Method for preparing biochar by taking organic solid wastes of agriculture and forestry as raw materials in wet thermal cracking manner

A technology of organic solids and biochar, applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of low yield of biochar, and achieve the effect of reducing carbon emissions, increasing production added value, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

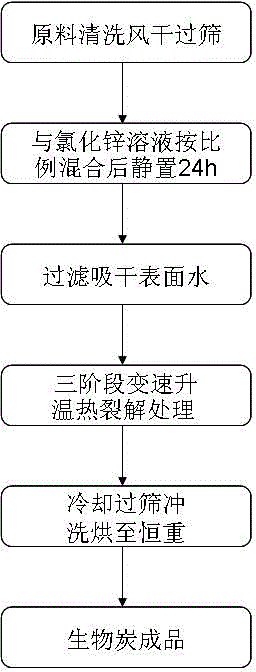

[0026] Such as figure 1 As shown, a method for preparing biochar by wet pyrolysis using agricultural and forestry organic solid waste as raw material, including the following steps: after cleaning the wheat straw raw material from impurities such as sediment, washing it with deionized water, air-drying naturally, and crushing through a 60-mesh sieve . Prepare a concentration of 0.20 mol / L zinc chloride solution, mix and stir wheat straw and zinc chloride solution at a ratio of 1:10, let stand for 24 hours, then filter with quantitative filter paper, absorb the surface water of wheat straw with absorbent paper, and place In a tubular atmosphere furnace, nitrogen was used as a protective gas for thermal cracking. Nitrogen flow rate is 0.1m 3 / h, in the first stage, the temperature is raised rapidly to 200°C, and then kept for 10 minutes, with a heating rate of 50°C / min; the second stage is a sub-slow heating process, with a heating rate of 5°C / min, heated to 350°C, and kept f...

Embodiment 2

[0028] Such as figure 1 As shown, a method for preparing biochar by wet thermal cracking of agricultural and forestry organic solid waste as raw material, comprising the following steps: after cleaning the corncob raw material from impurities such as sediment, washing it with deionized water, air-drying naturally, and crushing through a 60-mesh sieve . Prepare a concentration of 0.20 mol / L zinc chloride solution, mix corncob and zinc chloride solution at a ratio of 1:10, let stand for 24 hours, then filter with quantitative filter paper, dry the surface water of corncob with absorbent paper, and place In a tubular atmosphere furnace, nitrogen was used as a protective gas for thermal cracking. Nitrogen flow rate is 0.1m 3 / h, in the first stage, the temperature is raised rapidly to 200°C, and then kept for 10 minutes, with a heating rate of 50°C / min; the second stage is a sub-slow heating process, with a heating rate of 5°C / min, heated to 350°C, and kept for 1 hour; In the ...

Embodiment 3

[0030] Such as figure 1 As shown, a method for preparing biochar by wet pyrolysis using agricultural and forestry organic solid waste as raw material comprises the following steps: after cleaning the sawdust raw material from impurities such as sediment, washing it with deionized water, air-drying naturally, and crushing through a 60-mesh sieve. Prepare a concentration of 0.20 mol / L zinc chloride solution, mix and stir the sawdust and zinc chloride solution at a ratio of 1:10, let it stand for 24 hours, then filter it with quantitative filter paper, absorb the water on the surface of the sawdust with absorbent paper, and place it in a tube In a type atmosphere furnace, nitrogen is used as a protective gas for heating and cracking. Nitrogen flow rate is 0.1m 3 / h, in the first stage, the temperature is raised rapidly to 200°C, and then kept for 10 minutes, with a heating rate of 50°C / min; the second stage is a sub-slow heating process, with a heating rate of 5°C / min, heated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com