Aluminum screw packaging tank and production method

A production method and technology for packaging cans, which are applied in the directions of packaging, transportation and packaging, bottle/can components, etc., can solve the problems of inability to adapt to fillers, low added value, limited sealing performance, etc., and achieve convenient long-term storage, The effect of improving the storage effect and improving the product grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

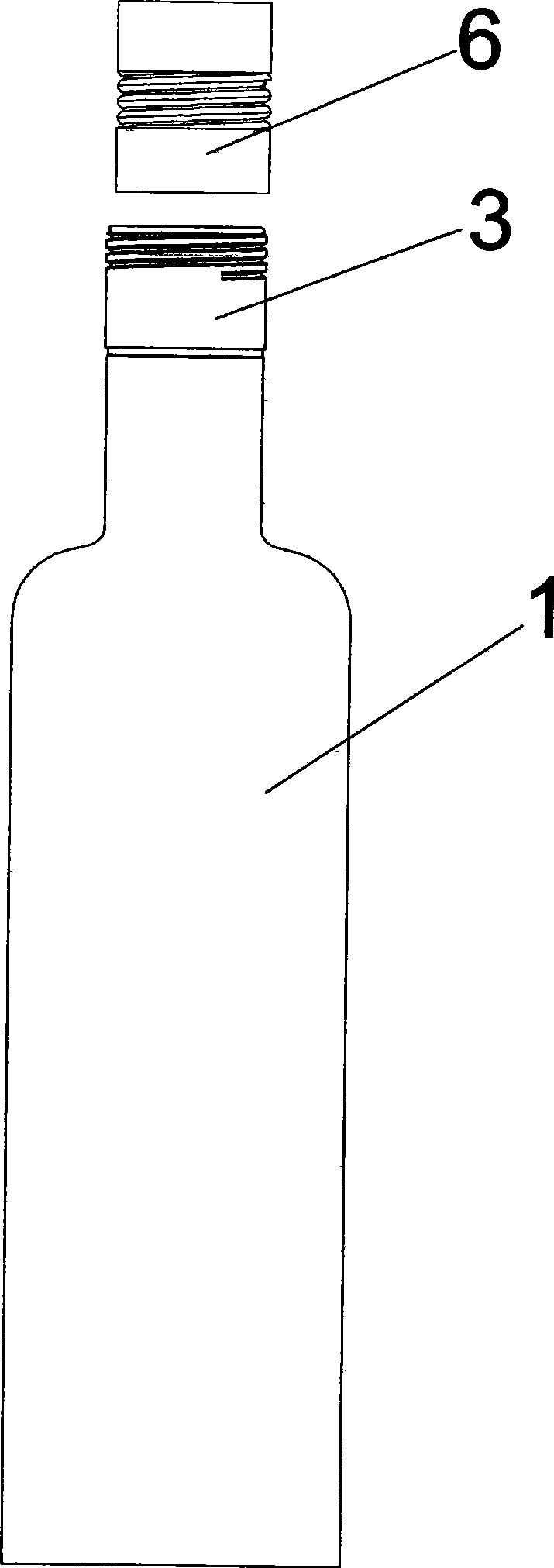

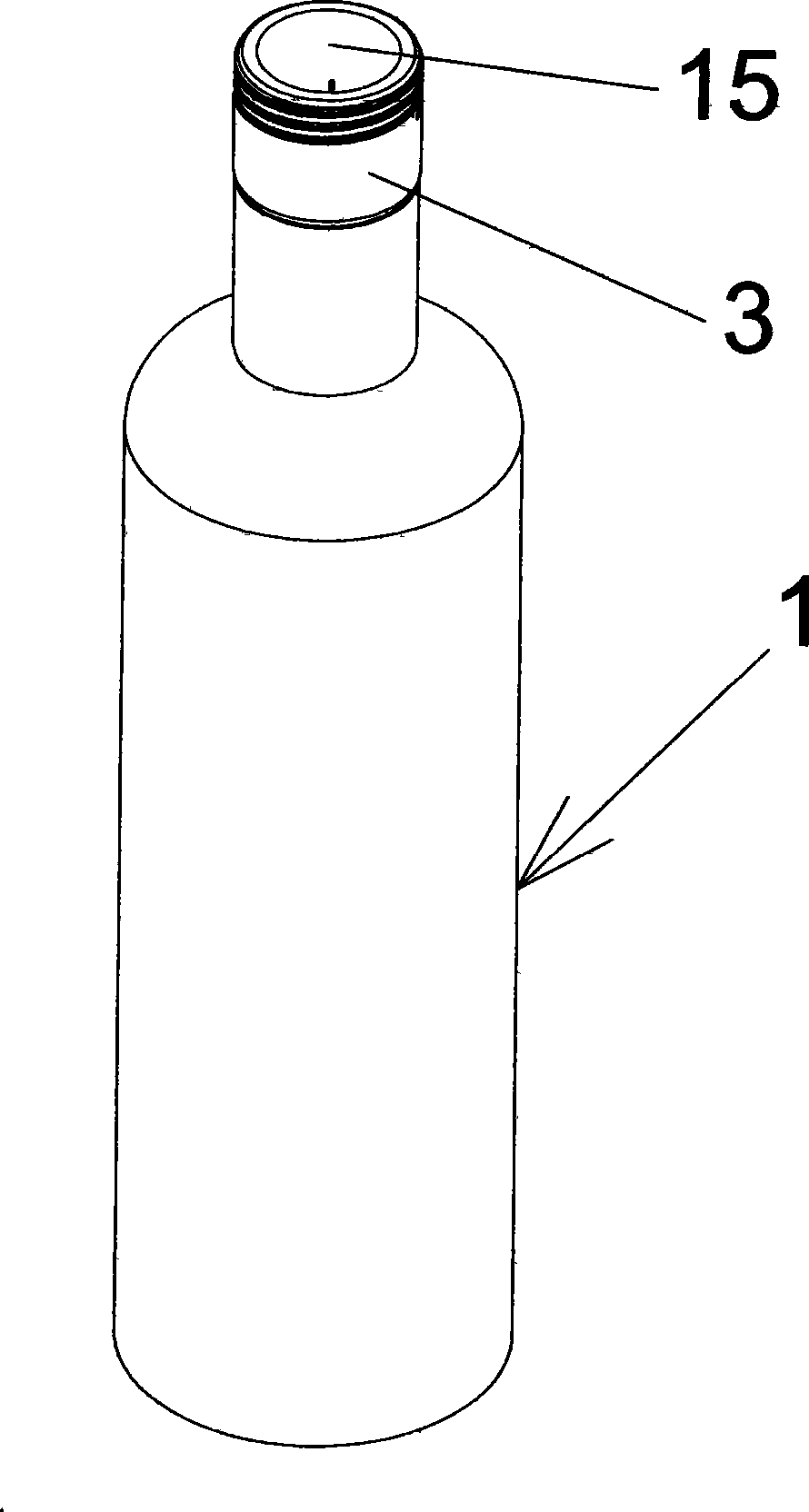

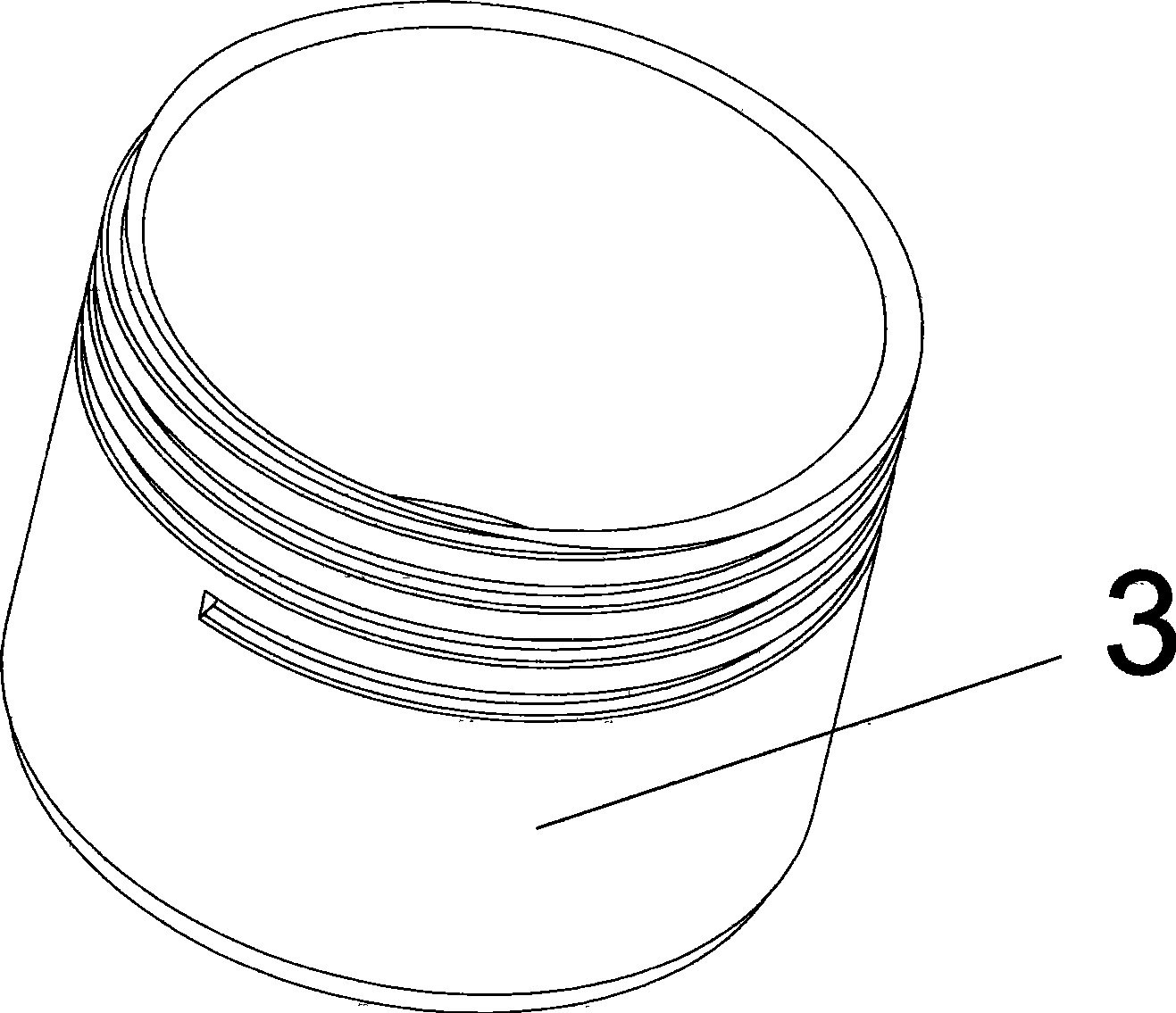

[0034] As shown in the figure, an aluminum screw-top packaging can includes a tank wall 11, a tank bottom 12, a tank shoulder 13, a tank neck 14 with a smooth inner wall and a tank mouth 15, and the tank wall 11, tank bottom 12, tank shoulder 13 and The tank neck 14 is integrally formed, and a sleeve 3 with external threads is tightly sleeved on the outside of the tank neck 14. In the present invention, the sleeve 3 is a plastic sleeve, and the number of turns of the external thread on the sleeve 3 is not more than 5. The sleeve sleeve 3 is used to be threadedly connected with a tank cover 6 with an internal thread.

[0035] Wherein, the upper edge of the tank bottom 12 extends upwards to be the tank wall 11. In the present invention, the tank wall 11 is a hollow cylinder, and the tank wall 11 shrinks upwards to form a tank shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com