Method for preparing trifluoromethyl sulfonic acid CF3SO3H by electrochemical fluorination gas-phase product of methanesulfonyl fluoride CH3SO2F

A technology for CH3SO2F, CF3SO3H, applied in the field of preparing trifluoromethanesulfonic acid CF3SO3H, can solve the problems of high raw material cost, many process steps, low product quality and the like, and achieve the effects of low raw material cost, simple process and short process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Main equipment: tank-type stirred chemical reactor, leaching equipment, evaporation equipment, cooling equipment, filtering equipment.

[0048] Main raw material: Methylsulfonyl fluoride CH 3 SO 2 F electrochemical fluorination gas phase product, potassium hydroxide KOH, leaching agent acetone, hydrochloric acid HCl.

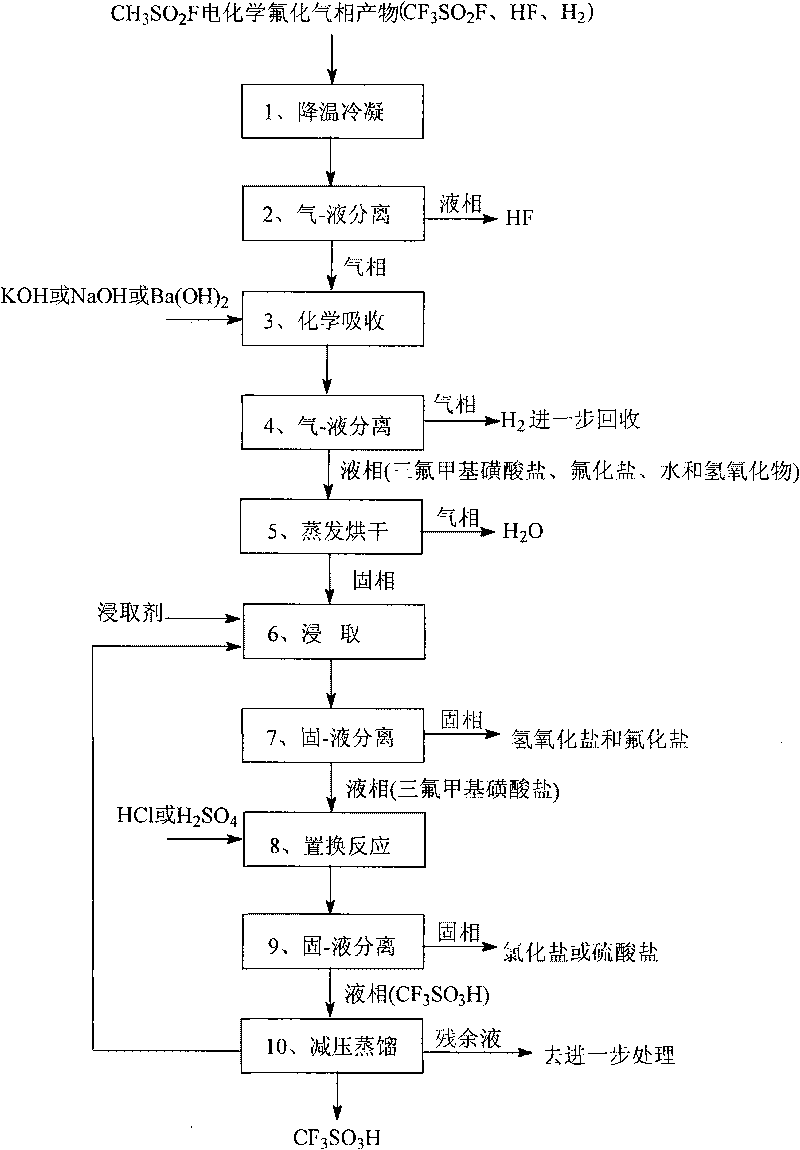

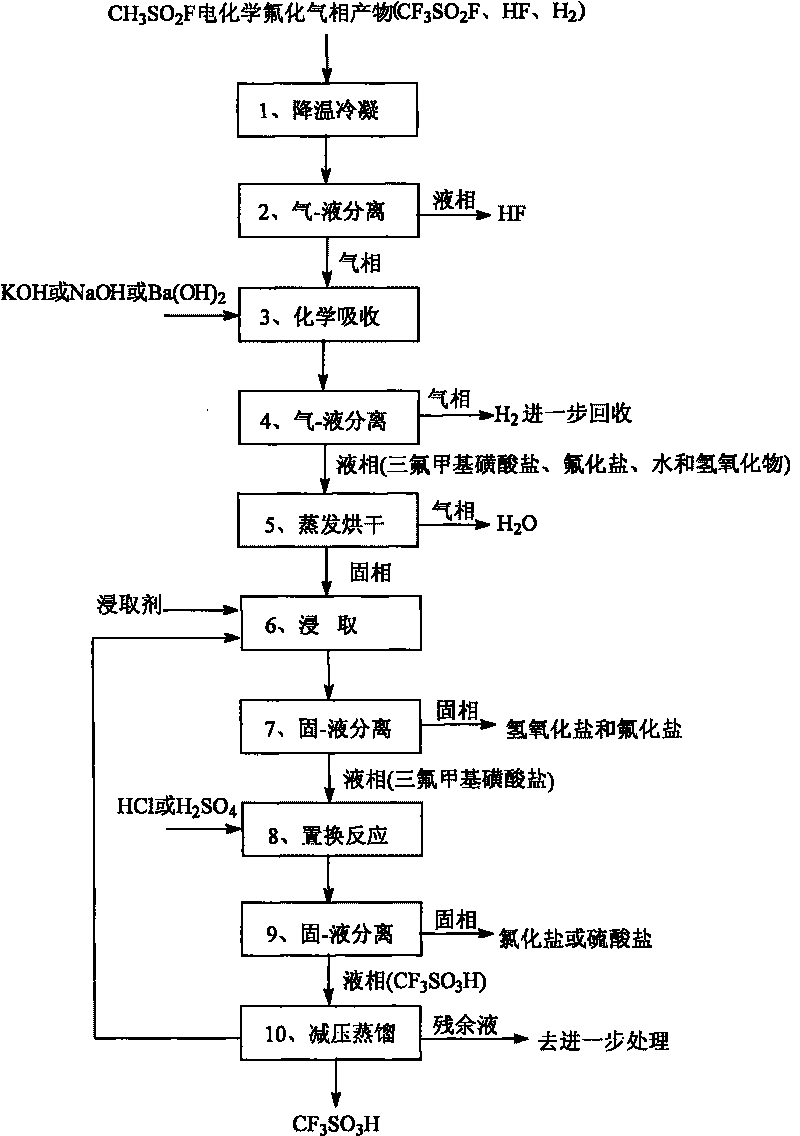

[0049] As shown in the figure, a methanesulfonyl fluoride CH 3 SO 2 F Electrochemical fluorination of gas phase products to prepare trifluoromethanesulfonic acid CF 3 SO 3 The method of H is based on methanesulfonyl fluoride CH 3 SO 2 F electrochemical fluorination gas phase product is raw material, and described method step is as follows:

[0050] (1) Cooling and condensation: In the cooling equipment, methylsulfonyl fluoride CH 3 SO 2 The gas phase product of F electrochemical fluorination is cooled and condensed. The operating temperature of cooling and condensing is 0°C, and the operating absolute pressure is 1.0 MPa, so that hydrogen fluorid...

Embodiment 2

[0061]Main equipment: tubular chemical reactor, leaching equipment, displacement reactor, evaporation equipment, cooling equipment, filtering equipment.

[0062] Main raw material: Methylsulfonyl fluoride CH 3 SO 2 F Electrochemical fluorination gas phase product, sodium hydroxide NaOH, leaching agent ethanol, hydrochloric acid HCl.

[0063] As shown in the figure, a methanesulfonyl fluoride CH 3 SO 2 F Electrochemical fluorination of gas phase products to prepare trifluoromethanesulfonic acid CF 3 SO 3 The method of H is based on methanesulfonyl fluoride CH 3 SO 2 F electrochemical fluorination gas phase product is raw material, and described method step is as follows:

[0064] (1) Cooling and condensation: In the cooling equipment, methylsulfonyl fluoride CH 3 SO 2 The gas phase product of F electrochemical fluorination is cooled and condensed. The operating temperature of cooling and condensing is -10°C, and the operating absolute pressure is 0.8 MPa, so that the h...

Embodiment 3

[0075] Main equipment: chemical absorption tower, leaching equipment, static mixer, evaporation equipment, cooling equipment, filtering equipment.

[0076] Main raw material: Methylsulfonyl fluoride CH 3 SO 2 F Electrochemical fluorination gas phase product, barium hydroxide Ba(OH) 2 , leaching agent acetone, hydrochloric acid HCl.

[0077] As shown in the figure, a methanesulfonyl fluoride CH 3 SO 2 F Electrochemical fluorination of gas phase products to prepare trifluoromethanesulfonic acid CF 3 SO 3 The method of H is based on methanesulfonyl fluoride CH 3 SO 2 F electrochemical fluorination gas phase product is raw material, and described method step is as follows:

[0078] (1) Cooling and condensation: In the cooling equipment, methylsulfonyl fluoride CH 3 SO 2 The gas phase product of F electrochemical fluorination is cooled and condensed. The operating temperature of cooling and condensing is -20°C, and the operating absolute pressure is 0.1MPa, so that the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com