Method for reducing hydrolysis in red mud separation and washing processes

A technology of washing process and red mud, which is applied in the field of red mud hydrolysis to reduce the hydrolysis in the separation and washing process of red mud. It can solve the problems of easy hydrolysis reaction and other problems, so as to reduce the loss of alumina hydrolysis, reduce the energy consumption of pulp transportation, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

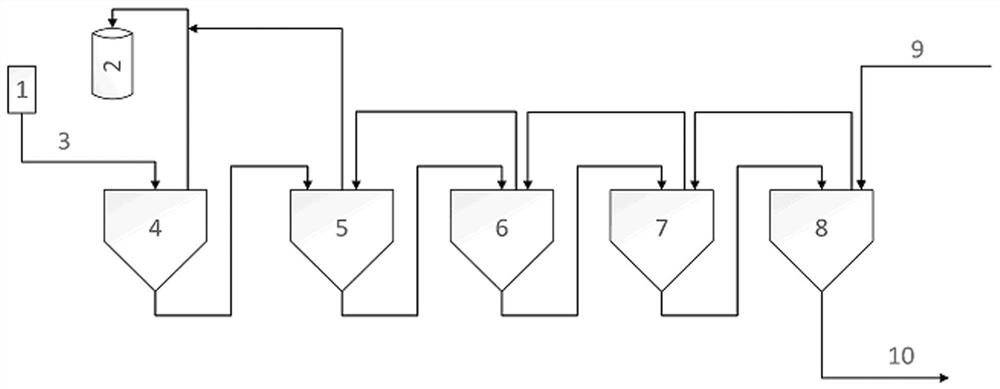

[0020] Such as figure 1 As shown, the present invention is a method for reducing hydrolysis during separation and washing of red mud. The final flash tank 1 uses self-pressure to mix the dissolved ore pulp 3 with a flocculant through a self-dilution system and then injects it into the separation tank 4 . Among them, the alkali concentration of the dissolved ore pulp N k =150g / L, the temperature is 109°C, and the molecular ratio of the eluate is 1.29. At this time, the supersaturation of alumina in the separation tank 4 is 29.54%. Washing water 9 (96°C, 2.0t / tAl 2 o 3 ) into the last washing tank, after several times of countercurrent washing, the overflow of the first washing tank 5 and the overflow of the separation tank 4 are mixed and then enter the crude liquid tank 2, the crude liquid molecular ratio is 1.31, the silicon content index is 210, and the separation tank 4 The underflow of the first washing tank 5 enters the primary washing tank 5, the underflow of the prim...

Embodiment 2

[0022] Such as figure 1 As shown, the present invention is a method for reducing hydrolysis during separation and washing of red mud. The final flash tank 1 uses self-pressure to mix the dissolved ore pulp 3 with a flocculant through a self-dilution system and then injects it into the separation tank 4 . Among them, the alkali concentration of the dissolved ore pulp N k =168g / L, the temperature is 115°C, and the molecular ratio of the eluate is 1.30. At this time, the supersaturation of alumina in the separation tank 4 is 28.30%. Washing water 9 (95°C, 1.8t / tAl 2 o 3 ) into the last washing tank, after several times of countercurrent washing, the overflow of the first washing tank 5 and the overflow of the separation tank 4 are mixed and then enter the crude liquid tank, the molecular ratio of crude liquid is 1.32, and the silicon quantity index is 207. During the separation and washing process The hydrolysis loss of medium alumina is 1.5%. Others are with embodiment 1.

Embodiment 3

[0024] Such as figure 1 As shown, the present invention is a method for reducing hydrolysis in the separation and washing process of red mud. The final flash tank 1 uses self-pressure to mix the dissolved ore pulp 3 with a flocculant through a self-dilution system and then injects it into the separation tank 4 . Among them, the alkali concentration of the dissolved ore pulp N k =175g / L, the temperature is 111°C, and the molecular ratio of the eluate is 1.31. At this time, the supersaturation of alumina in the separation tank 4 is 27.11%. Washing water 9 (98°C, 1.9t / tAl 2 o 3 ) into the final washing tank, after several times of countercurrent washing, the overflow of the first washing tank 5 and the overflow of the separation tank 4 are mixed and then enter the crude liquid tank, the molecular ratio of crude liquid is 1.33, and the silicon quantity index is 220. During the separation and washing process The hydrolysis loss of medium alumina is 1.15%. Others are with embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com