Preparation method for carbon nanofiber electrode

A carbon nanofiber and electrode technology, applied in the field of carbon nanofiber electrode preparation, can solve the problems of uneven distribution on the surface of the current collector, obliteration of the advantages of carbon nanofibers, and inability to fully utilize them, so as to facilitate the transmission of ions and solve the preparation efficiency The effect of low and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

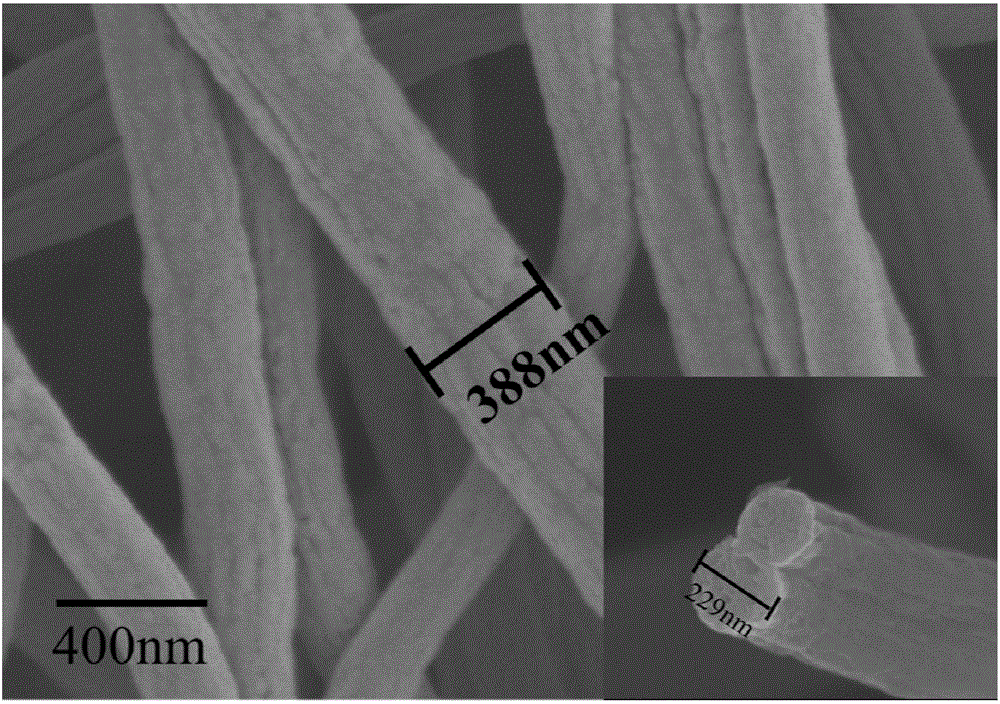

[0029] Step 1. Preparation of carbon nanofibers: Add polyacrylonitrile powder, polymethyl methacrylate powder and graphene to N, N-dimethylformamide, and stir evenly with a magnetic stirrer to obtain homogeneously dispersed The transparent spinning solution is then spun with an electrospinning device at a temperature of 35°C to obtain a fiber film. The electrospun carbon nanofiber film is a network structure composed of fibers of about 150nm to 400nm , then spread the fiber film on a high-temperature-resistant quartz plate, put it into a tube furnace for pre-oxidation treatment, and finally obtain a carbon nanofiber film; the polyacrylonitrile powder, polymethyl methacrylate powder and The mass ratio of N,N-dimethylformamide is 2:1:30; the added amount of the graphene is 0.3% of the total mass of the polyacrylonitrile powder and polymethyl methacrylate powder;

[0030] The electrospinning device is produced by Beijing Fuy...

Embodiment 2

[0037] This embodiment includes the following steps:

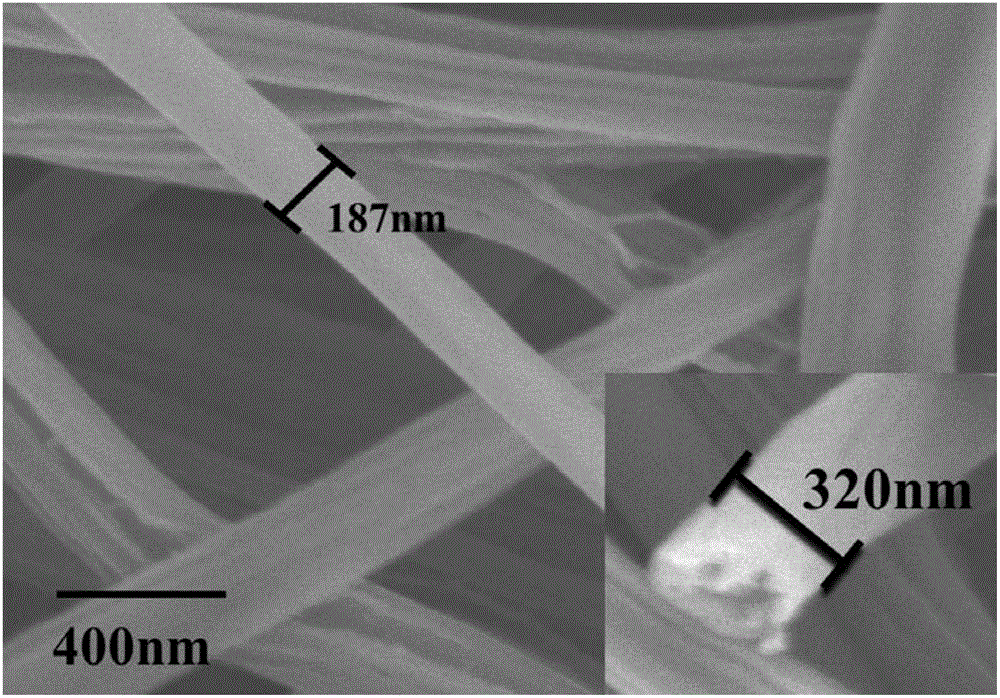

[0038] Step 1. Preparation of carbon nanofibers: Add polyacrylonitrile powder and polymethyl methacrylate powder to N, N-dimethylformamide, and stir evenly with a magnetic stirrer to obtain homogeneously dispersed transparent spinning liquid, and then use an electrospinning device to spin at a temperature of 33°C to obtain a fiber film, then spread the fiber film on a high-temperature resistant quartz plate, and then put it into a tube furnace for pre-oxidation treatment , to finally obtain a carbon nanofiber film; the mass ratio of the polyacrylonitrile powder, polymethyl methacrylate powder and N,N-dimethylformamide is 2:1:30;

[0039] The electrospinning device is produced by Beijing Fuyouma Technology Co., Ltd., and the model is 1206. The process parameters of the electrospinning are: the voltage of the high-voltage power supply is 25kV, the distance from the needle tip to the drum receiver is 18cm, and the spinning S...

Embodiment 3

[0045] This embodiment includes the following steps:

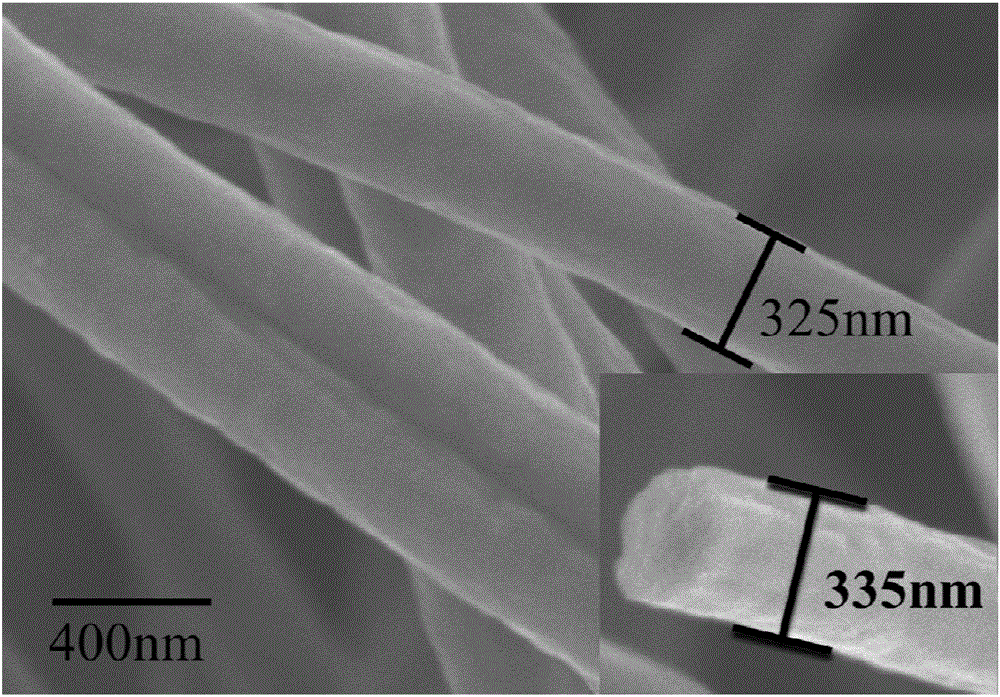

[0046] Step 1. Preparation of carbon nanofibers: Add polyacrylonitrile powder to N,N-dimethylformamide, stir evenly with a magnetic stirrer to obtain a homogeneously dispersed transparent spinning solution, and then use an electrospinning device Spinning at a temperature of 30°C to obtain a fiber film, then spread the fiber film on a high-temperature-resistant quartz plate, and then put it into a tube furnace for pre-oxidation treatment, and finally obtain a carbon nanofiber film; The mass ratio of the polyacrylonitrile powder to N,N-dimethylformamide is 1:10;

[0047] The electrospinning device is produced by Beijing Fuyouma Technology Co., Ltd., and the model is 1206. The process parameters of the electrospinning are: the voltage of the high-voltage power supply is 25kV, the distance from the needle tip to the drum receiver is 18cm, and the spinning Silk flow rate is 2mL / h;

[0048] The specific process of the pre-oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com