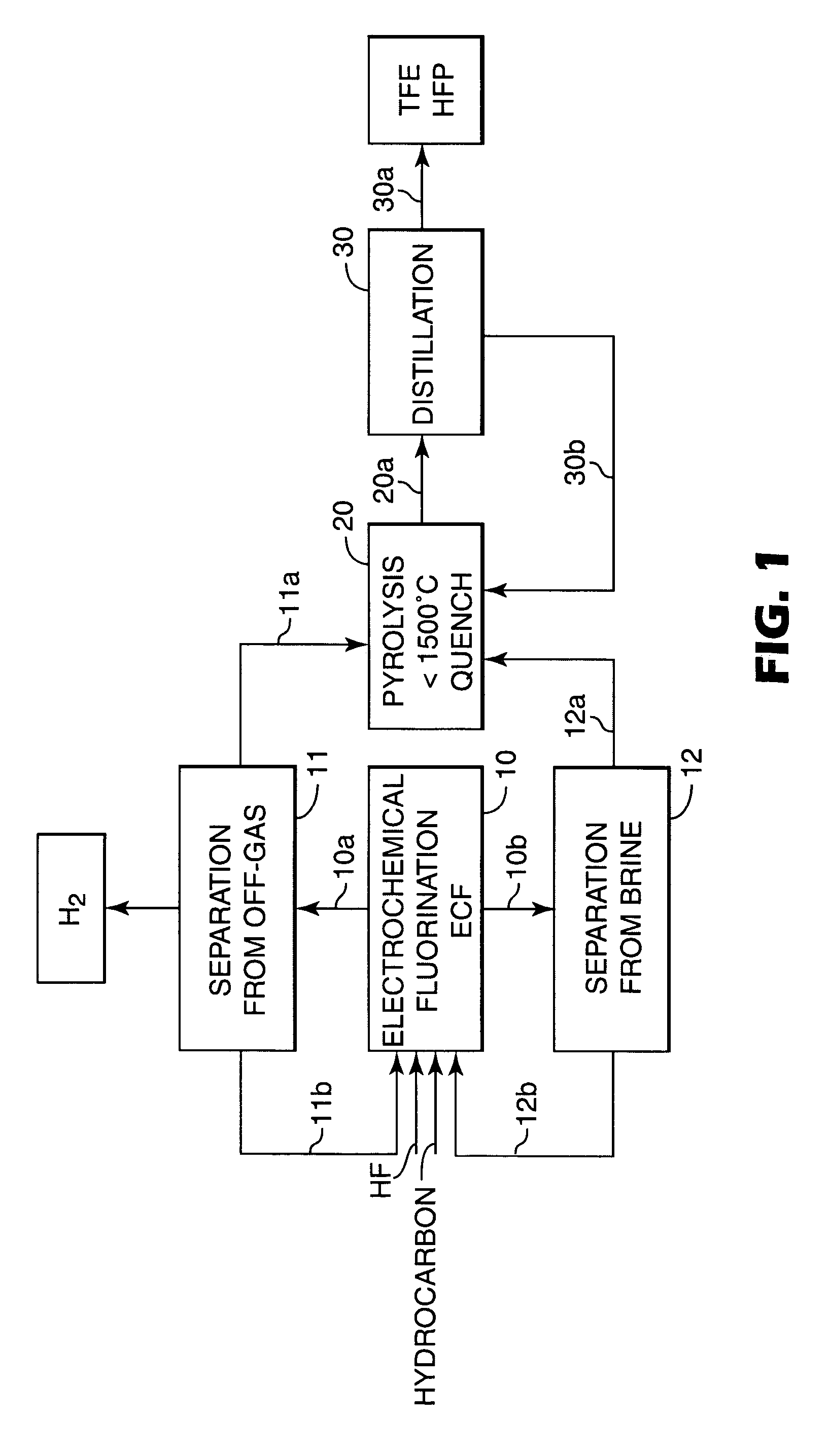

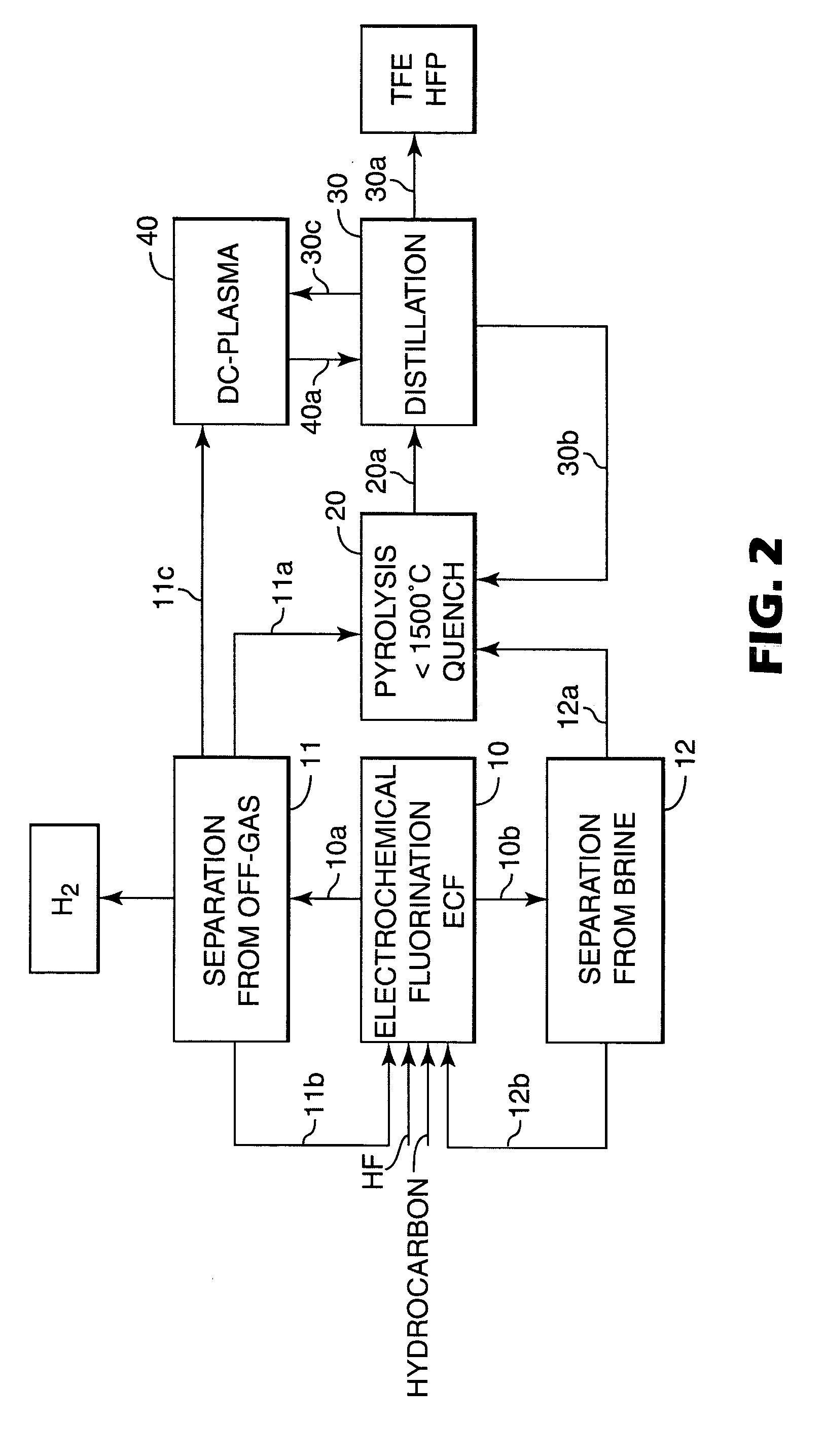

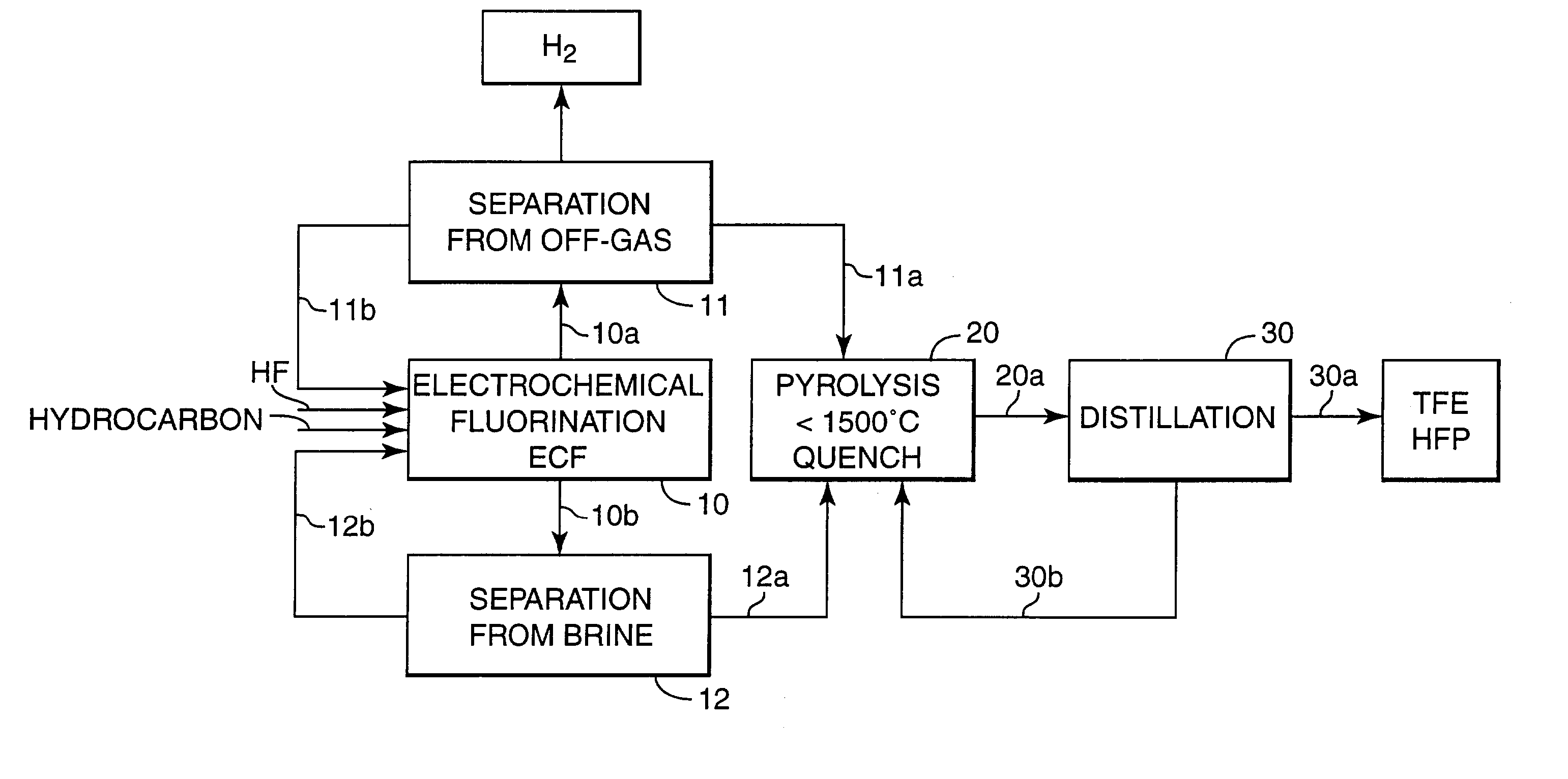

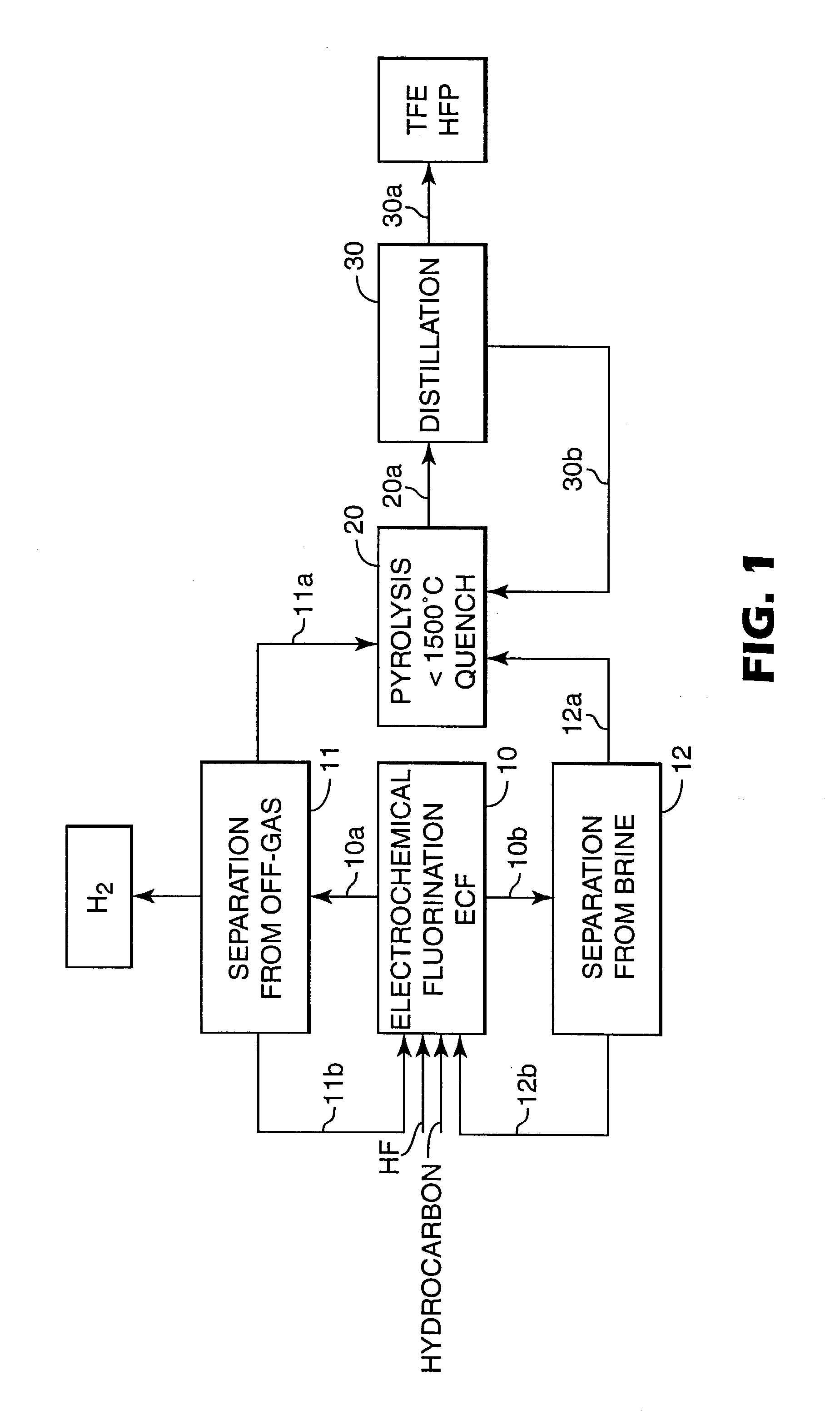

Process for manufacturing fluoroolefins

InactiveUS6919015B2Efficient yieldLess separation effortPreparation by dehalogenationElectrolysis componentsHydrogenHexafluoropropylene

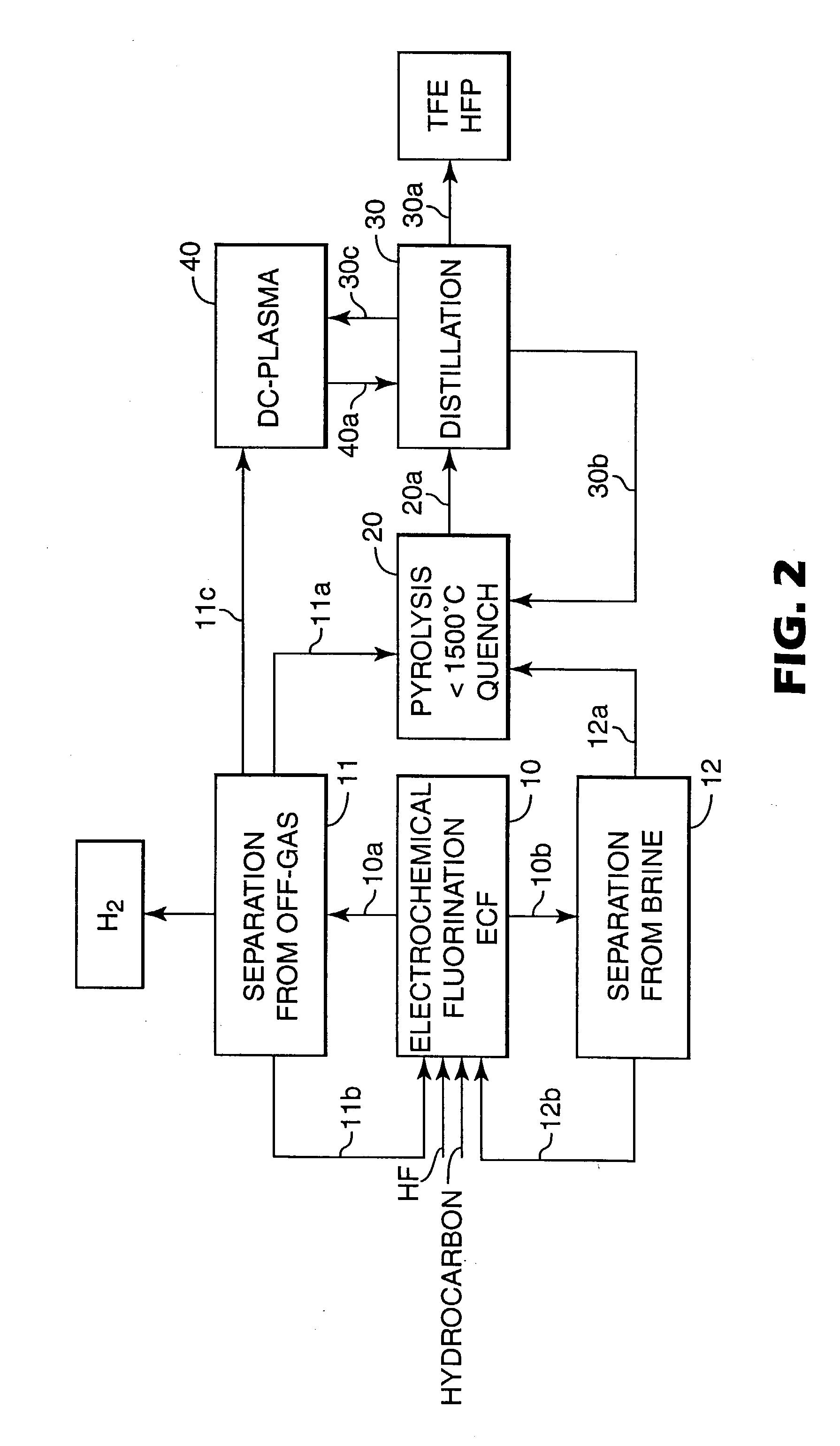

A process for manufacturing fluoroolefins comprising perfluorinating a starting material comprising at least one carbon-bonded hydrogen by electrochemical fluorination, dissociating this separated effluent in a pyrolysis, quenching and separating the effluent to yield tetrafluoroethylene and / or hexafluoropropylene.

Owner:3M INNOVATIVE PROPERTIES CO

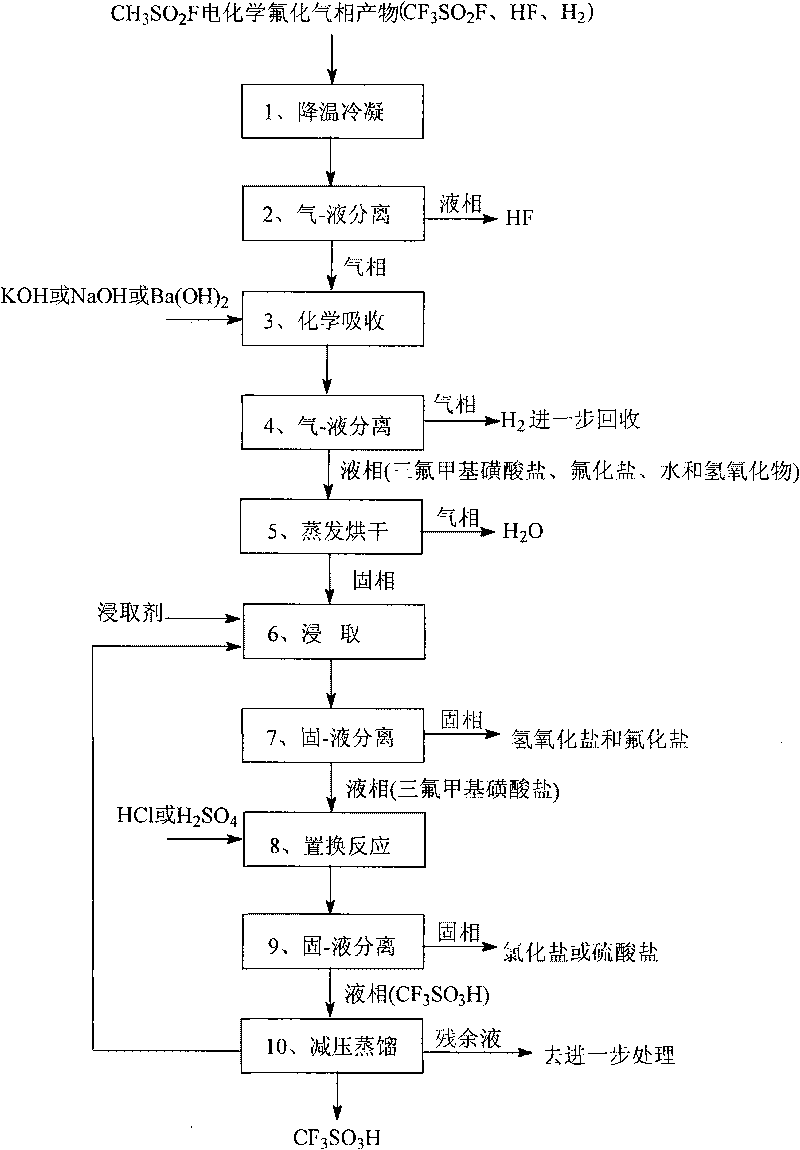

Method for preparing trifluoromethyl sulfonic acid CF3SO3H by electrochemical fluorination gas-phase product of methanesulfonyl fluoride CH3SO2F

InactiveCN101747240ATake advantage of specificityLow costOrganic chemistryOrganic compound preparationGas phaseEvaporation

The invention relates to a method for preparing trifluoromethyl sulfonic acid CF3SO3H by electrochemical fluorination gas-phase product of methanesulfonyl fluoride CH3SO2F, the steps of the method are as follows: (1) the gas-phase product of the CH3SO2F electrochemical fluorination is cooled and condensed; (2) gas-liquid separation; (3) the gas-phase material obtained at the last step is added to water solution of potassium hydroxide KOH or sodium hydroxide NaOH or barium hydroxide Ba (OH) 2, the chemical absorption of the trifluoromethyl sulfuryl fluoride CF3SO2F is conducted; (4) gas-liquid separation: (5) liquid-phase evaporation and drying; (6) the solid-phase material is leached; (7) solid-liquid separation; (8) the liquid-phase is added to hydrochloric acid HCL or sulfuric acid H2SO4 for replacement reaction; (9) solid-liquid separation; (10) liquid-phase fractionating is conducted, and the product trifluoromethyl sulfonic acid CF3SO3H is obtained. The advantages of the invention are as follows: the cost is low, the process is simple, the energy consumption is small, the invention is clean and environmental-friendly, and the quality of the product is good.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD +1

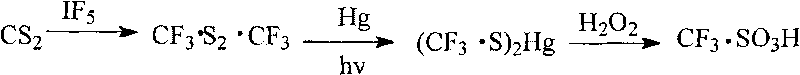

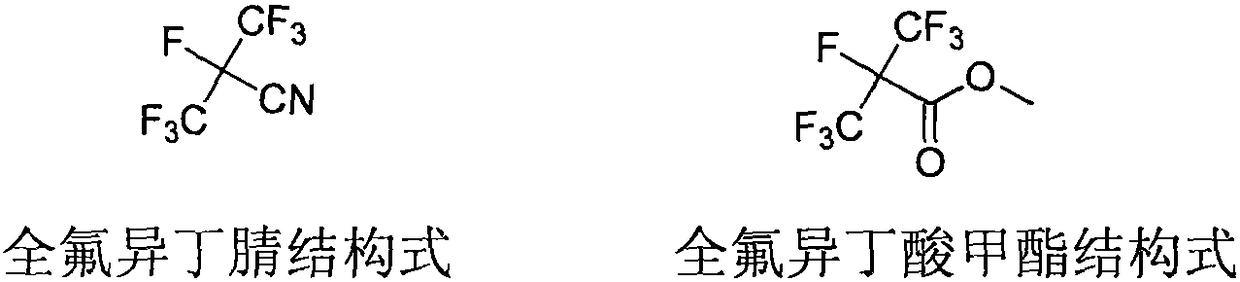

Method for preparing perfluoromethyl isobutyrate by electrochemical fluorination

ActiveCN108441883ASolve the problem of isomerizationGood reaction selectivityElectrolysis componentsElectrolytic organic productionHydrogen fluorideElectrochemical response

The invention discloses a method for preparing perfluoromethyl isobutyrate by electrochemical fluorination. The method comprises the following steps: taking methylacrylic acid and a derivative thereofas a starting material; carrying out electrochemical fluoridation on the starting material and hydrogen fluoride in an electrochemical reactor to obtain a gaseous product; feeding the obtained gaseous product in a methanol solution and fully reacting and esterifying; and distilling reaction liquid to collect the product. Methacrylic anhydride and the derivative thereof are used as the raw material, and the problem that isobutyric anhydride is isomerized in an electrochemical fluorination process is solved. The method has the characteristics of good reaction selectivity, zero isomer by-productand high yield.

Owner:昊华气体有限公司 +1

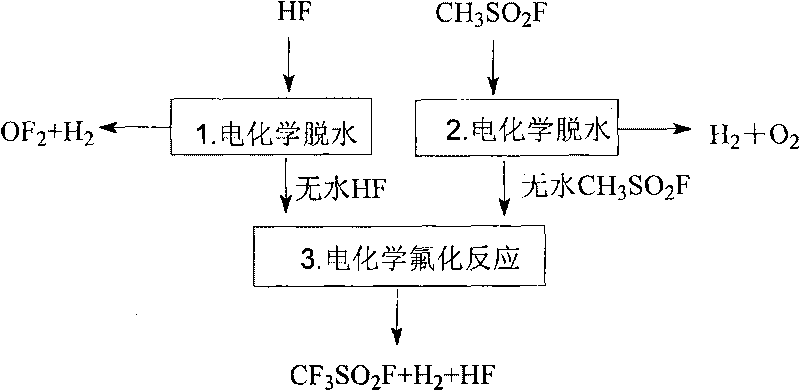

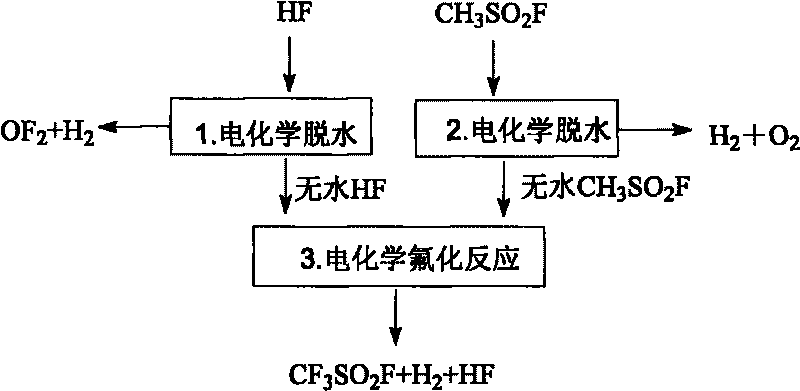

Method for preparing trifluoromethyl sulfuryl fluoride CF3SO2F by electrochemical fluorination of methanesulfonyl fluoride CH3SO2F

ActiveCN101748424AImprove current efficiencyHigh selectivityOrganic chemistryElectrolysis componentsElectrochemical responseHydrogen

The invention relates to a method for preparing trifluoromethyl sulfuryl fluoride CF3SO2F by electrochemical fluorination of methanesulfonyl fluoride CH3SO2F, the steps of the method are as follows: (1) water in HF is dehydrated through electrochemical method, and the anhydrous HF after dehydration is used as the reactant of CH3SO2F fluoridation at the third step and the solvent of the electrolyte; (2) water in the methanesulfonyl fluoride CH3SO2F is dehydrated through electrochemical method, and the anhydrous CH3SO2F after dehydration is used as the reactants of the electrochemical fluorination reaction at the third step; (3) for the anhydrous HF obtained at the first step and the anhydrous methanesulfonyl fluoride CH3SO2F obtained at the second step, the electrochemical fluorination reaction is conducted, gas-phase outlets of an electrochemical reactor 3 are trifluoromethyl sulfuryl fluoride CF3SO2F, hydrogen H2 and mixture formed through HF volatilization. The advantages of the invention are as follows: the preparation method is simple, the current efficiency of the product of electrochemical fluorination and the safety during the fluorination operation procedure are increased.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Method for preparing rare-earth oxide

The invention discloses a method for preparing a rare-earth oxide by using electrochemical fluorination residues generated by electrolyzing rare-earth metals. The method comprises the steps of treating, calcining, crushing, leaching and filtering raw materials, preparing the rare-earth oxide and the like. Compared with an alkaline method, the method has the advantages of simple process, short flow, easily controlled manufacture operation, low cost, small wastewater drainage and over 95 percent of recovery rate; and meanwhile, the method has strong adaptability to raw materials, can treat the electrochemical fluorination residues, rare-earth catalyst waste, waste battery scarp and the like, and can treat phosphor-containing xenotime and monazite.

Owner:益阳桃江金牛稀土厂

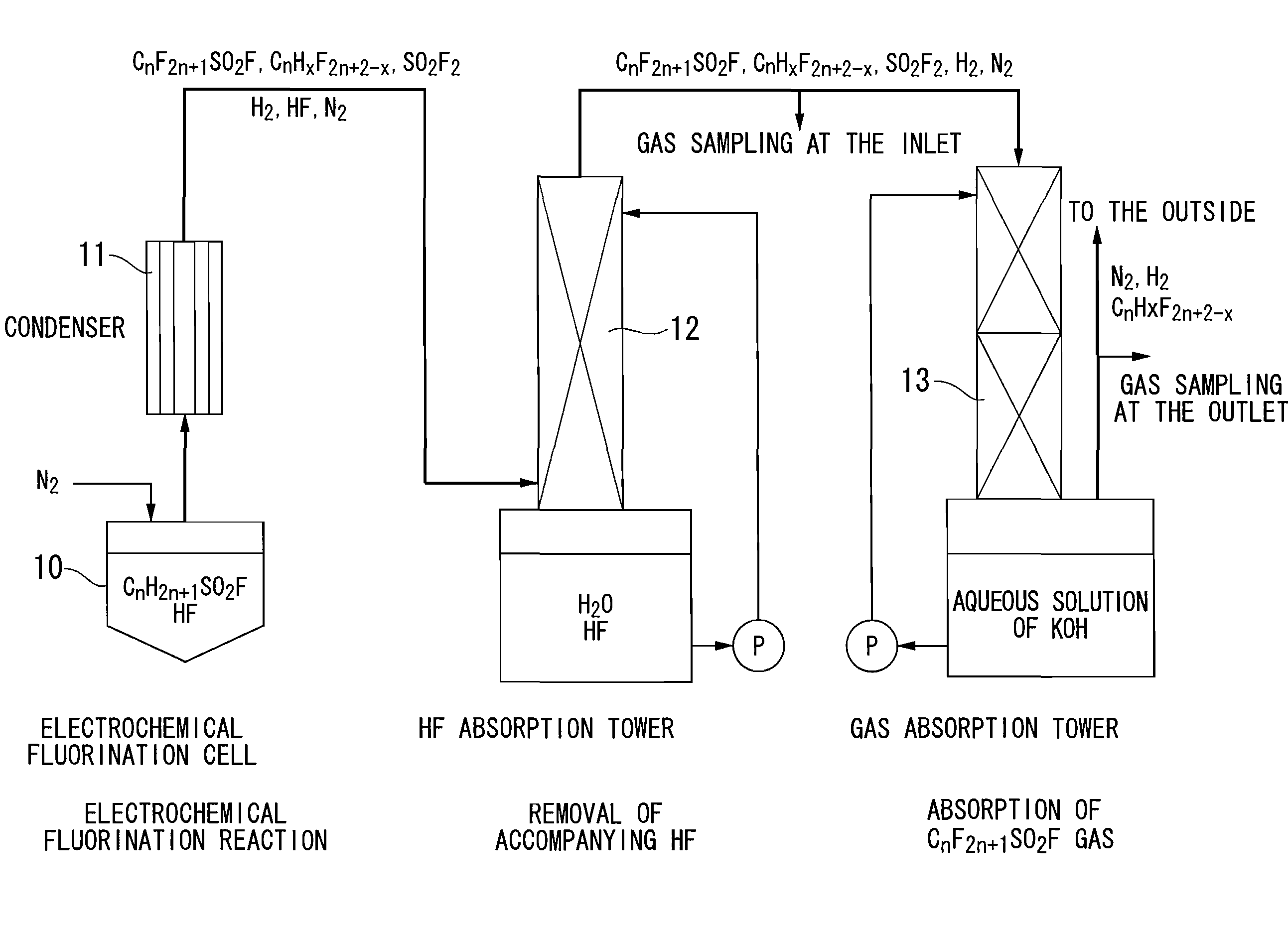

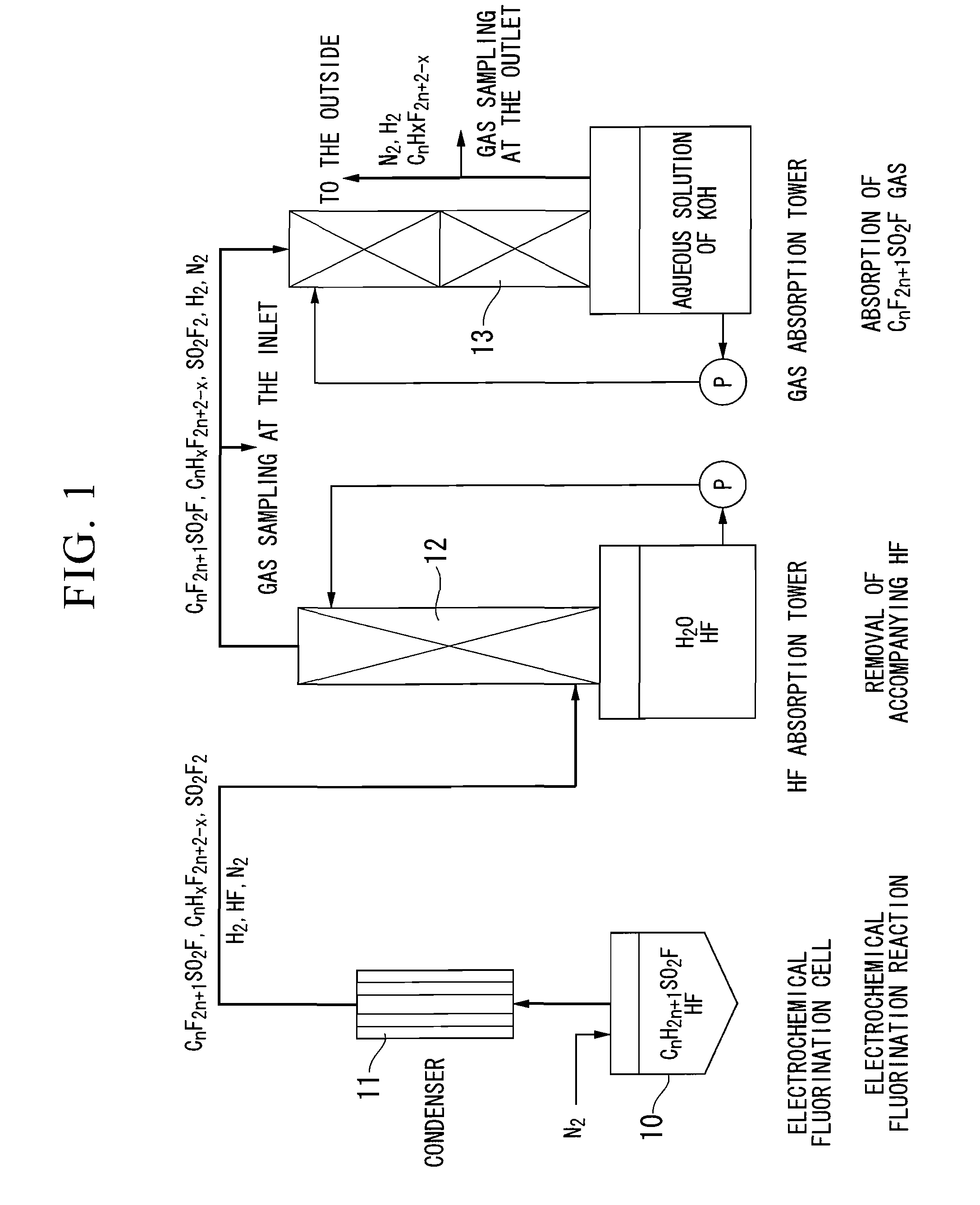

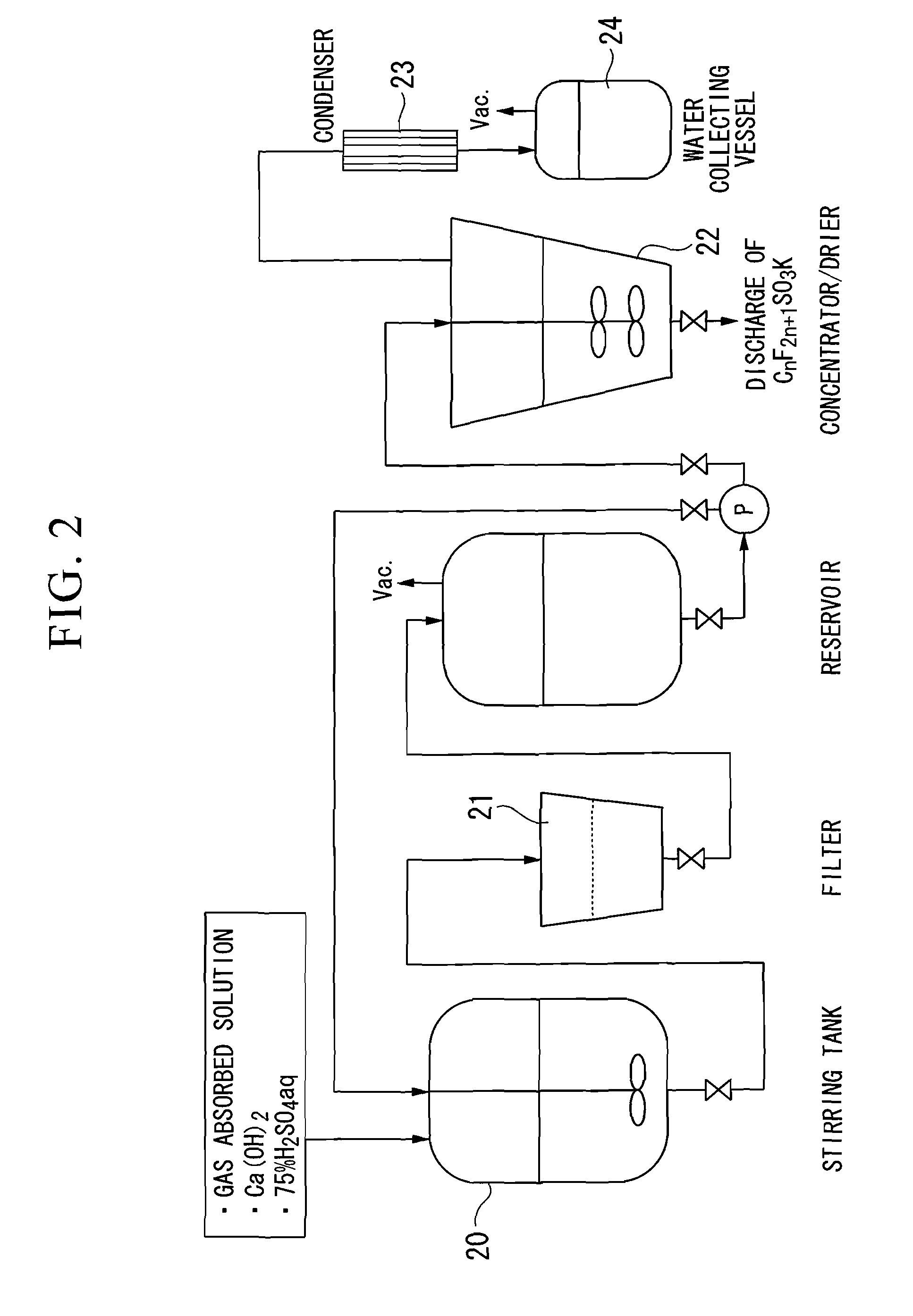

Potassium perfluoroalkanesulfonate and method for producing the same

InactiveUS20090143613A1Alkali concentration is decreasedThe process steps are simpleElectrolysis componentsOrganic compound preparationHydrogen fluoridePotassium fluoride

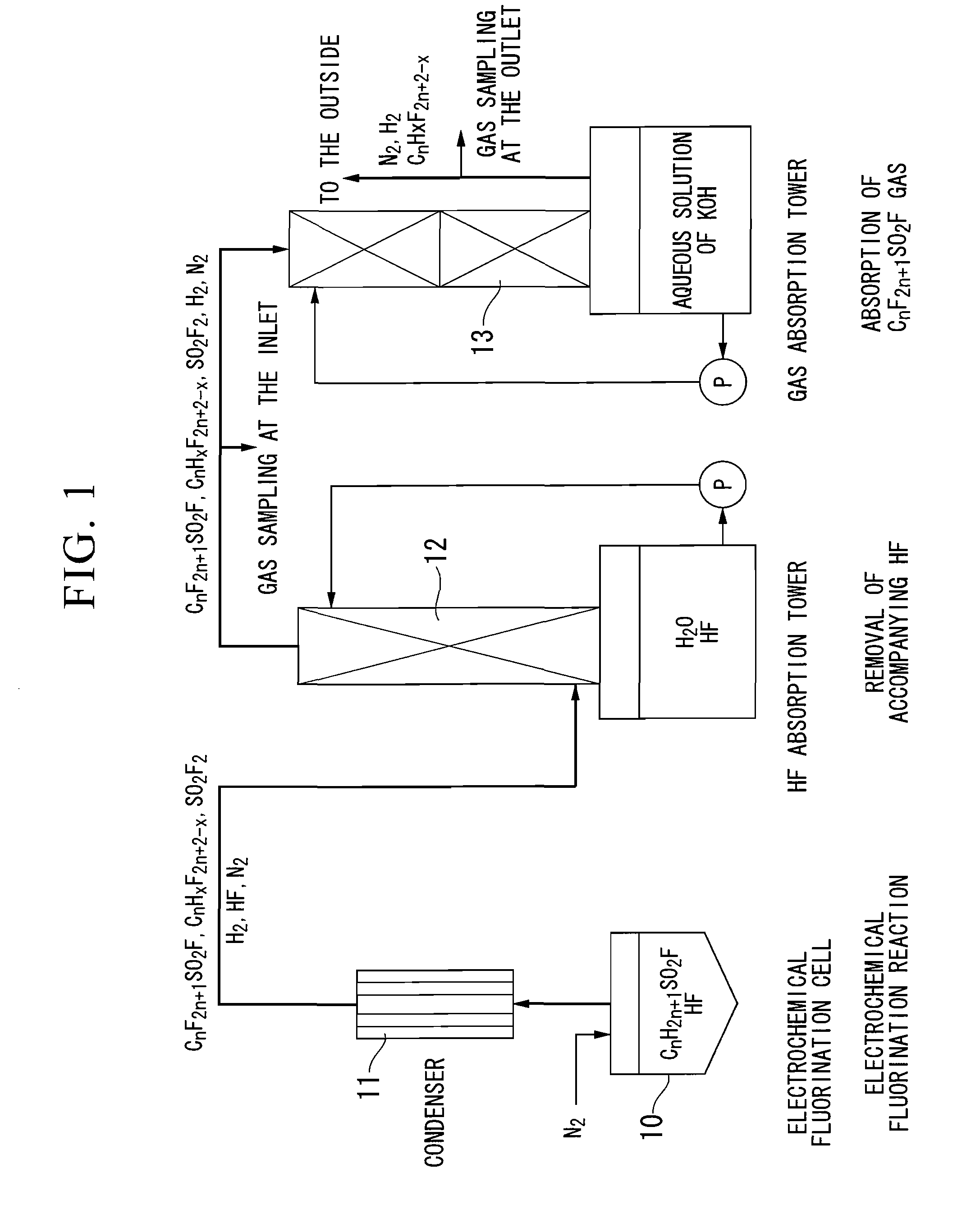

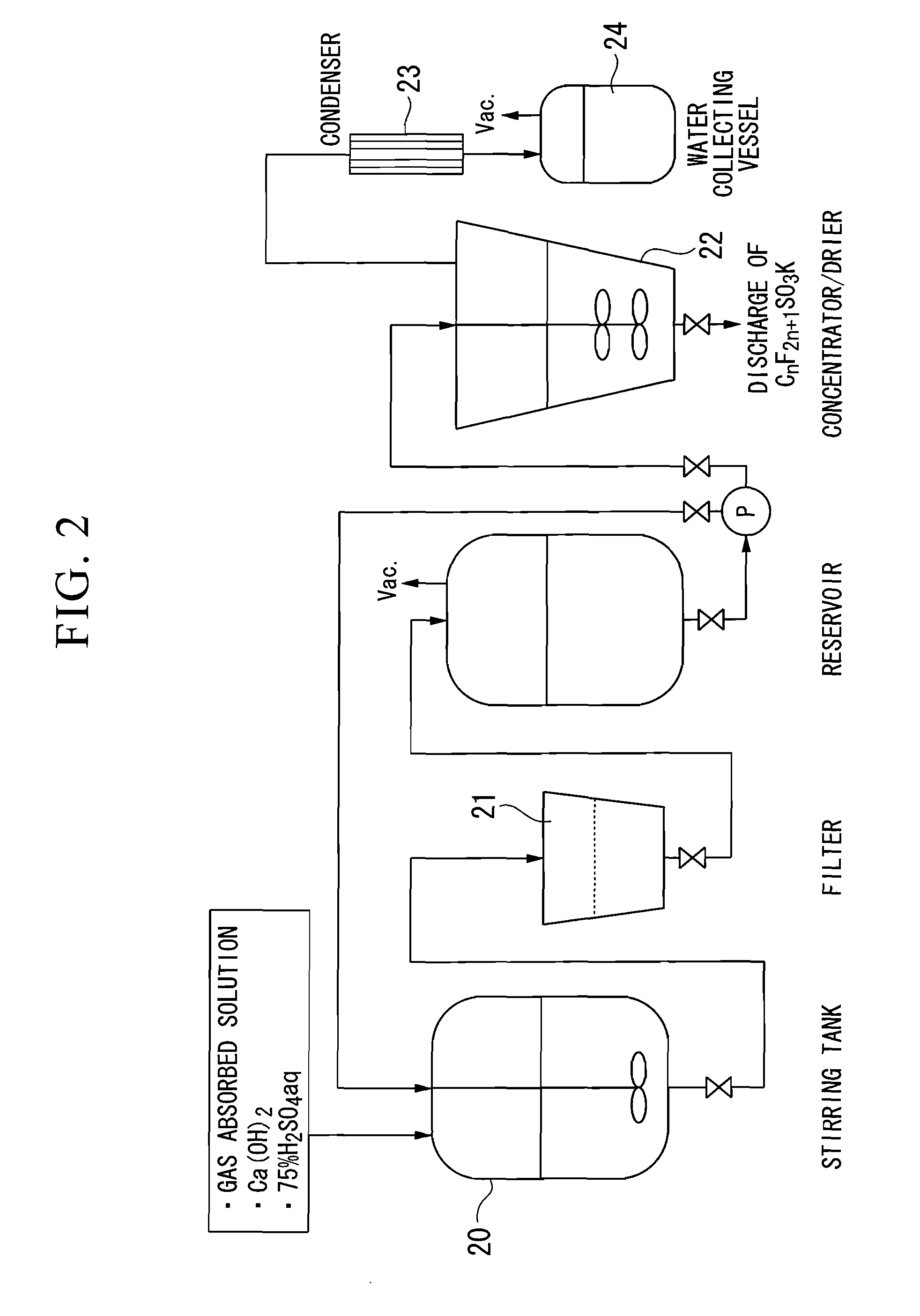

This method for producing a potassium perfluoroalkanesulfonate includes an electrochemical fluorination step in which an alkanesulfonyl halide compound is subjected to electrochemical fluorination in anhydrous hydrogen fluoride, thereby to generate a production gas containing perfluoroalkanesulfonyl fluoride as the main component. In addition, for example, the methods may include a gas absorption step in which the production gas is reacted with an aqueous solution of potassium hydroxide, thereby to generate a gas absorbed solution containing potassium perfluoroalkanesulfonate, a purification step in which impurities such as potassium fluoride, potassium hydroxide, and potassium sulfate, are removed, and a concentration and collection step in which the aqueous solution from which the impurities are removed is concentrated and dried. In the electrochemical fluorination, for example, it is possible that the proton concentration in the reaction solution is maintained in the range of 150 to 1,500 ppm to suppress the formation of byproducts.

Owner:MITSUBISHI MATERIALS CORP +1

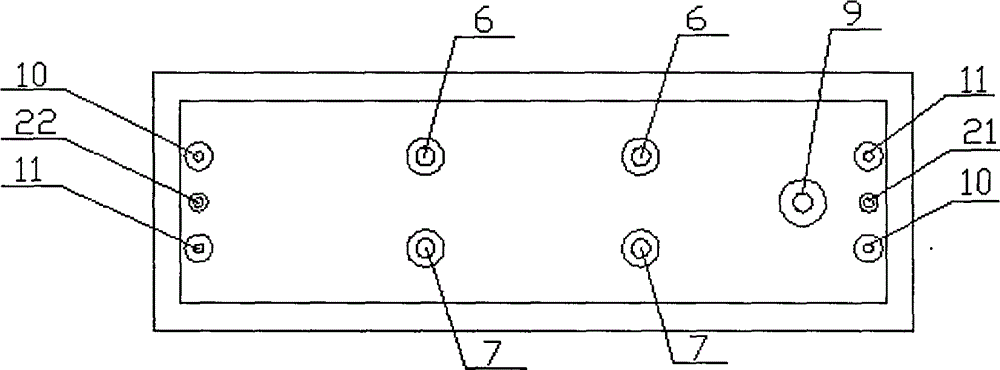

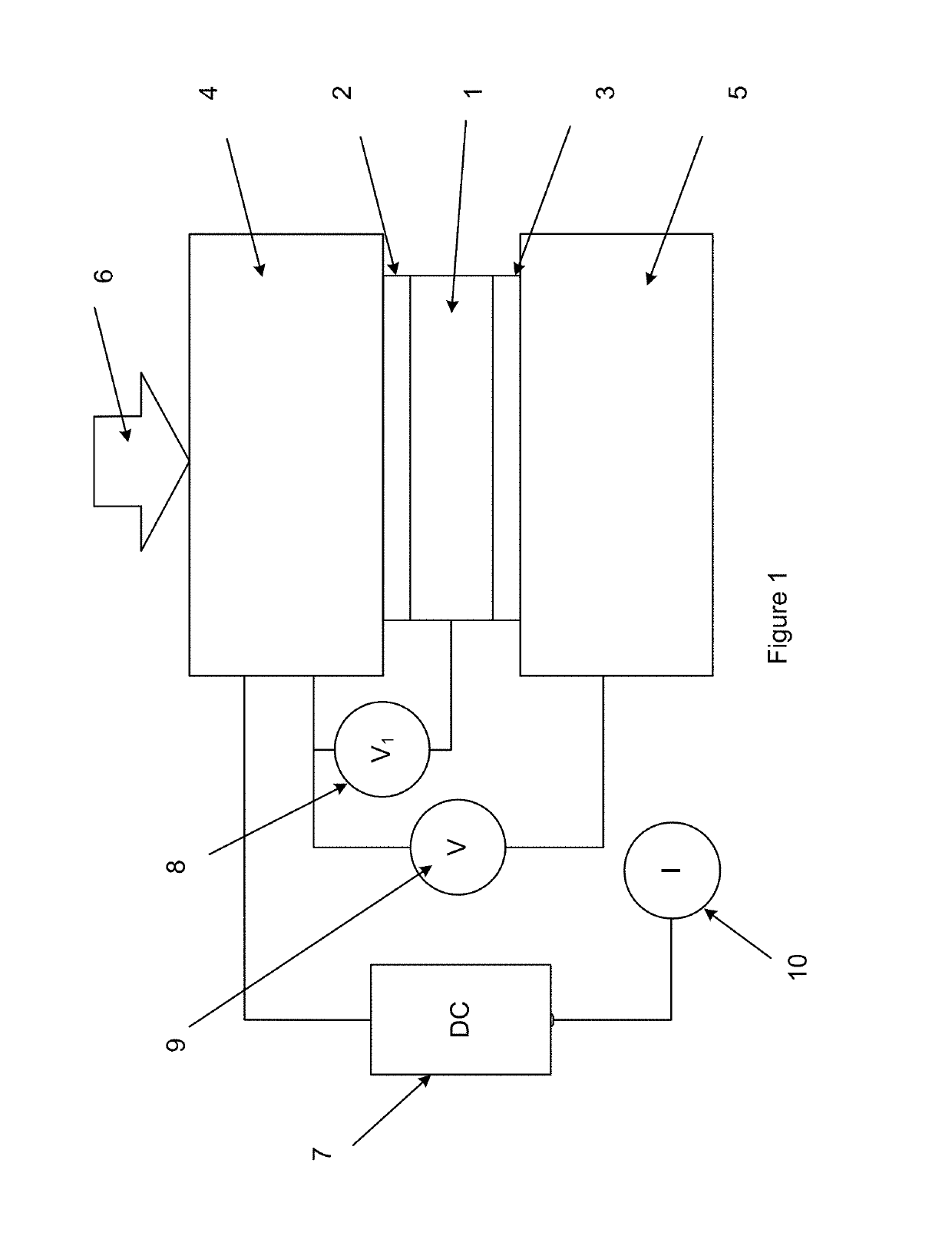

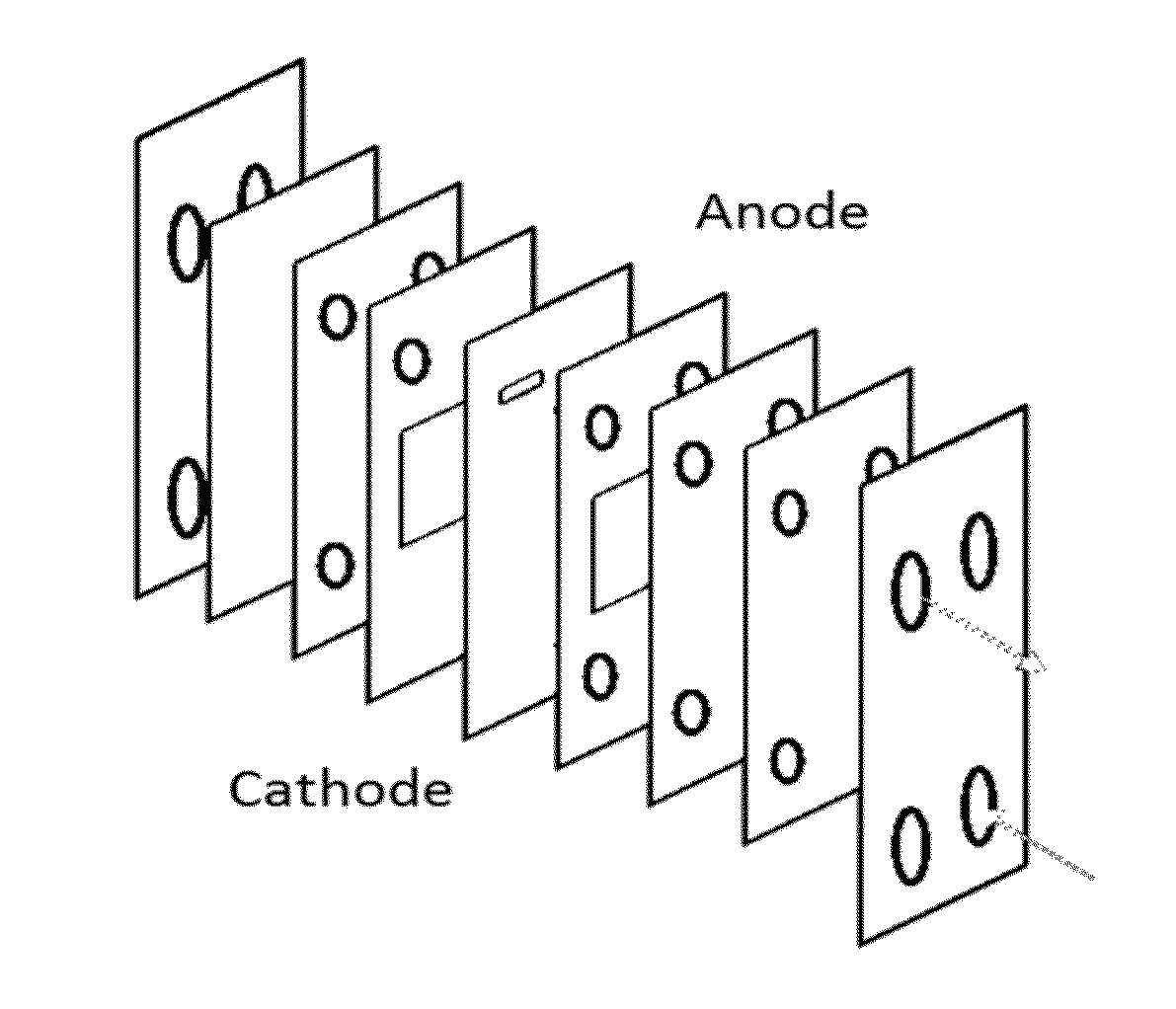

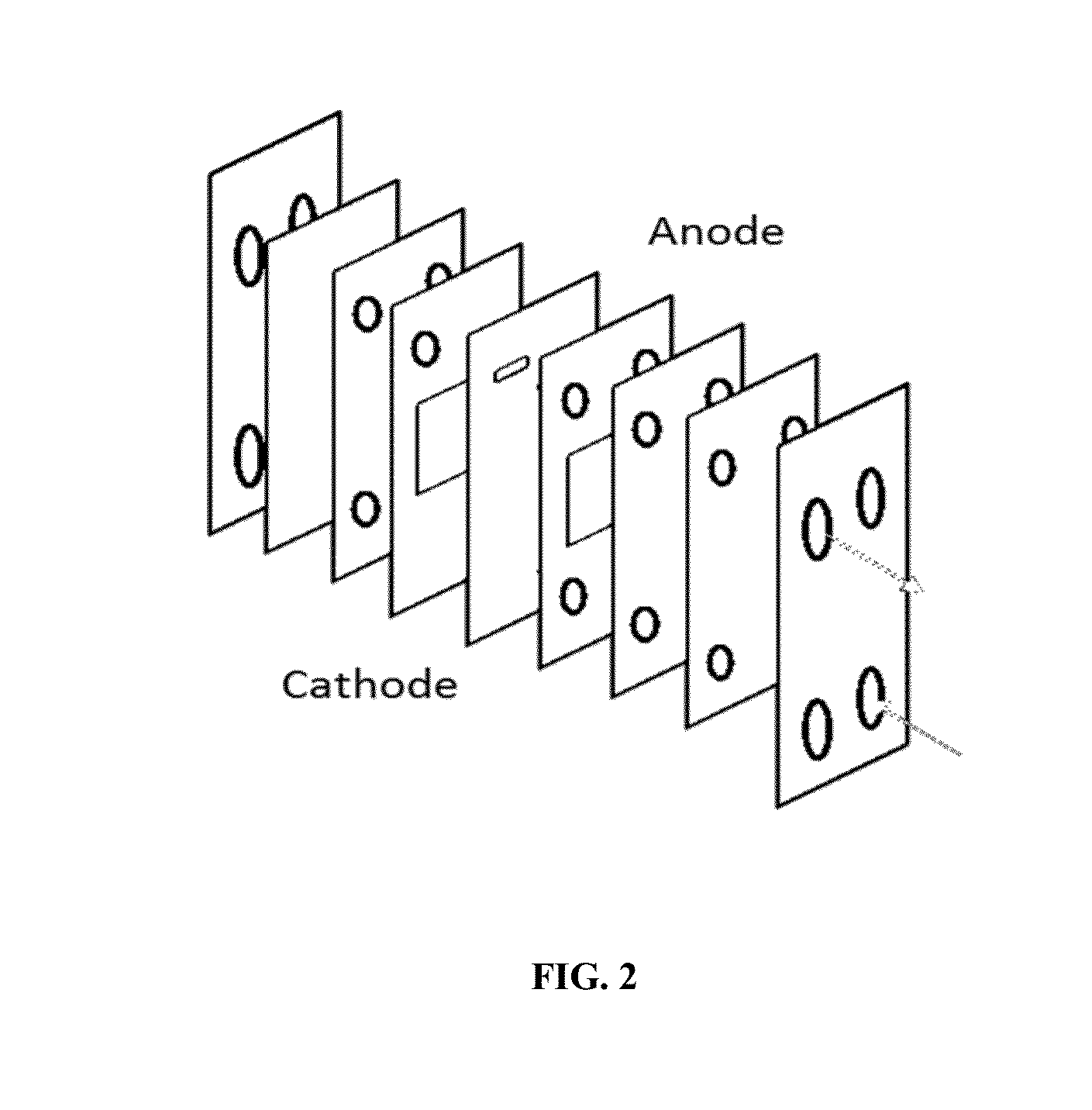

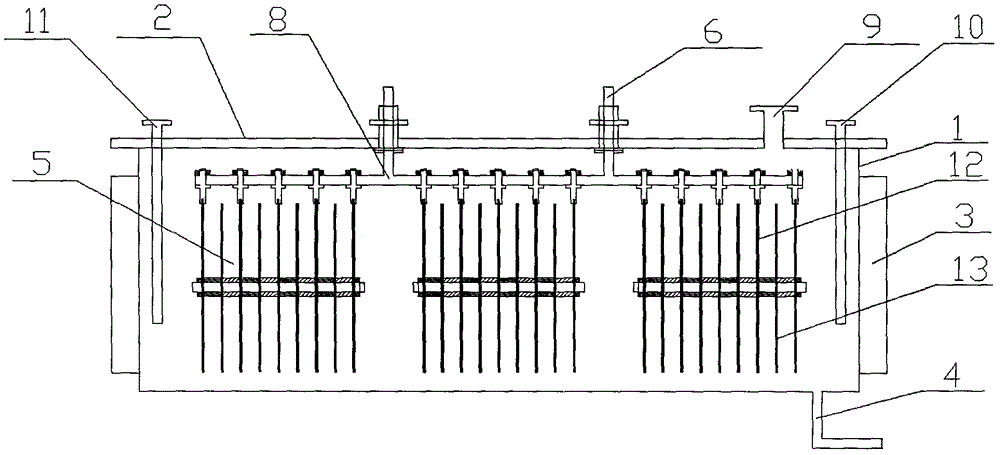

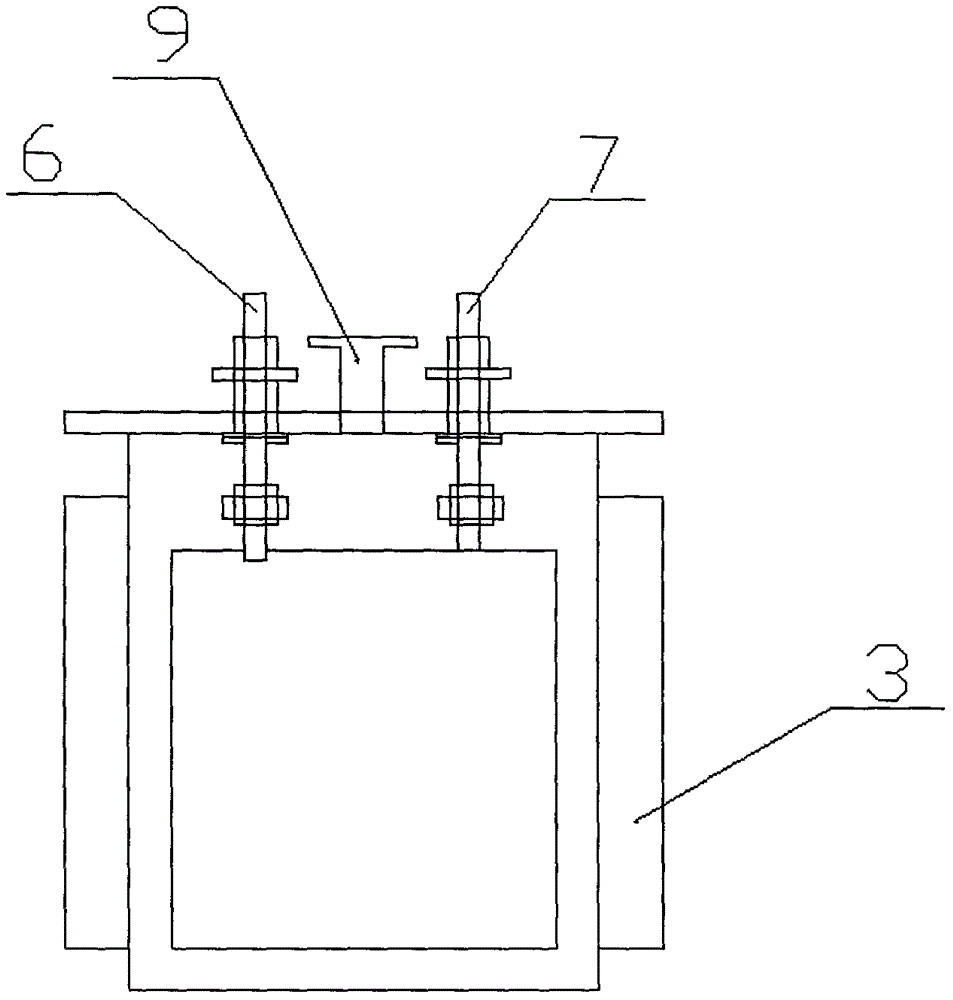

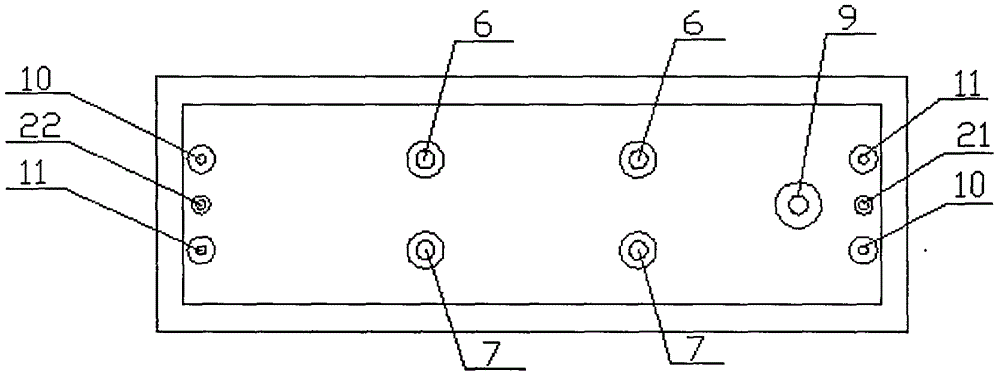

Electrochemistry fluorination electrolytic bath

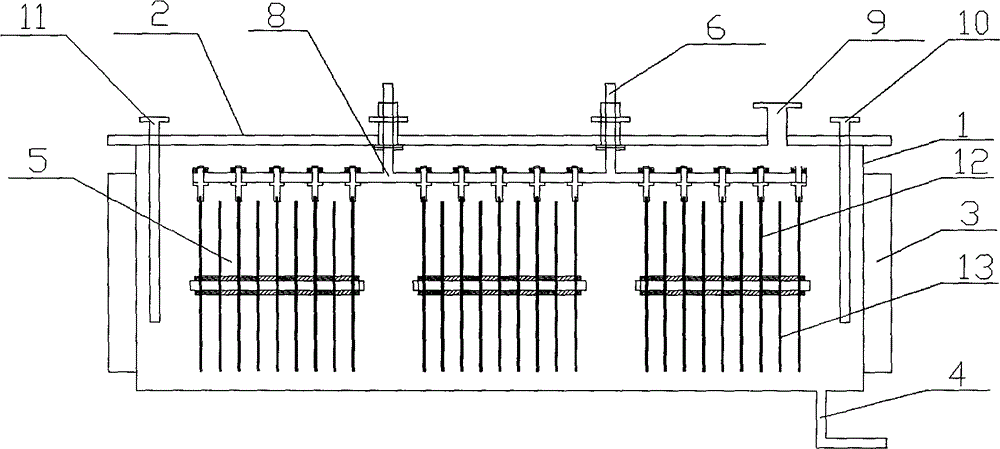

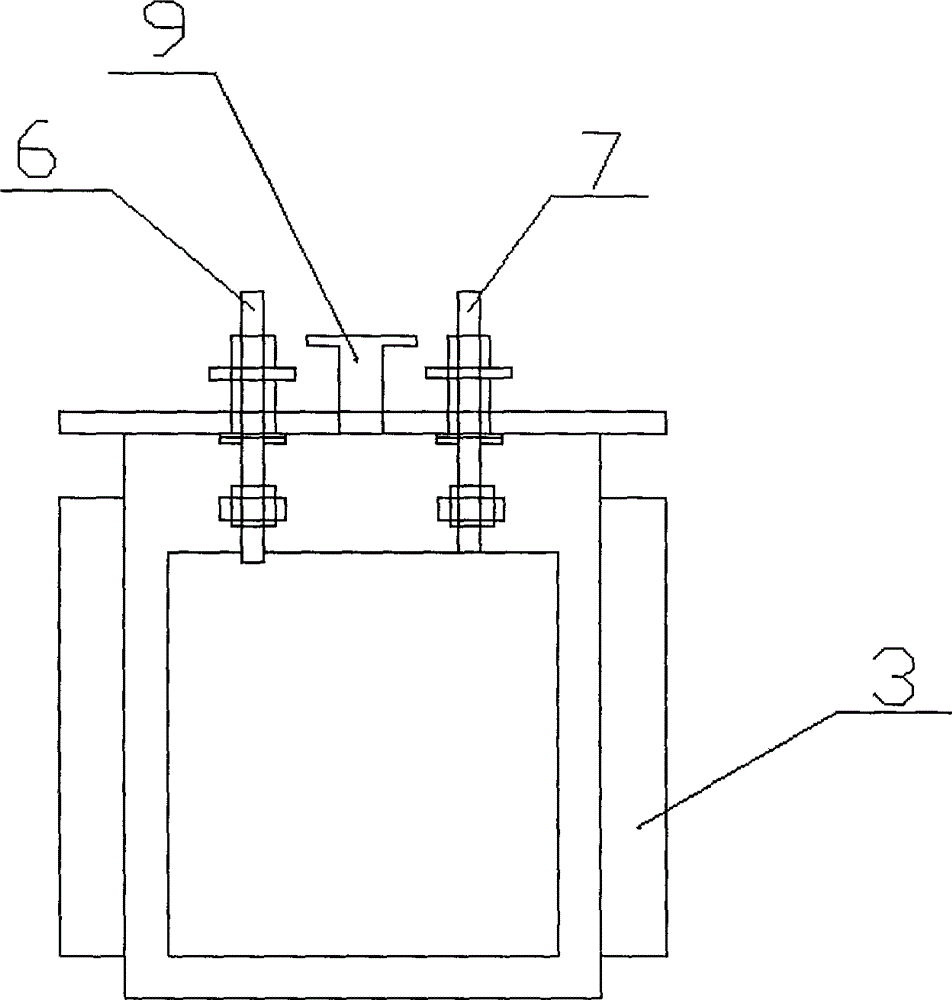

ActiveCN104532287AIncrease the effective electrolysis areaQuick disassemblyCellsElectrolytic organic productionTemperature controlElectrochemical fluorination

The invention discloses an electrochemistry fluorination electrolytic bath. The electrochemistry fluorination electrolytic bath comprises a bath body (1), a bath cover (2), a bath body side wall temperature control clamping sleeve (3), a bottom discharge valve (4), electrode sets (5), anode conductive rods (6), cathode conductive rods (7) and a conductive cross beam (8). Each electrode set is structurally characterized in that plate electrodes are fixed with fixing shafts (15) penetrating plate electrode center holes (19), the interval between the plate electrodes is controlled by annular insulation pads (17), and the fixing shafts fix the plate electrodes into one electrode set through insulation nuts (16) at the two ends. The conductive cross beam is of a hollow-out structure, electrode screw rods (20) on the plate electrodes penetrate through the hollow-out structure to be fixed on the conductive cross beam, and the conductive cross beam and the bath cover (2) are assembled together through the anode conductive rods (6) and the cathode conductive rods (7). The electrochemistry fluorination electrolytic bath has the advantages of being large in capacity, high in space utilization rate, large in effective electrolytic area and the like. The plate electrodes are movably connected with the conductive cross beam, dismounting is convenient, and assembly is easy.

Owner:昊华气体有限公司

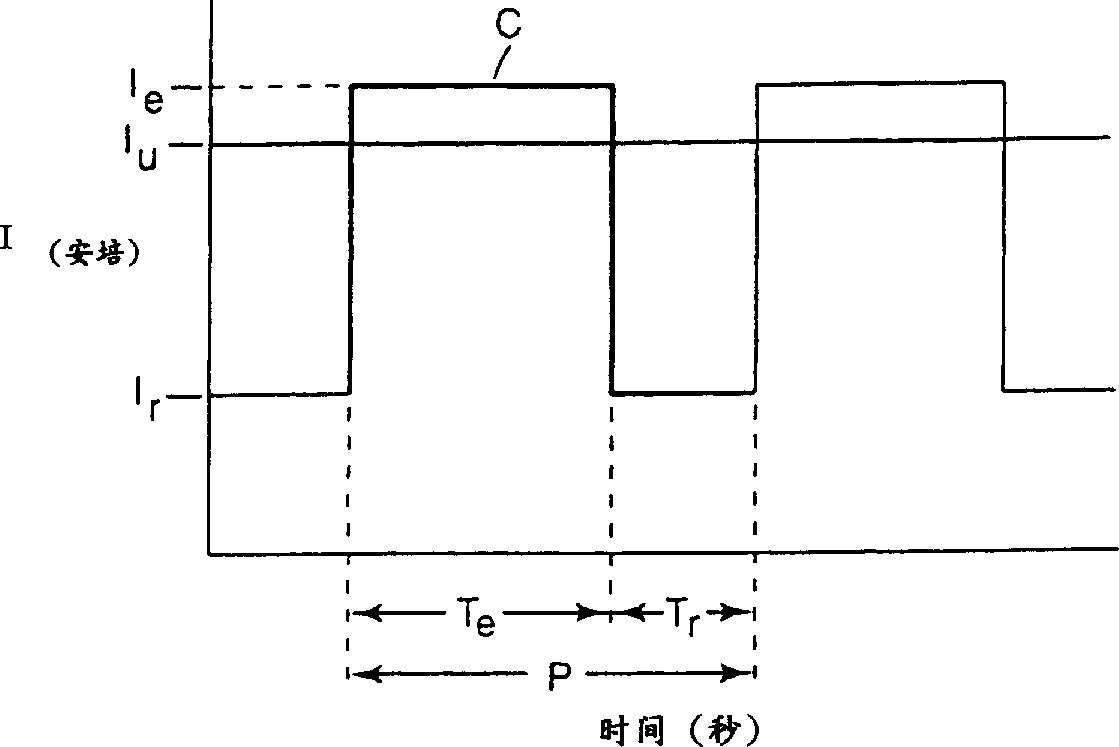

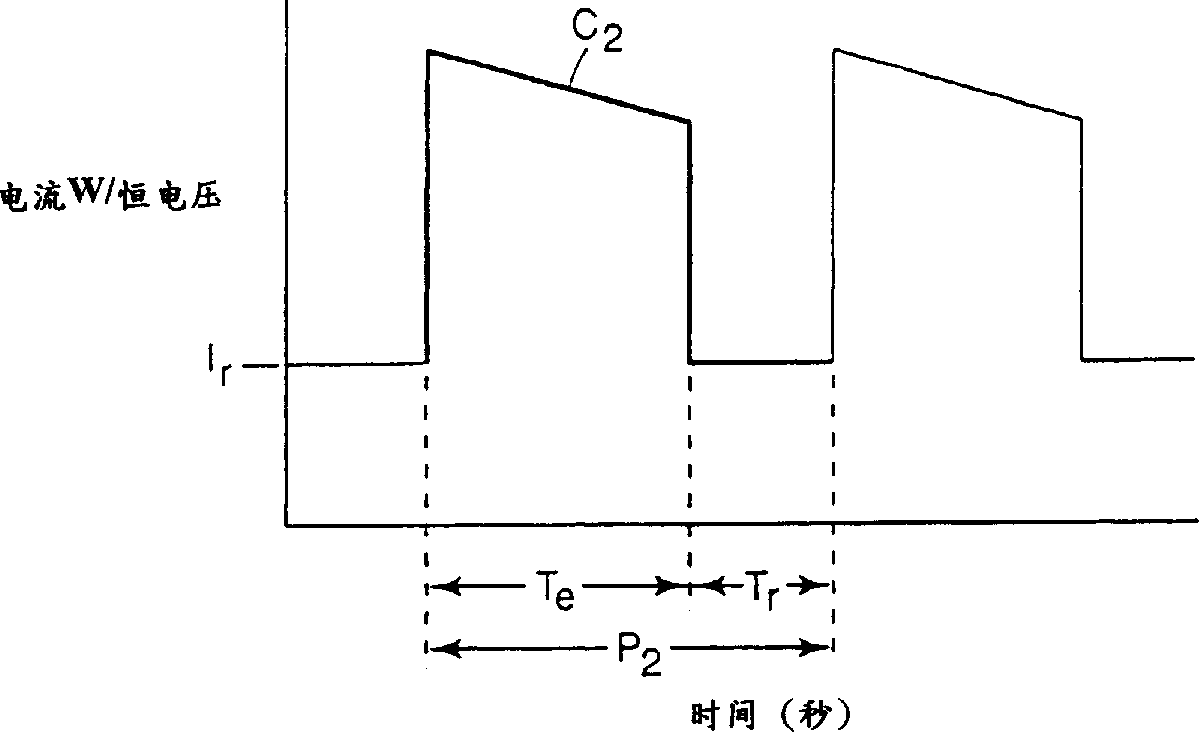

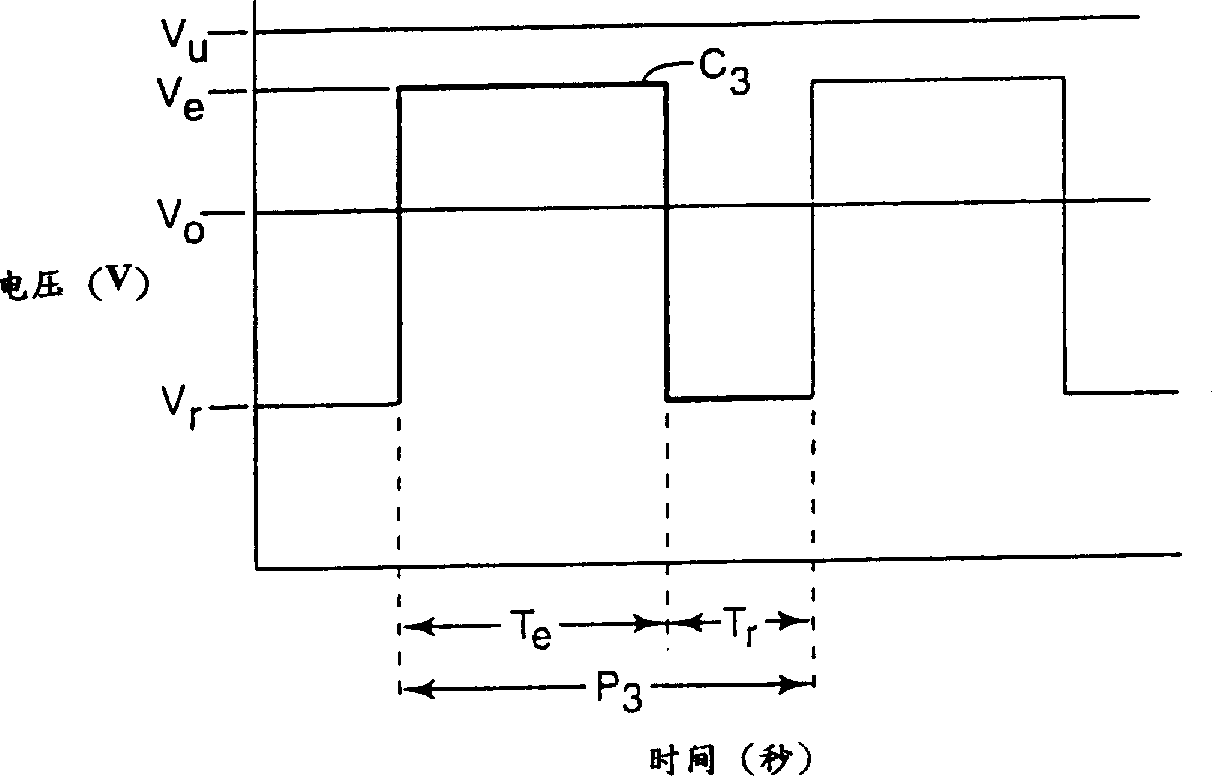

Electrochemical fluorination using interrupted current

InactiveCN1254386ALower resistanceElectrolysis componentsEnergy inputHydrogen fluorideElectrical resistance and conductance

A method for electrochemical fluorination of a substrate, the fluorination method comprising the steps of: providing a substrate containing at least one hydrogen bonded by a carbon bond; preparing a reaction solution containing the substrate and hydrogen fluoride; making a sufficient amount of electric current Passing through the reaction liquid so that one or more hydrogens on the substrate are replaced by fluorine, the current is interrupted by cycles defined by current levels including high current and low current; wherein, the current Intermittent in such a way that the resistance of the electrolyzer operated by intermittent current is lower than that of the electrolyzer operated by non-intermittent current.

Owner:3M CO

Process for manufacturing fluoroolefins

InactiveUS20050240067A1Efficient yieldLess separation effortPreparation by dehalogenationElectrolysis componentsHydrogenHexafluoropropylene

A process for manufacturing fluoroolefins comprising perfluorinating a starting material comprising at least one carbon-bonded hydrogen by electrochemical fluorination, dissociating this separated effluent in a pyrolysis, quenching and separating the effluent to yield tetrafluoroethylene and / or hexafluoropropylene.

Owner:3M INNOVATIVE PROPERTIES CO

Process for manufacturing fluoroolefins

InactiveUS20040112758A1Preparation by dehalogenationElectrolysis componentsHydrogenHexafluoropropylene

A process for manufacturing fluoroolefins comprising perfluorinating a starting material comprising at least one carbon-bonded hydrogen by electrochemical fluorination, dissociating this separated effluent in a pyrolysis, quenching and separating the effluent to yield tetrafluoroethylene and / or hexafluoropropylene.

Owner:3M INNOVATIVE PROPERTIES CO

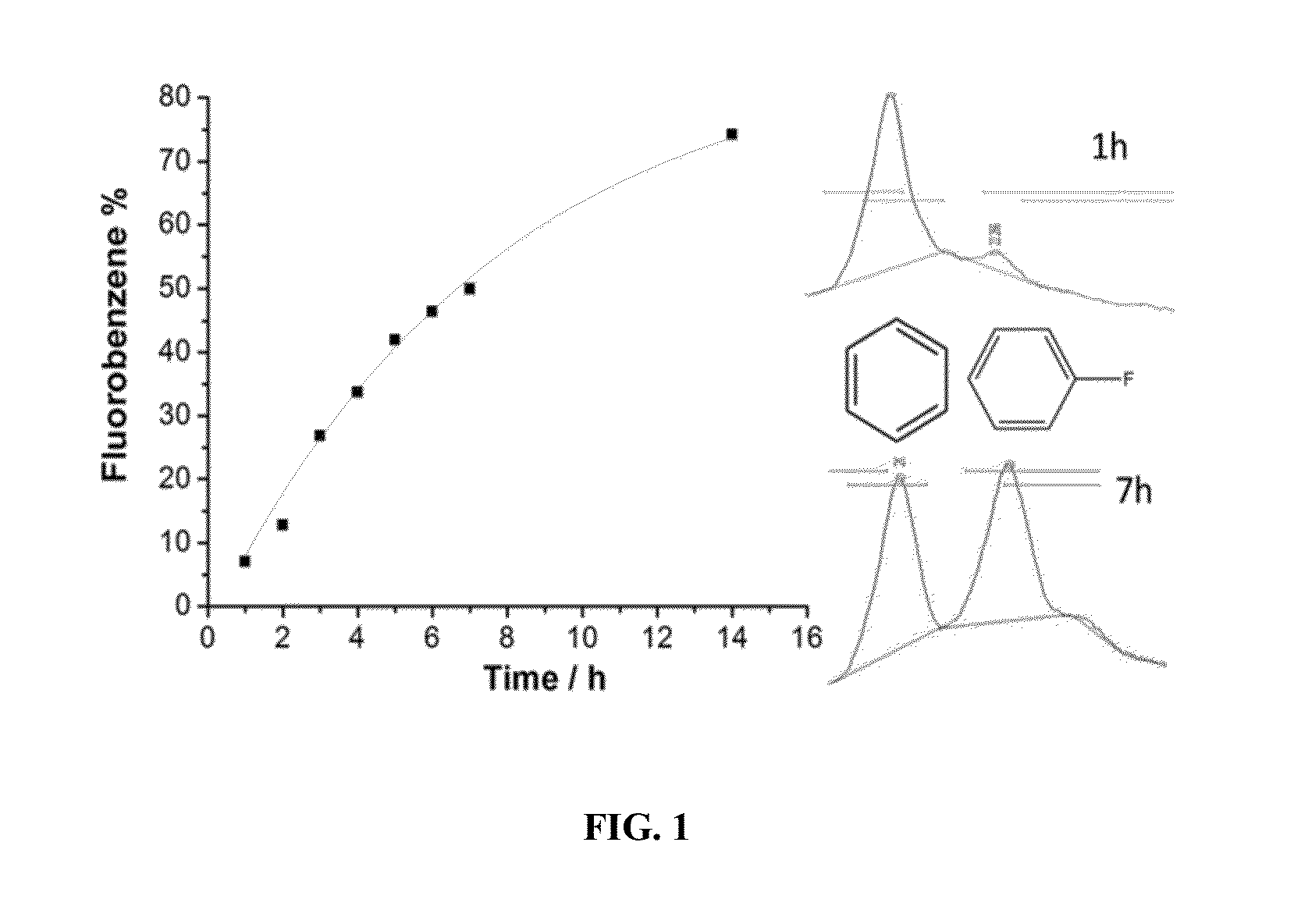

Method of discovering fluoro-containing compounds

InactiveUS20170283960A1Compound screeningApoptosis detectionElectrochemical fluorinationFindings methods

The present teachings relate to a methods for drug discovery. In one particular example, the method includes providing a substrate, modifying the substrate by using an electrochemical fluorination, screening a reaction mixture of the electrochemical fluorination, and identifying a fluorinated compound in the reaction mixture.

Owner:SHANXI CHEM RES INST

Method for electrochemically preparing trifluoromethylsulfonyl fluoride from methylsulfonyl chloride

ActiveCN112760672ARaw materials are easy to getSimple and fast operationElectrolysis componentsElectrolytic organic productionElectrolytic agentSulfonyl chloride

The invention relates to a method for electrochemically preparing trifluoromethylsulfonyl fluoride from methylsulfonyl chloride, and belongs to the field of fine chemical engineering. The method comprises the following steps: adding methylsulfonyl chloride, a conductive agent and anhydrous hydrogen fluoride into an electrolytic bath to form an electrolyte; subjecting the electrolyte to electrolytic dehydration for 2-10 h under the conditions that the temperature ranges from -10 DEG C to 20 DEG C and the voltage ranges from 3 V to 4.5 V; and under the conditions that the temperature ranges from -10 DEG C to 20 DEG C and the voltage ranges from 5 V to 7.5 V, conducting eletrolysis to obtain electrolysis gas, wherein the electrolysis gas contains trifluoromethylsulfonyl fluoride. According to the method, methylsulfonyl chloride is used as a raw material, a conductive agent and anhydrous hydrogen fluoride are added, an electrochemical fluorination reaction is carried out at a constant voltage, trifluoromethylsulfonyl fluoride can be obtained, wherein the anhydrous hydrogen fluoride is a solvent and a fluorinating agent of the electrolyte. The electrochemical preparation method of trifluoromethylsulfonyl fluoride provided by the invention is simple and convenient to operate, low in cost and suitable for large-scale application.

Owner:PERIC SPECIAL GASES CO LTD

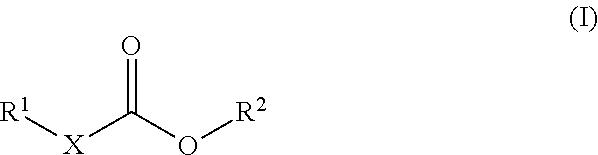

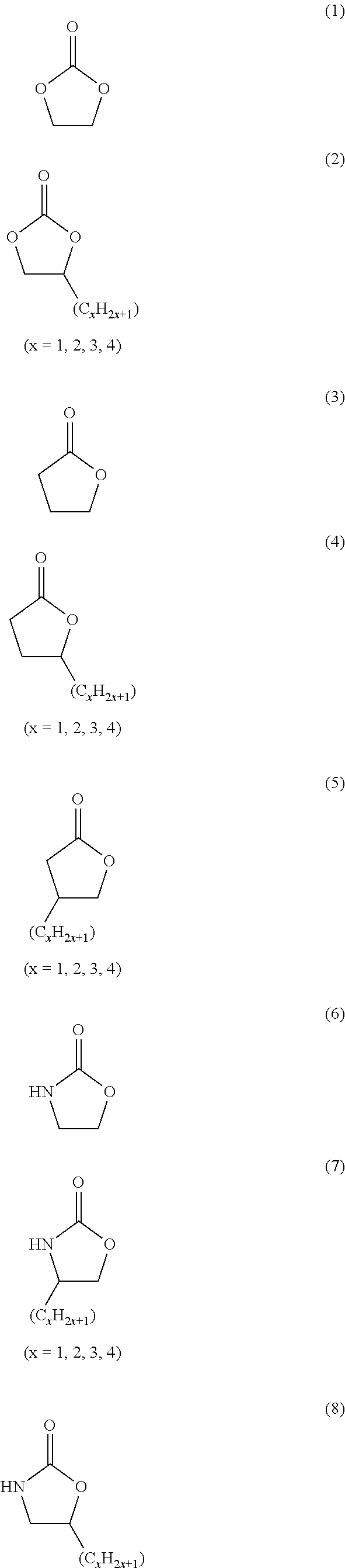

Process for the electrochemical fluorination of organic compounds

InactiveUS20120152757A1Increase conversionsHigh selectivityElectrolysis componentsElectrolytic organic halogenationSimple Organic CompoundsElectrochemical fluorination

The present invention relates to a process for the electrochemical fluorination of an organic compound, wherein a reaction solution comprising the organic compound and a fluorinating agent is subjected to electric current in an electrochemical fluorination cell.

Owner:BASF AG

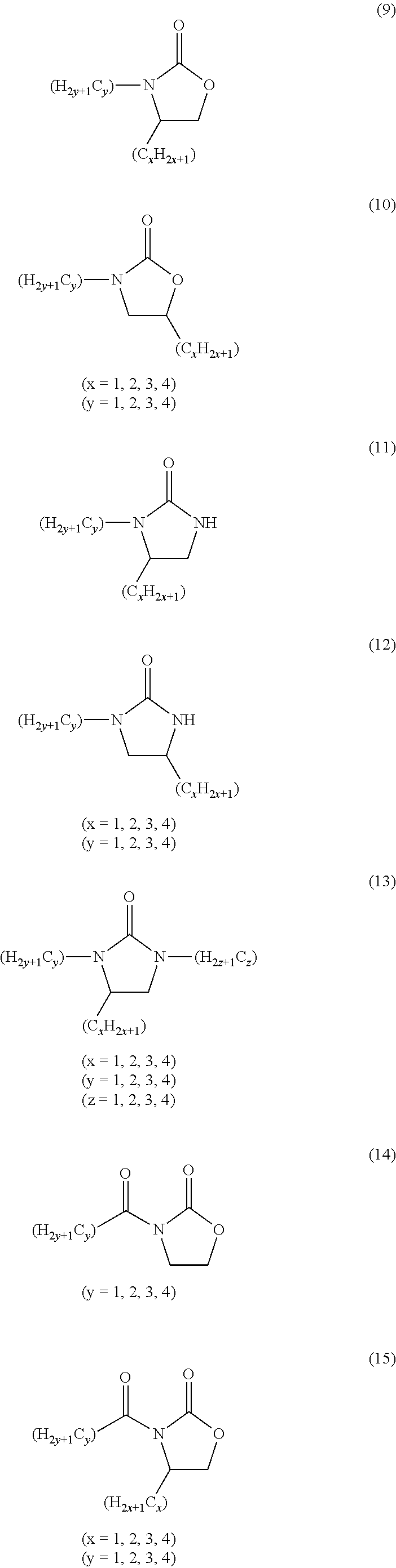

Electrochemical fluorination preparation method of hydrogen fluoride ether

ActiveCN107761130AConductivity effectGood fluorination performanceOrganic chemistryElectrolysis componentsHydrogen fluorideEther

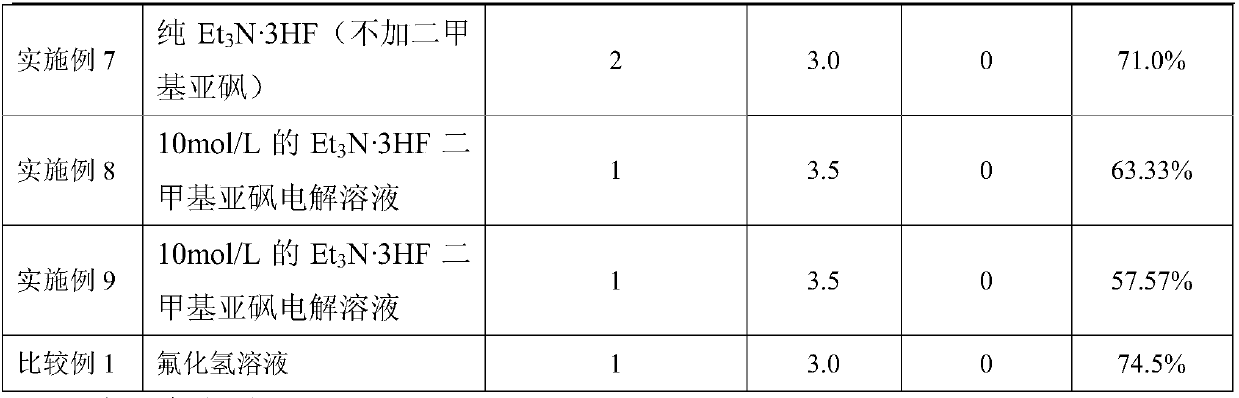

The invention relates to a preparation method of hdrogen fluoride ether, in particular to an electrochemical fluorination preparation method of hydrogen fluoride ether. A chloroether compound, a fluorination reagent and an aprotic solvent are added into a fluorination electrolytic cell for fluorination to generate a chlorine-free hydrogen fluoride ether product, and the fluorination reagent is Et3N-3HF; the aprotic solvent is dimethyl sulfoxide; the concentration of the Et3N-3HF in the dimethyl sulfoxide ranges from 10 to 15 mol / L; the electrode voltage of the fluorination electrolytic cell iscontrolled at 3.5 V. By the use of the Et3N-3HF, the selective fluorination performance is extremely high, and the product contains fewer impurities, is higher in purity, and is higher in yield underhigh selectivity; by the adding of the aprotic solvent, in the initial stage of electrolysis, relatively good influence is generated on the conductivity of the solution. According to the electrochemical fluorination preparation method of the hydrogen fluoride ether, by chloroether compound serving as a main raw material, various hdrogen fluoride ether compounds such as perfluoroethyl methyl ethercan be prepared; furthermore, the reaction replacement selectivity is improved; after post-treatment, the content of target products in the prepared product is 99.9 percent.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

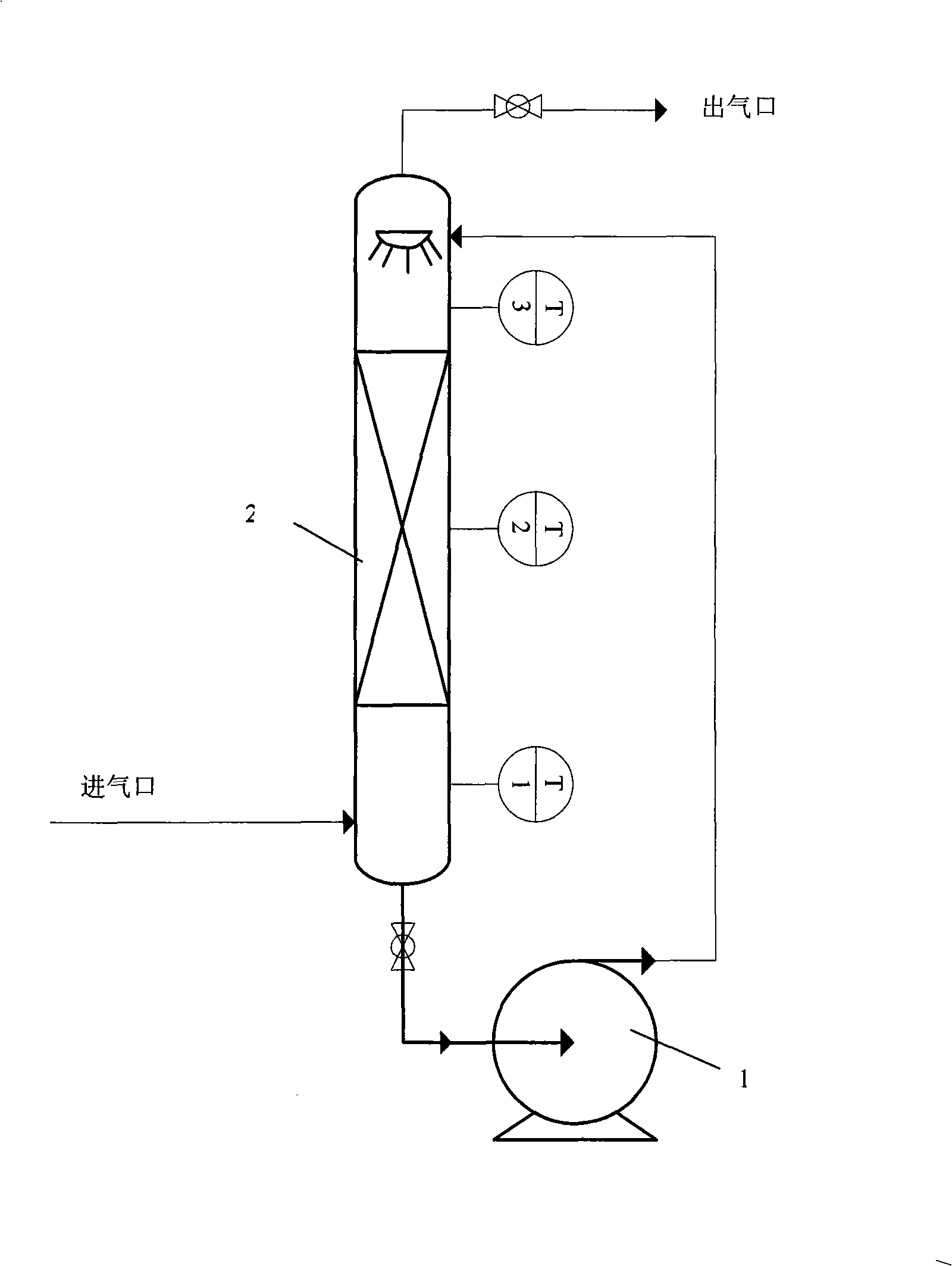

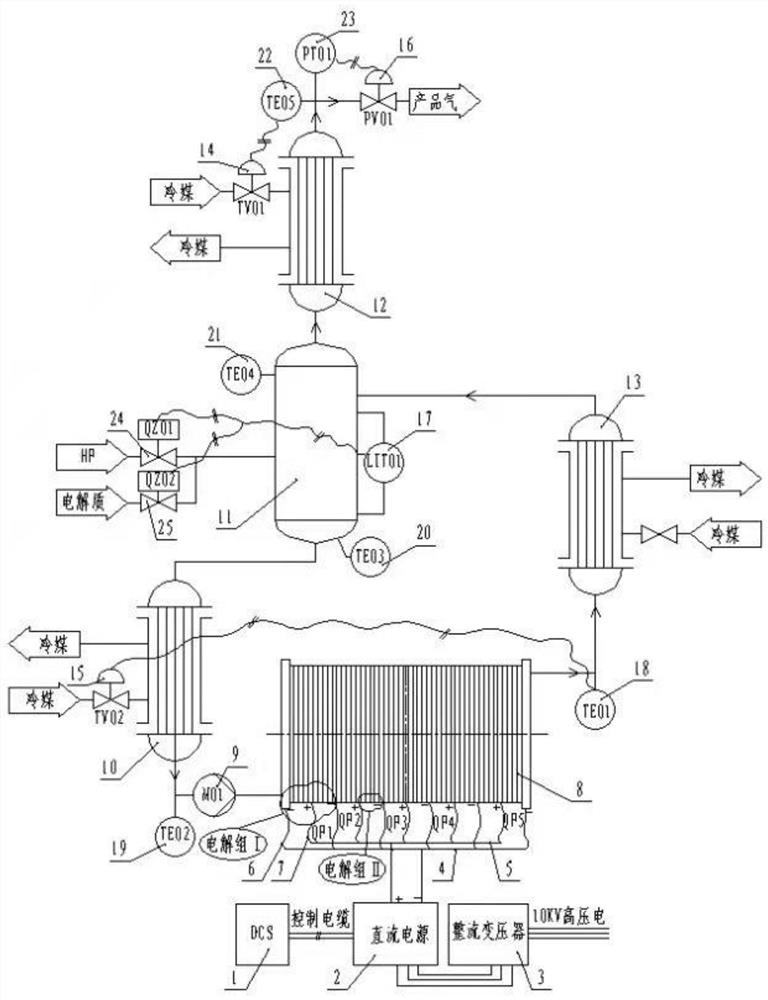

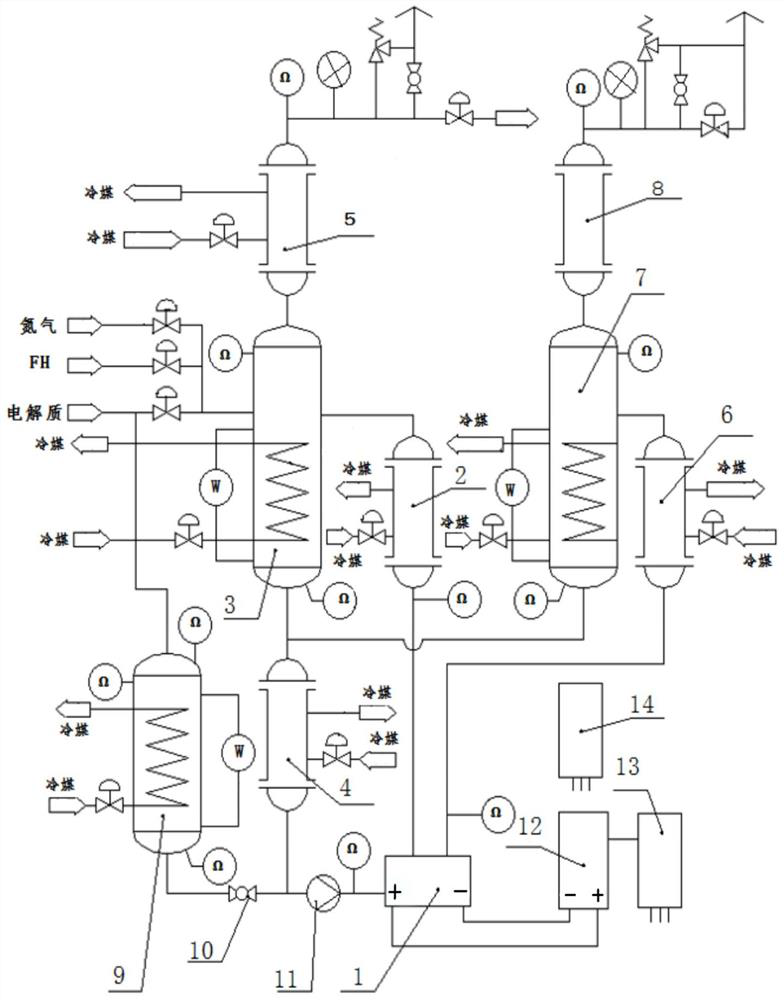

Electrochemical fluorination external circulation electrolysis system

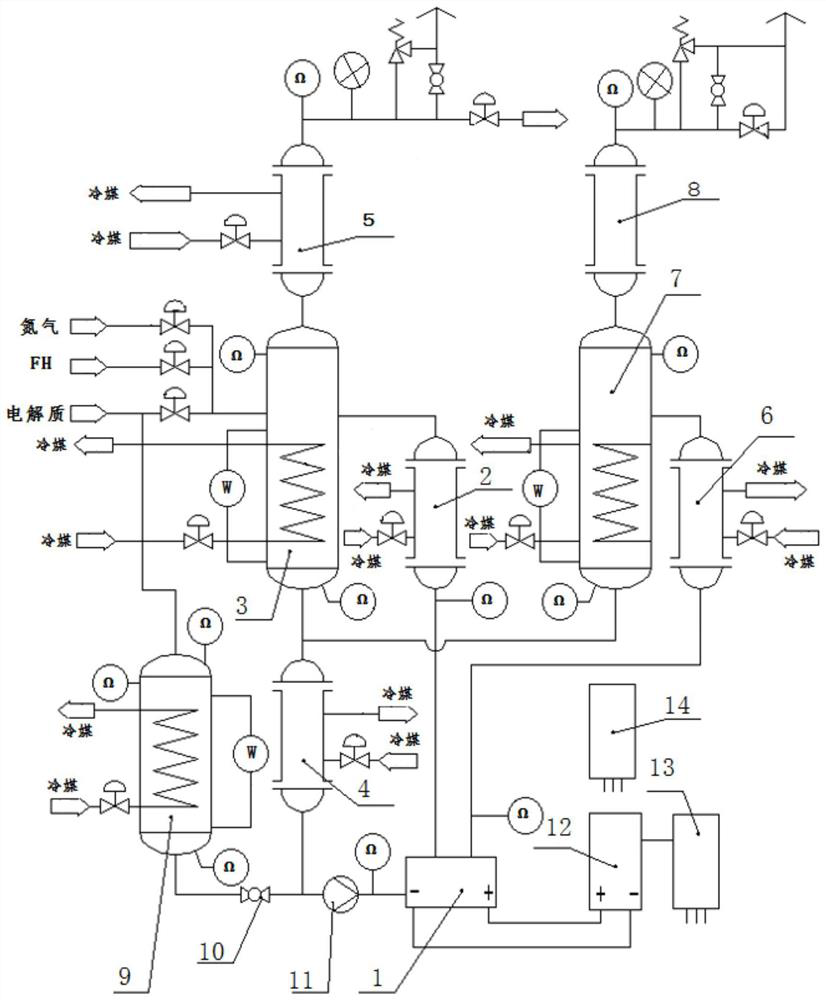

ActiveCN111850597AMiniaturizationImprove energy efficiency ratioCellsElectrolytic organic productionElectrolytic agentThermodynamics

The invention provides an electrochemical fluorination external circulation electrolysis system. The system comprises an electrolytic cell, an anode cooler, an anode gas-liquid separator, a main cooler, an anode condenser, a cathode cooler, a cathode gas-liquid separator and a cathode condenser. An anode liquid outlet of the electrolytic cell is connected with a liquid inlet of the anode cooler through a pipeline, and a liquid outlet of the anode cooler is connected with a liquid inlet in the upper portion of the anode gas-liquid separator through a pipeline. A liquid outlet in the bottom of the anode gas-liquid separator is connected with a liquid inlet in the top of the main cooler through a pipeline, and a liquid outlet in the bottom of the main cooler is connected with a liquid inlet of the electrolytic cell through a pipeline. The system facilitates miniaturization of the electrolytic cell, can eliminate the risks of refrigerant and electrolyte intermingling and negative and positive gas mixed explosion, obviously enhances the energy efficiency ratio of the electrolytic cell, is safe and reliable, finishes heat management by the coolers, can accurately control the electrolysistemperature, and can sufficiently obtain high-purity product gas through gas-liquid separation.

Owner:PERIC SPECIAL GASES CO LTD

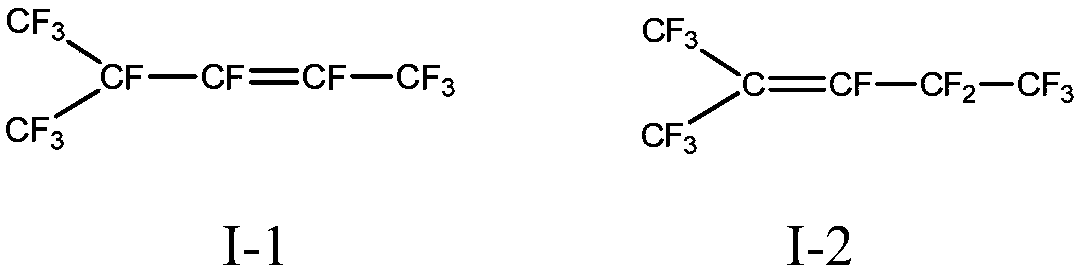

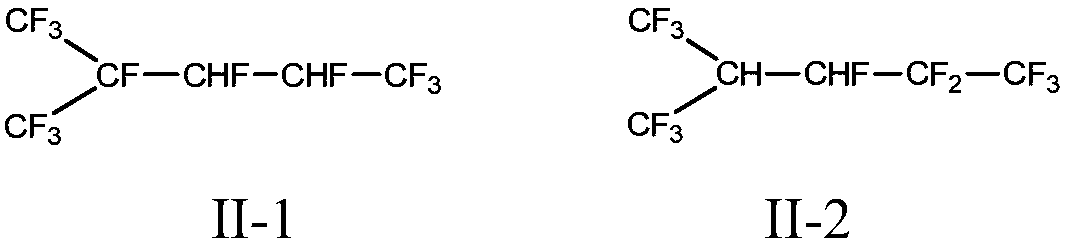

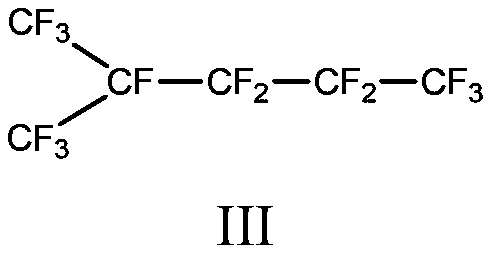

Method for preparing branched perfluorohexane

ActiveCN109652819ASolving Corrosion ProblemsNo self-fluorination problemElectrolysis componentsElectrolytic organic productionHydrofluoric acidHydrogen

The invention discloses a method for preparing branched perfluorohexane. The method includes the following steps: (1) reacting a hexafluoropropene dimer adopted as a raw material to a catalytic hydrogenation reaction in a reactor to synthesize dodecafluorodihydrohexane; and (2) introducing the dodecafluorodihydrohexane prepared in the step (1), anhydrous hydrofluoric acid and conductive auxiliarydimethyl disulfide into an electrolytic tank and preparing the branched perfluorohexane by Simons electrochemical fluorination. The method of the invention uses the perfluoropropylene dimer as the rawmaterial, performs the hydrogenation to obtain the saturated hydrofluoroalkane, and then performs electrochemical fluorination to replace the hydrogen to obtain the branched perfluoroalkane. The method for preparing the branched perfluorohexane has the advantages of high hydrogenation conversion rate and good selectivity, and so the electrochemical fluorination efficiency is significantly improved and the production cost is greatly reduced.

Owner:浙江佳汇新材料有限公司 +1

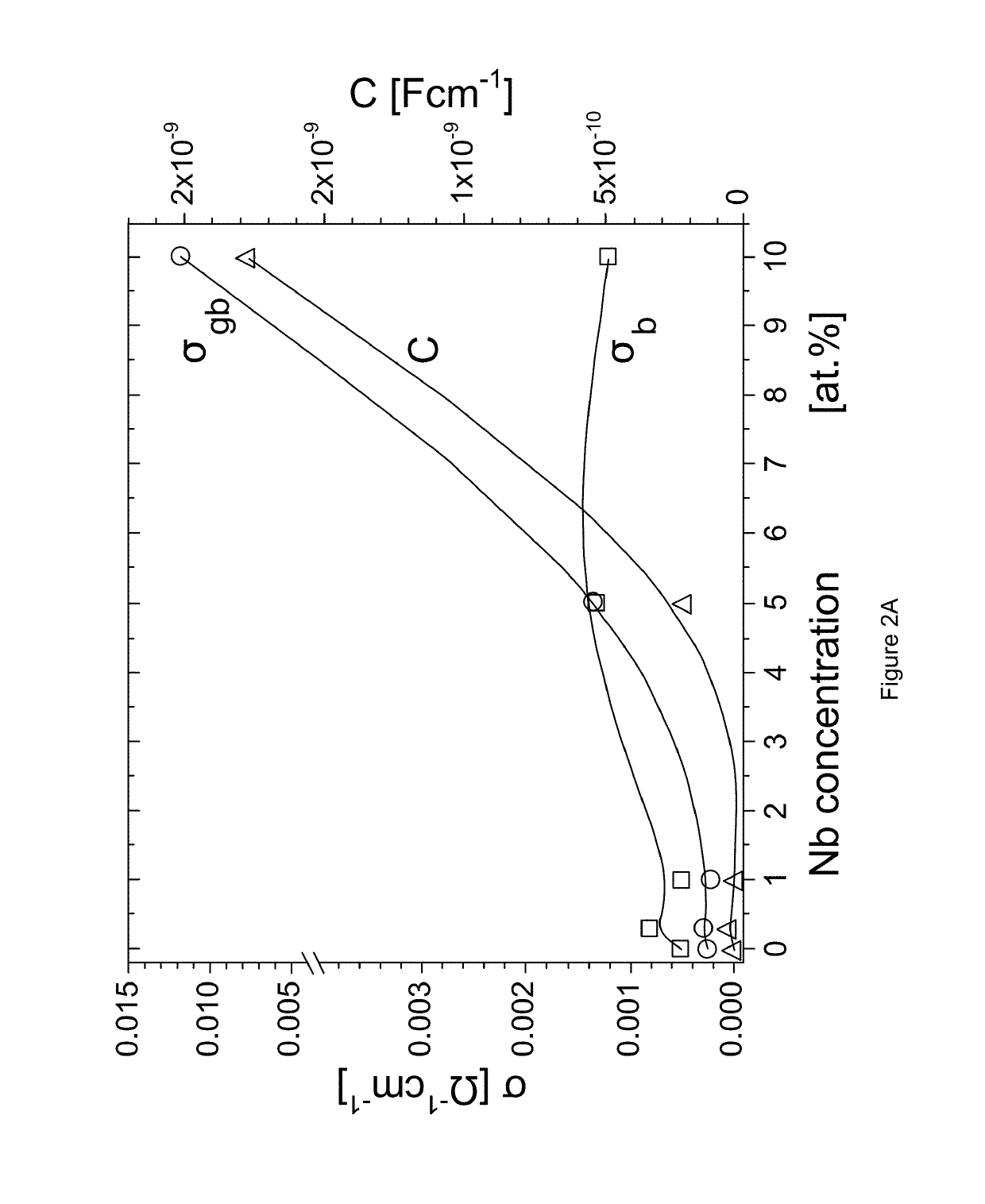

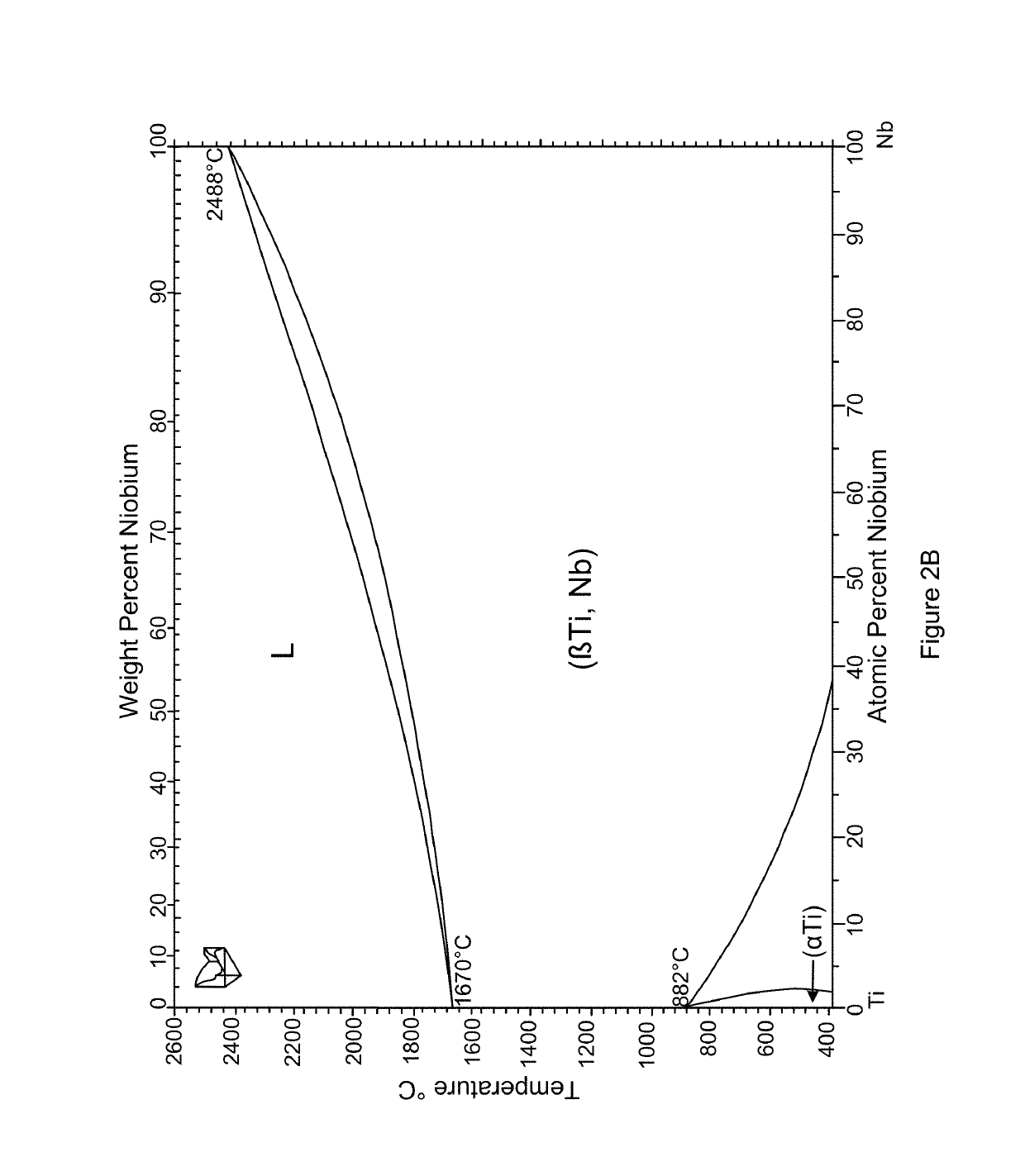

Method of metallic component surface modification for electrochemical applications

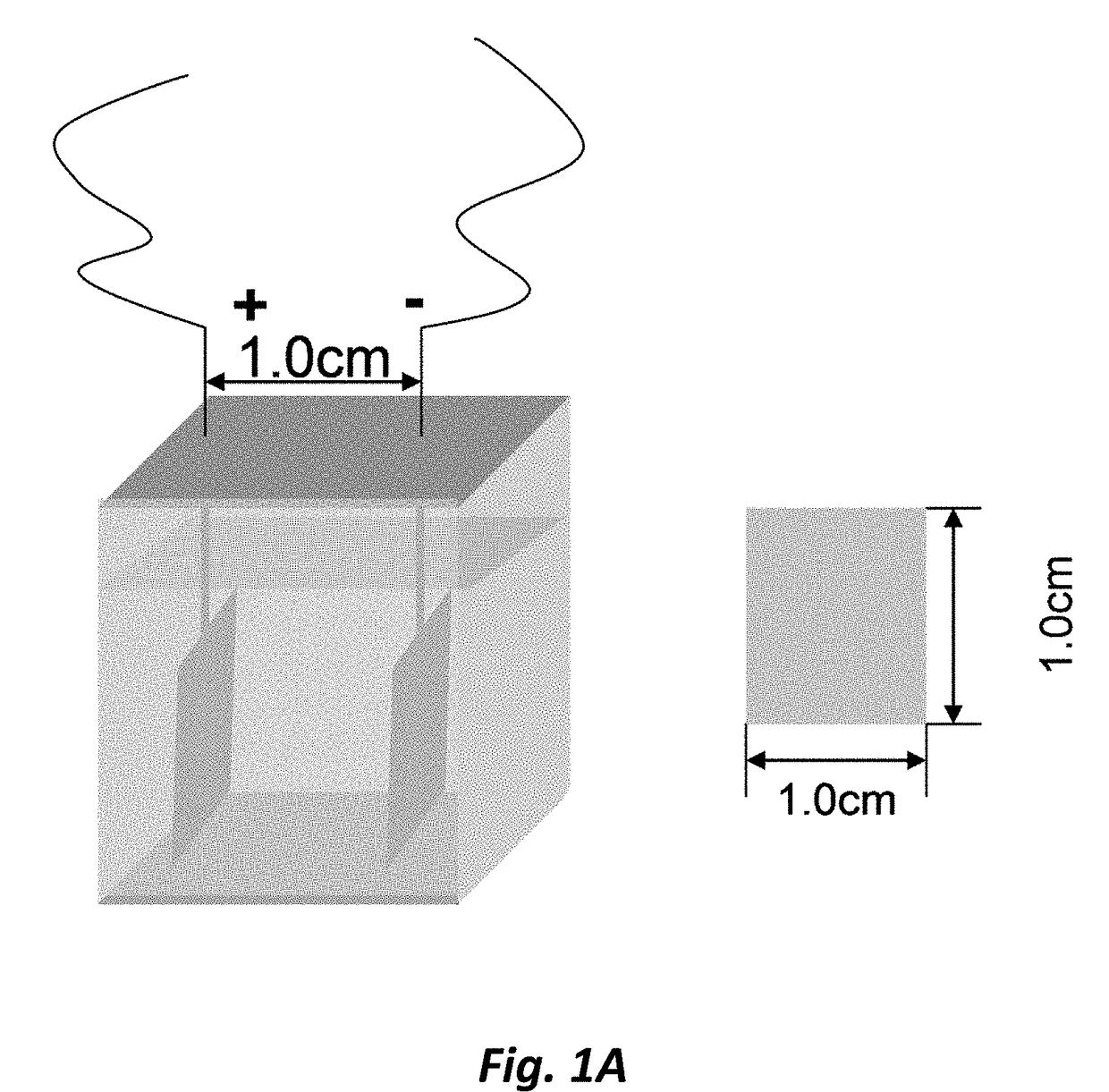

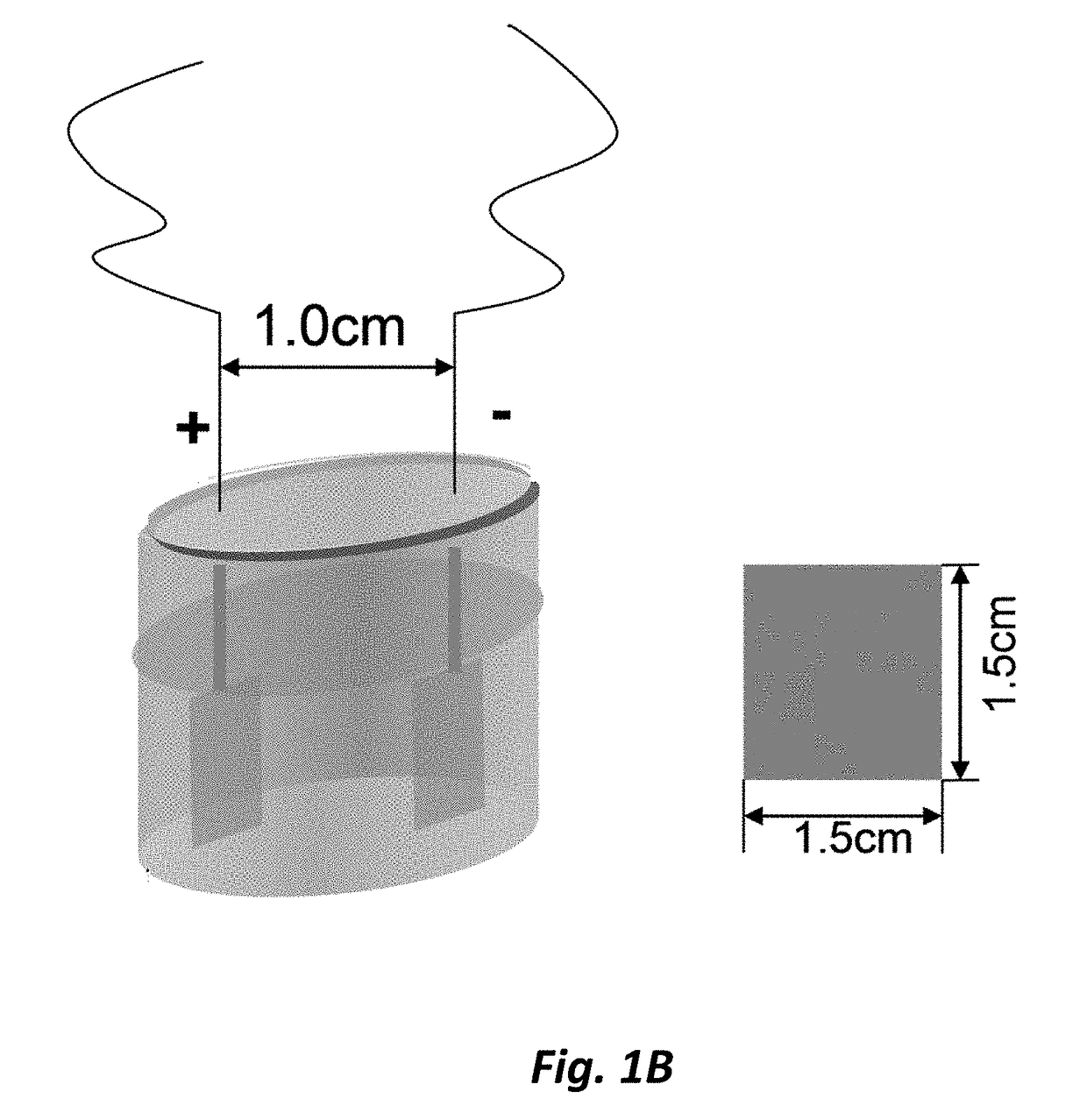

ActiveUS10435782B2Reduce contact resistanceMolten spray coatingElectrolytic capacitorsChemical compositionSmall peak

Method for forming a metallic component surface to achieve lower electrical contact resistance. The method comprises modifying a surface chemical composition and creating a micro-textured surface structure of the metallic component that includes small peaks and / or pits. The small peaks and pits have a round or irregular cross-sectional shape with a diameter between 10 nm and 10 microns, a height / depth between 10 nm and 10 microns, and a distribution density between 0.4 million / cm2 and 5 billion cm2.

Owner:TREADSTONE TECH INC

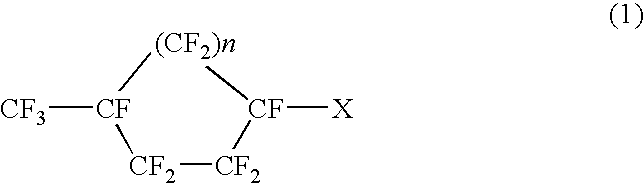

Perfluoronated cycle-containing tertiary amines used as a basis for gas-conveying emulsions and device for the production thereof

InactiveUS6878826B2Simplify and speed-up technological processHigh usefulnessElectrolysis componentsOrganic chemistryDissolutionOrganic compound

Owner:MASLENNIKOV IGOR ALEXEEVICH

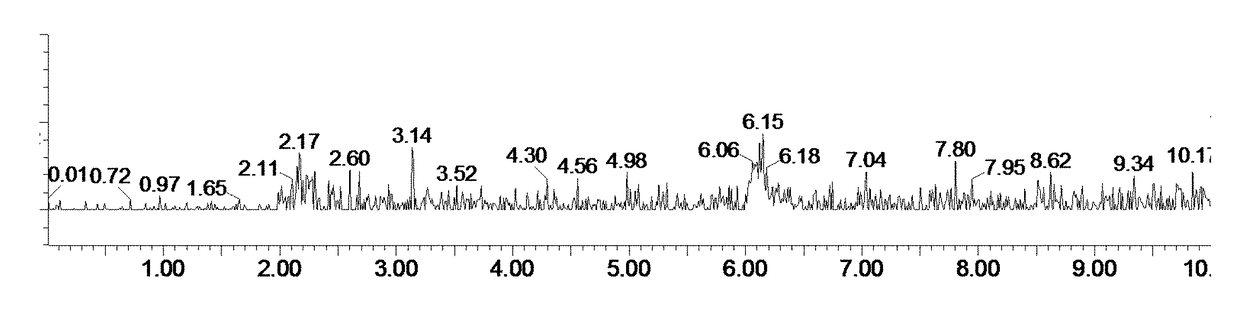

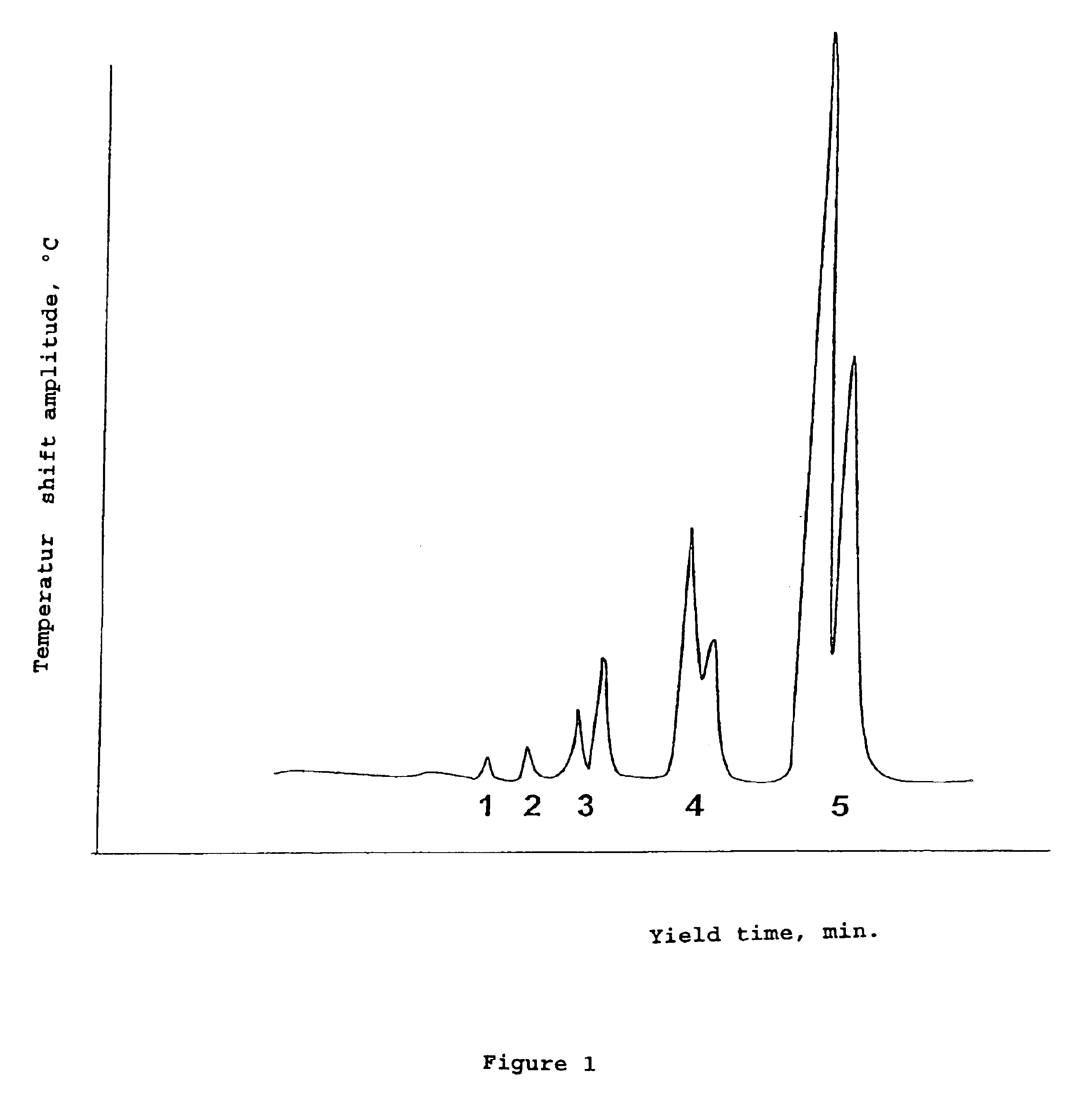

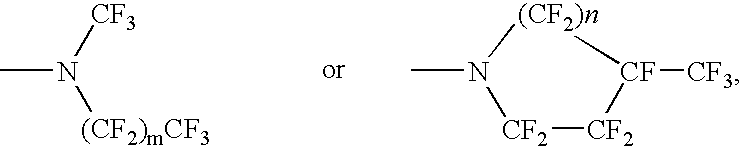

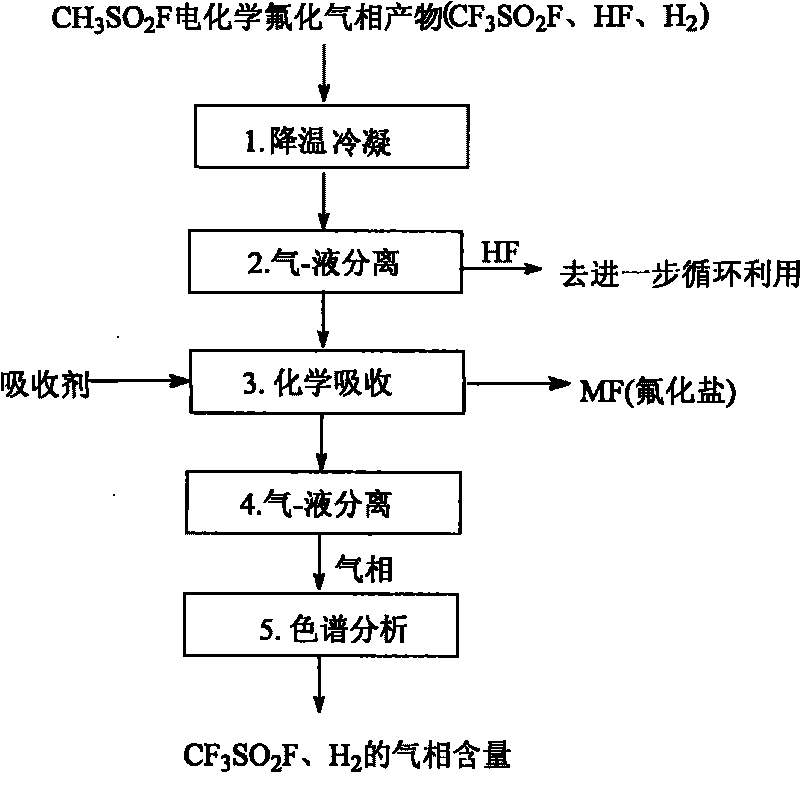

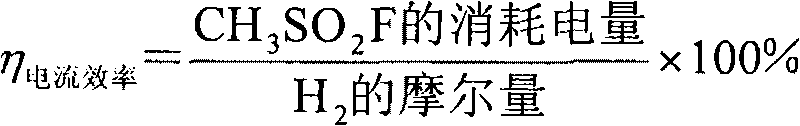

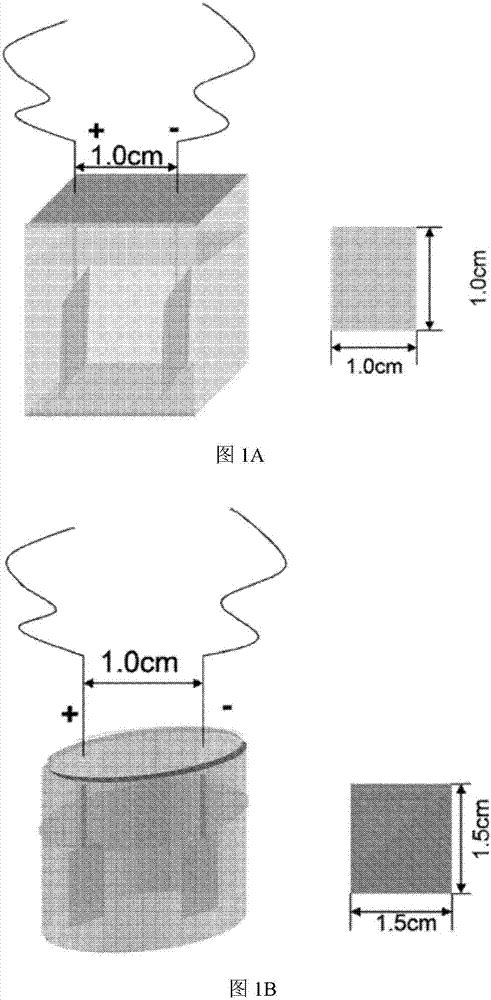

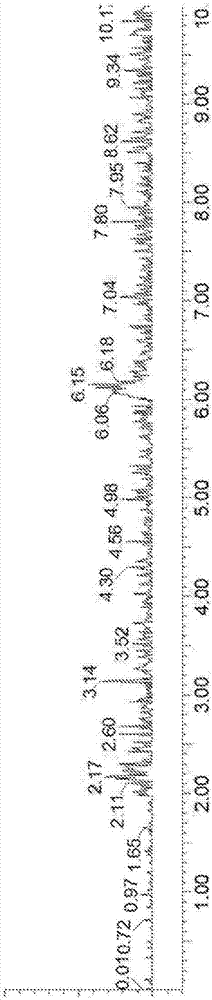

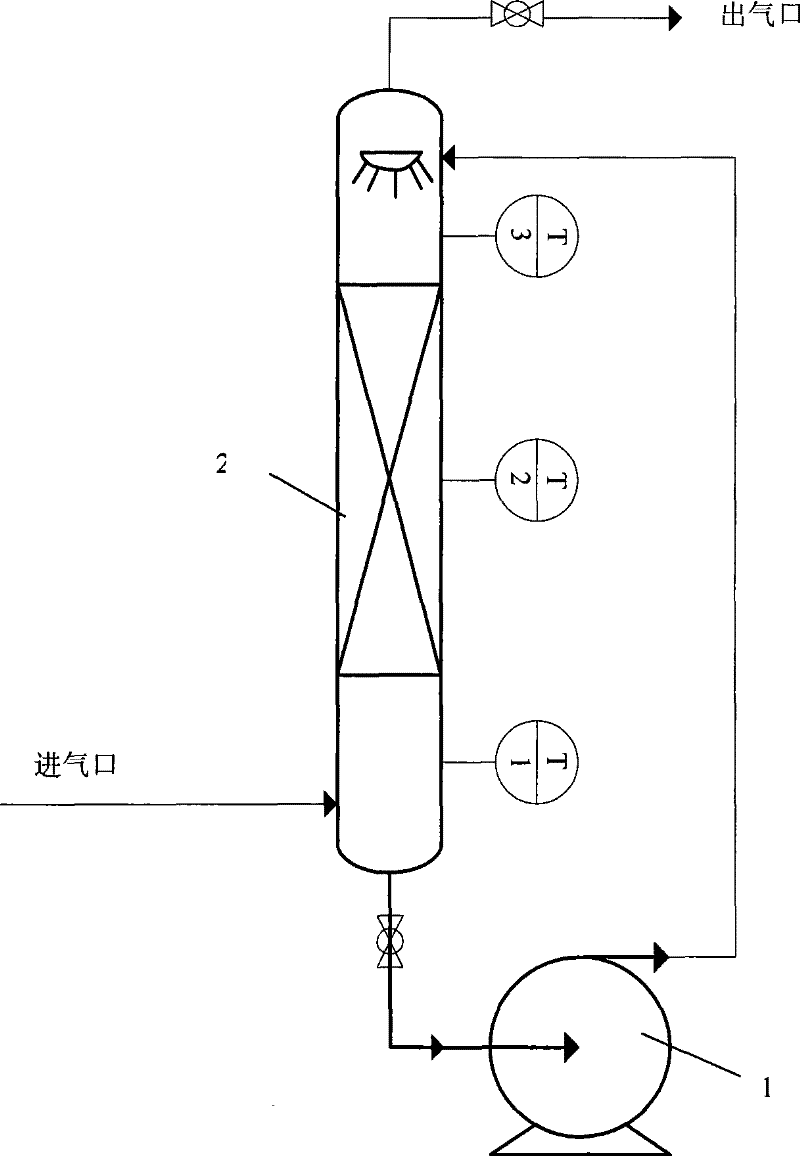

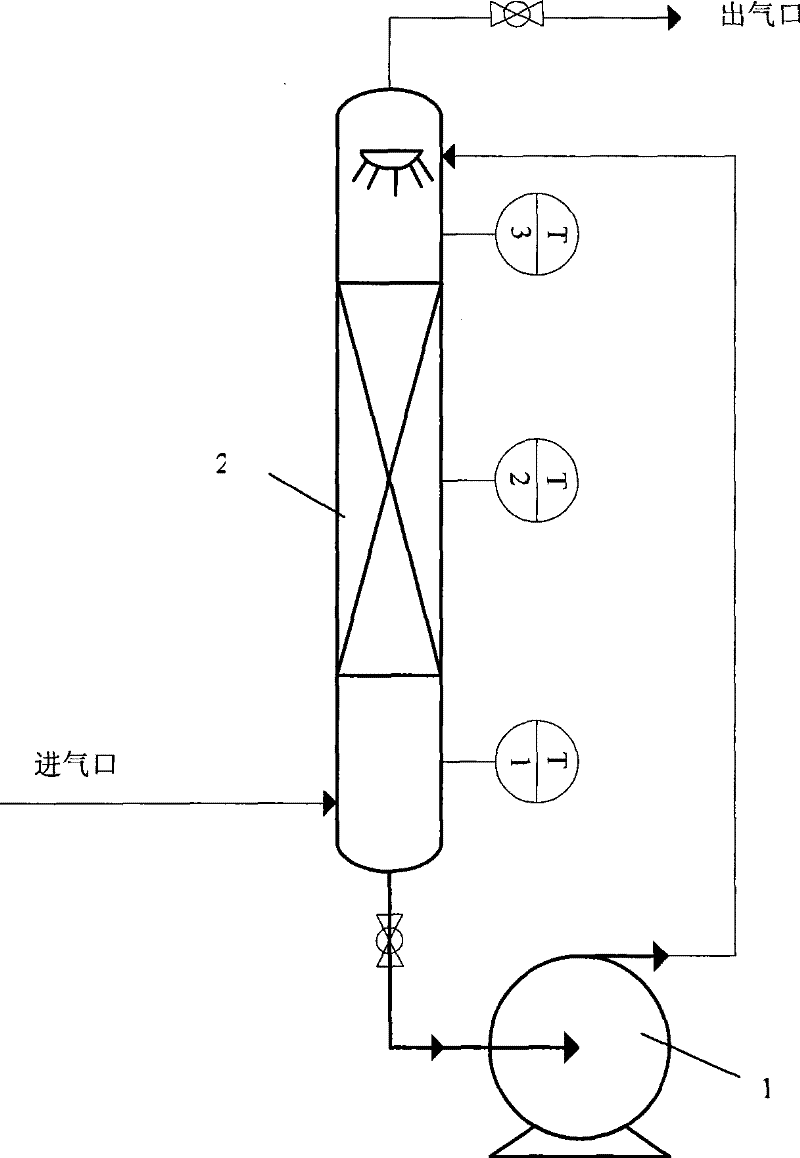

Analyzing and detecting method of electrochemical fluorination gas-phase product of methanesulfonyl fluoride CH3SO2F

The invention relates to an analyzing and detecting method of electrochemical fluorination gas-phase product of methanesulfonyl fluoride CH3SO2F, the steps of the method are as follows: (1) the gas-phase product of the CH3SO2F electrochemical fluorination is cooled and condensed, the HF in gas-phase is condensed to the HF in liquid-phase; (2) gas-liquid separation: the gas-phase product enters into the next step; (3) chemical absorption: the chemical absorbent is adopted, the acidic gas in the gas-phase product in the last step and the generated OF2 are neutralized and then are removed; (4) the gas-liquid separation: the gas-phase further enters a sampling analyzer of the gas chromatography; (5) chromatographic analysis: the gas-phase product gained at the last step enters a sample injector of the gas chromatography for analyzing and detecting, and then the relative molar percentage content of the CH3SO2F and H2 in the gas-phase product is obtained. The advantages of the invention are as follows: the operating procedure is simple, fast, the cost is low, on-site quantitative analyzing and detecting can be conducted, and the detected data is reliable.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Method of discovering fluoro-containing compounds

InactiveCN107110744ACompound screeningOrganic active ingredientsChemical compoundElectrochemical fluorination

The present teachings relate to a methods for drug discovery. In one particular example, the method includes providing a substrate, modifying the substrate by using an electrochemical fluorination, screening a reaction mixture of the electrochemical fIuorination, and identifying a fluorinated compound in the reaction mixture.

Owner:SHANXI CHEM RES INST +1

Process for preparing high-purity trifluoromethyl sulphonic acid

ActiveCN101402591BFast hydrolysisAdequate responseElectrolysis componentsOrganic compound preparationAlkaline earth metalDistillation

The invention relates to a process method for preparing high-purity trifluoromethane sulfonic acid. The process method comprises the following steps: firstly, hydrolyzing trifluoromethane sulfuryl fluoride gas prepared by an electrochemical fluorination method in alkaline metal or alkaline-earth metal hydroxide solution, recrystallizing the generated trifluoromethane sulphonate in a solvent to purify, and then reacting the trifluoromethane sulphonate with 100 percent of sulfuric acid in the presence of silicon dioxide to obtain an initial product of the trifluoromethane sulfonic acid, and finally purifying the trifluoromethane sulfonic acid through reduced pressure distillation. The process method not only effectively improves the hydrolysis speed of the trifluoromethane sulfuryl fluoridegas, leads the trifluoromethane sulfuryl fluoride gas to react more completely, and improves the yield, but also effectively reduces the content of F<-> in the trifluoromethane sulfonic acid product, and improves the purity of the product.

Owner:PERIC SPECIAL GASES CO LTD

Potassium perfluoroalkanesulfonate and method for producing the same

InactiveUS8026391B2Alkaline concentration decreasedThe process steps are simpleElectrolysis componentsOrganic compound preparationHydrogen fluoridePotassium fluoride

Owner:MITSUBISHI MATERIALS CORP +1

Electrochemical fluorination external circulation flexible electrolysis system

ActiveCN112376075AReduced risk of corrosionThe total electrolysis voltage is halvedCellsElectrolytic organic productionElectrolytic agentVapor–liquid separator

The invention discloses an electrochemical fluorination external circulation flexible electrolysis system which comprises a cathode copper bar, an anode copper bar, a cathode cable, an anode cable, anelectrolytic cell, a circulating pump, a cooler I, a gas-liquid separator, a gas condenser and a cooler II. A cell body of the electrolytic cell is internally provided with a left-end electrode cathode plate, a right-end electrode cathode plate and a plurality of electrolysis groups I. The electrolytic cell is formed by connecting n electrolysis groups I in parallel, each electrolysis group I isformed by connecting two electrolysis groups II in parallel, and each electrolysis group II is formed by connecting 2-20 electrolysis cabs in series. According to the invention, the electrolytic cellis highly integrated, the successfully developed bipolar series-parallel combined filter pressing type electrolytic cell is used, and heat generated by electrode reaction is completed through the cooler outside the electrolytic cell, so that the corrosion risk of an electrolyte channel is reduced, and the system risk caused by blockage of a certain cab is solved.

Owner:PERIC SPECIAL GASES CO LTD

Synthesis of fluorinated radiopharmaceuticals via electrochemical fluorination

ActiveUS20160137567A1Easy to controlReduced steric hindranceElectrolysis componentsOrganic compound preparationElectrochemical fluorinationCombinatorial chemistry

Provided herein are methods and compositions for the electrochemical selective radiofluorination of aromatic molecules. The resulting fluorine-18 labeled compounds are ideal radionuclides for use in Positron Emission Tomography (PET); they are also difficult to radiolabel efficiently and with high specific activity using existing approaches. For example, radiopharmaceuticals such as [F18]L-DOPA, which is indispensable in PET brain disease imaging, may be made electrochemically with high radiochemical yield and high specific activity using 18F-. The invention process described herein opens new possibilities and provides wider access to PET tracers such as 18F-L-Dopa, since 18F- is much more widely available than the 18F2, currently used for synthesis of electron rich substrates.

Owner:RGT UNIV OF CALIFORNIA

Perfluoropolyether electrochemical end capping method

ActiveCN110965072AReduce generationSimple operation processElectrolysis componentsElectrolytic organic productionHydrogen fluorideEndcapping

The invention belongs to the technical field of electrochemical fluorination, and particularly relates to a perfluoropolyether electrochemical end capping method, which comprises: carryingout vacuum dehydration degassing treatment on hydrogen-containing functional group-terminated perfluoropolyether used as a raw material, carrying out an electrochemical fluorination reaction with anhydrous hydrogen fluoride in an electrolyte-containing electrolytic cell, and carrying out alkali washing and water washing on the crude product to obtain the perfluorinated perfluoropolyether product. According tothe invention, the method is suitable for electrochemical end capping of perfluoropolyethers with various structures, the process is simple, the used reagents are cheap and easy to obtain, the operation process is safe, the product is easy to purify and high in purity, and the method is suitable for industrial production and application.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

An Electrochemical Fluorination External Circulation Electrolysis System

ActiveCN111850597BMiniaturizationImprove energy efficiency ratioCellsElectrolytic organic productionElectrolytic agentHeat management

The invention provides an electrochemical fluorination external circulation electrolysis system, comprising an electrolytic cell, an anode cooler, an anode gas-liquid separator, a total cooler, an anode condenser, a cathode cooler, a cathode gas-liquid separator and a cathode condenser The anolyte outlet of the electrolytic cell is connected to the liquid inlet of the anode cooler by means of pipes, and the liquid outlet of the anode cooler is connected to the liquid inlet of the upper part of the anode gas-liquid separator by means of pipes; the bottom of the anode gas-liquid separator The liquid outlet of the total cooler is connected with the liquid inlet at the top of the total cooler by means of pipes, and the liquid outlet at the bottom of the total cooler is connected with the liquid inlet of the electrolytic cell by means of pipes. The invention facilitates the miniaturization of the electrolytic cell, can eliminate the risk of inter-connection of refrigerants and electrolytes and the mixed explosion of yin and yang gases, significantly improves the energy efficiency ratio of the electrolytic cell, is safe and reliable, the heat management is completed by the cooler, and the electrolysis temperature can be accurately controlled. Liquid separation can fully obtain high-purity product gas.

Owner:PERIC SPECIAL GASES CO LTD

Perfluoropolyether electrochemical capping method

ActiveCN110965072BReduce generationSimple operation processElectrolysis componentsElectrolytic organic productionHydrogen fluorideEndcapping

The invention belongs to the technical field of electrochemical fluorination, and in particular relates to a perfluoropolyether electrochemical end capping method. Using perfluoropolyether whose end group is hydrogen-containing functional group as raw material, after vacuum dehydration and degassing treatment, electrochemical fluorination reaction is carried out with anhydrous hydrogen fluoride in an electrolytic cell containing electrolyte, and the crude product is washed with alkali and water to obtain Perfluorinated perfluoropolyether products. The invention is suitable for electrochemically capping perfluoropolyethers of various structures, and has the advantages of simple process, cheap and easily available reagents, relatively safe operation process, easy purification and high purity of the product, and is beneficial to industrial production and application.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Preparation method of heptafluorobutyric acid and derivatives thereof

ActiveCN106748712BHigh yieldPreparation from carboxylic acid saltsElectrolysis componentsN-Butyric acidElectrolysis

The invention provides a preparation method of heptafluorobutyric acid, comprising the following steps: A) performing electrochemical fluorination reaction with n-butyric acid, n-butyryl chloride or n-butyryl fluoride and anhydrous hydrogen fluoride to obtain electrolytic mixed gas; The current density of electrochemical fluorination reaction is 0.025~0.033A / cm 2 , the reaction temperature is 9 to 13°C; the electrochemical fluorination reaction is provided with a cooling reflux device, and the cooling medium temperature of the cooling reflux device is -45°C; B) the electrolytic mixed gas prepared in step A) is passed into A reaction kettle equipped with an acid-binding agent to obtain heptafluorobutyryl fluoride, the acid-binding agent being triethylamine; C) mixing the heptafluorobutyryl fluoride obtained in step B) with water, and hydrolyzing to generate an aqueous solution of heptafluorobutyric acid D) mixing the above-mentioned heptafluorobutyric acid aqueous solution with KOH until the KOH concentration is 40% to 45%, and naturally crystallizing to obtain potassium heptafluorobutyrate; E) acidifying the above-mentioned potassium heptafluorobutyrate with sulfuric acid to obtain heptafluorobutyrate acid.

Owner:阜新瑞宁化工有限公司

An electrochemical fluorination electrolyzer

ActiveCN104532287BIncrease the effective electrolysis areaQuick disassemblyCellsElectrolytic organic productionTemperature controlElectricity

The invention discloses an electrochemical fluorination electrolytic cell, which comprises a cell body (1), a cell cover (2), a temperature control jacket (3) on the side wall of the cell body, a bottom discharge valve (4), and an electrode group (5 ), the anode conductive rod (6), the cathode conductive rod (7), the conductive beam (8), the structure of the electrode group is: the electrode plate is fixed by the fixed shaft (15) passing through the pole plate center hole (19) , the distance between the electrode plates is controlled by an annular insulating pad (17), and the fixed shaft fixes the electrode plates into a group of electrode groups through the insulating nuts (16) at both ends; the conductive beam has a hollow structure, and the electrodes on the electrode plates The screw rod (20) passes through the hollow structure and is fixed on the conductive beam, and the conductive beam is assembled with the tank cover (2) through the negative and anode conductive rods. The electrolytic cell has the characteristics of large capacity, high space utilization rate, and large effective electrolysis area. The electrode plate is movably connected with the conductive beam, which is easy to disassemble and assemble.

Owner:昊华气体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com