Method for refining high-purity anthracene and carbazole from crude anthracene

A high-purity, carbazole technology, used in distillation purification/separation, crystallization purification/separation, organic chemistry, etc., can solve problems such as clogging of distillation systems, improve product quality and yield, reduce energy consumption, and overcome clogging problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

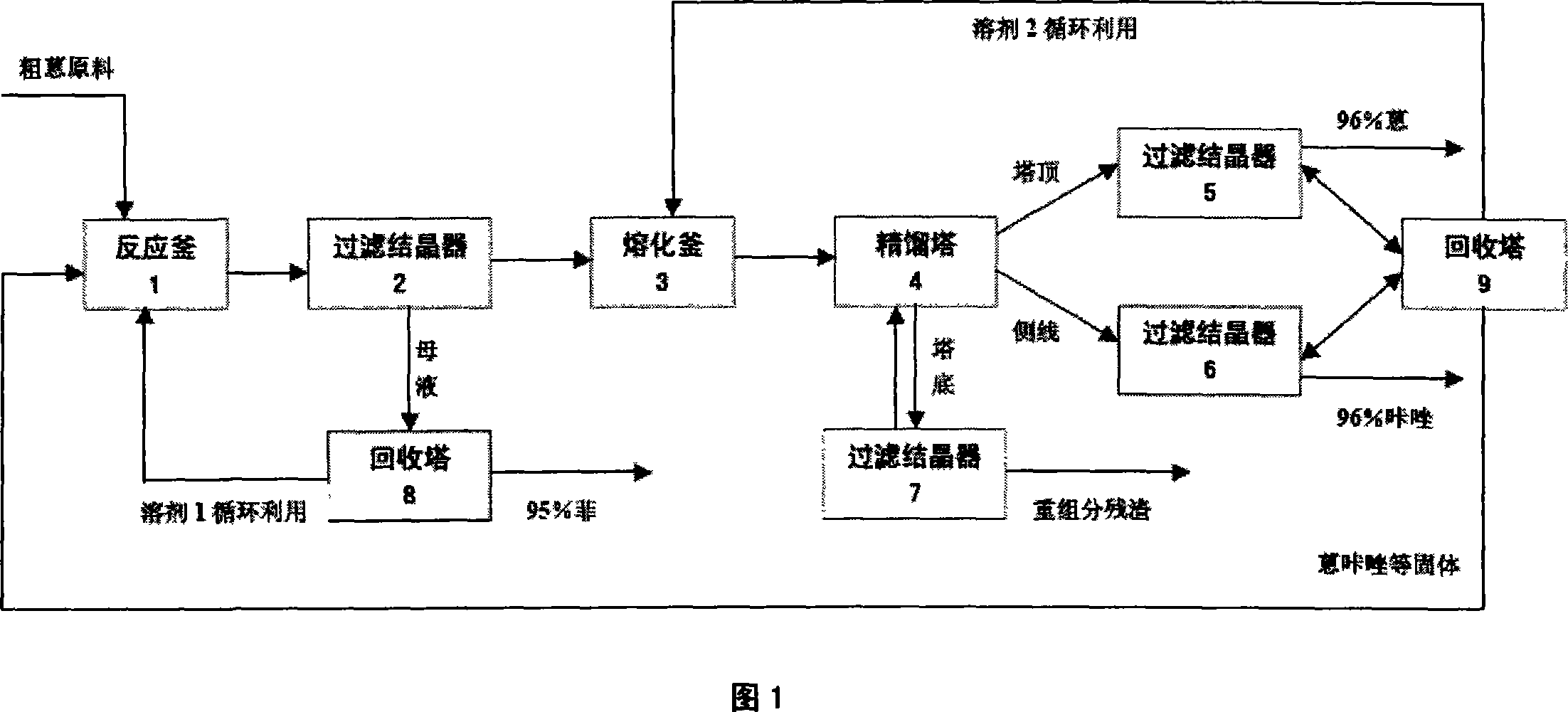

[0033] Embodiment 1: Separation and purification of refined anthracene and carbazole in crude anthracene

[0034]The crude anthracene raw material of a chemical enterprise contains a small amount of light components, 26% of anthracene, 22% of carbazole, and 35% of phenanthrene, and the rest are heavy components. The feed rate is 1200kg / h, the temperature is 20°C, and the pressure is 300kPa. Adopt the method of the present invention, add crude anthracene in the reactor 1 that crude benzene solvent is housed, the ratio of crude anthracene and solvent crude benzene is 1: 1.5 (mass ratio), the mixed solvent temperature is 60 ℃, slowly heats to 70 ℃, The material is discharged into the filter crystallization device 2, cooled to normal temperature, and centrifuged to obtain 650 kg / h of anthracene and carbazole solid phase mixture. Add the obtained solid-phase mixture of anthracene and carbazole into melting kettle 3 containing 200# solvent oil (hereinafter referred to as solvent 2),...

Embodiment 2

[0038] Embodiment 2: Separation and purification of refined anthracene and carbazole in crude anthracene

[0039] The crude anthracene raw material of a chemical enterprise contains a small amount of light components, 26% of anthracene, 22% of carbazole, and 35% of phenanthrene, and the rest are heavy components. The feed rate is 1200kg / h, the temperature is 20°C, and the pressure is 300kPa. Adopt the method of the present invention, add crude anthracene in the reactor 1 that crude benzene solvent is housed, the ratio of crude anthracene and solvent crude benzene is 1: 2.5 (mass ratio), the mixed solvent temperature is 60 ℃, slowly heats to 70 ℃, The material is discharged into the filter crystallization device 2, cooled to normal temperature, and centrifuged to obtain 650 kg / h of anthracene and carbazole solid phase mixture. Add the obtained solid-phase mixture of anthracene and carbazole into the melting tank 3 containing heavy benzene (hereinafter referred to as solvent 2),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com