Method for producing calcium carbide raw materials through carbide slag

A technology of calcium carbide slag and raw materials, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of carbide slag waste, difficult impurities to effectively remove calcium hydroxide products, etc., to improve purity and increase production additional Value, the effect of high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

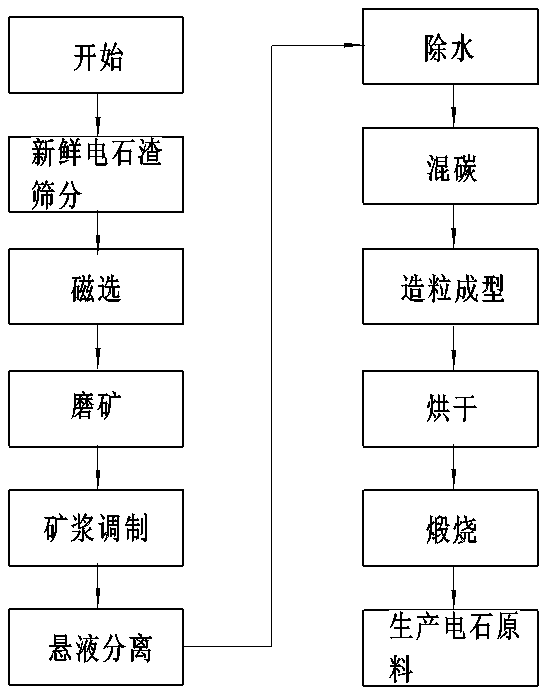

[0048] refer to figure 1 , figure 2 According to the flow chart of a method for producing calcium carbide raw materials by utilizing calcium carbide slag according to the present invention, the specific implementation methods are as follows:

[0049] (1) fresh carbide slag screening: adopt 60 mesh vibrating screens to remove larger particles in the fresh carbide slag;

[0050] (2) Magnetic separation: adopt a dry powder magnetic separator to remove iron impurities in the calcium carbide slag obtained after screening;

[0051] (3) Grinding: adopt pulverizer to grind the calcium carbide slag particles after magnetic separation to less than 25 μm;

[0052] (4) Ore slurry preparation: the calcium carbide slag after the ore grinding and water are mixed into an ore slurry by a mass concentration of 20%, and the calcium carbide slag and water are mixed evenly by an agitator;

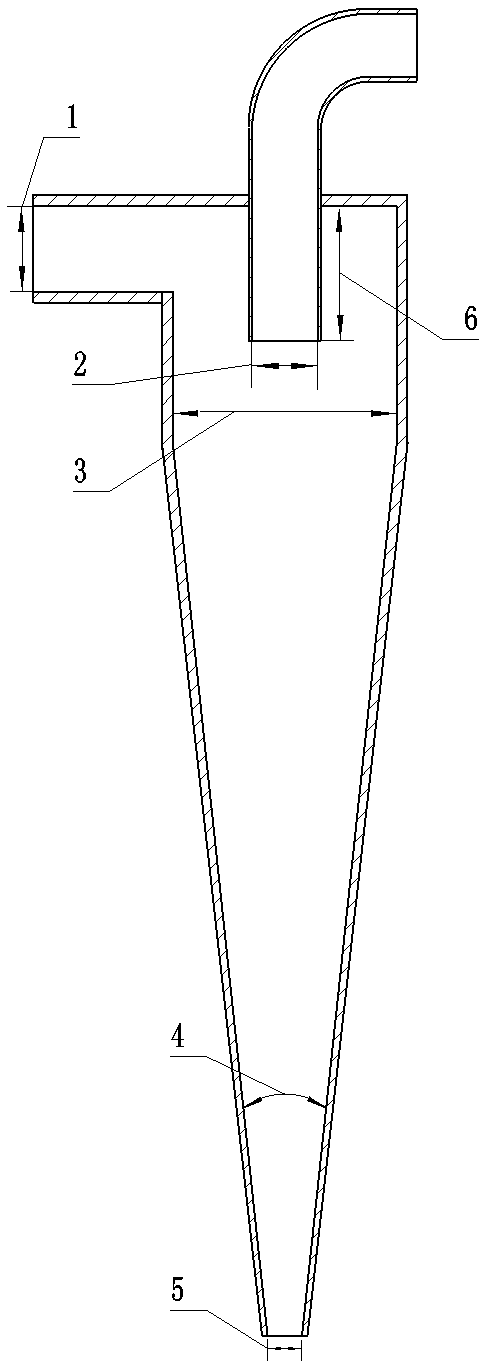

[0053] (5) Suspension Separation: Sewage pumps are used to send the modulated ore slurry i...

Embodiment 2

[0061] This embodiment is a method for producing calcium carbide raw materials by utilizing calcium carbide slag, which mainly includes the following steps:

[0062] (1) Fresh carbide slag screening: adopt 70 mesh vibrating screens to remove larger particles in the carbide slag;

[0063] (2) Magnetic separation: adopt dry powder magnetic separator to remove iron impurities in the calcium carbide slag obtained after step (1) screening;

[0064] (3) Grinding: using a pulverizer to grind the carbide slag particles to less than 40 μm;

[0065] (4) Ore slurry preparation: mix the carbide slag after grinding with water at a mass concentration of 15% to form an ore slurry, and mix the calcium carbide slag and water evenly through the agitator;

[0066] (5) Suspension separation: adopt the sewage pump to send the modulated ore slurry into the hydrocyclone, collect the slurry discharged from the overflow port of the hydrocyclone; the inlet velocity of the hydrocyclone is 3...

Embodiment 3

[0074] This embodiment is a method for producing calcium carbide raw materials by utilizing calcium carbide slag, which mainly includes the following steps:

[0075] (1) Fresh carbide slag screening: adopt 80 mesh vibrating screens to remove larger particles in the carbide slag;

[0076] (2) Magnetic separation: adopt dry powder magnetic separator to remove iron impurities in the calcium carbide slag obtained after step (1) screening;

[0077] (3) Grinding: using a pulverizer to grind the carbide slag particles to less than 35 μm;

[0078] (4) Ore pulp preparation: mix the carbide slag after grinding with water at a mass concentration of 18% to form an ore slurry, and mix the carbide slag and water evenly through the agitator;

[0079] (5) Suspension separation: adopt the sewage pump to send the modulated ore slurry into the hydrocyclone, and collect the slurry discharged from the overflow port of the hydrocyclone; the inlet velocity of the hydrocyclone is 4m / s, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com