Patents

Literature

83results about How to "Increase the added value of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

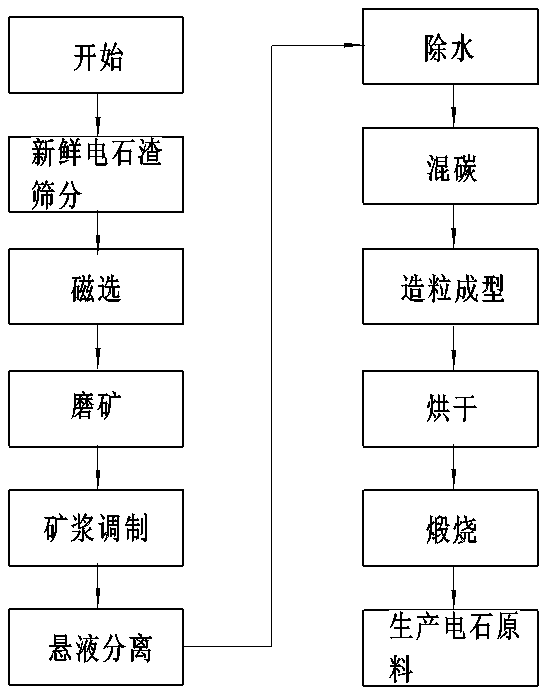

Method for producing calcium carbide raw materials through carbide slag

ActiveCN105502460AAvoid influenceImplement extractionCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideSlag

The invention relates to the field of carbide slag recycling in calcium carbide method acetylene production, in particular to a method that after physical separation is performed on carbide slag impurities, a calcium hydroxide component in the carbide slag impurities is extracted, and then calcium carbide raw materials are produced through carbide slag. The method for producing the calcium carbide raw materials through the carbide slag mainly comprises the following steps of fresh carbide slag screening; magnetic separating; ore grinding; ore pulp preparing; suspension separating; dewatering; carbon mixing, wherein filter cakes which are obtained after dewatering is performed and contain certain moisture are mixed with carbon material particles of which the particle size is smaller than or equal to 2 mm and the fixed carbon content is larger than or equal to 70% in a mixing machine according to the mass fraction ratio of 1.63:1-2.91:1; granulating and forming; drying; calcining. According to the method for producing the calcium carbide raw materials through the carbide slag, the shortcomings and defects in the prior art can be effectively overcome, reclamation recycling of the carbide slag is achieved, the impurities in the carbide slag can be effectively removed, the technology is simple and convenient, and the economical efficiency and practicability are achieved.

Owner:丰镇市嘉鑫硅锰合金有限公司

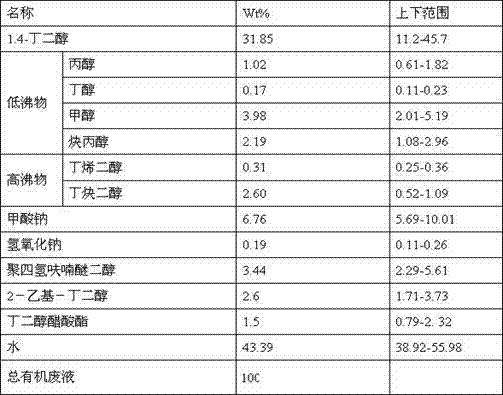

Method for innocently treating organic waste liquid generated in BDO production

ActiveCN105439820AHigh yieldReduce pollutionOrganic compound preparationPlastic recycling1,4-ButanediolAdditional values

The invention discloses a method for innocently treating an organic waste liquid generated in BDO production. According to the method, an organic waste liquid generated in BDO production is treated to obtain high-purity 1,4-butanediol (BDO), high-boiling residues, low-boiling residues, sodium nitrate and polyether polyol products, and innocent, recycling and zero emission treatment of the organic waste liquid generated in BDO production can be realized. The whole method is simple in process, easily controllable in condition and high in finished product yield, and all prepared products have high purity, little equipment investment, low production cost and energy consumption conservation. The method is applied to recycling treatment of organic waste liquid generated in BDO industrial production process to prepare products (industrial raw materials) which can be utilized in industrial production, meanwhile, innocent treatment and zero emission of pollutants can be realized. The method has extremely economic meaning and social meaning in the aspects of increasing production additional values, reducing environmental pollution and the like.

Owner:迪邦(泸州)化工有限公司

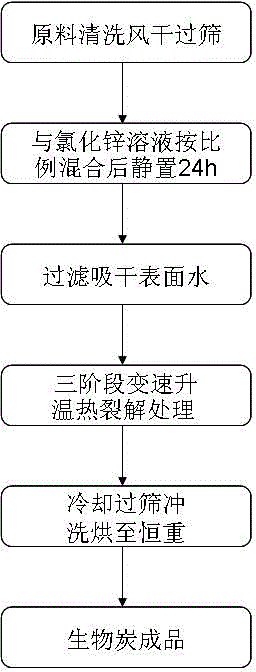

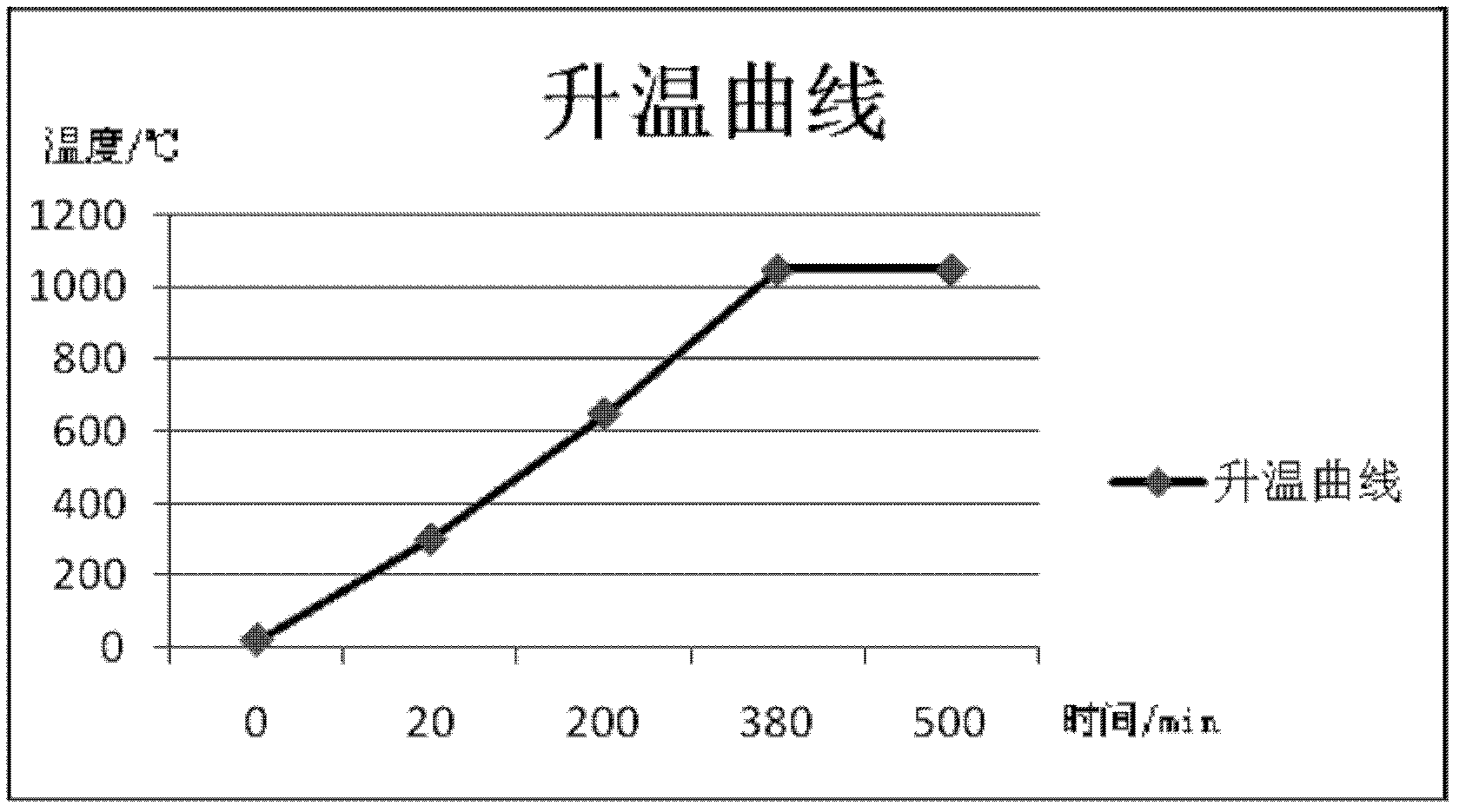

Method for preparing biochar by taking organic solid wastes of agriculture and forestry as raw materials in wet thermal cracking manner

InactiveCN104087326AWide variety of sourcesLower requirementBiofuelsSpecial form destructive distillationMoistureBiochar

The invention relates to a method for preparing biochar by taking organic solid wastes of agriculture and forestry as raw materials in a wet thermal cracking manner. The method comprises the following steps: cleaning, airing, crushing and screening raw materials, and then mixing and stirring the raw materials with 0.20mol / L zinc chloride solution according to the ratio of 1 to 10, and filtering the mixture after standing for 24 hours, wherein the moisture content of the raw materials is controlled between 45.23% and 69.65%; then putting the raw materials into a tubular atmosphere furnace, and carrying out heating cracking by taking nitrogen of which the flow rate is 0.1m<3> / h as a protective gas, wherein at the first stage, quick heating to 200 DEG C, and then heat preservation for 10 minutes are performed, and the heating rate is 50 DEG C / min; the second stage is a slow heating process, the heating rate is 5 DEG C / min, and heating to 350 DEG C and heat preservation for an hour are performed; the third stage is a slow heating stage, the heating rate is 1 DEG C / min, and heat preservation is performed for 2 hours after heating to 400 DEG C; finally screening the solid substances by a 200-mesh sieve; rinsing and baking into constant weight, so as to obtain a biochar product. The method is wide in raw material source, simple in process, and high in biochar yield; the produced biochar has excellent adsorptive property; the production additional value can be increased by tar, smoke and the like generated in the preparation process; the production cost is reduced.

Owner:ANHUI SCI & TECH UNIV

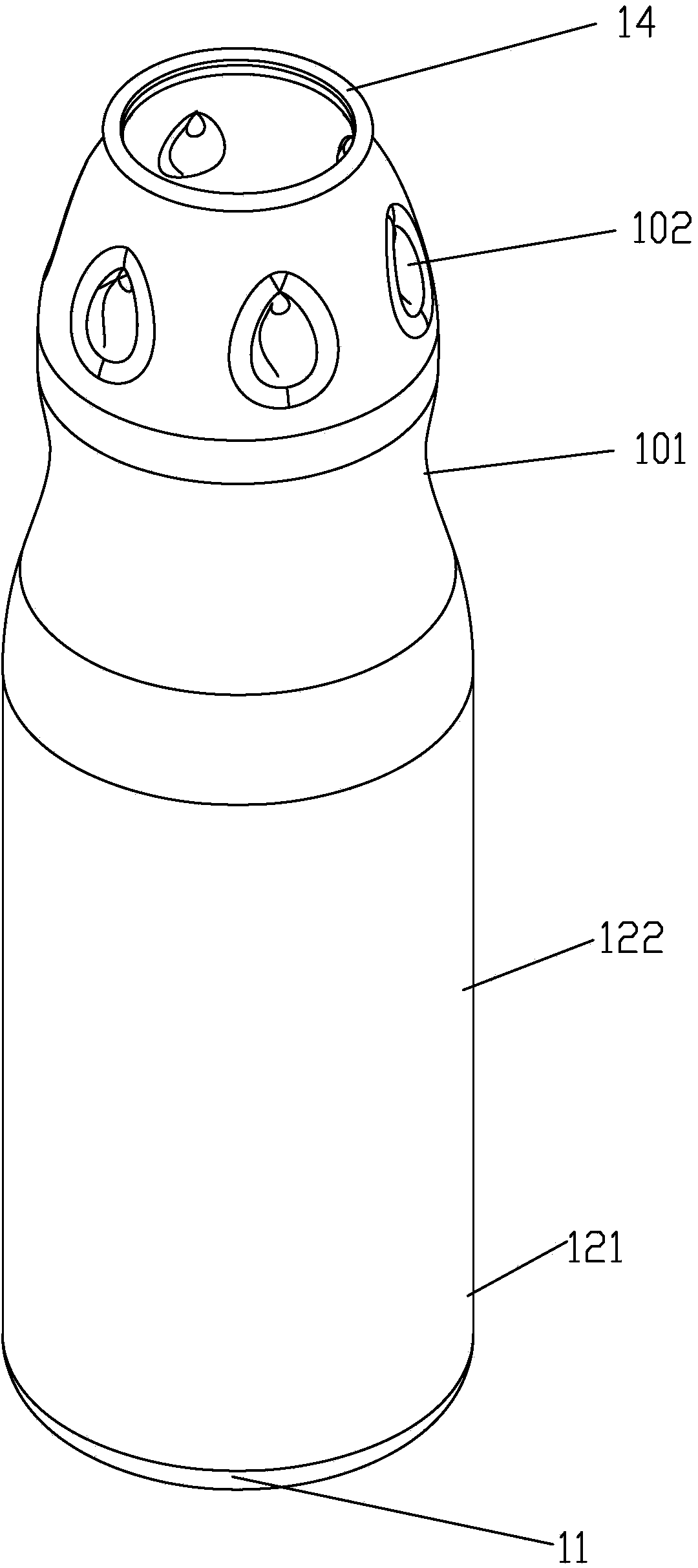

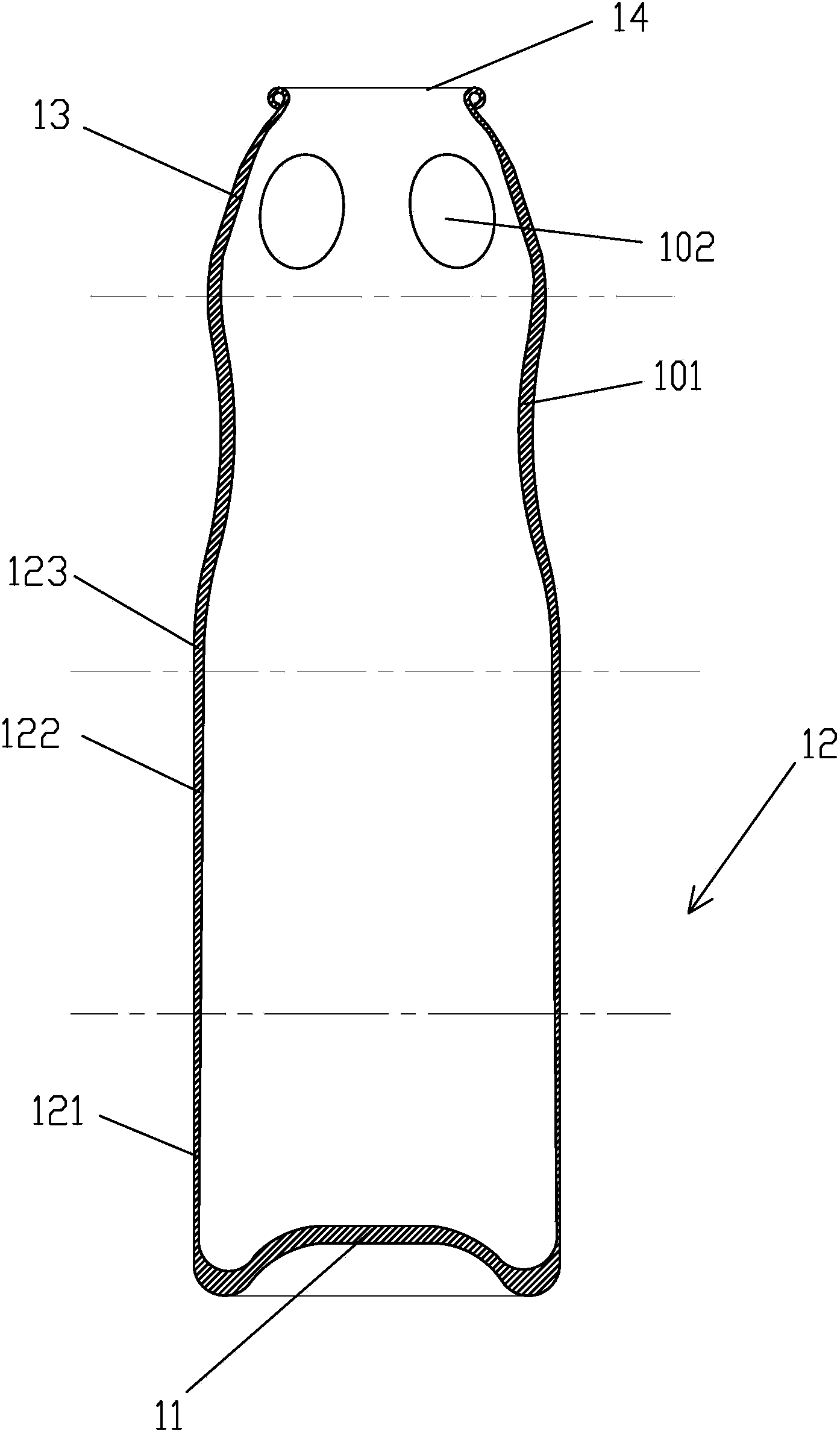

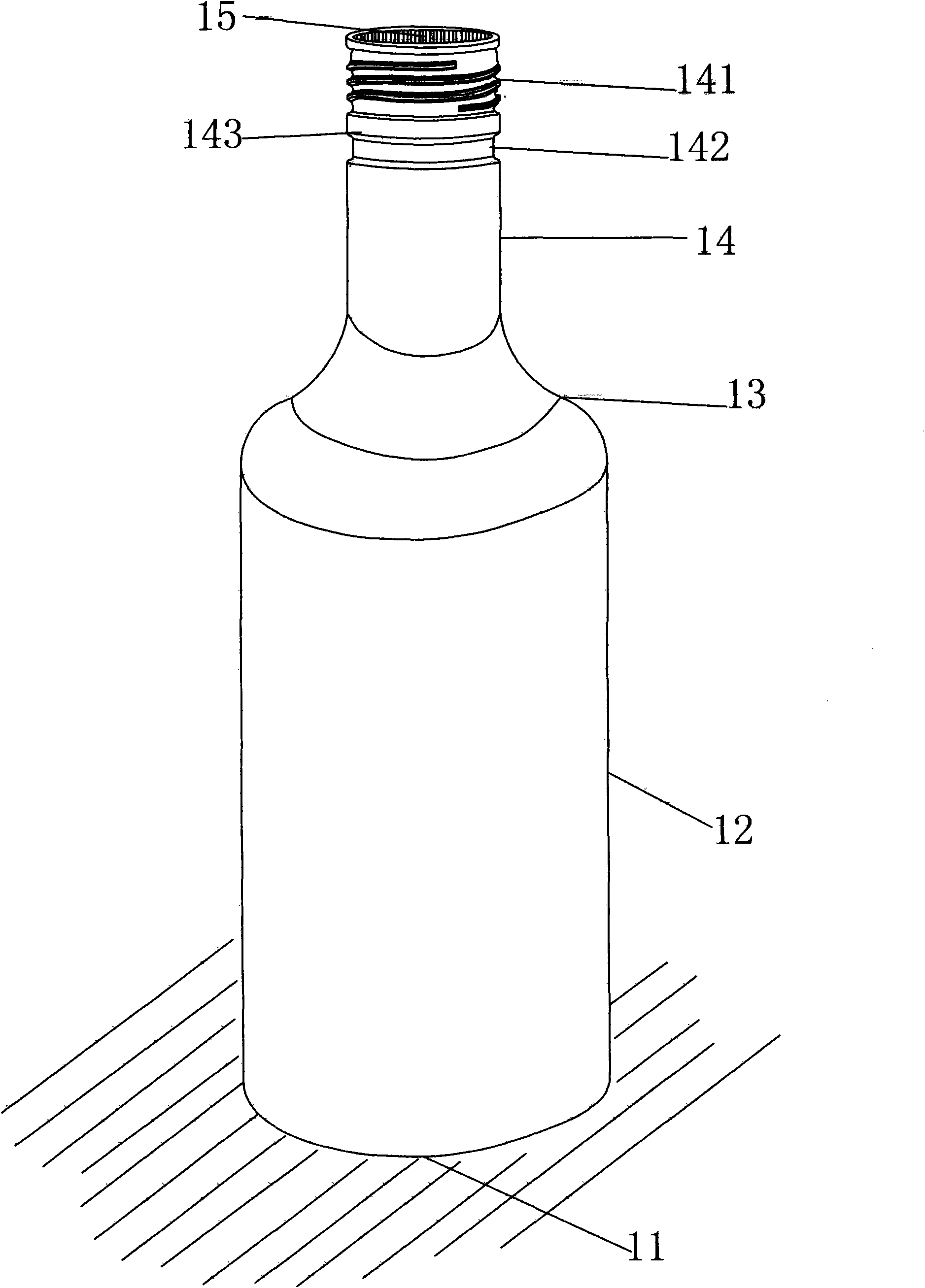

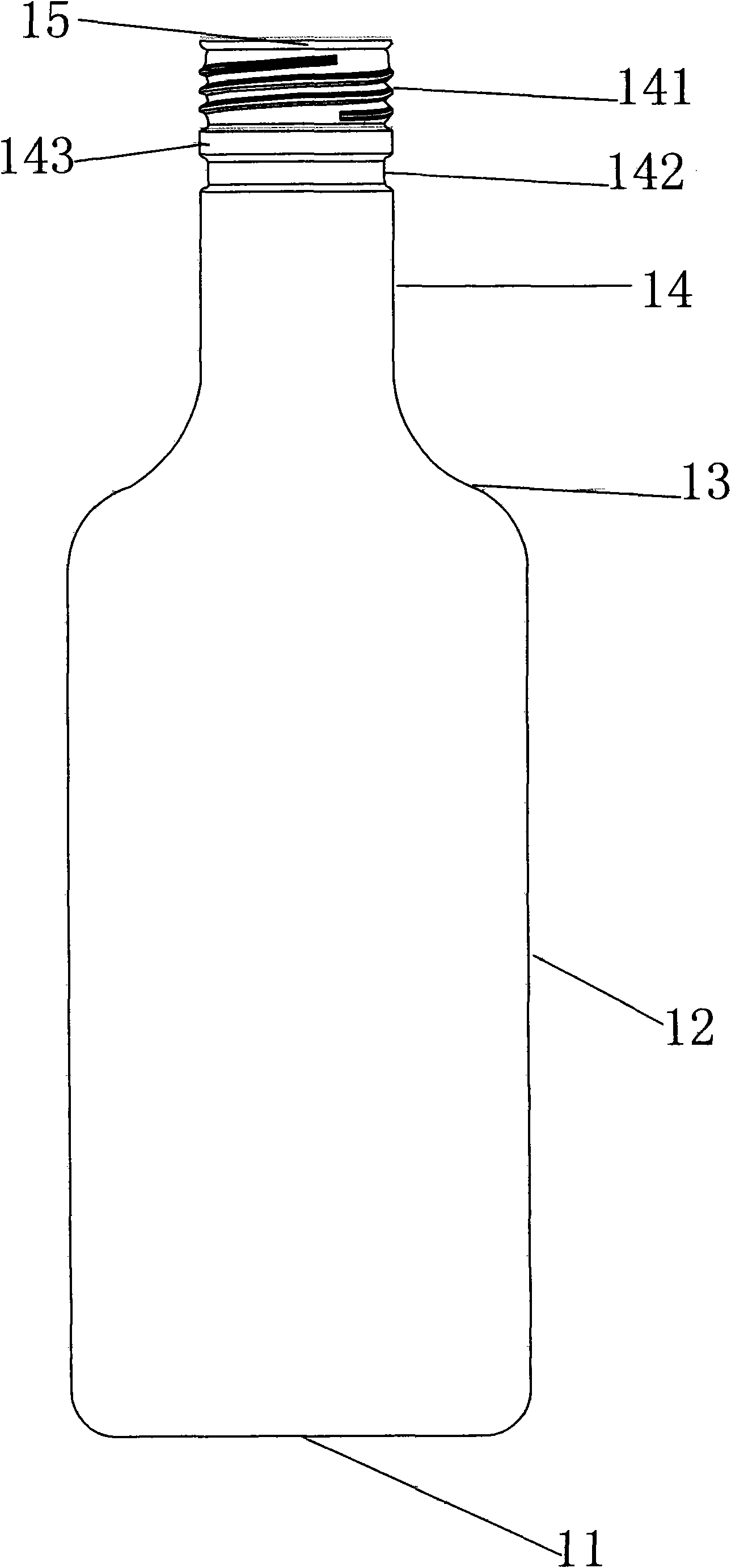

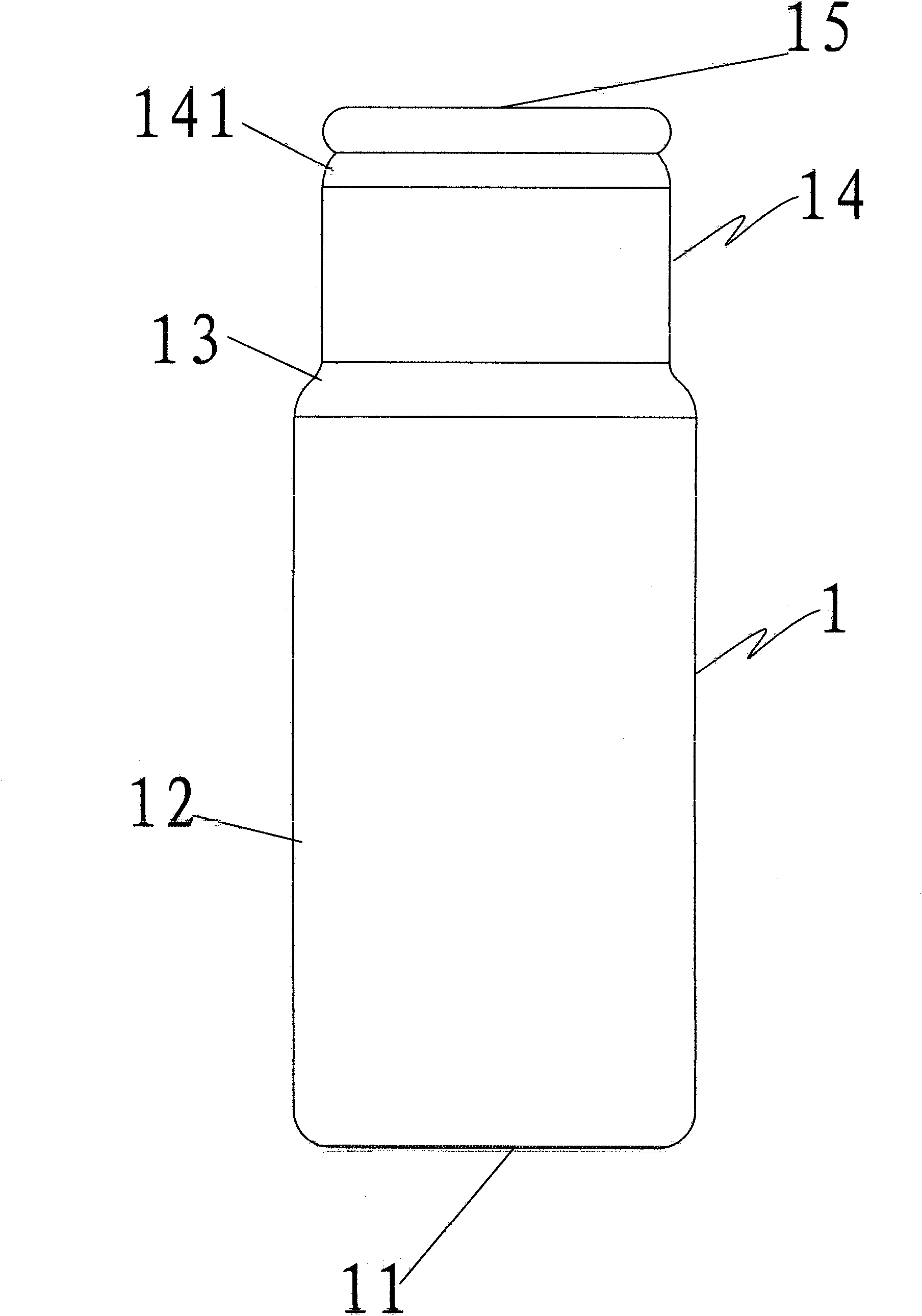

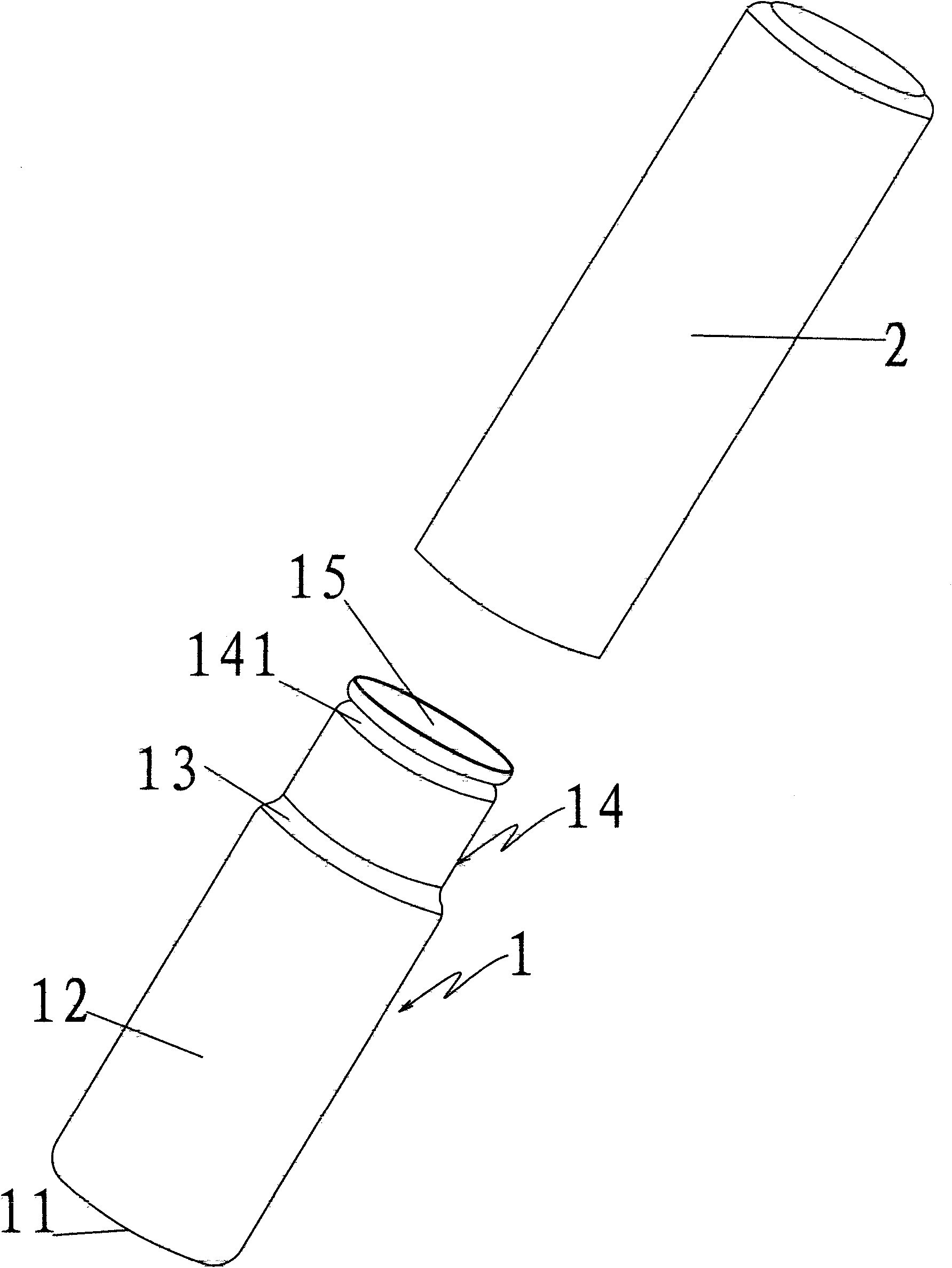

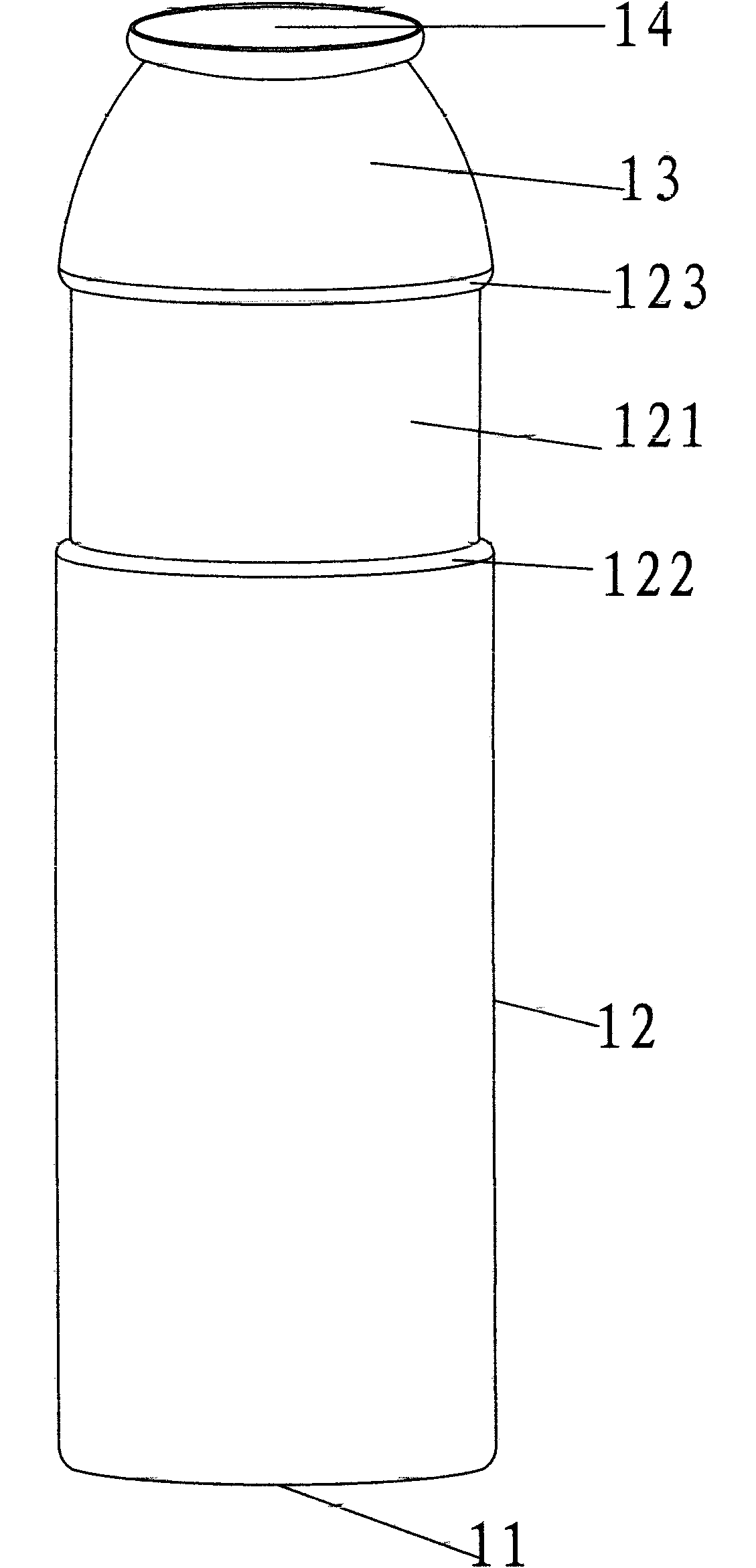

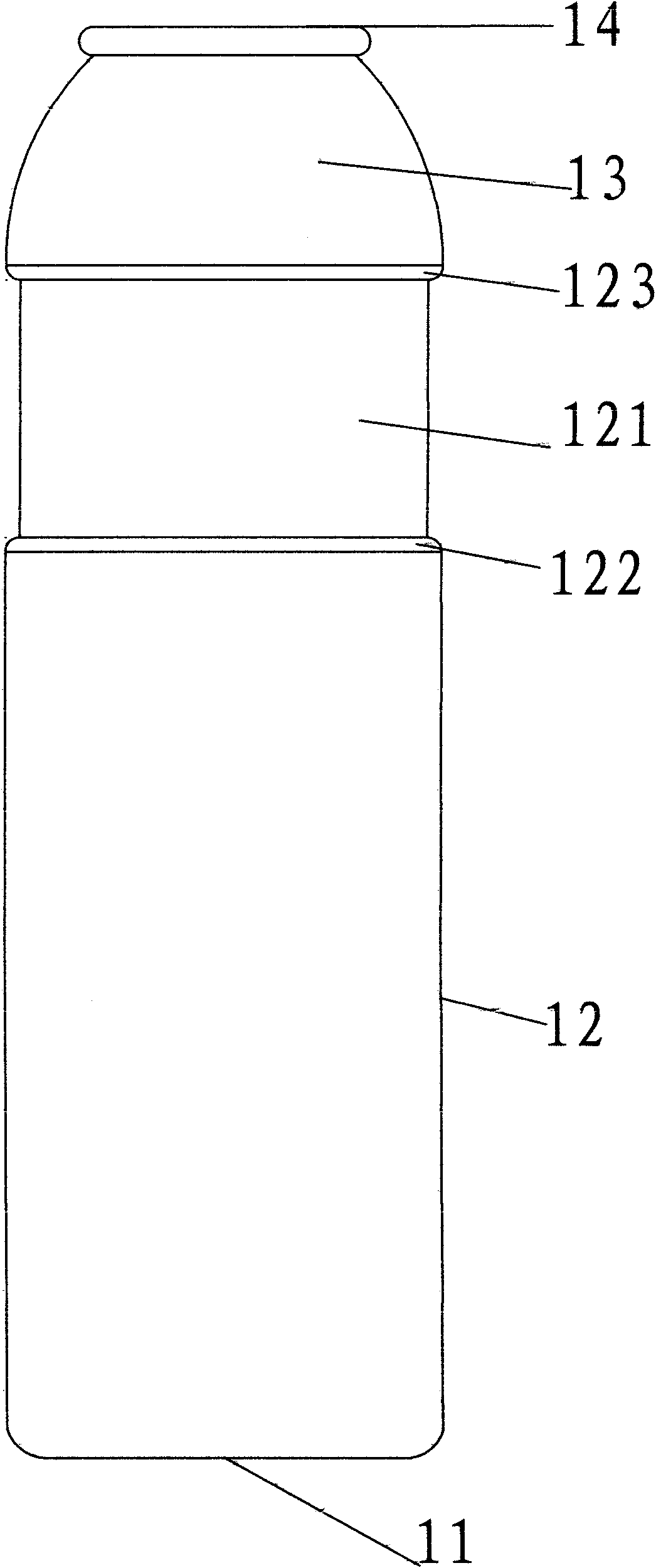

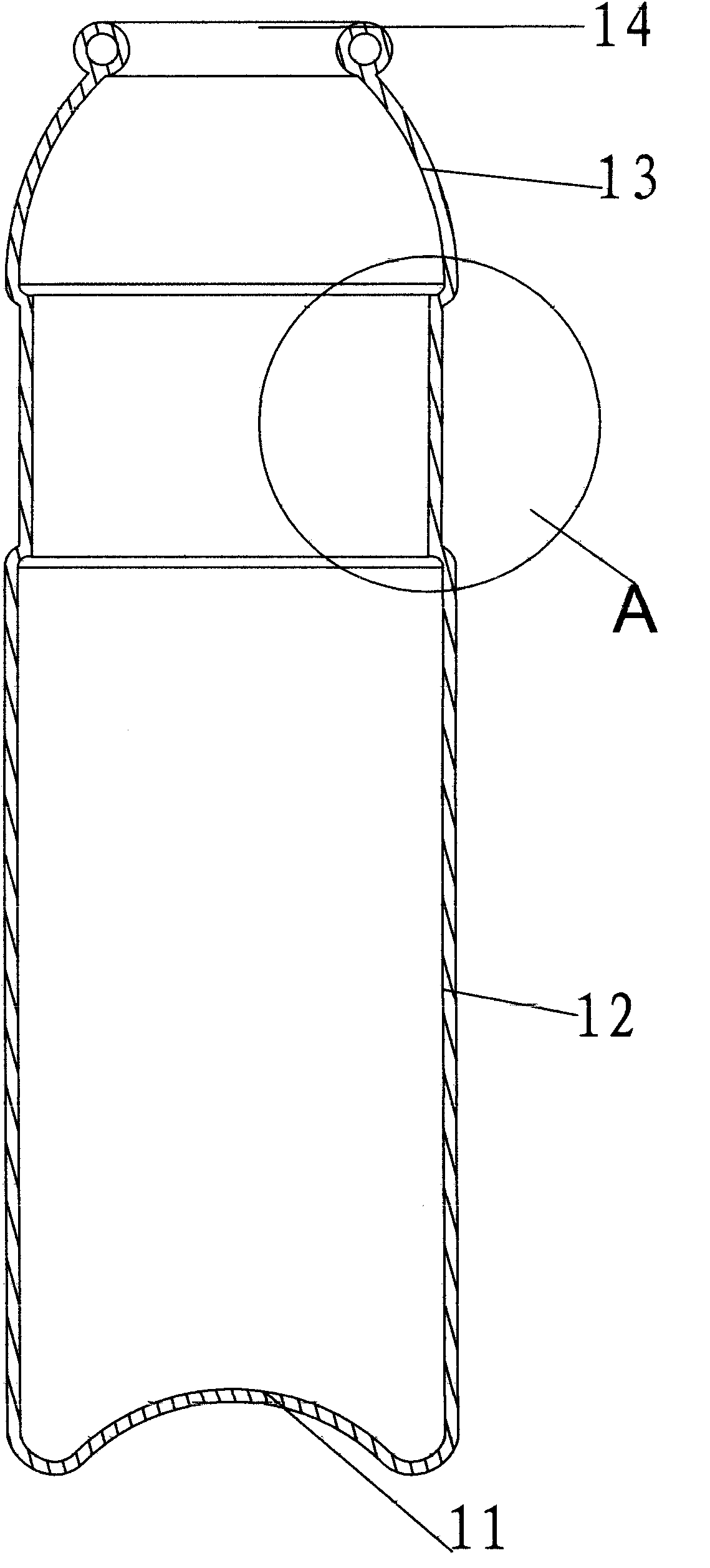

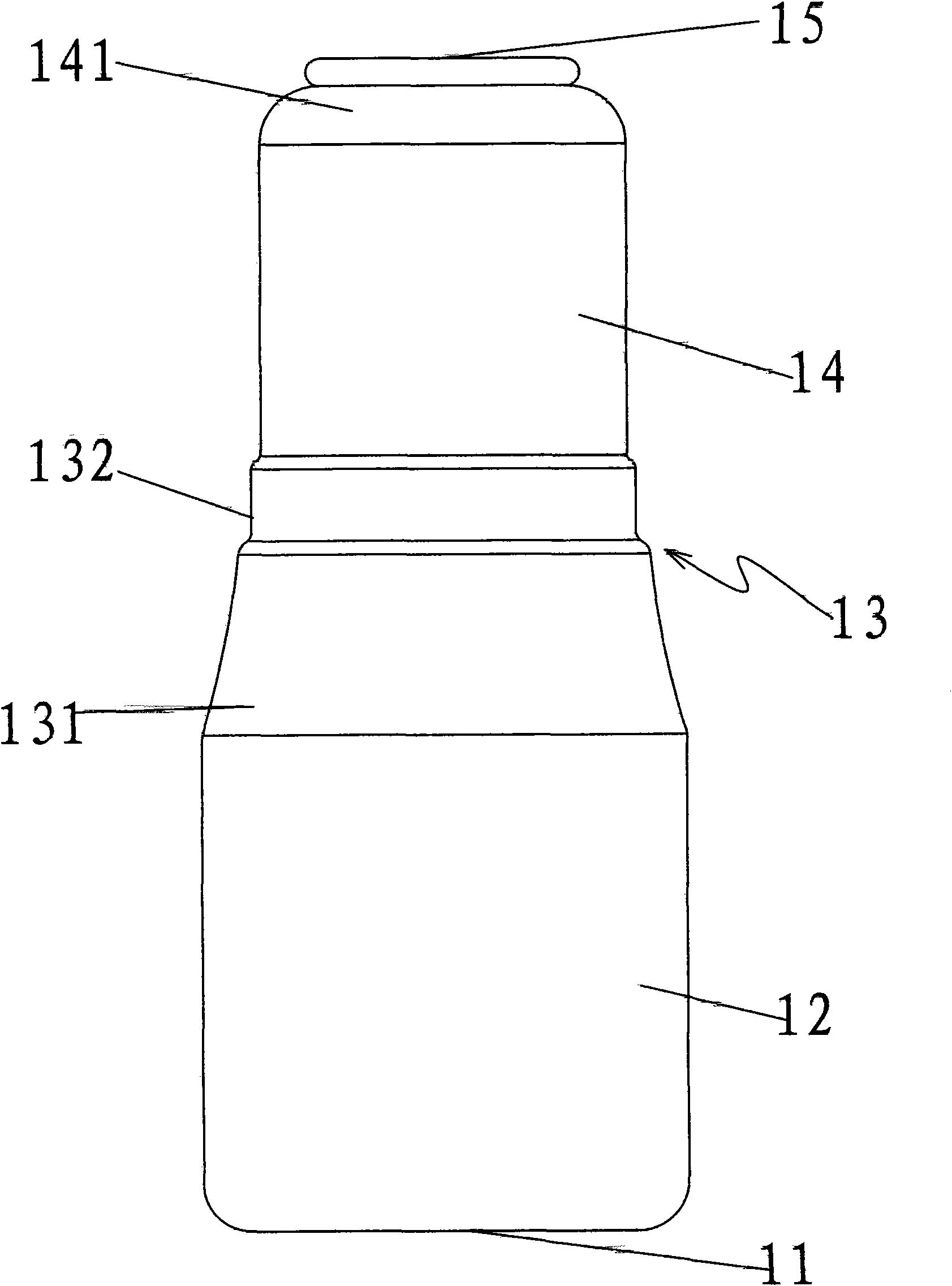

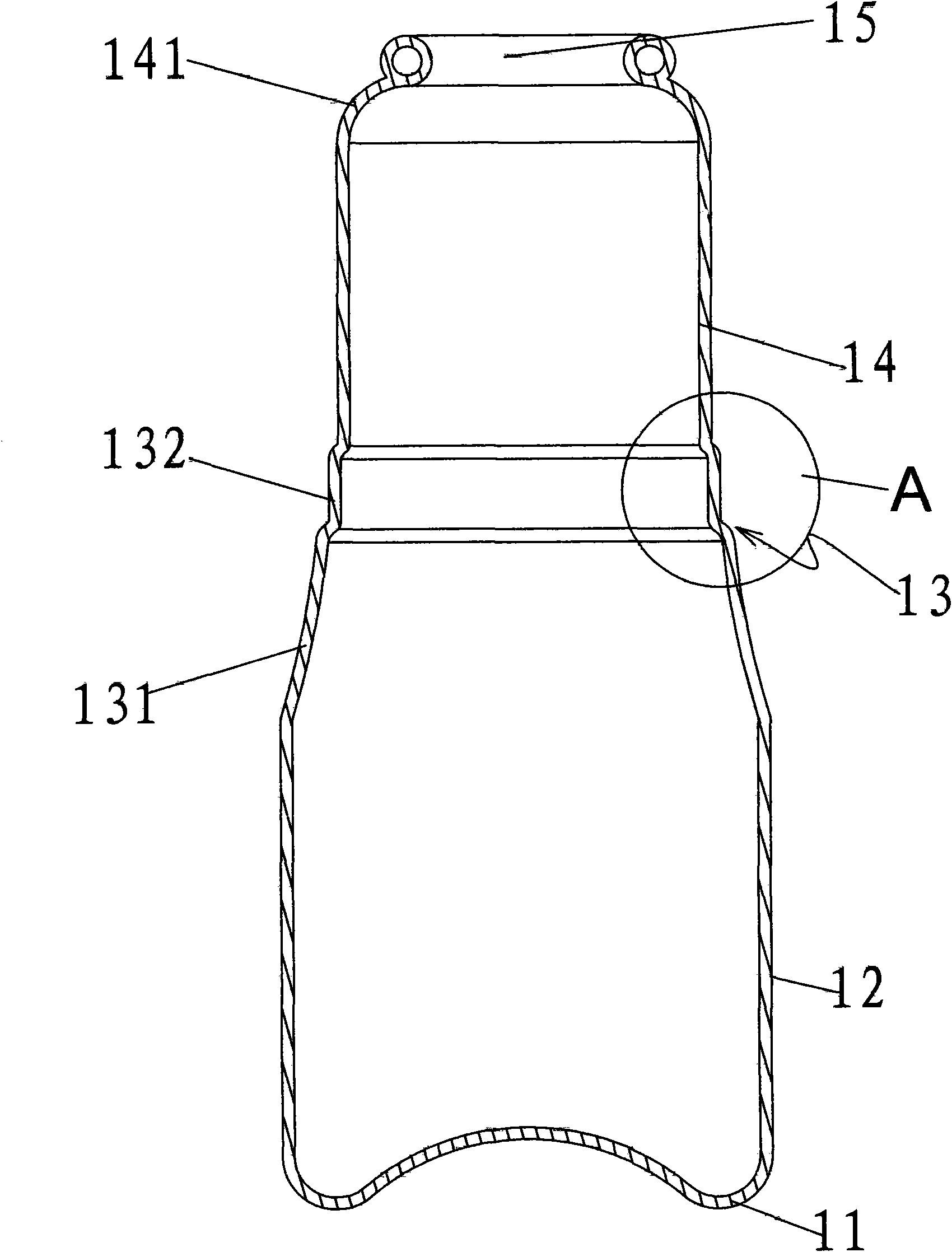

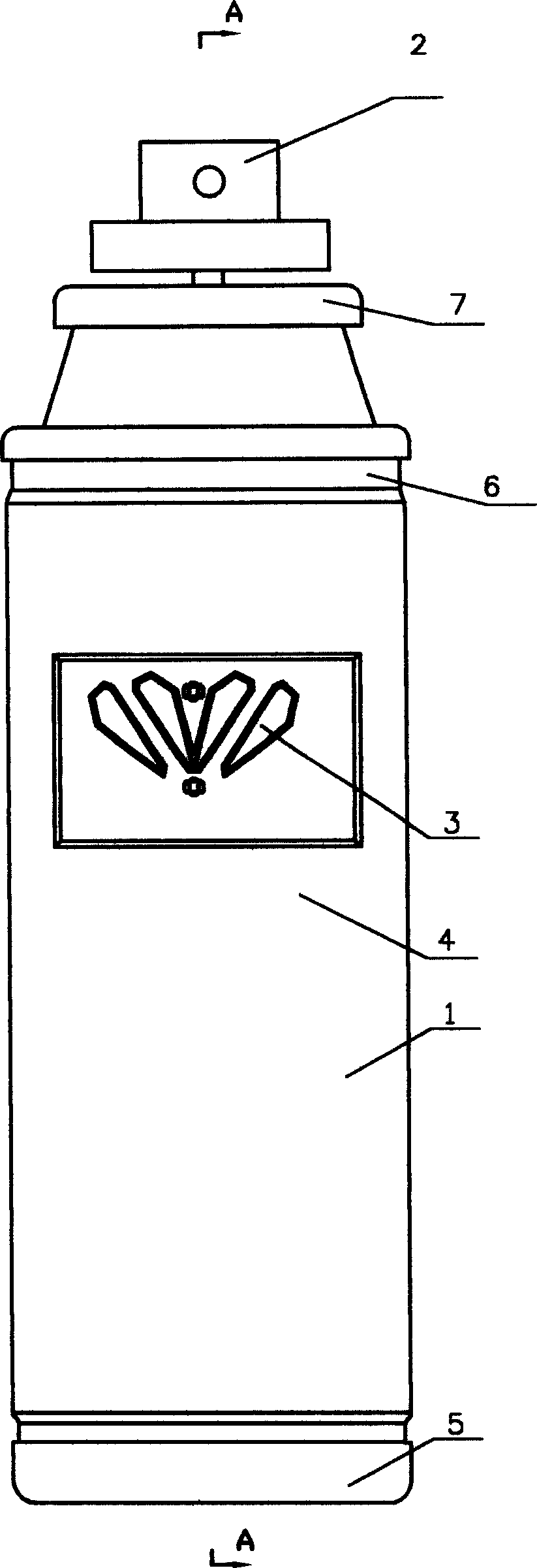

Aluminum variable wall special-shaped packaging tin and manufacturing method thereof

The invention discloses an aluminum variable wall special-shaped packaging tin and a manufacturing method thereof. The aluminum variable wall special-shaped packaging tin comprises a tin bottom, a tin barrel, a tin shoulder and a tin opening. The tin barrel is divided into a barrel body lower section, a barrel body middle section and a barrel body upper section, and the wall thickness of the barrel body lower section, the wall thickness of the barrel body middle section and the wall thickness of the barrel body upper section are sequentially increased. An annular groove capable of enabling a user to grab the tin conveniently is formed in the barrel body upper section, and accordingly the hand feeling is more comfortable and firmer. The tin shoulder is conical, a plurality of pits which are recessed inwards are formed in the outer wall of the tin, so that the aluminum variable wall special-shaped packaging tin is overall more attractive, and the visual stereoscopic impression is enhanced. Anti-counterfeiting can also be effectively achieved, and enterprise brands are made to be highlight. The aluminum variable wall special-shaped packaging tin which is simple in manufacturing method, simple in structure, attractive in appearance, convenient to grab, capable of effectively achieving the anti-counterfeiting function and low in production cost and the method for manufacturing the packaging tin are provided.

Owner:GUANGDONG EURO ASIA PACKAGING

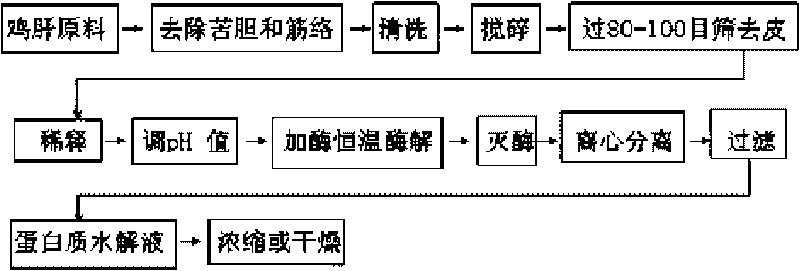

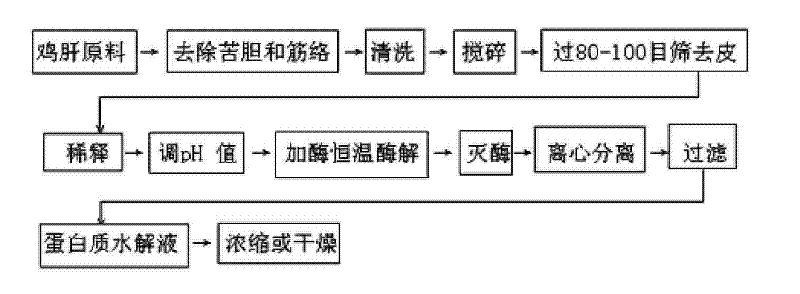

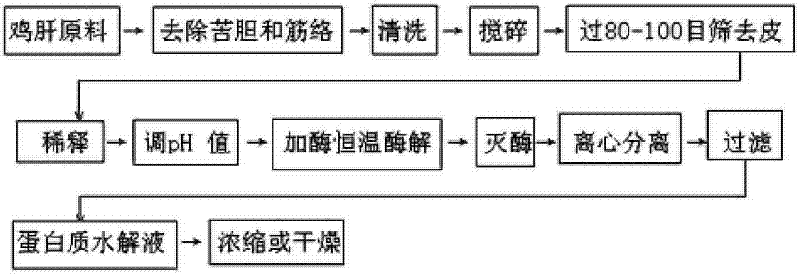

Process for preparing chicken liver hydrolyzed protein with proteases

The invention provides a process for preparing chicken liver hydrolyzed protein with proteases, aiming at solving the problems that the chicken liver has heavy fishy smell and high content of cholesterol and hereby has low utilization rate. The influence of the raw material processing method, the proteolysis temperature, the pH value, the protease dosage (E / S), the substrate concentration and the proteolysis time to the hydrolysis capacity of all the proteases is investigated and the proteolysis effect of all the proteases under the optimum condition is compared in the single factor experiment by using the chicken liver as the raw material, selecting 5 proteases and taking the hydrolysis degree as the index. The high proteolysis products with optimum hydrolysis effect and flavor are obtained by optimizing the compound dual-protease proteolysis condition. The chicken liver hydrolyzed protein is prepared through proteolysis, and the main components of the chicken liver hydrolyzed protein are amino acid and small molecule peptide which have no bitter flavor. Detection shows that the chicken liver hydrolyzed protein contains no cholesterol and has some antioxidant activity.

Owner:FUZHOU UNIVERSITY

A kind of culture medium for fermentative production of bacterial cellulose

ActiveCN102260724ALow costIncrease the added value of productionMicroorganism based processesFermentationFermentable sugarSlurry

The invention relates to a culture medium for producing bacterial cellulose through fermentation. The culture medium contains coconut flesh slurry which accounts for 20 to 80 percent of the total weight of the culture medium, wherein the coconut flesh slurry is obtained by adding water into coconut flesh and beating. In the invention, the coconut flesh with higher yield is treated and then is taken as a culture substrate for bacterial cellulose fermentation producing bacteria, and replaces fermentable sugar or coconut water which is cultured and used by the conventional method and is higher in cost, so that the cost is reduced; meanwhile, the application range of the coconut flesh is extended, the production added value of the coconut flesh is improved, and the resource is saved. Coconut flesh tissues contain rich nutrient substances which are adequate to provide a carbon source and a nitrogen source which are needed by the fermentation of the bacterial cellulose, and are good fermentation substrates.

Owner:HAINAN YEGUO FOODS

Method for brewing sleeve-fish sauce by taking sleeve-fish viscus as raw material

InactiveCN102334668AIncrease varietyIncrease the added value of productionFood preparationNutritionPasteurization

The invention relates to the field of an aquatic product and particularly relates to a method for brewing a sleeve-fish sauce by taking sleeve-fish viscus as a raw material. The method provided by the invention comprises the following steps: (1) getting sleeve-fish viscus, smashing the sleeve-fish viscus and adding salt into the sleeve-fish viscus, thereby acquiring a fermenting material; (2) fermenting at a temperature of 20-55 DEG C; (3) stirring at a fixed time during the fermenting process, continuously separating upper fermenting floating oil and suitably replenishing evaporated water; (4) after ending fermentation, separating fermentation liquor from residuals, thereby acquiring the fermentation liquor; and (5) pasteurizing the fermentation liquor and then bottling to obtain the sleeve-fish sauce. According to the method provided by the invention, the waste, namely the sleeve-fish viscus, generated during a sleeve-fish processing process is taken as the raw material, thus the production cost is low. The brewed sleeve-fish sauce tastes fresh and nice and is a novel seafood seasoning which is full of nutriments and contains nutrition constituents, such as various amino acids, mineral substances, and the like.

Owner:SOUTH CHINA AGRI UNIV

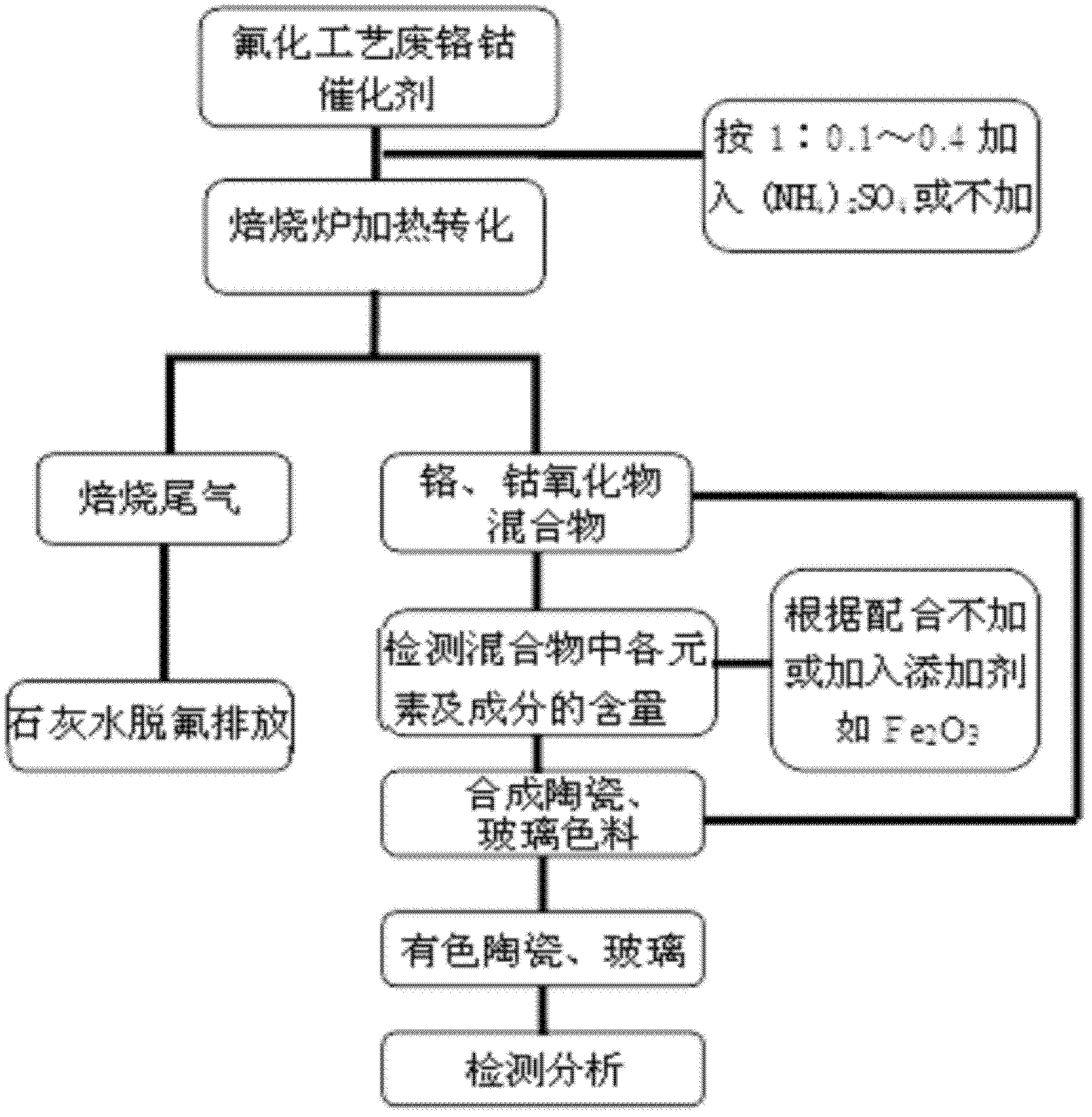

Method for producing ceramic glass colorant using waste chromium cobalt catalyst in fluorination process as raw material

The invention discloses a method for producing ceramic and glass pigment by using waste chromium and cobalt catalysts from a fluorination process as raw materials, which comprises: directly placing waste chromium and cobalt catalysts into a roasting furnace, heating and roasting, or adding (NH4)2SO4 into the waste chromium and cobalt catalysts, heating and roasting, wherein the heating temperature of the roasting furnace is 150 to 1,300 DEG C, and the waste chromium and cobalt catalysts are all converted into a mixture of chromium oxide and cobalt oxide; directly using the mixture of chromiumoxide and cobalt oxide as a ceramic pigment or a glass pigment, or using the chromium oxide and cobalt oxide as raw materials for synthesizing a ceramic pigment or glass pigment; and introducing the tail gas into lime stone water and performing innocent treatment. The method for producing ceramic and glass pigment by using waste chromium and cobalt catalysts from the fluorination process as the raw materials, which is disclosed by the method, eliminates damage caused by chromium and cobalt, provides a new use and realizes environment protection and resource recycling.

Owner:佛山市三水天宇陶瓷颜料有限公司

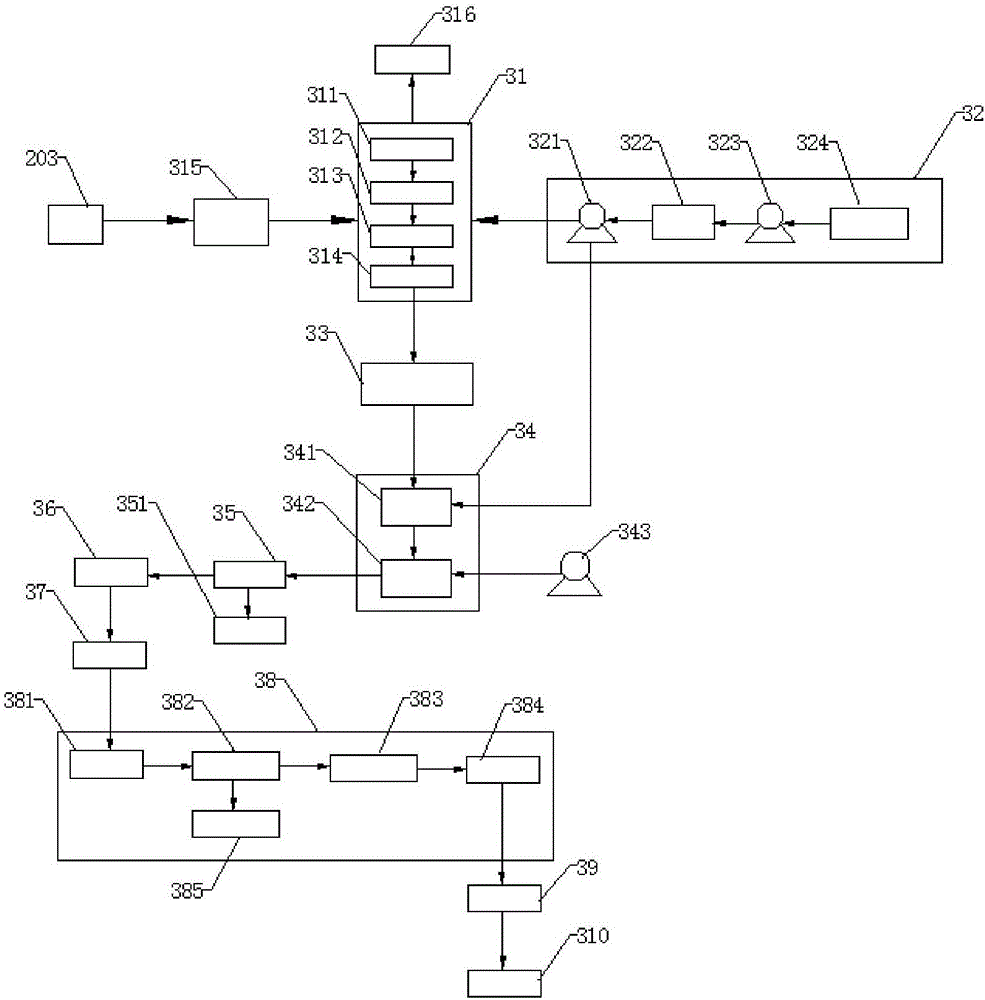

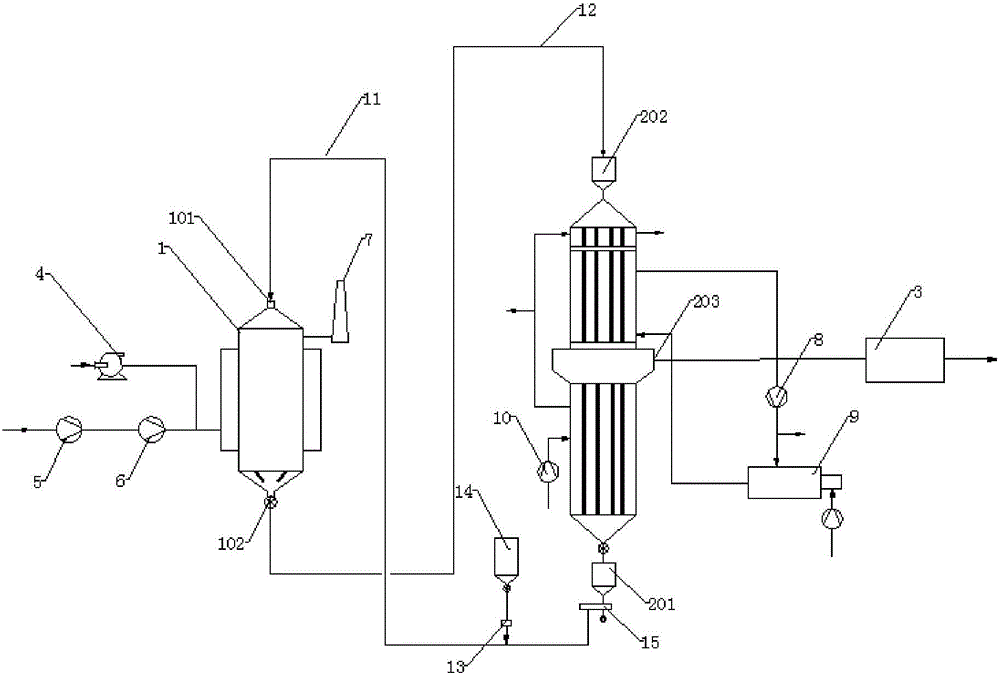

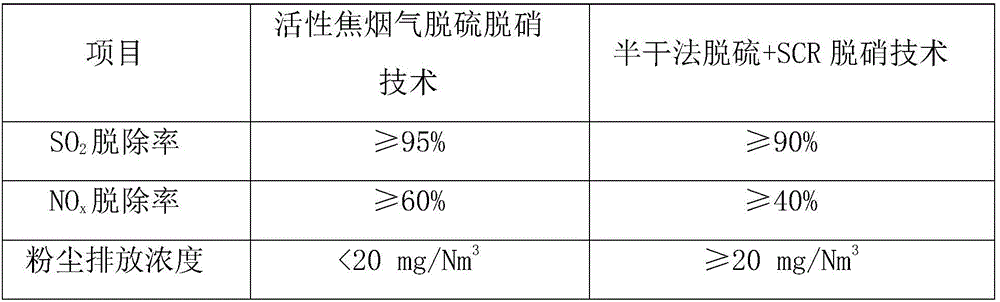

Conversion device of desulfurized and denitrified side products of active-coke flue gas, desulfurizing and denitrifying system and method

InactiveCN106178819AWide range of usesWaterproofGas treatmentDispersed particle separationEngineeringGas release

The invention belongs to the technical field of environmental protection, and relates to an integrated purification technology of flue (waste) gas, in particular to a conversion device of desulfurized and denitrified side products of active-coke flue gas, a desulfurizing and denitrifying system and a method. The conversion device comprises an absorbing tower, an alkali preparation unit, an intermediate-product storage tank, a neutralizing kettle, an evaporator, a concentrated-material tank, a centrifugal unit and a drying device, wherein the absorbing tower is provided with a gas inlet end which is connected with a output end of sulfur-dioxide gas released in the desulfurizing and denitrifying system of the active-coke flue gas; and the alkali preparation unit, the absorbing tower, the intermediate-product storage tank, the neutralizing kettle, the evaporator, the concentrated-material tank, the centrifugal unit and the drying device are connected in sequence. The conversion device, the desulfurizing and denitrifying system and the method have the advantages that the production additional value of the desulfurizing and denitrifying system of the active-coke flue gas can be increased, and the economic benefit can be improved, so that the economic and environment-friendly effects are achieved; the process is simple, the layout is compact, the energy consumption is low, and no waste water, solid waste and secondary pollution are caused, so that the resource recycling is realized.

Owner:朱双跃

Process for extracting both active embryonic peptide and natural corn oil from embryo bud of corn

InactiveCN1396175AImprove physiological function and nutritional potencyGood economic benefitsPeptide preparation methodsPlant peptidesPelletizingPeptide

A process for preparing the active embryonic peptide with coproduct of corn oil from the embryo bud of corn at the same time includes such steps as wet and thermal pretreating, grinding by colloid mill, multi-stage zymolysis, centrifugal separation to obtain fibres, corn oil and milk, concentrating the milk by nanometre filtering membrane, further concentrating, homogenizing, emulsifying, drying and granulating.

Owner:徐昌洪

Fermentation medium for bacterial cellulose

ActiveCN102250985ASolve the problem of raw material sourceLow costMicroorganism based processesFermentationBiotechnologySlurry

The invention relates to a culture medium used for fermenting to produce bacterial cellulose. The culture medium contains slurry obtained by uniformly mixing copra meal with water, wherein the weight of the copra meal is 30-90% of the total weight of the culture medium. In the invention, waste copra meal is adopted as a culture substrate used for fermenting the bacterial cellulose to produce fungus after treatment in general, and replaces higher-cost fermentable sugars or coconut water which is adopted in conventional culture, so that cost is reduced, the application range of the copra meal is greatly expanded, the production added value of the copra meal is increased, and resources are greatly saved; and moreover, the secondary utilization of worldwide high-yield copra meal is realized, the most important problem of the source of raw materials during the production of the bacterial cellulose is solved, and the production cost of the bacterial cellulose is also greatly reduced. The copra meal contains rich nutrient substances in spite of reduced grease content, thereby being capable of providing sufficient carbon source and nitrogen source needed by fermenting the bacterial cellulose, so that the copra meal is a very good substrate for fermentation.

Owner:HAINAN YEGUO FOODS

Method for producing environment-friendly white cardboard

InactiveCN102535252AGood production added valueIncrease the added value of productionNon-fibrous pulp additionCoatings with pigmentsEnvironmental resistanceCardboard

The invention relates to a method for producing environment-friendly white cardboard, and belongs to the technical field of papermaking processes. The method comprises the following steps of: preparing raw materials; crushing; pulping; preliminarily forming; coating; and obtaining a finished product. The method is reasonable in design and easy to operate; and by the method, waste paper raw materials can be better used for producing packing paper with high added value, utilization value is improved, a large amount of native wood or wood pulp for making the white cardboard originally is saved, 3 to 4 cubic meters of wood and 10 to 30 cubic meters of water can be saved when 1 ton of environment-friendly white cardboard is produced, the emission of a large amount of carbon and chemical oxygen demand (COD) can be reduced, production cost can be reduced by over 20 percent, and comprehensive energy consumption is reduced by over 20 percent.

Owner:FUYANG HUALI PAPER

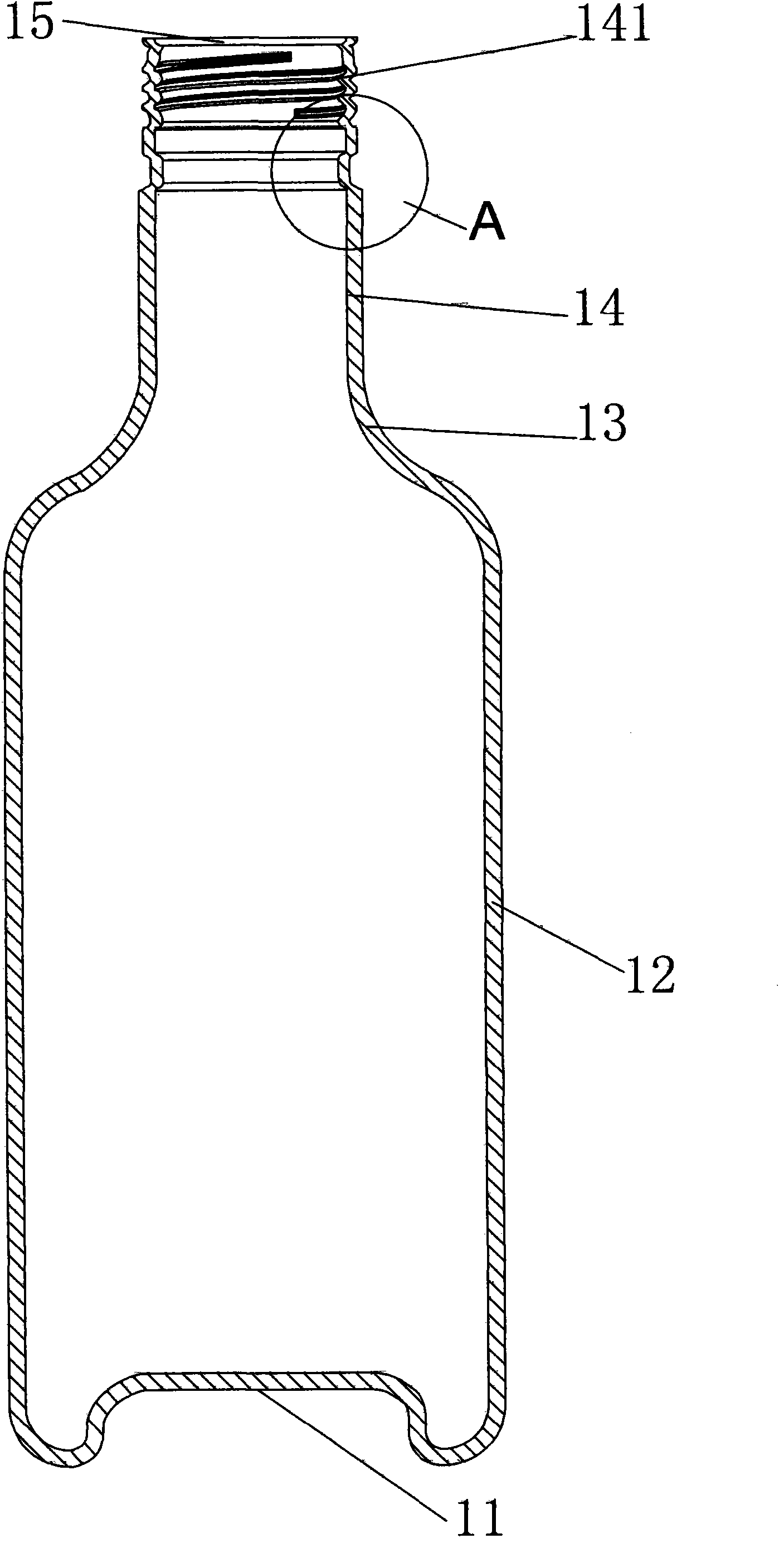

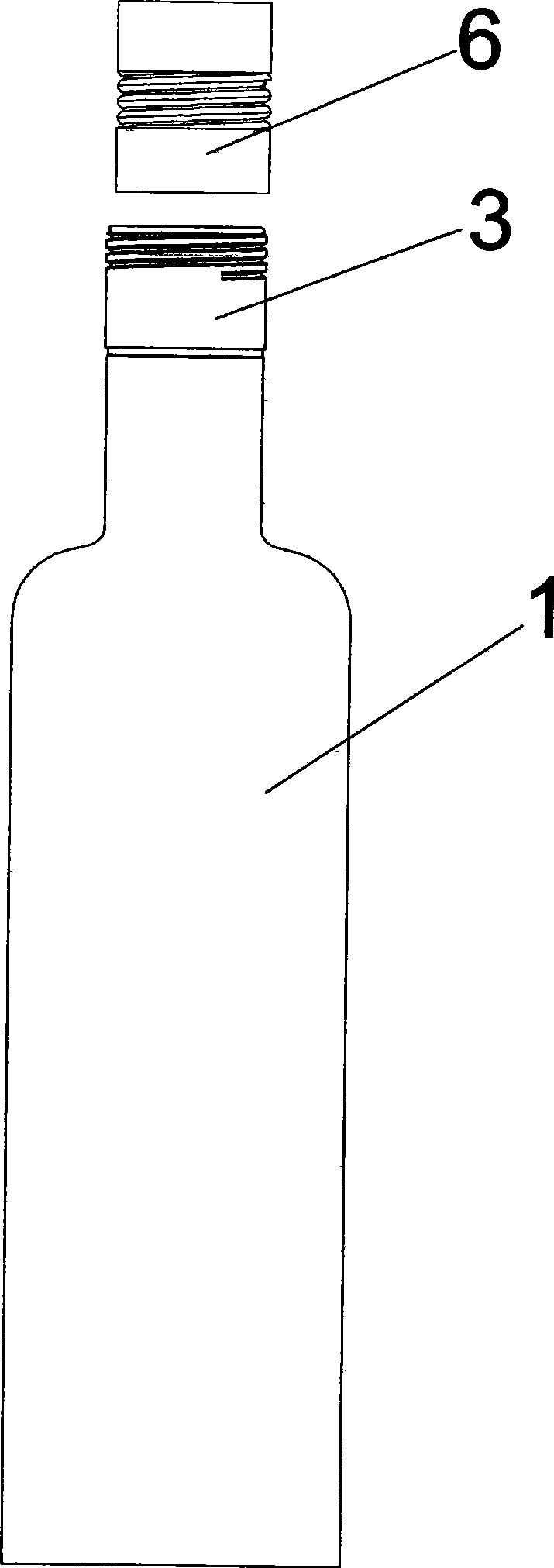

Aluminum screw packaging tin and manufacturing method thereof

InactiveCN101830303AGood anti-counterfeiting effectEnhance the three-dimensional senseJarsHollow articlesThin walledTin

The invention discloses an aluminum screw packaging tin, which comprises a tin bottom, a tin body, a tin shoulder, a tin neck and a tin mouth, wherein an external thread is arranged on the outer wall of the tin neck, an annular groove is arranged below the external thread in the outer wall of the tin neck, and a convex ring is formed between the annular groove and the external thread. The invention also discloses a manufacturing method of the aluminum screw packaging tin, which comprises the following steps: roasting an aluminum sheet; stamping; trimming; cleaning; carrying out protective treatment; retracting to form the tin neck; and shaping the tin neck: rolling an external thread on the outer wall of the tin neck close to the screw, and then indenting an annular groove below the external thread in the outer wall of the tin neck to form an annular convex edge between the annular groove and the external thread. The invention has advantages of beautiful integral appearance, good visual effect, thin wall, low manufacturing cost, good forgery prevention effect, high added value, high grade and the like, and can fixedly lock the threaded cover locking mouth ring connected with the tin mouth.

Owner:GUANGDONG EURO ASIA PACKAGING

Method for processing cold-bending welding square quarter bend with punched hole

InactiveCN101406908AMeet the new needs of processingMeet the processing requirements of large quantitiesMetal-working feeding devicesPositioning devicesProduction linePunching

The invention discloses a method for machining a square rectangular tube through punching, cold bending and welding and belongs to the field of metal machining. The method mainly comprises the following steps: firstly, punching equipment is utilized to punch strip steel which is machined to a specific specification; and secondly, the strip steel is machined through cold bending, welding and other molding process; and the punching and the cold bending, welding and molding of the strip steel are combined together. The punching equipment can select a punching machine set consisting of a plurality of punching machines according to the operating speed of a production line, and the number and the density of punching holes which are to be treated with machining. The machining method can directly machine and complete the cold-bending welded tubes with the punched holes and various specifications and meet new requirements of machining a metal section. Further, the machining method can perform continuous machining by utilizing the production line, can meet the machining requirements of high efficiency and large batch. Moreover, compared with the prior machining method through drilling, the machining method greatly reduces cost.

Owner:武钢集团有限公司

Processing method of bamboo shoot fiber powder

InactiveCN104351682AIncrease the added value of productionNatural colorFood preparationFiberAdditional values

The invention discloses a processing method of bamboo shoot fiber powder. The processing method comprises the following steps: removing shells, washing, dicing, immersing, rinsing, dehydrating, drying, puffing, crushing, sterilizing, sub-packaging, putting into a storage and packaging and the like. Oxalic acid and colloid in bamboo shoots can be removed by a series of operation. Compared with the prior art, the processing method has the following advantages that the machined bamboo shoot fiber powder is smooth and fine, and white, and has natural color and luster, fine and smooth mouth feel and fragrant flavor; the content of soluble dietary fibers, the water-holding power and the swelling force are improved to different extents; the bamboo shoot fiber powder can be stored under the environment at 0-5 DEG C and the guarantee period can be up to be more than 18 months; and the processing method is simple in operation conditions and is reliable; and the comprehensive utilization of bamboo shoot resources is realized and a production additional value of the bamboo shoots is improved.

Owner:ANHUI PROVINCE JIXI COUNTY LAOMO IND

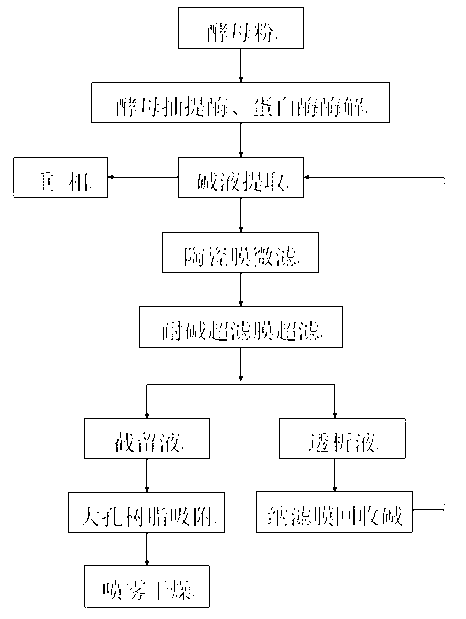

Process for extracting mannan from beer yeast powder

The invention relates to a process for extracting mannan from beer yeast powder. The beer yeast powder is used as a substrate, and the process comprises the steps of enzymolysis extraction, alkaline extraction, microfiltration and ultrafiltration of an extracting solution, recovery of alkali liquor through nanofiltration, purification by using macroporous adsorption resin, spray drying and the like. The process combines an enzyme method with an alkaline method, an industrial alkali-resistant membrane separation technology and a macroporous adsorption resin purification technology are used, an organic solvent is not used, an alkali-resistant nanofiltration membrane system can recover 90 percent of extracting alkali liquor, and the extracting alkali liquor is reused in the extraction steps, so that the pollution to the environment is greatly reduced, the produced mannan is high in yield and purity, low in production cost, and suitable for large-scale production.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

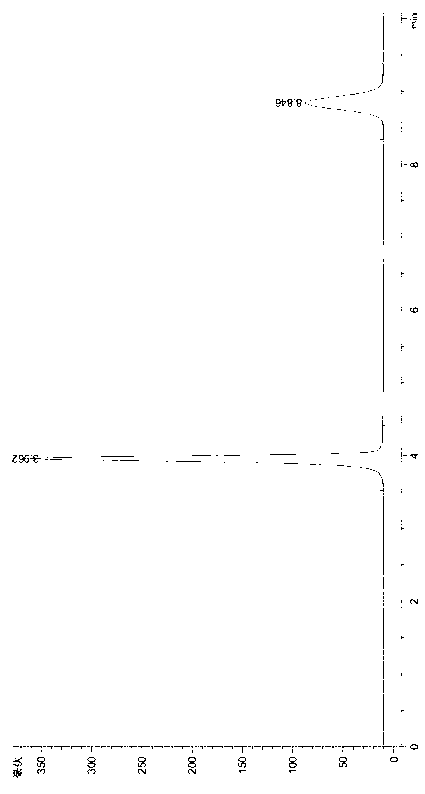

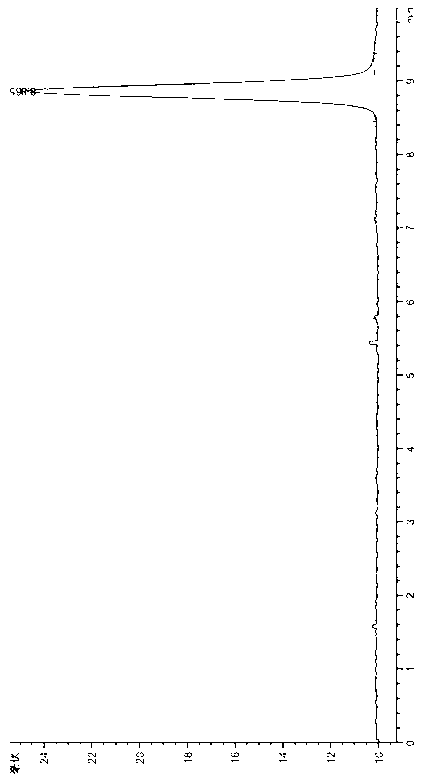

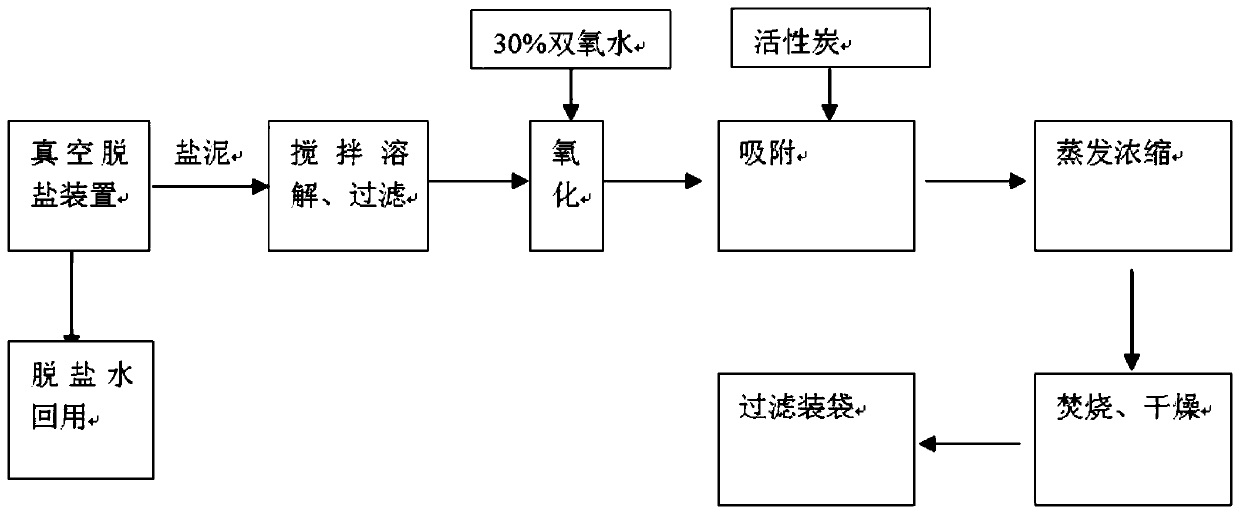

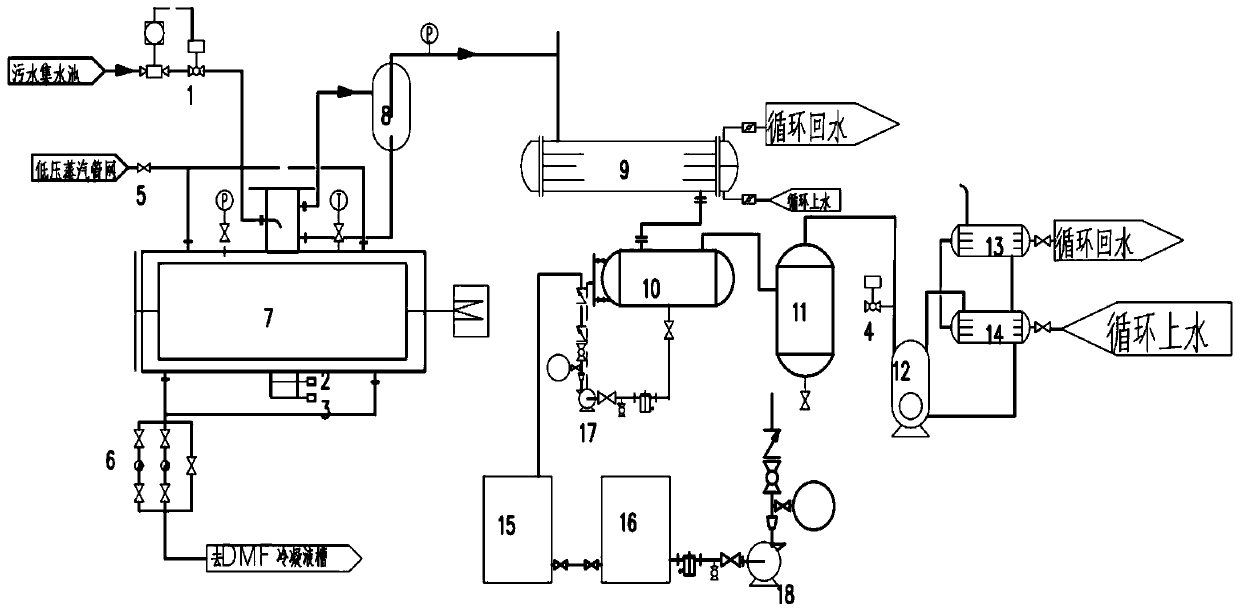

Process and device for treating dimethylformamide production wastewater and recycling substances

PendingCN109942131AEffective desalinationEfficient recyclingSludge treatmentOrganic compound preparationChemical industrySalt content

The invention belongs to the technical field of chemical industry production and particularly relates to a process and device for treating dimethylformamide production wastewater and recycling substances. The process comprises the following steps: heating to evaporate high salinity wastewater produced during the preparation of dimethylformamide through low-pressure steam, condensing the evaporatedwater steam so as to obtain desalted wastewater, and carrying out cyclic utilization; collecting solid salt mud remained after the evaporation, and extracting sodium formate. According to the process, the high salinity wastewater produced during the production of DMF can be effectively desalted and recycled; the salt content of the wastewater is decreased from 600000mg / L to 2000mg / L, and the problem of treatment of the high salinity wastewater is solved. According to the device, the utilization efficiency of water is increased, and the energy consumption is reduced.

Owner:LUXI CHEM GRP

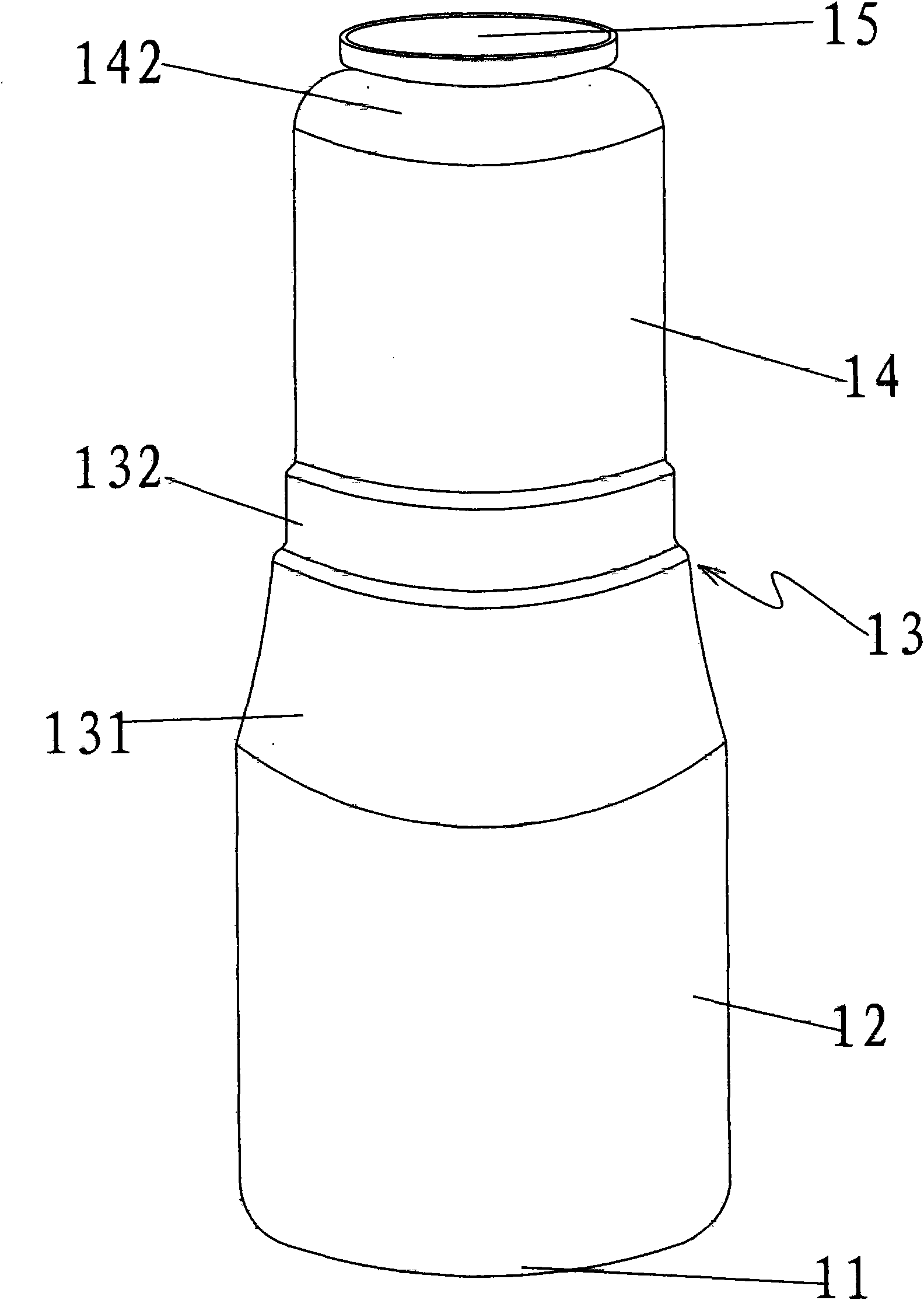

Novel aluminum package tank and manufacture method thereof

InactiveCN101774446AWon't breakImprove sealingRemovable lids/coversJarsPunchingBiochemical engineering

The invention discloses a novel aluminum package tank, which comprises a tank body, wherein the tank body consists of a tank bottom, a tank body, a tank shoulder, a tank neck and a tank opening, a cover body which integrally covers the tank neck and the tank opening is sheathed on the upper end of the tank body, the upper end of the cover body is provided with a cover, the lower end of the cover body is provided with an opening, the inner wall of the lower end of the cover body is tightly sheathed on the outer wall of the tank neck, and the end part of the lower end of the cover body is tightly butted against the tank shoulder. The invention also discloses a manufacture method of the novel aluminum package tank, which comprises the flowing steps: slice stir frying; punching; trimming; cleaning; protection processing; tank body manufacture: contracting the opening part of a coarse tank blank for forming the tank shoulder, upwards extending the tank shoulder for forming the tank neck, flanging the upper part of the tank neck for forming the tank opening with a lip, and completing the tank body manufacture; and cover body manufacture: extruding aluminum materials into the cover body with the cover at the upper end and the opening at the lower end, and integrally covering the tank neck and the tank opening by the cover body. The invention has the advantages of difficult damage of the cover by collision, good sealing effect, high quality of products, beautiful appearance of the whole body, high added value, high grade and the like.

Owner:GUANGDONG EURO ASIA PACKAGING

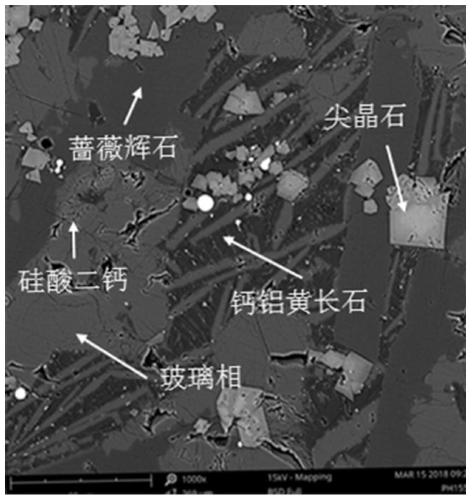

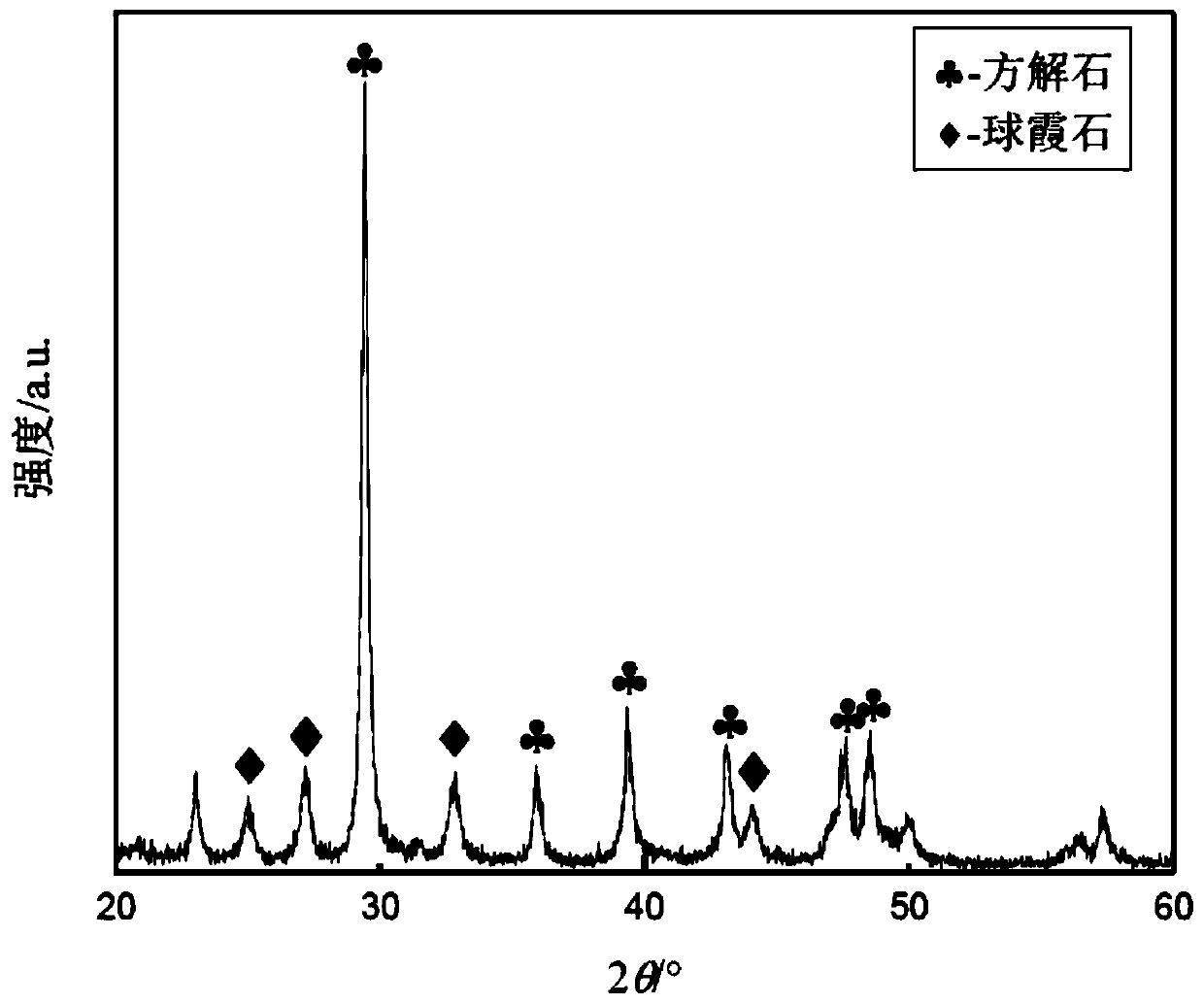

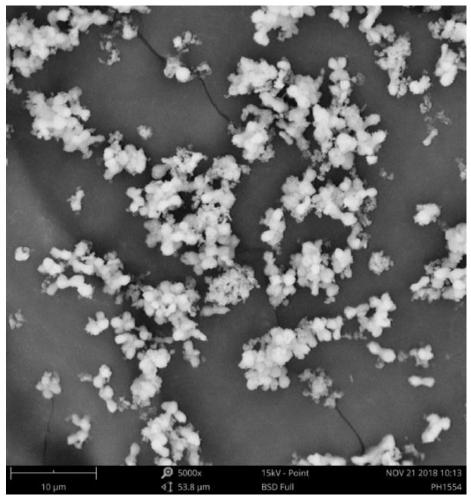

Method for preparing carbonate powder by smelting wastes by using stainless steel

ActiveCN110451547AAchieve synergyRealize online regulationCalcium/strontium/barium carbonatesMagnesium carbonatesResource utilizationFiltration

The invention belongs to the technical field of comprehensive utilization of metallurgical resources, and particularly relates to a method for preparing carbonate powder by smelting wastes by using stainless steel. The method for preparing the carbonate powder by smelting the wastes by using the stainless steel comprises the steps that stainless steel smelting slag is subjected to on-line ore phase reconstruction, after cooling, leaching is conducted by using a metallurgical waste acid solution, and after filtration, a calcium and magnesium-rich solution is obtained, the pH value of a filter liquor is adjusted, and a structure-directing agent is added; metallurgical waste gas containing CO2 is introduced into the obtained solution to form a precipitate, and after filtration and drying, calcium carbonate powder and magnesium carbonate powder with regular shapes and sizes are obtained in sequence. By means of the method, on-line ore phase reconstruction of the stainless steel slag is achieved, a lot of calcium and magnesium are enriched into a phase easy to leach, chromium is enriched into a spinel phase, while chromium stabilization is considered, the resource utilization rate of the stainless steel slag is improved greatly, the carbonate powder can be widely used in the industries of building, paper making, rubber, medicines and the like, and it is achieved that wastes are controlled by wastes, and wastes are prepared into valuable things.

Owner:NORTHEASTERN UNIV

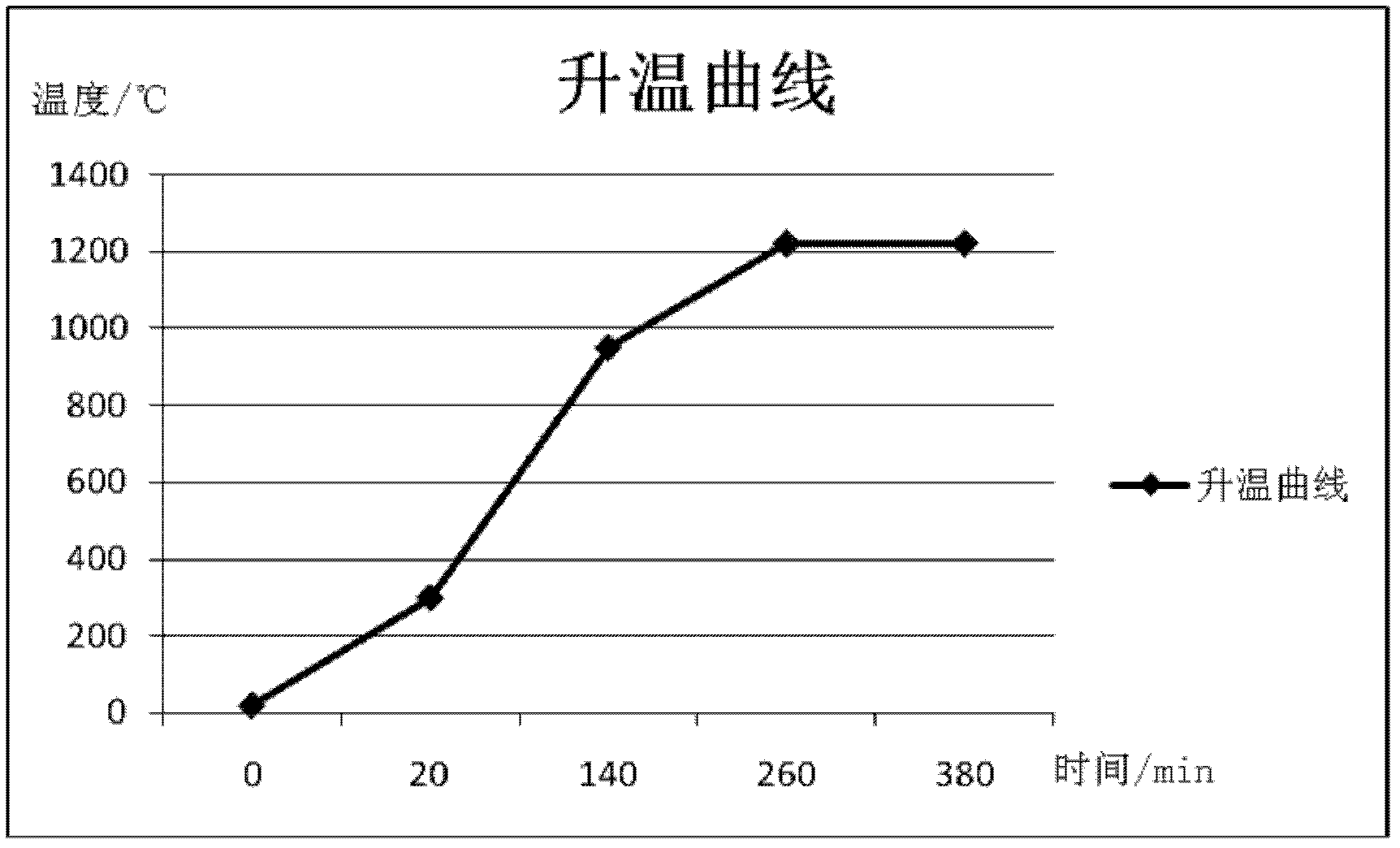

Production method of equisetum ramosissimum straw activated carbon

InactiveCN104843703ALarger than surfaceImprove adsorption capacityActivated carbonPotassium hydroxide

The invention relates to a production method of equisetum ramosissimum straw activated carbon and belongs to the activated carbon production technical field. The production method is characterized in that equisetum ramosissimum straw serves as raw materials and potassium hydroxide serves as an activating agent. The production method comprises the main steps of cleaning, drying and crushing the equisetum ramosissimum straw, uniformly mixing with the potassium hydroxide according to a certain alkali carbon ratio after carbonization, drying into the constant weight after dipping for 24 hours, performing activation for 2.5 to 3.5 hours at 300 to 350 DEG C, performing pickling and washing after cooling until a pH (Potential Of Hydrogen) value reaches 7 and obtaining the equisetum ramosissimum straw activated carbon after filtration, drying and screening. The production method of the equisetum ramosissimum straw activated carbon is simple and effective, the cost is low, the speed is high, and an iodine adsorption value and a methylene blue adsorption value of the produced activated carbon reach the first-grade product standard of the activated carbon for national wooden water purification; the equisetum ramosissimum belongs to common farmland weeds and accordingly resources are rich; the equisetum ramosissimum resources are fully utilized and accordingly the waste materials are recycled, the good economic, environmental and social benefits are produced, and new raw materials are developed for manufacture of the activated carbon.

Owner:李国平

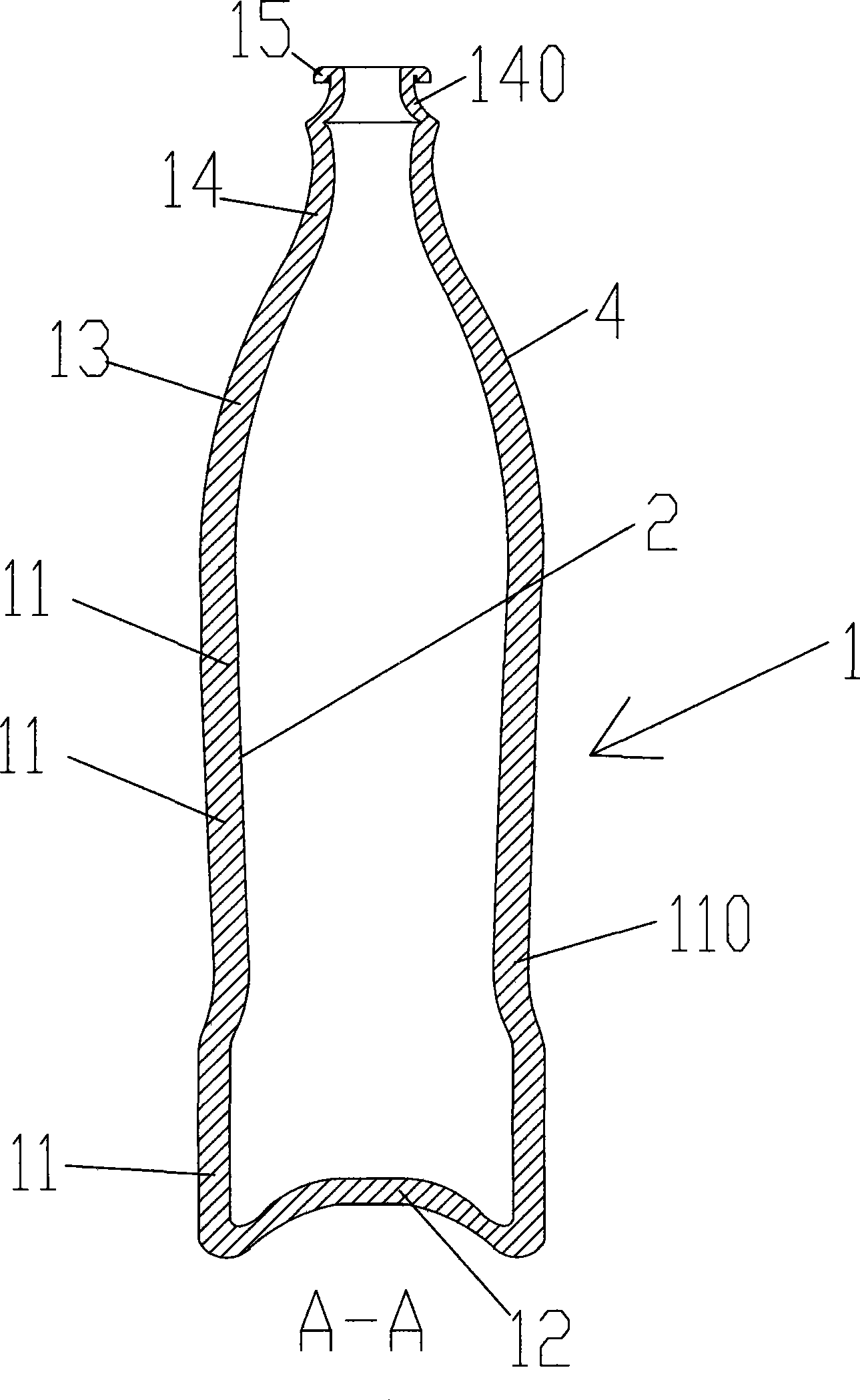

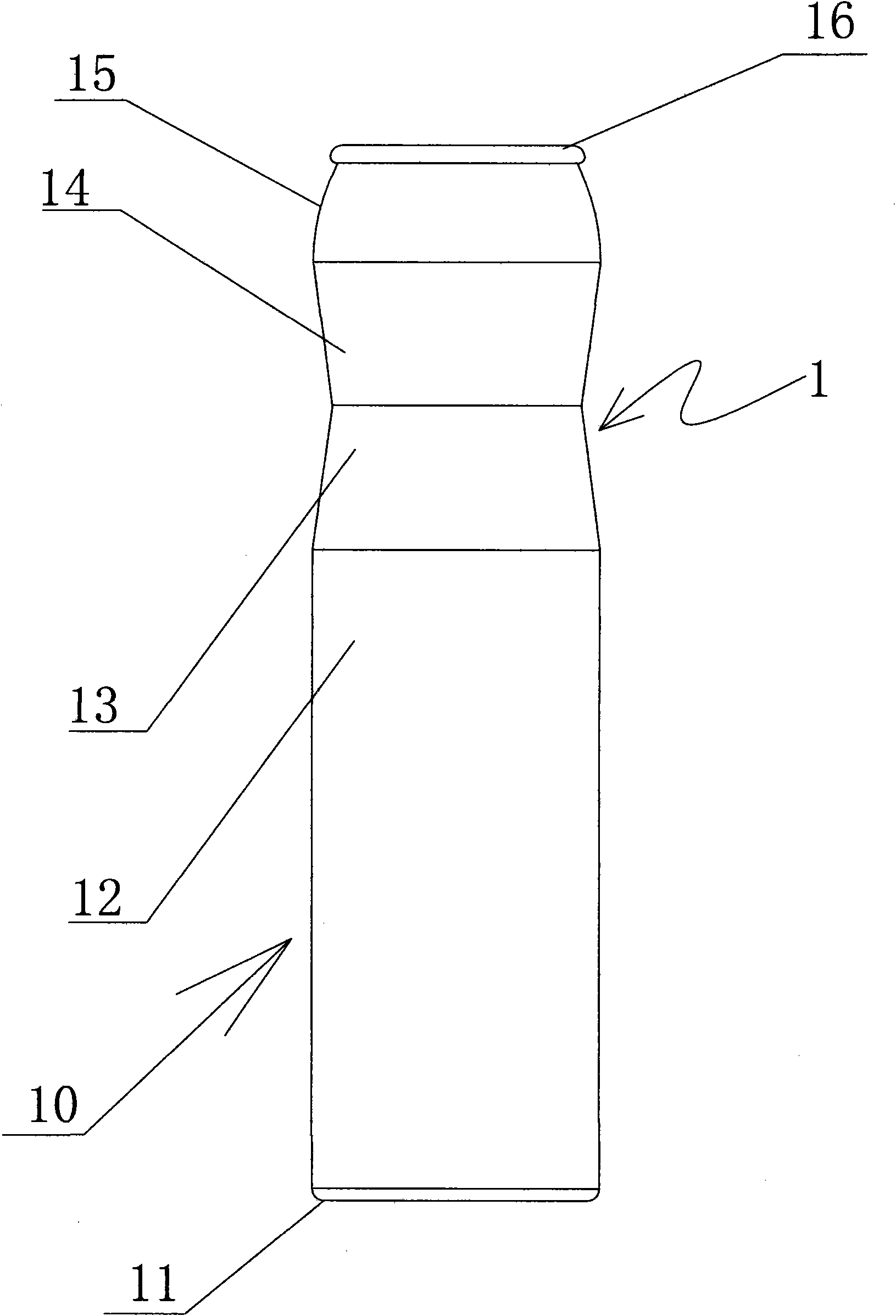

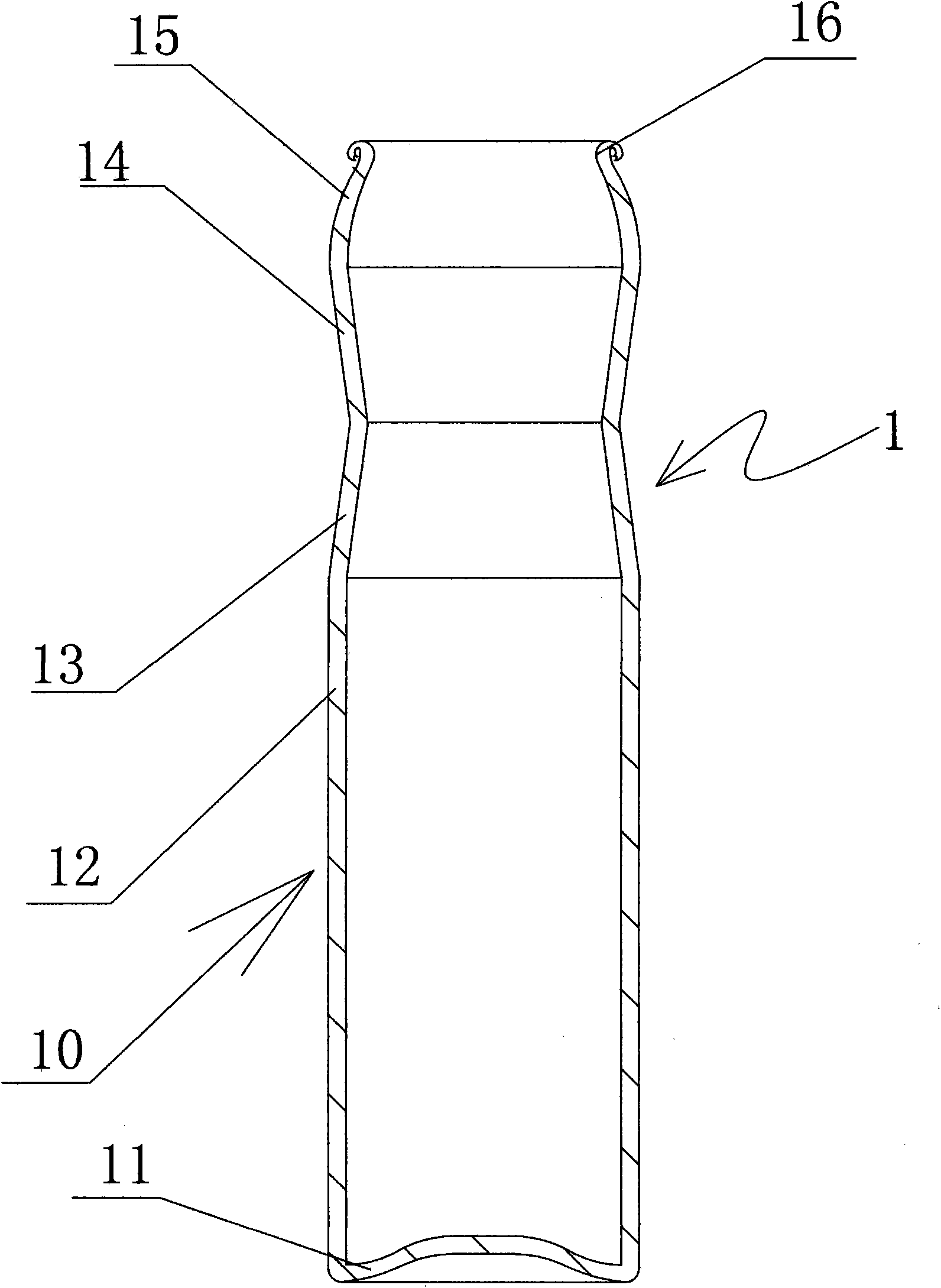

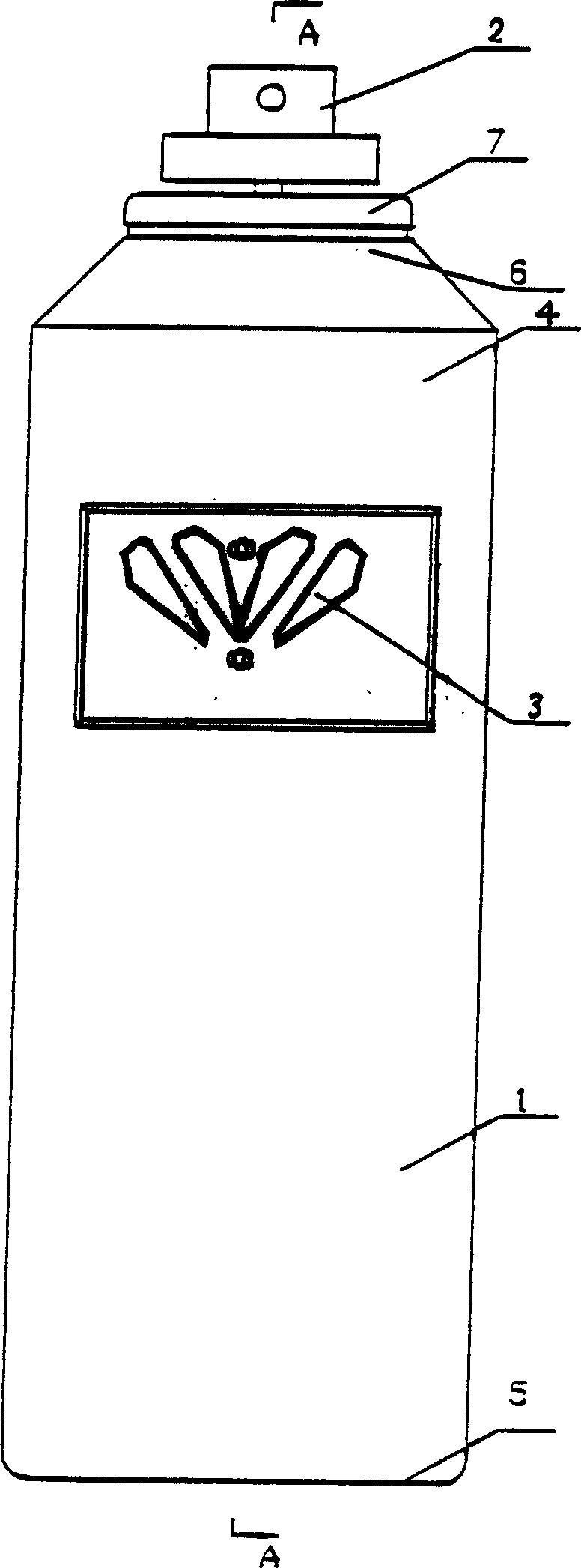

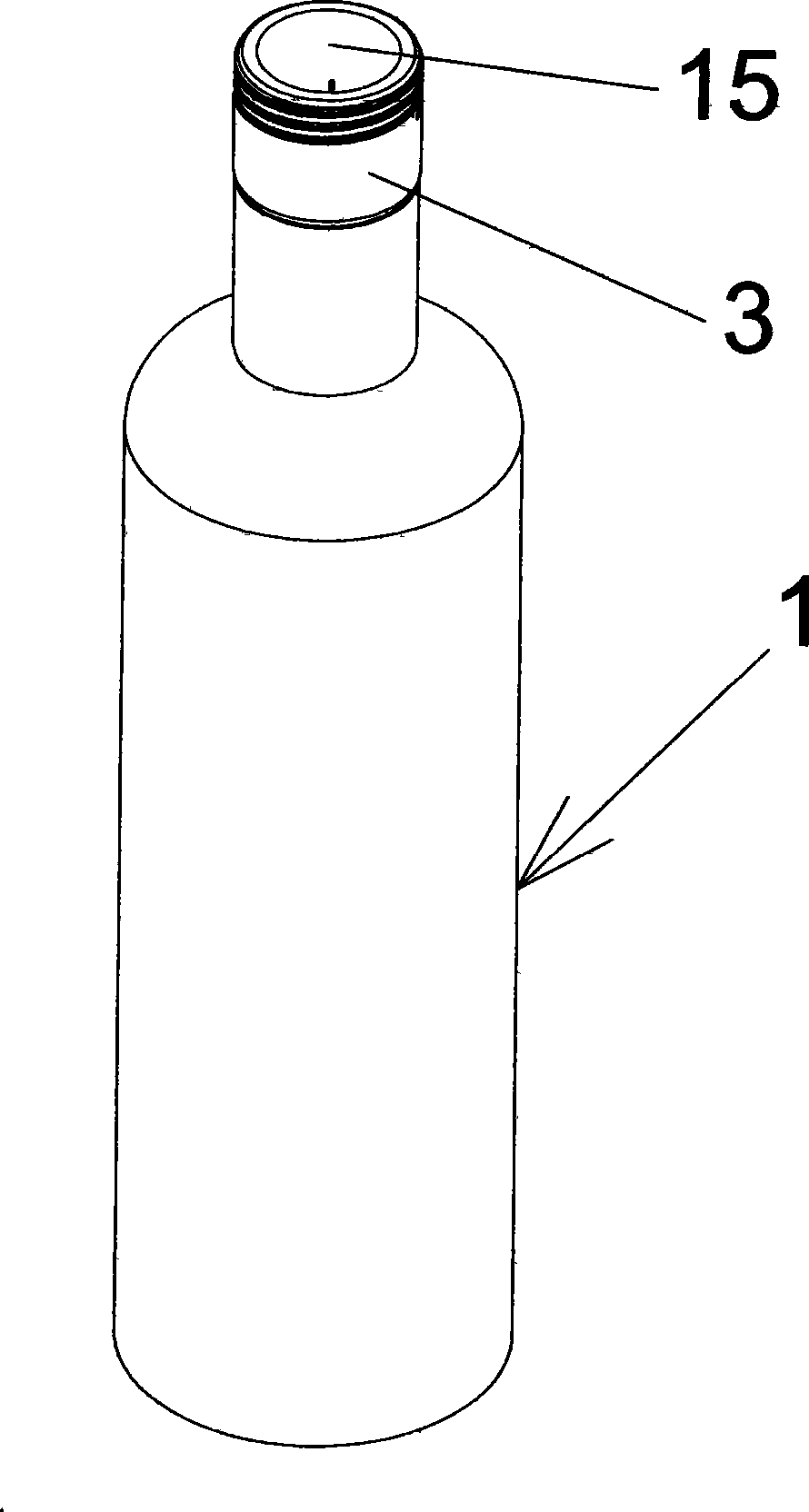

Aluminium packaging can and production method

The invention discloses an aluminum packaging tank which comprises a tank cylinder, a tank bottom, tank shoulders, a tank neck and a tank port. An inward concave part which is inward concave arc shape and can be held in hands conveniently shrinks in the middle part of the tank cylinder. The tank cylinder on the lower part of the inward concave part is cylindrical, and a longitudinal cross section of the tank cylinder on the upper part is arc shape extruding outwards. Due to the inward concave part, the tank can be held conveniently and comfortably. As the friction force is added, the aluminum packaging tank can not creep down from hands easily.

Owner:GUANGDONG EURO ASIA PACKAGING

Method for extracting acid mucopolysaccharide and sodium hyaluronate from freshwater mussel gravy

The invention discloses a method for extracting acid mucopolysaccharide and sodium hyaluronate from freshwater mussel gravy. Through the processes of enzymolysis, complex precipitation, centrifugation, ultrafitration classification and vacuum drying in the adopted extraction method, the damage caused in the process of degrading sodium hyaluronate is reduced, the macromolecular characteristic of sodium hyaluronate is remained, sodium hyaluronate is closer to HA (Hyaluronic Acid) required by a human body, and two-stage products including the acid mucopolysaccharide with the content of more than 90% and the finished sodium hyaluronate with the glucuronic acid content of more than 43% can be obtained in sequential extraction. The HA extracted by using the method disclosed by the invention is wide in raw material source, low in price, safe and reliable and capable of replacing the HA extracted by taking cockscombs and human umbilical cords as raw materials, and the production yield of natural HA can be greatly increased. The method disclosed by the invention is simple and convenient to operate, high in separation efficiency and free of phase change and can be widely applied to the fields of medicines, aesthetic health care and health foods.

Owner:HUZHOU TAIHUXING BIOLOGICAL TECH

Method for separating naphthenic acid from mixed organic matter

ActiveCN110407686AMild method conditionsMild conditionsOrganic compound preparationCarboxylic acid salt preparationWastewaterMicroemulsion

The invention relates to a method for separating a naphthenic acid from mixed organic matter. The method comprises the steps that (1) the naphthenic acid is separated through a microemulsion method, organic matter 0 containing the naphthenic acid is taken to a heatable container, under a condition of heating, the organic matter 0 and circulating water phase a2 solution are mixed at 25-85 DEG C for1-60min at a ratio of 3:1-1:10 in 25-85, and after mixed reaction, a mixed solution is split into phases by standing and then separated to obtain organic phase 01 and the aqueous phase a1; (2) the naphthenic acid is recycled, the aqueous phase a1and alkali B of a monovalent cation are mixed at a ratio of 10:1-3:1 for 1-60min at the temperature of 25-85 DEG C, and after the mixing reaction, a mixed solution is split into phases by separating, and organic phase 02 and the circulating aqueous phase a2 are obtained; and (3) the above step (1) and step (2) are repeated. According to the method forseparating the naphthenic acid from the mixed organic matter, the condition is mild, the cost is low, environmental friendliness is achieved, all alkaline solutions are recycled, and no waste water is discharged.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

Aluminum packaging can and manufacturing method

The invention discloses an aluminum packaging can, comprising a can bottom, a can body, a can shoulder and a cab opening. A ring inward depression is arranged at the position where the upper part of the can body is connected with the can shoulder. A lower ring step which is convex outwards is arranged between the ring inward depression and the lower can body, and an upper ring step which is convex outwards is arranged between the ring inward depression and the can shoulder. The invention also discloses a manufacturing method of the aluminum packaging can, which comprises the following steps of frying, stamping, dressing, cleaning, protection processing, forming the ring inward depression, the upper part of the coarse can billet is shrunk to form the inward depression, and collaring. The invention has the advantages of good integral appearance, good visual effect, high added value, high grade and the like.

Owner:GUANGDONG EURO ASIA PACKAGING

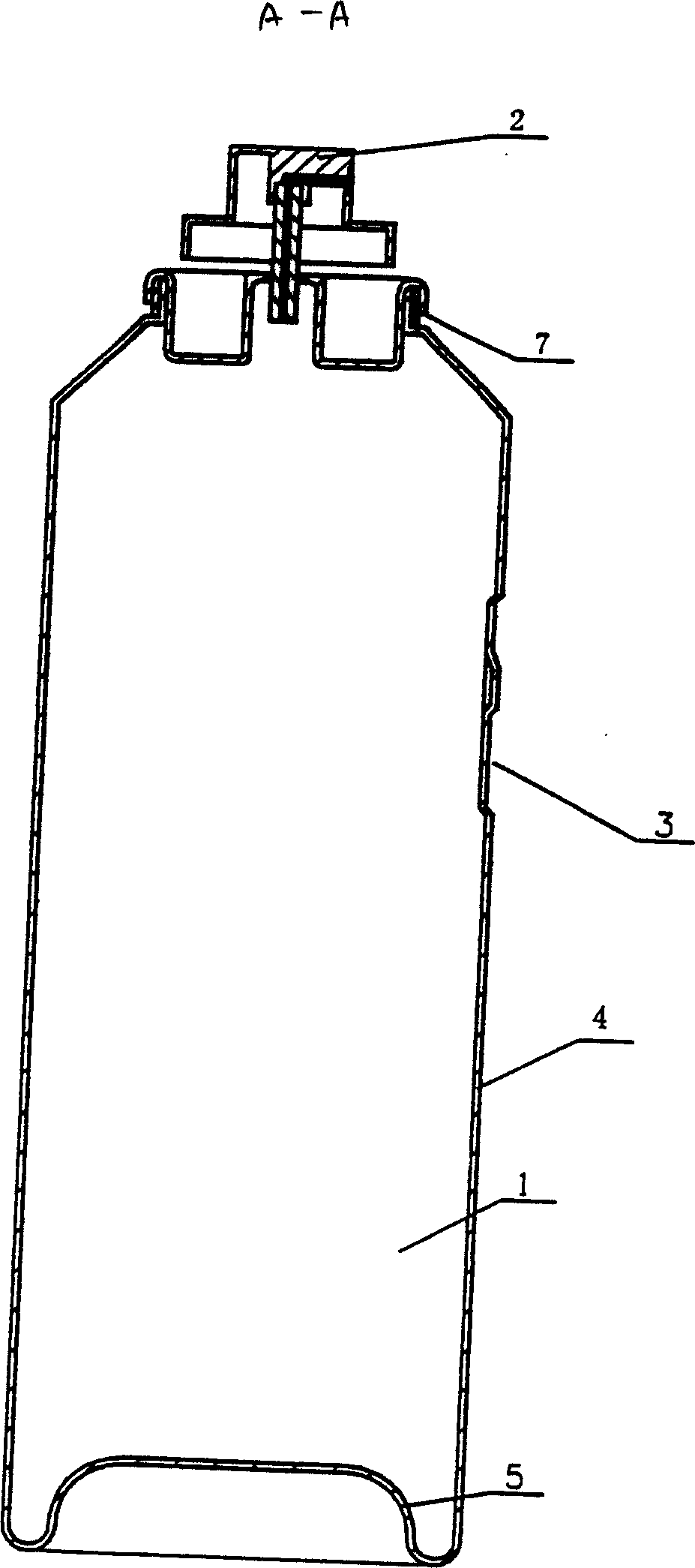

Double-waist aluminum packaging tin and production method

ActiveCN101817413AEasy to holdStrong three-dimensional senseJarsHollow articlesPunchingMaterials science

The invention discloses a double-waist aluminum packaging tin, which comprises a tin bottom, wherein the edge of the tin bottom extends upward to form a lower tin body; the upper of the lower tin body shrinks upward to form a first level tin waist; the upper of the first level tin waist shrinks upward to form a second level tin waist; the upper of the second level tin waist shrinks upward again to form an upper tin body; the upper of the upper tin body shrinks upward to form a tin shoulder; and the upper part of the tin shoulder is flanged to form a tin port with a lip. The invention also discloses a production method for the double-waist aluminum packaging tin. The method comprises the following steps: frying slices, punching; finishing; cleaning; protection treatment; and necking which is as follows: open of the crude tin blank is shrunk to form the first level tin waist, the lower tin body is partly formed between the first tin waist and the tin bottom, the upper part of the first level tin waist is shrunk upwardly to form the second level tin waist, the upper part of the second level tin waist is shrunk upwardly again to form the upper tin body, the upper part of the upper tin body is shrunk upwardly to form the tin shoulder, and the upper part of the tin shoulder is flanged to the tin port with lips. The invention has the advantages of easy and firm holding, overall attractive appearance, strong vision and touch stereoscopic impression, high added value, high grade and the like.

Owner:GUANGDONG EURO ASIA PACKAGING

Aluminum packaging can and production method thereof

InactiveCN101683902ACompact structureStrong three-dimensional senseJarsLinings/internal coatingsEngineeringVertical cylinder

The invention discloses an aluminium packaging can and a production method thereof. The design key points of the aluminium packaging lie in comprising a can bottom which extends upwards to form a hollow cylindrical vertical cylinder; the opening at the upper end of the vertical cylinder shrinks upwards to form a conical part; the opening at the upper end of the conical part expands upwards to forman inverted conical part; the conical degree of the longitudinal section of the inverted conical part is equal to that of the conical part; the opening at the upper end of the inverted conical part shrinks upwards to form a can shoulder and turns up to form a can opening with a lip. The invention aims at providing a production method of the aluminium packaging can with simple processing method and high degree of automation and an aluminium packaging can with strong tank body stereoscopic impression and simple structure manufactured by the method.

Owner:GUANGDONG EURO ASIA PACKAGING

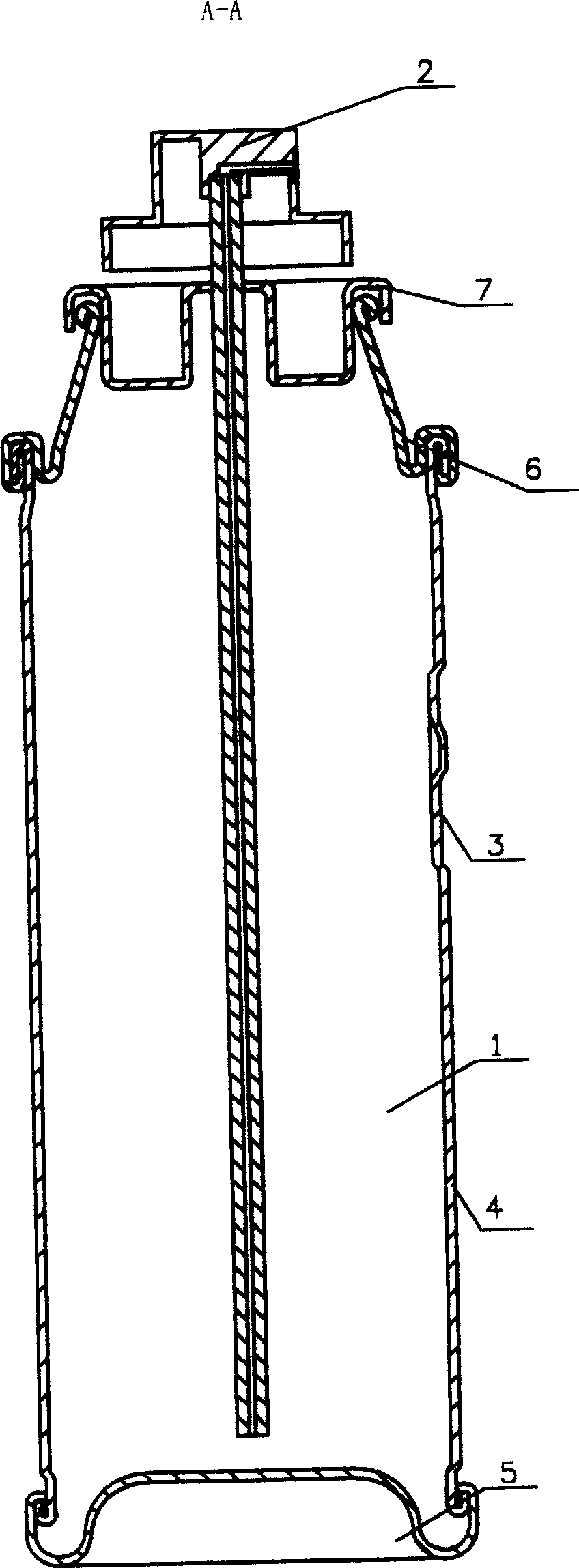

Packing pot of aerosol and its production

ActiveCN1613732AImprove aestheticsEffective anti-counterfeitingLiquid dispensingHollow articlesEngineeringAerosol

An aerosol packing can features that a relief-style concave-convex pattern is made on its cylindrical surface. Its manufacturing process includes such steps as coating priming paint on tinned sheet, printing pattern and trademark, coating bright paint, embossing to form relief-style pattern, rolling and welding to form cylindrical body, and assembling it with bottom and shoulder by seaming.

Owner:GUANGDONG EURO ASIA PACKAGING

Aluminium packing pot of aerosol and its production

ActiveCN1613733AImprove aestheticsEffective anti-counterfeitingLiquid dispensingHollow articlesMaterials scienceAerosol

An aerosol packing can features that a relief-style concave-convex pattern is made on its cylindrical surface. Its manufacturing process includes such steps as adding lubricating powder to small aluminium blocks, stirring, die pressing to obtain can blank, trimming, washing, spraying paint on its inner surface, coating priming paint, printing, coating bright pain, embossing to form relief-style pattern, and reducing and seaming to form shoulder and mouth.

Owner:GUANGDONG EURO ASIA PACKAGING

Aluminum screw packaging tank and production method

InactiveCN101372267AEasy to store for a long timeEasy to storeBottlesHollow articlesPackaging TankAluminum can

The invention discloses a screw-type packaging aluminum can and a production method thereof; the design key point lies in that the production method includes the following steps: the upper edge of a can bottom extends upwards to form a can wall, the can wall is contracted upwards to form a can shoulder and a can neck, the upper part of the can neck is also contracted to form an assembly part which is equipped with a threaded sleeve, a ring-shaped step is formed between the assembly part and the lower part of the can neck, an opening at the upper end of the assembly part is flanged to form a can mouth with a lip, the threaded sleeve is sheathed between the ring-shaped step and the lip of the can mouth, and the can wall, the can bottom, the can shoulder and the can neck are integrally formed. The invention aims at providing a screw-type packaging aluminum can which has beautiful appearance, light-shading property, good sealing performance as well as high added value and high level; furthermore, the invention provides a production method of the screw-type packaging aluminum can with simple processing method and high degree of automation.

Owner:GUANGDONG EURO ASIA PACKAGING

Process for preparing chicken liver hydrolyzed protein with proteases

InactiveCN101717807BIncrease the added value of productionLow costFermentationPretreatment methodCholesterol

The invention provides a process for preparing chicken liver hydrolyzed protein with proteases, aiming at solving the problems that the chicken liver has heavy fishy smell and high content of cholesterol and hereby has low utilization rate. The influence of the raw material processing method, the proteolysis temperature, the pH value, the protease dosage (E / S), the substrate concentration and theproteolysis time to the hydrolysis capacity of all the proteases is investigated and the proteolysis effect of all the proteases under the optimum condition is compared in the single factor experiment by using the chicken liver as the raw material, selecting 5 proteases and taking the hydrolysis degree as the index. The high proteolysis products with optimum hydrolysis effect and flavor are obtained by optimizing the compound dual-protease proteolysis condition. The chicken liver hydrolyzed protein is prepared through proteolysis, and the main components of the chicken liver hydrolyzed protein are amino acid and small molecule peptide which have no bitter flavor. Detection shows that the chicken liver hydrolyzed protein contains no cholesterol and has some antioxidant activity.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com