Method for preparing trifluoromethyl sulfuryl fluoride CF3SO2F by electrochemical fluorination of methanesulfonyl fluoride CH3SO2F

A technology of CH3SO2F and trifluoromethylsulfonyl fluoride, applied in organic chemistry, electrolysis process, electrolysis components, etc., can solve the problems of reducing the current efficiency of electrochemical fluorination products, difficulty in product separation and purification, and safety, etc. The effect of improved safety and reliability, safe and reliable process, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

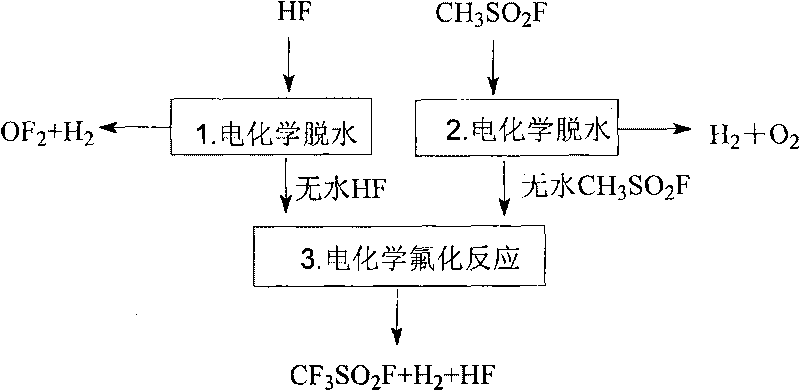

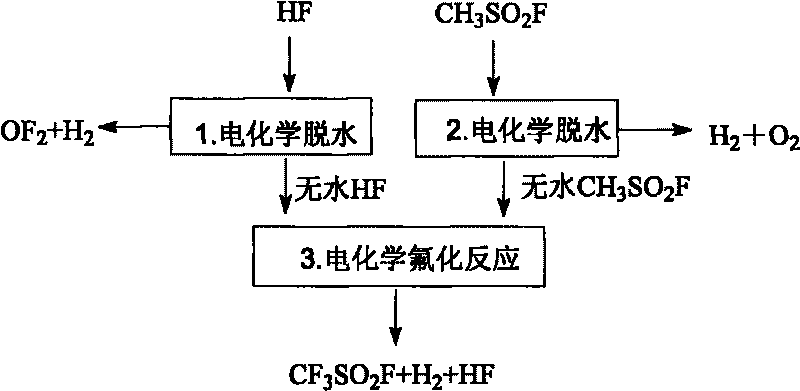

[0019] As shown in the figure, a methanesulfonyl fluoride CH 3 SO 2 Preparation of trifluoromethanesulfonyl fluoride CF by electrochemical fluorination of F 3 SO 2 The method of F, described method step is as follows:

[0020] (1) Electrochemical method to remove water in hydrogen fluoride HF: add hydrogen fluoride HF in the flat-plate electrochemical reactor 1 that the anode material is Ni wire, the cathode material is Ni plate, and the distance between the cathode and the anode is 2mm, and the electrochemical reaction The operating voltage of device 1 is 4.0V~8.2V, the operating temperature of electrochemical reaction is -10℃~10℃, and the operating absolute pressure is 0.1MPa~1.0MPa for electrochemical dehydration reaction. When the operating voltage of electrochemical reaction reaches 8.2V, the apparent Operating current density≤1.0mA / cm 2 , indicating that the dehydration reaction is basically completed, and the anhydrous HF after dehydration is used as the third step ...

Embodiment 2

[0024] As shown in the figure, a methanesulfonyl fluoride CH 3 SO 2 Preparation of trifluoromethanesulfonyl fluoride CF by electrochemical fluorination of F 3 SO 2 The method of F, described method step is as follows:

[0025] (1) Electrochemical method to remove water in hydrogen fluoride HF: add hydrogen fluoride HF in the fixed bed electrochemical reactor 1 that the anode material is a Ni plate, the cathode material is a Ni plate, and the distance between the cathode and the anode is 8mm. The operating voltage of device 1 is 4.0V~8.2V, the operating temperature of electrochemical reaction is -10℃~10℃, and the operating absolute pressure is 0.1MPa~1.0MPa for electrochemical dehydration reaction. When the operating voltage of electrochemical reaction reaches 8.2V, the apparent Operating current density≤2.0mA / cm 2 , indicating that the dehydration reaction is basically completed, and the anhydrous HF after dehydration is used as the third step CH 3 SO 2 The reactant of F...

Embodiment 3

[0029] As shown in the figure, a methanesulfonyl fluoride CH 3 SO 2 Preparation of trifluoromethanesulfonyl fluoride CF by electrochemical fluorination of F 3 SO 2 The method of F, described method step is as follows:

[0030] (1) Electrochemical method removes the water in the hydrogen fluoride HF: add hydrogen fluoride HF in the plate type electrochemical reactor 1 that the anode material is a low-carbon steel plate, the cathode material is a low-carbon steel plate, and the distance between the cathode and the anode is 8mm. The operating voltage of the chemical reactor 1 is 4.6V-8.0V, the operating temperature of the electrochemical reaction is -10°C-10°C, and the operating absolute pressure is 0.1MPa-1.0MPa for the electrochemical dehydration reaction. When the operating voltage of the electrochemical reaction reaches 8.2V, Apparent operating current density≤1.0mA / cm 2 , indicating that the dehydration reaction is basically completed, and the anhydrous HF after dehydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com