Aluminum packaging can and production method thereof

A packaging can, aluminum technology, applied in cans, lining/interior coating, covering/exterior coating, etc., can solve problems such as single shape, achieve compact structure, enhance competitiveness, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

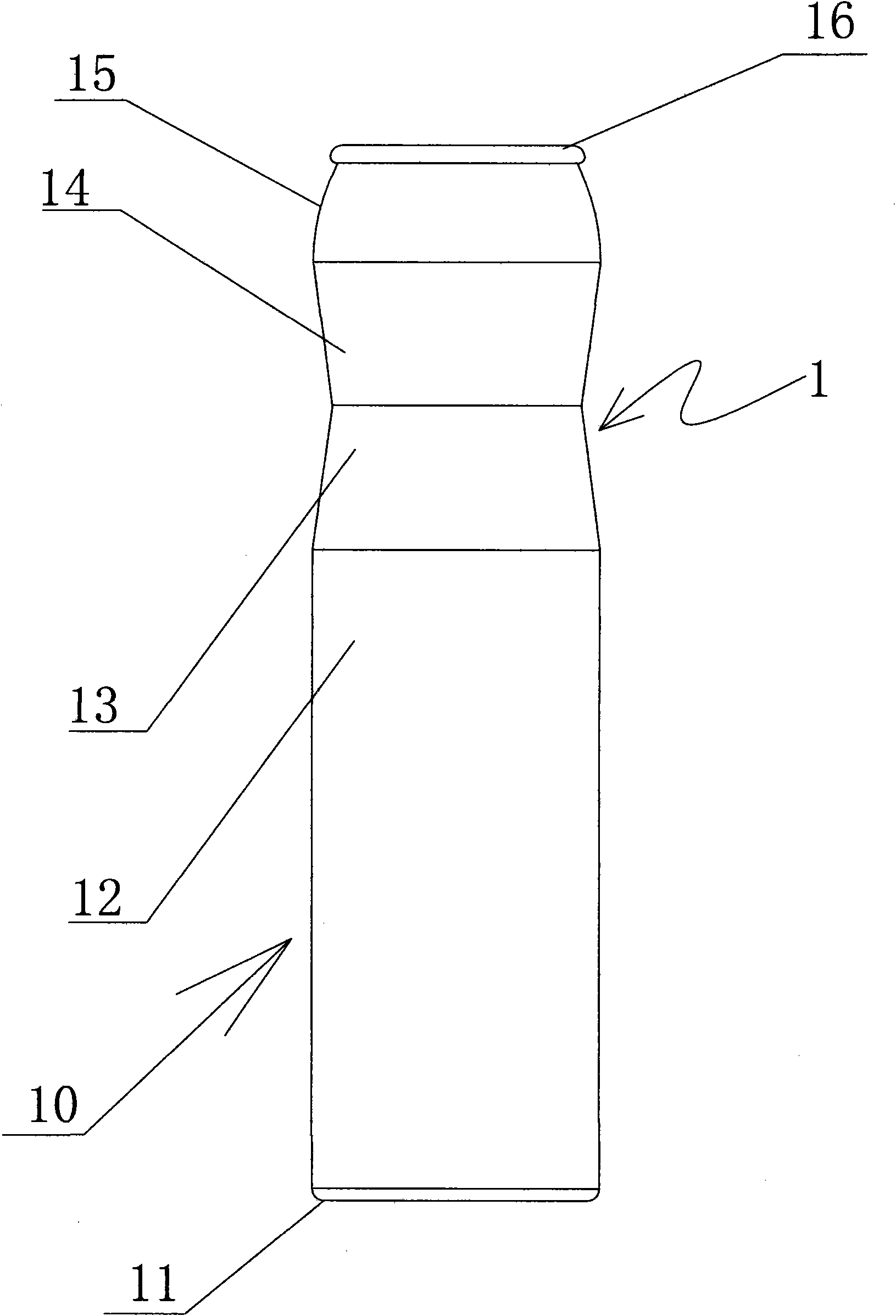

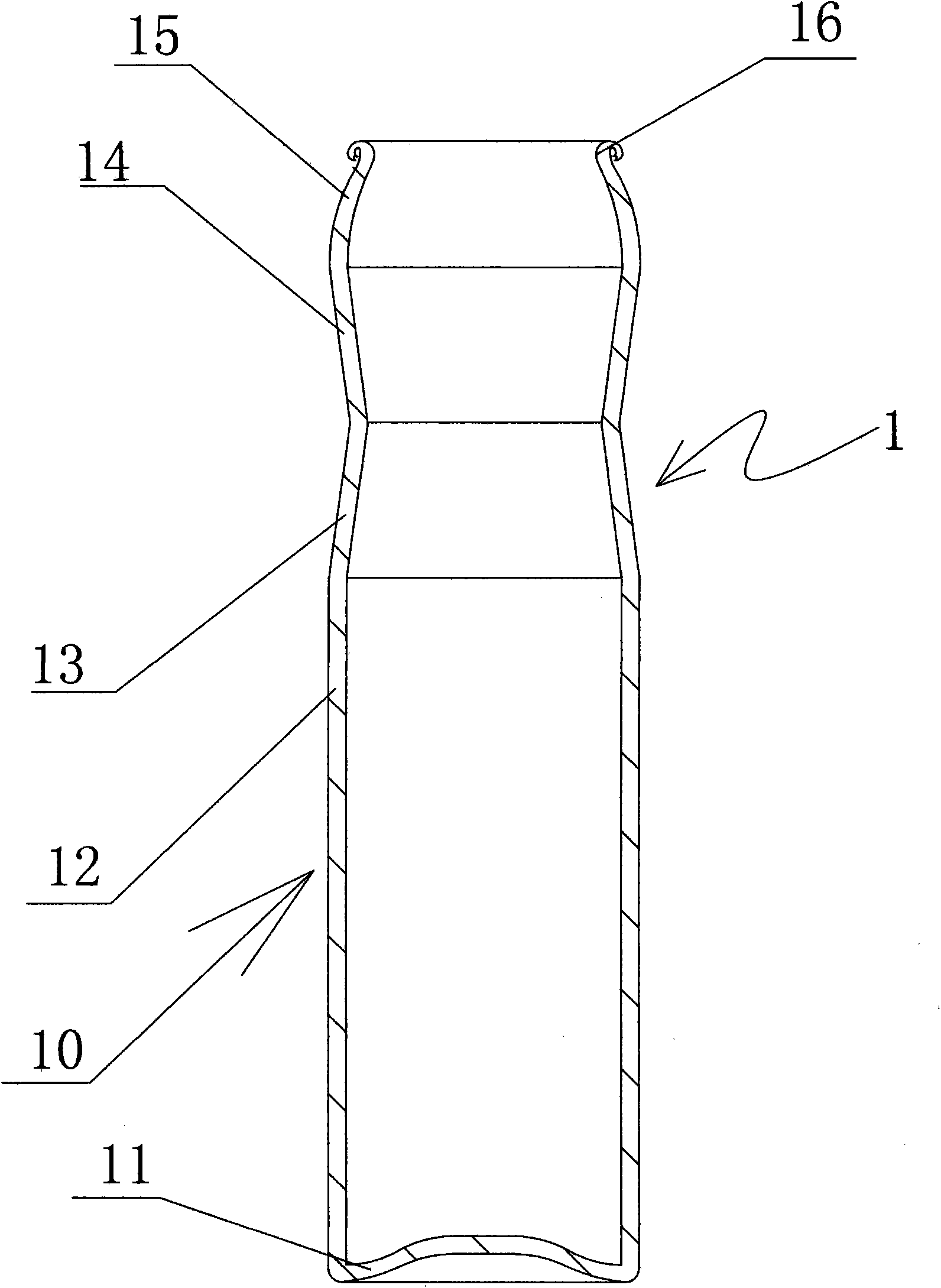

[0024] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

[0025] As shown in the figure, an aluminum packaging can related to the present invention includes an aluminum can body 1. The aluminum can body 1 is made by adding an appropriate amount of lubricant to a certain amount of aluminum flakes and fully stirring it evenly. The stamping machine of the mold extrudes, trims the length, shrinks the shoulders and flangs through mechanical action. The aluminum tank body 1 is sprayed with a protective film (not shown) for anti-corrosion, so that the shelf life of the aluminum tank body 1 is longer after storing the liquid agent; the aluminum tank body 1 outer surface can also be coated with a mimeograph layer ( Not shown in the figure), so that it is convenient to mimeograph patterns and characters on the primer, mimeograph patterns and characters can be carried out according to customer requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com