Method for innocently treating organic waste liquid generated in BDO production

A technology of harmless treatment and organic waste liquid, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as non-harmless treatment, increase production added value, reduce environmental pollution, The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

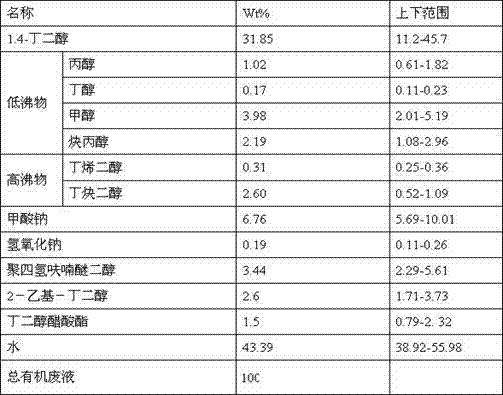

Method used

Image

Examples

Embodiment 1

[0044] In the first step, throw 4 tons of BDO organic waste liquid into the refining tank and heat up.

[0045] a. Separation of low boilers: Feed the organic waste liquid into the refining tank, raise the temperature of the tank to 95°C, and adjust the reflux ratio to 2:1 under normal pressure. storage tanks;

[0046] b. Separation of water: after the separation of low boilers, the remaining bottom liquid is rectified to separate the water, and the refining tank continues to heat up to 115°C, and the vacuum pump is turned on, and the vacuum degree is 0.07MPa negative pressure refining, and the reflux ratio is 1:2 for separation Water, with the reduction of water output, gradually adjust the return flow ratio to 2:1 to continue to separate water;

[0047] c. Separation of 1,4-butanediol: After the separation of water is completed, the temperature of the refining tank continues to rise to 130°C, and the reflux ratio is adjusted to 1:2 to separate 1,4-butanediol (BDO). When th...

Embodiment 2

[0061] In the first step, throw 4 tons of BDO organic waste liquid into the refining tank and heat up.

[0062] a. Separation of low boilers: Feed the organic waste liquid into the refining tank, raise the temperature of the tank to 65°C, and adjust the reflux ratio to 3:1 under normal pressure. storage tanks;

[0063] b. Separation of water: after the separation of low boilers, the remaining bottom liquid is rectified to separate the water, and the refining tank continues to heat up to 105°C, and the vacuum pump is turned on, the vacuum degree is 0.095MPa negative pressure refining, and the reflux ratio is 1:3 for separation Water, with the reduction of water output, gradually adjust the return flow ratio to 3:1 to continue to separate water;

[0064] c. Separation of 1,4-butanediol: After the separation of water is completed, continue to heat up the refining kettle to 150°C, and adjust the reflux ratio to 1:3 to produce 1,4-butanediol (BDO). When the BDO content reaches mo...

Embodiment 3

[0078] In the first step, throw 4 tons of BDO organic waste liquid into the refining tank and heat up.

[0079] a. Separation of low boilers: Feed the organic waste liquid into the refining tank, raise the temperature of the tank to 80°C, and adjust the reflux ratio to 4:1 under normal pressure. storage tanks.

[0080] b. Separation of water: after the separation of low boilers, the remaining bottom liquid is rectified to separate the water, and the refining tank continues to heat up to 110°C, and the vacuum pump is turned on, the vacuum degree is 0.085MPa negative pressure refining, and the reflux ratio is 1:4 for separation Water, with the reduction of water output, gradually adjust the return flow ratio to 4:1 and continue to separate water.

[0081] c. Separation of 1,4-butanediol: After the separation of water is completed, continue to heat up the refining kettle to 170°C, and adjust the reflux ratio to 1:4 to produce 1,4-butanediol (BDO). When the BDO content reaches m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com