Patents

Literature

40results about How to "Alkaline concentration decreased" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of tobermorite

ActiveCN103708478ACrystal stableAlkaline concentration decreasedAlkaline-earth metal silicatesPulverized fuel ashSODIUM SILICATE SOLN

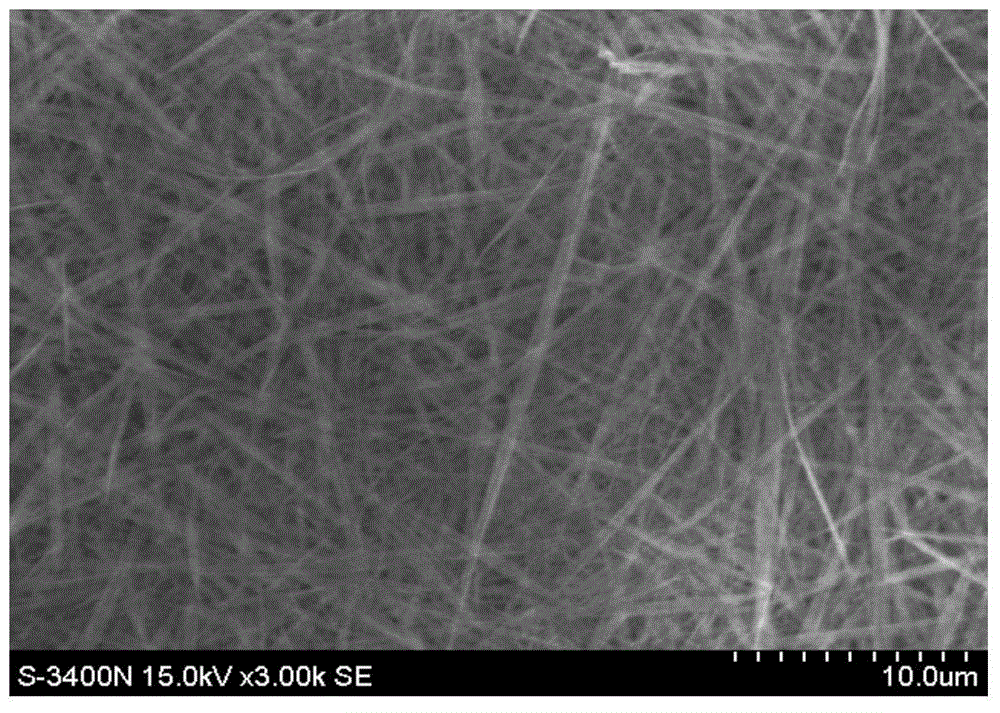

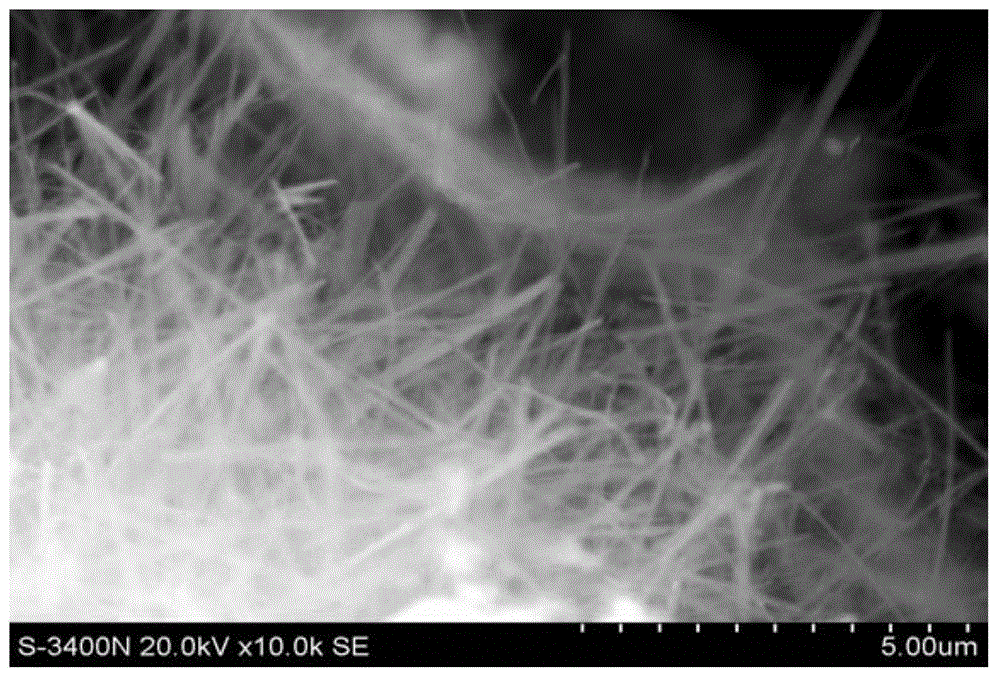

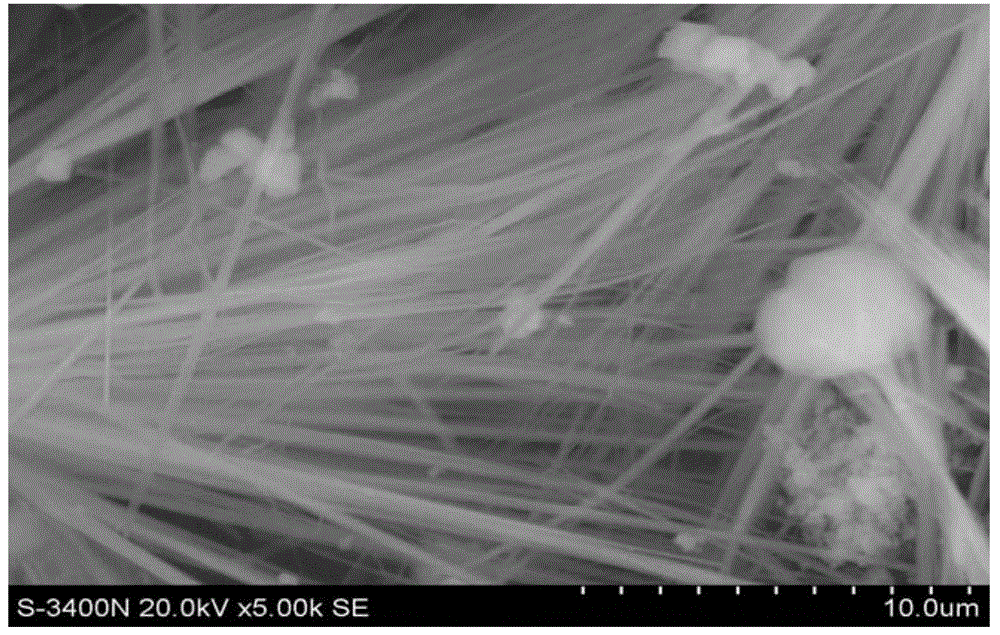

The invention discloses a preparation method of tobermorite. The preparation method comprises the following steps: removing amorphous activated SiO2 in pulverized fuel ash by use of sodium hydroxide alkaline liquor so as to obtain a sodium silicate solution with an appropriate concentration, wherein the sodium silicate solution is used as a siliceous material; further performing hydro-thermal synthesis with refined lime milk to finally obtain a tobermorite product.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Quick degumming method for low-alkali cotton stalk bark fibre in high temperature

InactiveCN101509151AQuality improvementGood alkali concentrationBleaching apparatusFibre treatment to obtain bast fibreFiberHydrogen

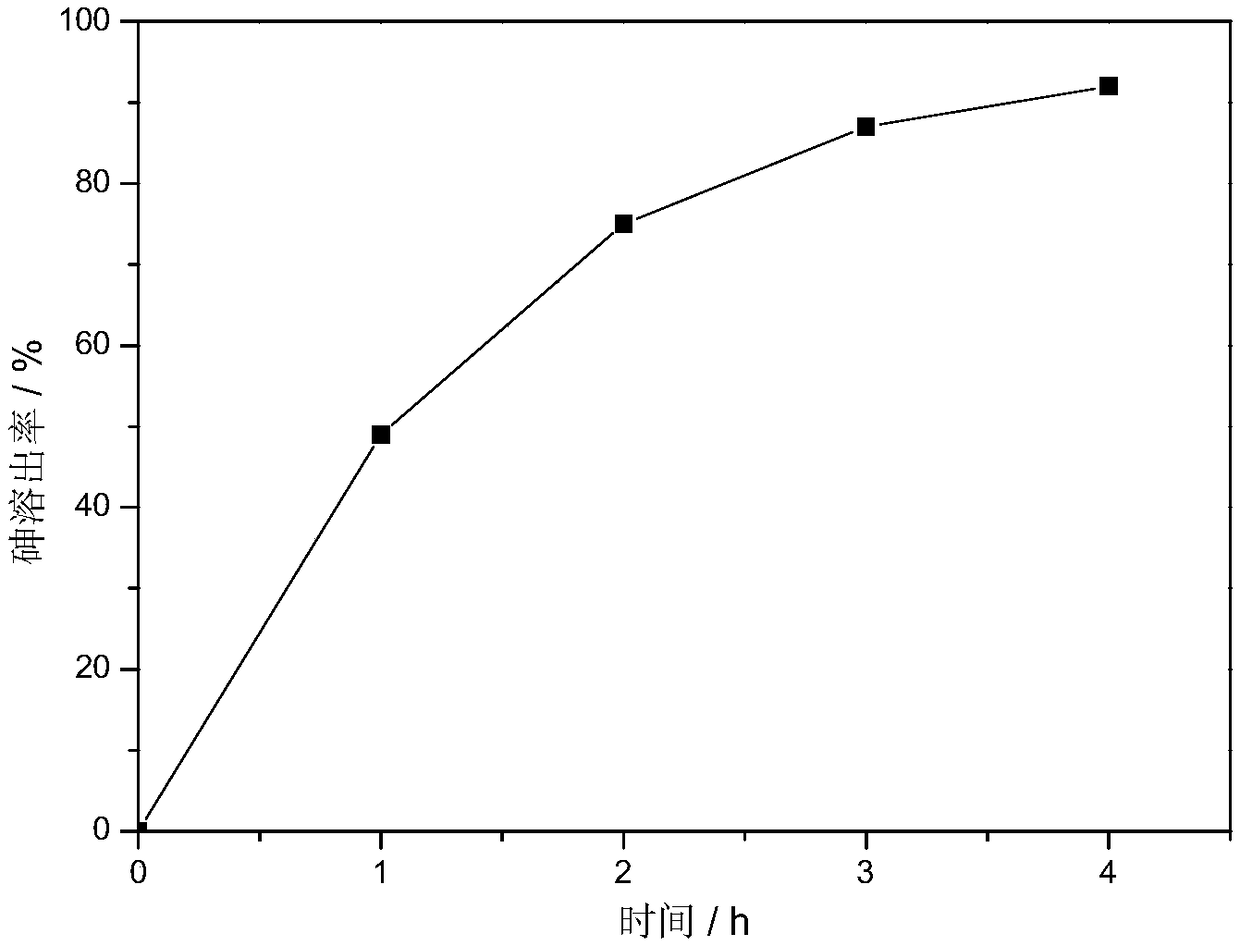

The invention discloses a fast colloid-removing method for high-temperature low-alkali cotton stack bark fiber. The technique flow thereof comprises: washing the cotton stack bark, drying, high-temperature low-alkali colloid-removing, washing, bleaching, washing, dehydrating, softening by applying oil, deoiling, drying and subtle drying of the cotton stack bark fiber, namely adopting the technique of boiling-bleaching-softening. The high-temperature high-pressure low-alkali technology is directly adopted to deeply degrade the hemicellulose and lignine in the cotton stack bark, and in the end hydrogen peroxiden is used for bleaching and softening the cotton stack bark fiber to prepare white and soft cotton stack bark fiber with high quality. The colloid removal rate of the cotton stack bark fiber after processing can achieve around 90%, and the removal rate of the hemicellulose content is around 97%. Compared with the disclosed patent technique of cotton stack bark fiber, as the invention adopts the technique of boiling-bleaching-softening, the processing period is greatly shortened; an orthogonal experiment is performed to control the alkaline amount to be the minimum and the colloid removal effect is optimum, thus saving resources and reducing discharge.

Owner:ZHEJIANG SCI-TECH UNIV +1

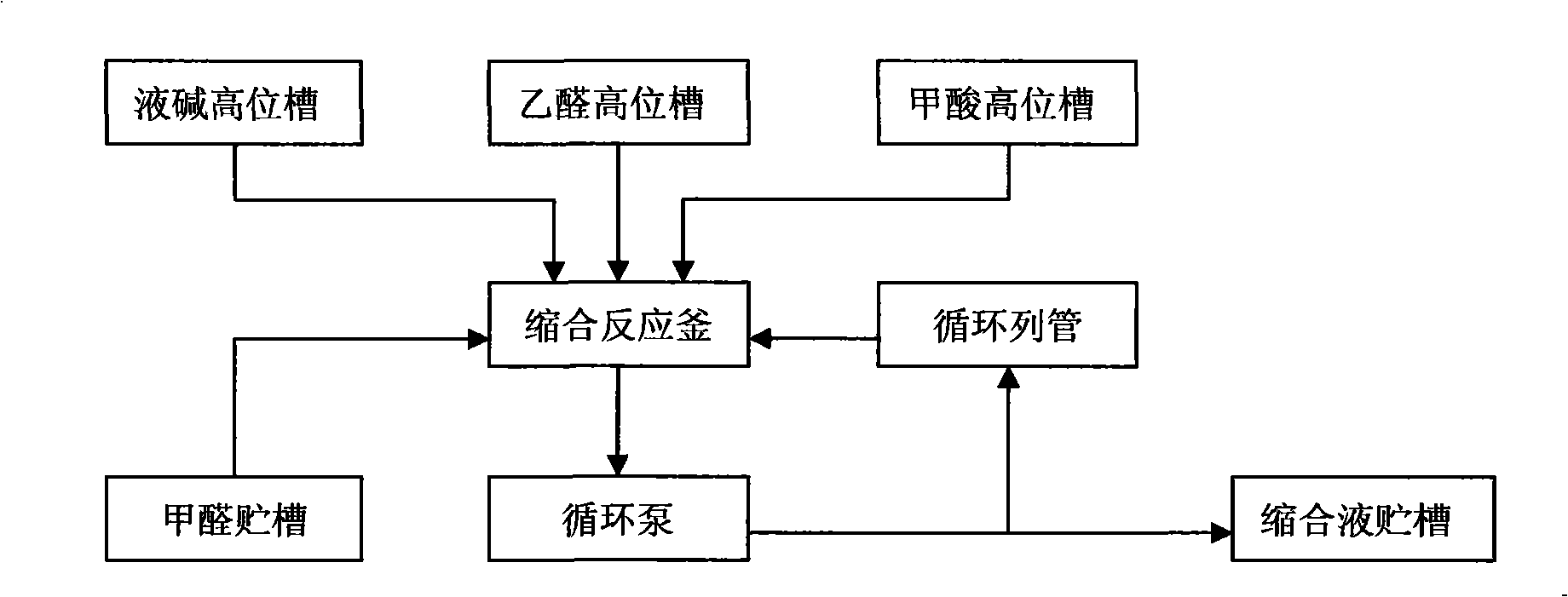

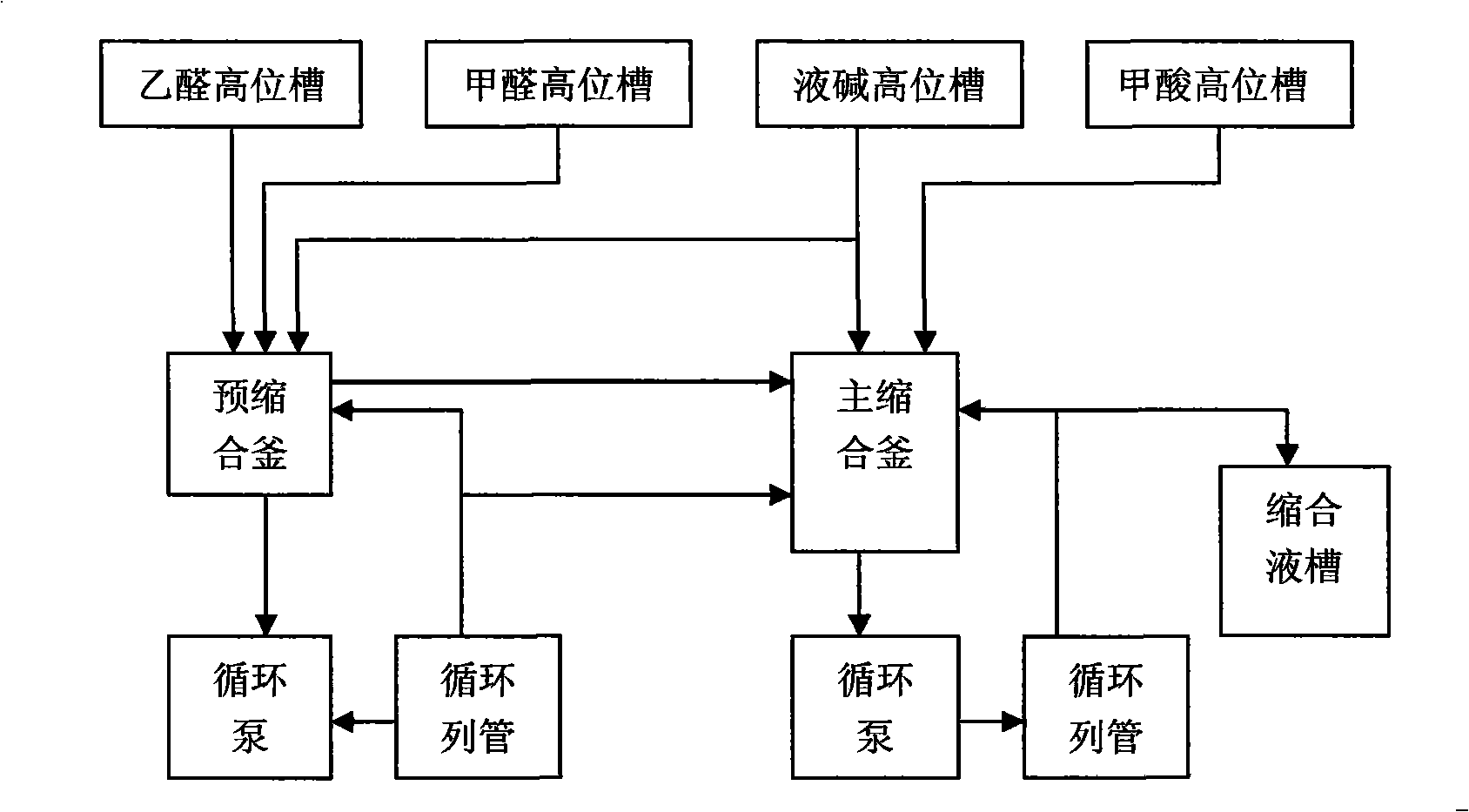

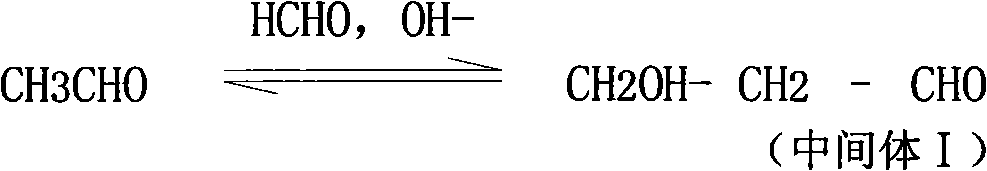

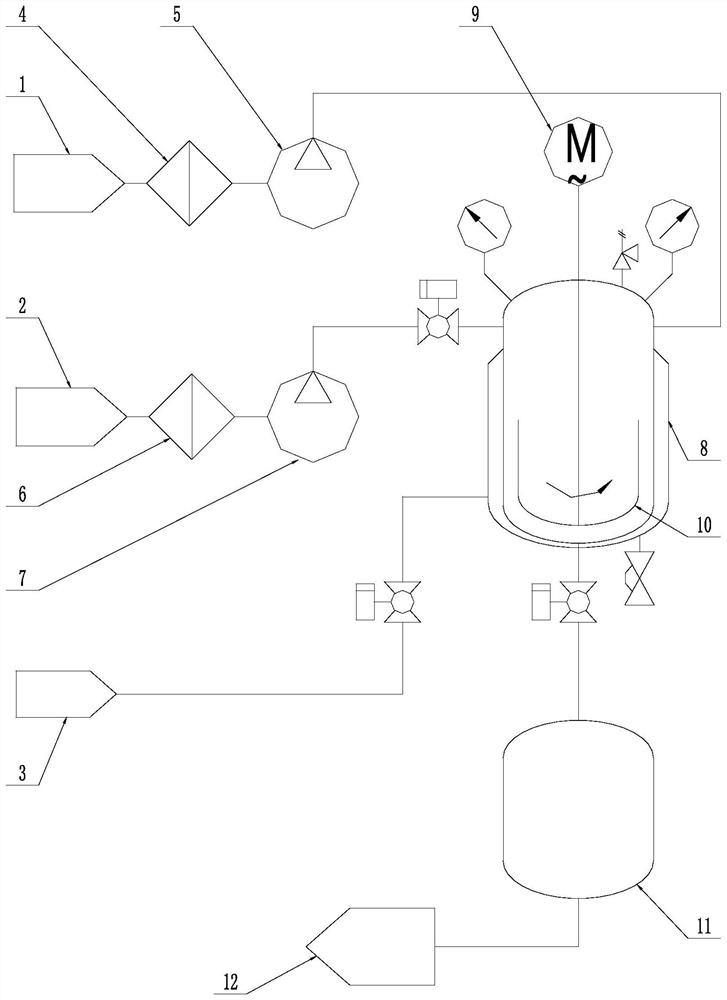

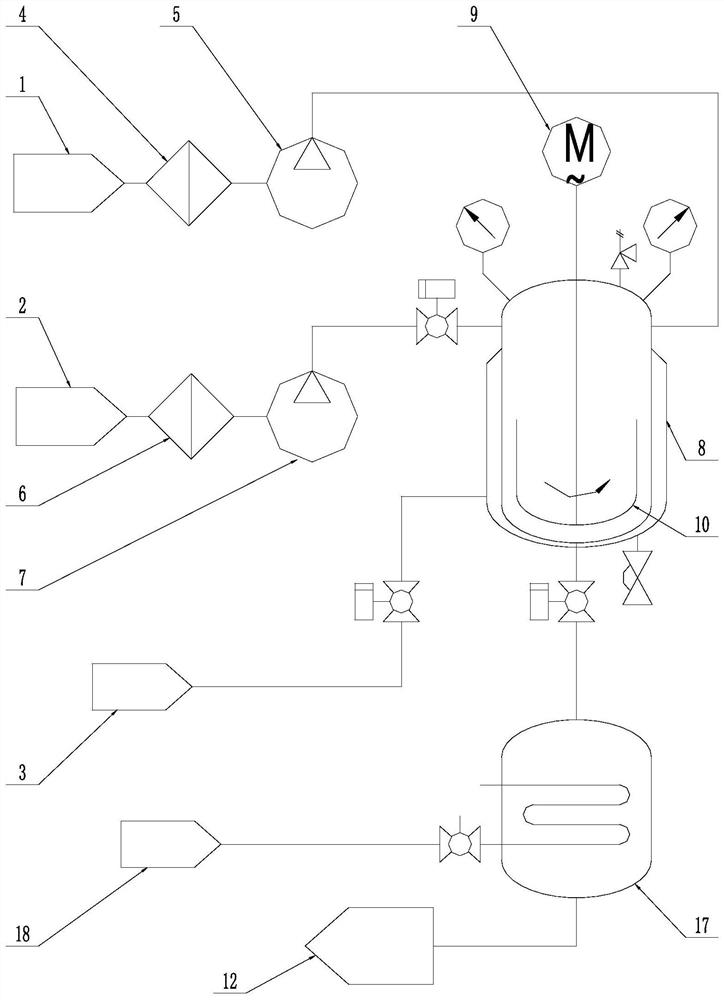

Method for producing monopentaerythritol, bipentaerythritol and tripentaerythritol

ActiveCN101265166AHigh selectivityAlkaline concentration decreasedOrganic compound preparationHydroxy compound preparationCalcium hydroxideFormic acid

The invention discloses a method of producing mono-pentaerythritol, dipentaerythritol and tri-pentaerythritol. The adopted production raw materials comprise acetaldehyde and formaldehyde. An activator adopts liquid alkali. The liquid alkali is sodium hydroxide or calcium oxide; neutralization reagent adopts formic acid solution; the acetaldehyde and the formaldehyde are both dived into a pre-condensation kettle which is pressurized with inert gases. Reaction liquid reacts for a period in the pre-condensation kettle, and then the reaction liquid is shifted to a main condensation kettle which is pressurized with the inert gases to keep on reacting. The alkalinity of the reaction liquids in both reaction kettles is maintained to be different. The concrete method comprises the following steps: materials preparation, charging pre-condensation, the diversion of the reaction liquid, constant temperature condensation, neutralization and separation, etc. By adopting the technology, the yield rate of the dipentaerythritol is enhanced to 45 percent from existing 21 percent, and the main conversion rate of the acetaldehyde is more than 90 percent.

Owner:CHIFENG RUIYANG CHEM

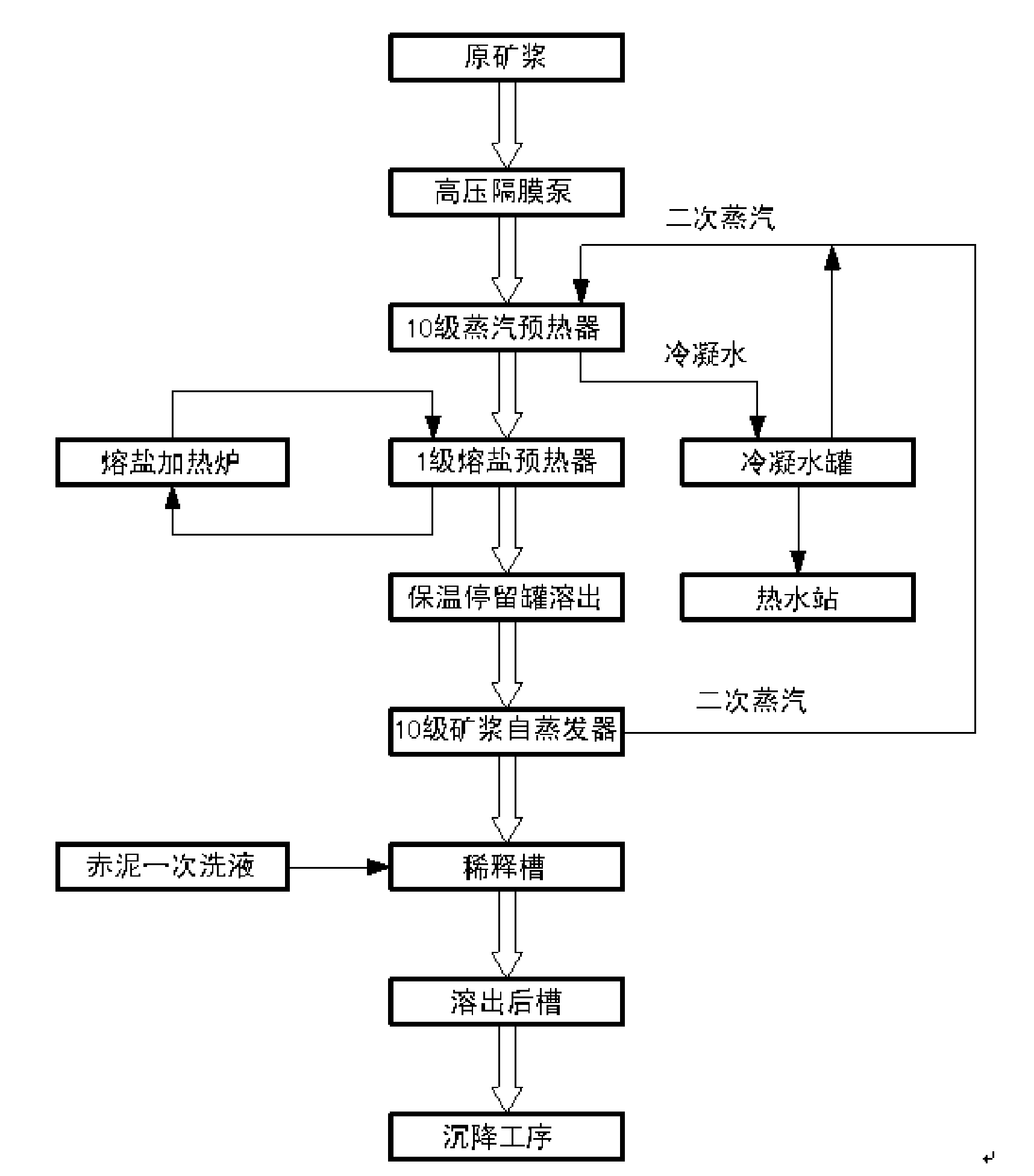

Alumina melting method

InactiveCN101671042AReduce scarring speedHigh heating temperatureAluminium oxides/hydroxidesAlkalinityRed mud

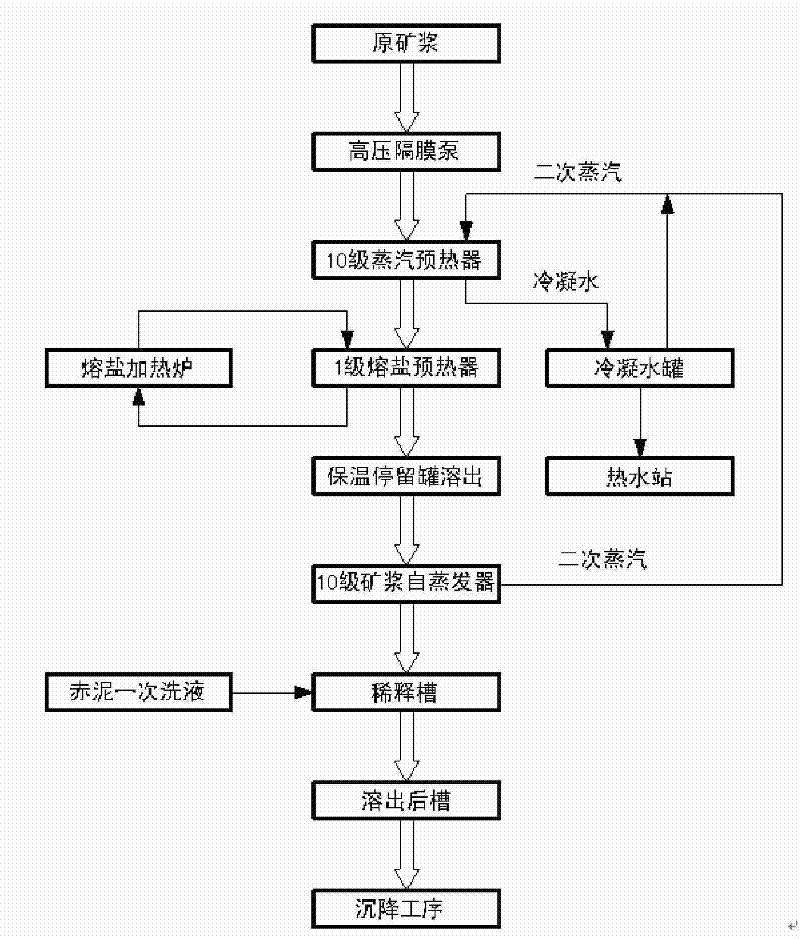

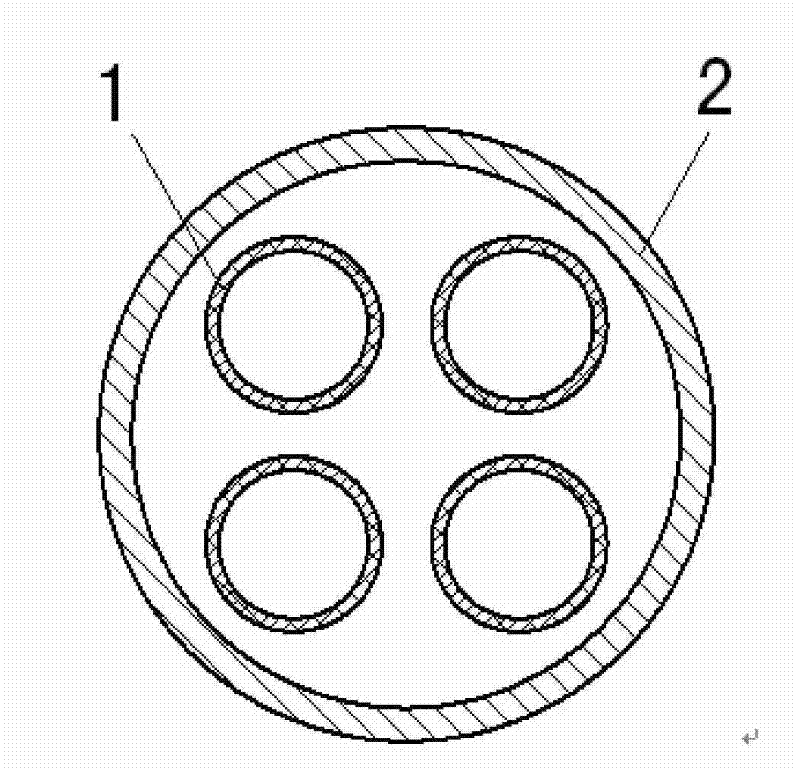

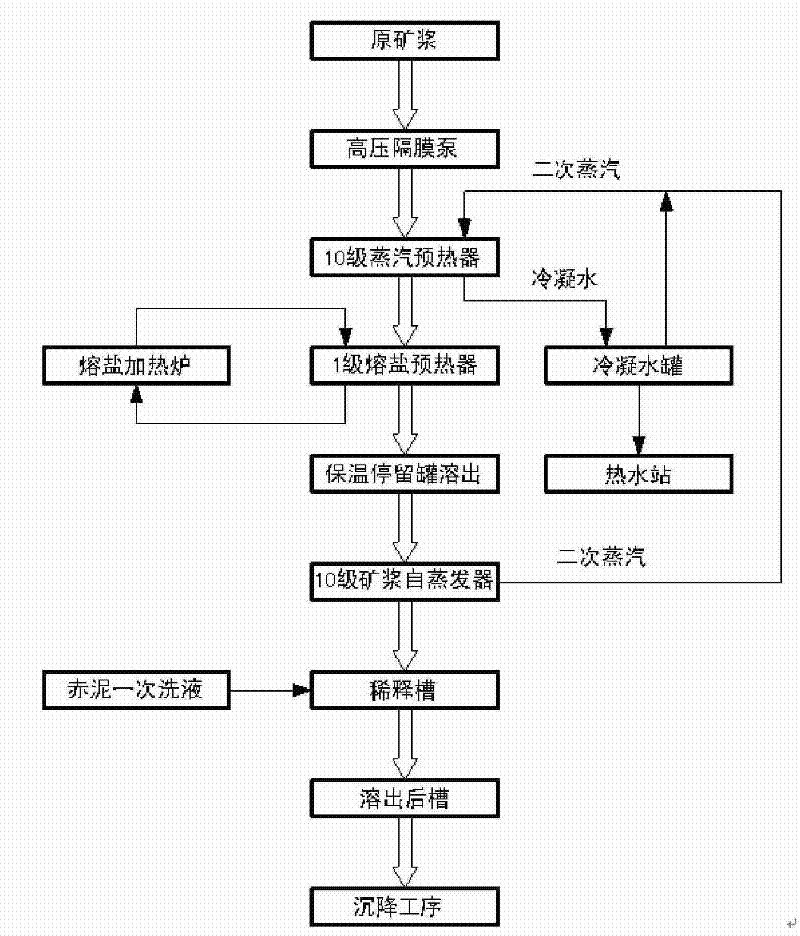

The invention discloses an alumina melting method. The melting method comprises the following steps: a. conveying primary ore pulp from a normal-pressure desiliconization process with the temperatureof 85-100 DEG C into a vapor preheater for preheating to 200-230 DEG C; b. conveying the ore pulp preheated by the vapor preheater into a molten salt heater for heating to 260-280 DEG C; c. conveyingthe ore pulp heated by the molten salt heater into an insulated melting tank for heat preservation for 30-45 minutes until a melting process is finished; d. conveying the melted ore pulp into a ore pulp self evaporator to decrease temperature and pressure; and e. conveying the ore pulp evaporated and concentrated in the self evaporator into a diluting tank, and diluting and mixing with a primary red mud washing fluid. The invention improves the heating temperature of the ore pulp to 280 DEG C, decreases the alkalinity of the primary ore pulp, saves the construction investment and equipment cost, reduces the energy consumption of an evaporation process, improves the utilization rate of secondary vapor heat, delays the scaring speed of a sleeve and decreases the equipment maintenance cost.

Owner:中铝国际技术发展有限公司

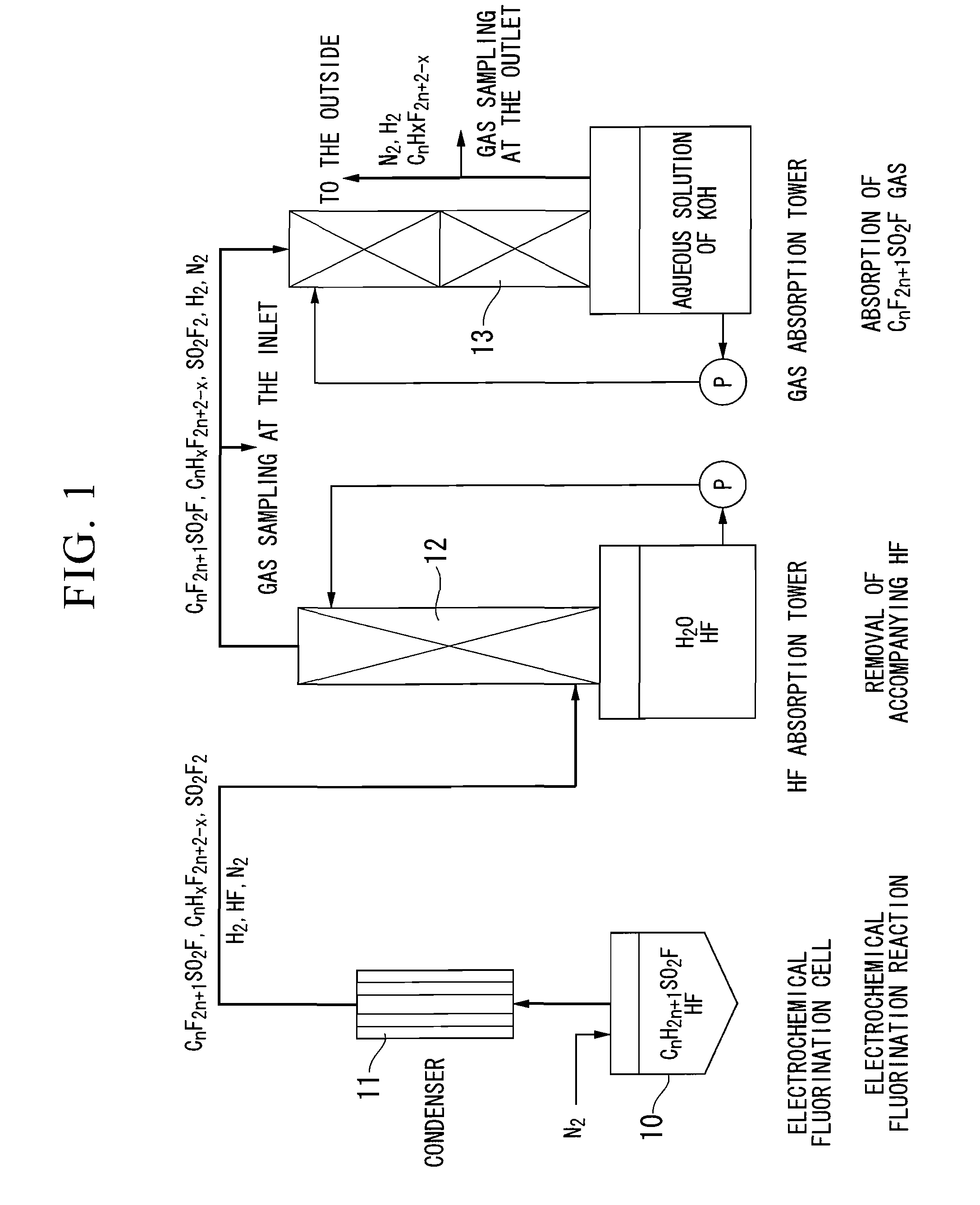

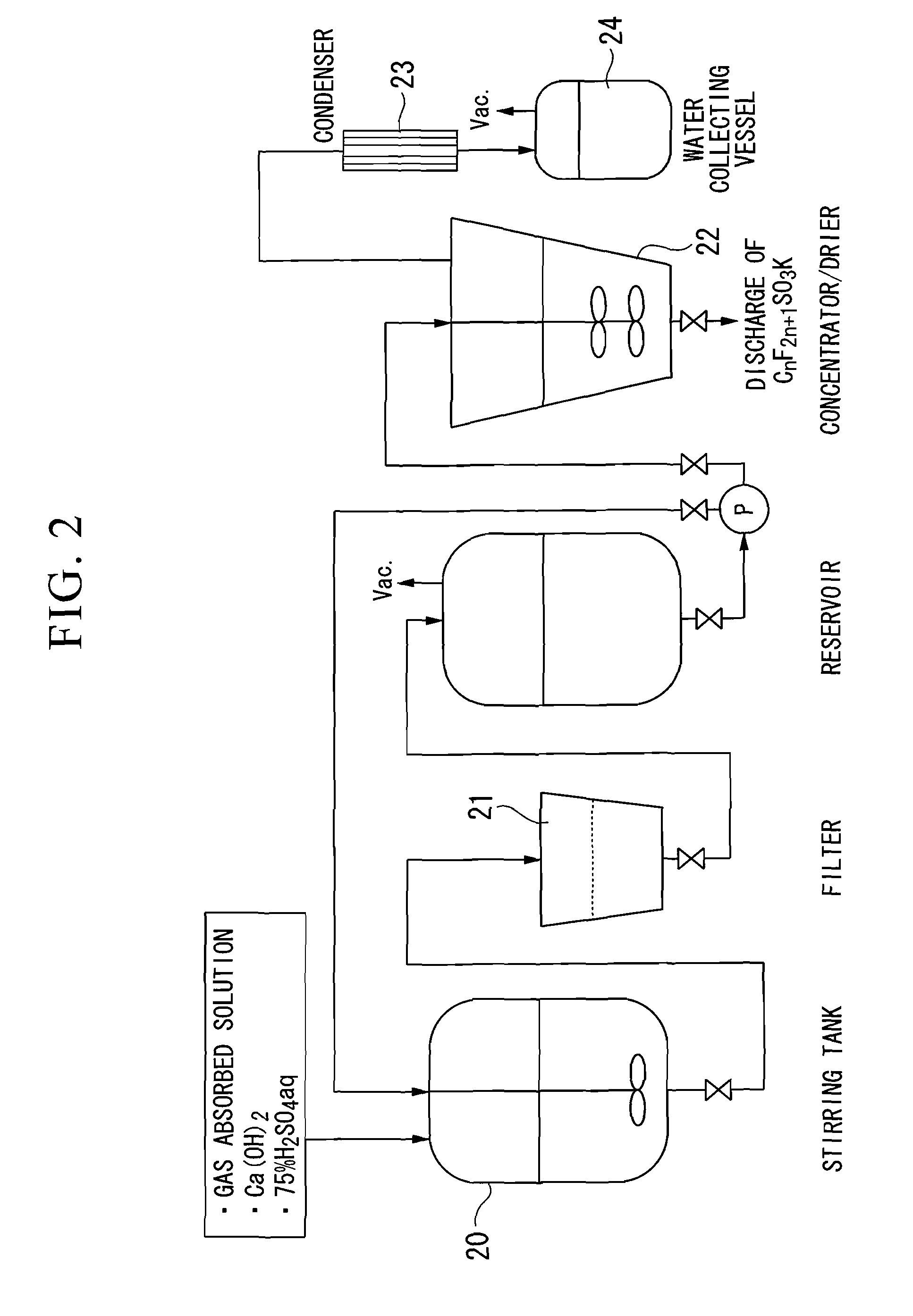

Potassium perfluoroalkanesulfonate and method for producing the same

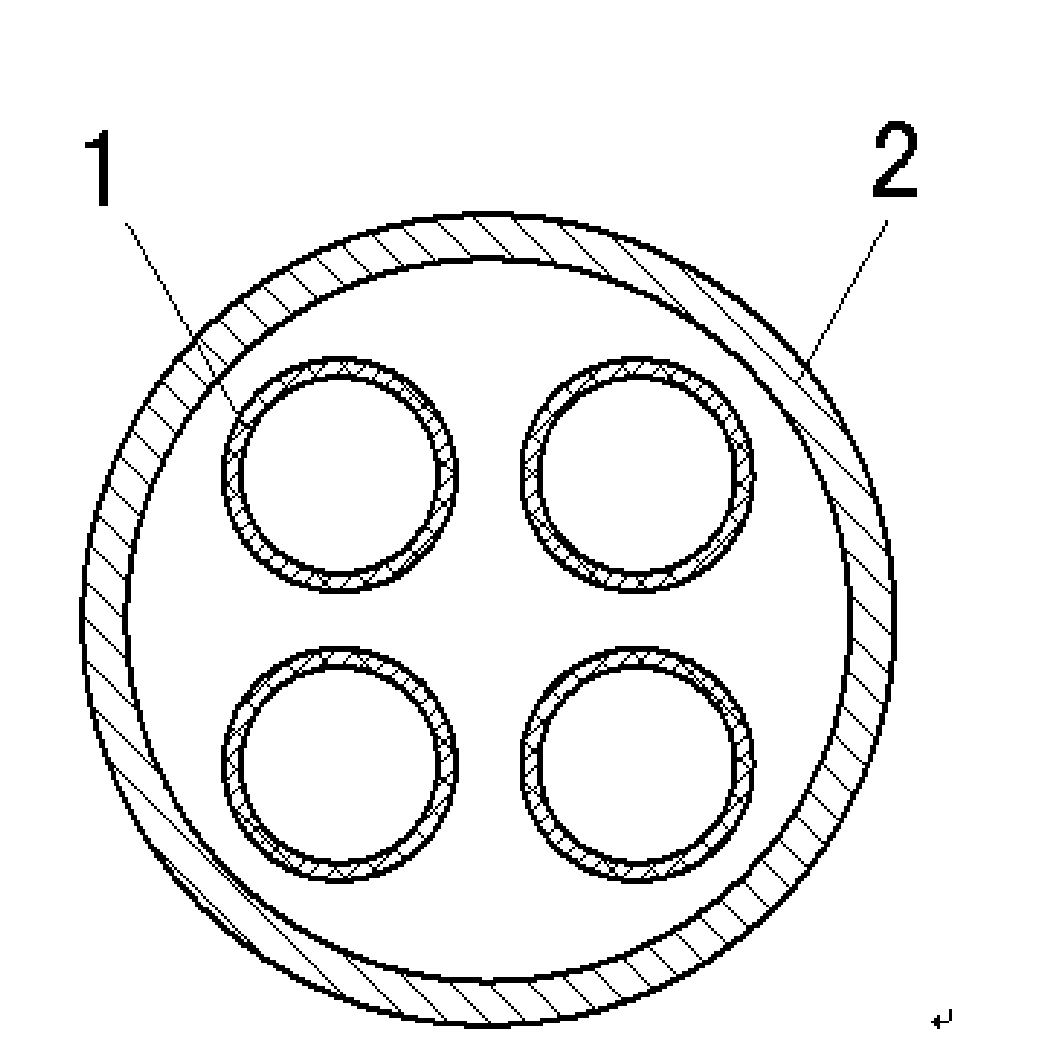

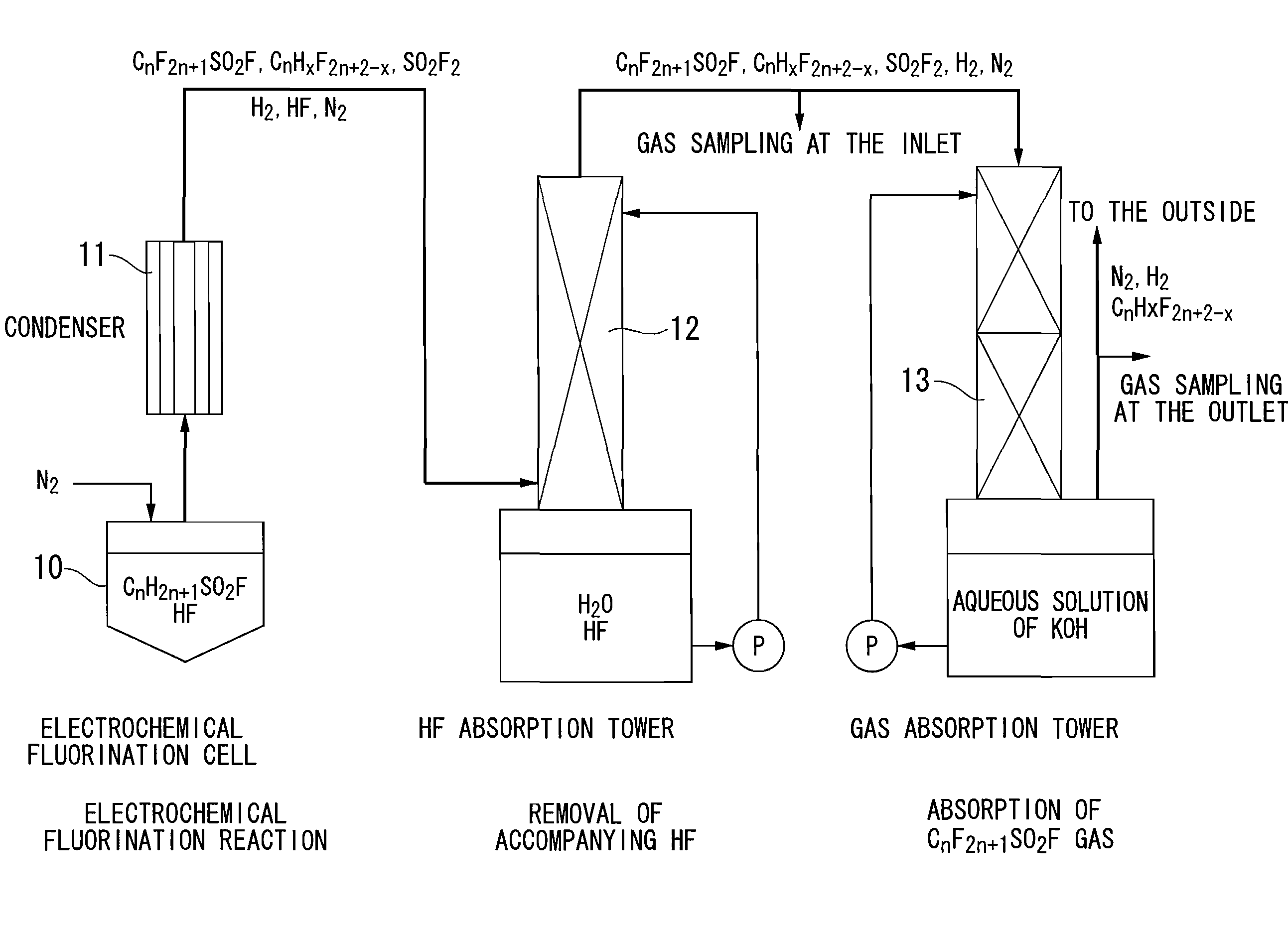

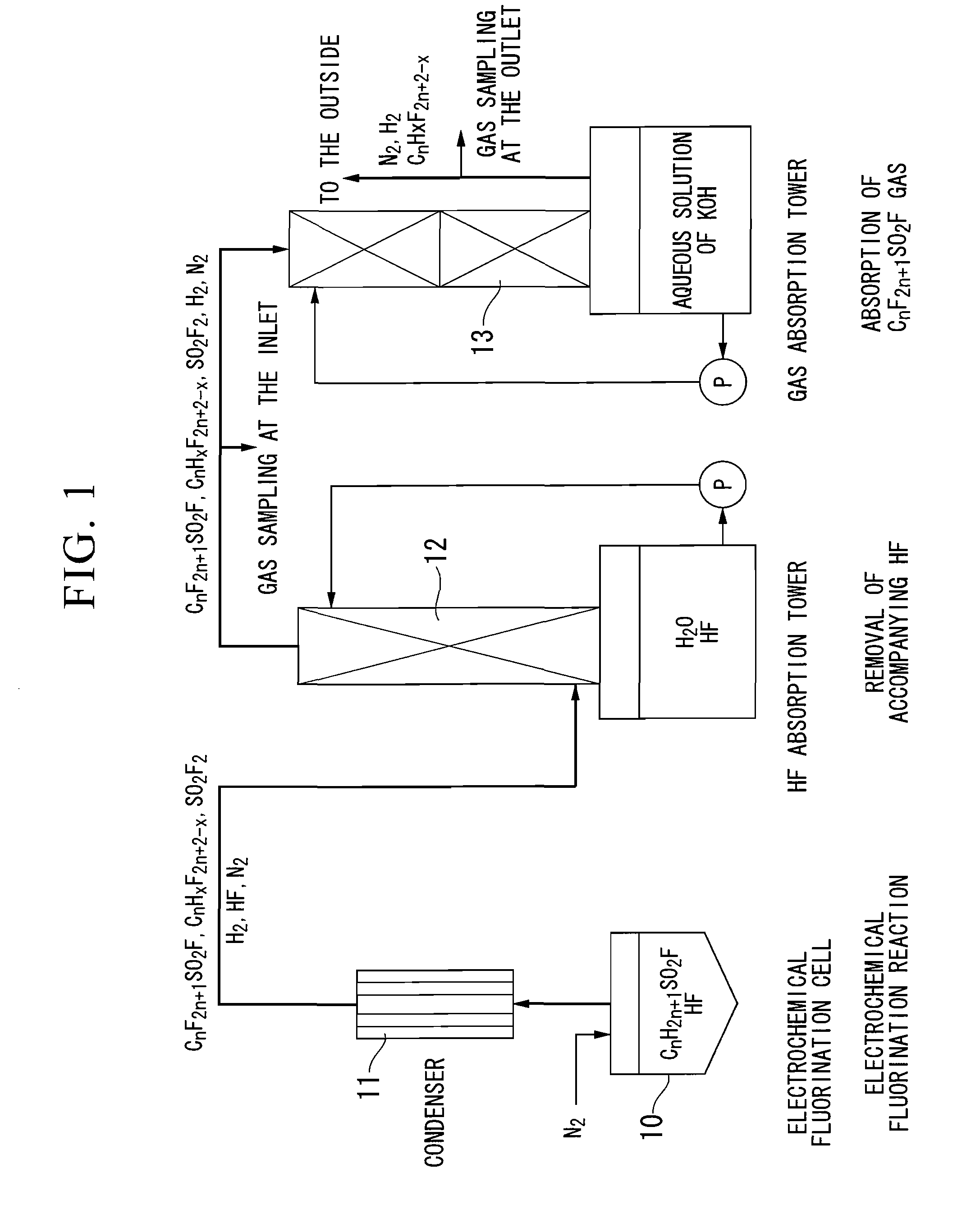

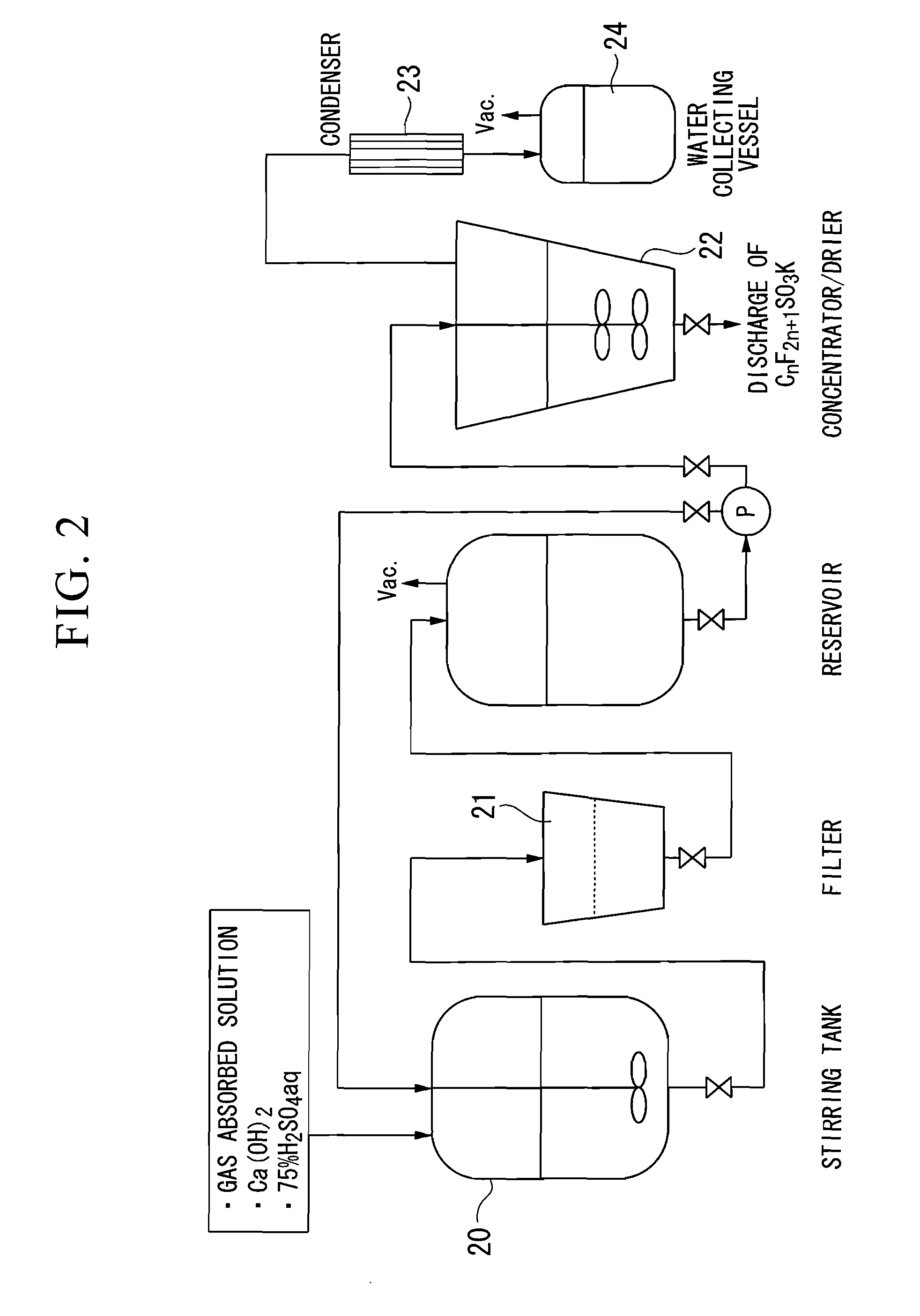

InactiveUS20090143613A1Alkali concentration is decreasedThe process steps are simpleElectrolysis componentsOrganic compound preparationHydrogen fluoridePotassium fluoride

This method for producing a potassium perfluoroalkanesulfonate includes an electrochemical fluorination step in which an alkanesulfonyl halide compound is subjected to electrochemical fluorination in anhydrous hydrogen fluoride, thereby to generate a production gas containing perfluoroalkanesulfonyl fluoride as the main component. In addition, for example, the methods may include a gas absorption step in which the production gas is reacted with an aqueous solution of potassium hydroxide, thereby to generate a gas absorbed solution containing potassium perfluoroalkanesulfonate, a purification step in which impurities such as potassium fluoride, potassium hydroxide, and potassium sulfate, are removed, and a concentration and collection step in which the aqueous solution from which the impurities are removed is concentrated and dried. In the electrochemical fluorination, for example, it is possible that the proton concentration in the reaction solution is maintained in the range of 150 to 1,500 ppm to suppress the formation of byproducts.

Owner:MITSUBISHI MATERIALS CORP +1

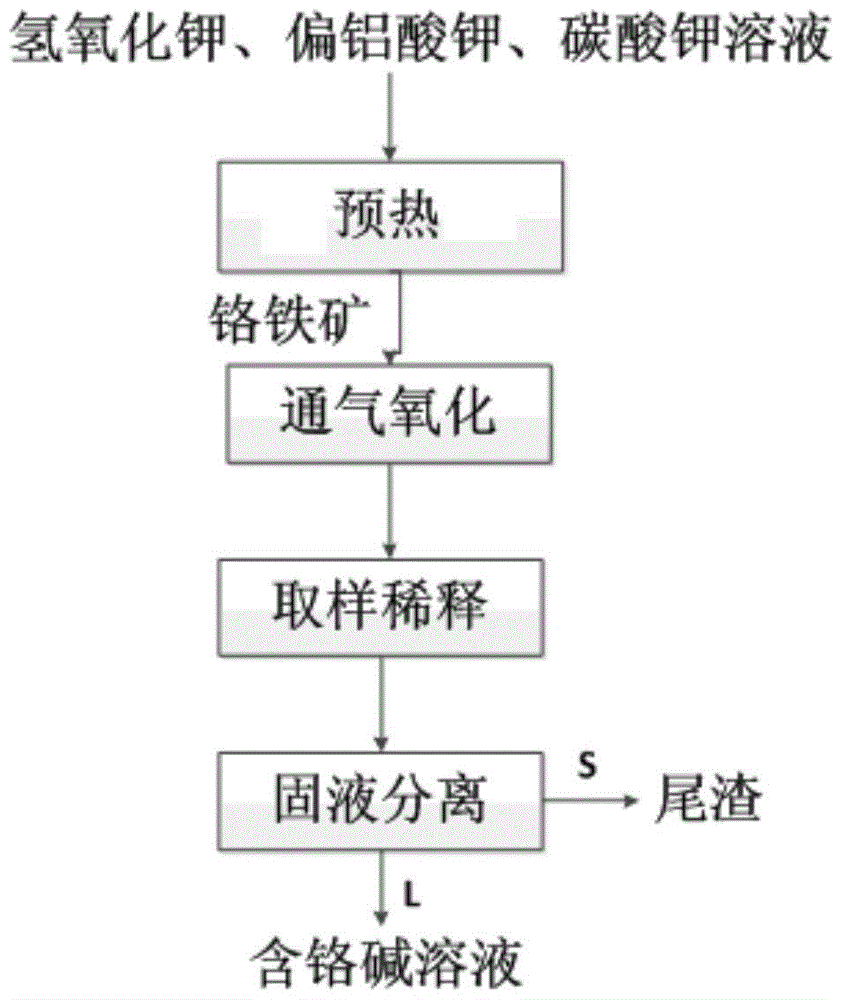

Method for decomposing chromite by low-temperature atmospheric-pressure fluidization

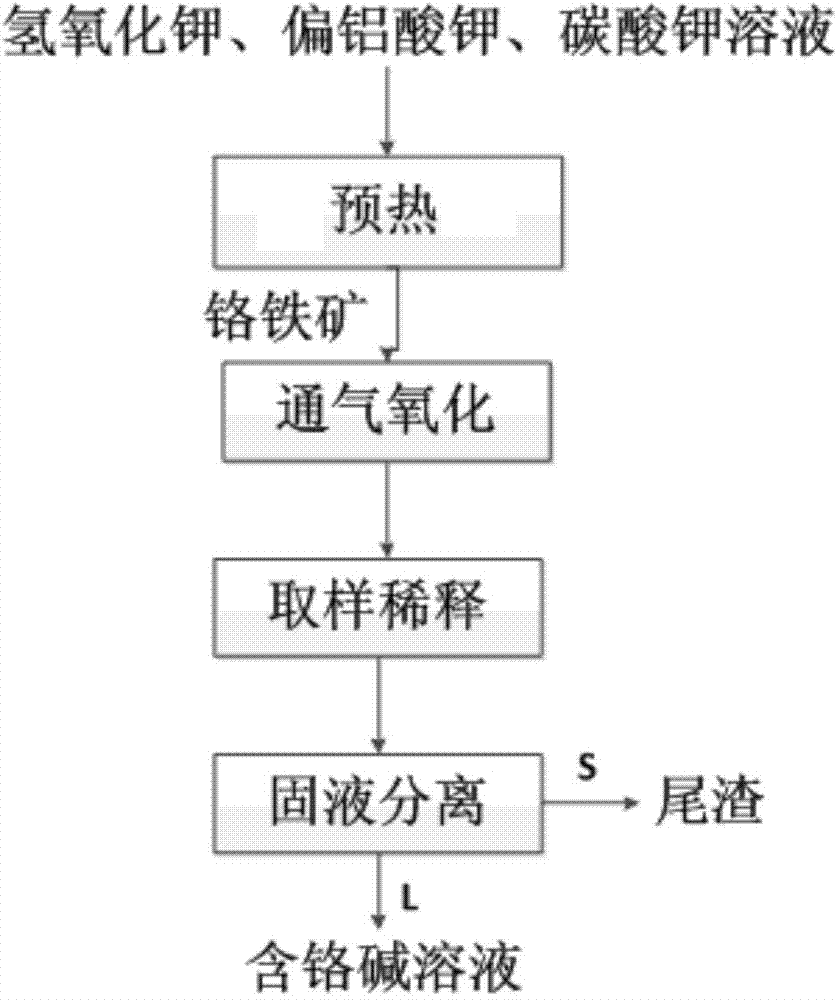

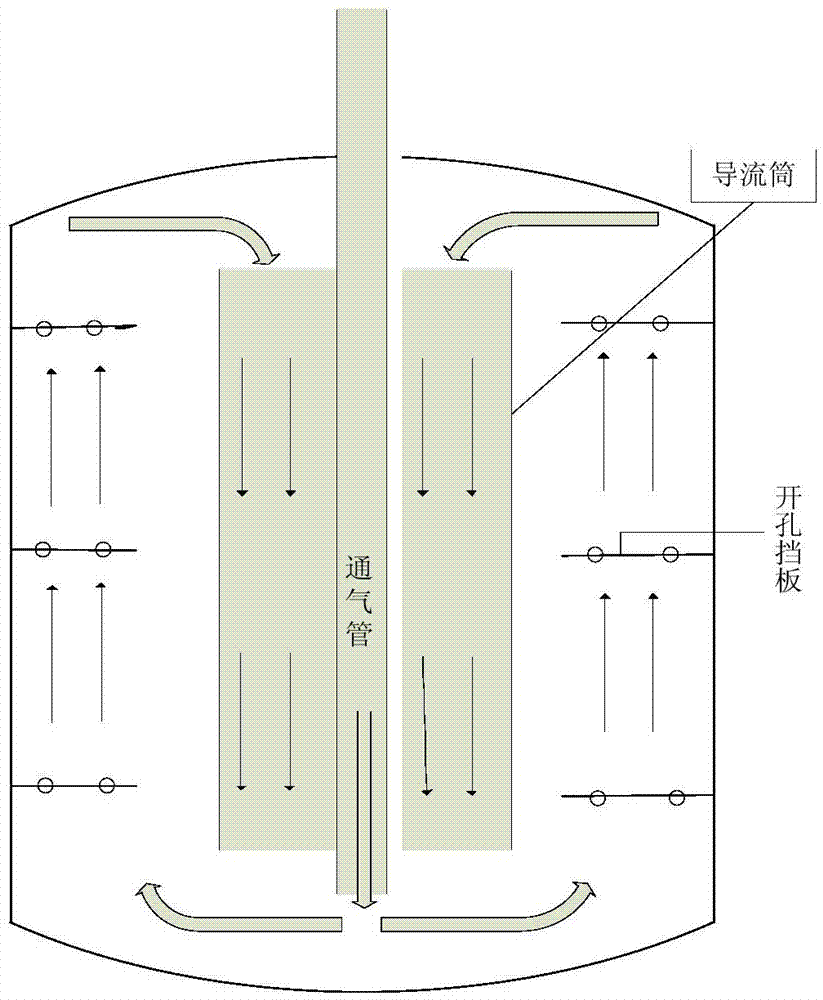

ActiveCN104726689ASimple ingredientsEasy to industrializeProcess efficiency improvementReaction temperaturePotassium hydroxide

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

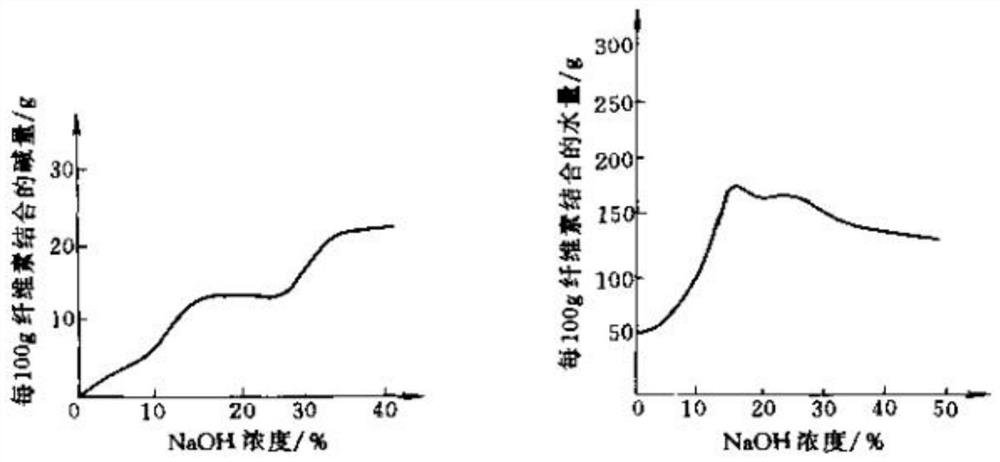

Method for producing calcium carboxymethyl cellulose

InactiveCN102863540AIncrease contact areaReduce the temperatureCarboxymethyl celluloseCARBOXYMETHYLCELLULOSE CALCIUM

A method for producing calcium carboxymethyl cellulose includes: soaking refined cotton in diluted hydrochloric acid, then neutralizing and activating the soaked refined cotton with diluted sodium hydroxide, enabling the prepared refined cotton to react with sodium chloroacetate so as to generate sodium carboxymethyl cellulose, displacing by hydrochloric acid and calcifying so that the calcium carboxymethyl cellulose is obtained finally. The method for producing the calcium carboxymethyl cellulose is simple in production process and operation, low in cost, small in wastewater generation quantity and less destructive to the environment.

Owner:WUXI KAILI PHARMA

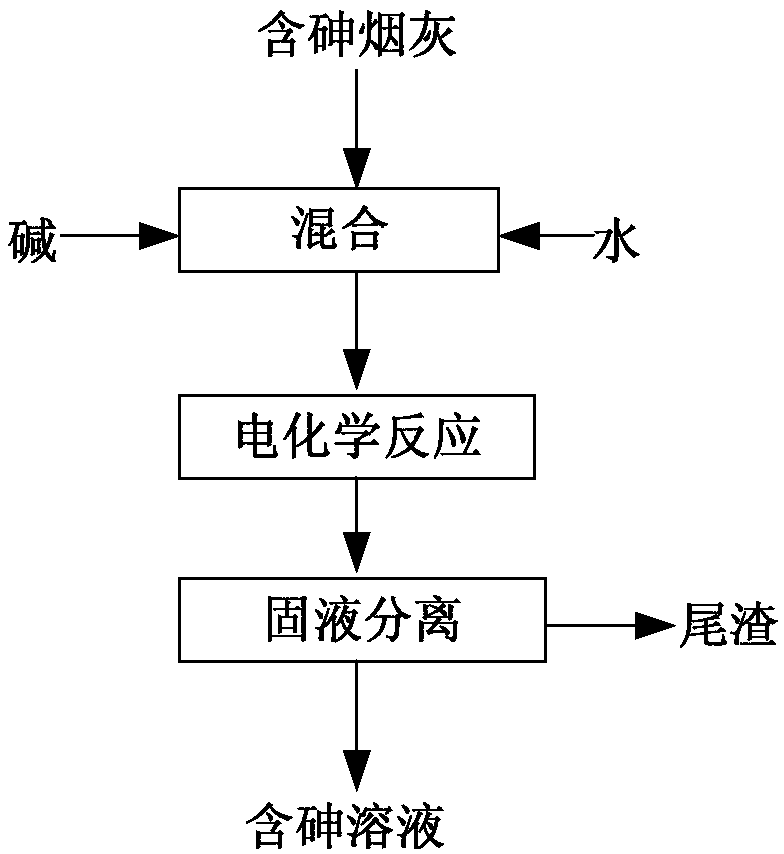

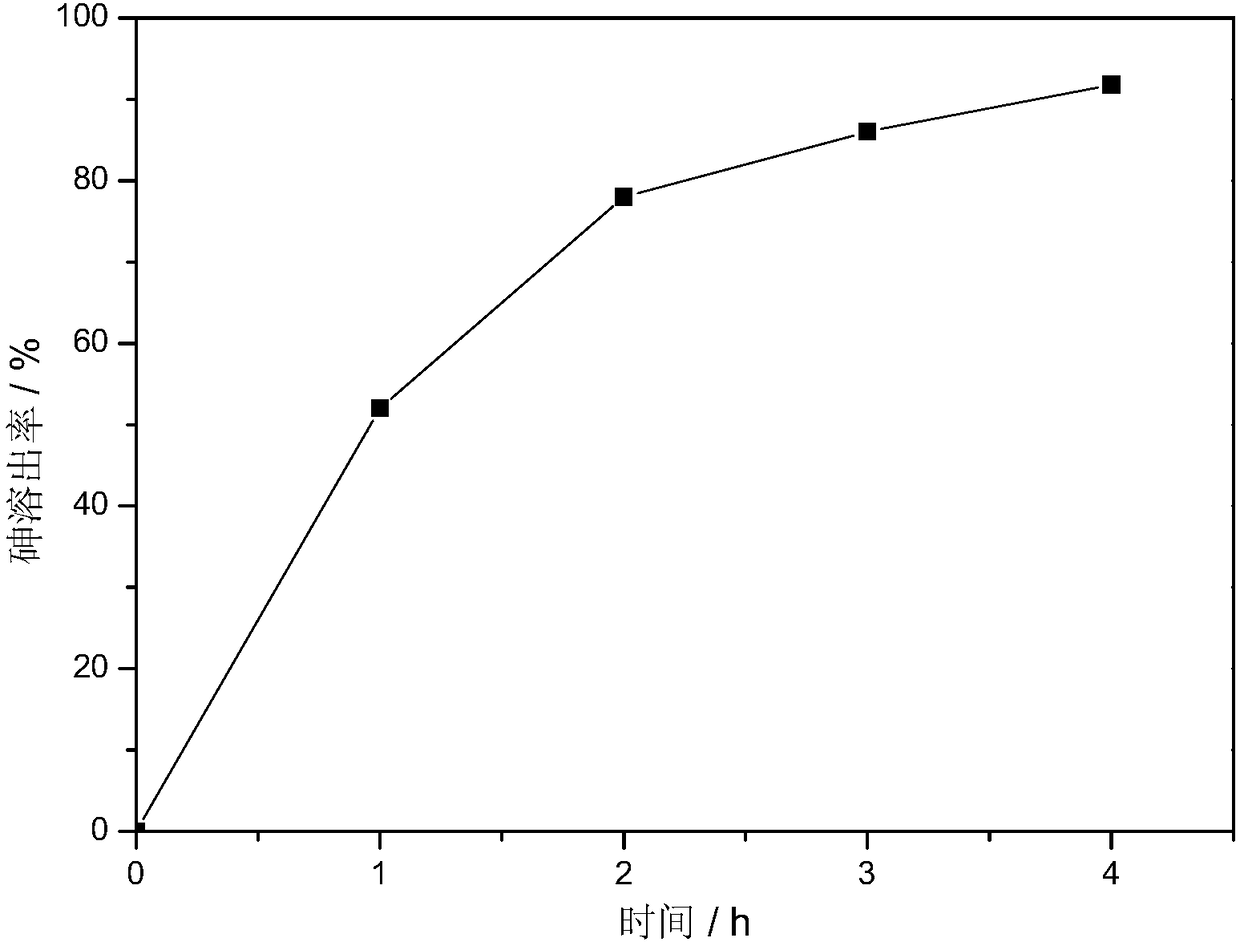

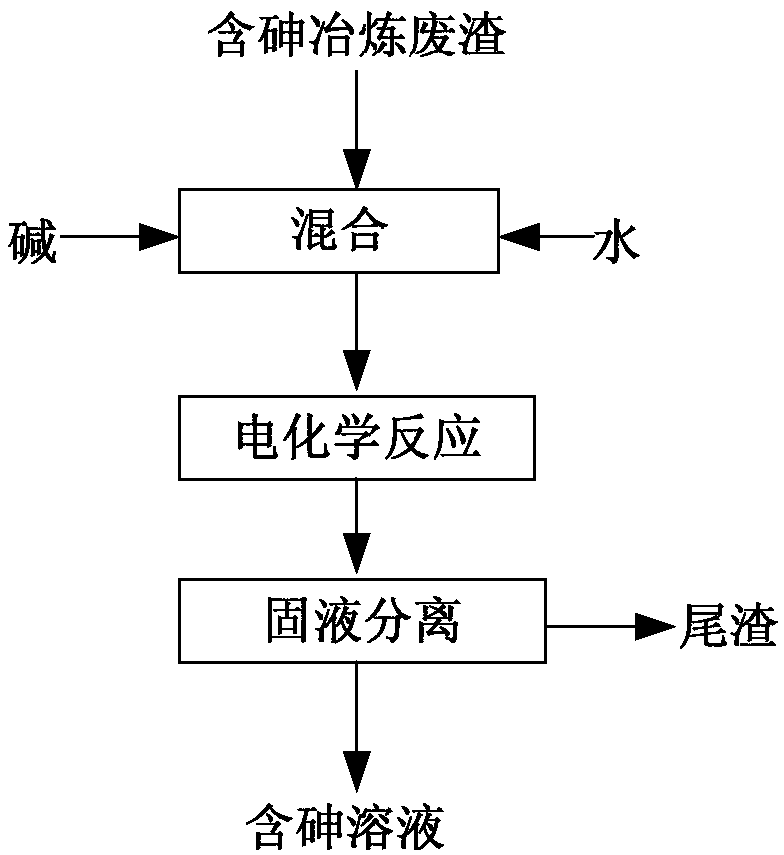

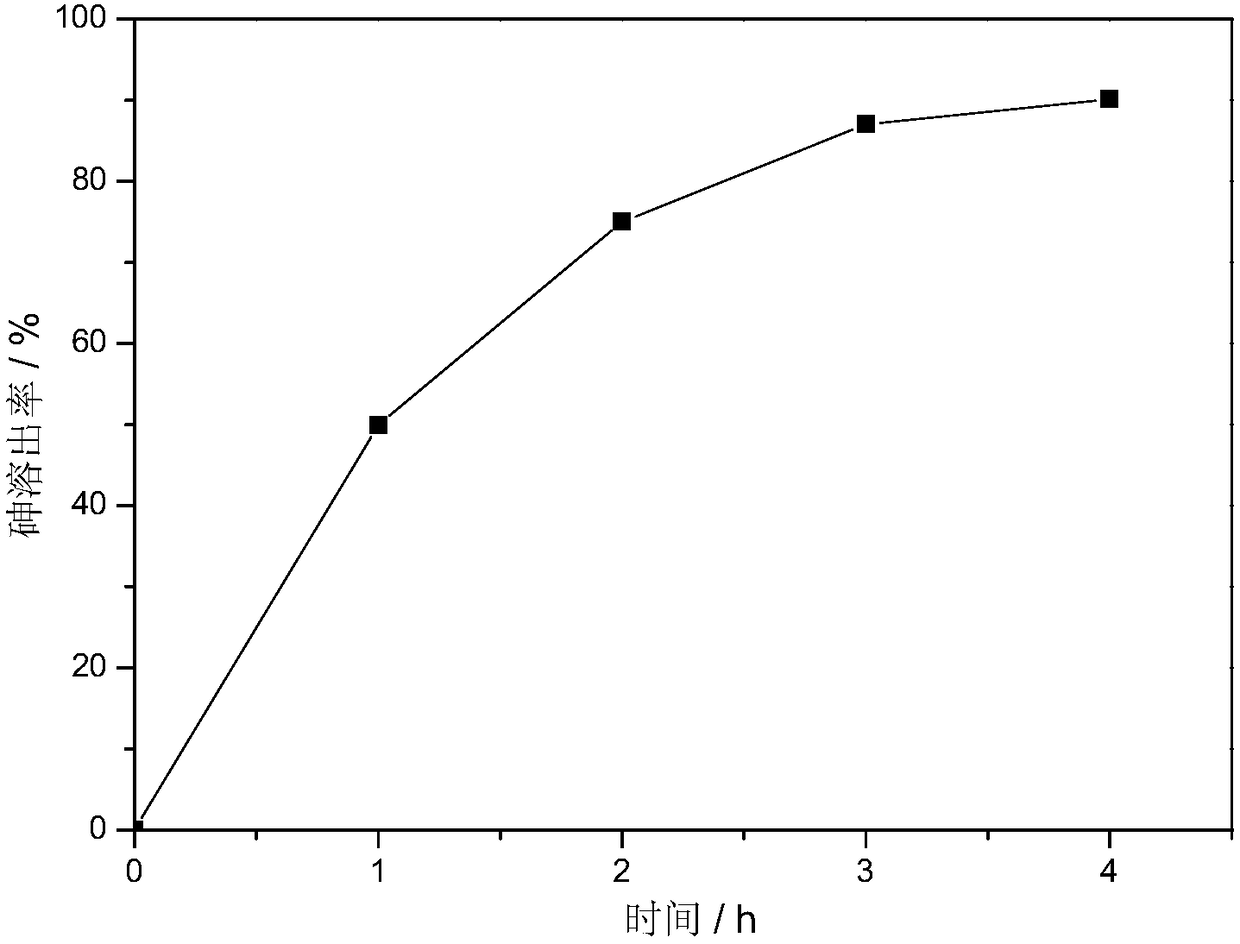

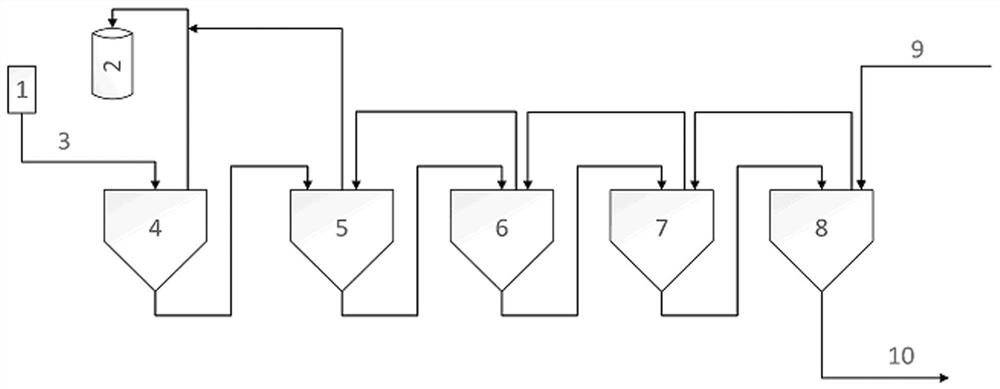

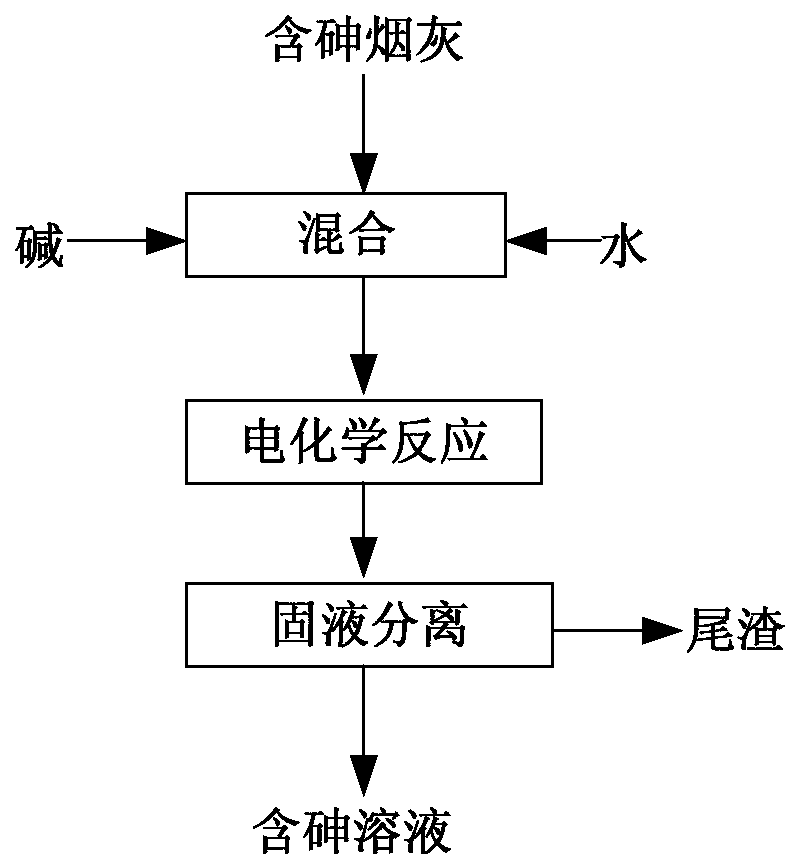

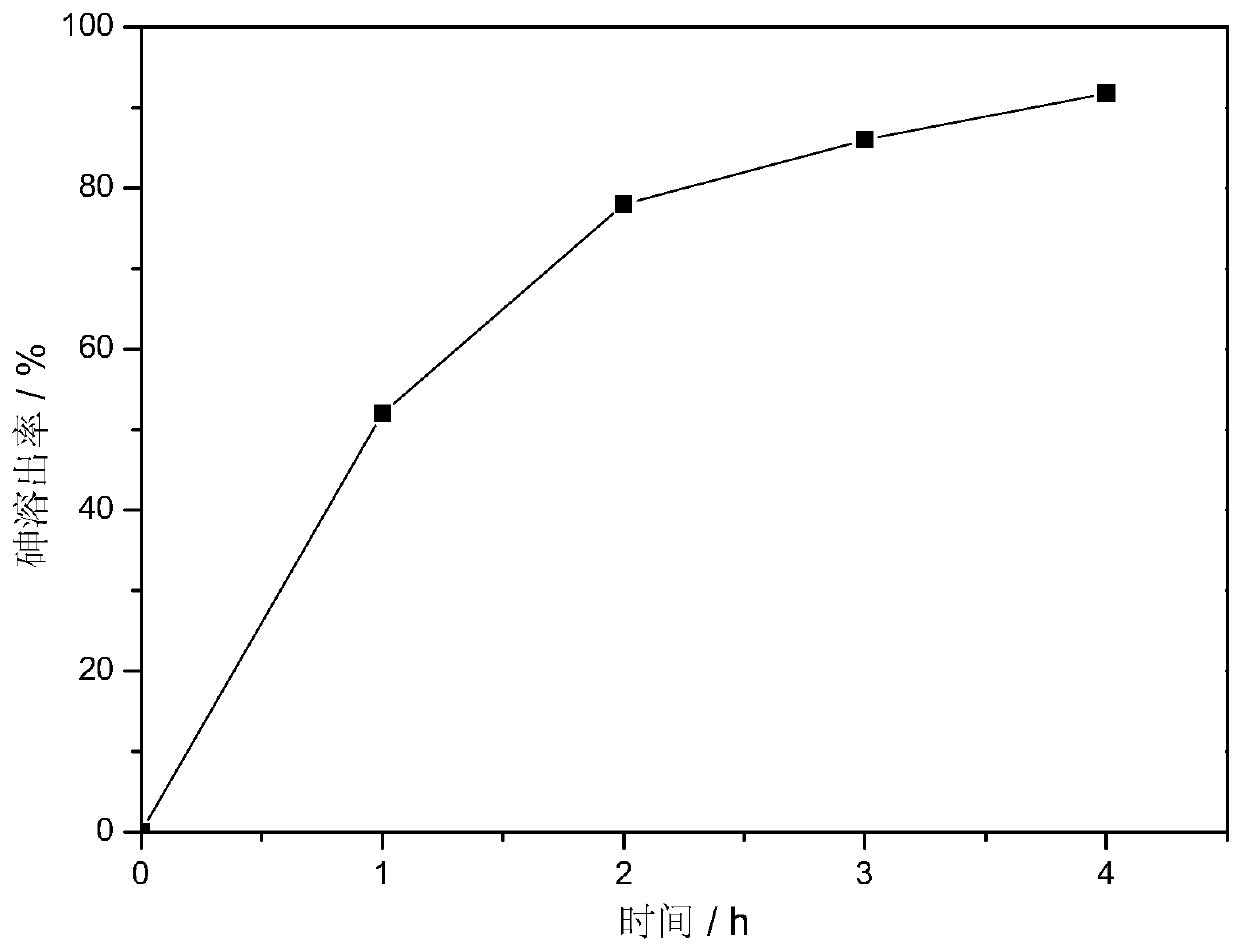

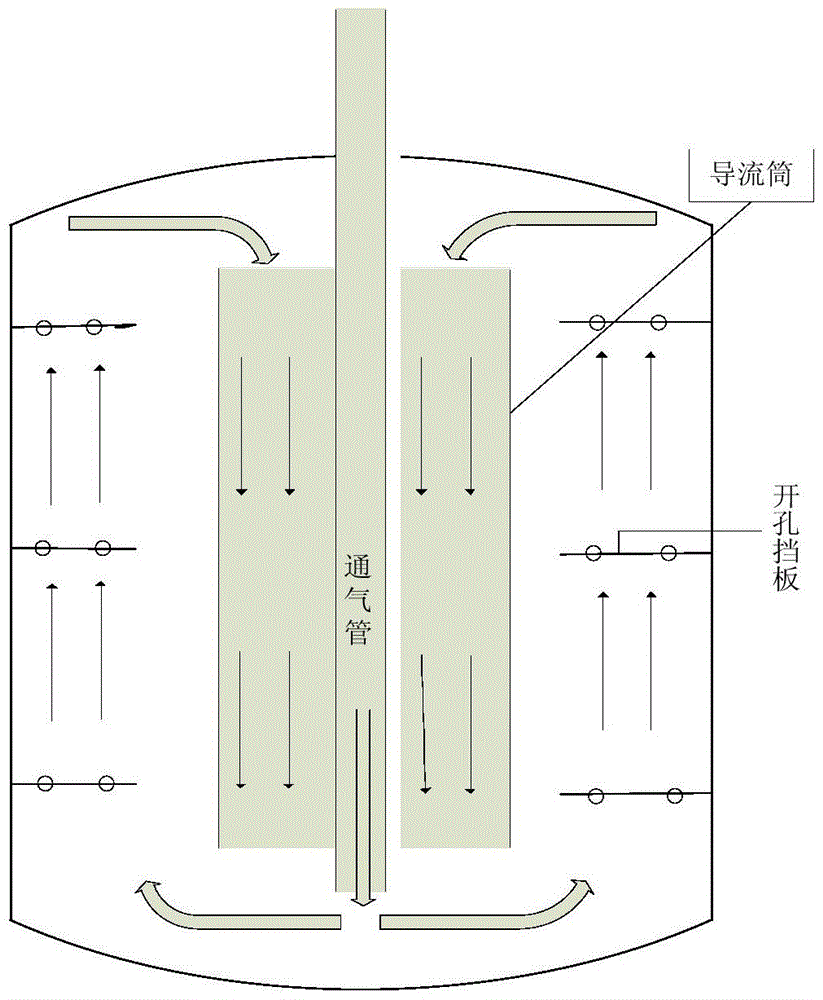

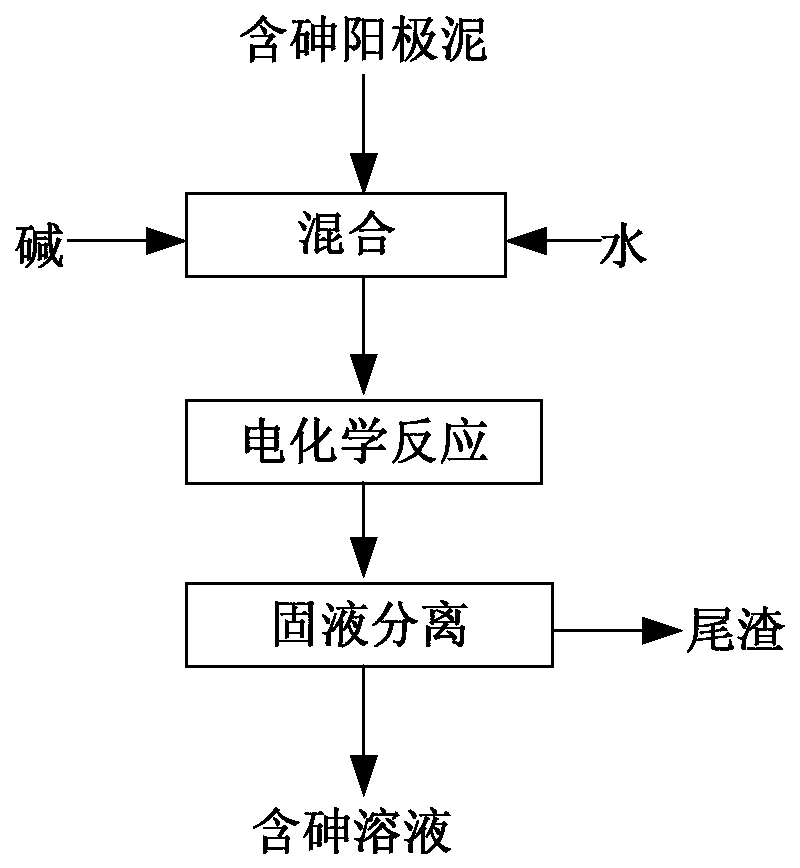

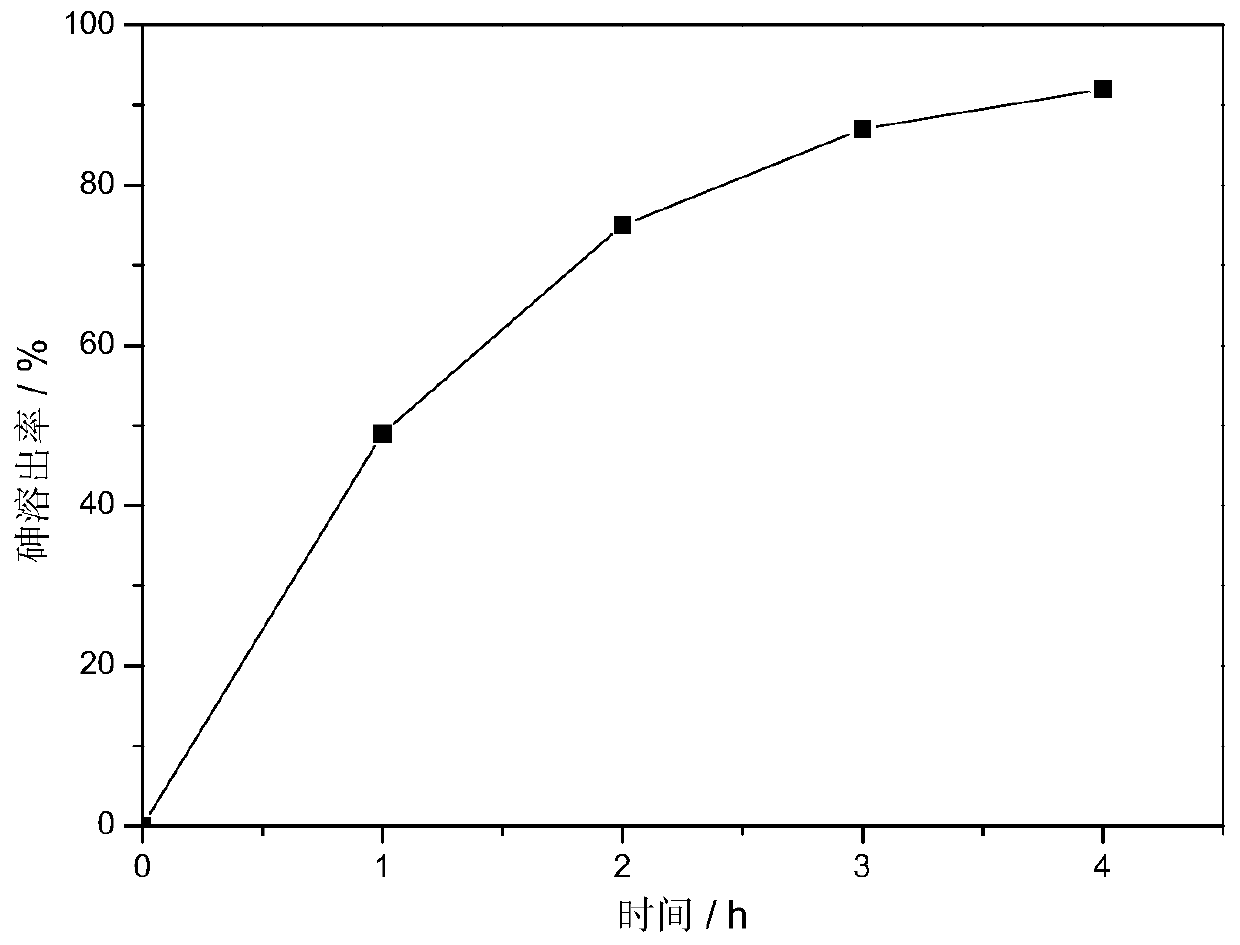

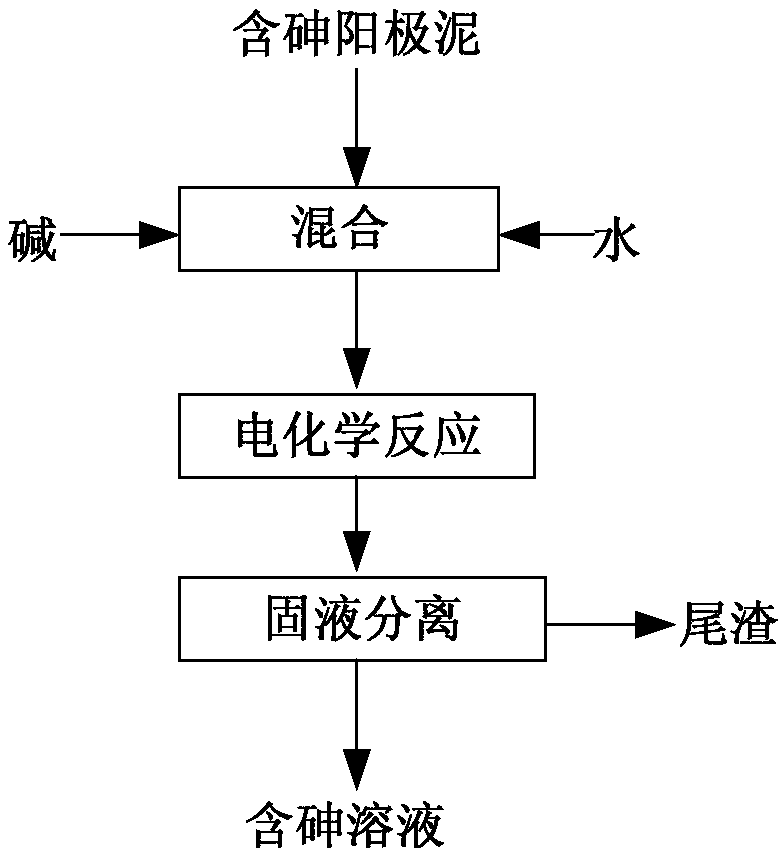

Electrochemical treatment method for arsenic-containing soot

ActiveCN108570684AEfficient extractionReduce concentrationElectrode shape/formsProcess efficiency improvementElectrochemical responseSolvent

The invention provides an electrochemical treatment method for arsenic-containing soot. The electrochemical treatment method comprises: (1) mixing an alkali and a solvent or mixing an alkali solutionand arsenic-containing soot to obtain a mixture; (2) placing the mixture as an electrolyte in an electrochemical reaction device, carrying out an electrochemical reaction, and introducing an oxidizinggas into the electrolyte during the electrochemical reaction; and (3) carrying out solid-liquid separation on the reaction product obtained in the step (2) to obtain the arsenic-containing solution.According to the present invention, the method has advantages of high extraction rate of arsenic, cleaning property, no pollution, mild process condition, low cost and low requirements on equipment; the impurity is not introduced so as to conveniently perform the subsequent separation; the concentration of the used alkali is low so as to reduce the alkali consumption; and the automation degree ishigh so as to reduce the manpower input, the good economic and social benefits can be provided, and the good application prospect can be provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method of continuous culture of anaerobic bacterium

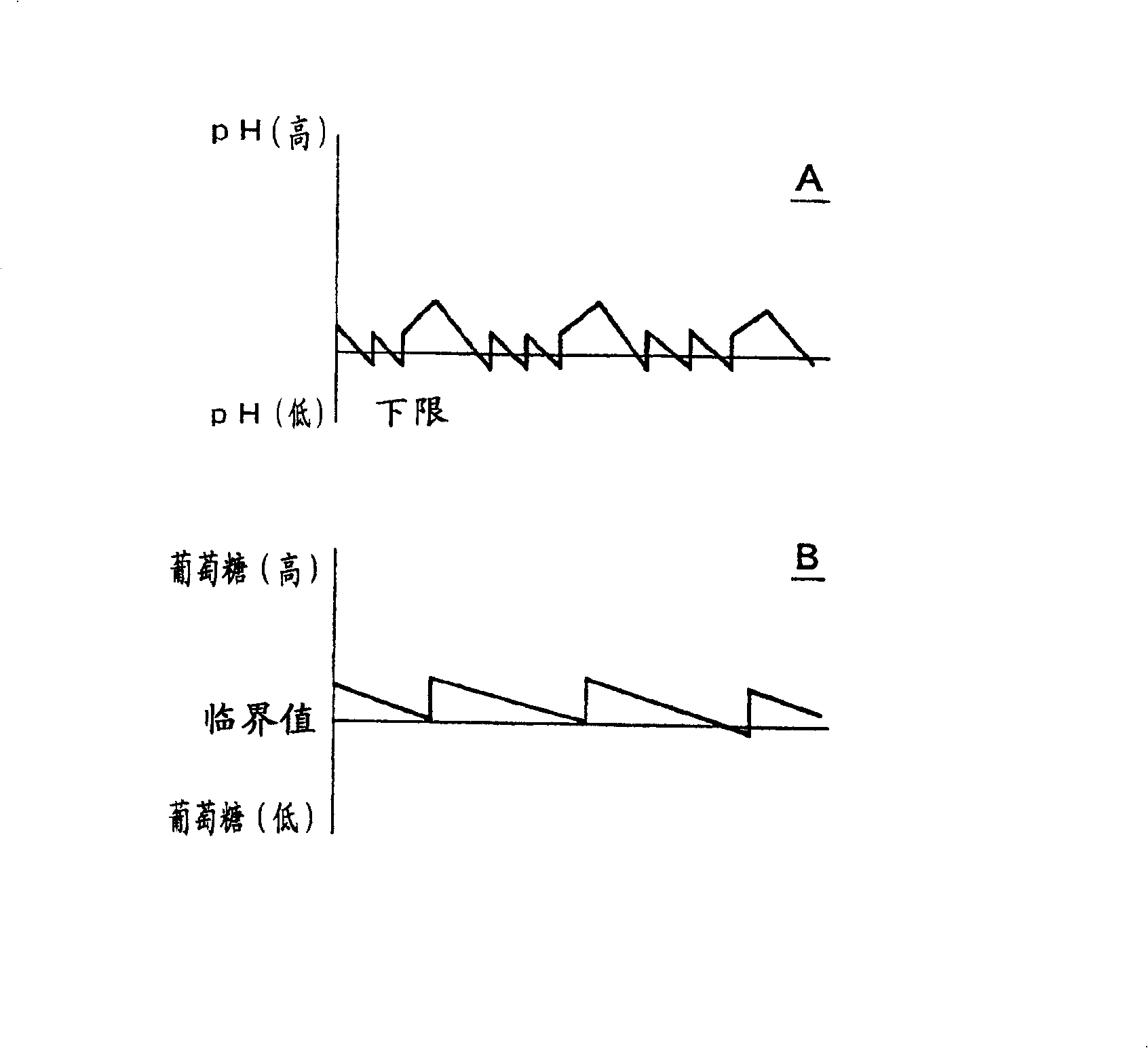

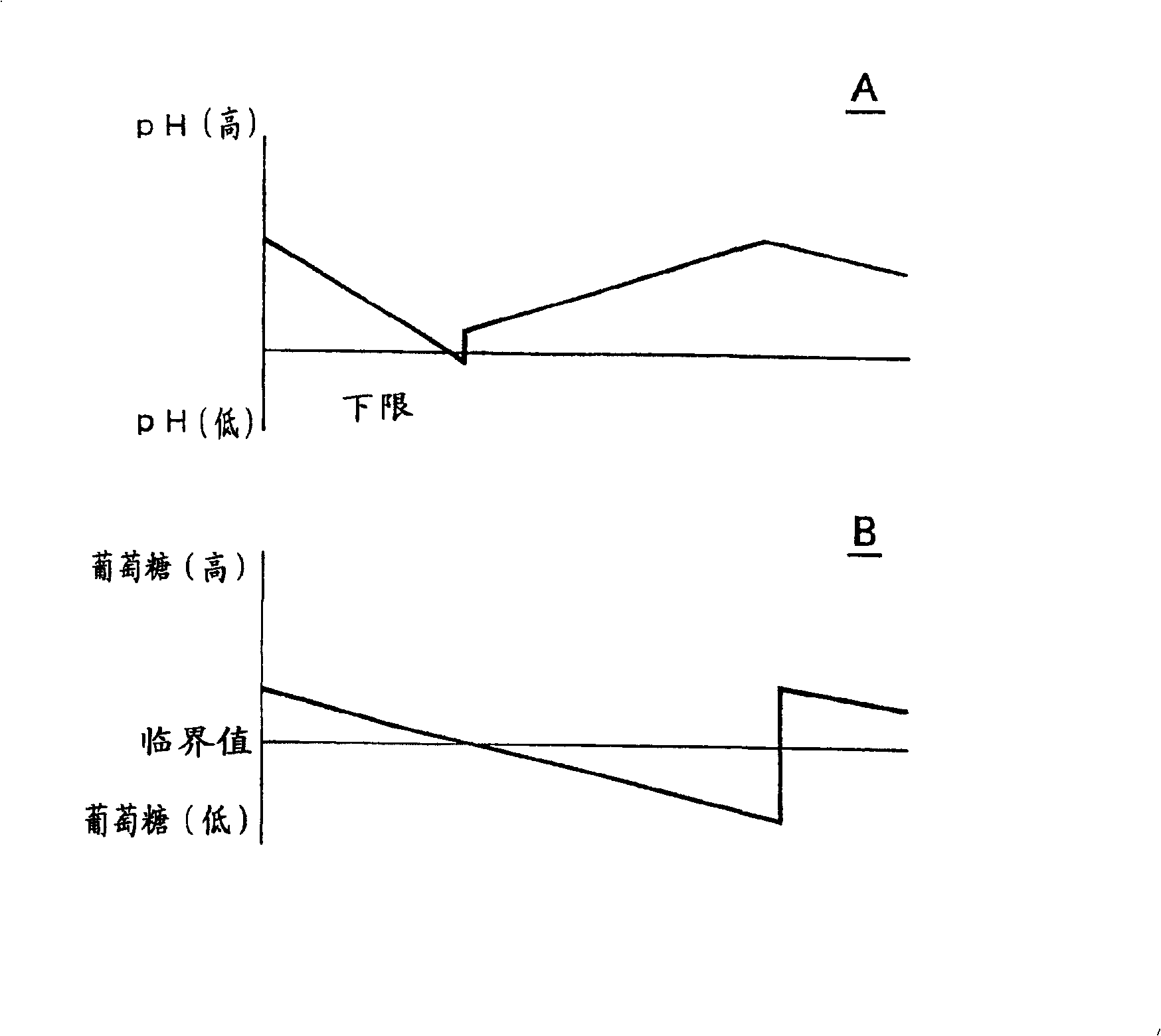

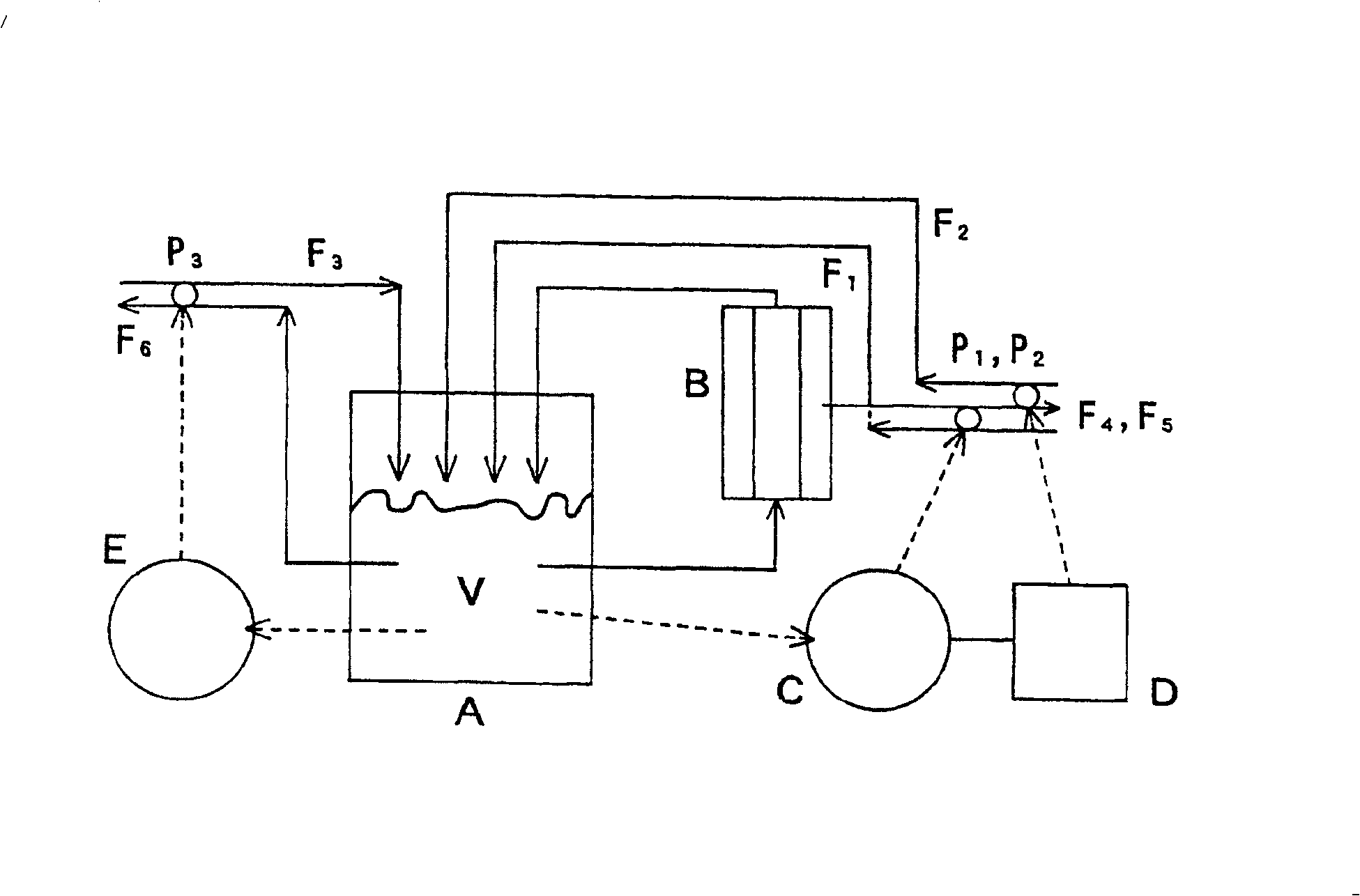

InactiveCN100434509CReduce inhibitionIncrease concentrationBacteriaBiofuelsOrganic acidContinuous fermentation

In a continuous fermentation system whereby an organic acid or an alcohol is continuously produced with the use of an aerobic bacterium, a substrate is fed based on the cumulative consumption (expressed in mole number) of an alkali added to regulate the pH value of the liquid culture medium at a constant level to thereby regulate the concentration of saccharides remaining in the liquid culture medium at a constant level.

Owner:SANWA SHURUI +1

Saline and alkaline land stock growing method and application

InactiveCN107912211AEasy to drainAlkaline concentration decreasedCultivating equipmentsSoil-working methodsAlkali soilWater filter

The invention relates to the field of plant cultivation, and particularly provides a saline and alkaline land stock growing method and application. A plant pit is provided, a water filter layer, a decaying plant straw layer and a soil improving layer are successively laid on the bottom wall of the plant pit, a waterproof layer and a decaying plant straw layer are successively laid on a side wall of the plant pit, and a tube is inserted in the plant pit. The purpose of reducing saline concentration can be achieved, and time and conditions for stocks to adapt to the environment are provided. Meanwhile, the water filter layer facilitates water drainage; after the decaying plant straw layer are decayed deeply, acid can be formed, and the effect of reducing alkaline concentration of soil is achieved; by the soil improving layer, the survival rate of stocks can be improved while soil quality is improved; and the tubes not only can breath and drain water, but also has a heat-dissipation effect. The stock growing method is simple to operate, the labor and materials are saved, the cultivation cost is low, the method is environmentally friendly, the survival rate of the stock is high, effects of wind prevention and sand fixation are achieved, water resources are improved, and thus, the saline and alkaline land stock growing method can be applied to production and life on a large scale.

Owner:CHENGBANG ECO ENVIRONMENT CO LTD

Potassium perfluoroalkanesulfonate and method for producing the same

InactiveUS8026391B2Alkaline concentration decreasedThe process steps are simpleElectrolysis componentsOrganic compound preparationHydrogen fluoridePotassium fluoride

Owner:MITSUBISHI MATERIALS CORP +1

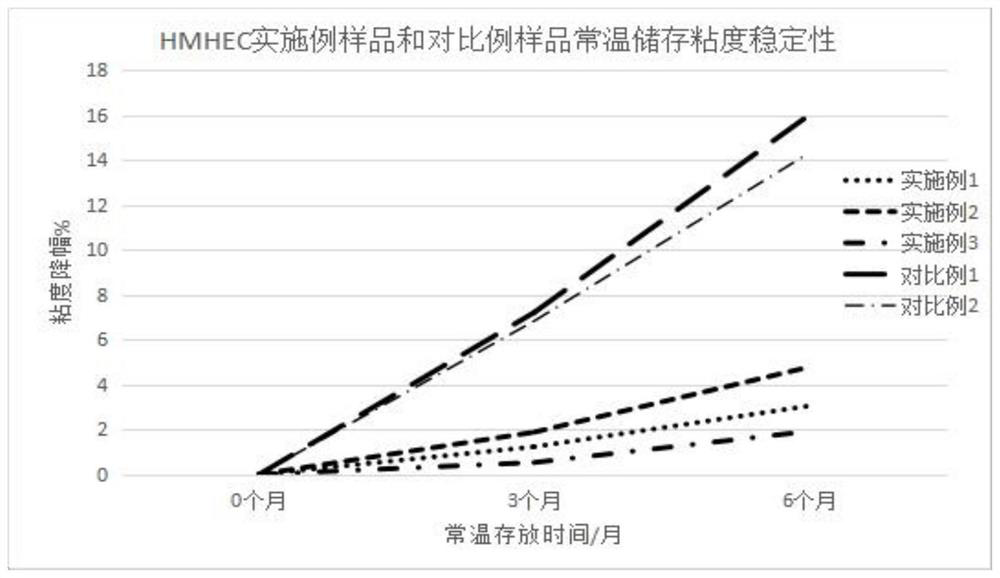

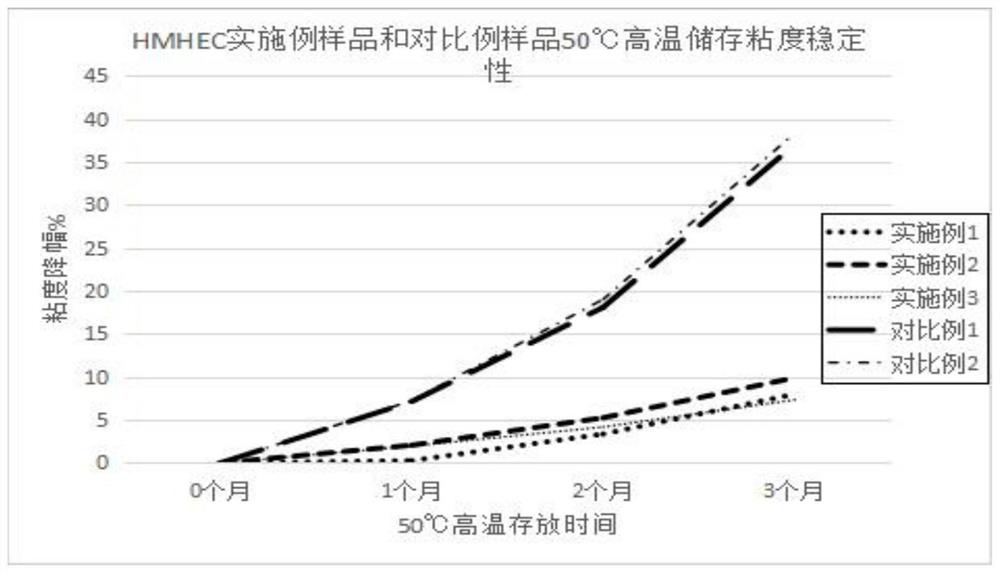

Preparation method of high-stability carboxymethyl hydroxyethyl cellulose

InactiveCN112409498AAlkaline concentration decreasedSlow reaction rateCelluloseHydroxyethyl cellulose

The invention discloses a preparation method of high-stability carboxymethyl hydroxyethyl cellulose, and belongs to the technical field of cellulose production. In order to solve the problem of poor viscosity stability of carboxymethyl hydroxyethyl cellulose, the invention provides a preparation method of high-stability carboxymethyl hydroxyethyl cellulose, which comprises the following steps: cellulose activation reaction, first-stage etherification reaction, partial neutralization, second-stage etherification reaction, neutralization, washing, crosslinking and drying. Carboxymethylation reaction and hydroxyethylation reaction are carried out under different alkali concentration conditions, so that the uniformity of hydroxyl substitution at 2, 3 and 6 sites of glucose units is improved, the uniformity of the product is improved, and the stability of the viscosity of CMHEC under the conditions of normal temperature and high temperature is remarkably improved. And the application fieldof the CMHEC is expanded.

Owner:泸州北方纤维素有限公司

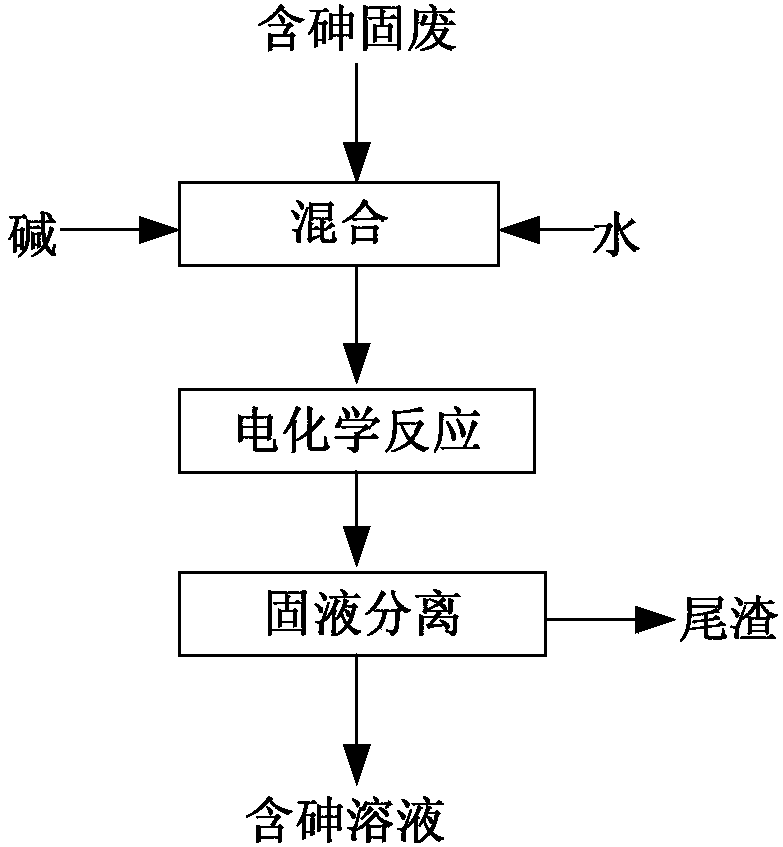

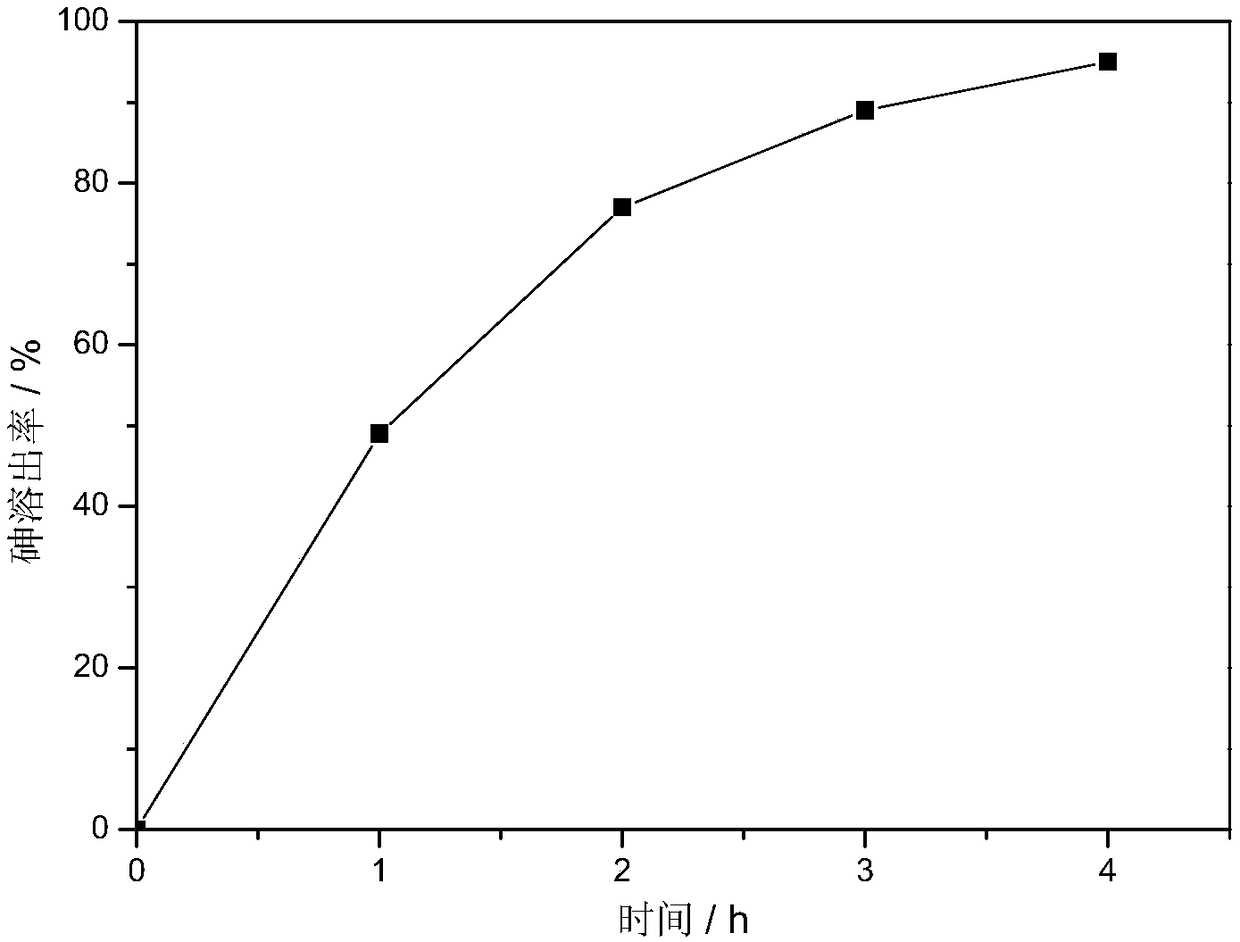

Electrochemical treatment method for arsenic-containing solid waste

ActiveCN108570694AGood effect in treating solid waste containing arsenicLow reaction temperaturePhotography auxillary processesElectrolysis componentsElectrochemical responseSocial benefits

The invention provides an electrochemical treatment method for arsenic-containing solid waste. The electrochemical treatment method comprises: (1) mixing an alkali and a solvent or mixing an alkali solution and arsenic-containing solid waste to obtain a mixture; (2) placing the mixture as an electrolyte in an electrochemical reaction device, carrying out an electrochemical reaction, and introducing an oxidizing gas into the electrolyte during the electrochemical reaction; and (3) carrying out solid-liquid separation on the reaction product obtained in the step (2) to obtain the arsenic-containing solution. According to the present invention, the method has advantages of high extraction rate of arsenic, cleaning property, no pollution, mild process condition, low cost and low requirements on equipment; the impurity is not introduced so as to conveniently perform the subsequent separation; the concentration of the used alkali is low so as to reduce the alkali consumption; and the automation degree is high so as to reduce the manpower input, the good economic and social benefits can be provided, and the good application prospect can be provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

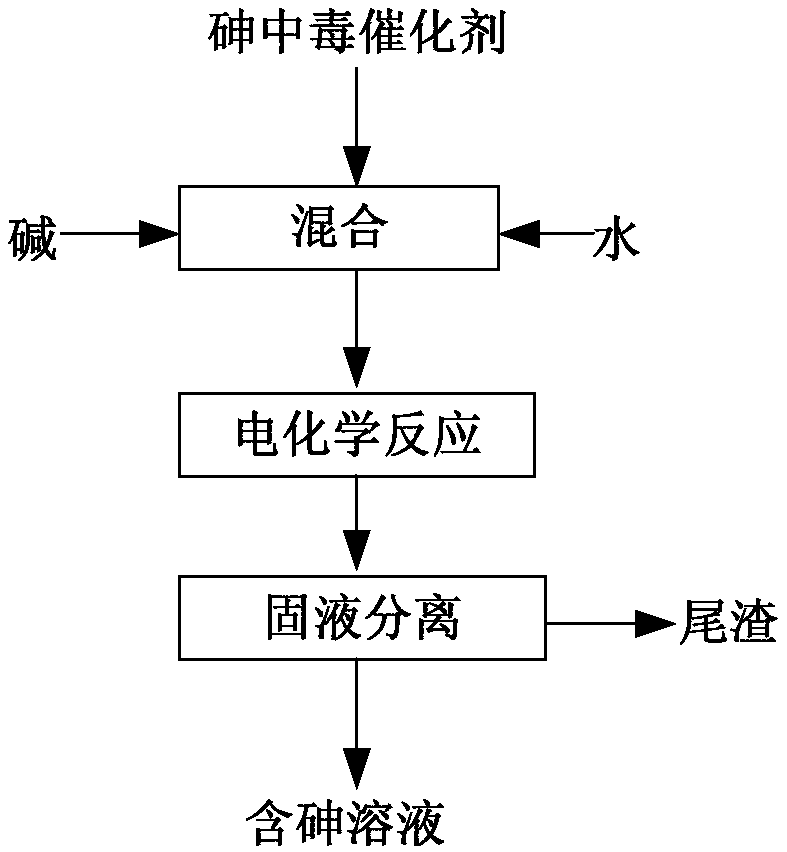

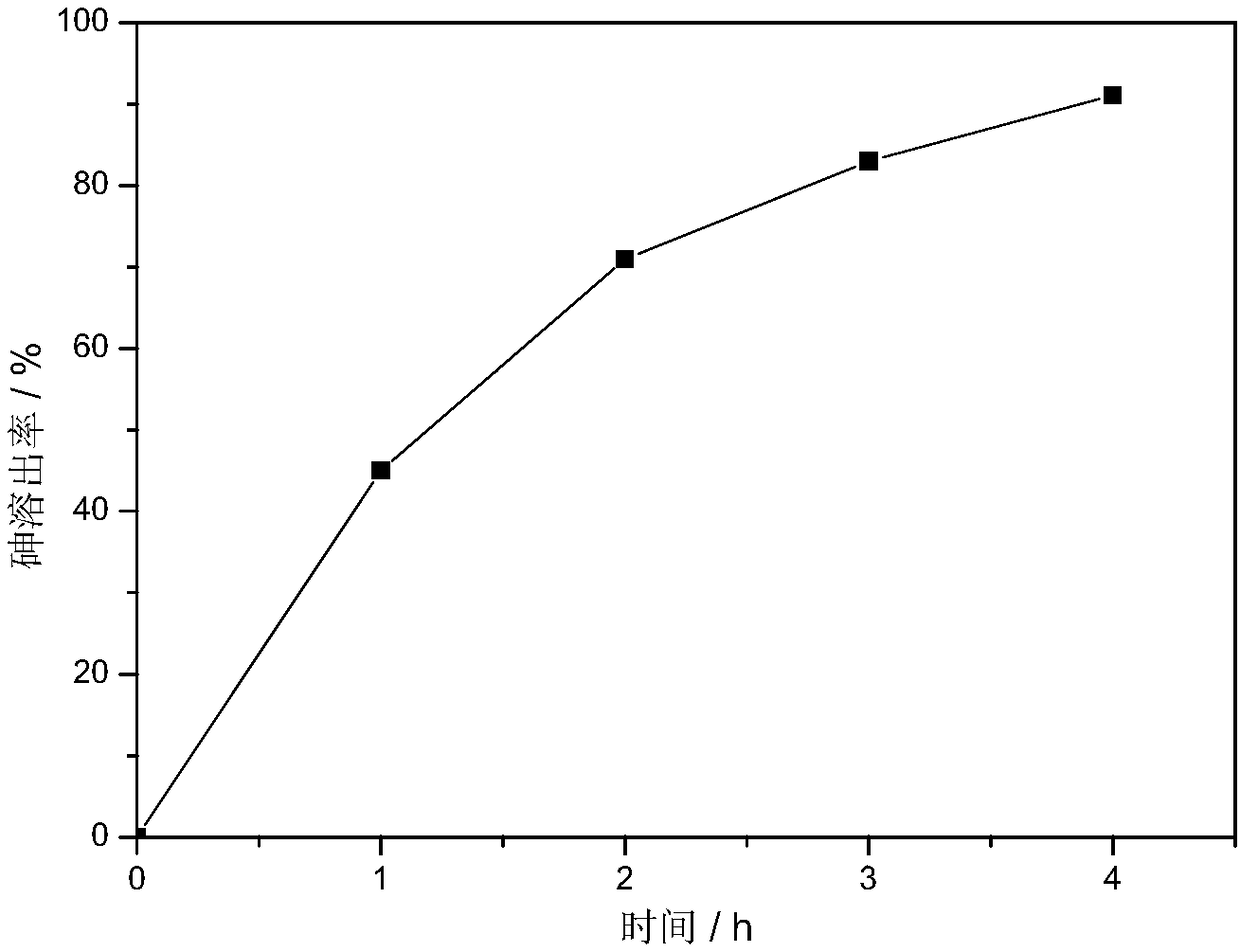

Electrochemical treatment method for an arsenic poisoning catalyst

ActiveCN108570685ALow reaction temperatureReduce energy consumptionElectrodesSolventElectrochemical response

The invention provides an electrochemical treatment method for an arsenic poisoning catalyst. The electrochemical treatment method comprises: (1) mixing an alkali and a solvent or mixing an alkali solution and an arsenic poisoning catalyst to obtain a mixture; (2) placing the mixture as an electrolyte in an electrochemical reaction device, carrying out an electrochemical reaction, and introducingan oxidizing gas into the electrolyte during the electrochemical reaction; and (3) carrying out solid-liquid separation on the reaction product obtained in the step (2) to obtain the arsenic-containing solution. According to the present invention, the method has advantages of high extraction rate of arsenic, cleaning property, no pollution, mild process condition, low cost and low requirements onequipment; the impurity is not introduced so as to conveniently perform the subsequent separation; the concentration of the used alkali is low so as to reduce the alkali consumption; and the automation degree is high so as to reduce the manpower input, the good economic and social benefits can be provided, and the good application prospect can be provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Electrochemical treatment method for arsenic-containing smelting waste residue

ActiveCN108570562ALow reaction temperatureReduce energy consumptionProcess efficiency improvementElectrochemical responseElectrochemistry

The invention provides an electrochemical treatment method for arsenic-containing smelting waste residue. The electrochemical treatment method comprises: (1) mixing an alkali and a solvent or mixing an alkali solution and arsenic-containing smelting waste residue to obtain a mixture; (2) placing the mixture as an electrolyte in an electrochemical reaction device, carrying out an electrochemical reaction, and introducing an oxidizing gas into the electrolyte during the electrochemical reaction; and (3) carrying out solid-liquid separation on the reaction product obtained in the step (2) to obtain the arsenic-containing solution. According to the present invention, the method has advantages of high extraction rate of arsenic, cleaning property, no pollution, mild process condition, low costand low requirements on equipment; the impurity is not introduced so as to conveniently perform the subsequent separation; the concentration of the used alkali is low so as to reduce the alkali consumption; and the automation degree is high so as to reduce the manpower input, the good economic and social benefits can be provided, and the good application prospect can be provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

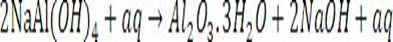

Method for reducing hydrolysis in red mud separation and washing processes

PendingCN112573551AImprove overall recoveryReduce supersaturationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRed mudProcess engineering

The invention relates to a method for hydrolyzing red mud, in particular to a method for reducing hydrolysis in a red mud separation and washing process in a Bayer process aluminum oxide production process. According to the method, dissolved ore pulp is directly injected into a separation tank by a final flash tank through self-pressing, washing water is added into a final washing tank, countercurrent washing is conducted for multiple times, overflow of a primary washing tank and overflow of the separation tank are mixed and then enter a coarse liquid tank, underflow of the separation tank enters the primary washing tank, underflow of each washing tank enters a next-stage washing tank, and red mud is finally discharged from a last-stage washing tank. According to the method, the alkali concentration of the ore pulp entering the separation tank is increased by 15-25g / L, and the degree of supersaturation of aluminum oxide is reduced by 5%-50%; a dilution tank and a dilution rear tank areomitted, the process is simplified, and investment and ore pulp conveying energy consumption are reduced; and the hydrolysis loss of alumina in the red mud separation and washing process is reduced by 50%, and the total recovery rate of the whole plant is improved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

A method for producing xonotlite with fly ash as raw material

The invention discloses a method for producing xonotlite by taking pulverized fuel ash as a raw material. The method comprises the following steps: with the pulverized fuel ash as a raw material, preparing a refined desilicification solution by adopting an alkali dissolution method, and mixing the refined desilicification solution with a refined lime milk solution to carry out a hydro-thermal synthesis reaction to obtain the xonotlite. According to the method for producing the xonotlite by taking the pulverized fuel ash as the raw material, the pulverized fuel ash is used as the main raw material and is effectively subjected to desilicification by using dilute alkali liquor, so that the dosage of the alkali liquor is reduced, and meanwhile, exploitation and utilization of ores, such as silica sand, kieselguhr and the like are greatly reduced.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Method for promoting production of ethanol from poplar through hydrothermal and NaOH aqueous solution pretreatment

ActiveCN113122587AImprove accessibilityImprove the conversion rate of enzymatic hydrolysisBiofuelsMicroorganism based processesEnvironmental chemistryAlcohol ethyl

The invention provides a method for promoting production of ethanol from poplar through hydrothermal and NaOH aqueous solution pretreatment. The method comprises the following steps: crushing poplar, reacting with water at 180-200 DEG C for 5-30 minutes, mixing filter residues obtained by separation with a NaOH aqueous solution, reacting at 80-120 DEG C for 30-120 minutes, separating to obtain pretreated residues, adding cellulase, a saccharomycetes activating solution and a nutrient solution, and carrying out diastatic fermentation. According to the method, a hydrothermal and NaOH aqueous solution two-section pretreatment combined mode is adopted, the influence of lignin on the enzymolysis and fermentation process is reduced, on the premise that the alkali concentration is reduced, production of ethyl alcohol from poplar can be effectively promoted, and the ethyl alcohol yield reaches up to 50.91%.

Owner:SOUTH CHINA AGRI UNIV

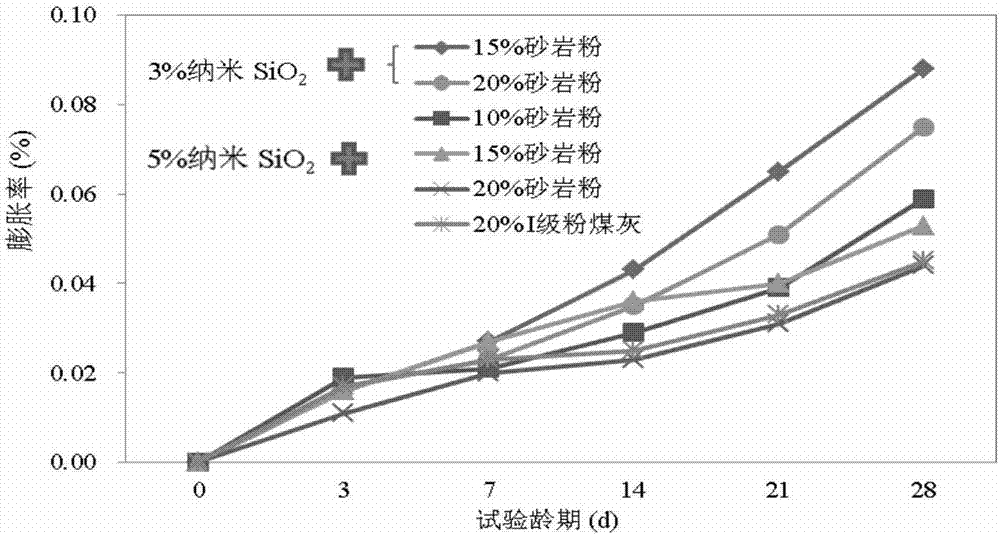

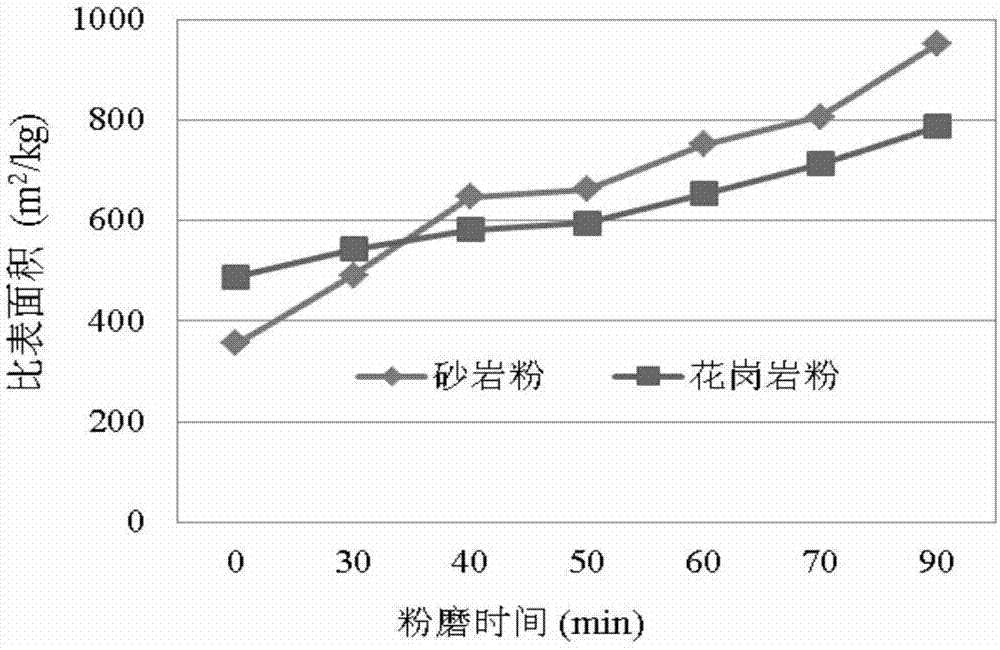

Alkaline activity inhibition material based on active sandstone aggregate and preparation method thereof

The invention provides an alkaline activity inhibition material based on active sandstone aggregate and a preparation method of the alkaline activity inhibition material. By adopting the sandstone aggregate with potential alkaline activity, sandstone powder with the specific surface area of (645 to 950) m<2> / kg is prepared through twice grinding of a vertical mill and a ball mill, and the sandstone powder is uniformly mixed with medium heat cement and nano SiO2 in a certain proportion. The inhibition material is prepared from the following raw materials in percentages by weight: 75% to 87% of the medium heat cement, 10% to 20% of the sandstone powder and 3% to 5% of the nano SiO2. The alkaline activity inhibition material prepared in the invention has the technical advantages that the raw materials are easy to get, the machinability is good, the preparation technology is simple, the alkaline activity inhibition effect is obvious, and the preparation process is free of pollution to the environment, and is beneficial to large-scale production and application of engineering.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Method and system for separating biomass from activated sludge and application

PendingCN112830645AReduce usageAlkaline concentration decreasedSludge treatmentActivated sludgeMicroorganism

The invention discloses a method and system for separating biomass from activated sludge and application. The method comprises the following steps: carrying out high-temperature reaction on alkaline thick slurry and activated sludge to be treated, and rapidly cooling the activated sludge mixture after the high-temperature reaction to 60-90 DEG C. Compared with an existing 'flash evaporation' cooling mode, the method has advantages that the temperature after cooling is greatly reduced, and the phenomenon that after the 'flash evaporation' cooling mode is adopted, the materials are further decomposed to generate a large amount of ammonia nitrogen after the reaction is completed, and the ammonia nitrogen is volatilized and separated out to form odor is avoided. Meanwhile, the use of alkaline thick slurry is reduced from the source, so that the alkaline concentration in the mud cake and the filtrate is reduced, the application of the mud cake is expanded, and the damage of the filtrate with overhigh pH to plants is avoided. The low reaction temperature is adopted, and energy consumption is reduced while it is guaranteed that harmful microorganisms are effectively killed. In addition, due to the reduction of the reaction temperature, a large amount of active nitrogen is preserved.

Owner:杨山林 +2

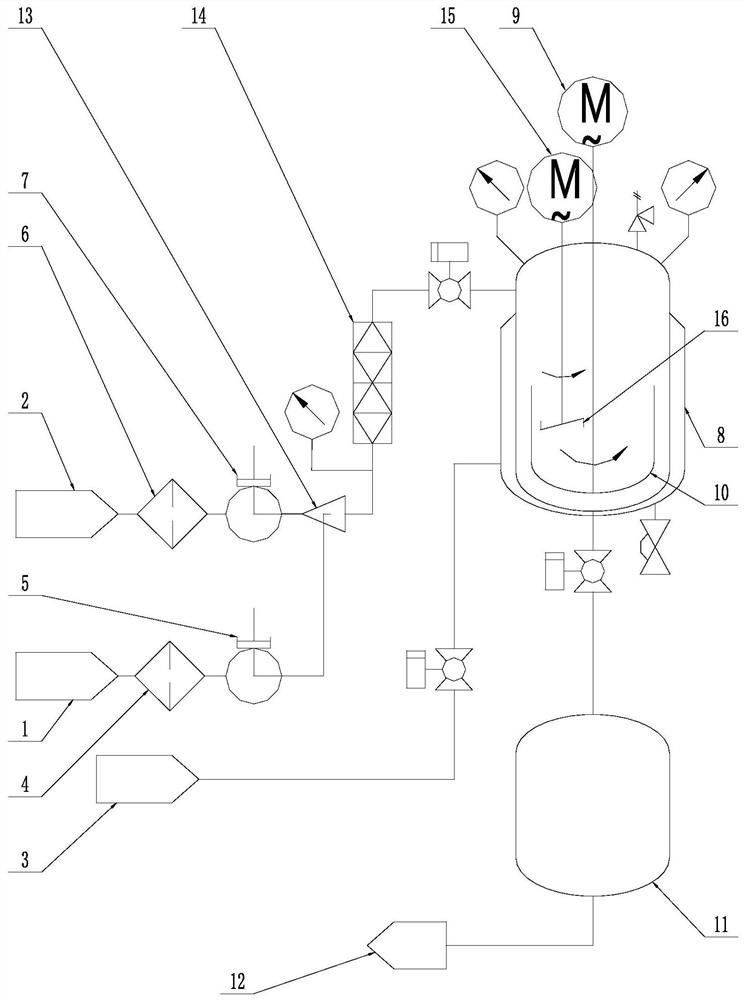

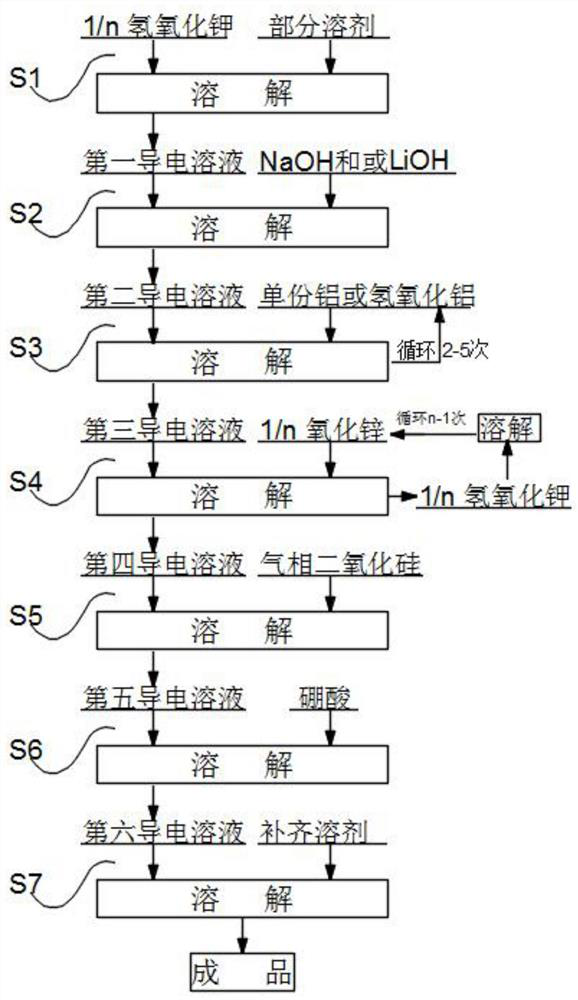

A kind of preparation method of electrolyte and the zinc-nickel battery of its application

ActiveCN112164832BAvoid depositionAvoid passivationFinal product manufactureComposite electrolytesElectrolytic agentLithium hydroxide

The invention discloses a method for preparing an electrolyte solution. The steps are as follows: S1, dissolving potassium hydroxide to prepare a first conductive solution; S2, mixing and dissolving sodium hydroxide and or lithium hydroxide with the first conductive solution to form a second conductive solution. Solution; S3, dissolving aluminum and or aluminum hydroxide to the second conductive solution step by step to obtain the third conductive solution; S4, adding zinc oxide and potassium hydroxide alternately step by step to the third conductive solution to obtain the fourth conductive solution ; S5, mixing and dissolving fumed silica and the fourth conductive solution to form the fifth conductive solution; S6, mixing and dissolving boric acid and the fifth conductive solution to form the sixth conductive solution; S7, adding a surplus of Solvent, the finished product electrolyte is obtained; The battery adopts the electrolyte of above-mentioned products, can reduce the dissolution corrosion of zinc pole and avoid the formation of zinc dendrite, and compared with the electrolyte that does not prepare according to this method, the electrolyte prepared by this method is more efficient. Stable, the battery cycle life of the application is longer.

Owner:山东合泰新能源有限公司

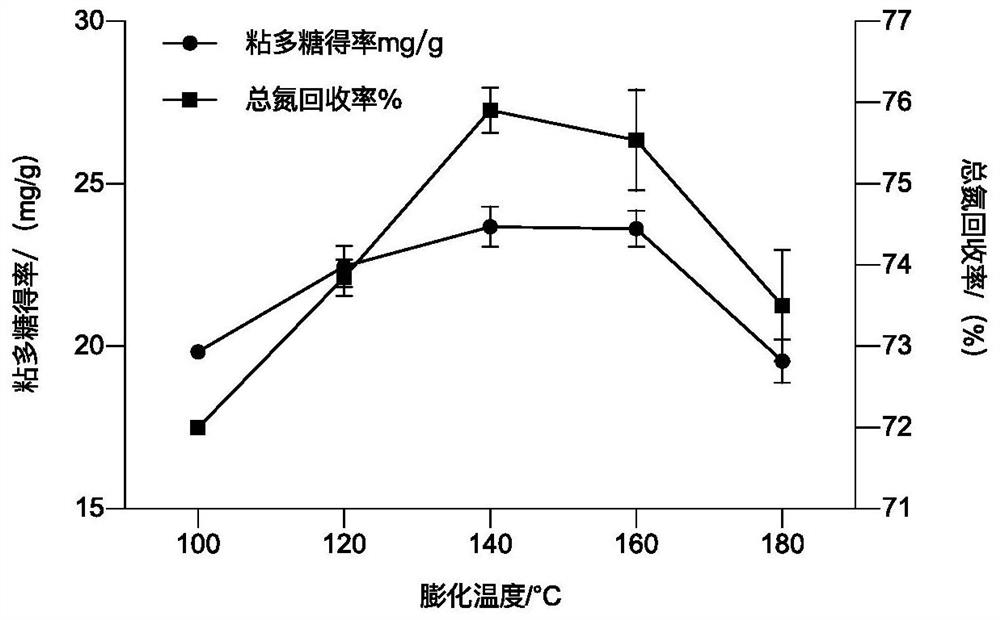

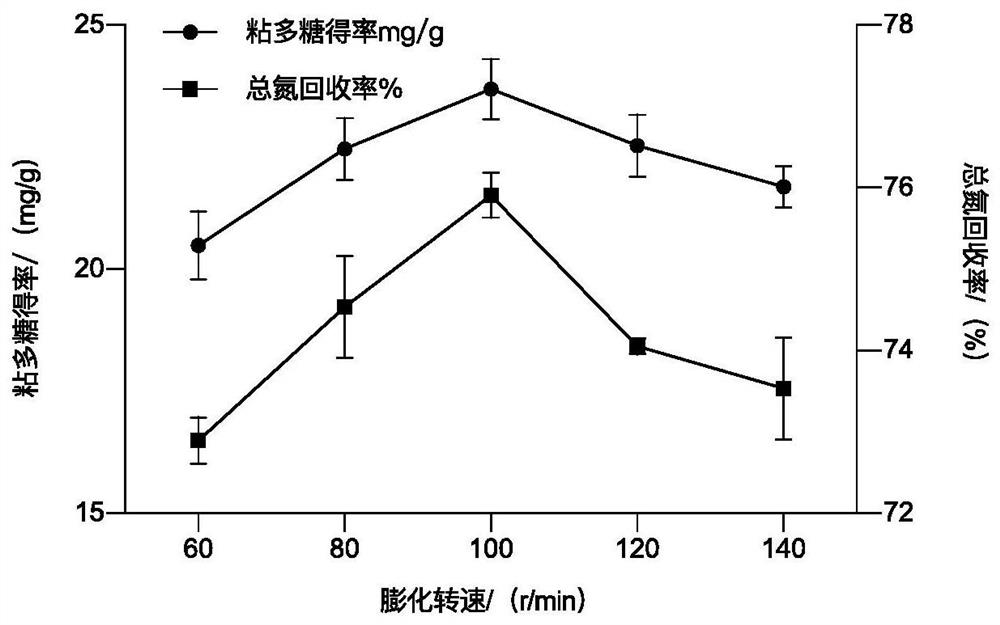

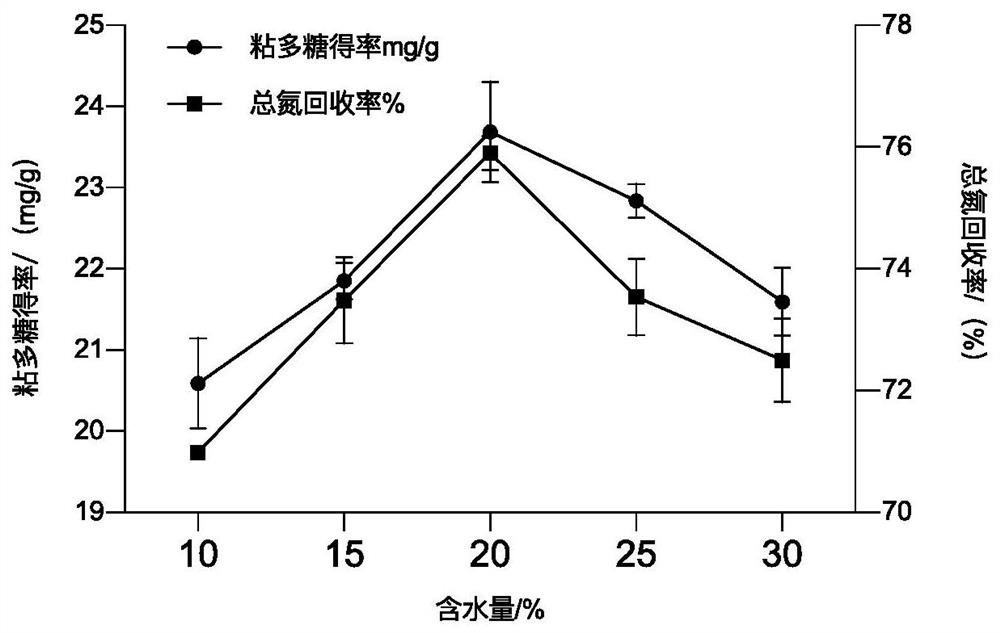

A kind of preparation method of eggshell membrane polypeptide

ActiveCN110699411BPromote dissolutionReduce usageConnective tissue peptidesDepsipeptidesEnzymatic hydrolysisEggshell membrane

The invention discloses a preparation method of eggshell membrane polypeptide, which belongs to the field of food. The present invention adopts a combination technology of extrusion, dilute alkali and enzymatic hydrolysis, that is, firstly extruding and dilute alkali pretreatment is performed on the eggshell membrane, and then enzymatic hydrolysis, in order to improve the efficiency of enzymatic hydrolysis and avoid the use of ionic liquids , organic solvents and other toxic reagents, thereby preparing shell membrane polypeptides with antioxidant properties, and rich in mucopolysaccharides, the yield of mucopolysaccharides reaches 23.58mg / g eggshell membrane, and the recovery rate of total nitrogen reaches 78.09%. The product eggshell membrane polypeptide has good antioxidant activity, and its molecular weight is mainly below 1000Da, accounting for 89.54%.

Owner:JIANGNAN UNIV

A kind of electrochemical treatment method of arsenic-containing soot

ActiveCN108570684BLow reaction temperatureReduce energy consumptionElectrode shape/formsProcess efficiency improvementElectrochemical responseChemical reaction

The invention provides an electrochemical treatment method for arsenic-containing soot. The electrochemical treatment method comprises: (1) mixing an alkali and a solvent or mixing an alkali solutionand arsenic-containing soot to obtain a mixture; (2) placing the mixture as an electrolyte in an electrochemical reaction device, carrying out an electrochemical reaction, and introducing an oxidizinggas into the electrolyte during the electrochemical reaction; and (3) carrying out solid-liquid separation on the reaction product obtained in the step (2) to obtain the arsenic-containing solution.According to the present invention, the method has advantages of high extraction rate of arsenic, cleaning property, no pollution, mild process condition, low cost and low requirements on equipment; the impurity is not introduced so as to conveniently perform the subsequent separation; the concentration of the used alkali is low so as to reduce the alkali consumption; and the automation degree ishigh so as to reduce the manpower input, the good economic and social benefits can be provided, and the good application prospect can be provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of powder paint stripping composition and its preparation method and application

InactiveCN106519781BAlkaline concentration decreasedReduce corrosionChemical paints/ink removersEpoxyAcrylic resin

The invention discloses a use of tert-butyl hydroperoxide in preparation of a powdery coating removal composition and the coating removal composition. The coating removal composition comprises, by mass, 48 to 60% of dichloromethane, 15 to 30% of methanol, 15 to 25% of tert-butyl hydroperoxide, 1 to 2% of liquid paraffin and 0.2 to 1% of sodium hydroxide. The coating removal composition provided by the invention has the advantages of low cost, less pollution, short coating removal time and strong penetrability, can realize complete separation of the coating and a base and does not produce corrosion to the base. The coating removal composition provided by the invention also has strong depainting ability to the thick coating, is recyclable and reused after being soaked or rinsed, is especially suitable for removing the metal surface coating, comprises epoxy resin, polyurethane or acrylic resin, and can provide a technical support for development of an industrial cleaning agent.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH +1

A method for decomposing chromite by fluidization at low temperature and normal pressure

ActiveCN104726689BSimple ingredientsEasy to industrializeProcess efficiency improvementReaction temperaturePotassium

The invention relates to a method for decomposing chromite by low-temperature atmospheric-pressure fluidization, which comprises the following steps: adding potassium hydroxide and an optionally added mixed water solution of potassium carbonate and / or potassium metaaluminate into a reactor, preheating, adding chromite and / or pretreated chromite, and introducing oxidizing gas to perform oxidizing reaction while heating; diluting the reaction slurry with a diluter to obtain a solution containing potassium chromate, potassium hydroxide, potassium carbonate, potassium metaaluminate and other water-soluble impurity components and an iron-rich tailing solid-liquid mixed slurry; and carrying out solid-liquid separation on the mixed slurry at 80-130 DEG C to obtain the iron-rich tailings and chromium-containing alkali liquor. The reaction temperature of the method is below the boiling point of the solution, and the process is performed under atmospheric pressure; and thus, the method has the advantages of low equipment cost, high safety and high chromium extraction yield (up to 95% above), and is easy to operate, and the operating temperature is much lower than the temperature of the traditional chromium extraction technique.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Hemp degumming process

InactiveCN100346011CStrong no lossThe process saves time and saves time compared with the general old degumming processVegetable materialHigh pressureTemperature and pressure

The invention discloses the process of the hemp come unglued. The hemp fiber is deal with the come unglued adopting the combination of the normal temperature, normal pressure and the high temperature, high pressure. The technical process is showed below: the pricking and loading the cave-the bath-the normal temperature and pressure-washing the hemp-cooking under the high temperature and pressure-washing with the hot water-the shaking hemp-pulling off the oil-the drying-the extracting dry hemp; the cooking smelting adopts the high temperature and the high pressure. The time used by the invention is shorter 1.5 hour than the time used by the normal come unglued process, the thickness of the alkali is depressed highly, the content percent of the xylogen of the hemp after the treatment is below the 0.5%, the loss of the mightiness of the fiber can be reduced to the least, the refining dry hemp is clean, relax and quality.

Owner:ZHEJIANG SCI-TECH UNIV

A kind of electrochemical treatment method of arsenic-containing anode slime

ActiveCN108570693BLow reaction temperatureReduce energy consumptionPhotography auxillary processesProcess efficiency improvementElectrochemical responseSocial benefits

The invention provides an electrochemical treatment method for arsenic-containing anode mud. The electrochemical treatment method comprises: (1) mixing an alkali and a solvent or mixing an alkali solution and arsenic-containing anode mud to obtain a mixture; (2) placing the mixture as an electrolyte in an electrochemical reaction device, carrying out an electrochemical reaction, and introducing anoxidizing gas into the electrolyte during the electrochemical reaction; and (3) carrying out solid-liquid separation on the reaction product obtained in the step (2) to obtain the arsenic-containingsolution. According to the present invention, the method has advantages of high extraction rate of arsenic, cleaning property, no pollution, mild process condition, low cost and low requirements on equipment; the impurity is not introduced so as to conveniently perform the subsequent separation; the concentration of the used alkali is low so as to reduce the alkali consumption; and the automationdegree is high so as to reduce the manpower input, the good economic and social benefits can be provided, and the good application prospect can be provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Electrochemical treatment method for arsenic-containing anode mud

ActiveCN108570693ALow reaction temperatureReduce energy consumptionPhotography auxillary processesProcess efficiency improvementSolventElectrochemical response

The invention provides an electrochemical treatment method for arsenic-containing anode mud. The electrochemical treatment method comprises: (1) mixing an alkali and a solvent or mixing an alkali solution and arsenic-containing anode mud to obtain a mixture; (2) placing the mixture as an electrolyte in an electrochemical reaction device, carrying out an electrochemical reaction, and introducing anoxidizing gas into the electrolyte during the electrochemical reaction; and (3) carrying out solid-liquid separation on the reaction product obtained in the step (2) to obtain the arsenic-containingsolution. According to the present invention, the method has advantages of high extraction rate of arsenic, cleaning property, no pollution, mild process condition, low cost and low requirements on equipment; the impurity is not introduced so as to conveniently perform the subsequent separation; the concentration of the used alkali is low so as to reduce the alkali consumption; and the automationdegree is high so as to reduce the manpower input, the good economic and social benefits can be provided, and the good application prospect can be provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Alumina melting method

InactiveCN101671042BReduce scarring speedHigh heating temperatureAluminium oxides/hydroxidesAlkalinityRed mud

The invention discloses an alumina melting method. The melting method comprises the following steps: a. conveying primary ore pulp from a normal-pressure desiliconization process with the temperature of 85-100 DEG C into a vapor preheater for preheating to 200-230 DEG C; b. conveying the ore pulp preheated by the vapor preheater into a molten salt heater for heating to 260-280 DEG C; c. conveyingthe ore pulp heated by the molten salt heater into an insulated melting tank for heat preservation for 30-45 minutes until a melting process is finished; d. conveying the melted ore pulp into a ore pulp self evaporator to decrease temperature and pressure; and e. conveying the ore pulp evaporated and concentrated in the self evaporator into a diluting tank, and diluting and mixing with a primary red mud washing fluid. The invention improves the heating temperature of the ore pulp to 280 DEG C, decreases the alkalinity of the primary ore pulp, saves the construction investment and equipment cost, reduces the energy consumption of an evaporation process, improves the utilization rate of secondary vapor heat, delays the scaring speed of a sleeve and decreases the equipment maintenance cost.

Owner:中铝国际技术发展有限公司

A kind of method for promoting poplar ethanol production by pretreatment of hydrothermal combined naoh aqueous solution

ActiveCN113122587BDestroy the recalcitrant structureIncrease production capacityBiofuelsMicroorganism based processesEnzymatic hydrolysisAlcohol ethyl

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com