Conversion device of desulfurized and denitrified side products of active-coke flue gas, desulfurizing and denitrifying system and method

A technology of desulfurization, denitrification, and conversion equipment, which is applied in chemical instruments and methods, separation methods, alkali metal sulfite/sulfite, etc., and can solve problems such as low economic benefits, environmental pollution, and difficulty in selling sulfuric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

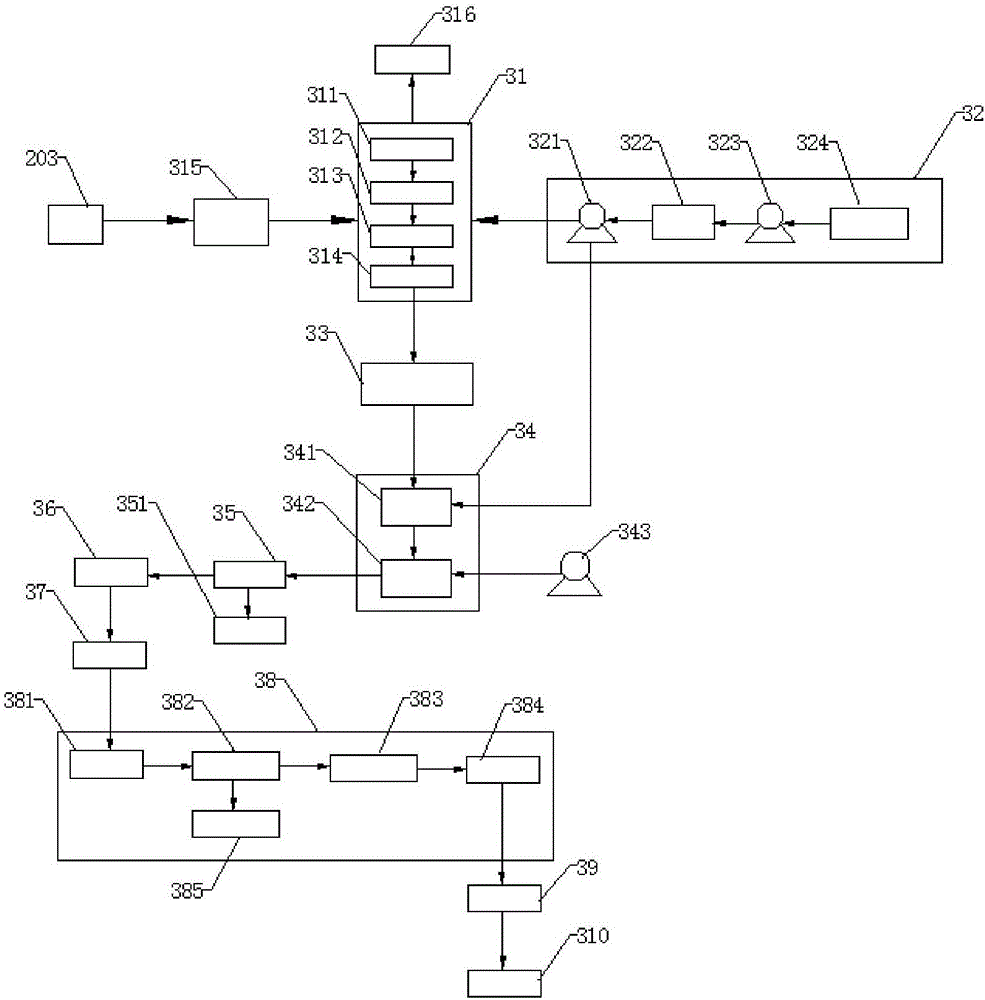

[0102] figure 1 Schematic diagram of activated coke flue gas desulfurization and denitrification by-product conversion device provided by the present invention, such as figure 1 As shown, an activated coke flue gas desulfurization and denitrification by-product conversion device includes an absorption tower 31, an alkali distribution unit 32, an intermediate product storage tank 33, a neutralization tank 34, an evaporator 35, a concentrated material tank 36, a centrifugal unit 37 and Drying device 38; absorption tower 31 is provided with an inlet port, which is connected to the output port 203 of sulfur dioxide gas analyzed in the activated coke flue gas desulfurization and denitrification system; alkali distribution unit 32, absorption tower 31, intermediate product storage tank 33 , neutralization tank 34, evaporator 35, concentrated material tank 36, centrifugal unit 37 and drying device 38 are connected in sequence.

[0103] Wherein, the alkali distribution unit 32 is a s...

Embodiment 2

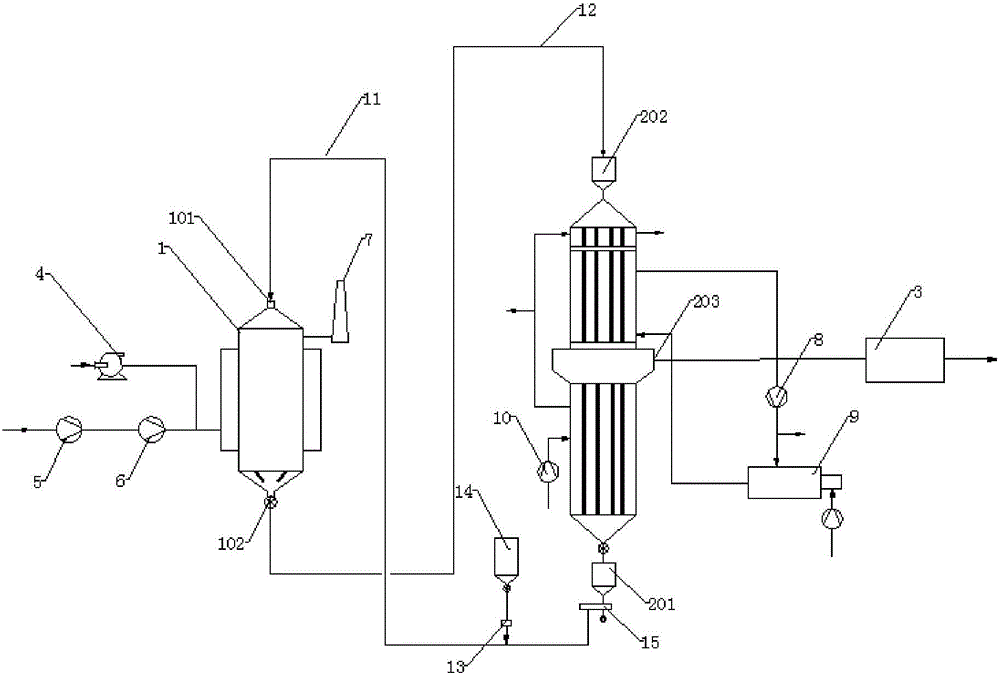

[0114] figure 2 The process flow diagram of the activated coke flue gas desulfurization and denitrification system provided by the present invention, such as figure 2 As shown, this embodiment provides an activated coke flue gas desulfurization and denitrification system, including the activated coke flue gas desulfurization and denitrification by-product conversion device 3 in Example 1, and also includes an adsorption tower 1 and a desorption tower 2; the lower side of the adsorption tower 1 The wall is provided with a flue gas inlet, the upper side wall is provided with a flue gas outlet, and the top and bottom are respectively provided with an active coke inlet and an active coke outlet. The adsorption tower 1 is connected with the ammonia system 4; the top and bottom of the analytical tower 2 are respectively A feed inlet and a feed outlet are provided, the active coke inlet of the adsorption tower 1 is connected with the discharge outlet of the desorption tower 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com