Patents

Literature

74results about How to "Feel stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

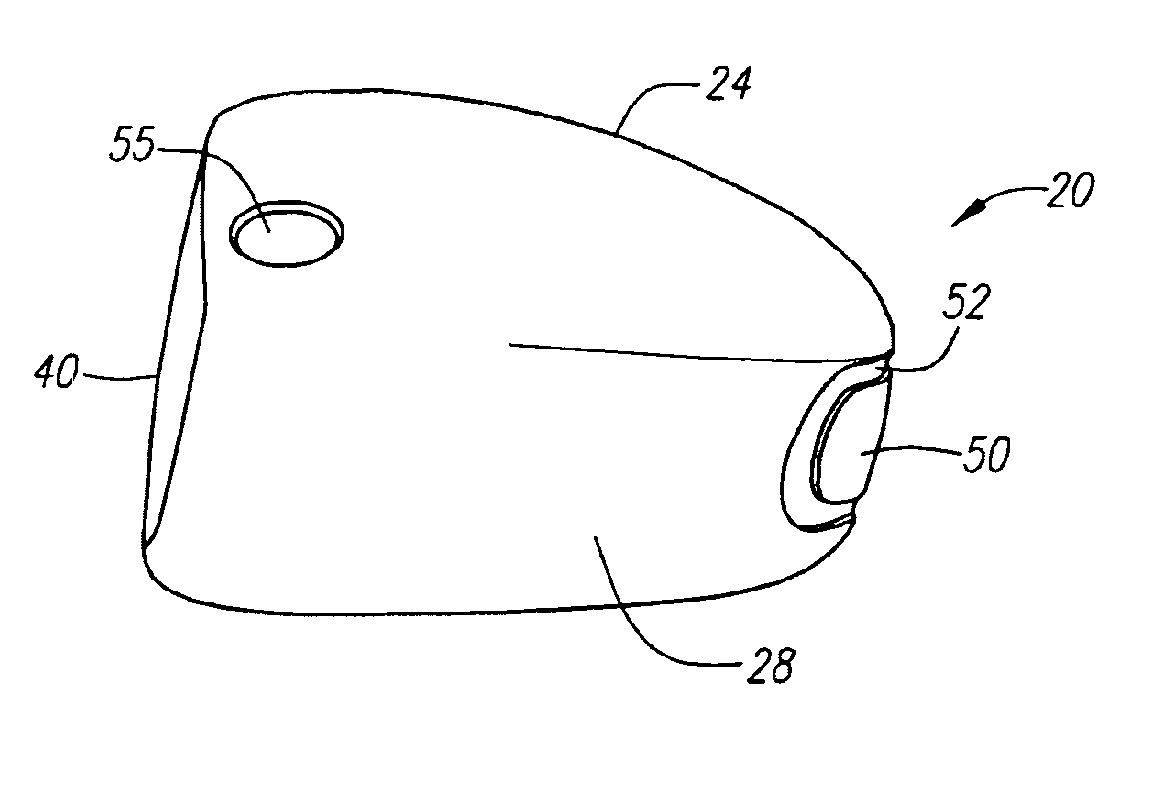

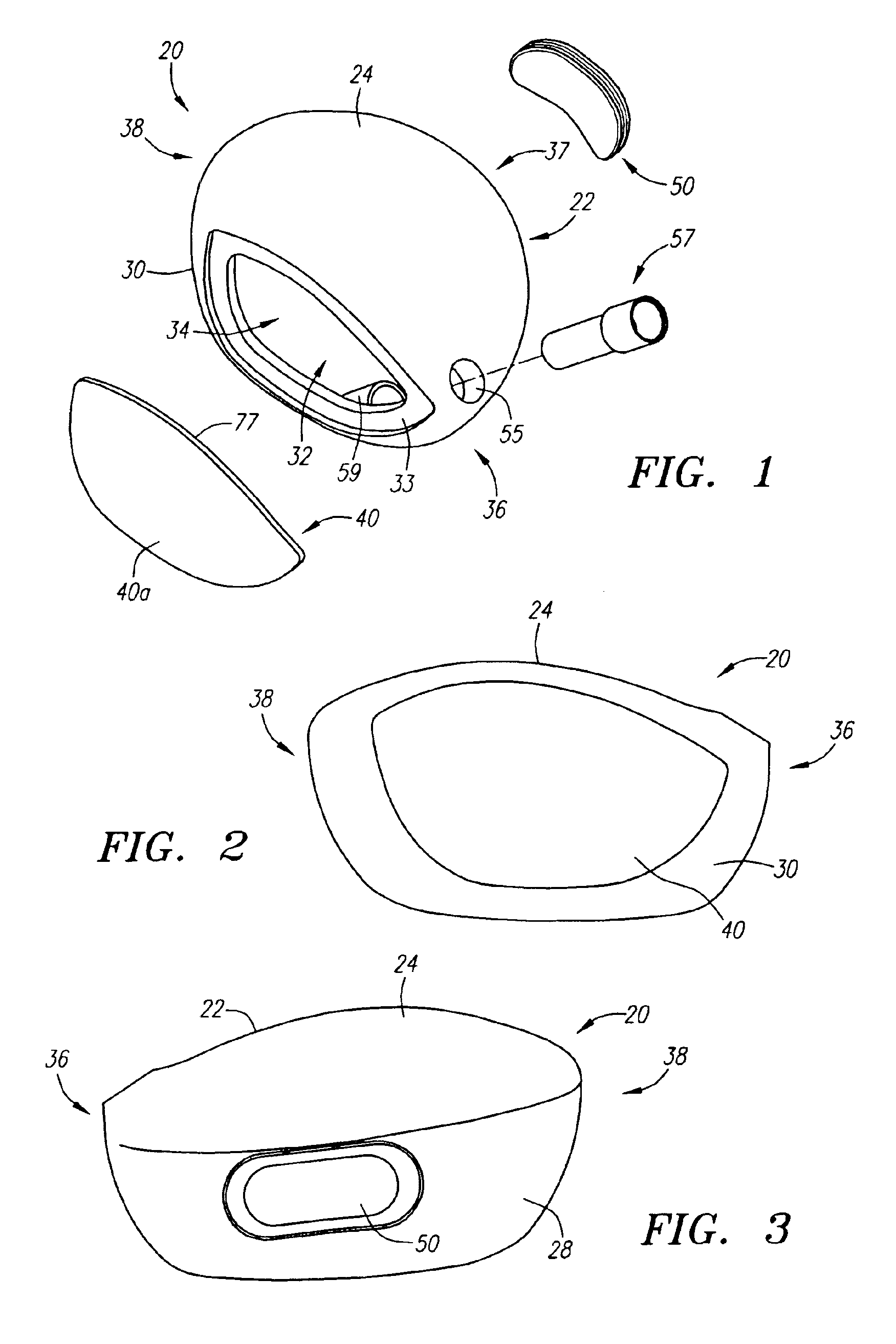

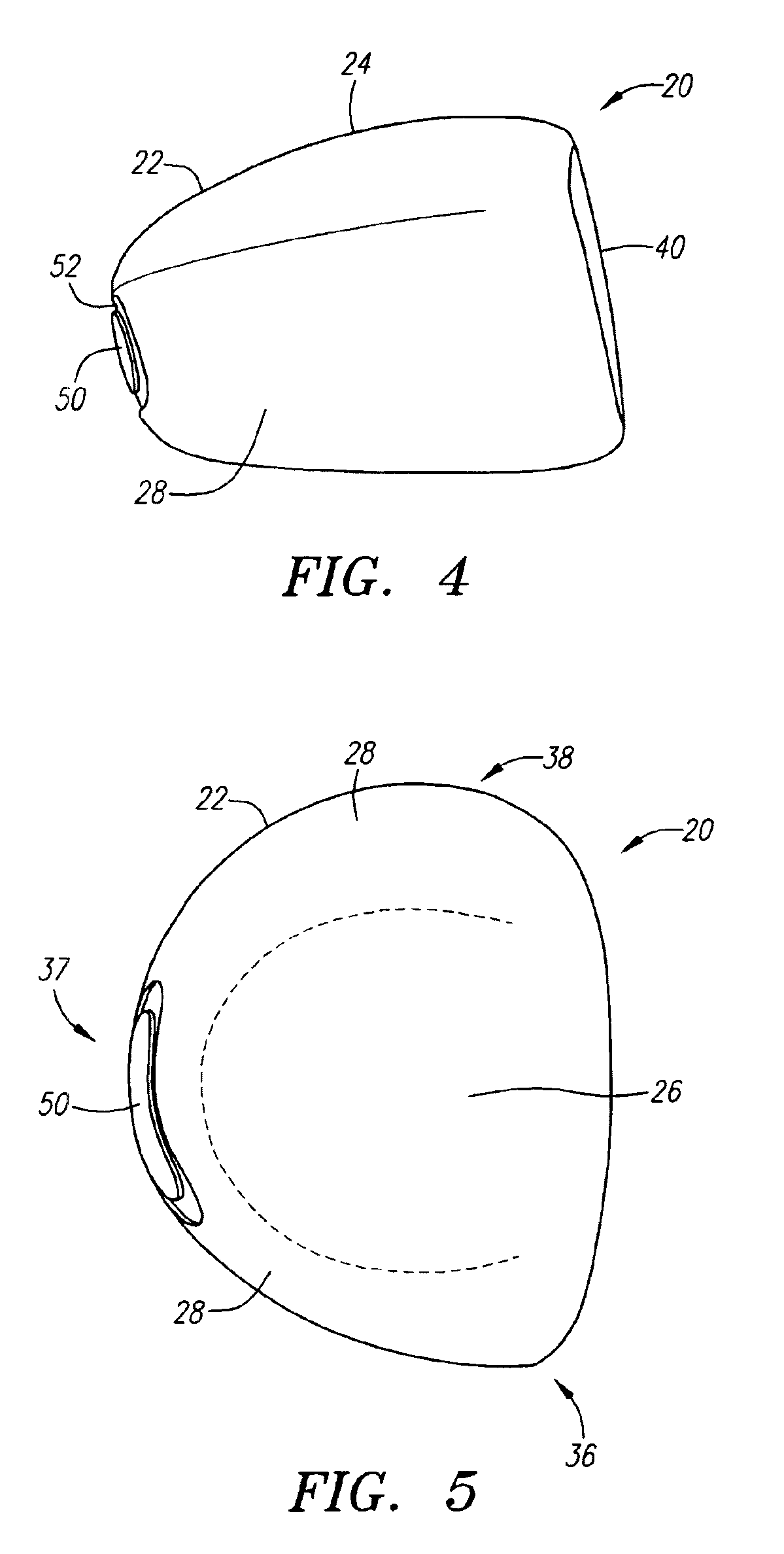

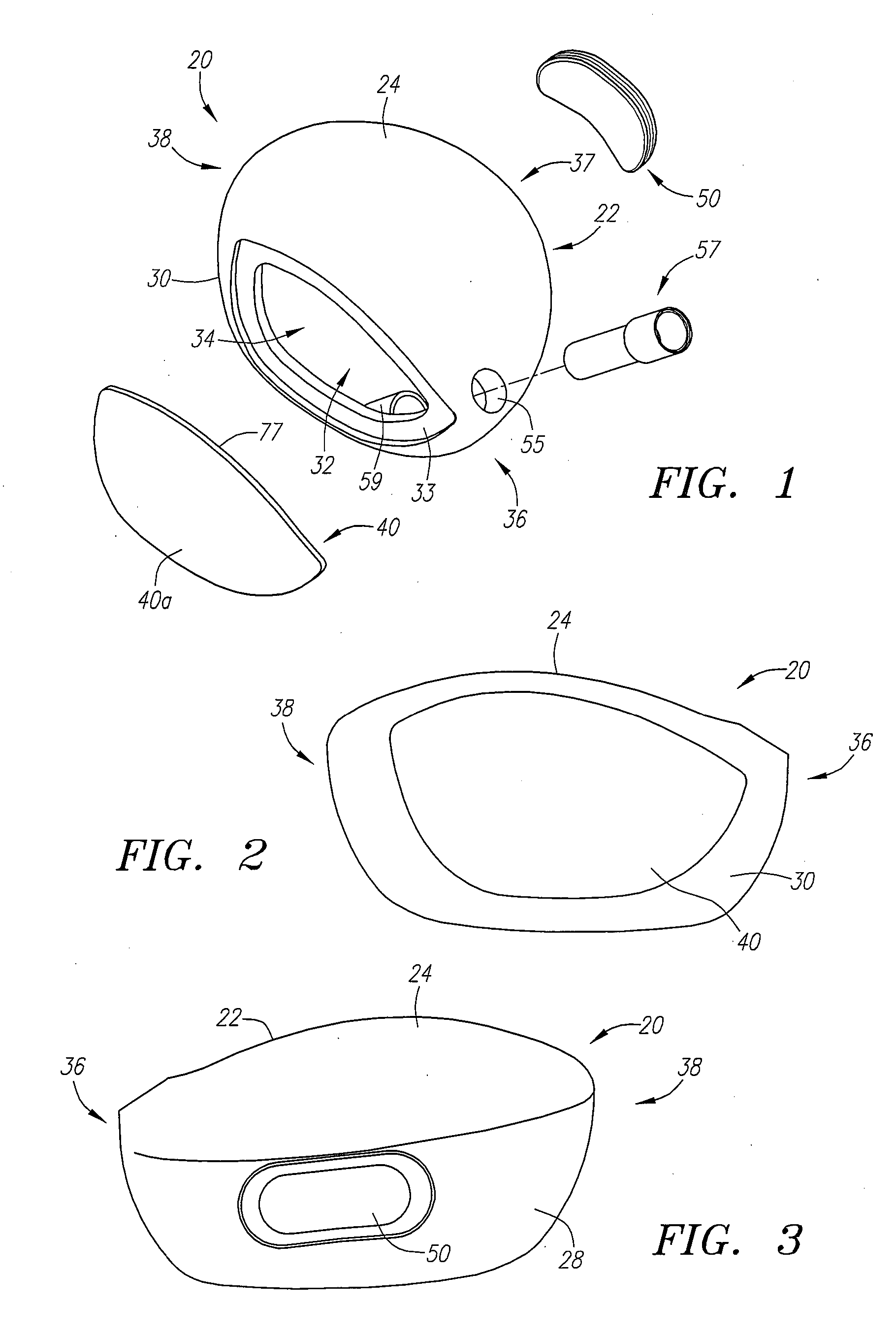

Golf club head (Corporate Docket PU2150)

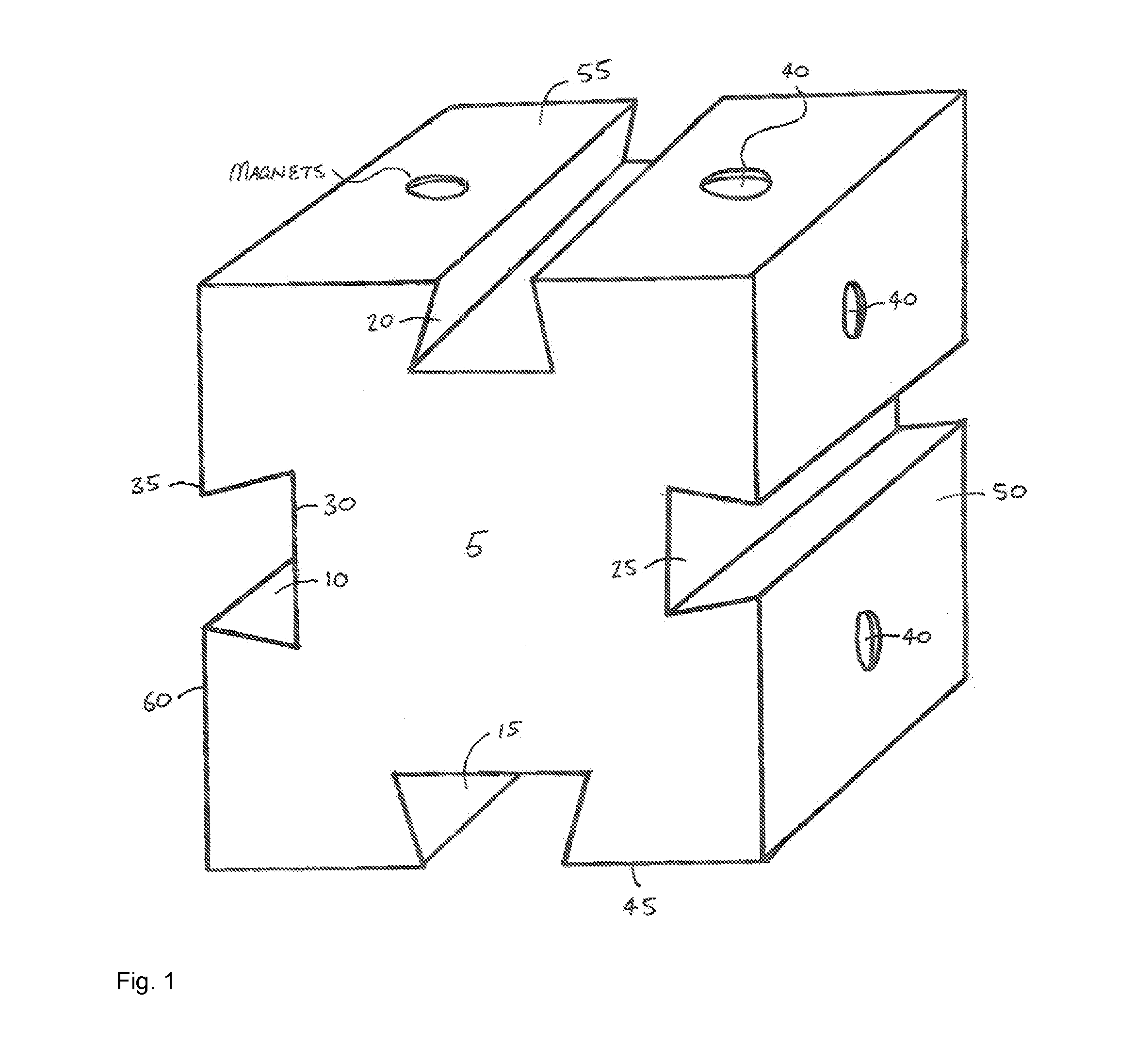

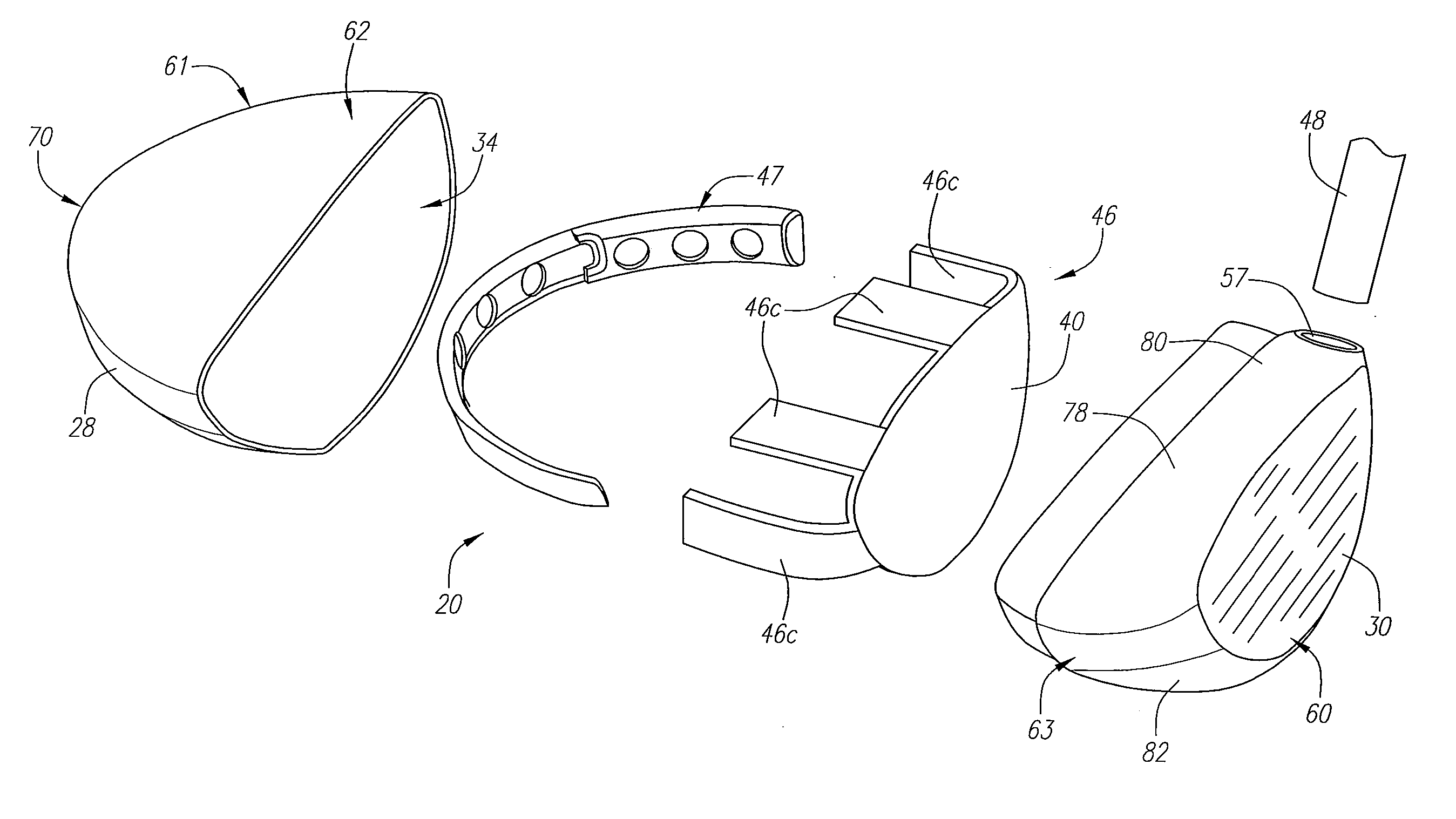

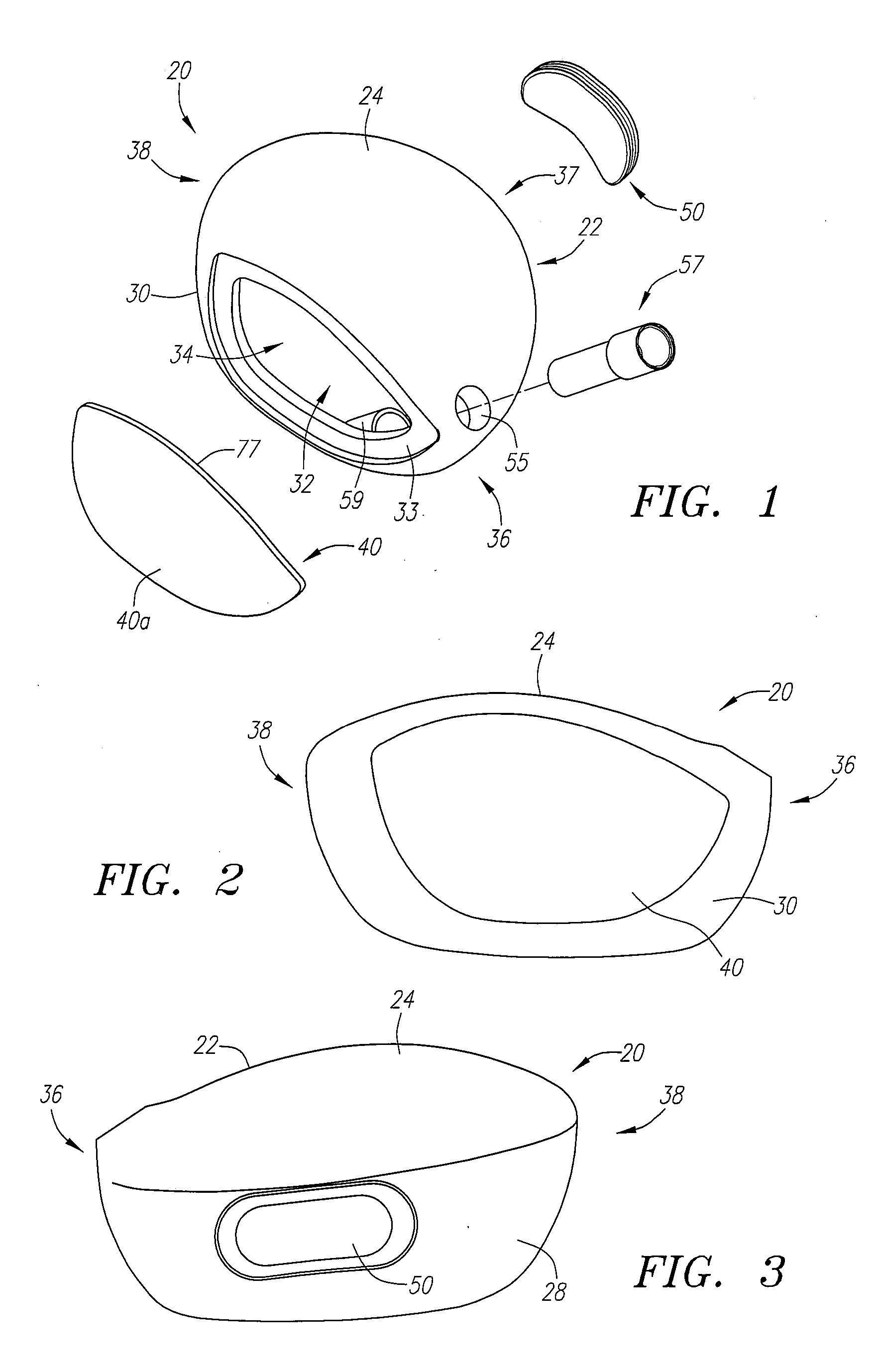

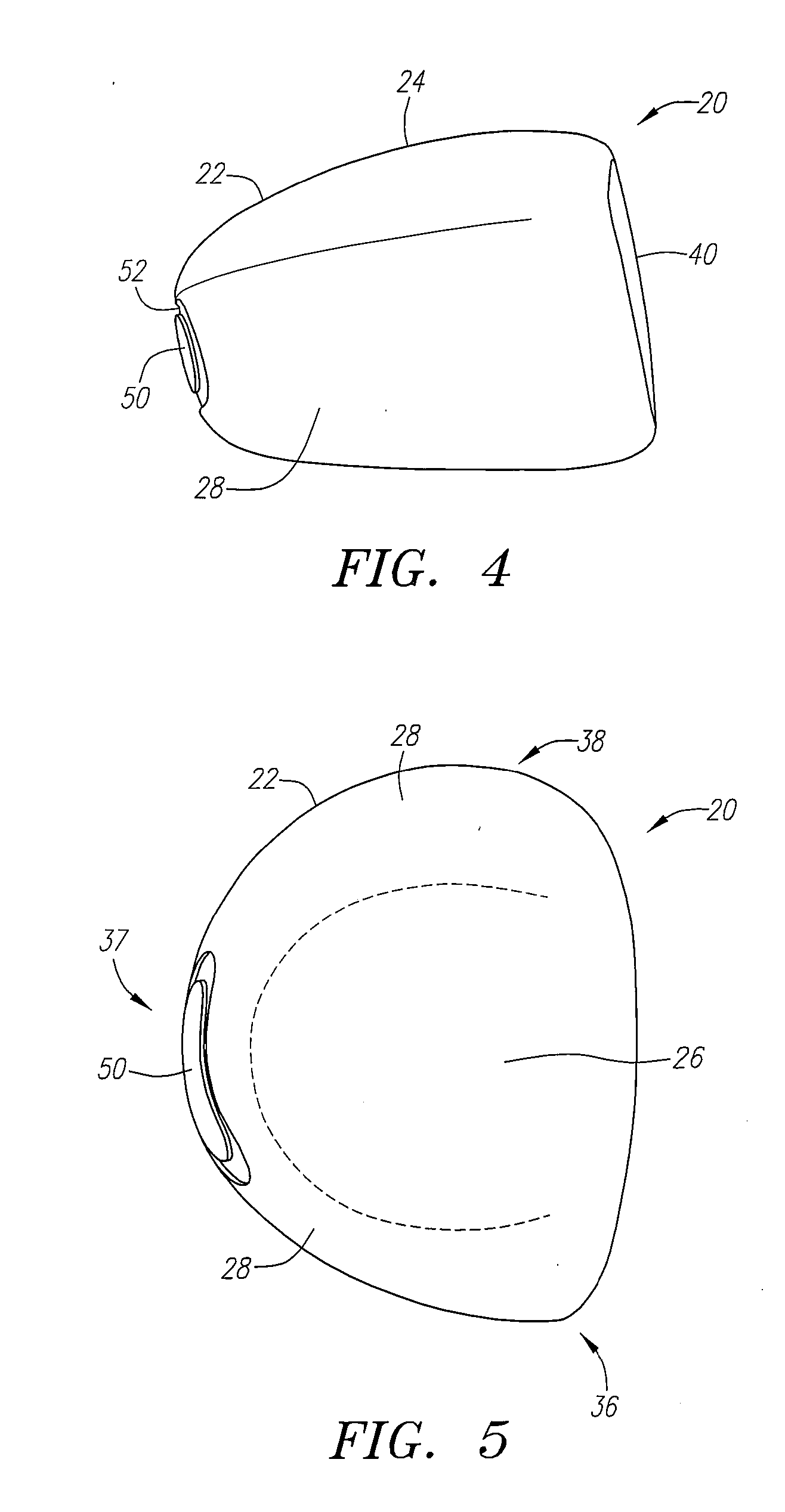

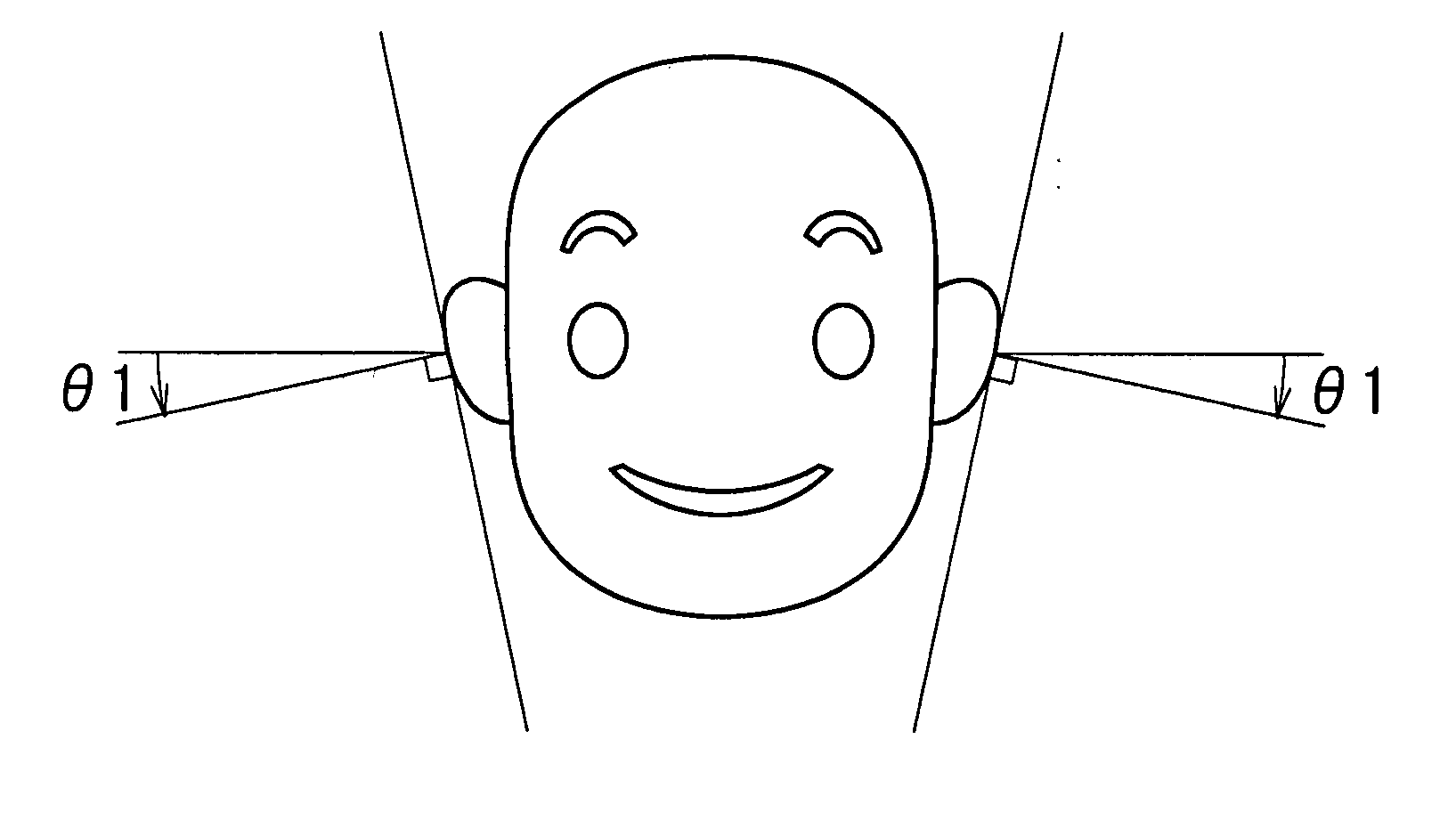

A golf club head (20) having a center of gravity located relatively forward toward the front wall (30) or striking plate (40) of the golf club head (20), and a relatively high moment of inertia about the Iyy axis through the center of gravity of the golf club head (20) is disclosed. The golf club head (20) preferably has a volume between 300 cubic centimeters and 500 cubic centimeters. The golf club head (20) preferably has a mass between 105 grams and 300 grams. The positioning of the of the center of gravity of the golf club head (20) and the relatively high moment of inertia Iyy through the center of gravity provide for a golf club with greater robustness and better performance.

Owner:TOPGOLF CALLAWAY BRANDS CORP

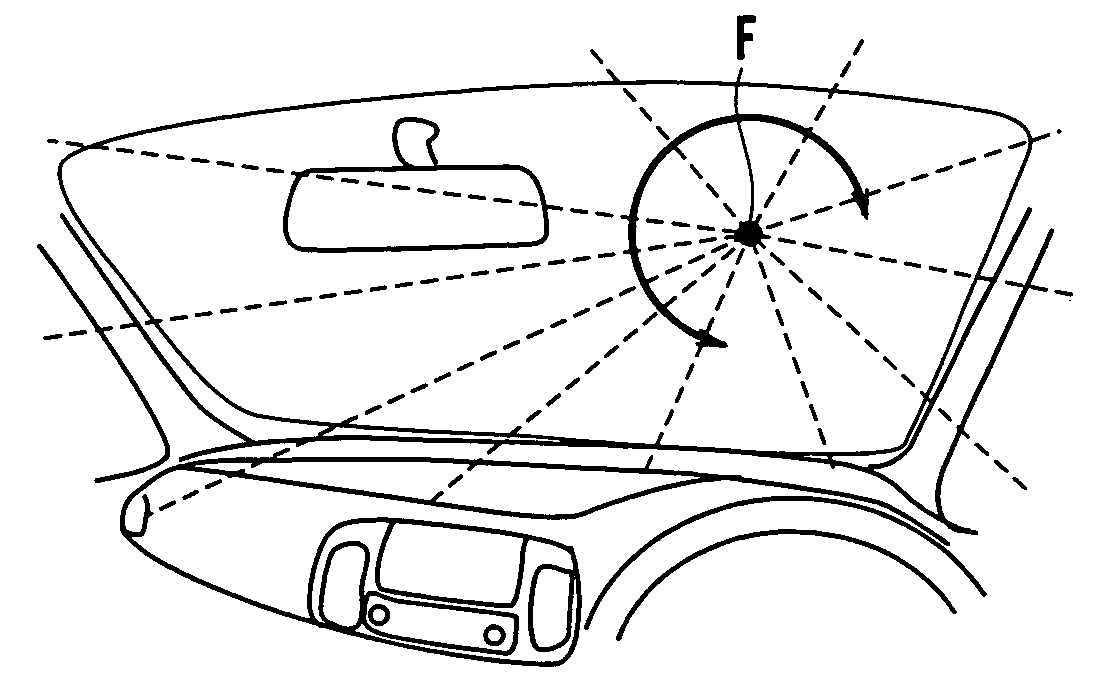

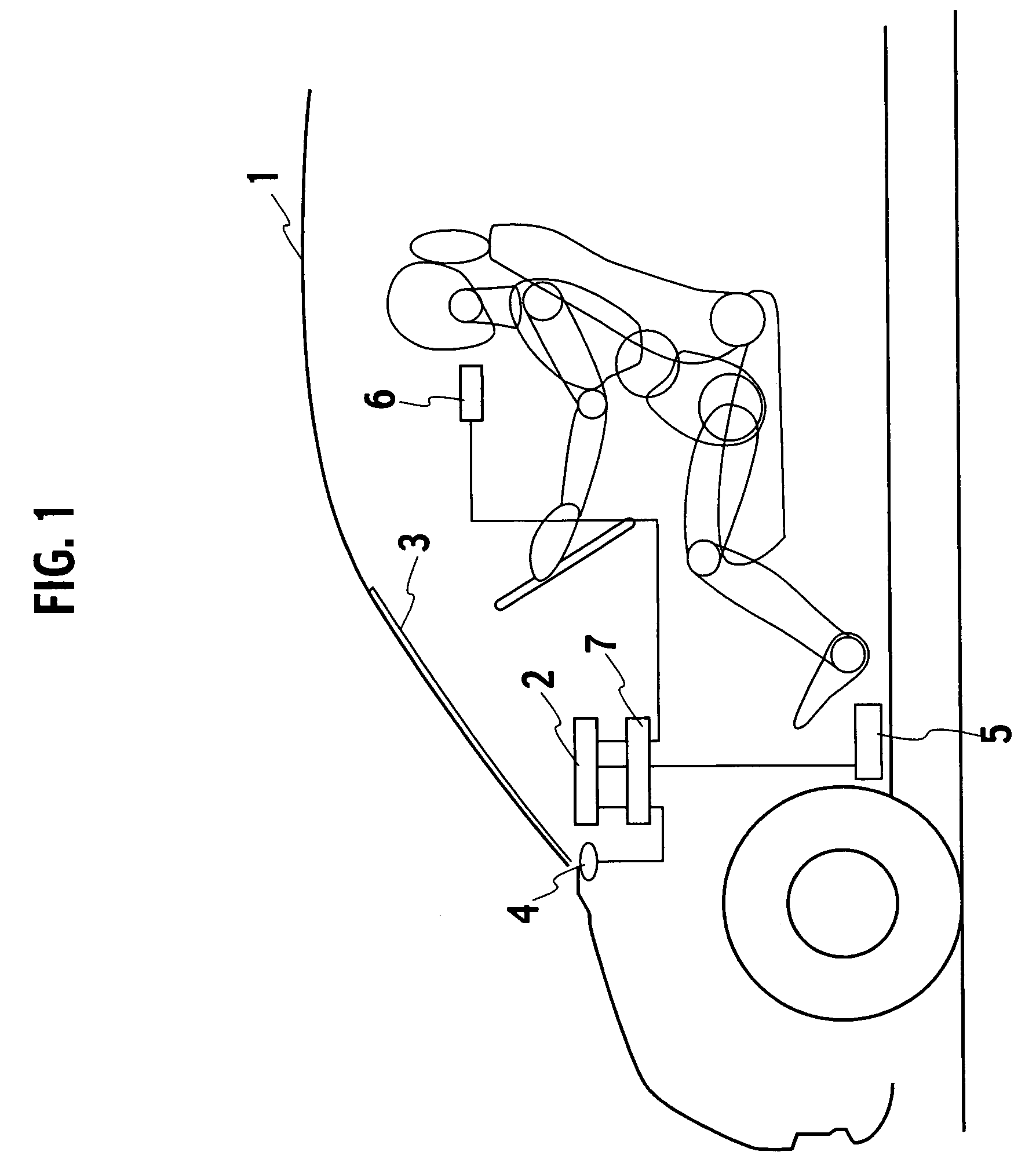

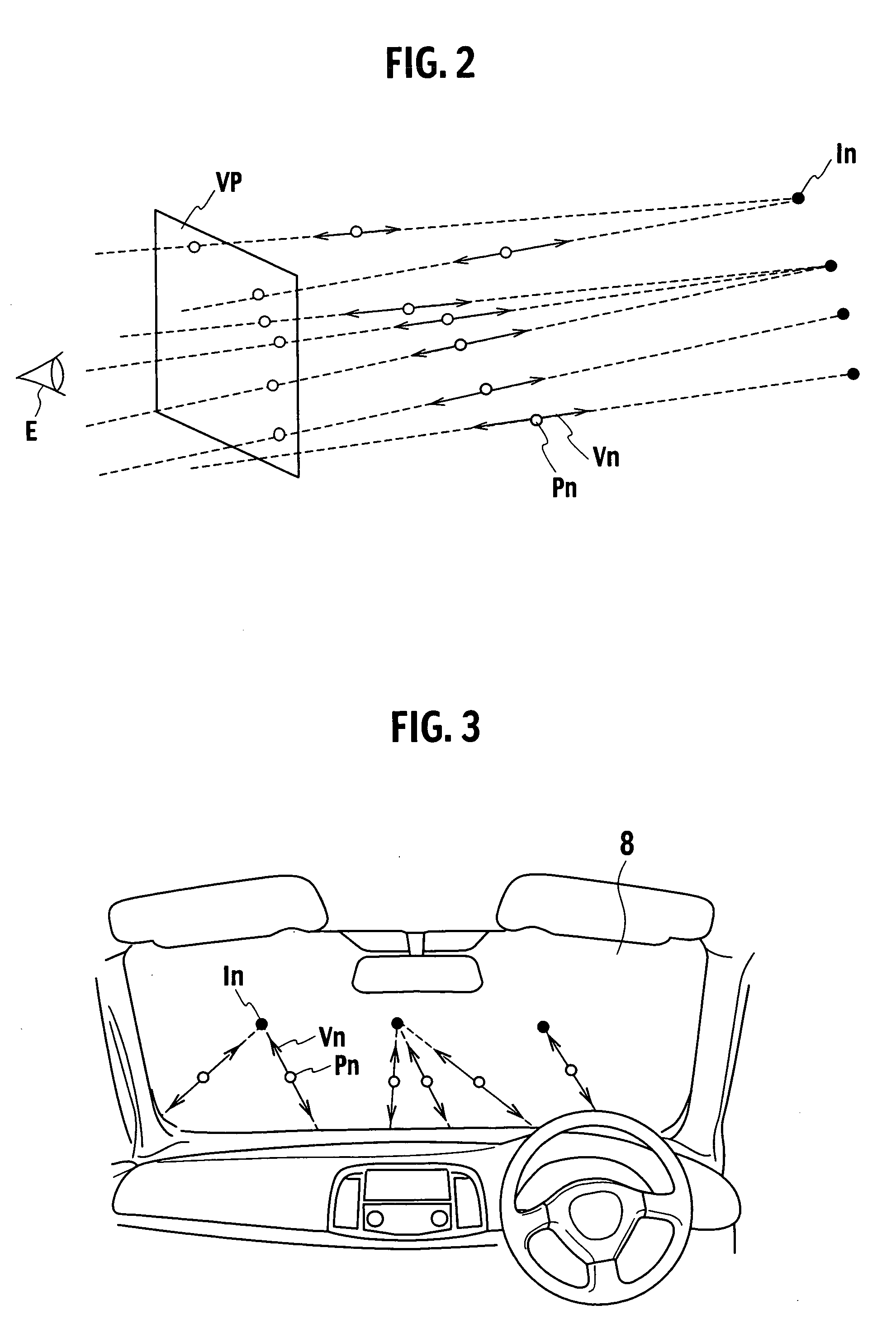

Drive sense adjusting apparatus and drive sense adjusting method

ActiveUS20060022808A1Feel stableIncrease the areaProjectorsAnti-collision systemsDriver/operatorEngineering

A control unit presents a visual stimulus onto a film adhered on an inner surface of a windscreen glass of a vehicle, and controls the visual stimulus so as to allow a driver to perceive the visual stimulus approaching the driver or receding therefrom in response to detection results of a driving environment detection unit, a vehicle status detection unit and a driver status detection unit. In such a way, visually induced vection can be produced for the driver by the visual stimulus. Accordingly, a drive sense of the driver can be adjusted in response to a vehicle state quantity, a driving environment and a driver state.

Owner:NISSAN MOTOR CO LTD

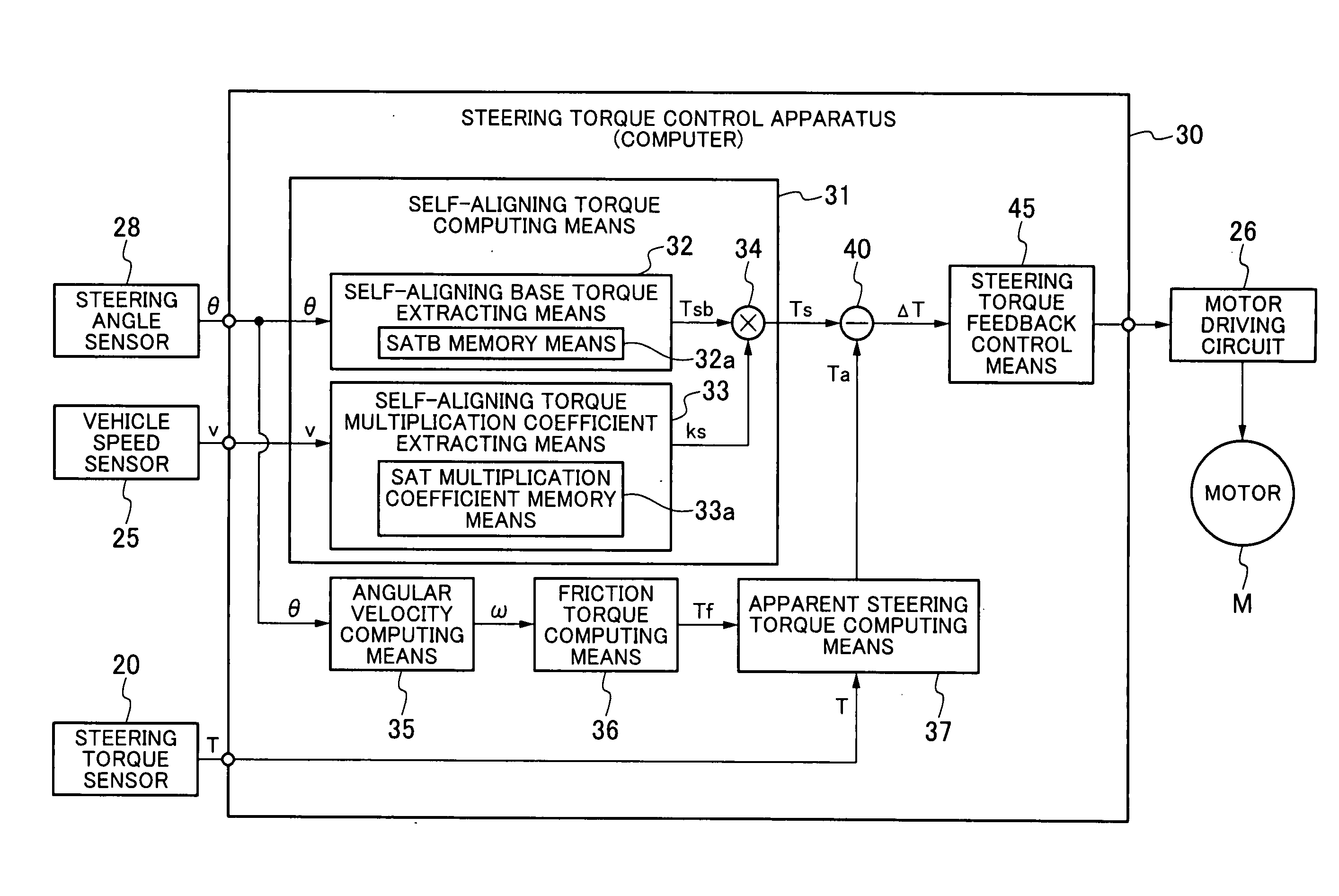

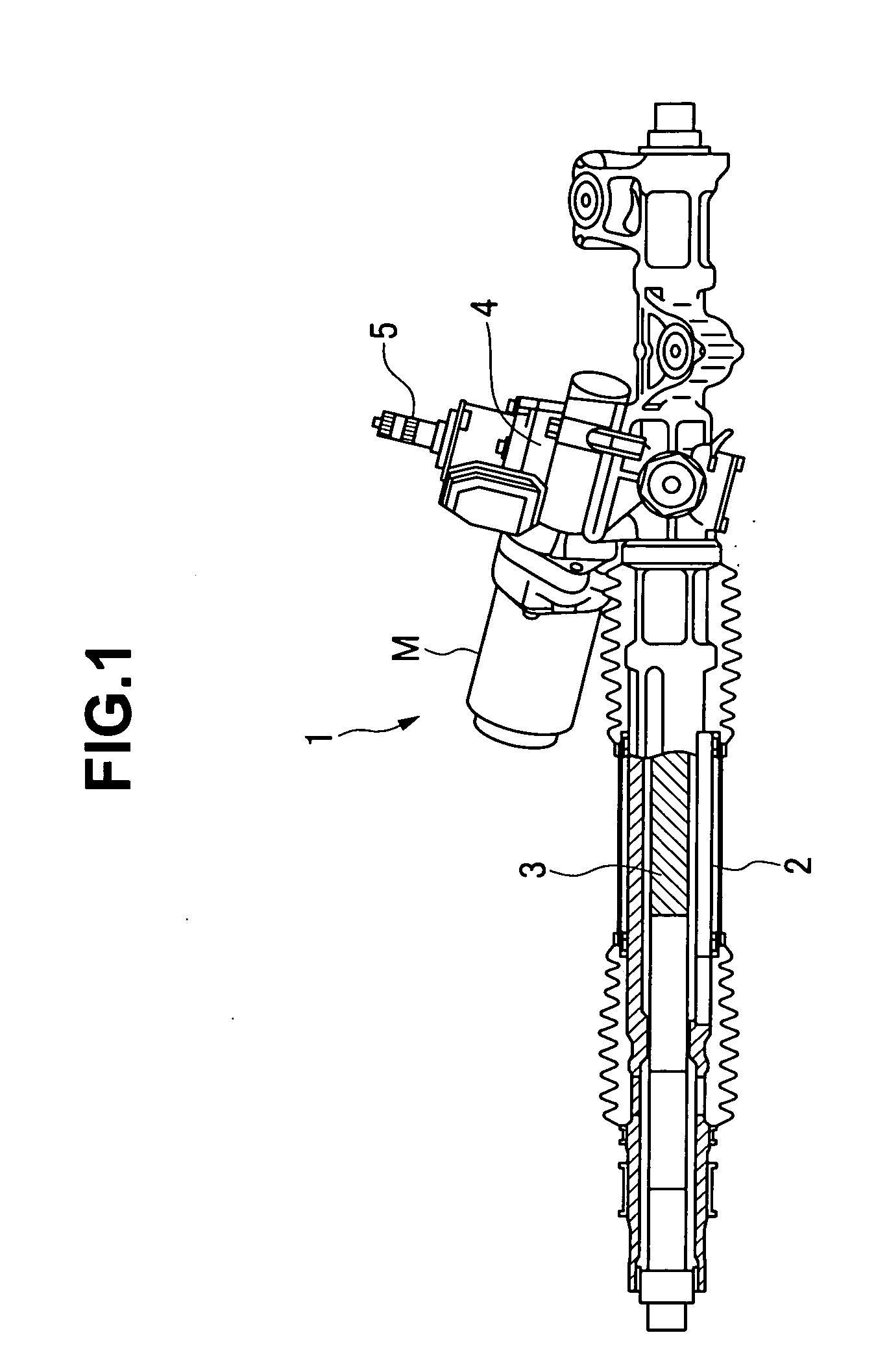

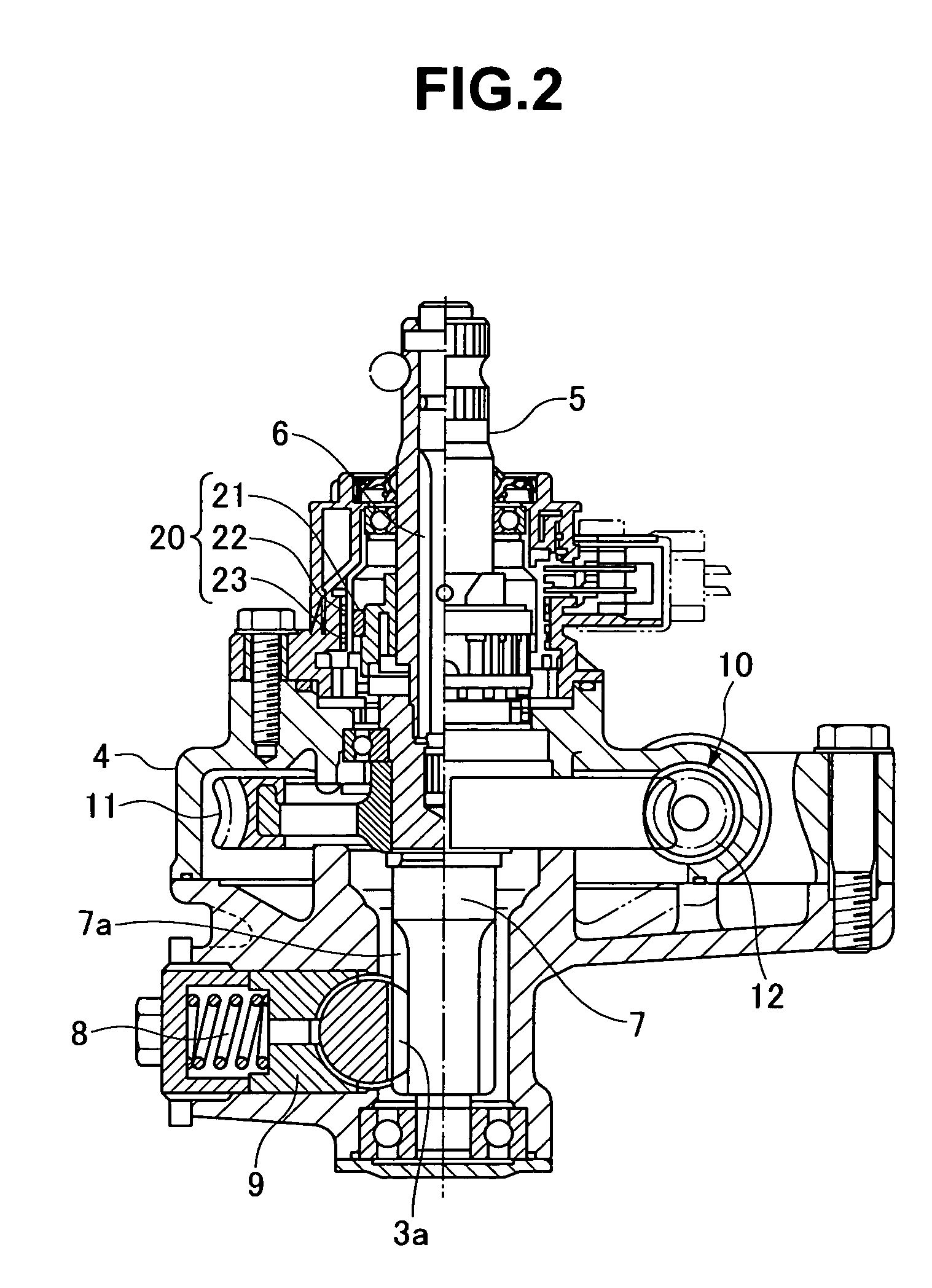

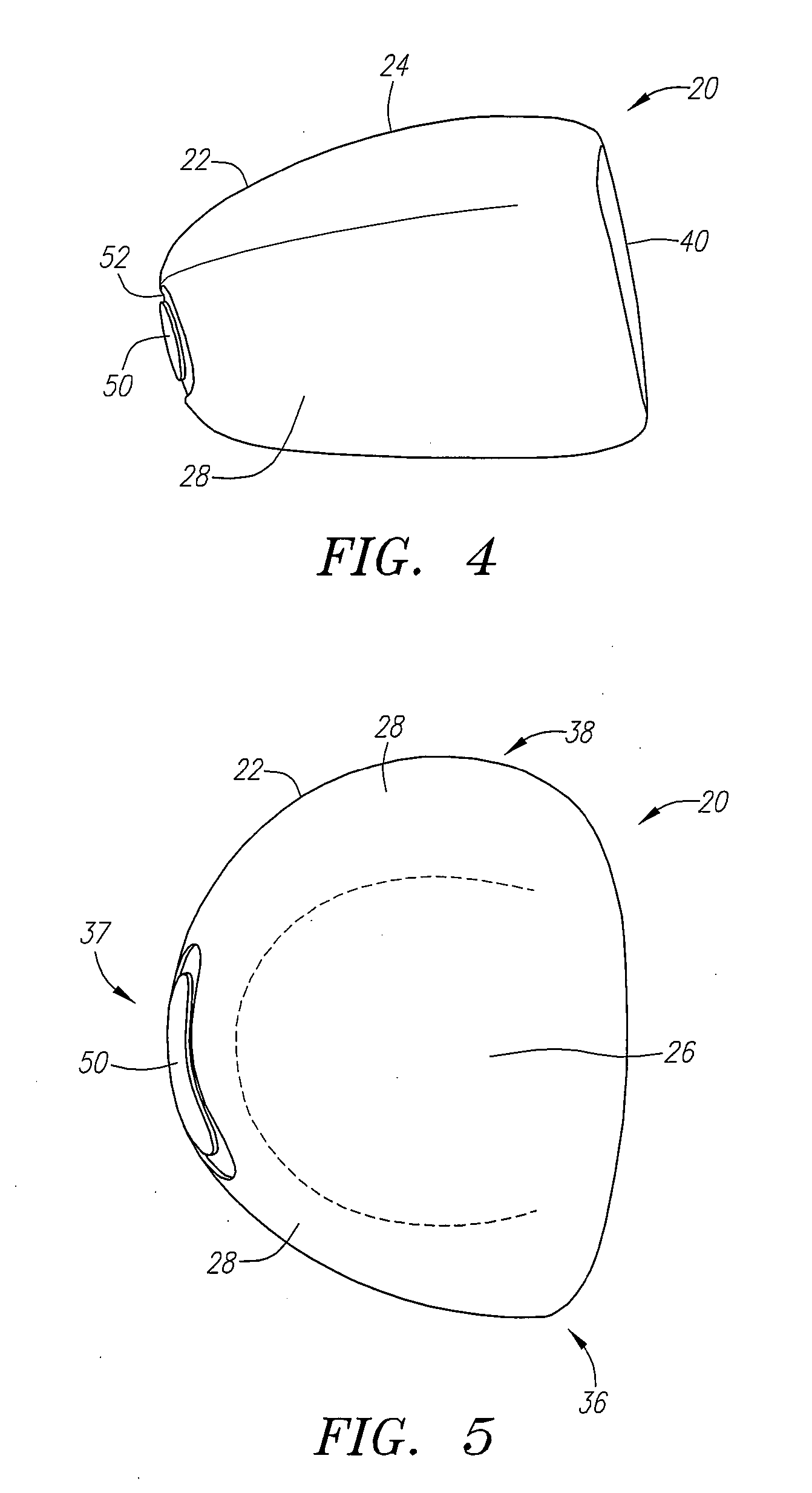

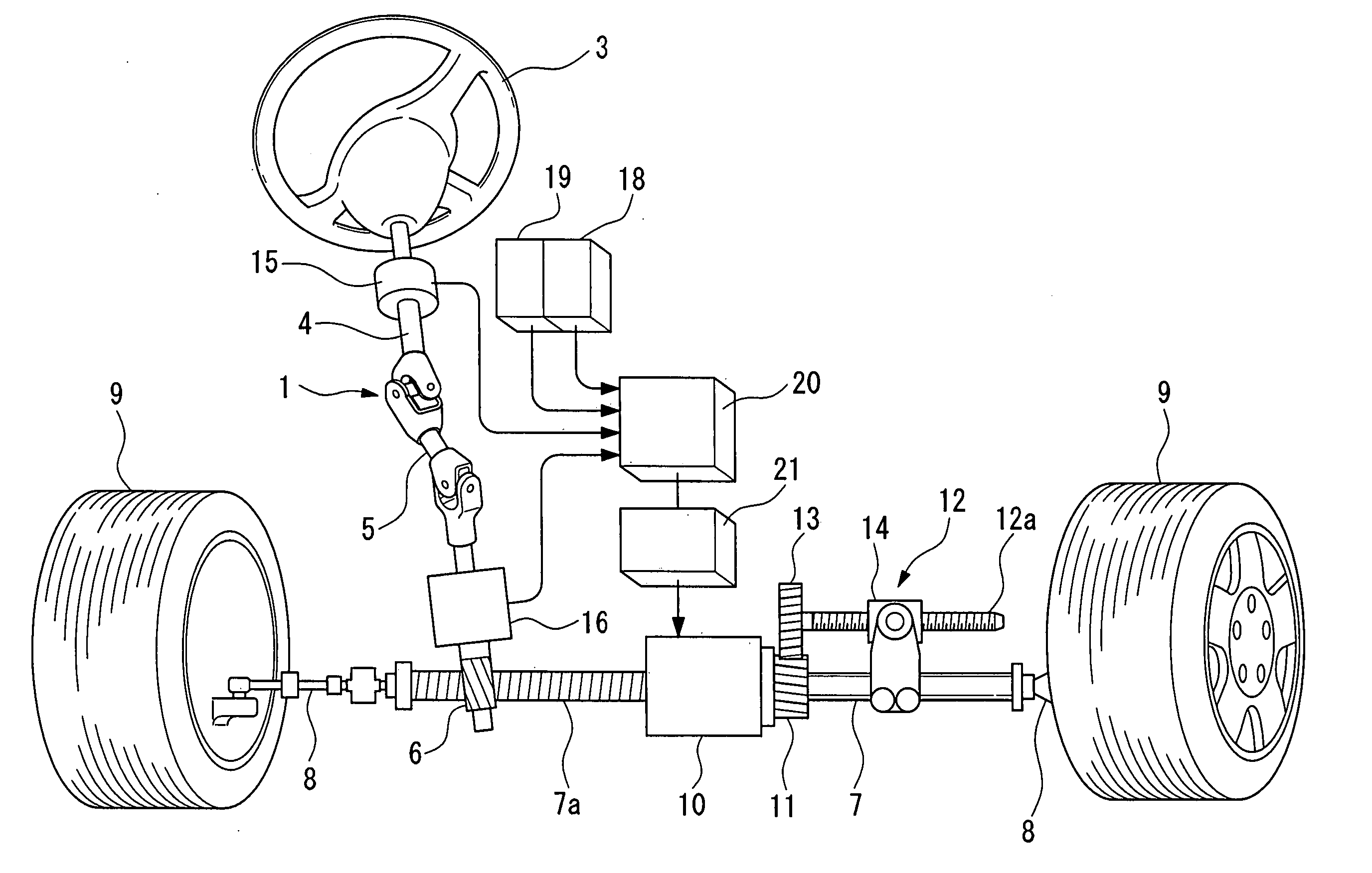

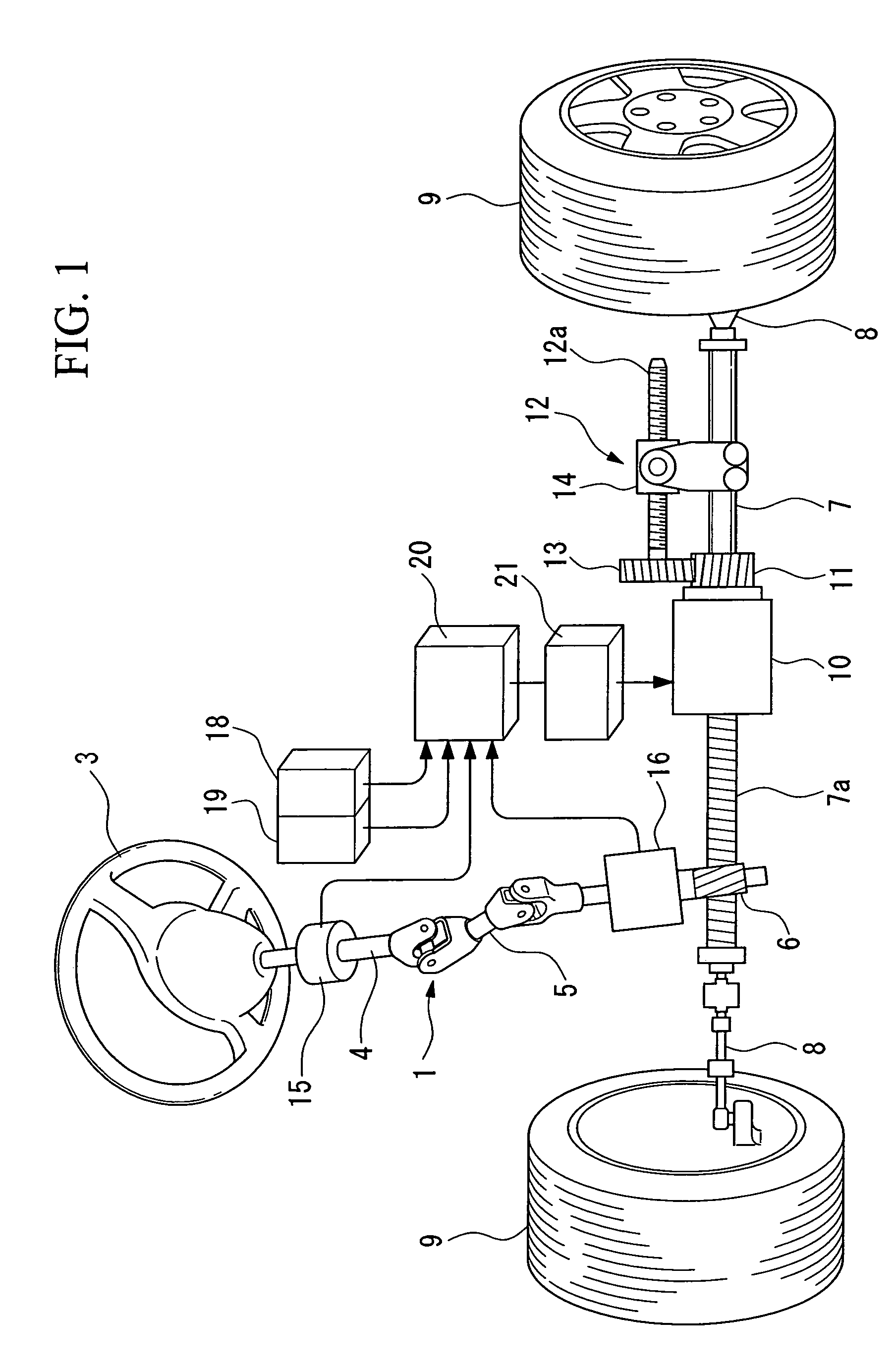

Motor-driven power steering apparatus

InactiveUS20070144824A1Feel stableDigital data processing detailsSteering initiationsElectric power steeringSteering angle

A motor-driven power steering apparatus is provided with a self-aligning torque computing means for computing a self-aligning torque based on of a steering angle and a vehicle speed, a friction torque computing means for computing a friction torque in accordance with a steering angle change from a steering angular velocity, an apparent steering torque computing means for computing an apparent steering torque from the friction torque and a steering torque, and a steering torque feedback control means for driving and controlling an assist motor in such a manner that a difference between the self-aligning torque and the apparent steering torque becomes 0.

Owner:SHOWA CORP

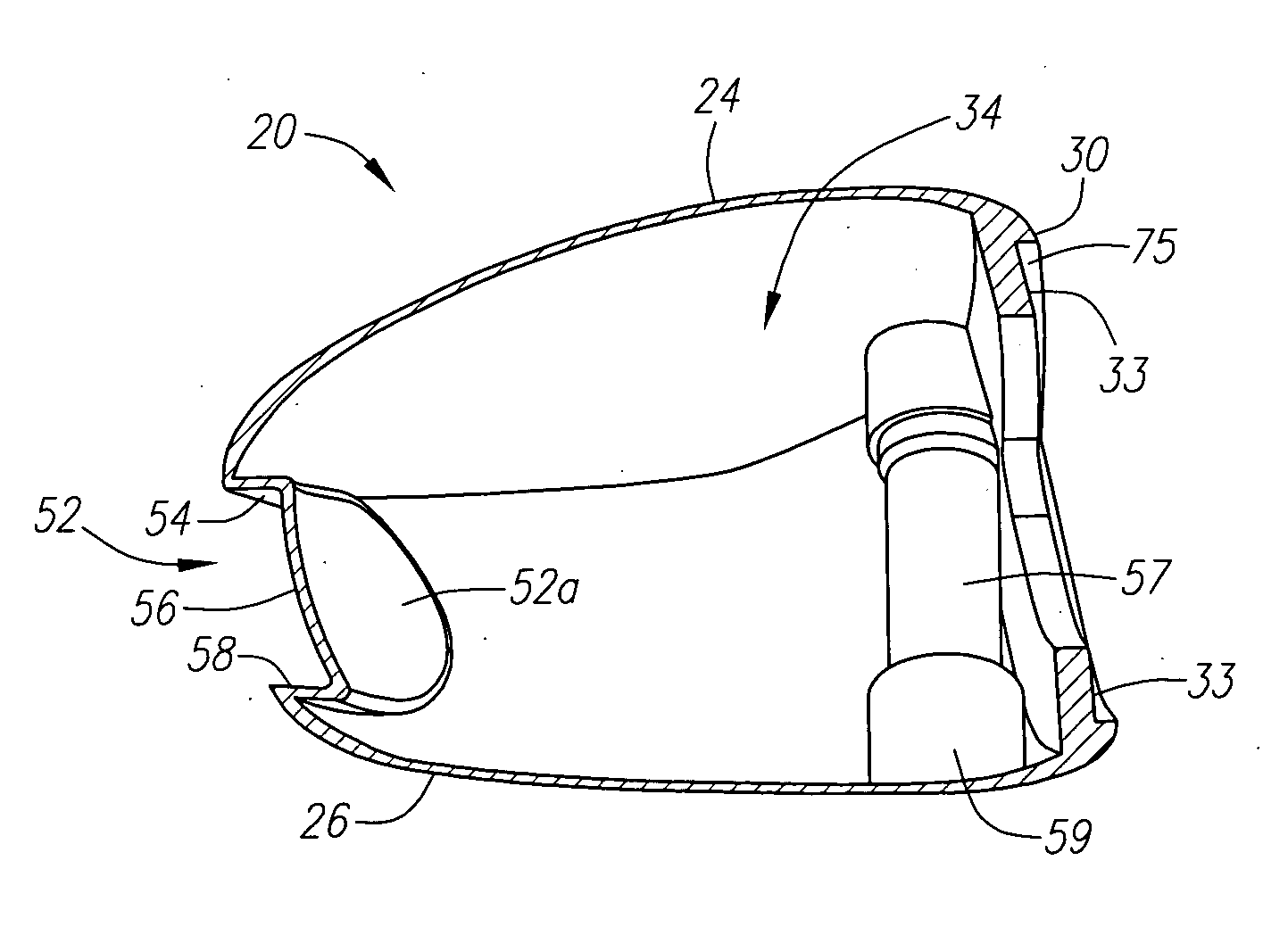

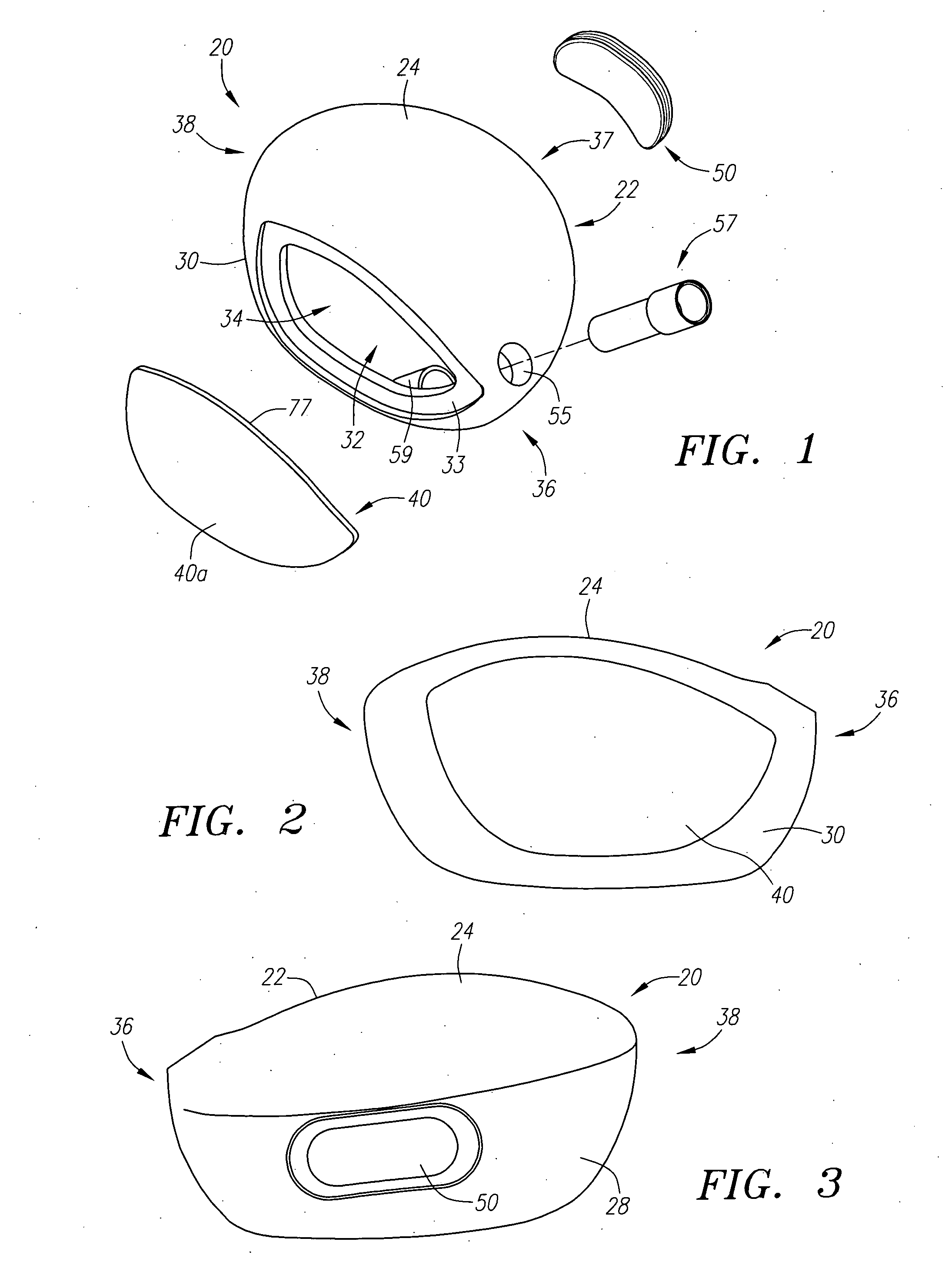

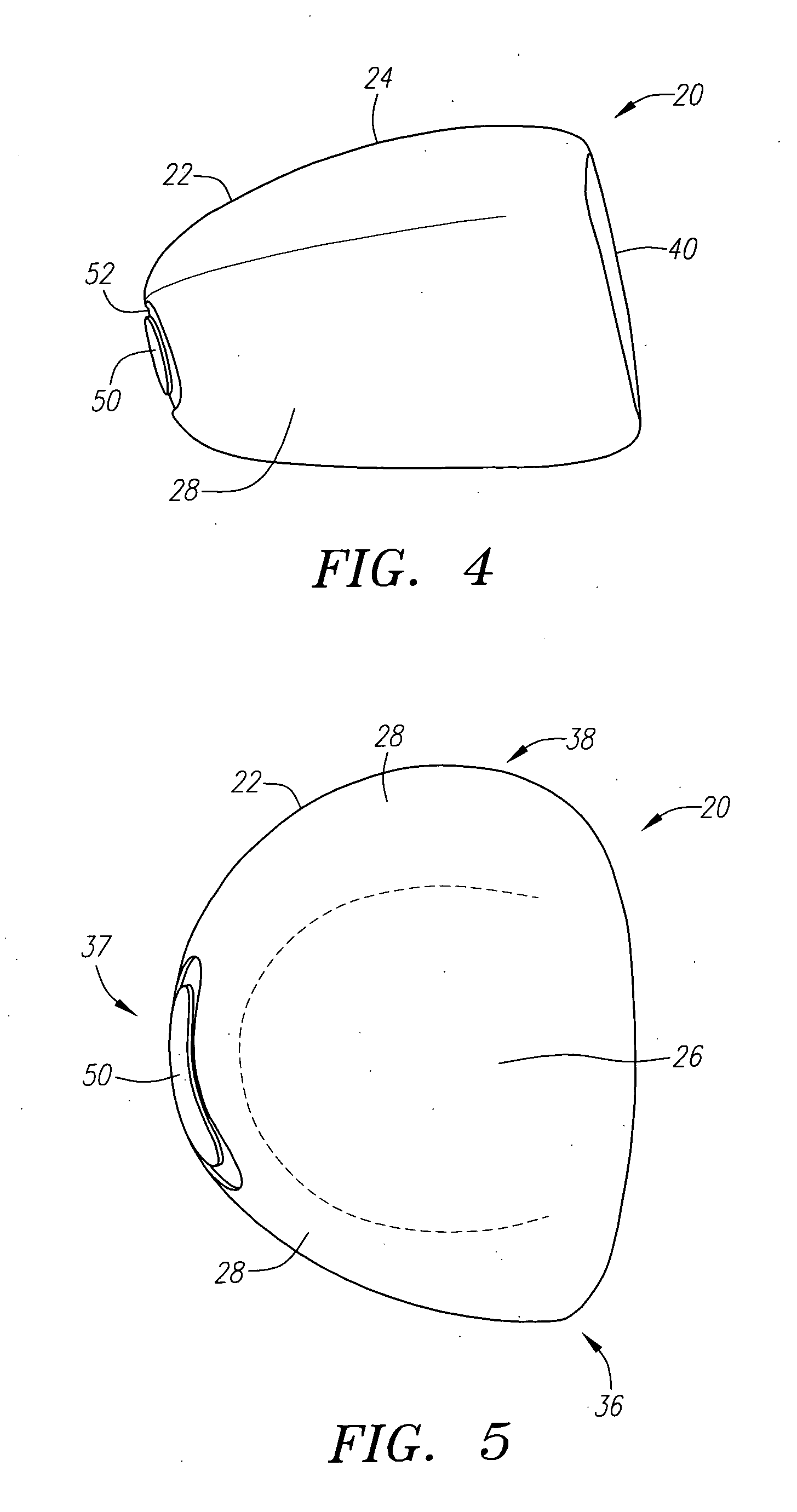

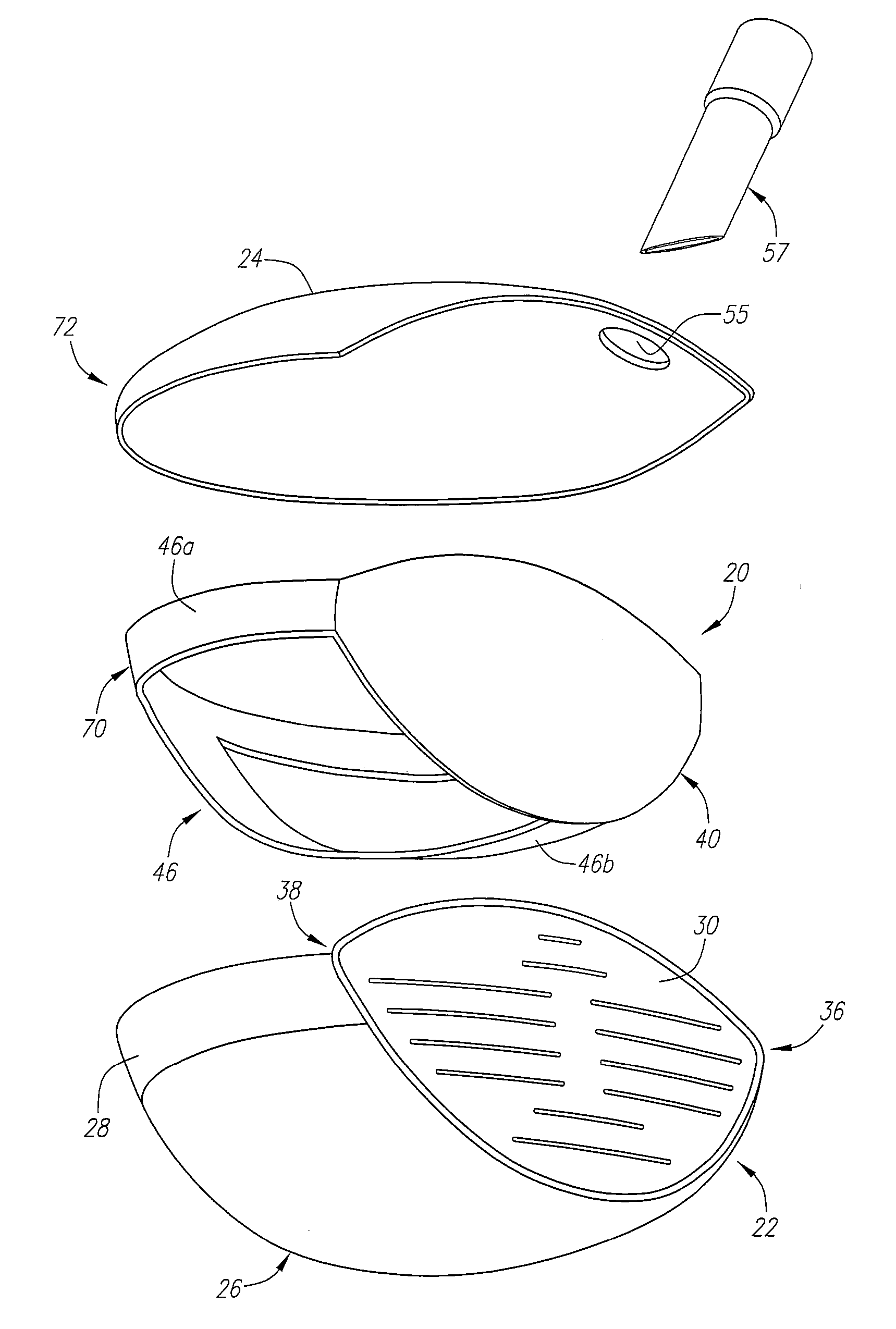

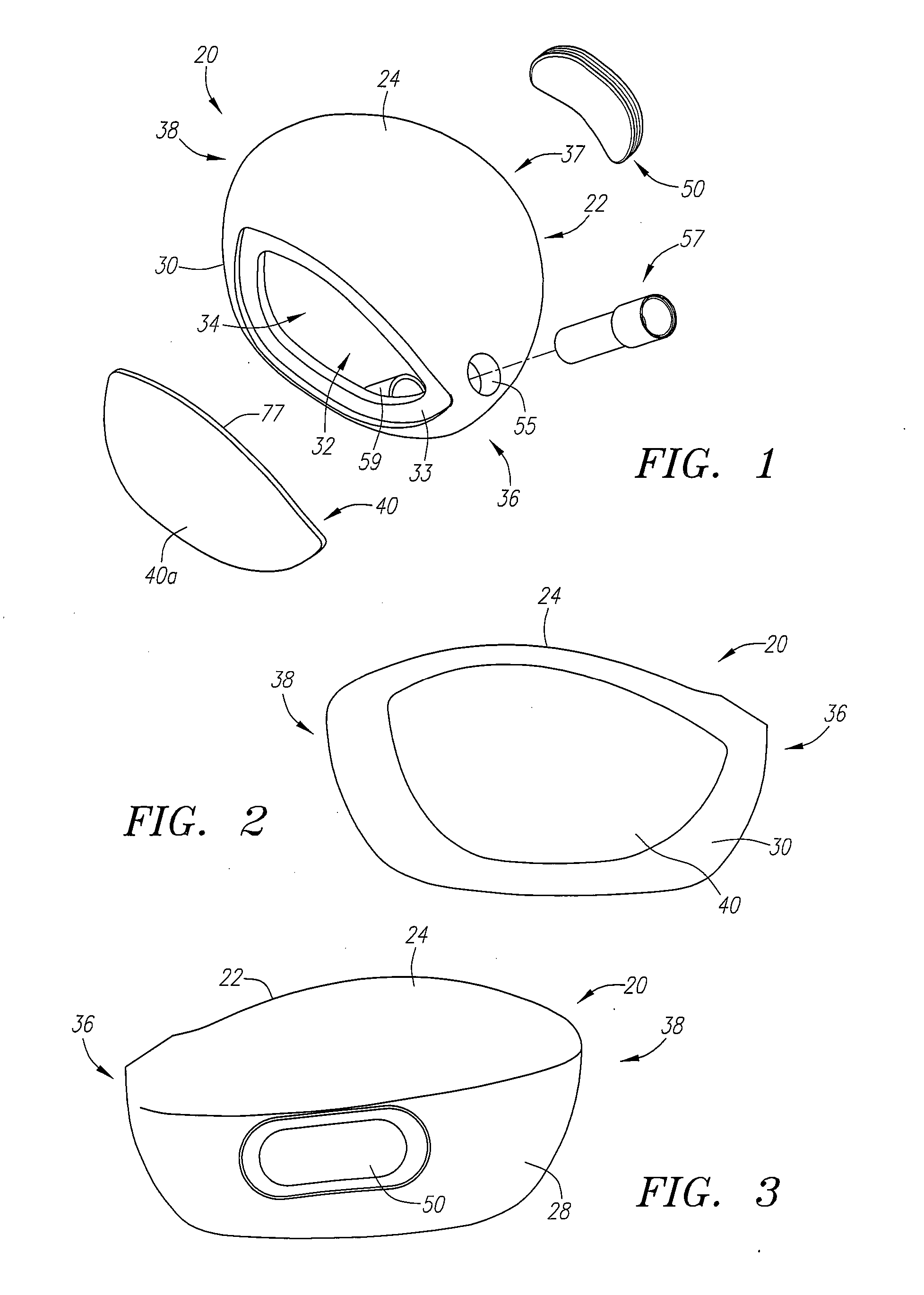

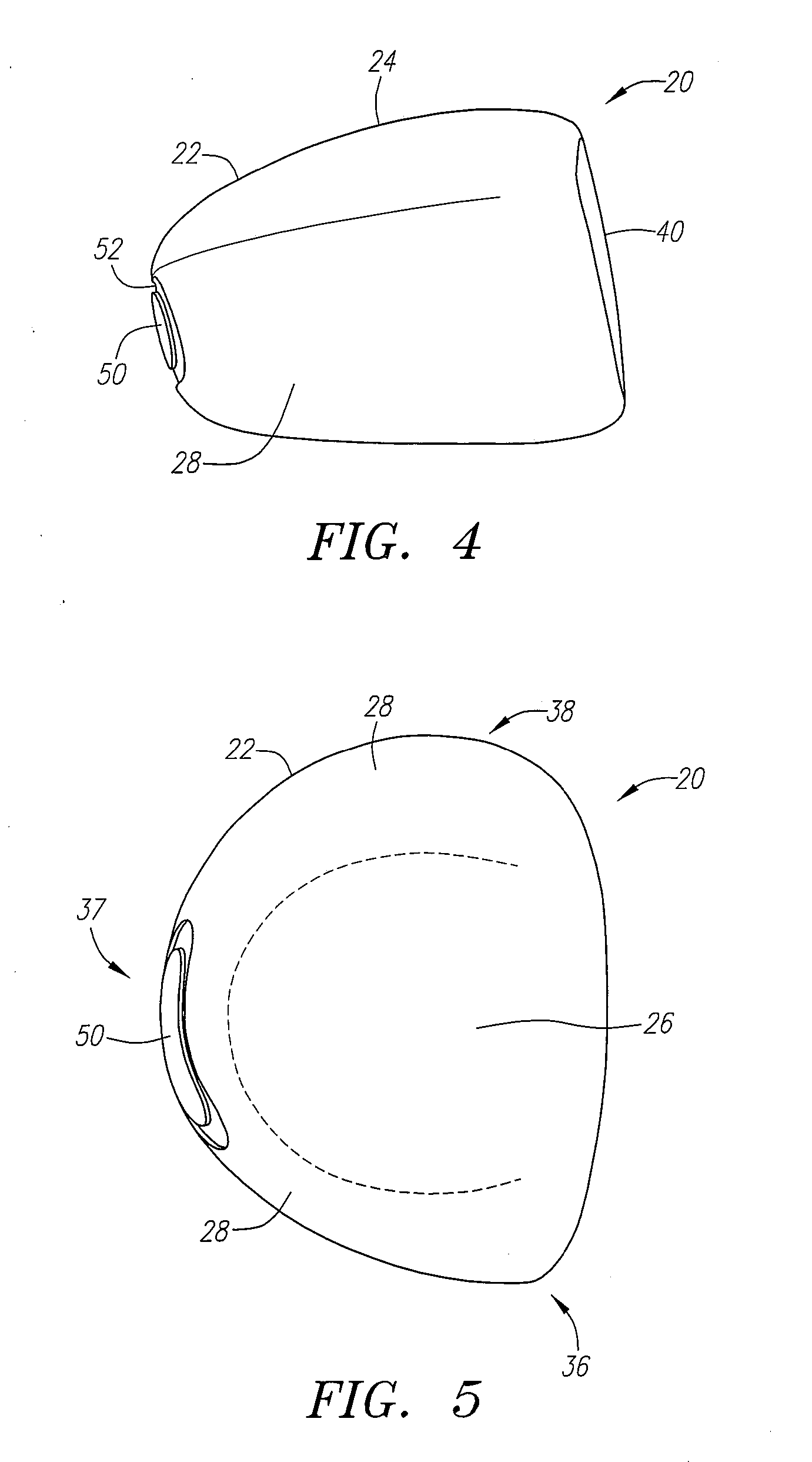

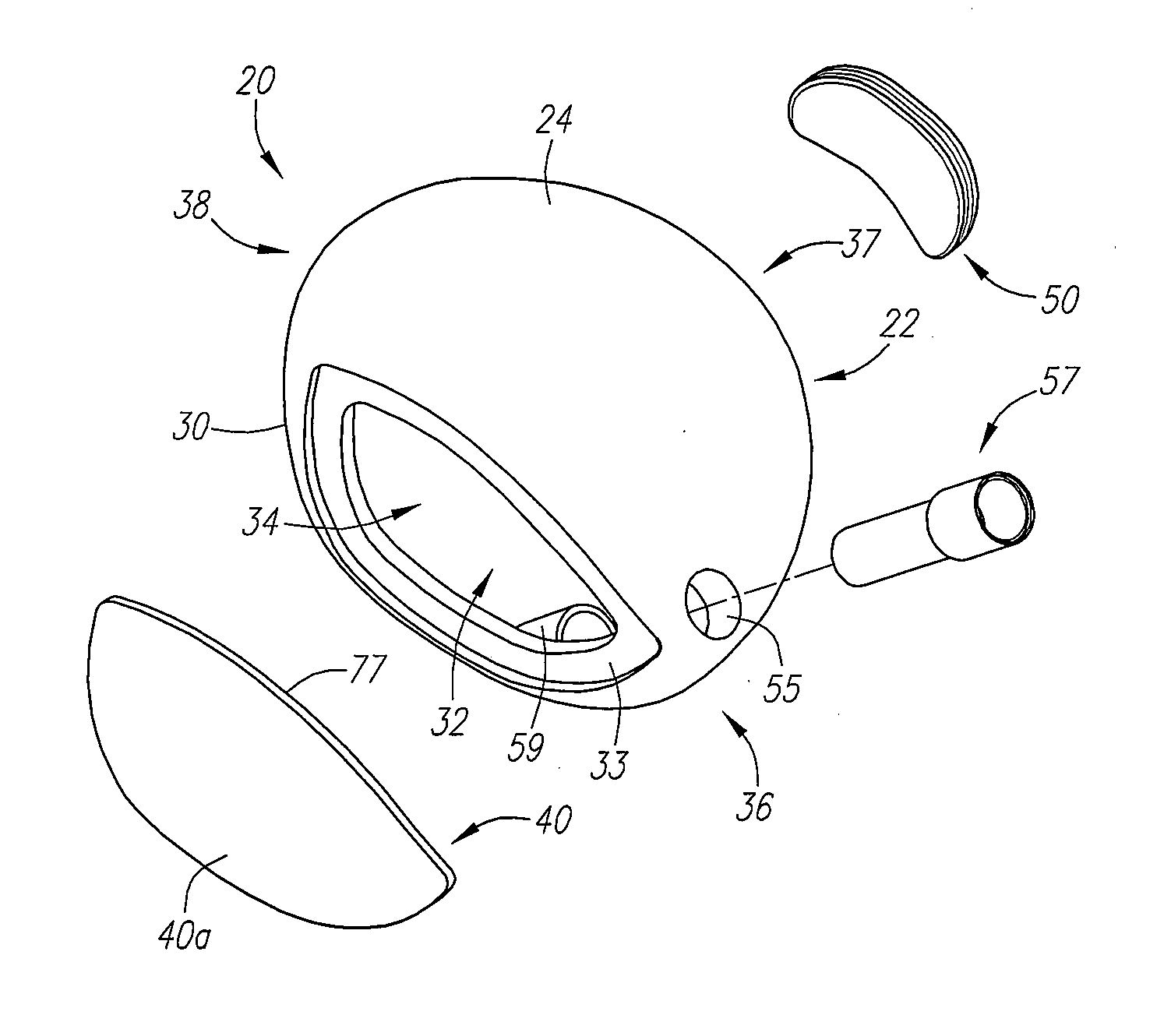

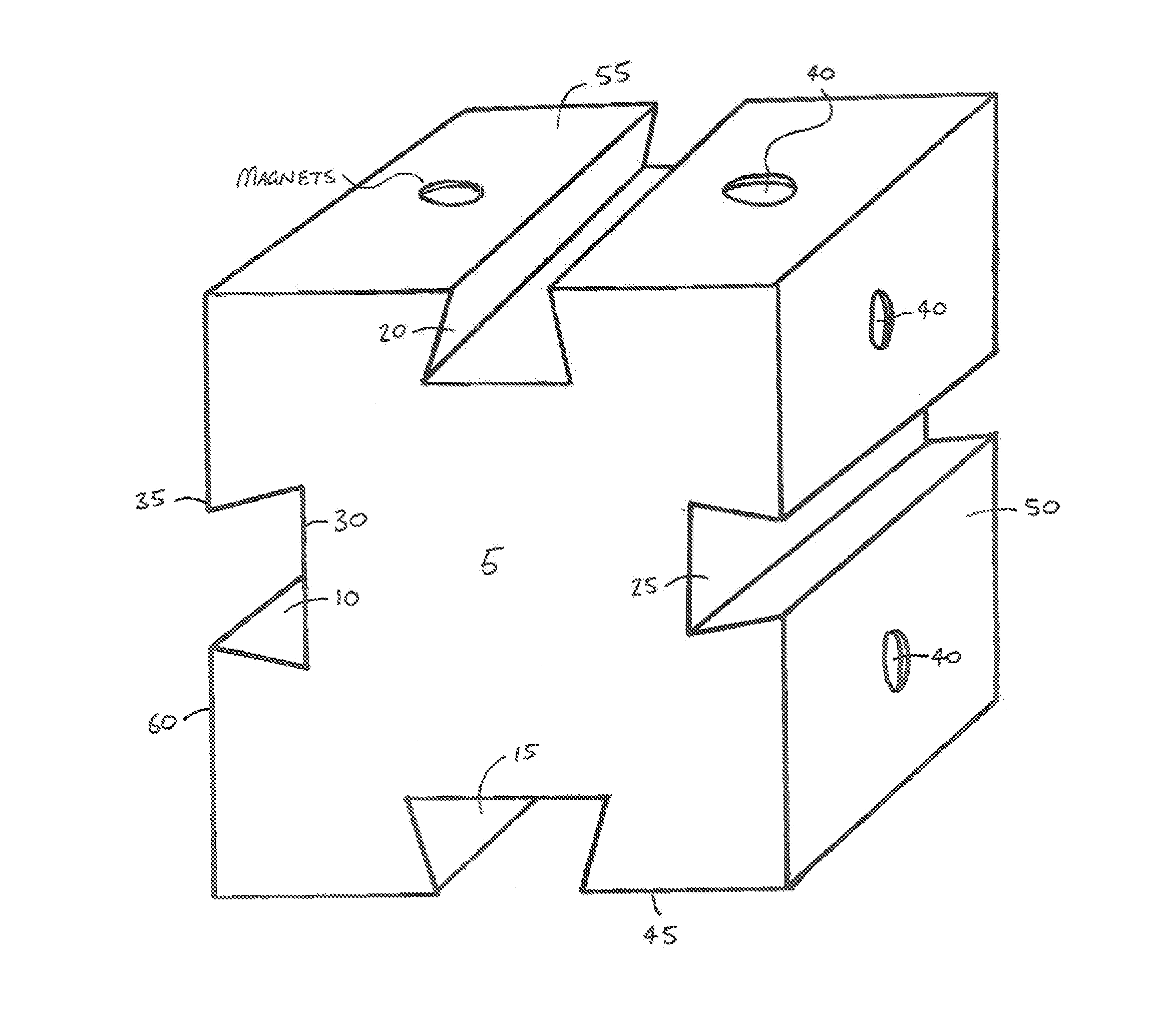

Golf club head

ActiveUS20050288124A1Improve mass distributionOptimized moments of inertiaGolf clubsRacket sportsEngineeringGravity center

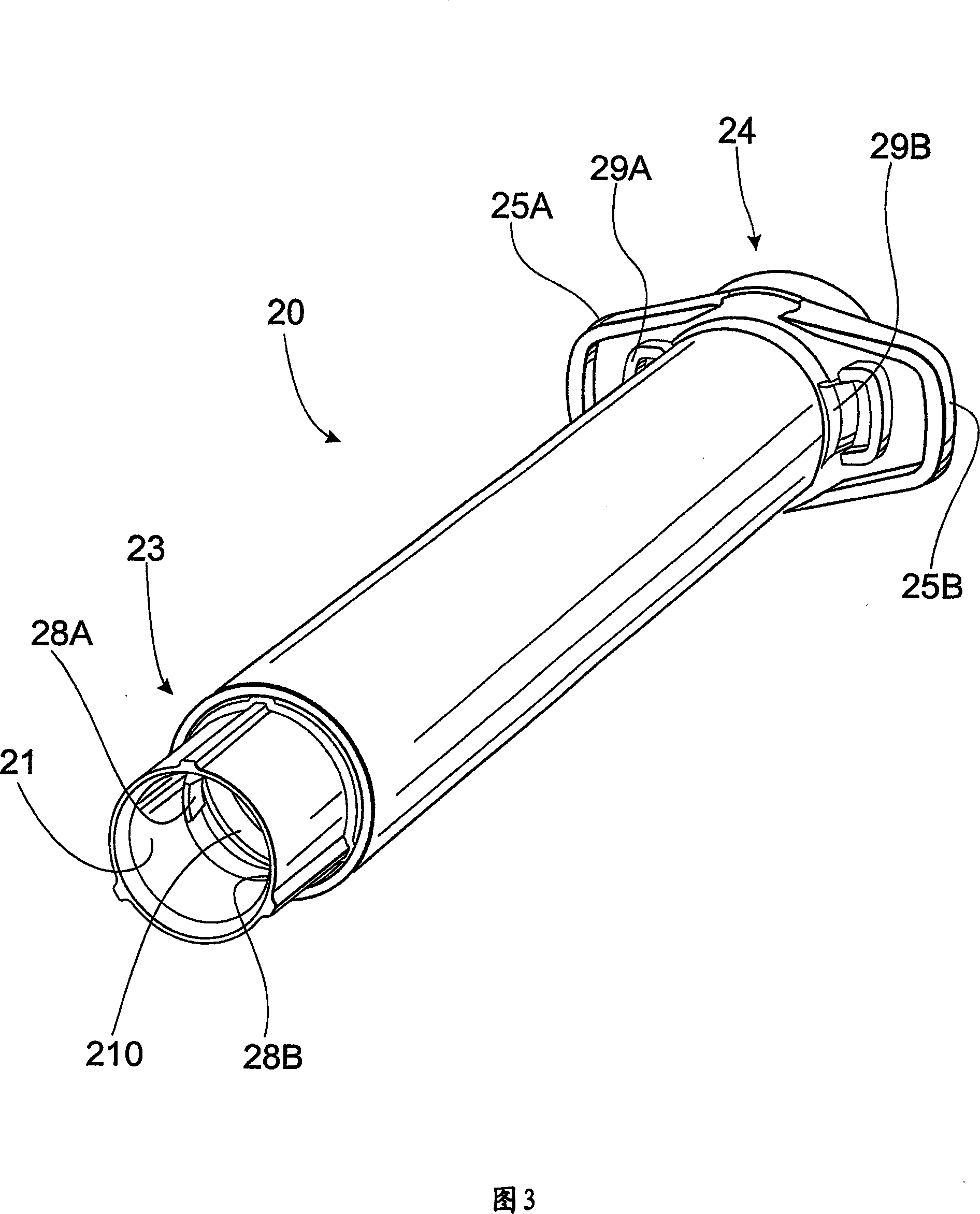

A golf club head (20) having optimized inertial properties and center of gravity is disclosed. The golf club head (20) preferably has a volume between 300 cubic centimeters and 500 cubic centimeters. The golf club head (20) has a center of gravity located less than 1.7 inches from an exterior surface of a front wall (30). The positioning of the center of gravity of the golf club head (20) and the optimized inertial properties provide the golf club with greater ball spin robustness and better performance.

Owner:CALLAWAY GOLF CO

Golf Club Head

ActiveUS20070004531A1Improve mass distributionOptimized moments of inertiaGolf clubsRacket sportsEngineeringGravity center

A golf club head (20) having optimized inertial properties and center of gravity is disclosed. The golf club head (20) preferably has a volume between 300 cubic centimeters and 500 cubic centimeters. The golf club head (20) has a center of gravity located less than 1.7 inches from an exterior surface of a front wall (30). The positioning of the center of gravity of the golf club head (20) and the optimized inertial properties provide the golf club with greater ball spin robustness and better performance.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Golf Club Head

A golf club head (20) having a center of gravity located relatively forward toward the front wall (30) or striking plate (40) of the golf club head (20), and a relatively high moment of inertia about the Iyy axis through the center of gravity of the golf club head (20) is disclosed. The golf club head (20) preferably has a volume between 300 cubic centimeters and 500 cubic centimeters. The golf club head (20) preferably has a mass between 105 grams and 300 grams. The positioning of the of the center of gravity of the golf club head (20) and the relatively high moment of inertia Iyy through the center of gravity provide for a golf club with greater robustness and better performance.

Owner:TOPGOLF CALLAWAY BRANDS CORP

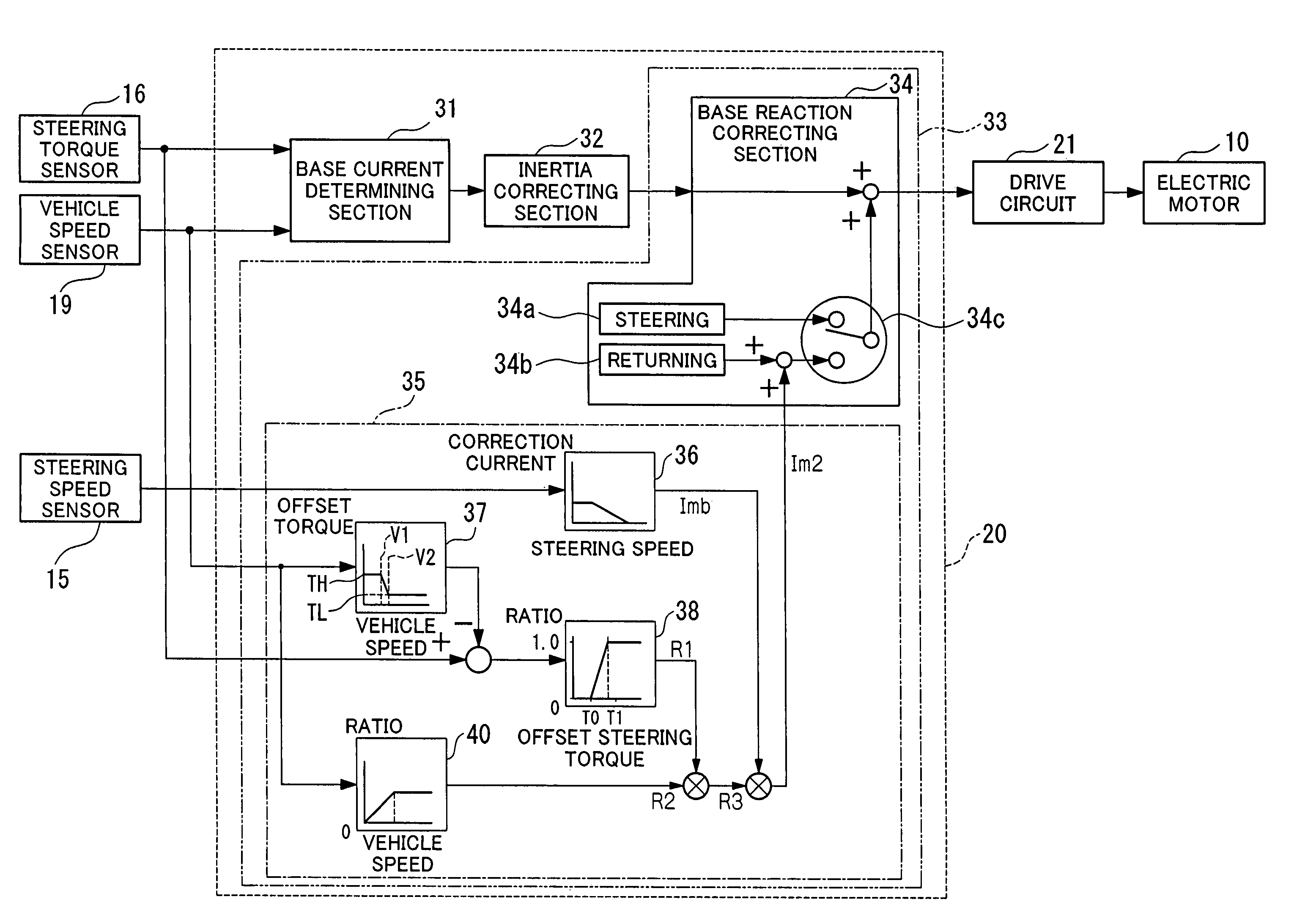

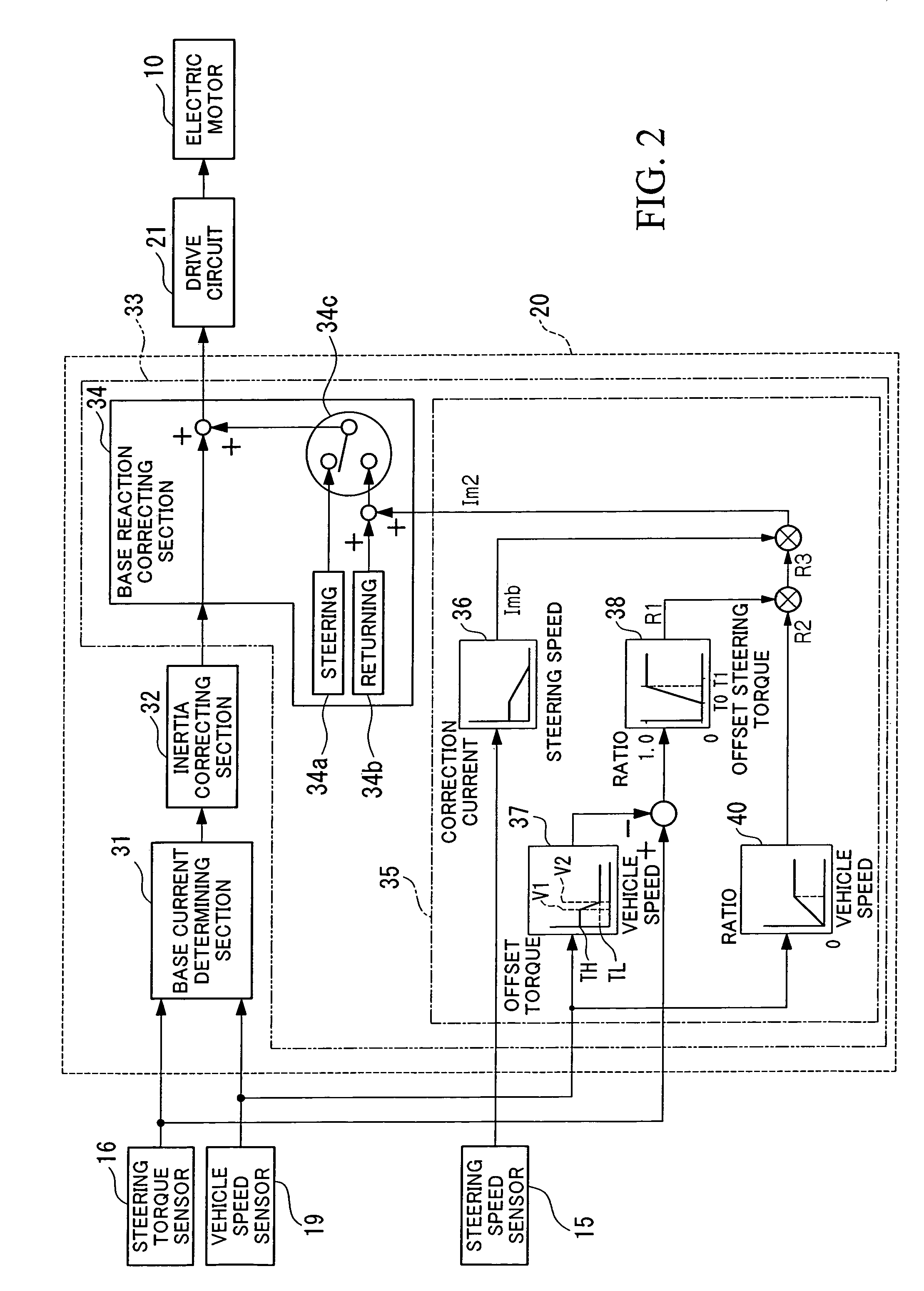

Reaction control system for obtaining preferable steering feeling

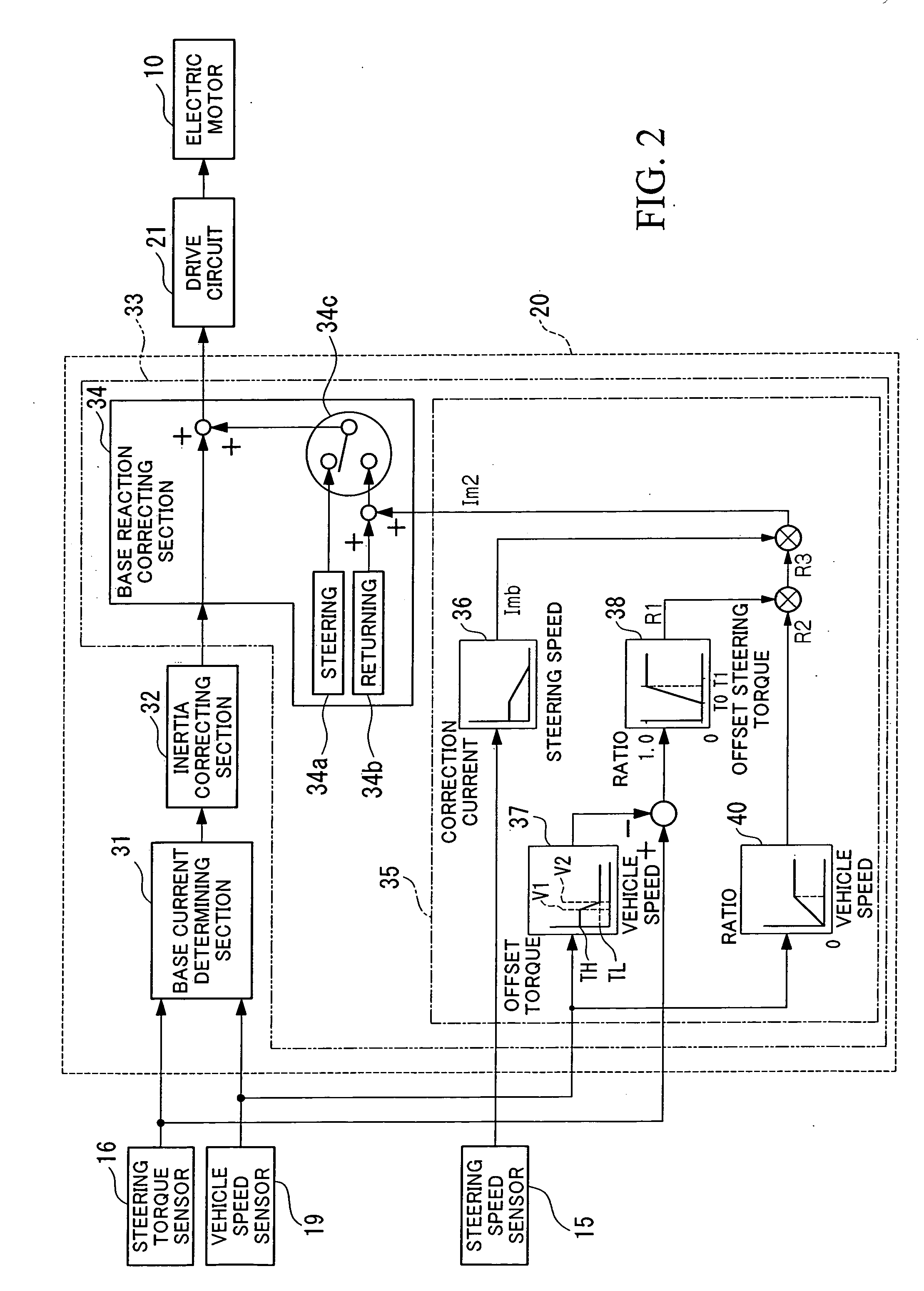

ActiveUS20060006021A1Preferable steeringFeel stableSteering initiationsDigital data processing detailsControl systemEngineering

A reaction control system controls a reactive force to be applied to an operating device operated by a driver of a vehicle. The system includes a device for measuring a steering speed of steering of the operating device; a device for measuring a steering torque applied to the operating device; and a reactive force correcting device for correcting the reactive force in a manner such that the corrected reactive force increases at least when the measured steering speed is zero, and that the higher the measured steering torque, the higher the corrected reactive force is. The reactive force correcting device may correct the reactive force in a manner such that the higher a speed of the vehicle, the higher the corrected reactive force is. A non-effectivity range of the steering torque in which the corrected reactive force is not influenced by the steering torque may be defined.

Owner:HONDA MOTOR CO LTD

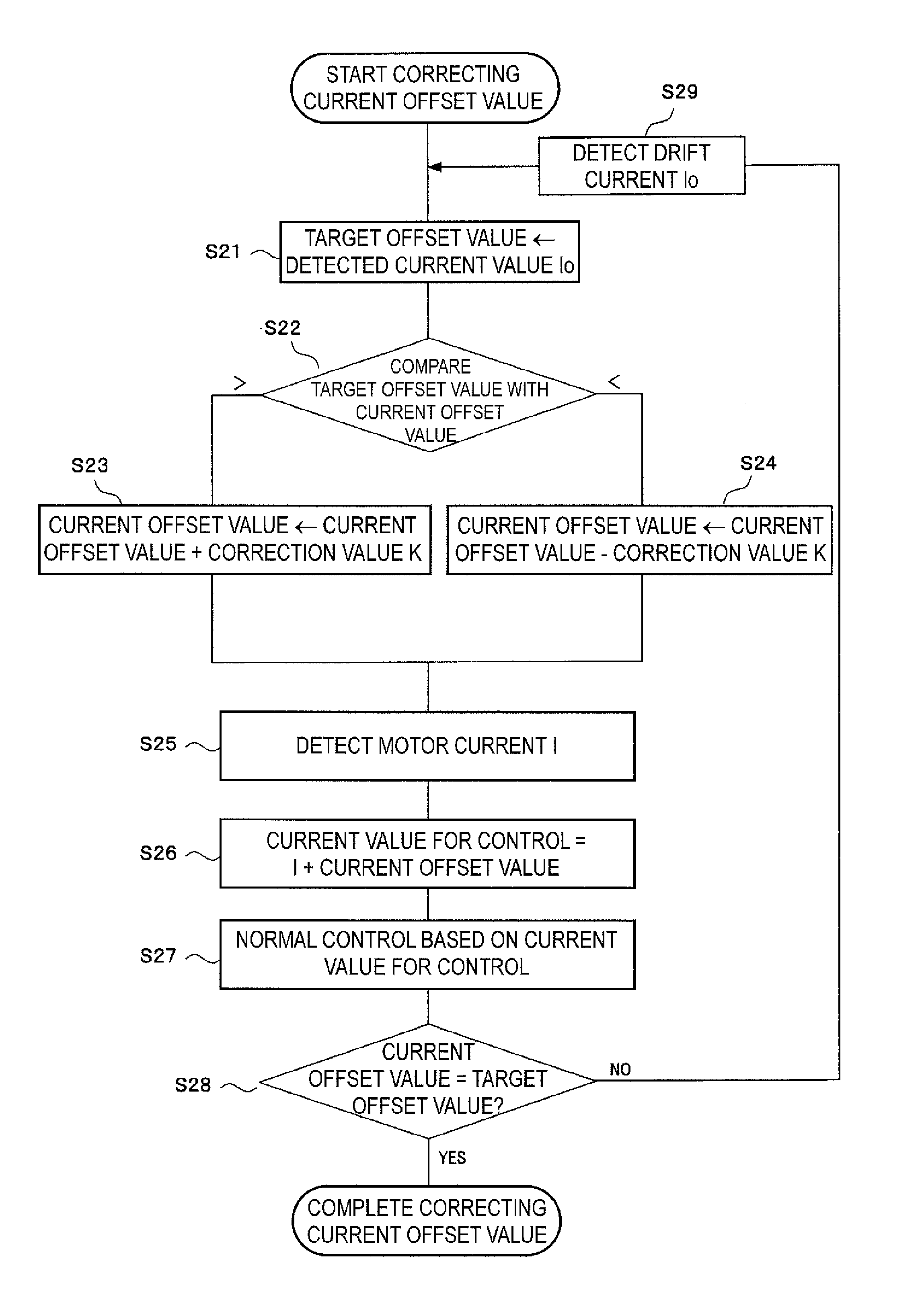

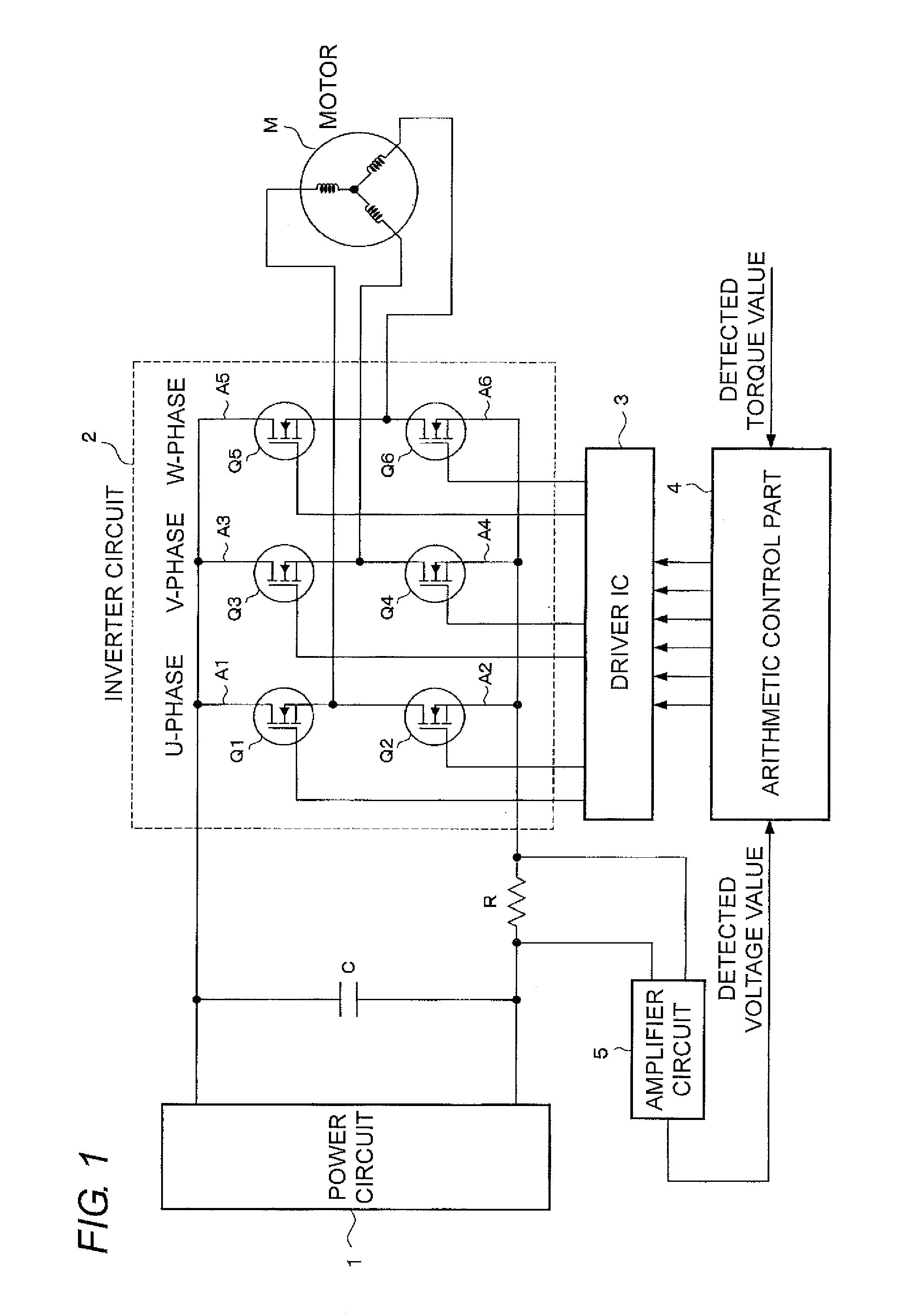

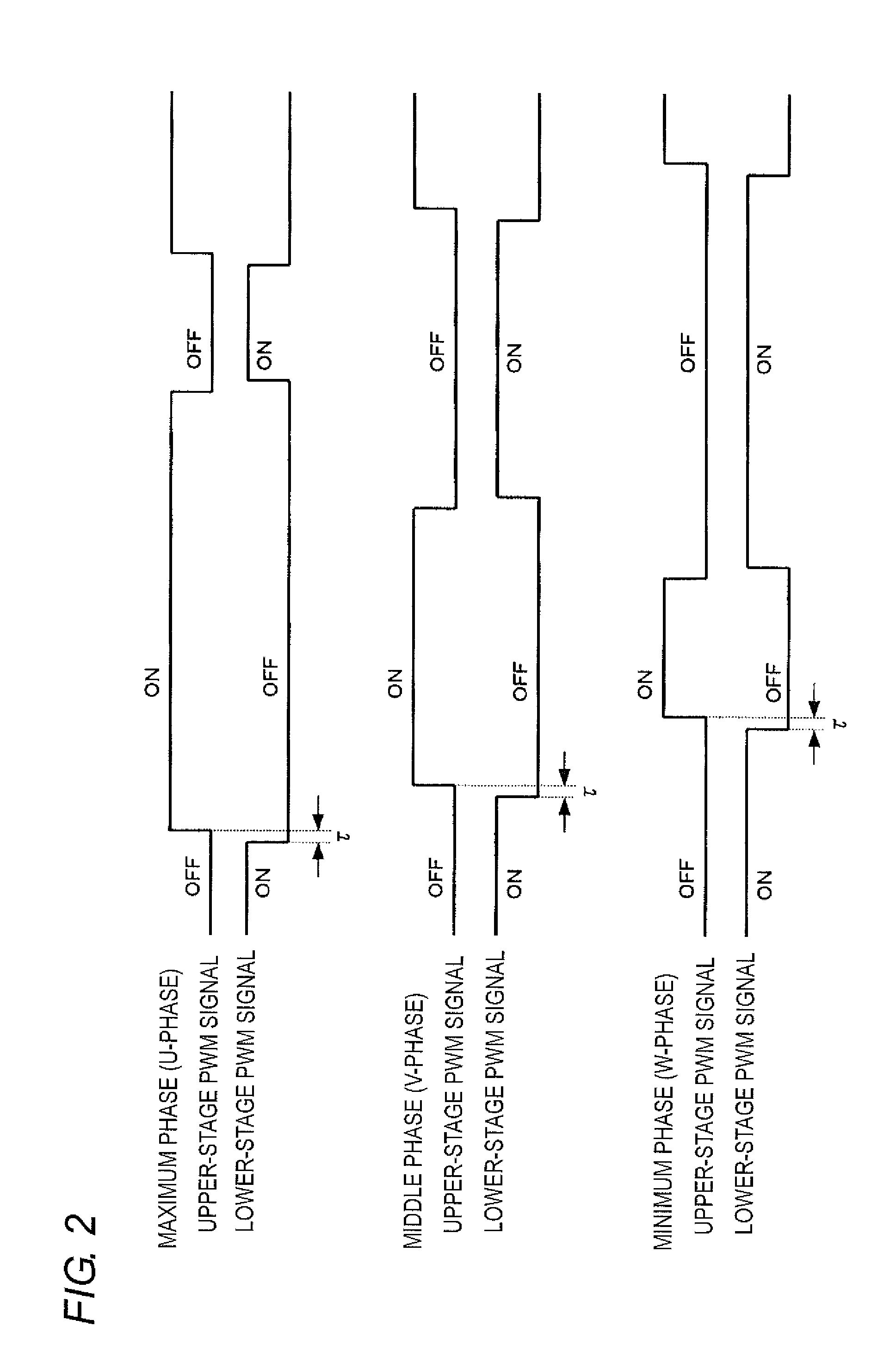

Motor control device

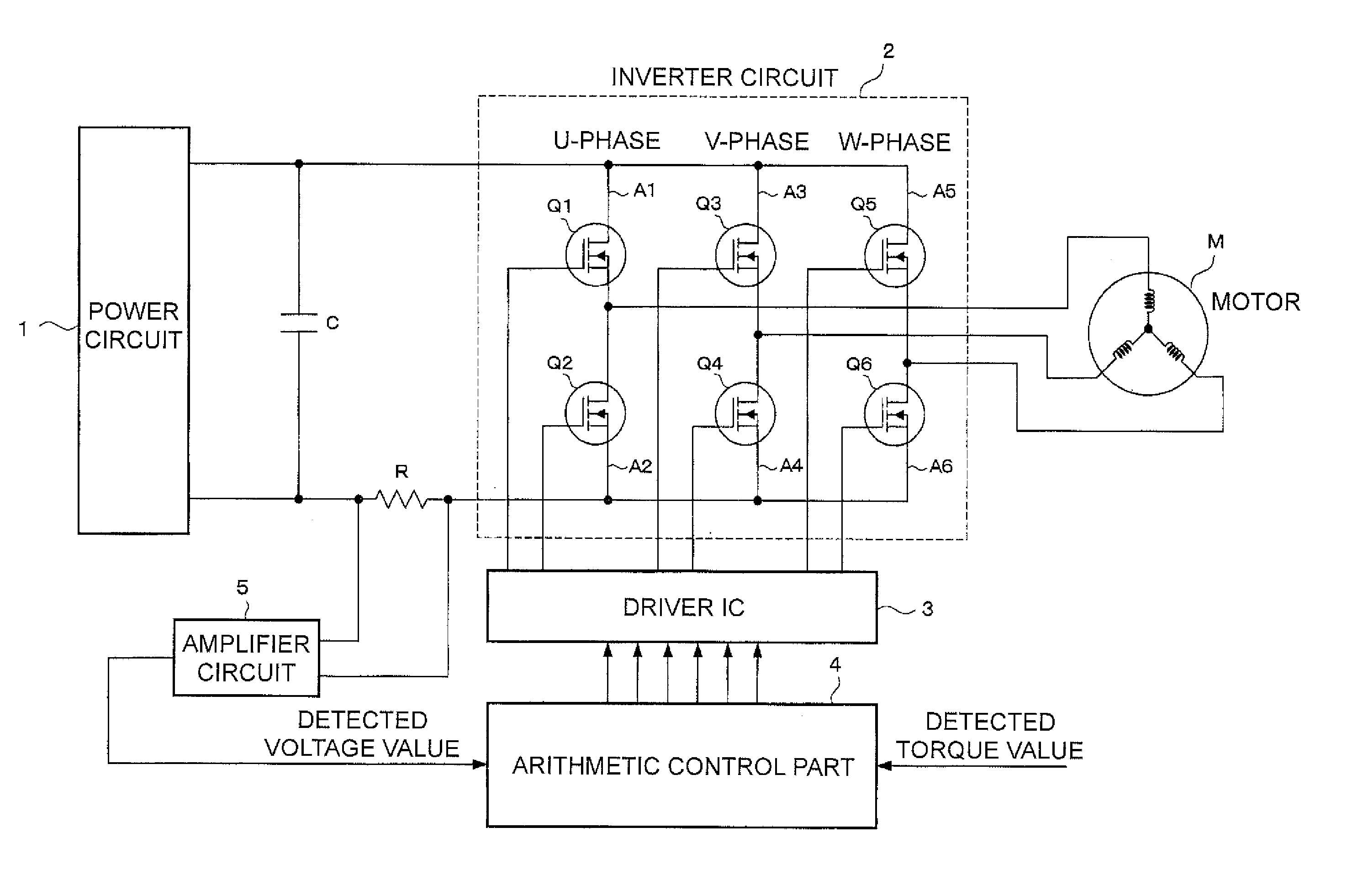

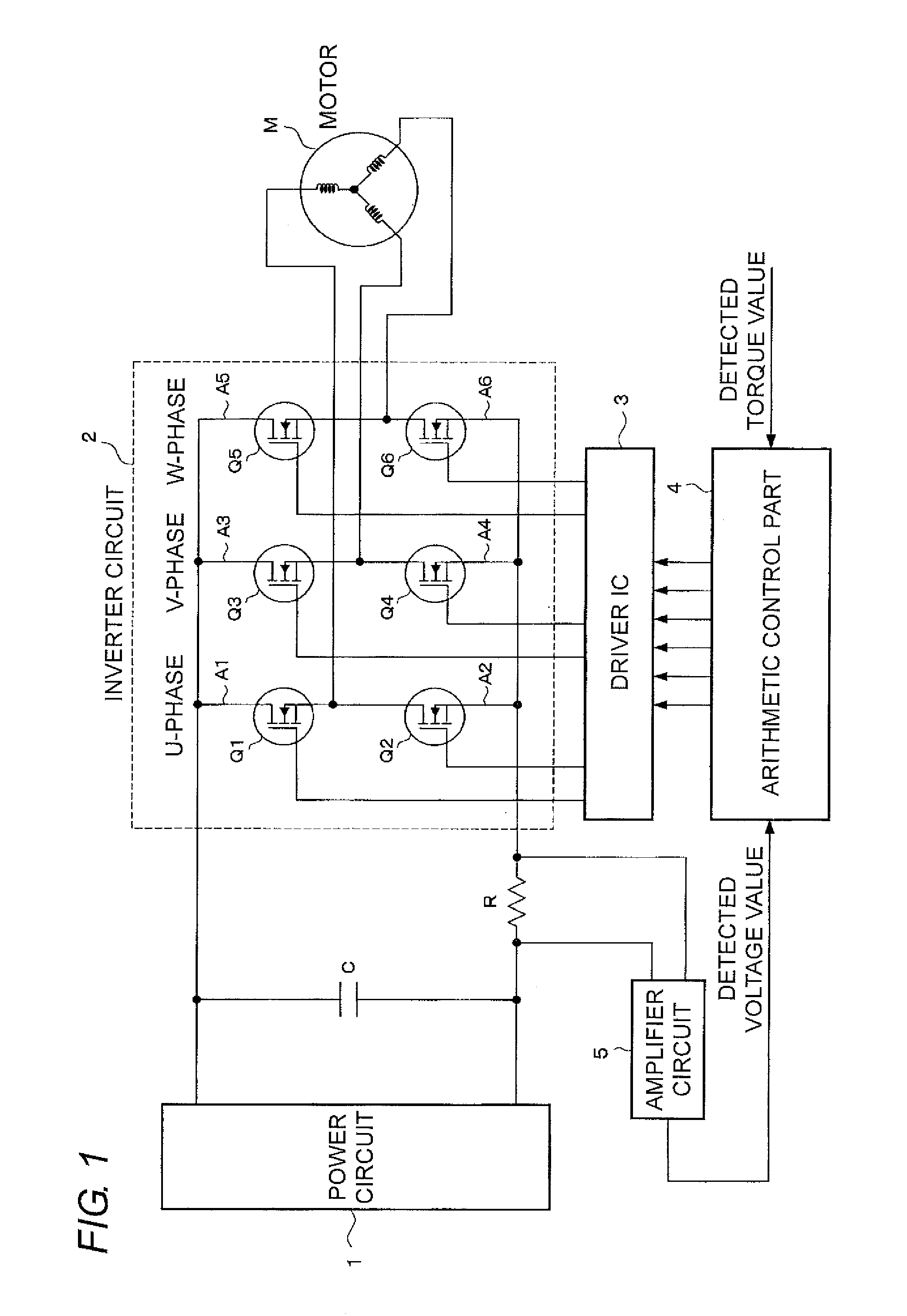

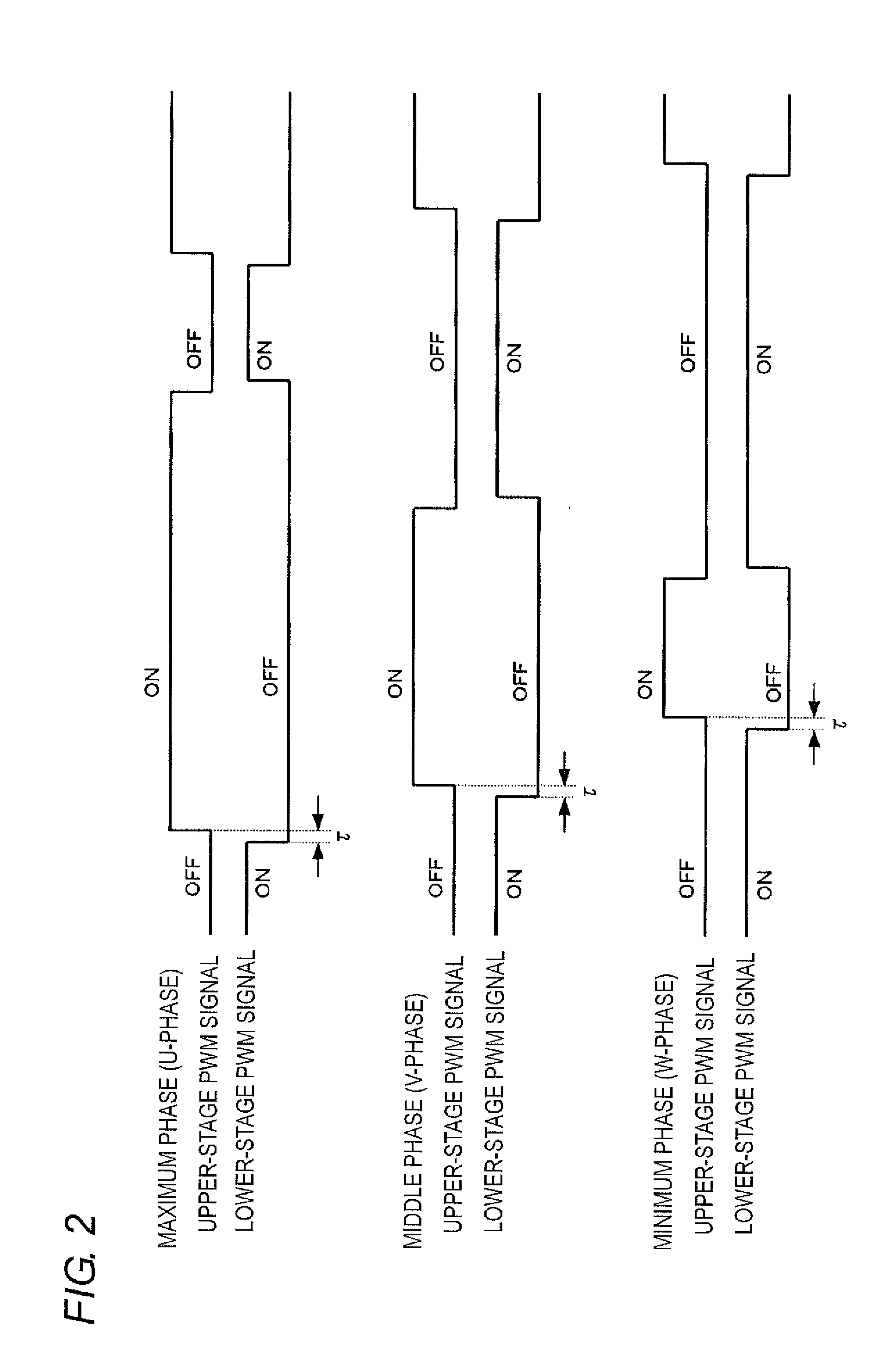

InactiveUS20130009587A1Feel stableAC motor controlElectric motor controlMotor Drive UnitElectrical current

A motor control device has a motor driving unit that drives a motor, a current detecting unit that detects a motor current flowing through the motor, a control unit that compares a detected current value of the motor current detected by the current detecting unit with a target current value to obtain a deviation, to control the motor driving unit based on the deviation, and a compensation unit that sets as a current offset value a detected current value of a drift current detected by the current detecting unit in a state where the motor current is regarded as zero, to compensate the detected current value of the motor current by the current offset value. The compensation unit sets a target offset value according to the current value of the detected drift current to correct the current offset value stepwise until the current offset value reaches the target offset value.

Owner:OMRON AUTOMOTIVE ELECTRONICS CO LTD

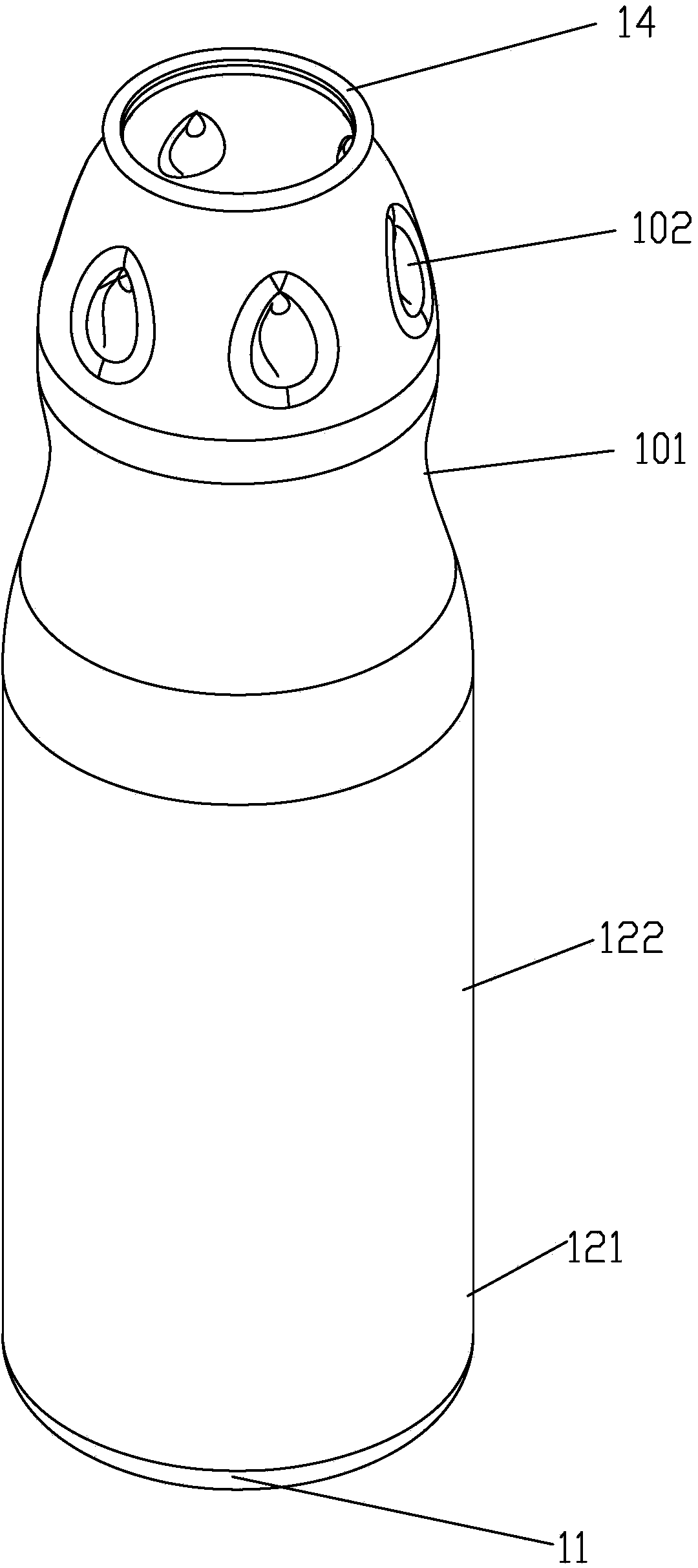

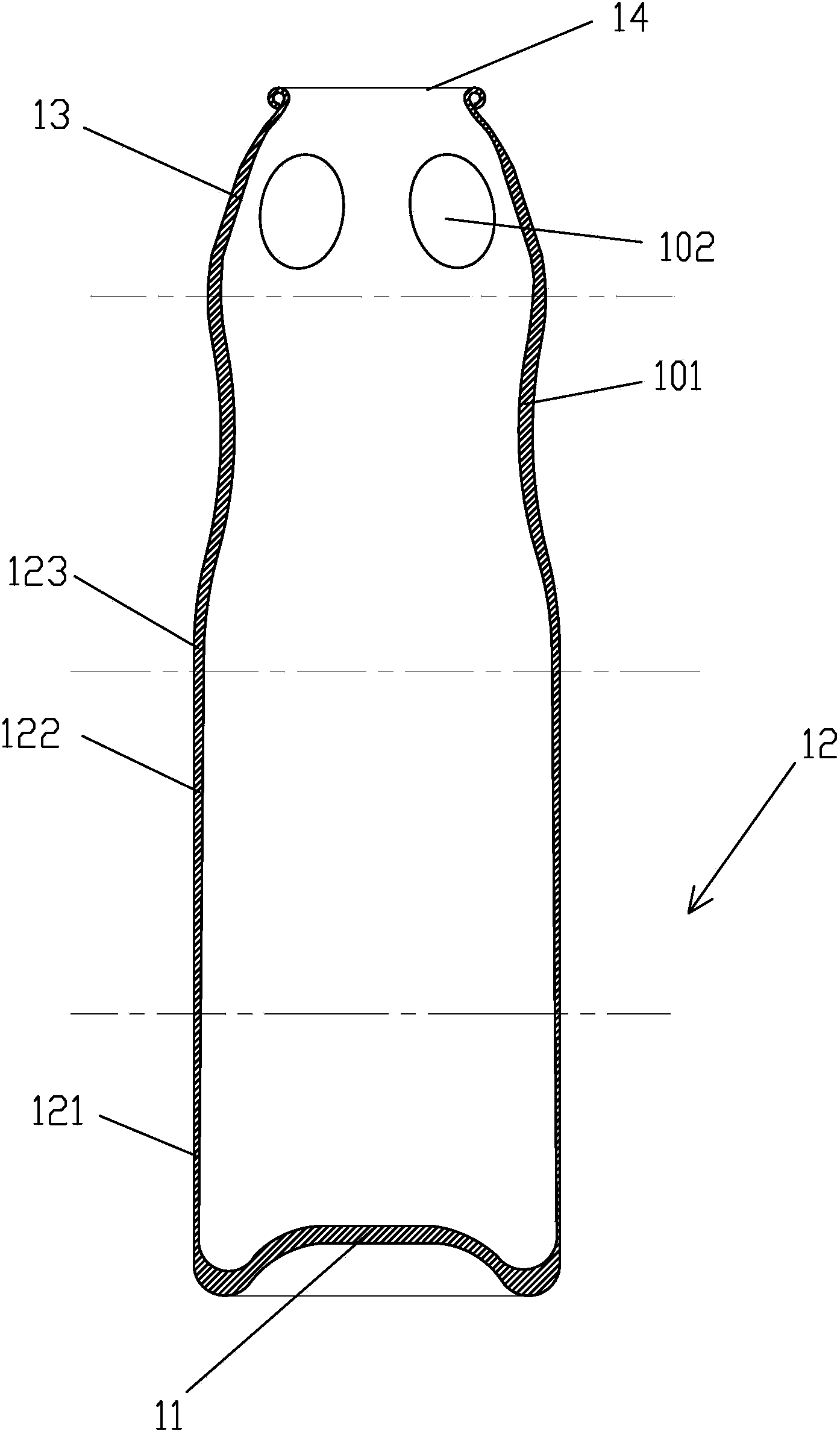

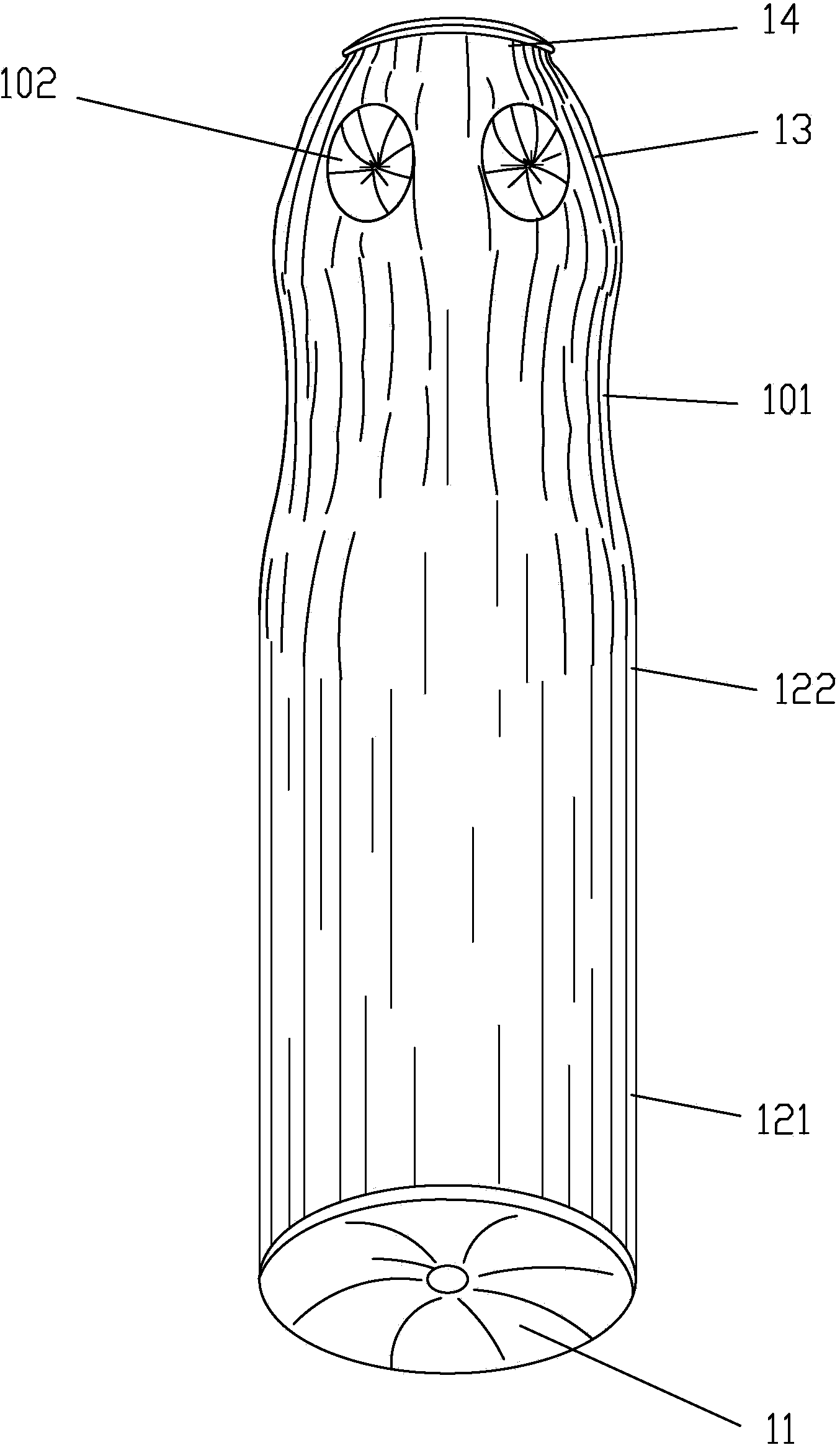

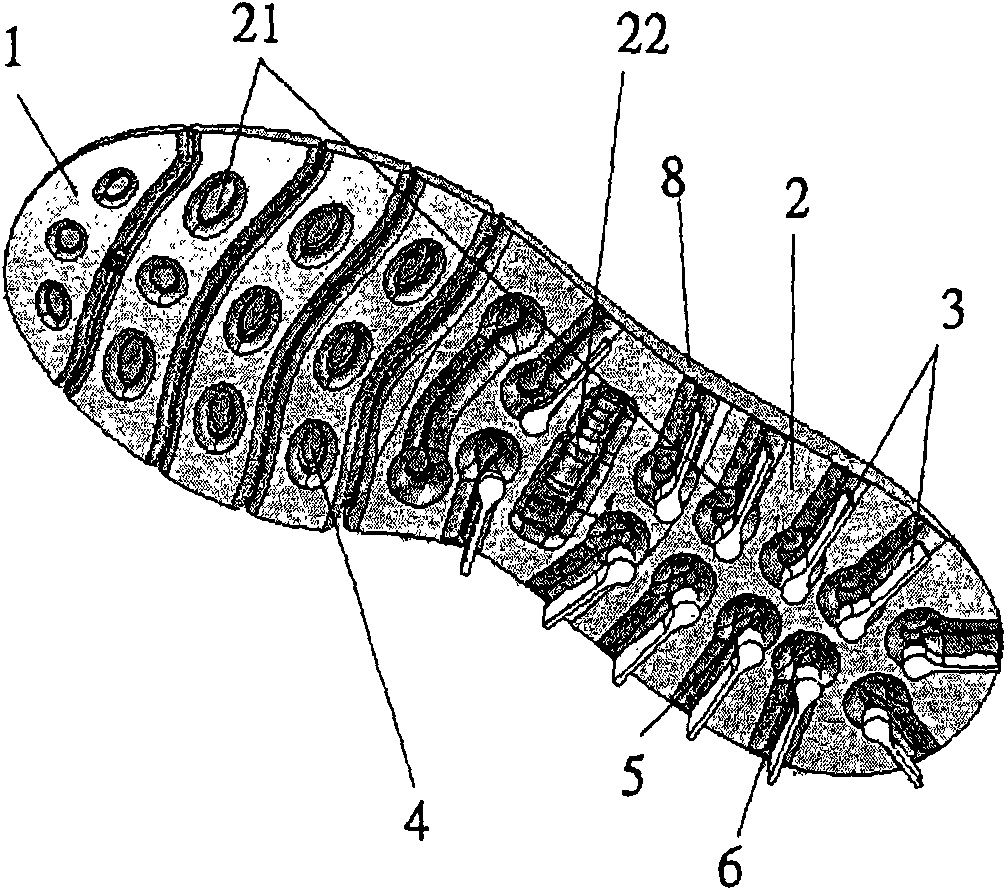

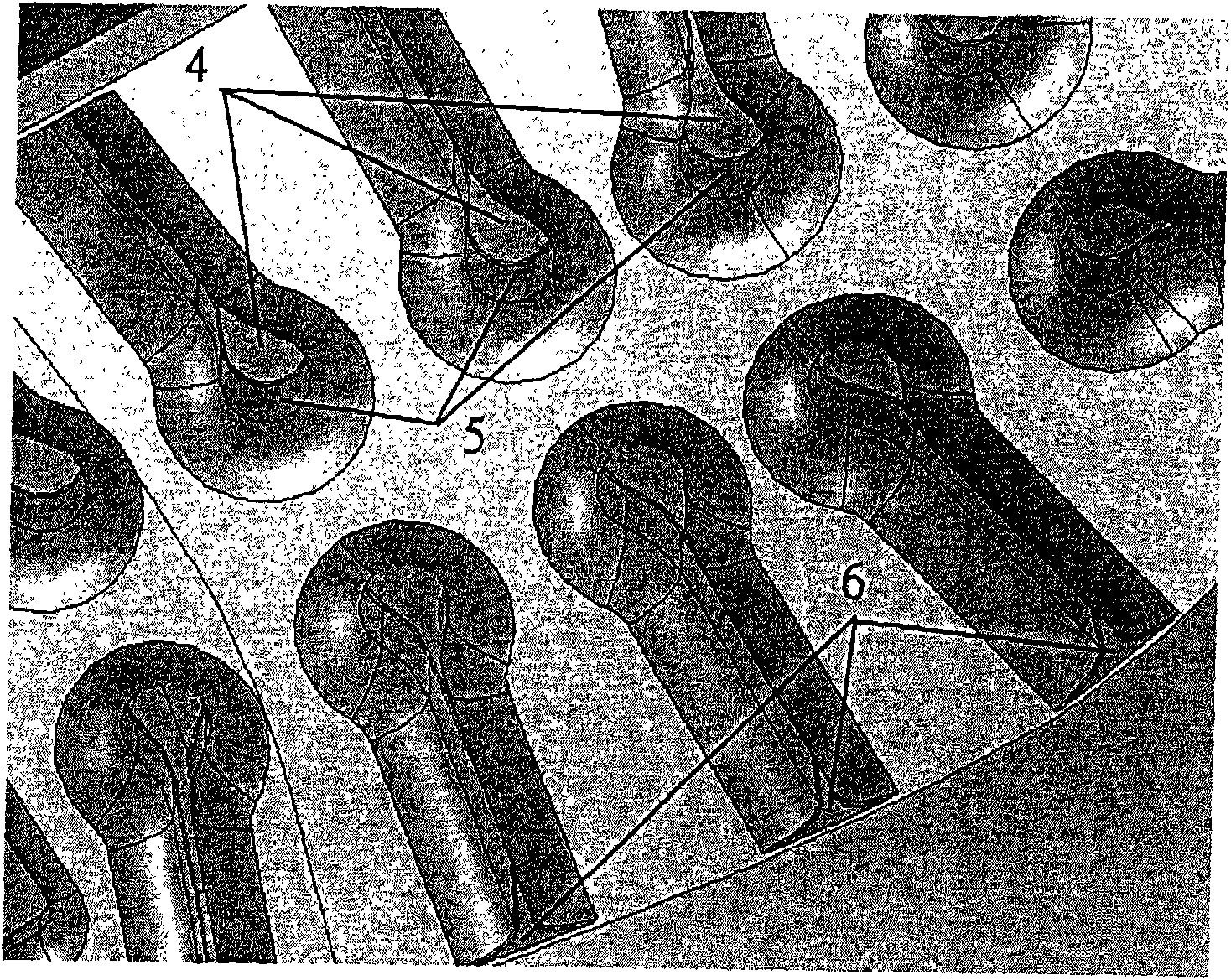

Aluminum variable wall special-shaped packaging tin and manufacturing method thereof

The invention discloses an aluminum variable wall special-shaped packaging tin and a manufacturing method thereof. The aluminum variable wall special-shaped packaging tin comprises a tin bottom, a tin barrel, a tin shoulder and a tin opening. The tin barrel is divided into a barrel body lower section, a barrel body middle section and a barrel body upper section, and the wall thickness of the barrel body lower section, the wall thickness of the barrel body middle section and the wall thickness of the barrel body upper section are sequentially increased. An annular groove capable of enabling a user to grab the tin conveniently is formed in the barrel body upper section, and accordingly the hand feeling is more comfortable and firmer. The tin shoulder is conical, a plurality of pits which are recessed inwards are formed in the outer wall of the tin, so that the aluminum variable wall special-shaped packaging tin is overall more attractive, and the visual stereoscopic impression is enhanced. Anti-counterfeiting can also be effectively achieved, and enterprise brands are made to be highlight. The aluminum variable wall special-shaped packaging tin which is simple in manufacturing method, simple in structure, attractive in appearance, convenient to grab, capable of effectively achieving the anti-counterfeiting function and low in production cost and the method for manufacturing the packaging tin are provided.

Owner:GUANGDONG EURO ASIA PACKAGING

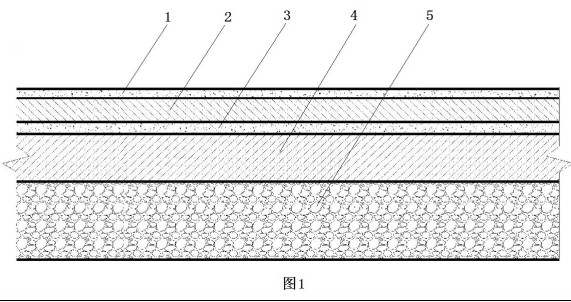

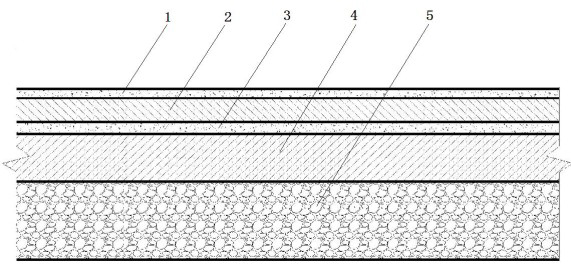

Bio-enzyme modified roller compacted concrete road engineering construction technology

InactiveCN102493308AHigh strengthImprove water stabilityIn situ pavingsRoller-compacted concreteEcological environment

The invention discloses a bio-enzyme modified roller compacted concrete road engineering construction technology in which bio-enzyme is used as a curing agent and which is low in construction cost, and is easy to implement, pollution-free, low-carbon and environment-friendly. The technology has the advantages that a road base has high intensity and water stability and a good effect of stabilizing and curing soil. Compared with the conventional road building material, a bio-enzyme road is high in load carrying property, good in road performance, and high in construction speed, and low in cost, and easy to construct; and compared with the conventional road building technology, a bio-enzyme road engineering construction technology can save fund by 10 to 20 percent, and has obvious economic benefit and social benefit; the road is easy to cure, and the bio-enzyme road engineering construction technology greatly reduces the using amount of lime and cement, so the resources are saved; the used materials are mostly waste slag, spoil, hole slag, building slag and other waste materials, damage to an ecological environment is reduced, and the bio-enzyme modified roller compacted concrete road engineering construction technology has obvious economic benefit and social benefit.

Owner:重庆康路科技有限公司秀山分公司

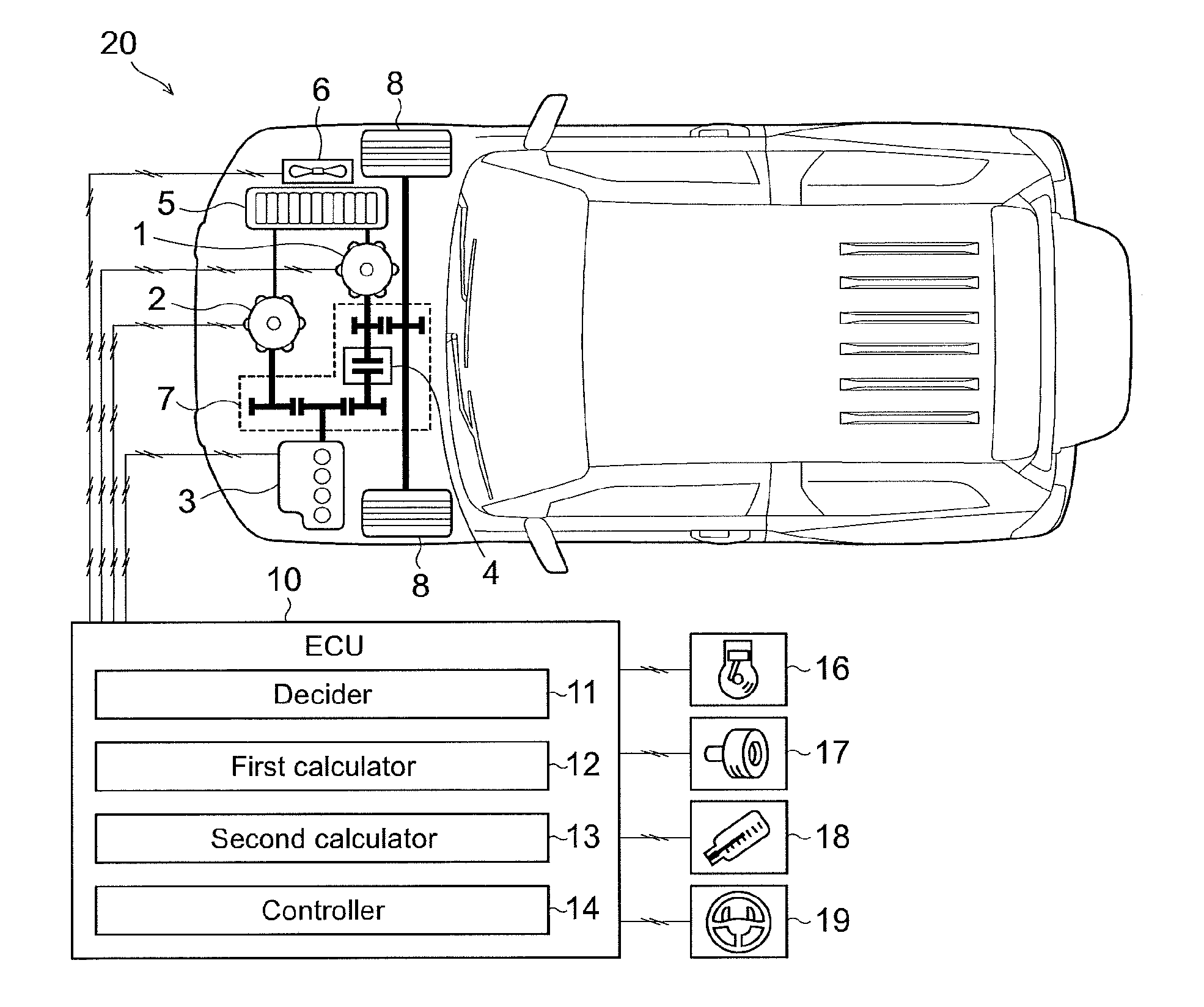

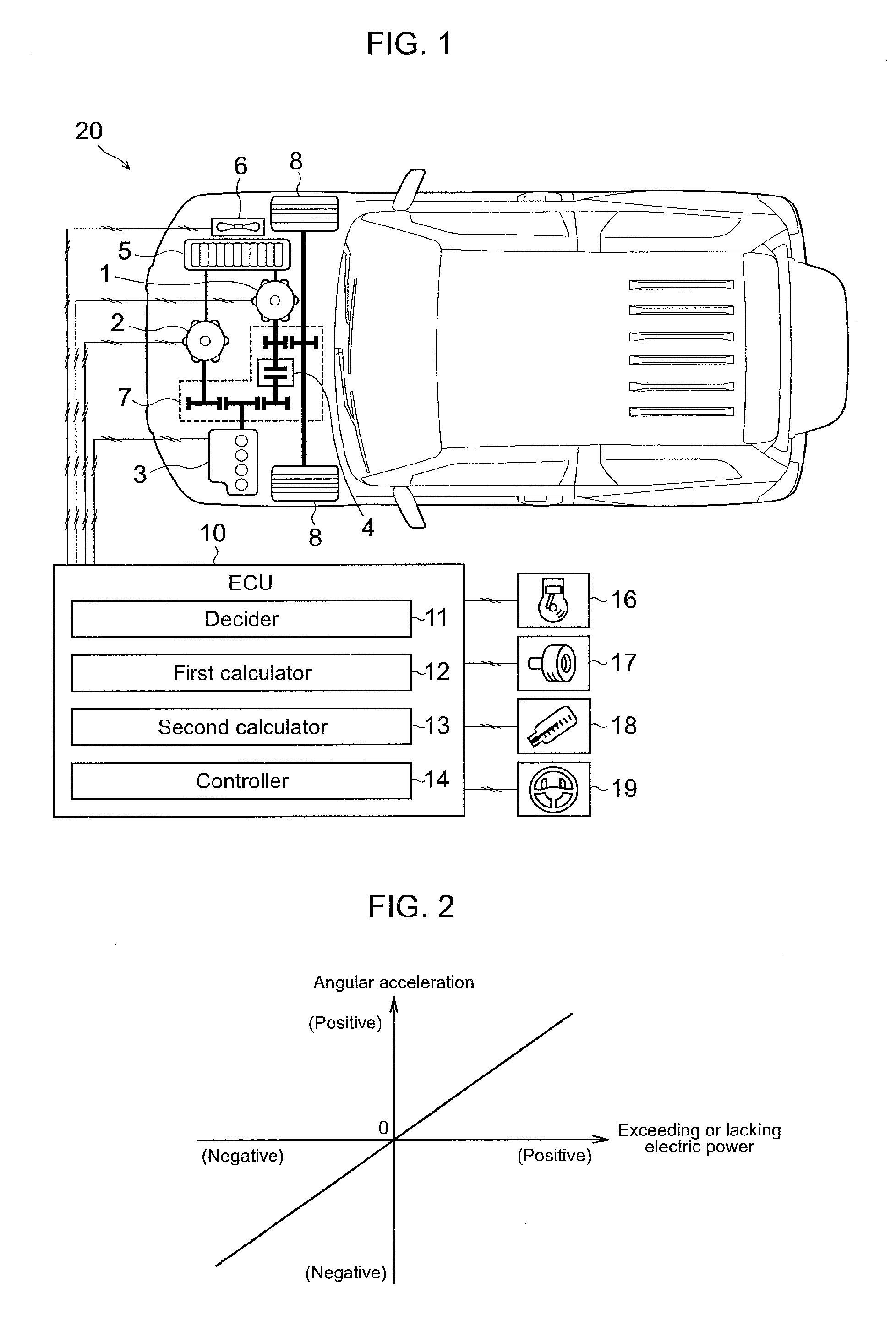

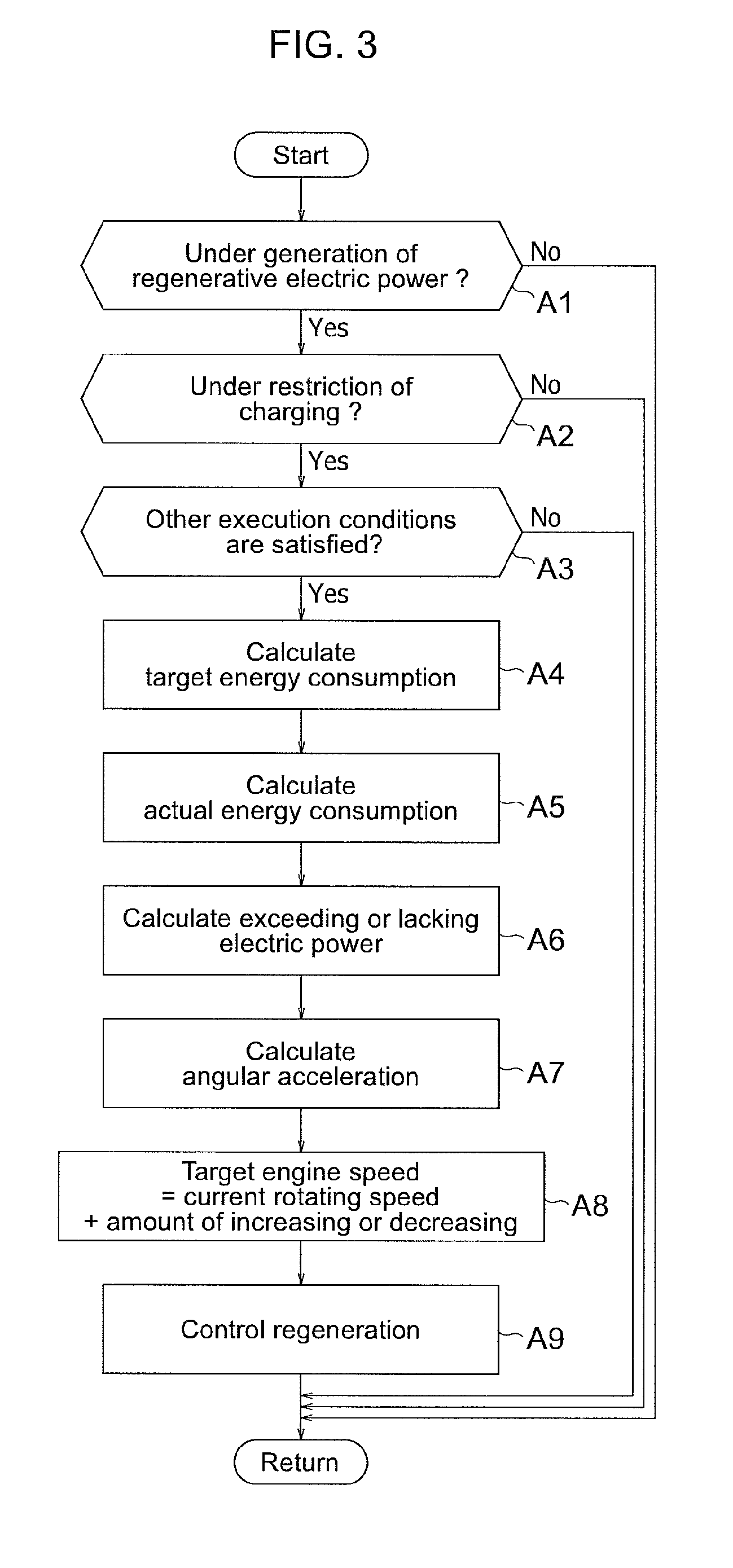

Vehicle

InactiveUS20160059843A1Feel stableHybrid vehiclesDigital data processing detailsElectric power systemEngineering

A vehicle includes a first motor, a second motor, a battery, a decider, a first calculator, a second calculator and a controller. The decider detects a state of the battery and determines whether the detected state is a state where charging the battery is restricted. The first calculator calculates, when the first motor generates the regenerative electric power under the state where charging the battery is restricted, a target energy consumption representing a target value of electric power that the second motor is to consume to drive the engine by using the regenerative electric power. The second calculator calculates an actual energy consumption that the second motor requests to maintain rotating speed of the engine. The controller adjusts angular acceleration of the engine and the second motor, using a difference between the target energy consumption and the actual energy consumption.

Owner:MITSUBISHI MOTORS CORP

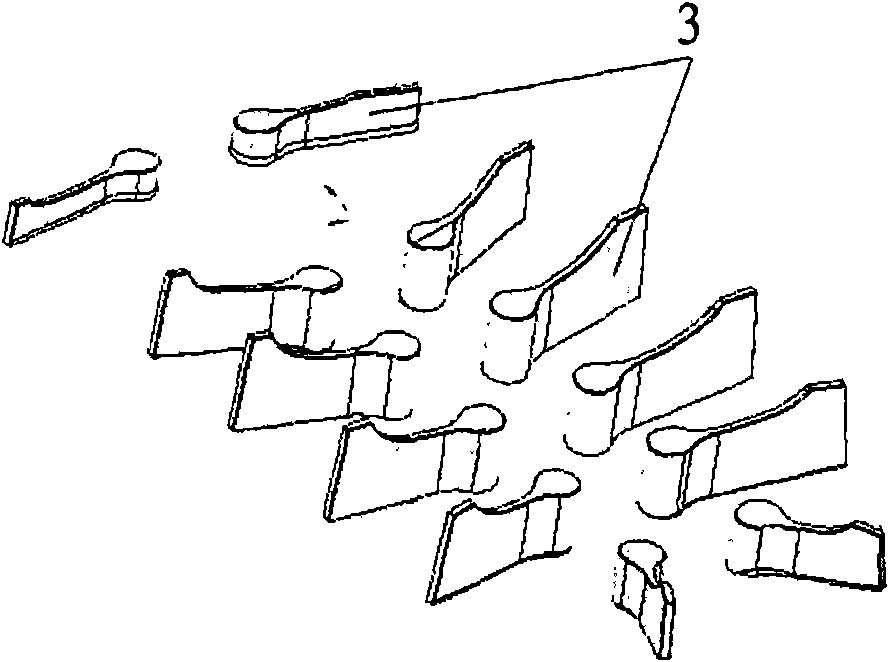

Stiffness reinforced floor panel for a raised floor system

InactiveUS20060191226A1Thin thicknessIncrease stiffnessCeilingsWallsHigh stiffnessUltimate tensile strength

A floor panel for a raised floor system is provided, where the floor panel includes a plate member with at least one longitudinal groove and a reinforcing member at least a portion of which is inserted into the longitudinal groove. The longitudinal groove is formed on the plate member of the floor panel for a raised floor system, and a stick type reinforcing member and / or a plate type reinforcing member is inserted into the longitudinal groove. Thereby, a thickness of the floor panel can be reduced and at the same time high stiffness and light weight of the floor panel can be achieved, and so a better walking feeling can be obtained and wider spacing of pedestals can be achieved. By coating the plate with a waterproof composition, it is possible to overcome drawbacks of a size and strength thereof being changed and deteriorated by being exposed to moisture.

Owner:LG CHEM LTD

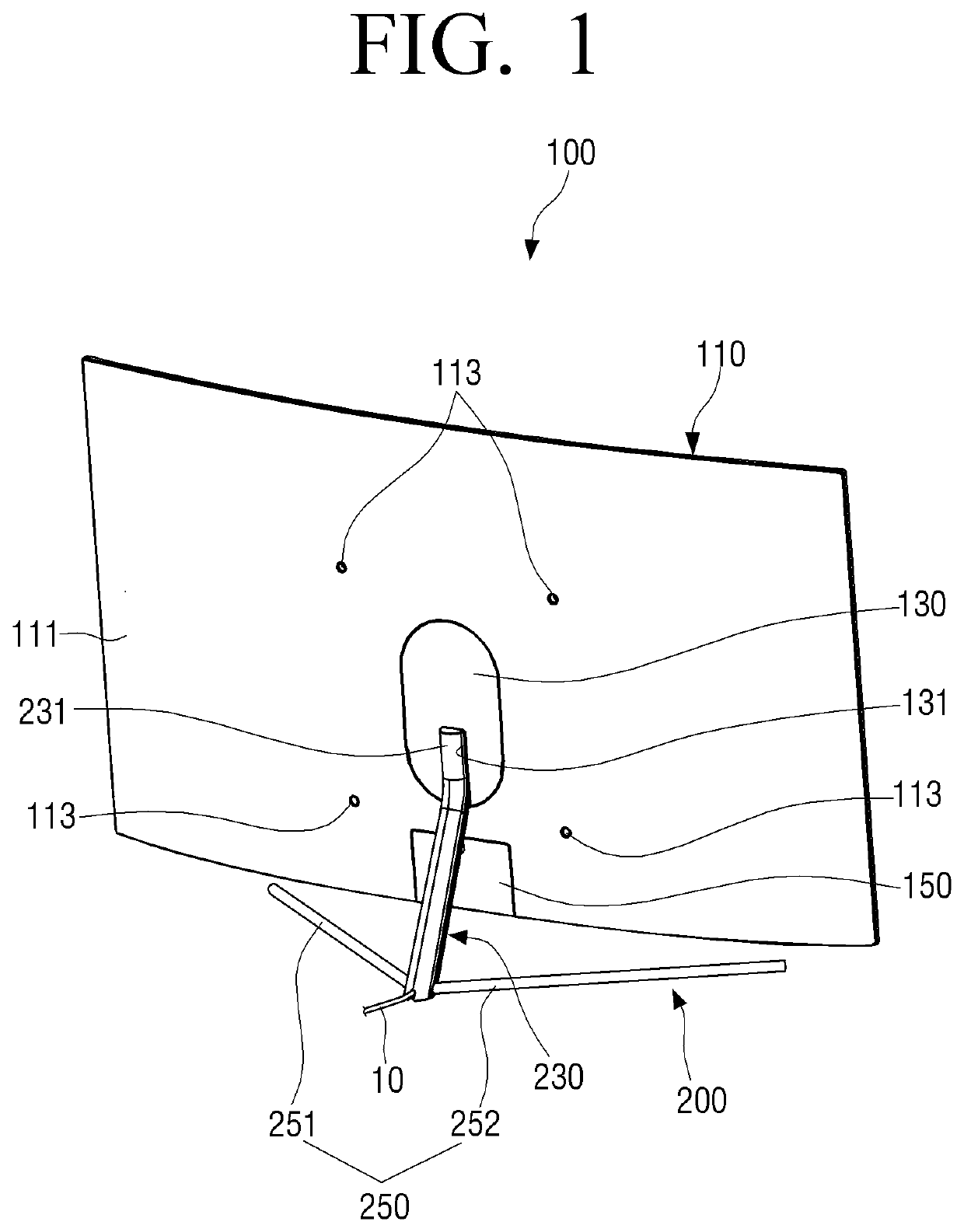

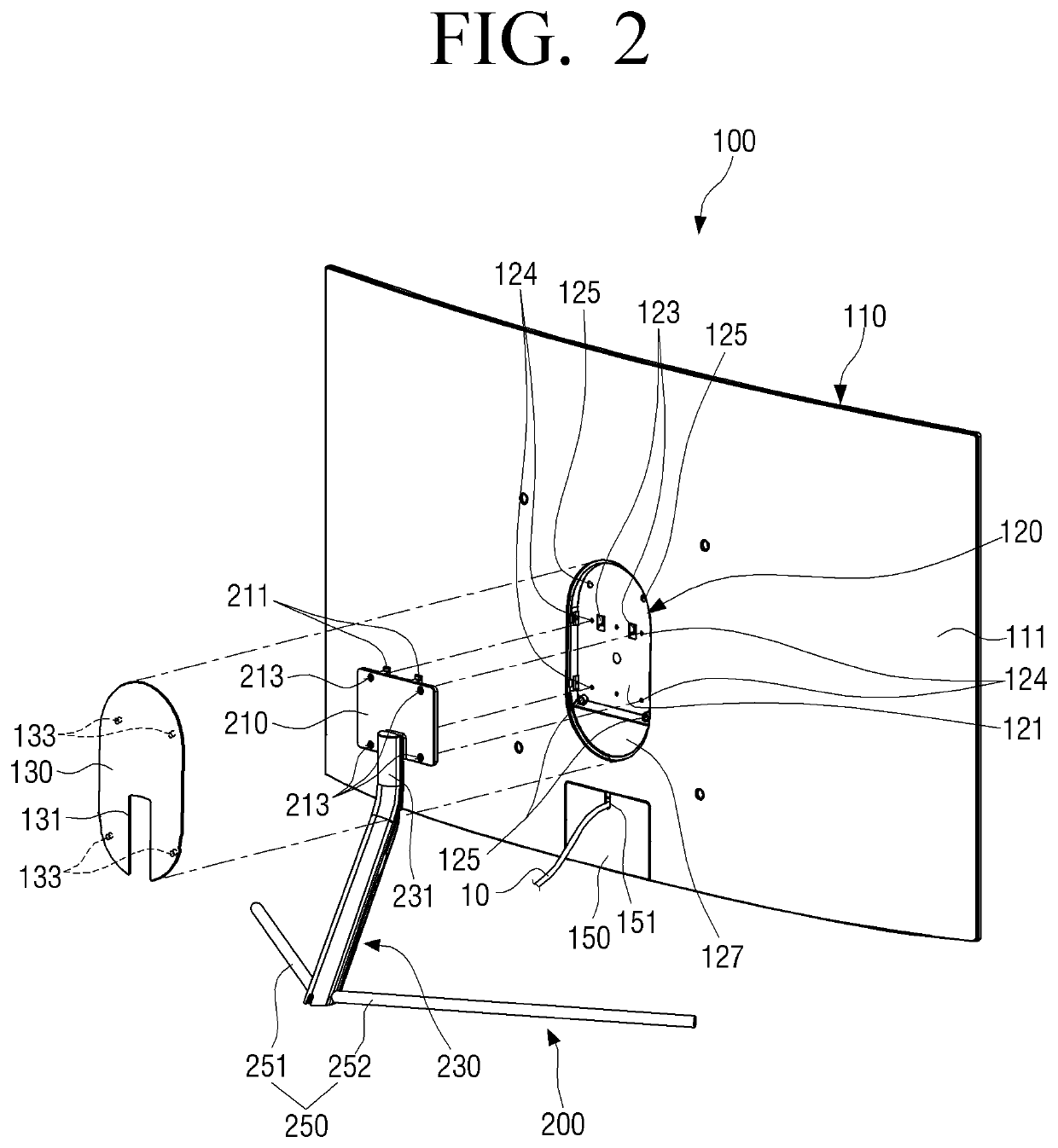

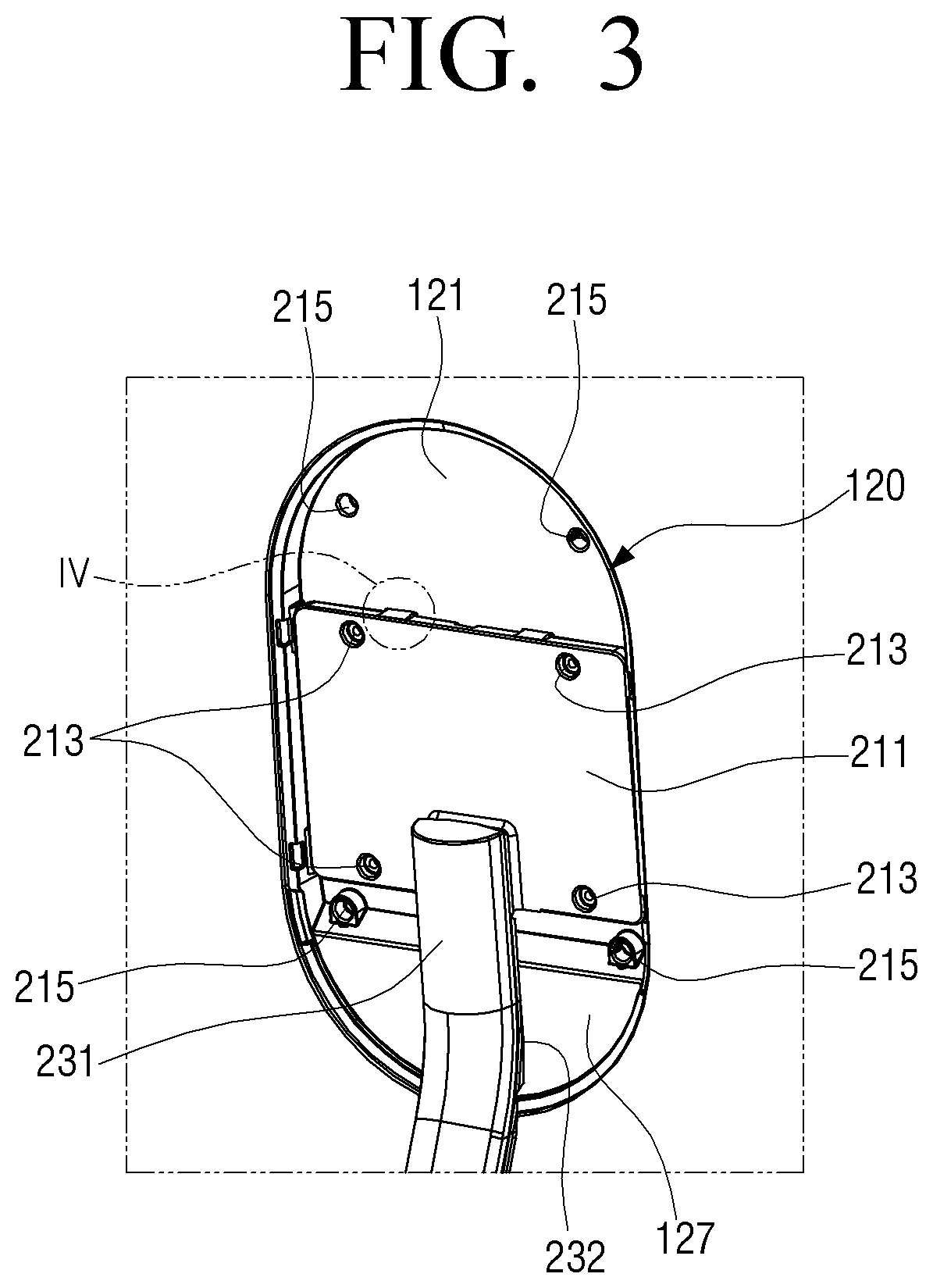

Display stand and display device comprising same

ActiveUS20200174515A1Prevent deviationDiversify the design of a display apparatusTelevision system detailsDigital data processing detailsComputer hardwareComputer graphics (images)

A display stand and a display device comprising the same are disclosed. The disclosed display device may comprise: a display body including a display panel and having a mounting groove formed on the rear surface thereof; a stand which is detachably mounted to the mounting groove and conceals a cable connected to the display body; and a display body cover which is detachably coupled to the display body so as to cover the mounting groove and through which a part of the stand passes.

Owner:SAMSUNG ELECTRONICS CO LTD

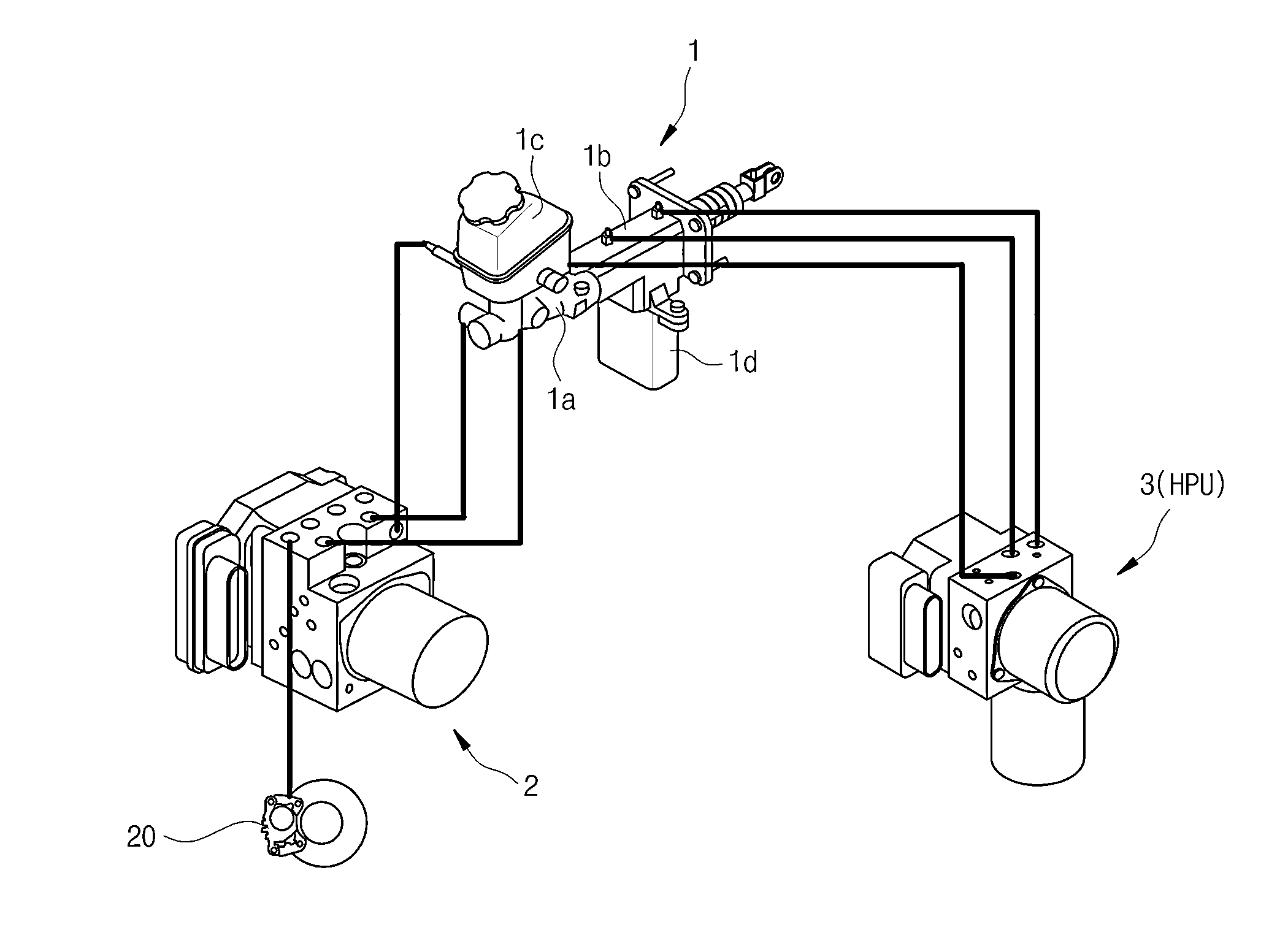

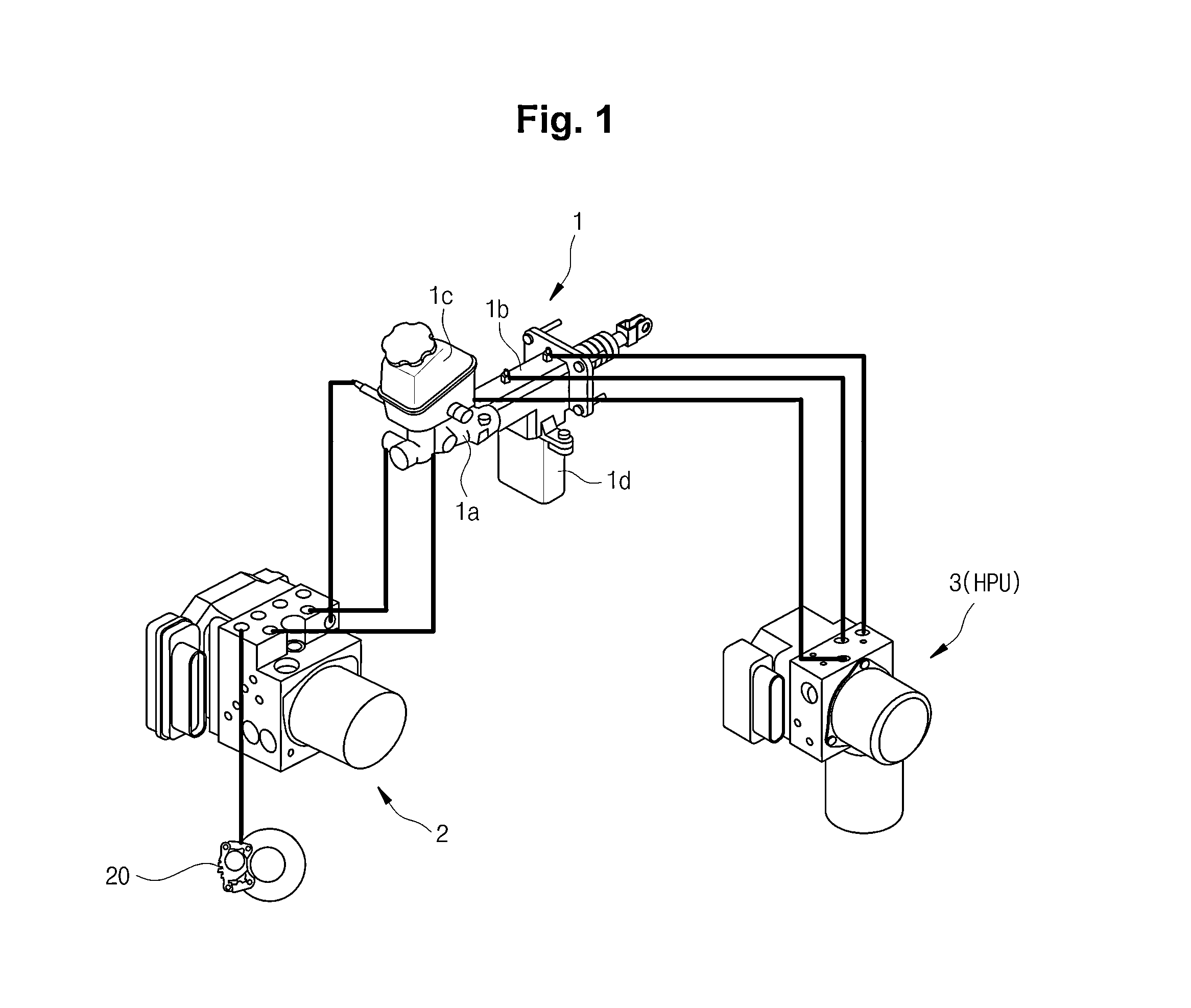

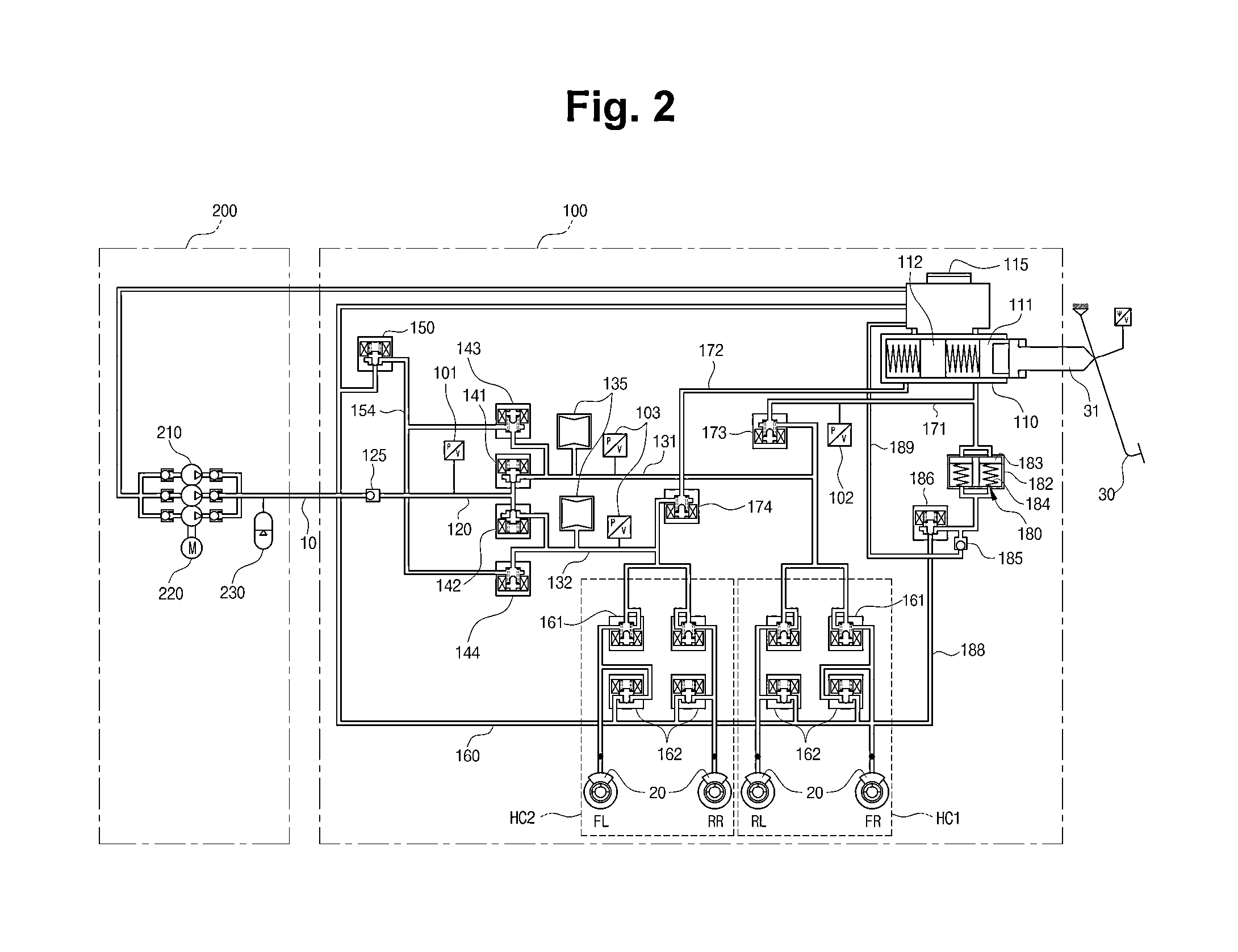

Integrated electro-hydraulic brake system

ActiveUS20150166028A1Simple configurationImprove securityFoot actuated initiationsFluid braking transmissionSolenoid valveCurrent range

There is provided an integrated electro-hydraulic brake system. The integrated electro-hydraulic brake system include a power source unit including an accumulator configured to store a pressure of a predetermined level, a pump configured to suck oil from a reservoir and discharge the oil to the accumulator in order to generate a pressure in the accumulator, and a motor configured to drive the pump; and an integrated hydraulic control device including a master cylinder having two hydraulic circuits and configured to generate a hydraulic pressure, a reservoir connected above the master cylinder and configured to store oil, an in-valve and an out-valve configured to control a pressure delivered from the accumulator to a wheel cylinder installed in each wheel, a shut off valve configured to control a fluid pressure delivered from the master cylinder to the wheel cylinder, a pedal simulator connected to the master cylinder and configured to provide a reaction force of a brake pedal, and a simulation valve installed in a rear end of the pedal simulator, wherein the power source unit is provided as a separate unit in order to isolate operating noises, and the integrated hydraulic control device and the power source unit are connected by an external pipe, and the out-valve is provided as a normally open type-solenoid valve that is used at low current ranges, normally maintains an open state in order to reduce heat generation, but is closed when a close signal is received, compared to a normally close type-solenoid valve that normally maintains a close state.

Owner:HL MANDO CORP

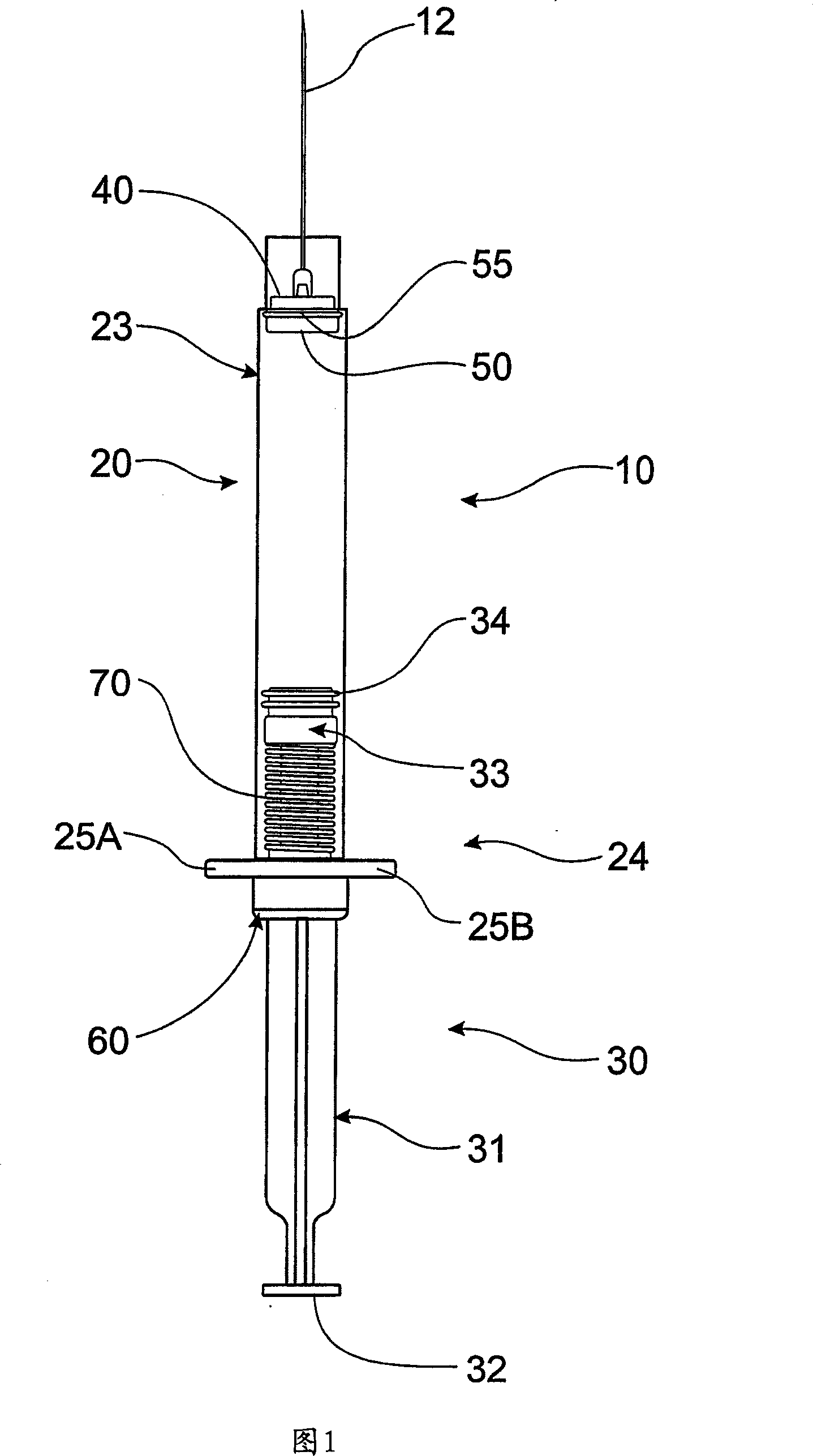

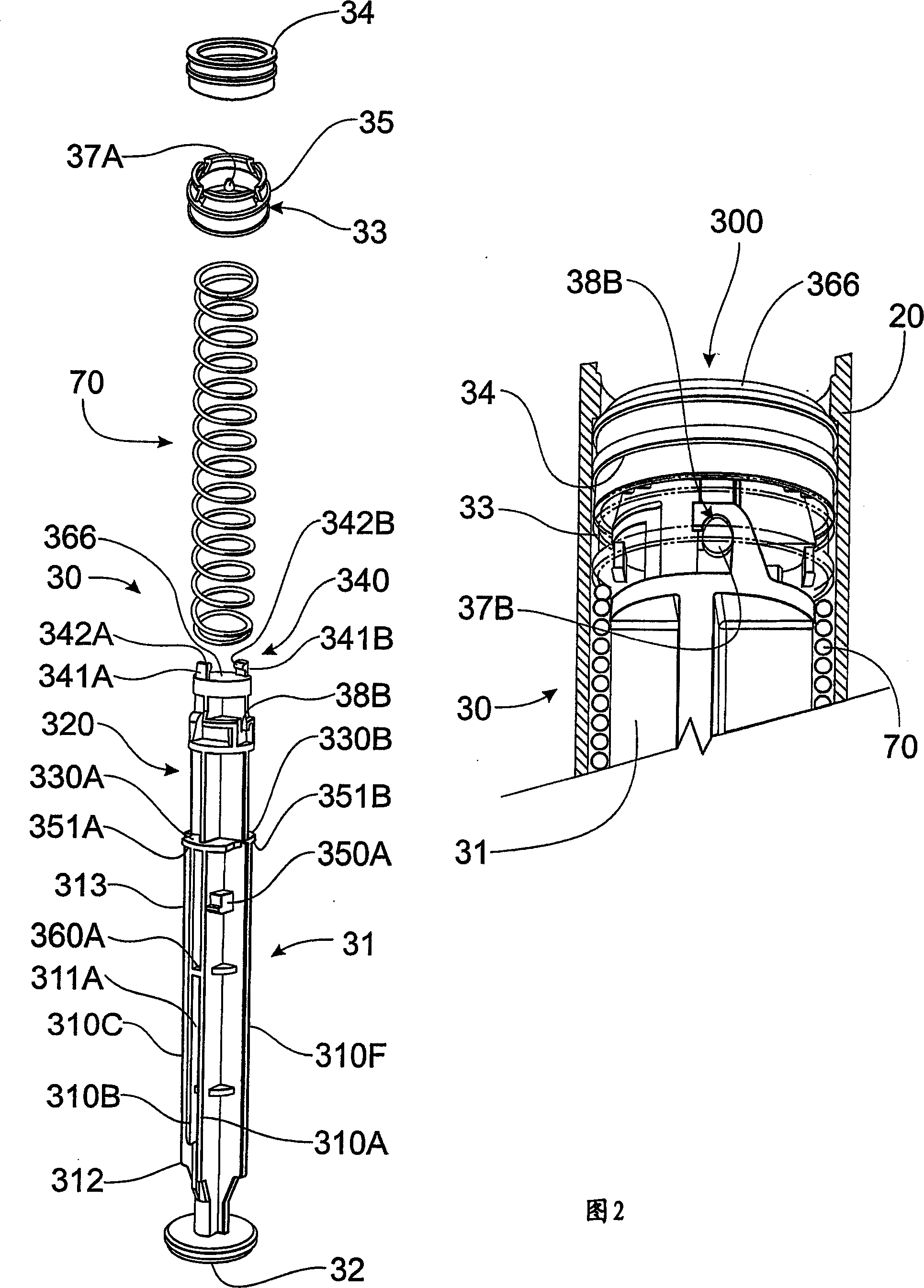

Retractable syringe with plunger disabling system

A retractable, single use syringe (10) comprises a barrel (20), a collar (60) mounted to the barrel, a retraction spring (70), a needle mount (40) located at a needle end (23) of the barrel and a plunger (30). The plunger comprises a first plunger member (31) and a second plunger member (33) that are releasably coupled to co-operatively maintain the retraction spring in an initial compressed state. The second plunger member (33) further comprises a seal (34) to prevent fluid leakage between plunger (30) and barrel (20). After depression of the plunger to deliver the fluid contents of the syringe, the first plunger member (31) engages the needle mount (40) with needle (12) attached thereto and is rotatably uncoupled from the second plunger member (33) to allow decompression of the retraction spring (70), which forces retraction of the first plunger member (31), needle mount (40) and needle (12) engaged therewith. The first plunger member (31) and the collar (60) comprise elements that co-operatively form a disabling means that prevents or at least minimizes the likelihood of subsequent depression or withdrawal of the plunger (30). Also following retraction of the first plunger member (31), the second plunger member (33) and seal (34) remains at the needle end (23) of the barrel (20) thereby preventing refilling and re-use of the syringe.

Owner:UNITRACT SYRINGE

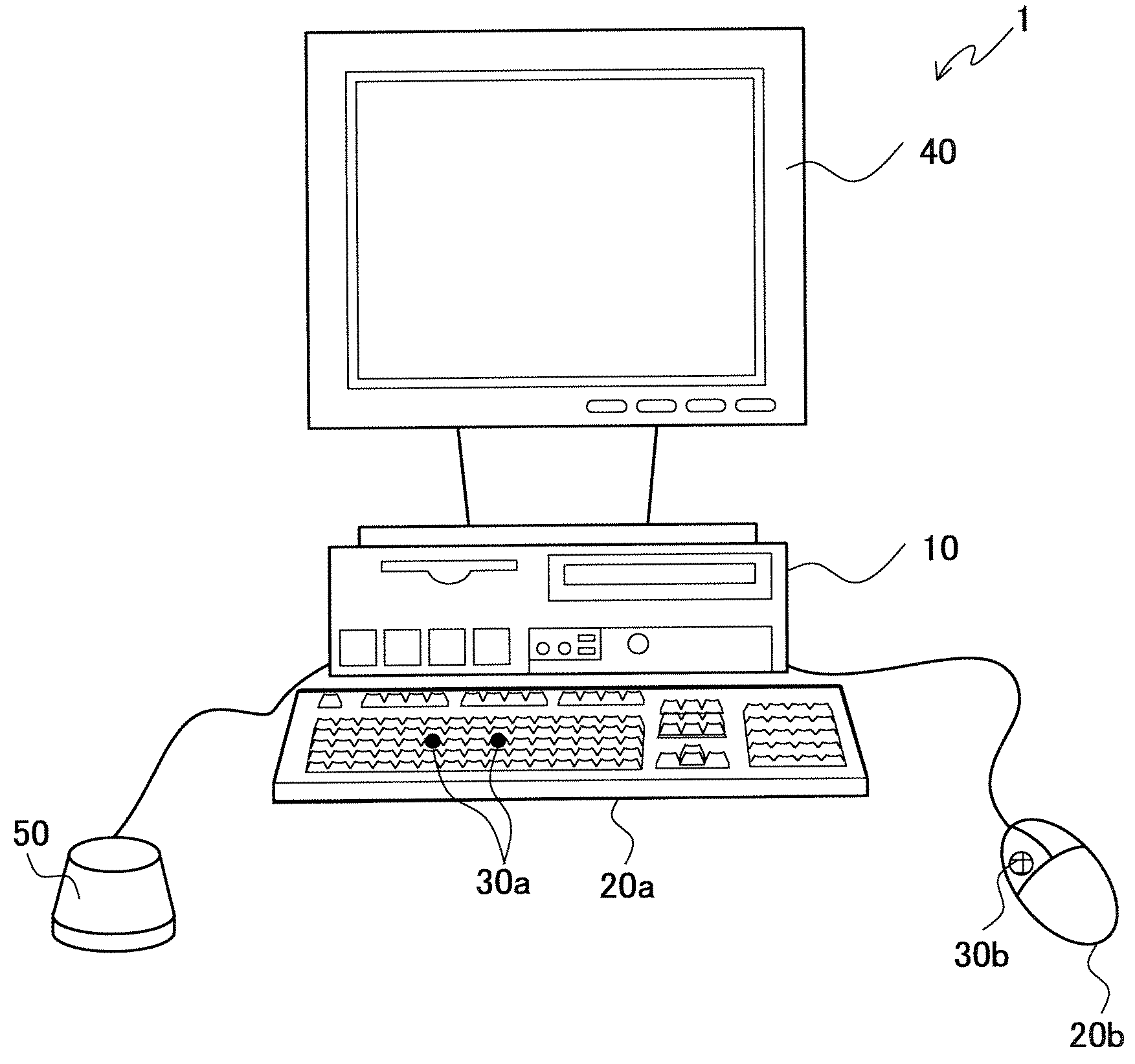

Feeling and physical condition stabilizer for stabilizing user's feeling and physical condition

InactiveUS20070098349A1Stable conditionFeel stableInput/output for user-computer interactionTelevision system detailsInformation processingCountermeasure

An information processing unit is provided which positively stabilizes a user's feeling and physical condition by deciding the user's feeling and physical condition based on the user's body temperature change and the like. Depending on the user's hand temperature, a CPU (110) automatically selects an aromatic for stabilizing the user's feeling and physical condition change, and directs an aromatic sprayer (50) to spray the aromatic, or directs a display part (40) to display a countermeasure message for maintaining the physical condition. This positively stabilizes the user's feeling and physical condition.

Owner:UNIVERSAL ENTERTAINMENT CORP

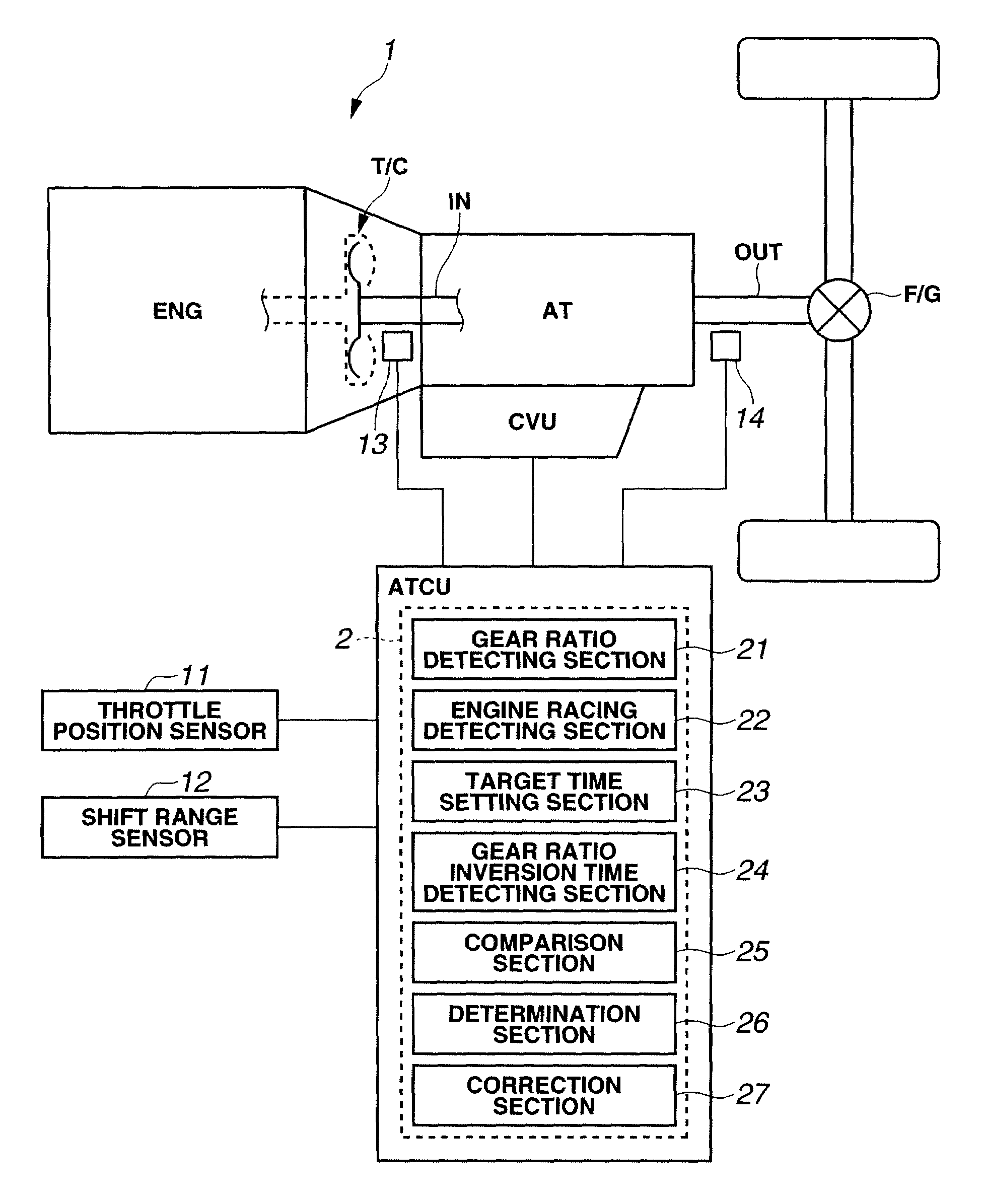

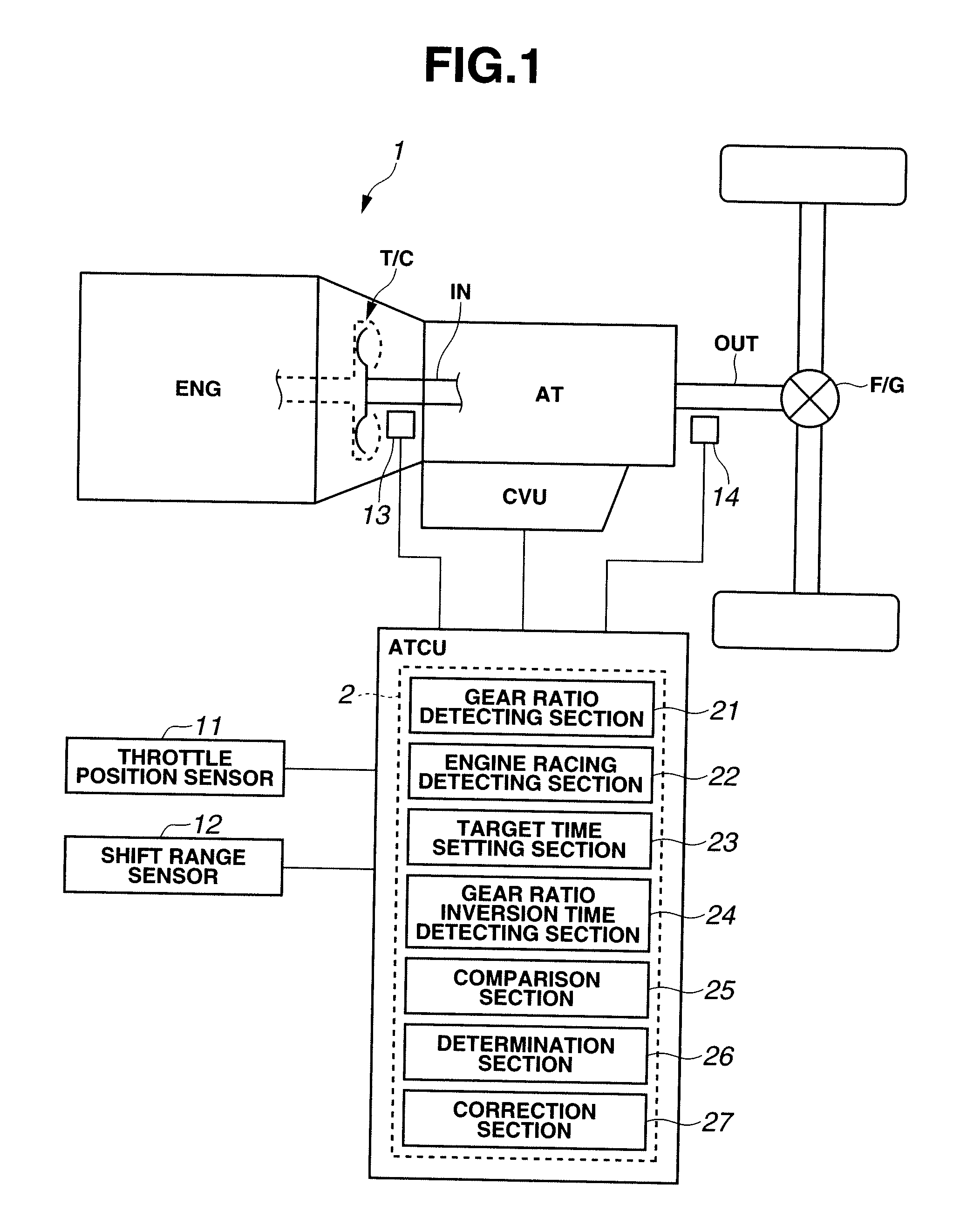

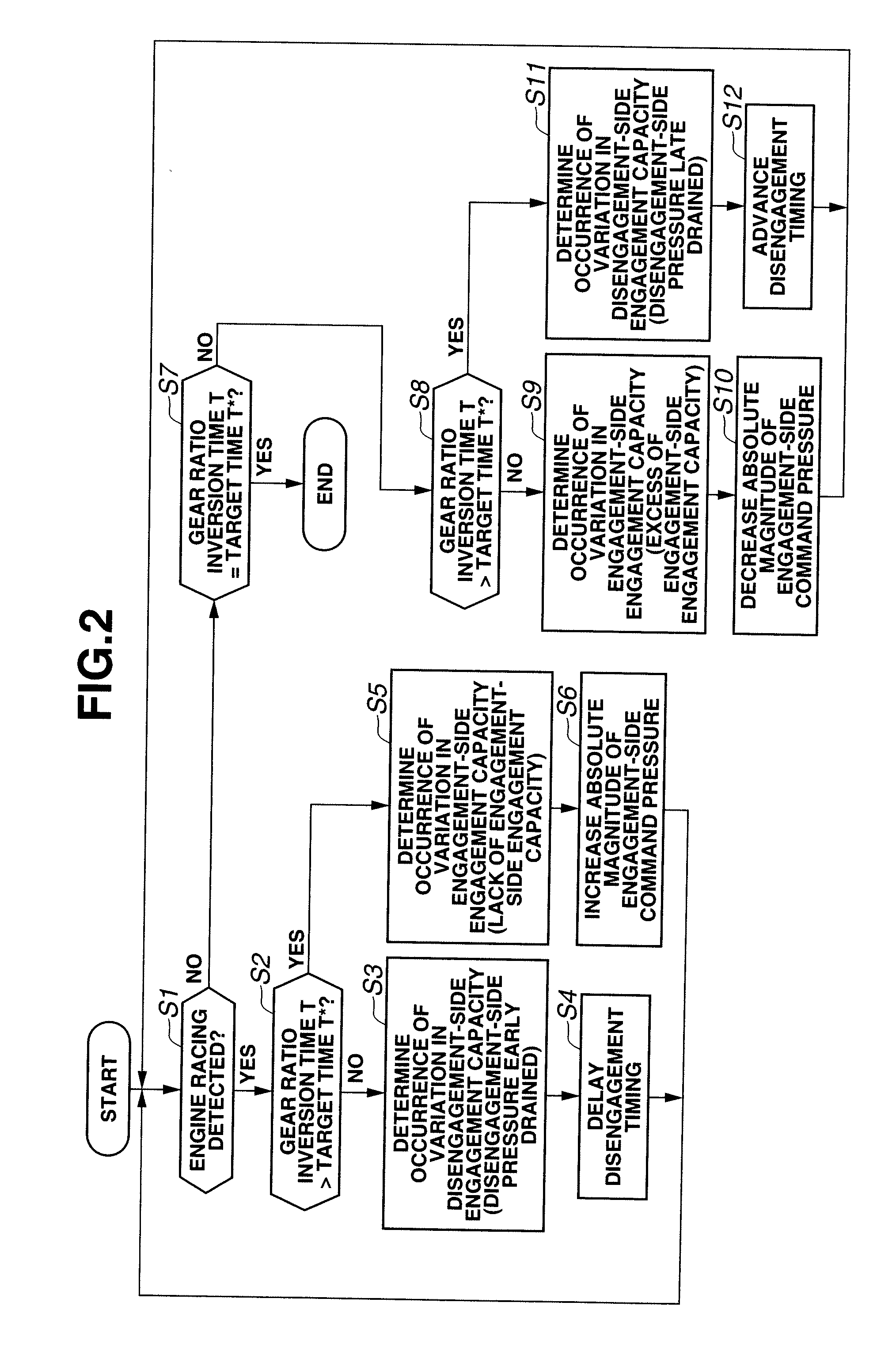

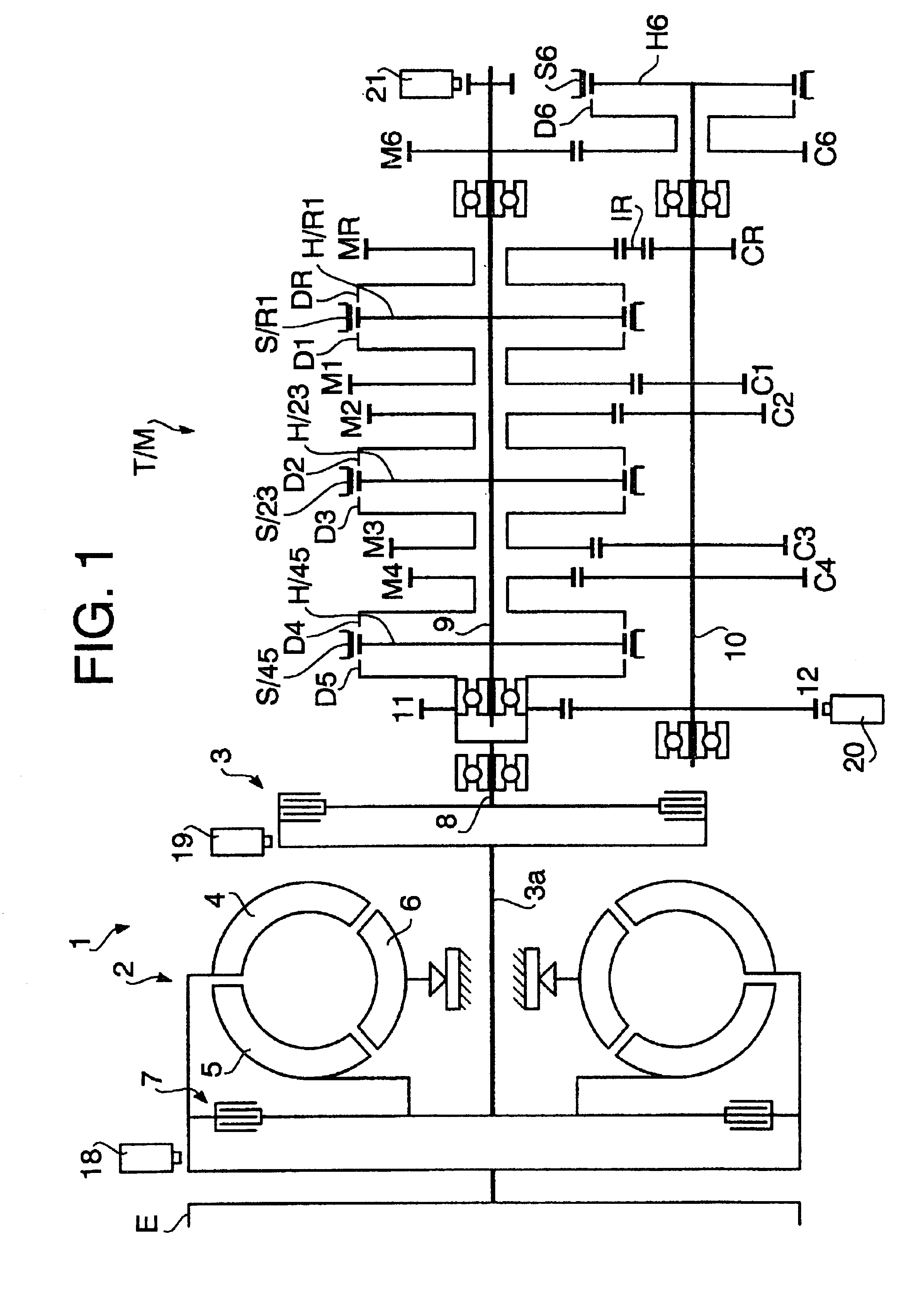

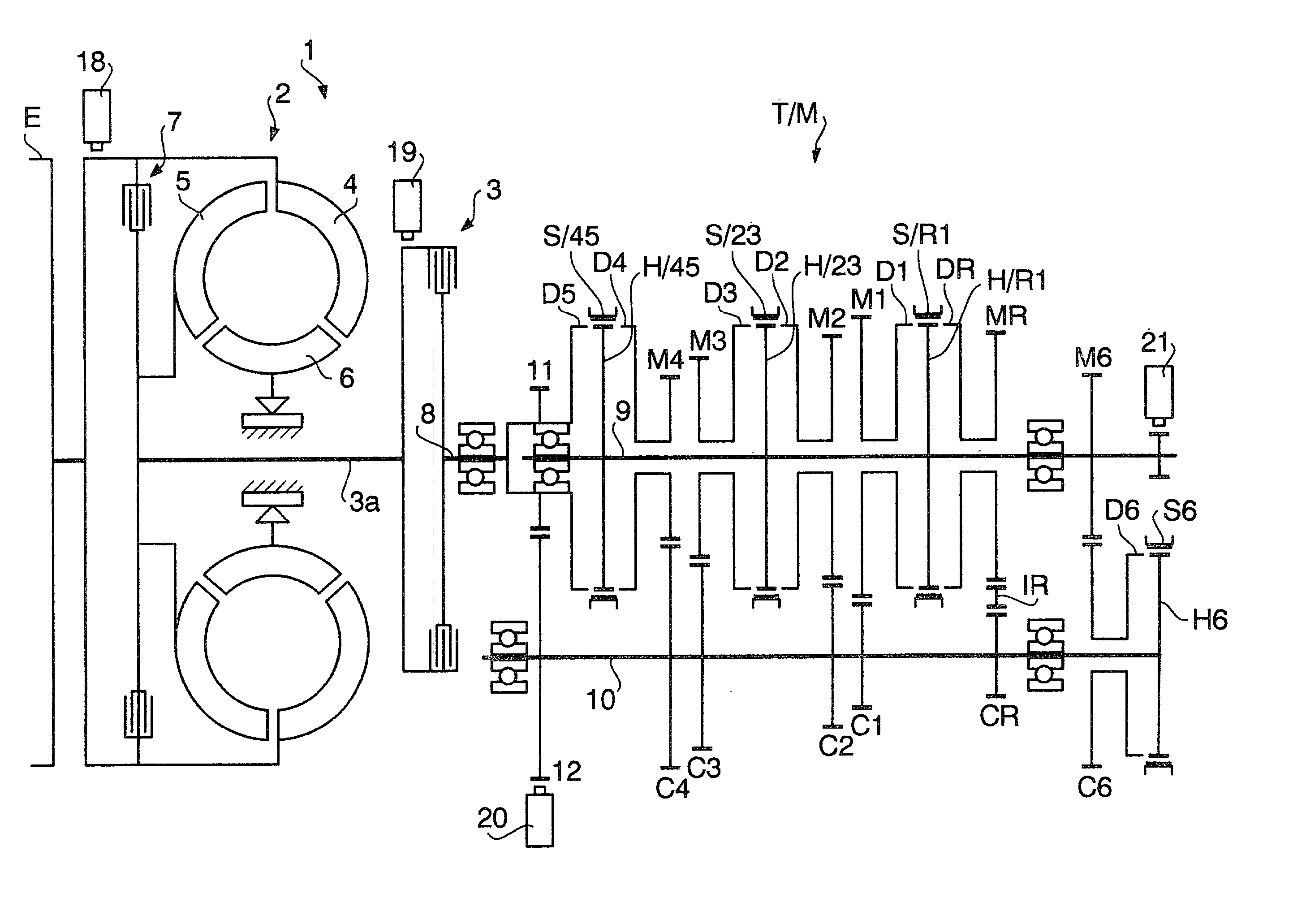

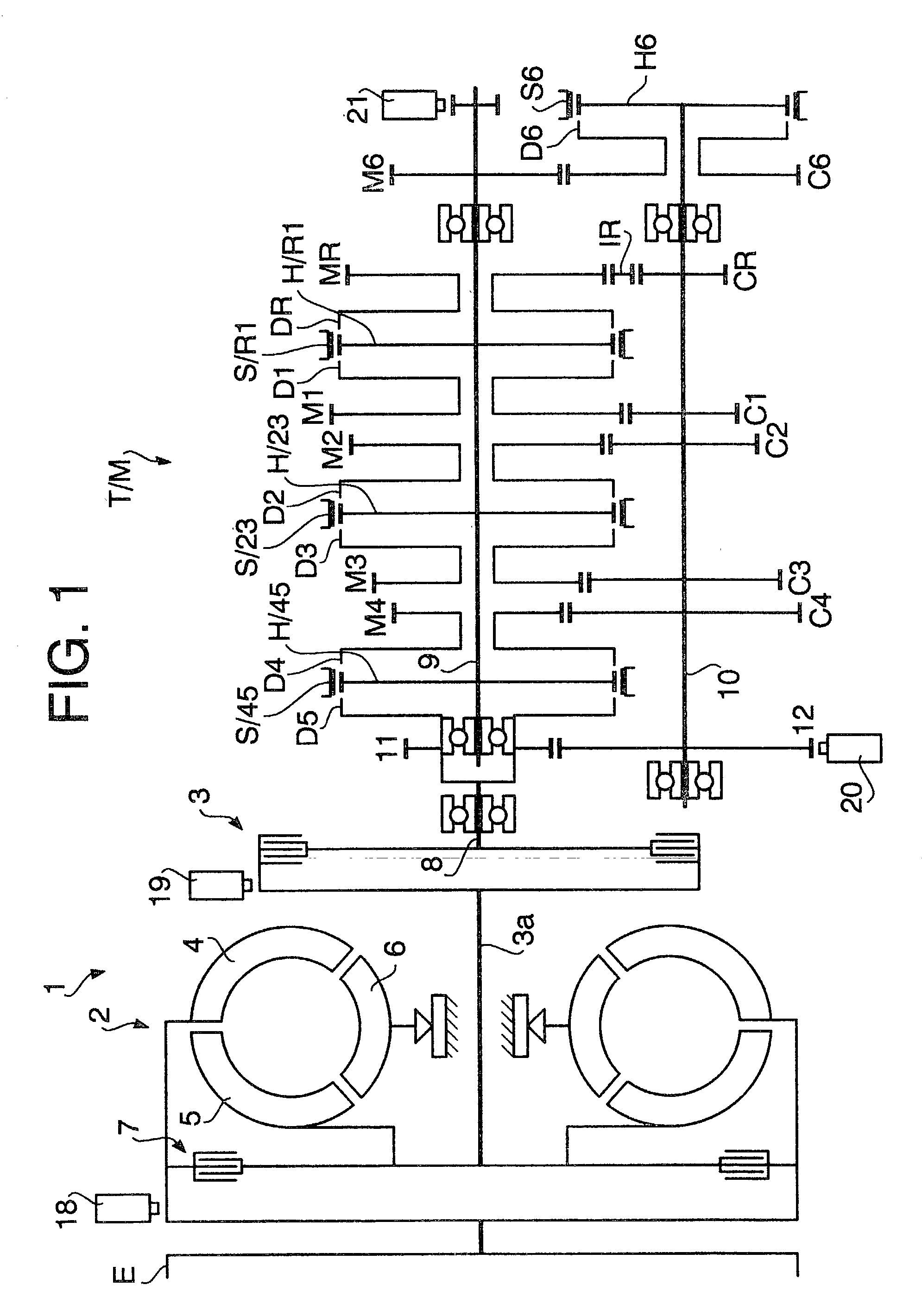

System and method of controlling an upshift in automatic transmission

ActiveUS20080300104A1Accurately determineFeel stableDigital data processing detailsGearing controlAutomatic transmissionControl system

An upshift control system for use in an automatic transmission including first and second friction elements, the upshift control system including a control unit that determines variation in an engagement capacity of the first friction element or an engagement capacity of the second friction element on the basis of combination of occurrence or non-occurrence of engine racing and compared lengths between a first time that elapses from output of a shift command to a start of an inertia phase and a second time that elapses from the out output of a shift command to a start of change in an actual gear ratio toward a target gear ratio to be achieved after the shifting, and performs a learning correction of a command pressure for the first friction element or a command pressure for the second friction element on the basis of the determination result.

Owner:JATCO LTD +1

Portable gun rest

InactiveUS20140215889A1Readily be used with different size gun stockEasy to reachAmmunition loadingWeapon cleaningEngineeringPolymer

Owner:IMPERO ENTERPRISES

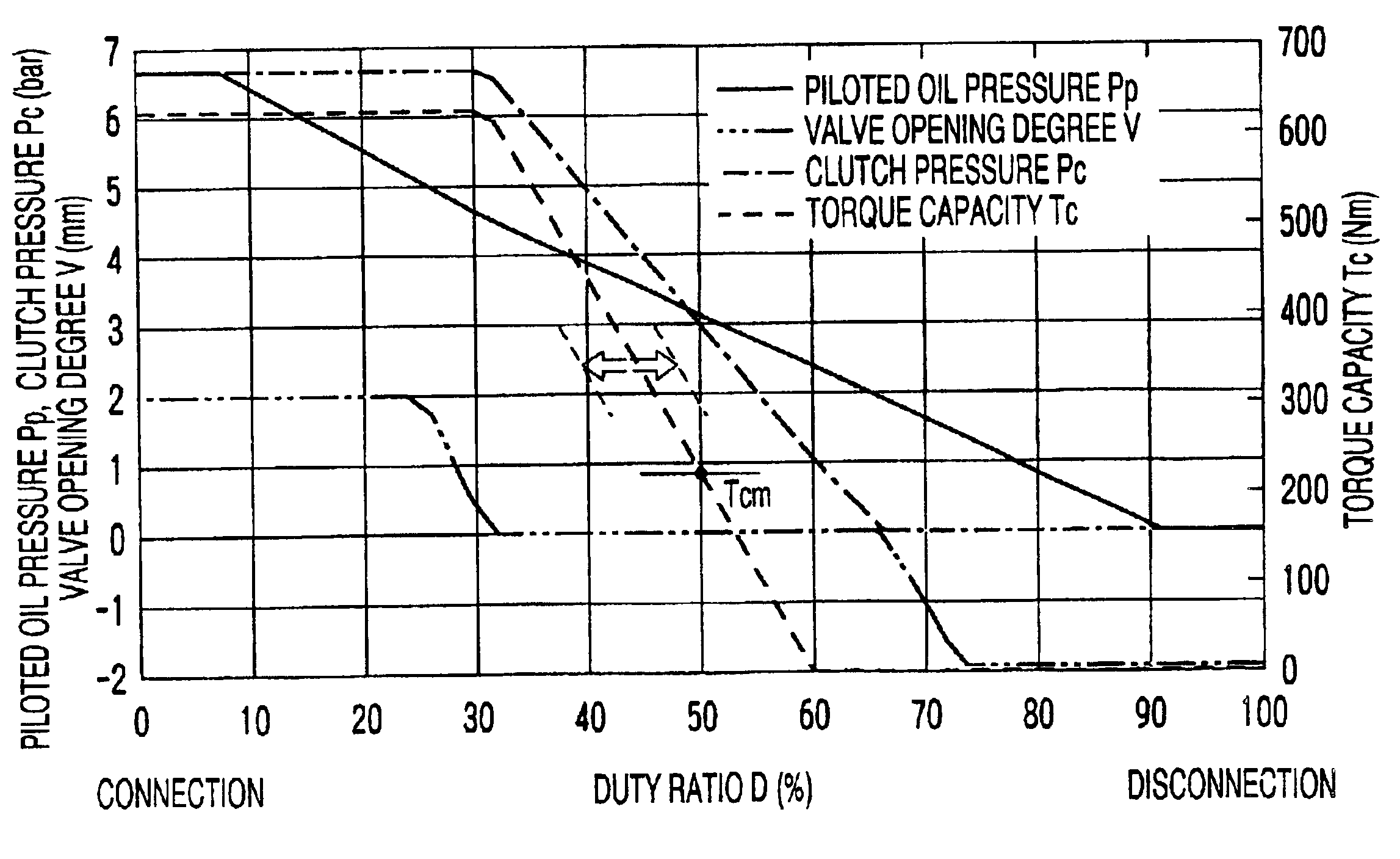

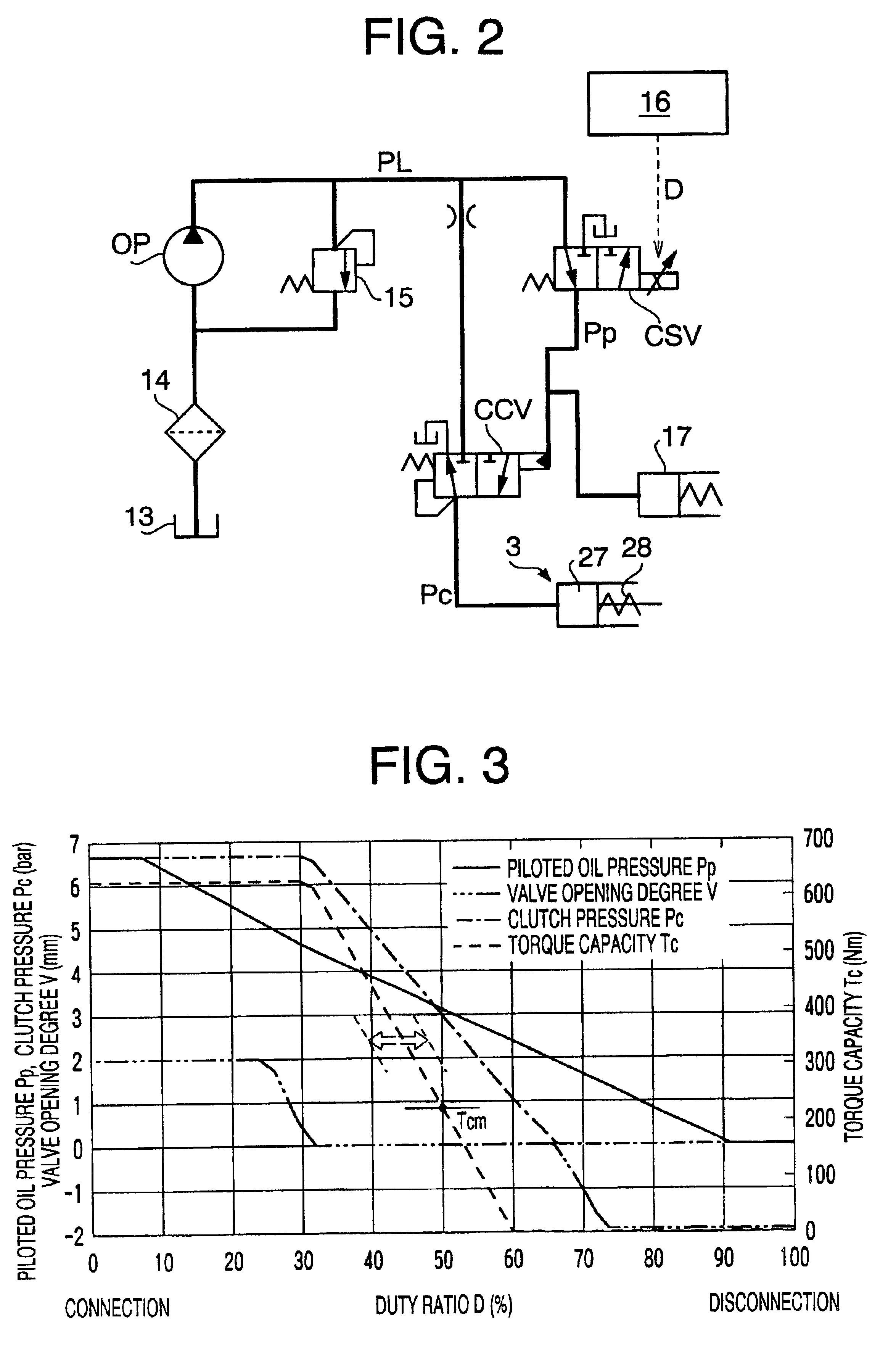

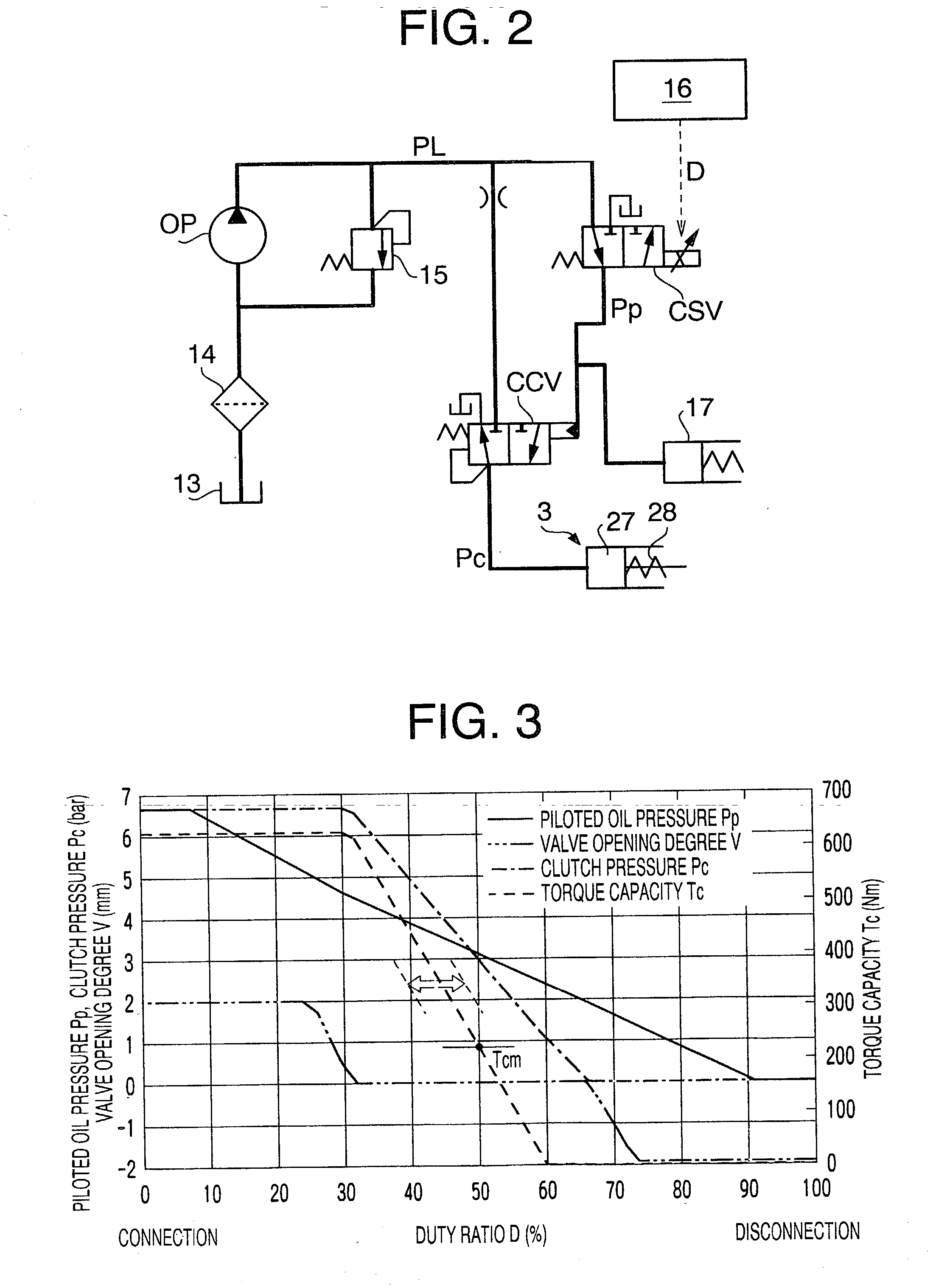

Clutch control method

The present invention provides a clutch connection method which controls the disconnection / connection of a wet friction clutch on the basis of a duty pulse outputted from an electronic control unit. When the clutch is connected, the electronic control unit initially outputs a start duty (Dst) for largely connecting the clutch as far as the vicinity of a torque point, and, thereafter, outputs, at prescribed time intervals (Δt), a gradual connection duty (Dk) for gradually connecting the clutch, and determines a gradual connection duty value on the basis of a clutch input / output side revolution difference ΔN. Since the clutch is gradually connected while monitoring the clutch connection state, variations between connection times and connection shock, resulting from individual clutch differences or the like, can be eliminated, whereby it is possible to achieve a stable feel. Further, in control which connects the clutch in sync with completion of a transmission gear shift, a plurality of clutch connection modes (an engine plus mode, an in-shaft plus mode, and a synchro mode) are preset, and the clutch connection modes are selected in accordance with the size of clutch input-side and output-side revolution numbers upon completion of a gear shift. Clutch connection is performed which conforms to actual conditions since a clutch connection mode is selected in accordance with the size of clutch input / output side revolution numbers rather than with respect to a shift-up or a shift-down.

Owner:ISUZU MOTORS LTD

Golf Club Head

ActiveUS20070004530A1Improve mass distributionOptimized moments of inertiaGolf clubsRacket sportsEngineeringGravity center

A golf club head (20) having optimized inertial properties and center of gravity is disclosed. The golf club head (20) preferably has a volume between 300 cubic centimeters and 500 cubic centimeters. The golf club head (20) has a center of gravity located less than 1.7 inches from an exterior surface of a front wall (30). The positioning of the center of gravity of the golf club head (20) and the optimized inertial properties provide the golf club with greater ball spin robustness and better performance.

Owner:TOPGOLF CALLAWAY BRANDS CORP

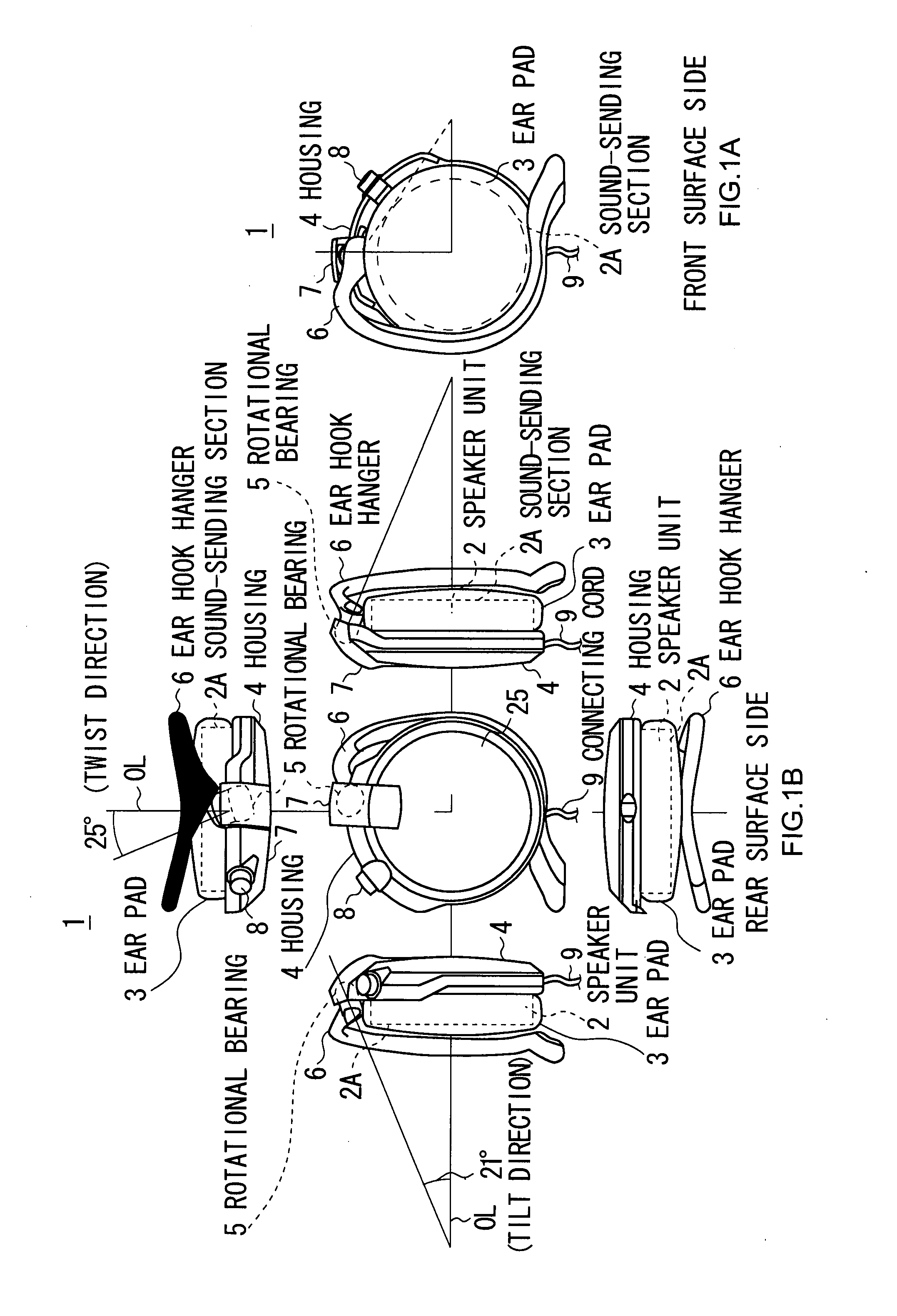

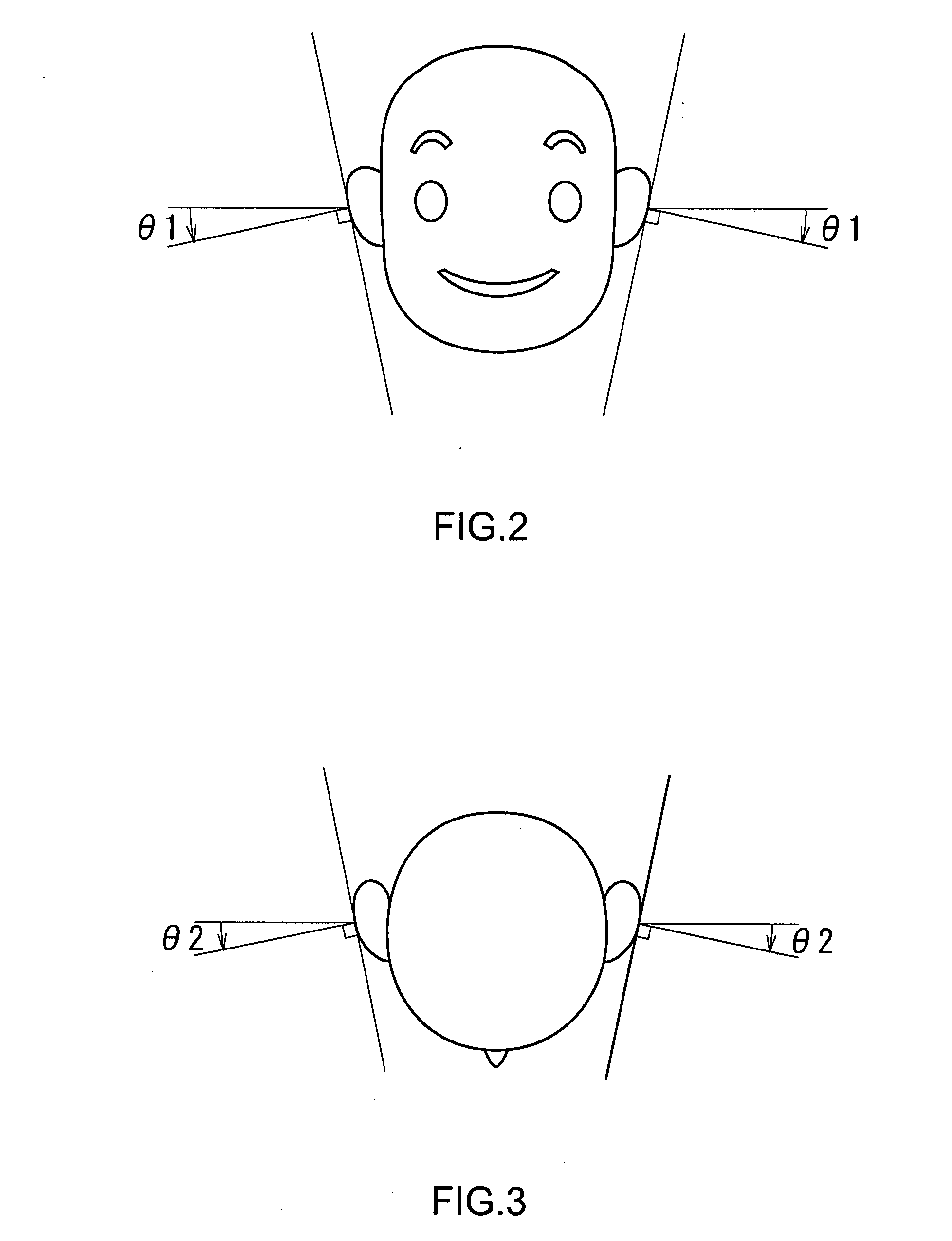

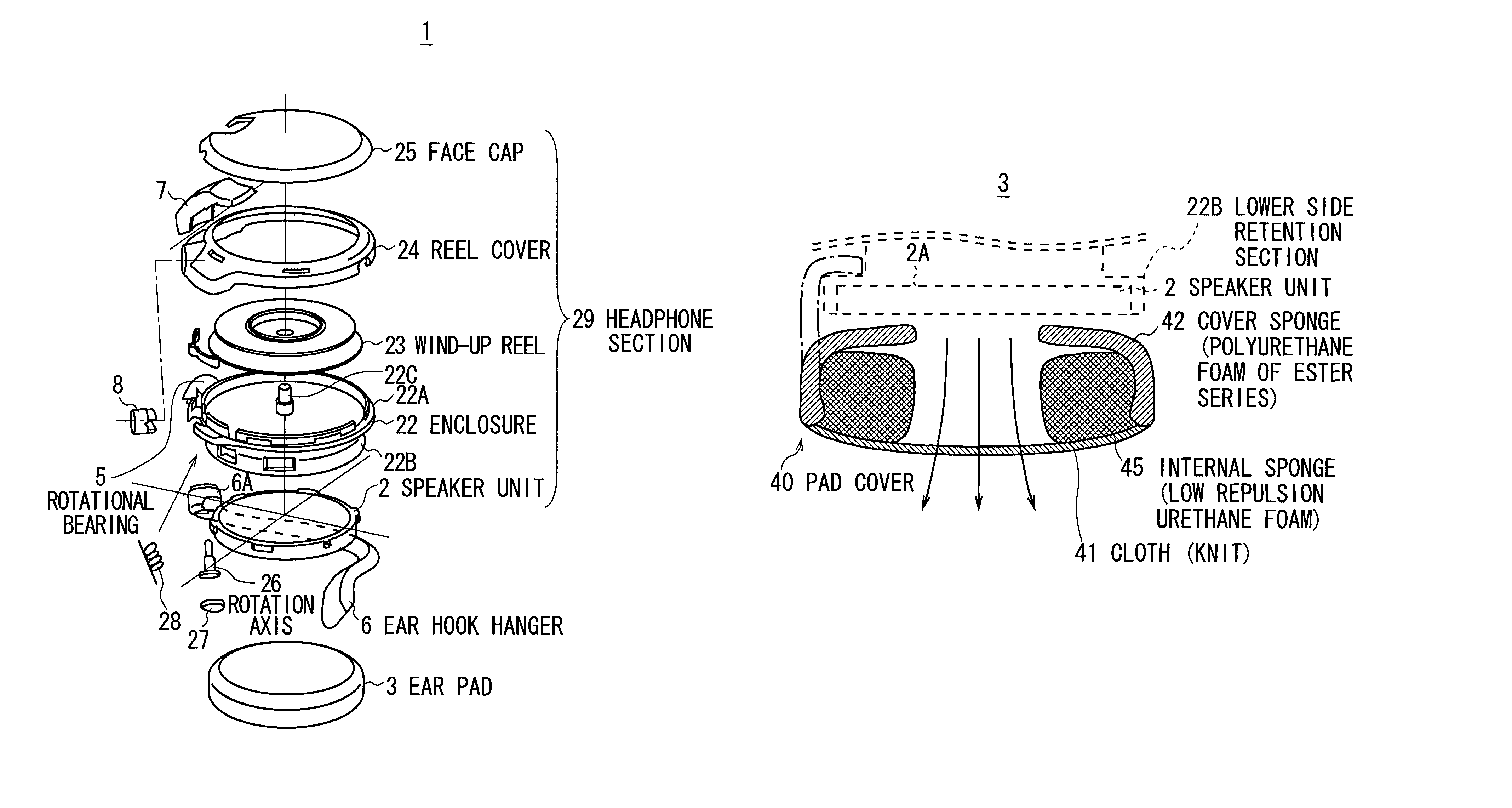

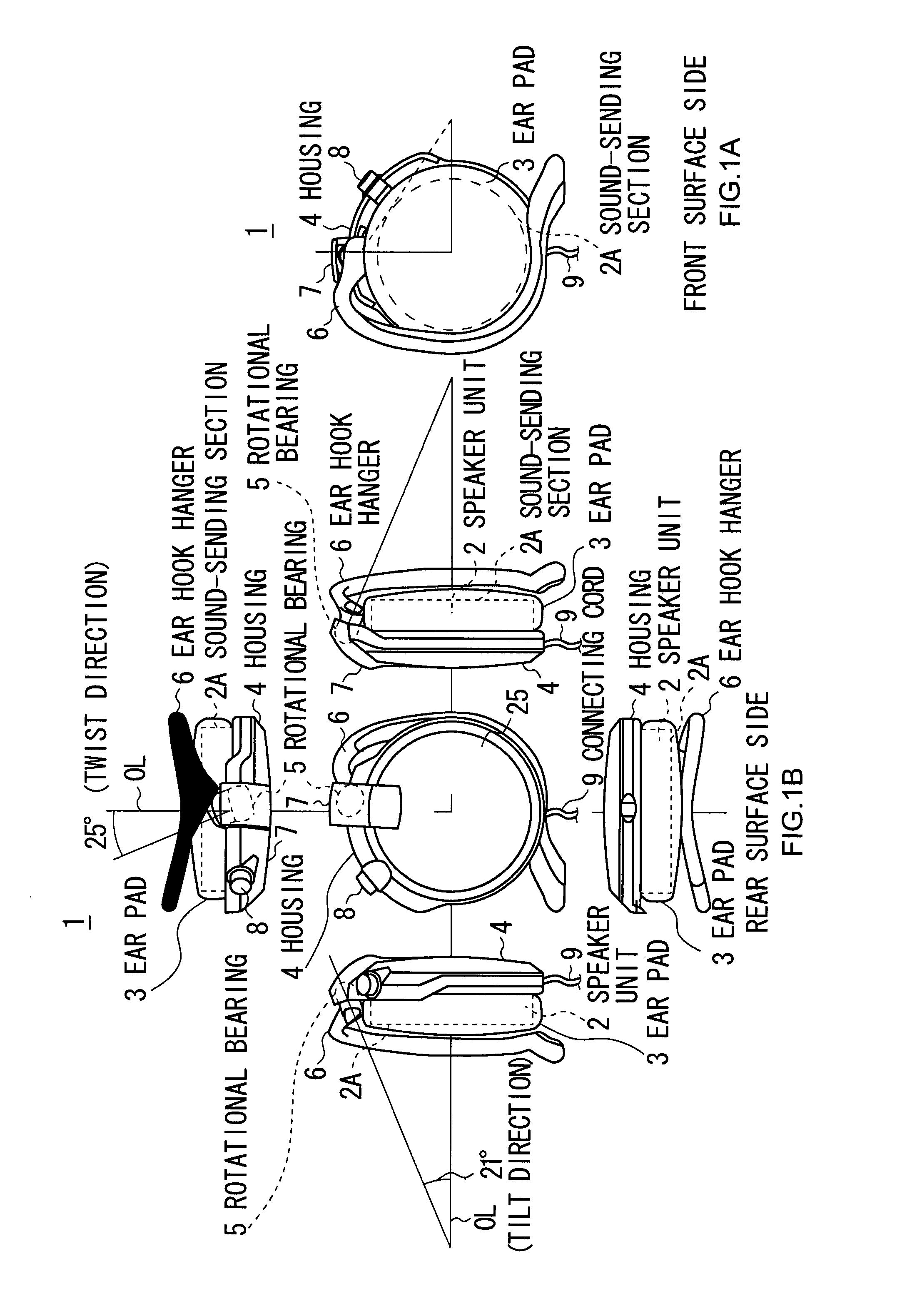

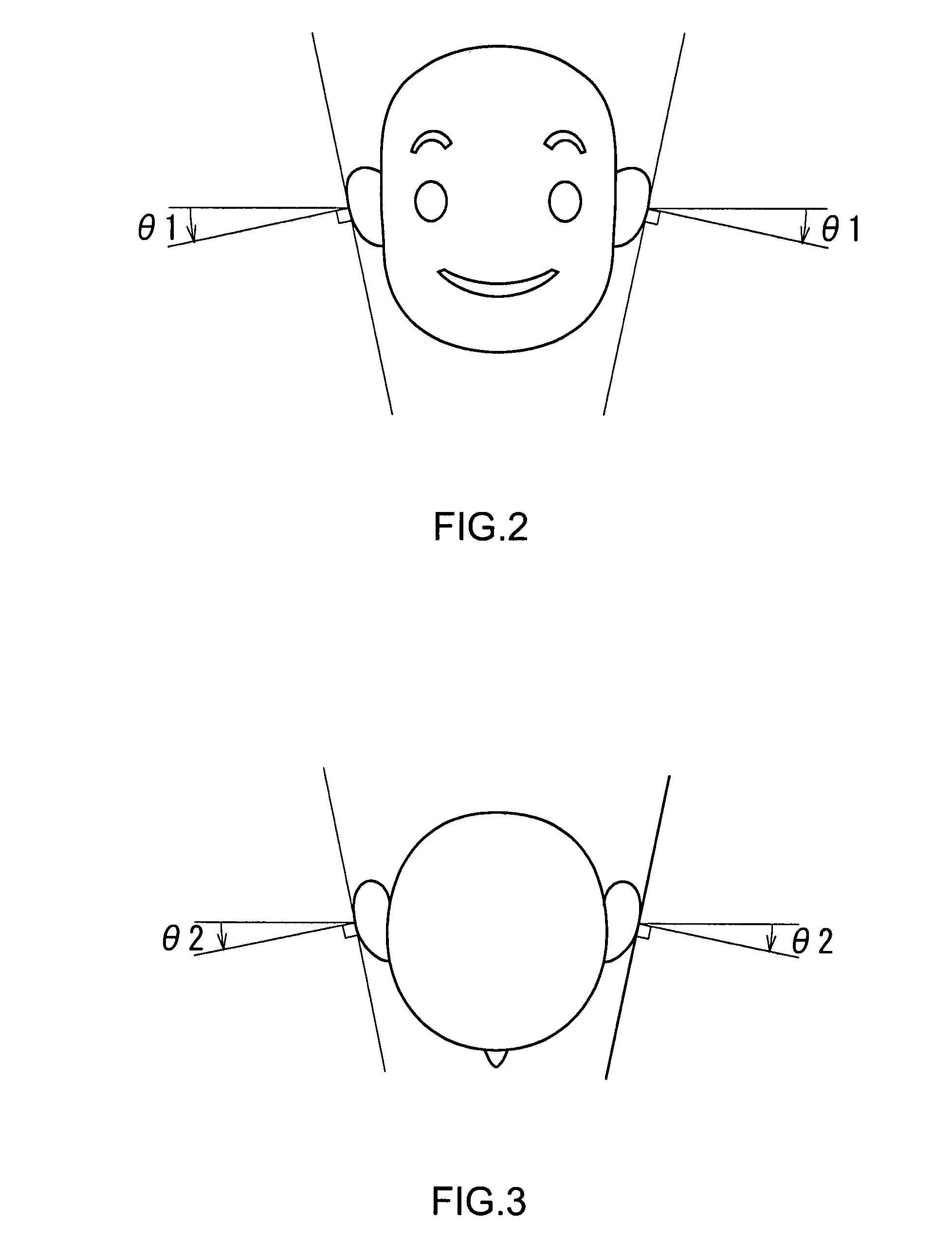

Headphone and ear pad

InactiveUS20080112586A1Feel comfortableFeel stableSupra/circum aural earpiecesDeaf-aid setsEngineeringEarmuffs

Owner:SONY CORP

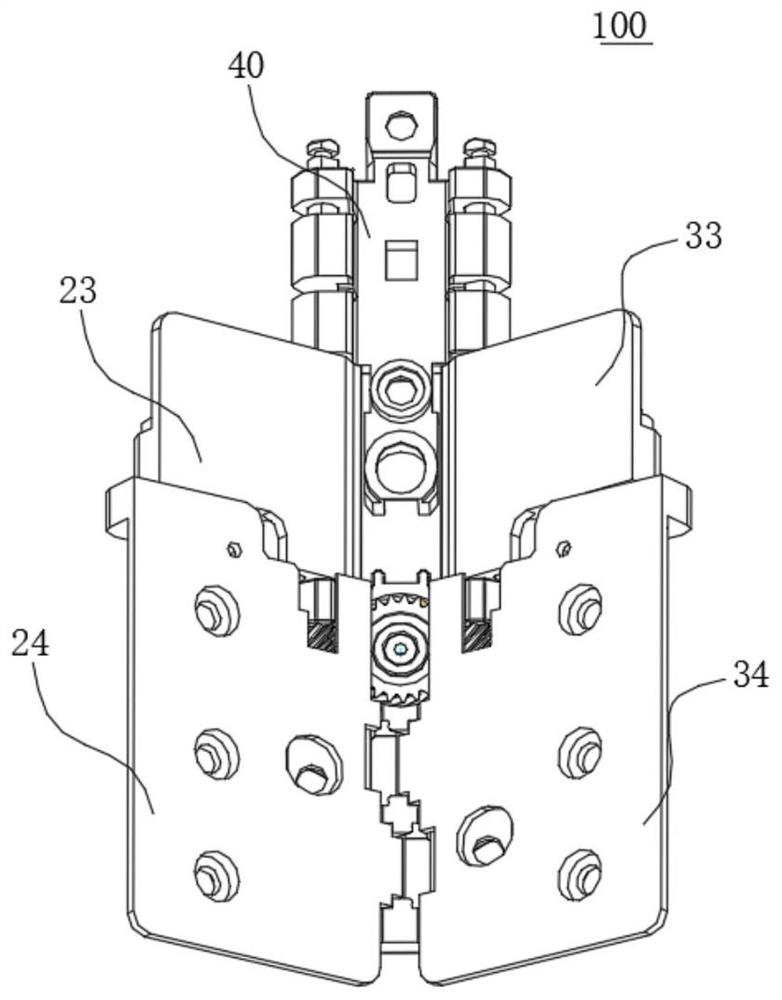

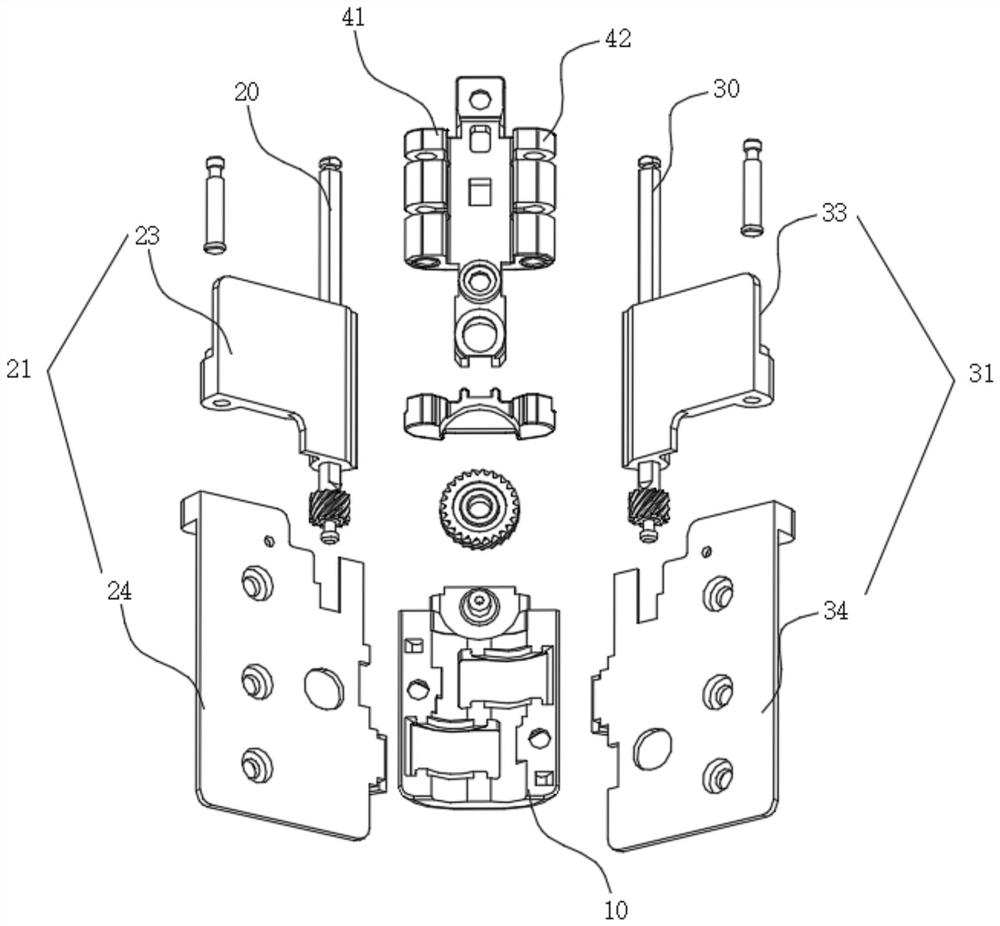

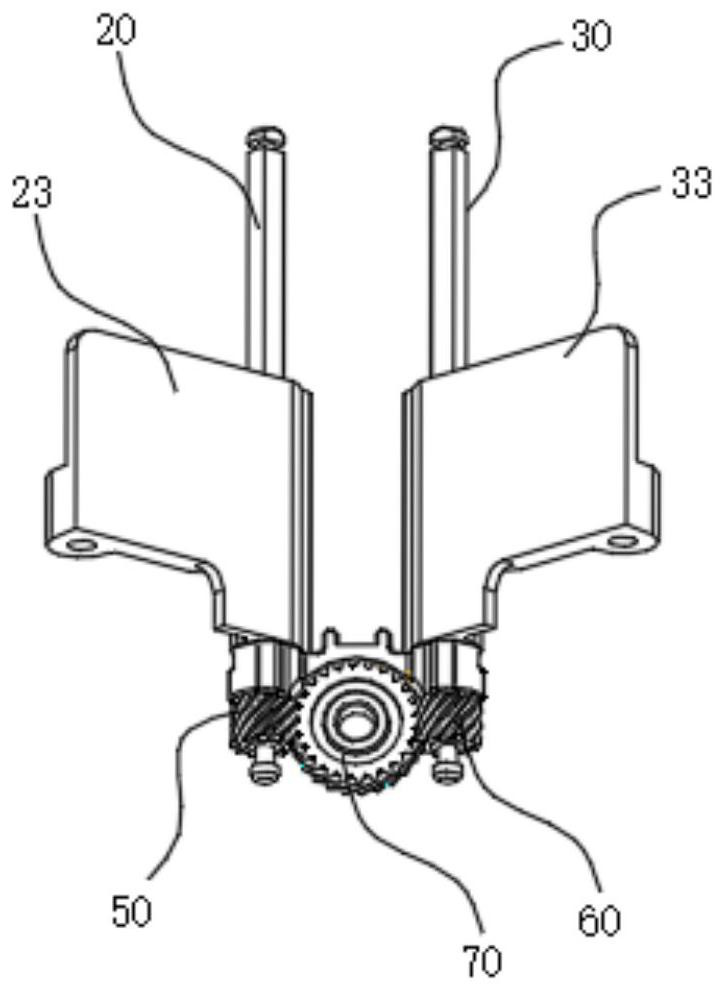

Hinge assembly and electronic equipment

ActiveCN112947692AAchieve foldingFeel goodDigital data processing detailsPin hingesStructural engineeringMechanical engineering

The invention discloses a hinge assembly and electronic equipment, the electronic equipment comprises a first part and a second part, and the hinge assembly comprises: a supporting seat; a first movable part which is movably connected with the supporting seat, wherein a first mounting part connected with the first part is arranged on the first movable part; a second movable part which is movably connected with the supporting seat, wherein the second movable part and the first movable part are oppositely arranged, and a second mounting part connected with the second part is arranged on the second movable part; and a damping assembly which is provided with a first matching part and a second matching part, wherein the first movable part can rotate around the axis of the first movable part so that damping can be generated between the damping assembly and the first movable part, and the second movable part can rotate around the axis of the second movable part so that damping can be generated between the damping assembly and the second movable part. Through cooperation of the first movable part, the second movable part and the damping assembly, stable damping is provided.

Owner:VIVO MOBILE COMM CO LTD

Reaction control system for obtaining preferable steering feeling

ActiveUS7311173B2Feel stableImprove lagDigital data processing detailsSteering initiationsControl systemResponse control

A reaction control system controls a reactive force to be applied to an operating device operated by a driver of a vehicle. The system includes a device for measuring a steering speed of steering of the operating device; a device for measuring a steering torque applied to the operating device; and a reactive force correcting device for correcting the reactive force in a manner such that the corrected reactive force increases at least when the measured steering speed is zero, and that the higher the measured steering torque, the higher the corrected reactive force is. The reactive force correcting device may correct the reactive force in a manner such that the higher a speed of the vehicle, the higher the corrected reactive force is. A non-effectivity range of the steering torque in which the corrected reactive force is not influenced by the steering torque may be defined.

Owner:HONDA MOTOR CO LTD

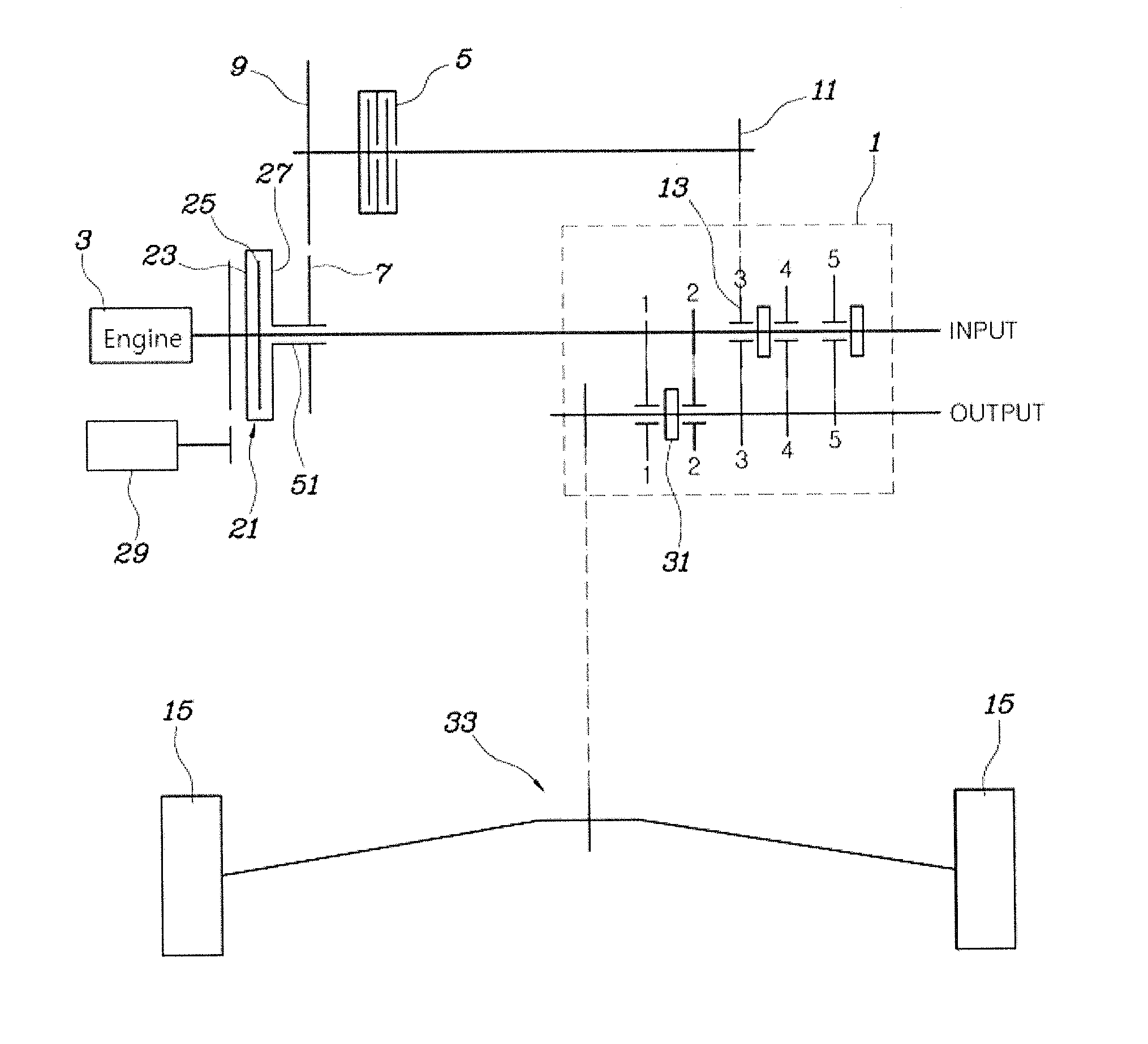

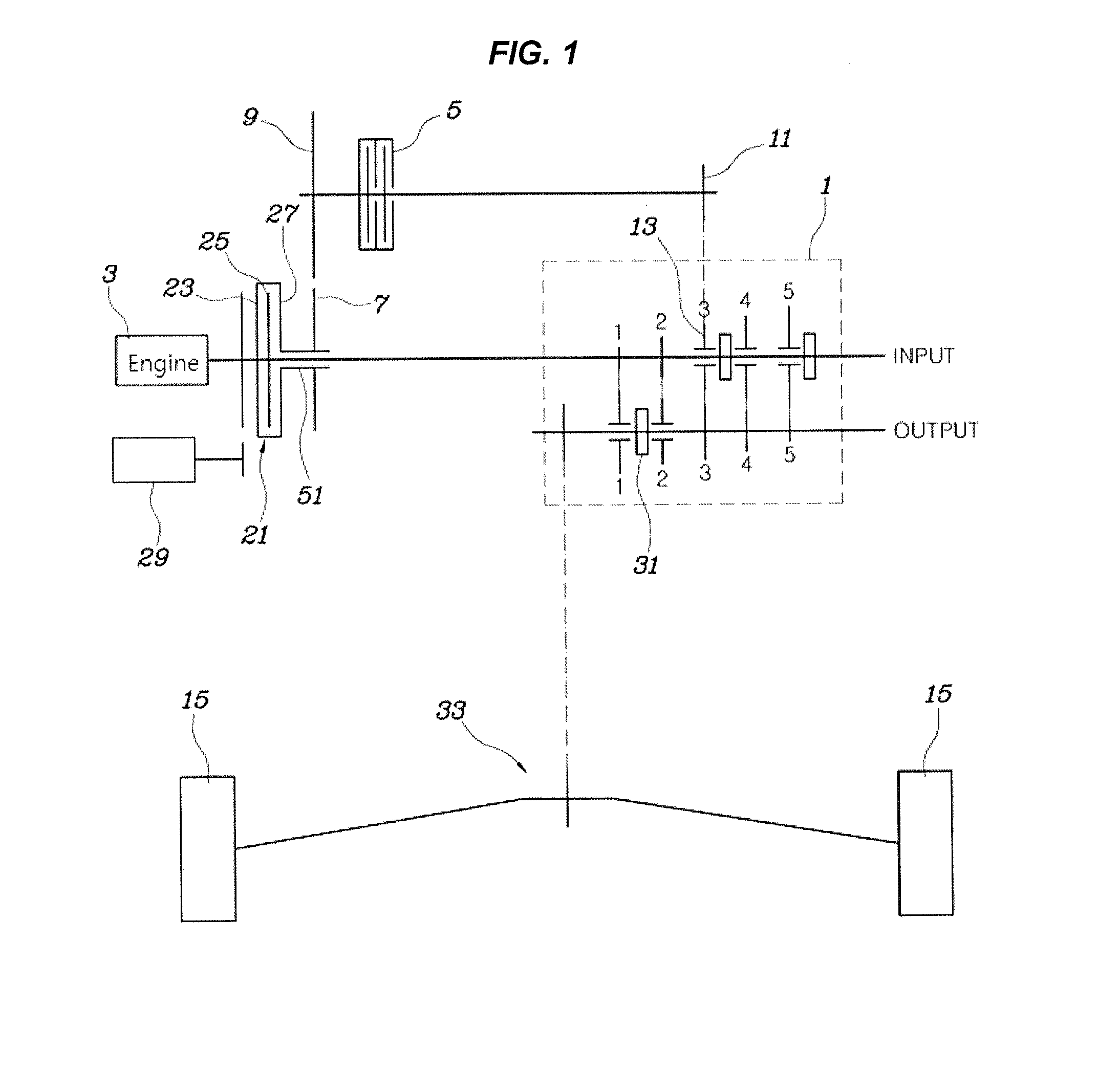

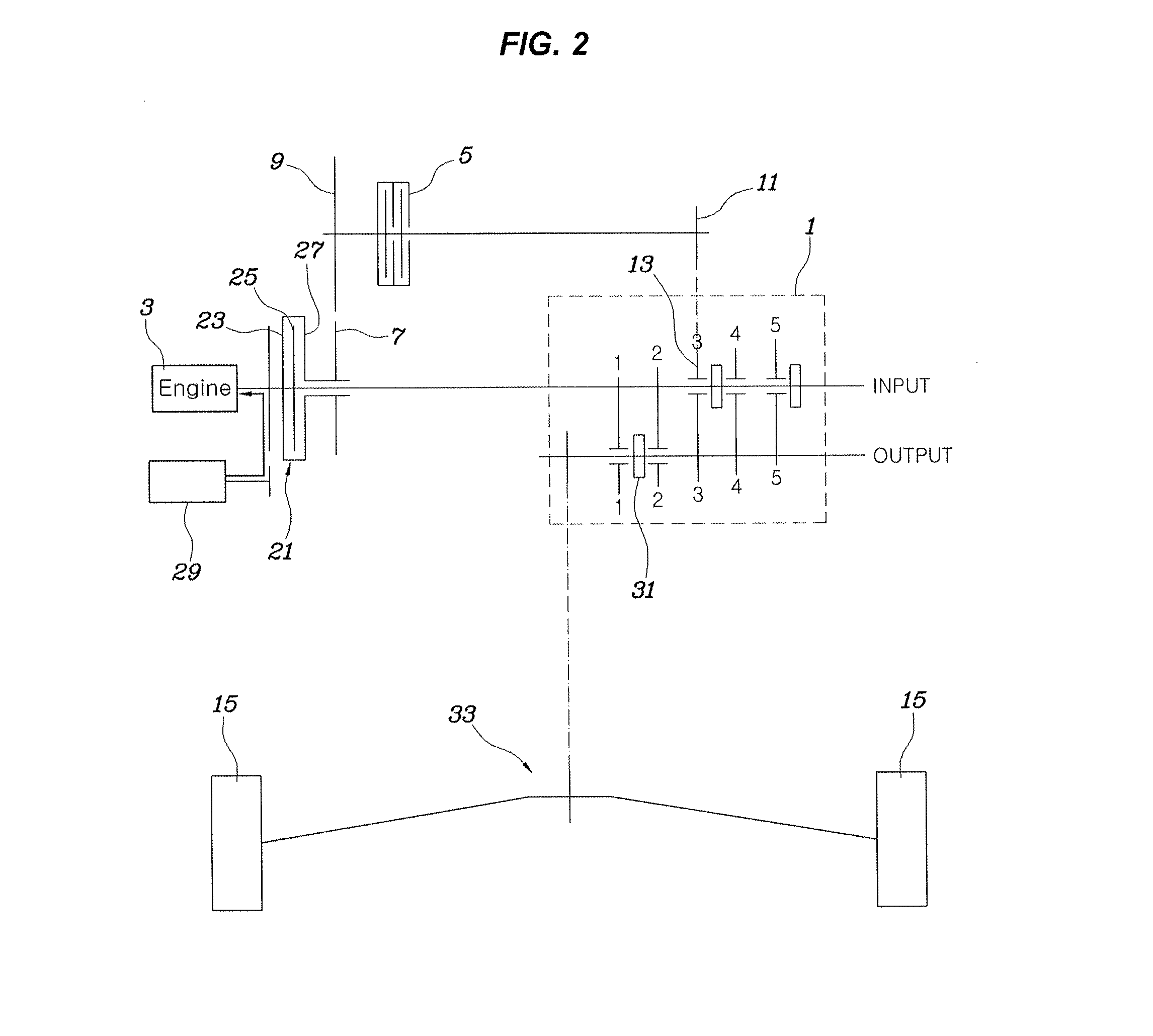

Automated manual transmission for vehicle

InactiveUS20140011634A1Feel stableSmooth and stable feelingToothed gearingsVehicle sub-unit featuresEngineeringGear ratio

An automated manual transmission for a vehicle may include a shifting section provided with a plurality of shifting units for implementing different gear ratio between an input shaft and an output shaft, and a variable power transfer unit transferring continuously and variably power of a power providing device to the shifting section in series by self-controllable slip operation, wherein the variable power transfer unit may be disposed between the power providing device and the shifting section.

Owner:HYUNDAI MOTOR CO LTD

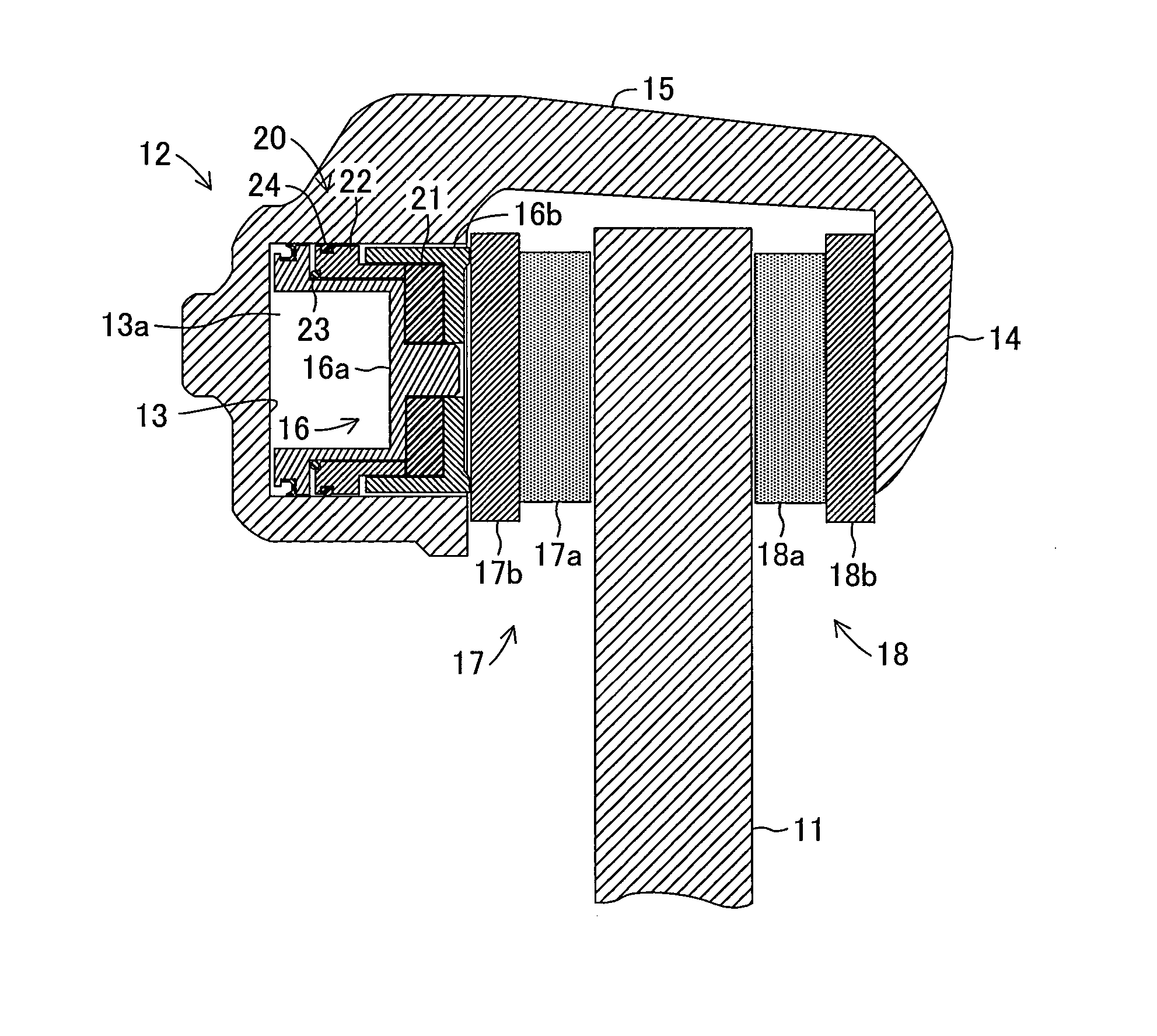

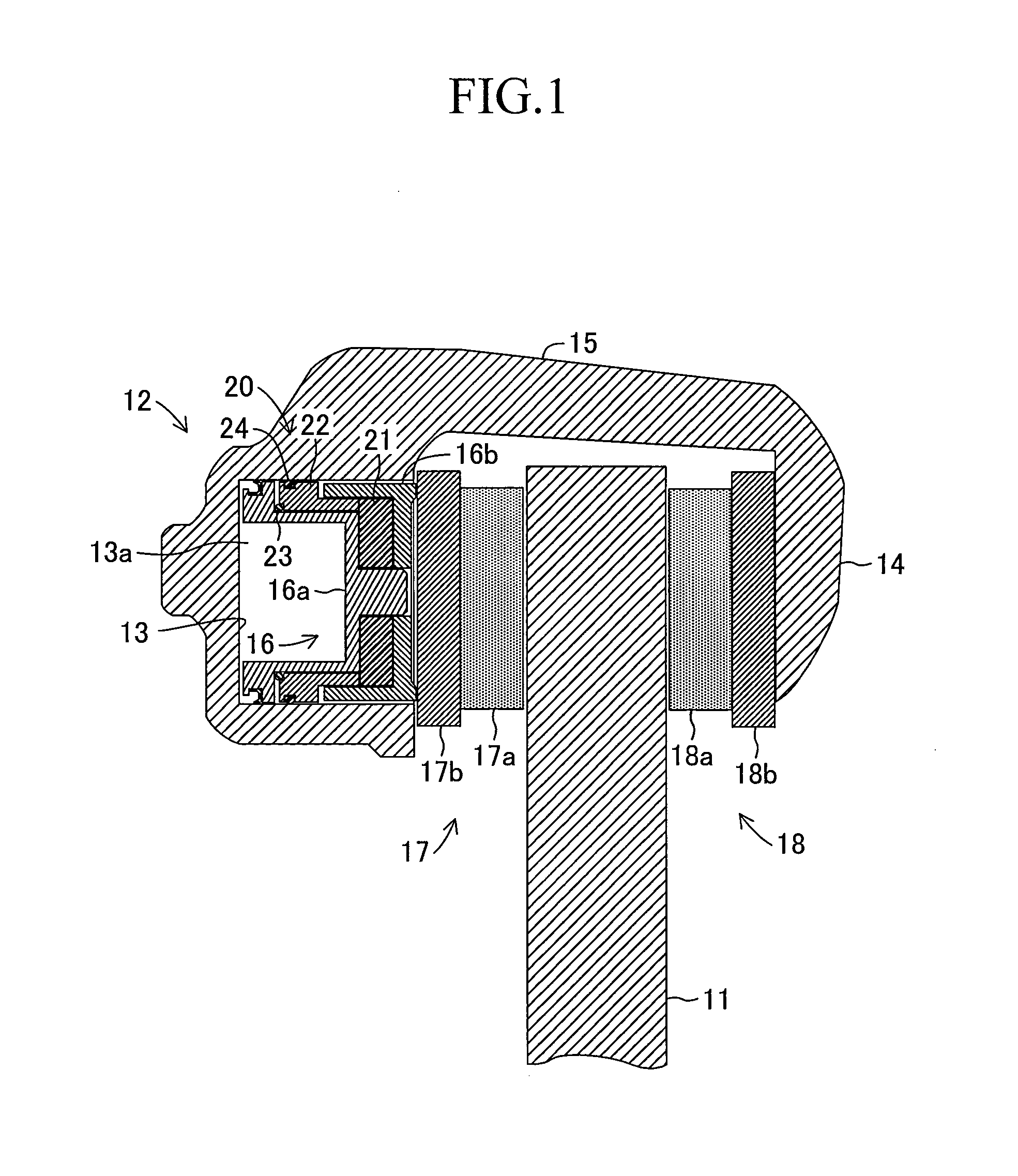

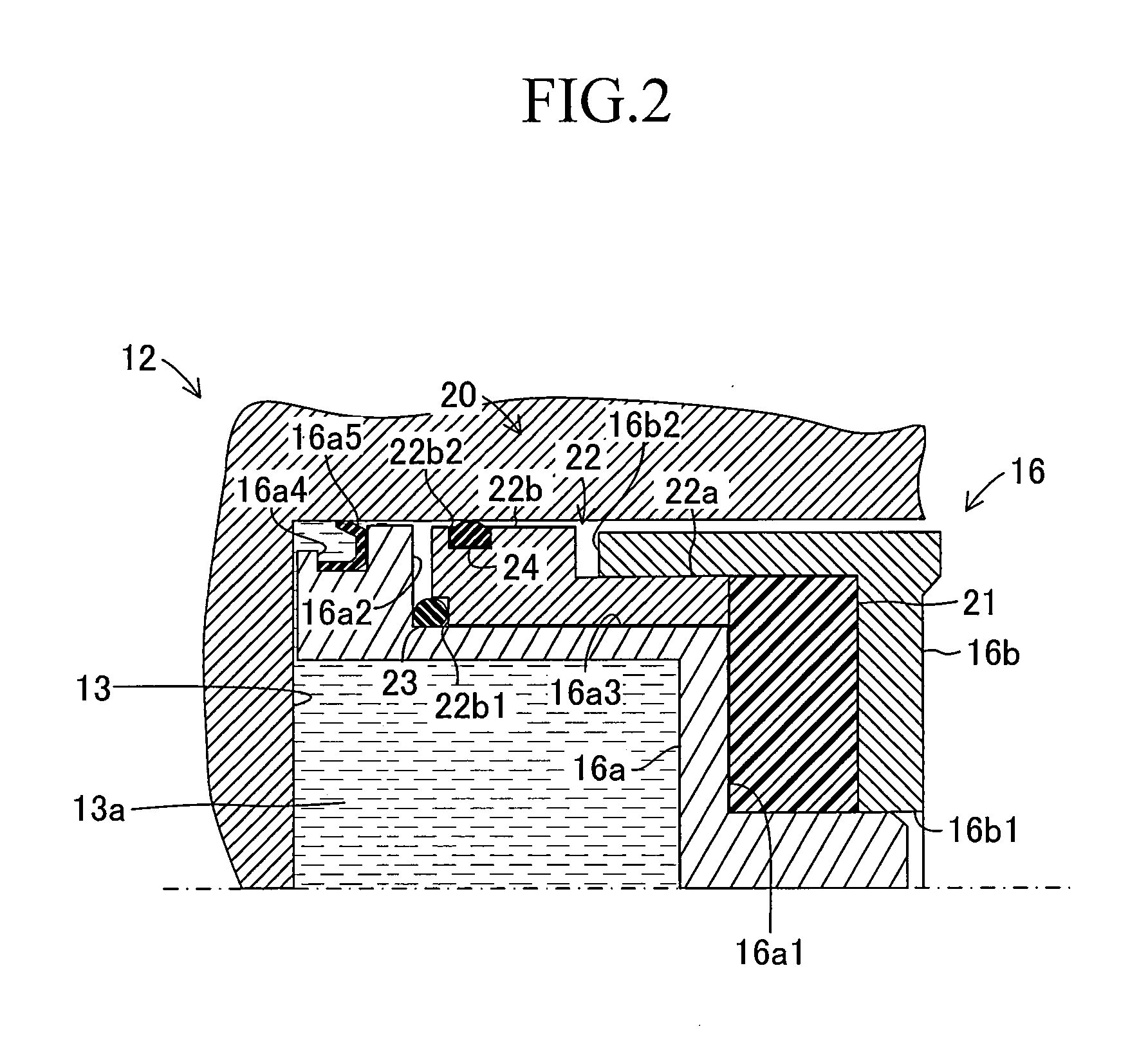

Disk brake device

ActiveUS20130068572A1Stable brake feelingStable returnBraking element arrangementsAxially engaging brakesEngineeringCalipers

A cylinder portion (13) formed in a caliper (12) supports a pressure receiving portion (16a) and a pressing portion (16b) of a piston (16) so as to allow the pressure receiving portion (16a) and the pressing section (16b) to advance and retreat. The piston (16) is provided with a retraction mechanism (20). The retraction mechanism (20) includes a reversing member (21) for generating a reversing force when compressed by the pressure receiving portion (16a) and the pressing portion (16b). The mechanism (20) further includes a movable element (22) moved in a retreating stroke due to the reversing force, and a first elastic member (23) for generating a restoring force and imparting the restoring force, the first elastic member (23) generating the restoring force when compressed by the movable element (22) and the pressure receiving portion (16a) which is moved in an advancing stroke. The mechanism (20) further includes a second elastic member (24) for generating a frictional force for maintaining the compression and deformation of the first elastic member. The reversing member (21) generates the reversing force along with the advance of the pressure receiving portion (16a), the movable element (22) relatively retreats due to the reversing force and compresses the first elastic member (23), and the generated restoring force returns the pressure receiving portion (16a) and the pressing portion (16b) along with a decrease in pressure of a brake fluid.

Owner:TOYOTA JIDOSHA KK

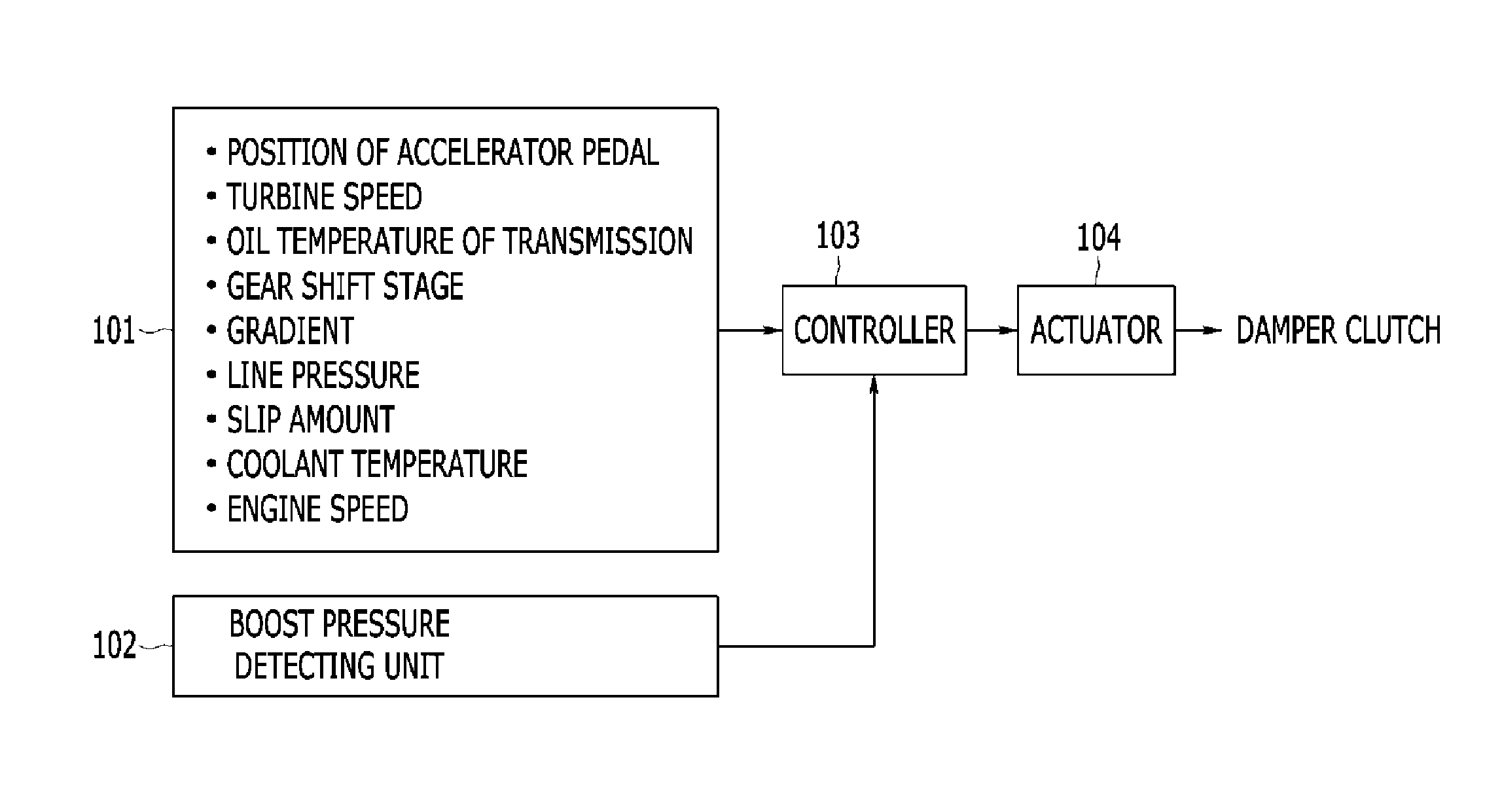

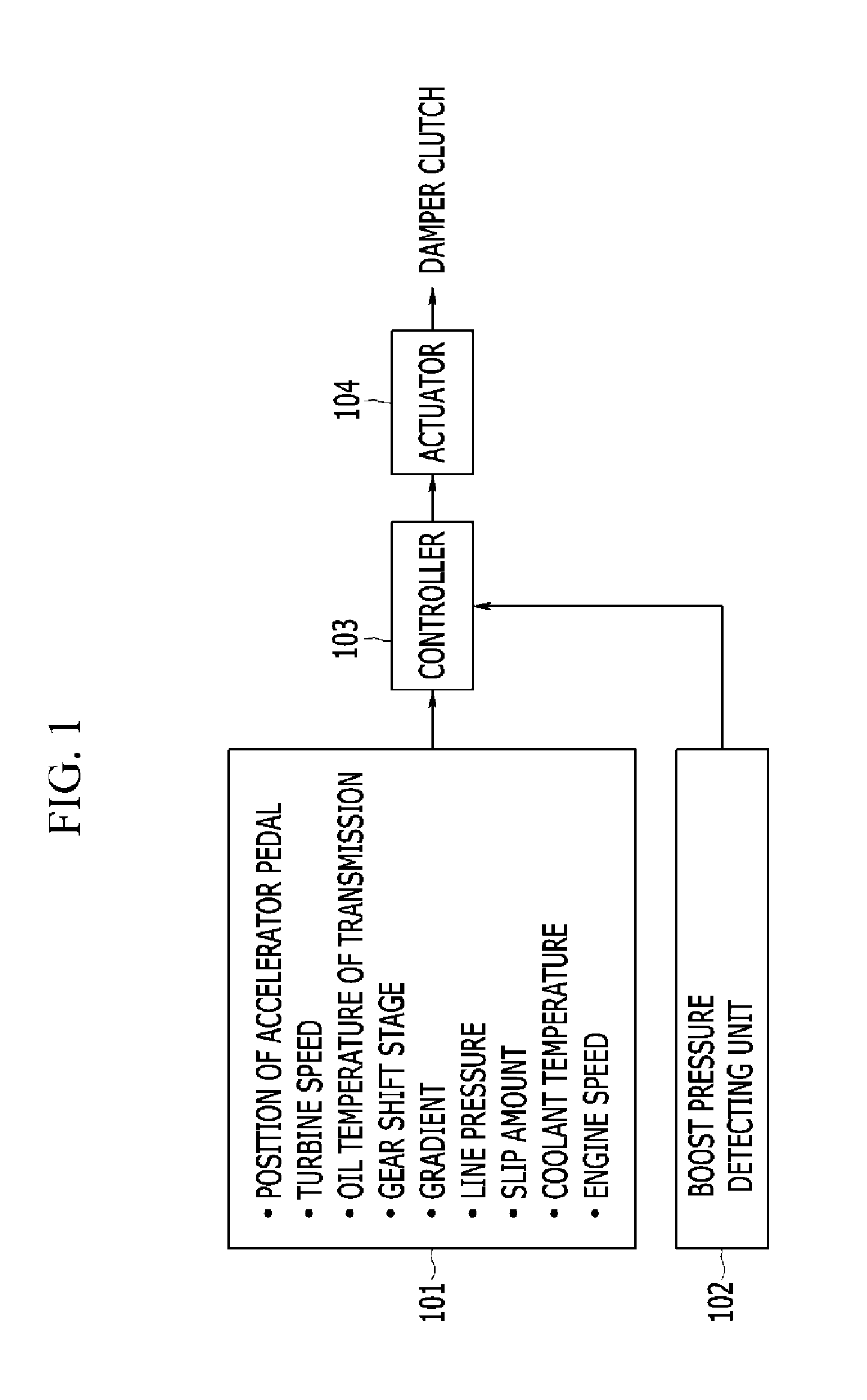

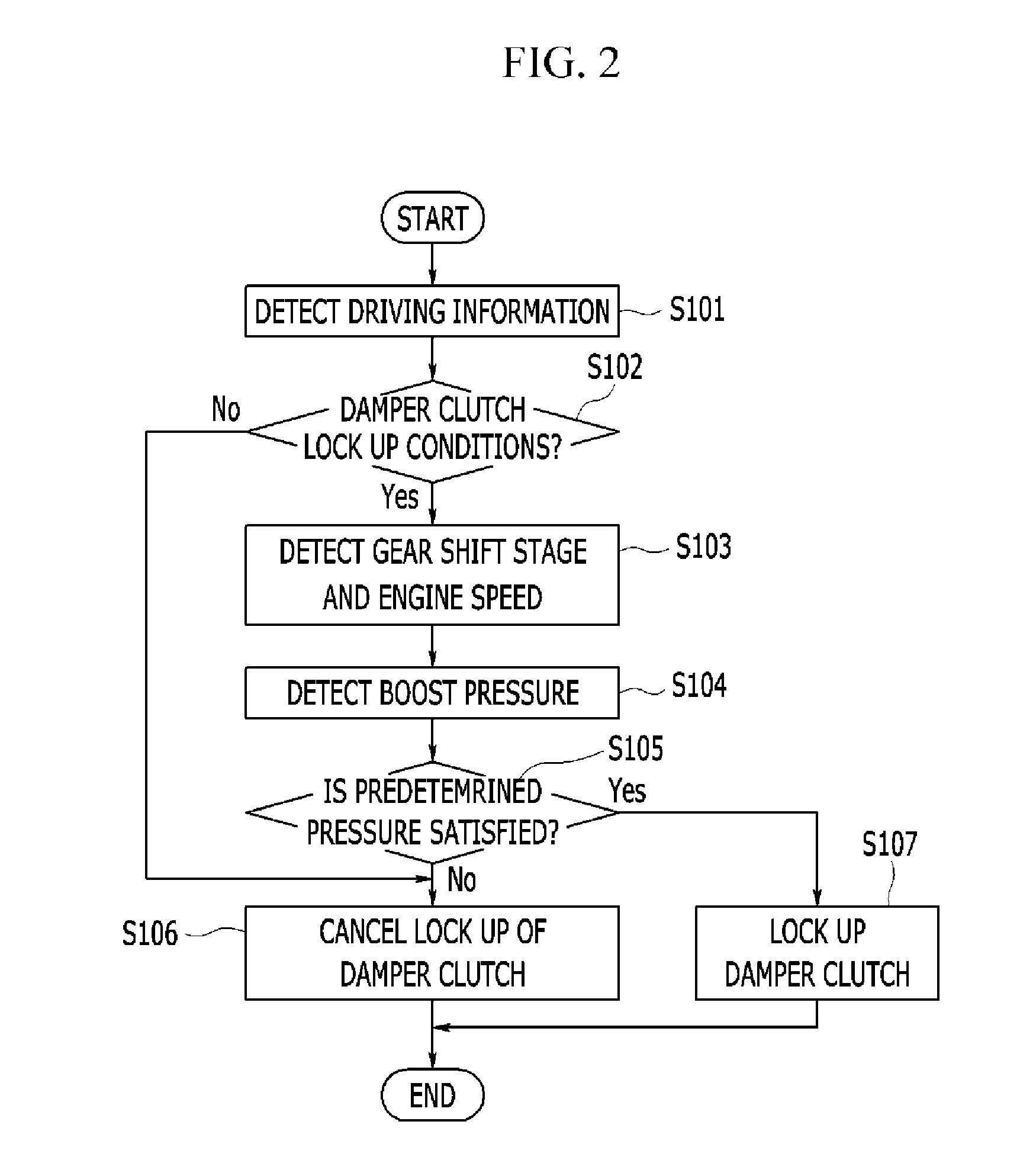

Apparatus and method for controlling damper clutch of automatic transmission vehicle

InactiveUS20140142824A1Stable pressurization processFeel stableClutchesGearing controlAutomatic transmissionTurbocharger

A method of controlling a damper clutch of a turbocharger mounted automatic transmission vehicle secures stable boost pressure to provide accelerating feeling is disclosed. The method may include detecting driving information from a turbocharger mounted vehicle to determine whether lock up conditions of a damper clutch are satisfied, determining an engine load by a gear shift stage and an engine speed when the lock up conditions of the damper clutch are satisfied, detecting supplied boost pressure to determine whether conditions of the engine load are satisfied, and canceling the lock up of the damper clutch for accelerating feeling when the boost pressure does not satisfy the conditions of the engine load.

Owner:HYUNDAI MOTOR CO LTD

Hollow bag with adjustable side surface supporting framework

The invention discloses a hollow bag with an adjustable side surface supporting framework, which comprises an upper surface, a lower surface and a side surface for connecting the two surfaces, wherein at least one concave cavity is formed in a selected area on at least one of the upper or the lower surfaces; the concave cavity comprises a surface of the selected area projecting in the direction of an opposite surface and a supporting surface enclosing the projecting surface; at least part of the supporting surface is connected with the inner side surface forming the hollow framework by connecting the two surfaces to form a framework for reinforcing the side surface support of a hollow object; and at least one predetermined supporting reinforced piece is filled in the concave cavity in the predetermined area connected with the side surface of the hollow bag. The invention utilizes different supporting materials arranged at the side surface of a hollow air cushion to achieve a predetermined visual and real effect, such as stability, safety and coordination function, and makes a wearer feel more stable actually and subconsciously through the reinforcement of the supporting materials.

Owner:黄英俊

Motor control device

InactiveUS8907610B2Feel stableAC motor controlSynchronous motors startersMotor controlMotor Drive Unit

A motor control device has a motor driving unit that drives a motor, a current detecting unit that detects a motor current flowing through the motor, a control unit that compares a detected current value of the motor current detected by the current detecting unit with a target current value to obtain a deviation, to control the motor driving unit based on the deviation, and a compensation unit that sets as a current offset value a detected current value of a drift current detected by the current detecting unit in a state where the motor current is regarded as zero, to compensate the detected current value of the motor current by the current offset value. The compensation unit sets a target offset value according to the current value of the detected drift current to correct the current offset value stepwise until the current offset value reaches the target offset value.

Owner:OMRON AUTOMOTIVE ELECTRONICS CO LTD

Headphone and ear pad

InactiveUS8150090B2Feel stableFeel comfortableSupra/circum aural earpiecesDeaf-aid setsEngineeringEarmuffs

Owner:SONY CORP

Clutch control method

The present invention provides a clutch connection method which controls the disconnection / connection of a wet friction clutch on the basis of a duty pulse outputted from an electronic control unit. When the clutch is connected, the electronic control unit initially outputs a start duty (Dst) for largely connecting the clutch as far as the vicinity of a torque point, and, thereafter, outputs, at prescribed time intervals (DELTAt), a gradual connection duty (Dk) for gradually connecting the clutch, and determines a gradual connection duty value on the basis of a clutch input / output side revolution difference DELTAN. Since the clutch is gradually connected while monitoring the clutch connection state, variations between connection times and connection shock, resulting from individual clutch differences or the like, can be eliminated, whereby it is possible to achieve a stable feel. Further, in control which connects the clutch in sync with completion of a transmission gear shift, a plurality of clutch connection modes (an engine plus mode, an in-shaft plus mode, and a synchro mode) are preset, and the clutch connection modes are selected in accordance with the size of clutch input-side and output-side revolution numbers upon completion of a gear shift. Clutch connection is performed which conforms to actual conditions since a clutch connection mode is selected in accordance with the size of clutch input / output side revolution numbers rather than with respect to a shift-up or a shift-down.

Owner:ISUZU MOTORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com