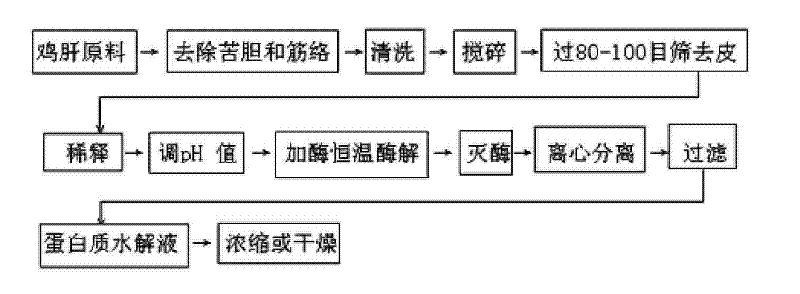

Process for preparing chicken liver hydrolyzed protein with proteases

A technology of chicken liver hydrolyzed protein and process method, applied in the direction of fermentation, etc., can solve the problem of chicken liver products with fishy smell and cholesterol content, etc., and achieve the effect of improving the utilization value of chicken liver, easy digestion and absorption, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Raw material processing: Remove the gall bladder and tendons from the fresh chicken liver. After washing, use a mixer to mash it to make 80 mesh chicken liver paste.

[0039] Hydrolysis: Add water to prepare a chicken liver slurry with a concentration of 10.0wt% (w / w, calculated as the percentage of dry chicken liver weight), adjust the pH to 8.0, control the reaction temperature to 58°C, add Alcalase alkaline protease, and add enzymes The amount (E / S) is 1.25wt%, and the reaction time is 3.5h.

[0040] Enzyme inactivation: Keep the reaction system at 90°C for 15 minutes.

[0041] Centrifugal filtration: Centrifuge at 3000 rpm for 20 minutes using a centrifuge to obtain the supernatant and bottom solid waste residue. The supernatant is filtered to obtain the hydrolyzed protein solution.

[0042] The supernatant is concentrated into a high-protein nutrient solution.

Embodiment 2

[0044] Raw material processing: remove the gall bladder and tendons from the fresh chicken liver, clean it, mash it with a mixer to make 100 mesh chicken liver paste.

[0045] Hydrolysis: Add water to prepare a chicken liver slurry with a concentration of 15wt% (w / w, calculated as the percentage of dry chicken liver weight), adjust the pH to 8.5, control the reaction temperature to 60°C, add Alcalase alkaline protease, and add the amount of enzyme (E / S) is 1.5wt%, and the reaction time is 2.5h.

[0046] Enzyme inactivation: Keep the reaction system at 85°C for 20 minutes.

[0047] Centrifugal filtration: Centrifuge at 4000 rpm for 10 minutes using a centrifuge to obtain the solid waste residue in the upper layer and the bottom layer. The supernatant is filtered to obtain the hydrolyzed protein solution.

[0048] The supernatant is lyophilized to prepare protein powder with certain biological activity.

Embodiment 3

[0050] Raw material processing: the fresh chicken liver is removed from the gall bladder and tendons, and after cleaning, it is crushed with a mixer to make 90 mesh chicken liver paste.

[0051] Hydrolysis: Add water to prepare chicken liver slurry with a concentration of 5wt% (w / w, calculated as the percentage of dry chicken liver weight), adjust pH to 7.5, control the reaction temperature to 55°C, add Alcalase alkaline protease, and add enzyme amount (E / S) is 1.0wt%, and the reaction time is 3h.

[0052] Enzyme inactivation: Keep the reaction system at 100°C for 10 minutes.

[0053] Centrifugal filtration: Centrifuge at 3500 rpm for 15 minutes using a centrifuge to obtain the solid waste residue of the upper layer and the bottom layer. The supernatant is filtered to obtain the protein hydrolysate solution.

[0054] The supernatant was spray-dried to prepare protein powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com