Special-shaped aluminum cup and production method thereof

A production method and special-shaped aluminum cup technology, which can be applied to other household utensils, rigid containers, drinking vessels, etc., can solve problems such as the single shape of aluminum cups, the inability to process a concave cup shape in the middle, and the inability to do integral printing on the surface of the cup body, etc. , to achieve the effect of ensuring attractiveness, beautiful surface printing, and reducing the chance of counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

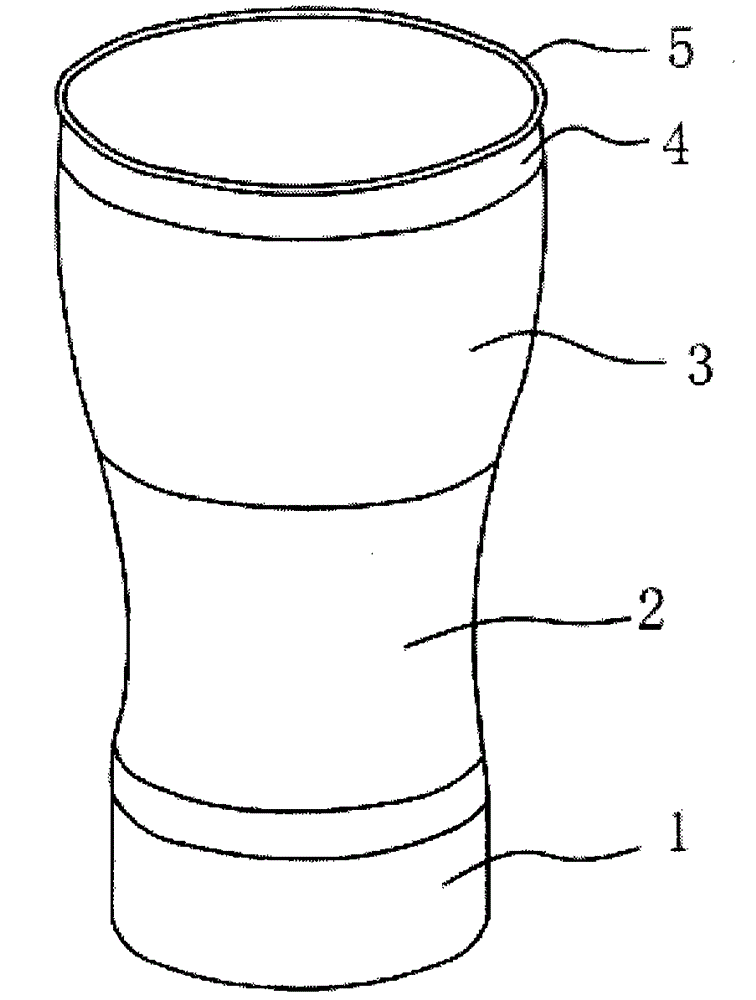

[0026] Such as figure 1 The special-shaped aluminum cup shown includes a cylindrical cup bottom 1, a concave cup body 2, a convex cup body 3, and a concave cup mouth 4 from bottom to top. A curling edge 5 is provided at the concave cup mouth 4. Moreover, the cup bottom 1, the concave cup body 2, the convex cup body 3, the concave cup mouth 4 and the curling edge 5 are an integral structure.

[0027] The production method of the above-mentioned special-shaped aluminum cup is as follows:

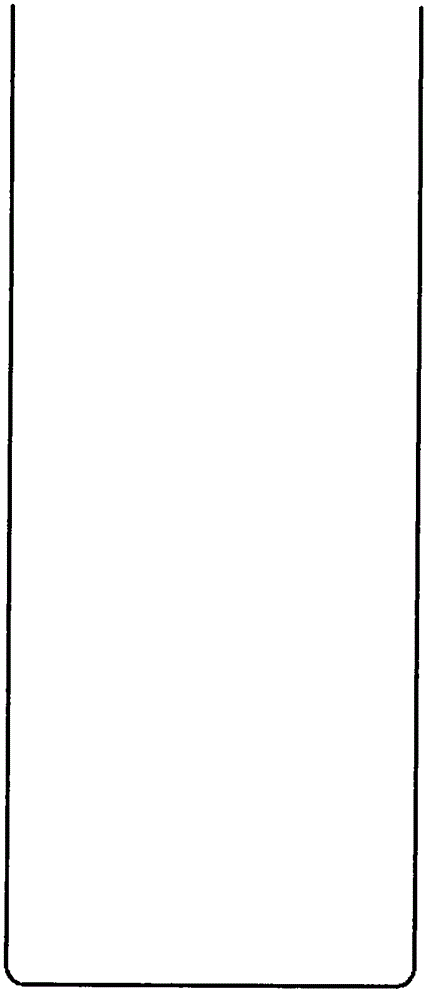

[0028] a. Steps to make straight aluminum cup blanks (such as figure 2 Shown);

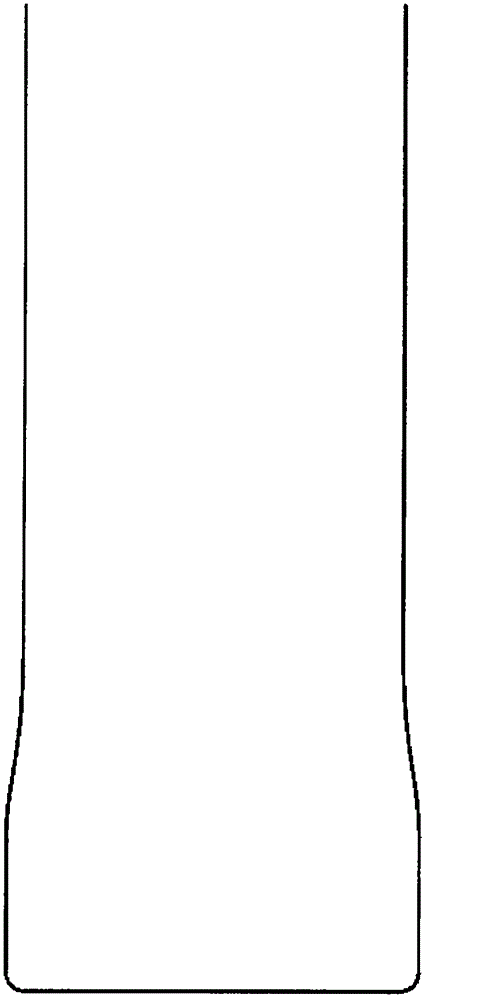

[0029] b. Shrink the top of the bottom of the aluminum cup blank through a shrinking machine to form a conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com