Electrochemical fluorination external circulation flexible electrolysis system

An electrolysis system and external circulation technology, applied in the field of electrochemical fluorination external circulation flexible electrolysis system, to achieve the effect of solving system risks and reducing corrosion risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

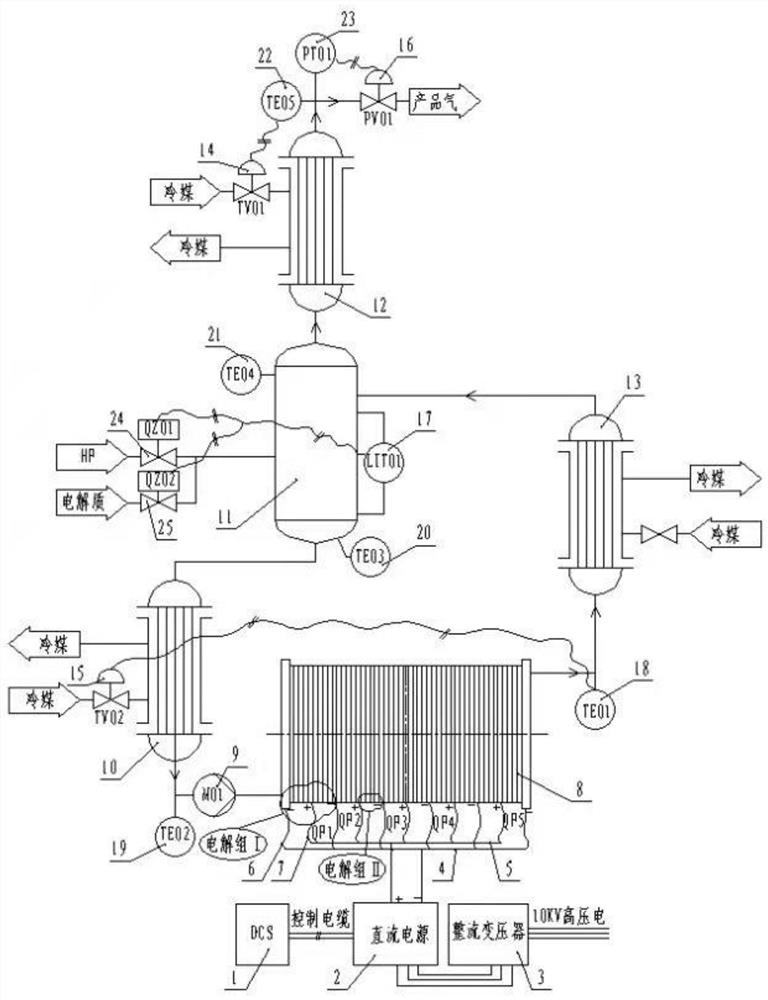

[0040] Example 1: The system implements forced circulation

[0041] The DCS cabinet 1 is started, and the electrolyte and hydrogen fluoride enter the gas-liquid separator 11 through the control valve at a certain ratio, and continue to feed the electrolyte until the liquid level of the electrolyte reaches one-third of the remote liquid level gauge in the anode gas-liquid separator 11. Stop feeding, start the circulation pump M01 after nitrogen purging of the electrolysis system, and start the DC power supply 2 to transmit power.

[0042] The anode gas and cathode gas engulf the electrolyte in the gas-liquid separator 11 respectively.

[0043] The gas phase rises into the gas condenser 12, and after fully recovering the carried liquid components, it flows out of the electrolysis system through a control valve, etc.; the liquid phase enters the cooler I under the action of gravity and enters under the drive of the circulation pump after heat exchange is completed. The electroly...

Embodiment 2

[0044] Example 2: The system implements natural circulation

[0045] The DCS cabinet 1 is started, and the electrolyte and hydrogen fluoride enter the gas-liquid separator 11 through the control valve at a certain ratio, and continue to feed the electrolyte until the liquid level of the electrolyte reaches one-third of the remote liquid level gauge in the anode gas-liquid separator 11. Stop feeding, start the circulation pump M01 after nitrogen purging of the electrolysis system, and start the DC power supply 2 to transmit power.

[0046] The anode gas and cathode gas engulf the electrolyte in the gas-liquid separator 11 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com