Patents

Literature

79results about How to "Fluffy texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

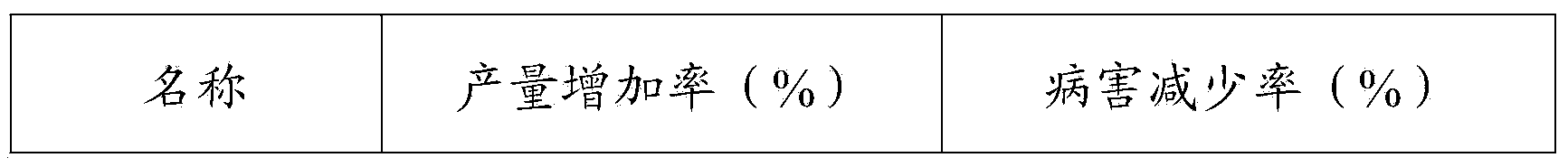

Preparation method of special organic matrix for cherry tomatoes

The invention discloses a preparation method of a special organic matrix for cherry tomatoes. The preparation method comprises the steps of fermentation treatment, air drying and crushing treatment, screening, cleaning and winnowing process treatment and the like on an organic matrix, wherein according to the prepared organic matrix disclosed by the invention, the total nitrogen content is 8-12 percent, the carbon content is 65-72 percent, the total sugar content is 8-12 percent, the reducing sugar content is 5-9 percent, the nicotine content is 1-1.8 percent and the humic acid content is 7-12 percent. With the adoption of the prepared organic matrix, the yield of the cherry tomatoes can be greatly increased, the quality is improved, and the occurrence of diseases can be effectively reduced.

Owner:陈凯

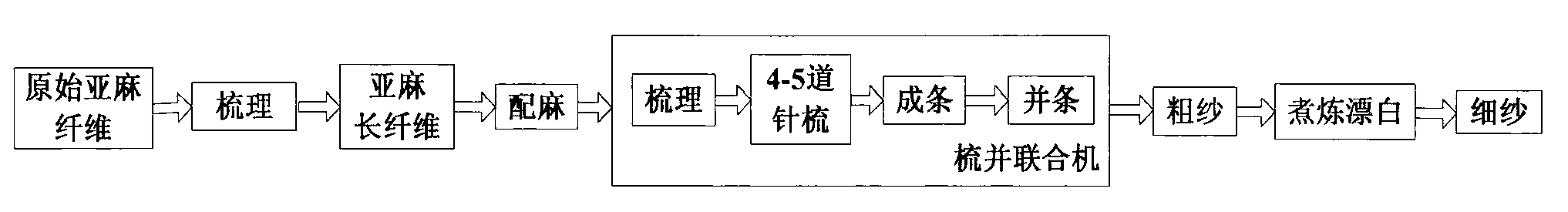

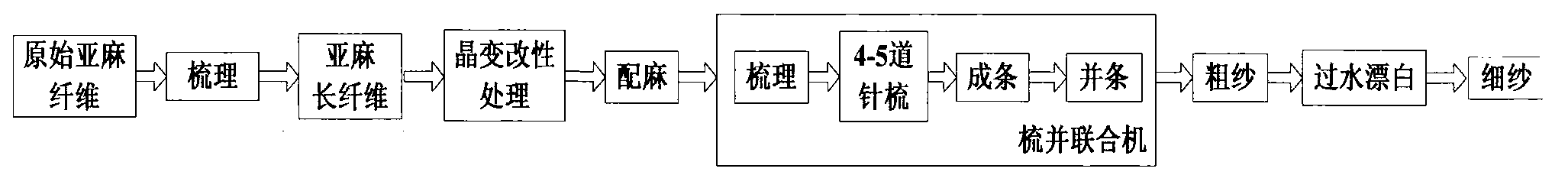

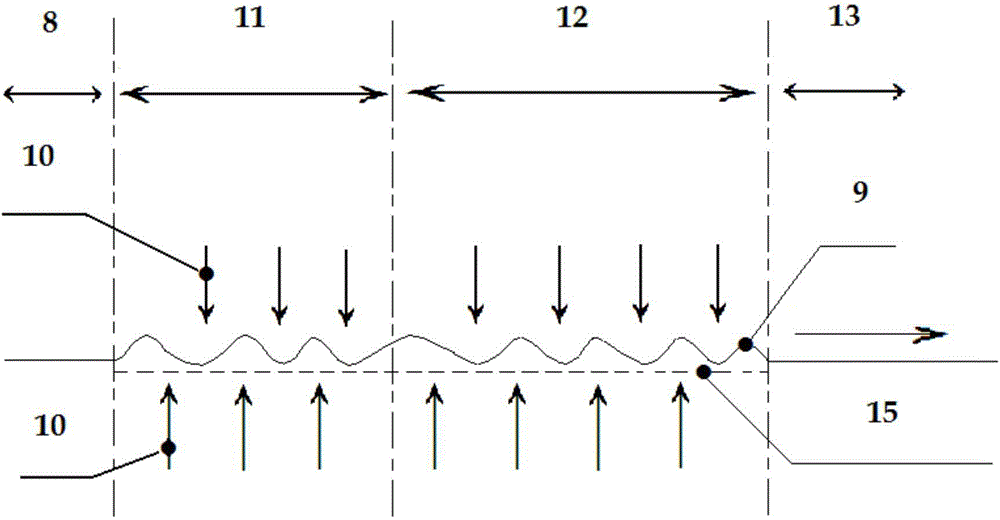

Wet spinning method of low-proportion high-spun flax macrofiber

The invention provides a wet spinning method of low-proportion high-spun flax macrofiber, which comprises the steps of: a first step, combing original flax fiber to obtain flax macrofiber; a third step, carrying out hemp proportioning on the flax macrofiber obtained after crystal transition modification in a former step, gilling, paralleling and spinning by a roving process to obtain flax roving; and a fifth step, carrying out wet spinning on the flax roving obtained after water blanching in a former step by a wet spinning frame to obtain the flax yarn. The wet spinning method is characterized in that a second step of carrying out crystal transition modification treatment on the flax macrofiber is performed between the first step and the third step, and a fourth step of carrying out water blanching on the flax roving is performed between the third step and the fifth step. The method has the advantages that the utilization ratio of the flax macrofiber is greatly improved and reaches more than 70%, and the material resources are saved; high-count linen yarn can be spun according to the fiber proportion of the traditional wet spinning method; and the water blanching replaces the scouring blanching in the traditional wet spinning method, so that the process is simplified, the energy sources are saved and the cost is lowered.

Owner:DONGHUA UNIV +1

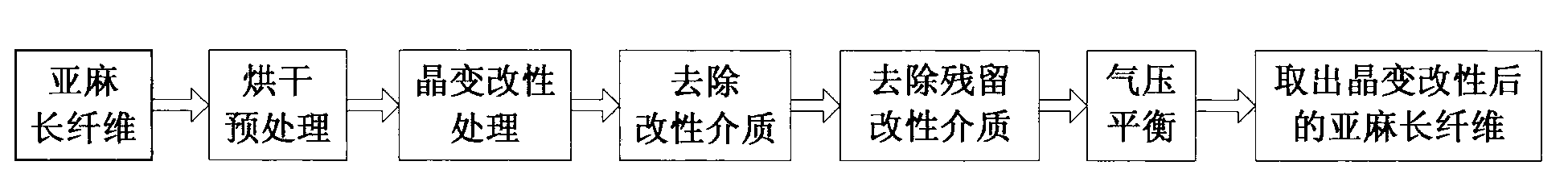

Method for preparing biochar by taking organic solid wastes of agriculture and forestry as raw materials in wet thermal cracking manner

InactiveCN104087326AWide variety of sourcesLower requirementBiofuelsSpecial form destructive distillationMoistureBiochar

The invention relates to a method for preparing biochar by taking organic solid wastes of agriculture and forestry as raw materials in a wet thermal cracking manner. The method comprises the following steps: cleaning, airing, crushing and screening raw materials, and then mixing and stirring the raw materials with 0.20mol / L zinc chloride solution according to the ratio of 1 to 10, and filtering the mixture after standing for 24 hours, wherein the moisture content of the raw materials is controlled between 45.23% and 69.65%; then putting the raw materials into a tubular atmosphere furnace, and carrying out heating cracking by taking nitrogen of which the flow rate is 0.1m<3> / h as a protective gas, wherein at the first stage, quick heating to 200 DEG C, and then heat preservation for 10 minutes are performed, and the heating rate is 50 DEG C / min; the second stage is a slow heating process, the heating rate is 5 DEG C / min, and heating to 350 DEG C and heat preservation for an hour are performed; the third stage is a slow heating stage, the heating rate is 1 DEG C / min, and heat preservation is performed for 2 hours after heating to 400 DEG C; finally screening the solid substances by a 200-mesh sieve; rinsing and baking into constant weight, so as to obtain a biochar product. The method is wide in raw material source, simple in process, and high in biochar yield; the produced biochar has excellent adsorptive property; the production additional value can be increased by tar, smoke and the like generated in the preparation process; the production cost is reduced.

Owner:ANHUI SCI & TECH UNIV

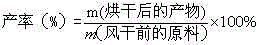

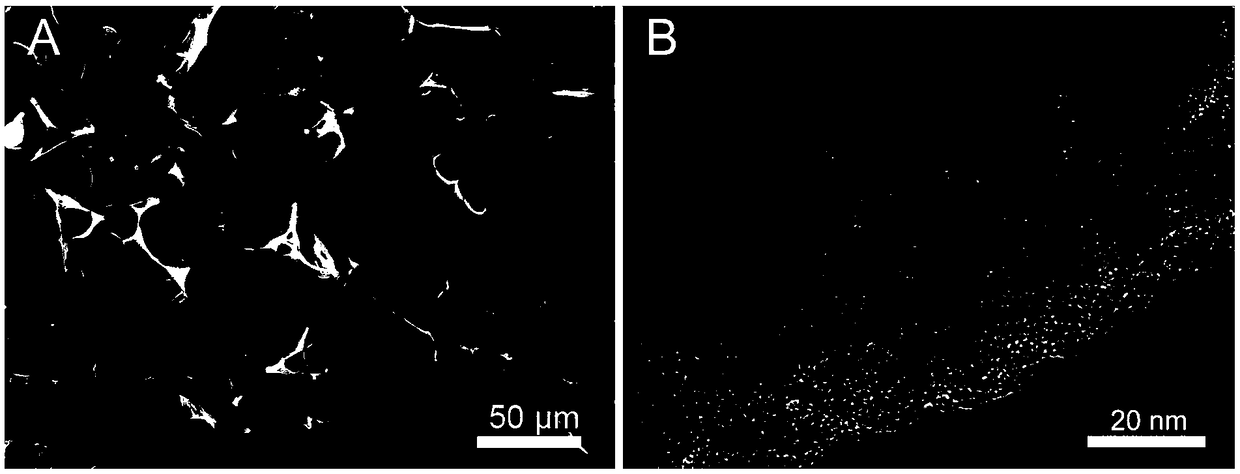

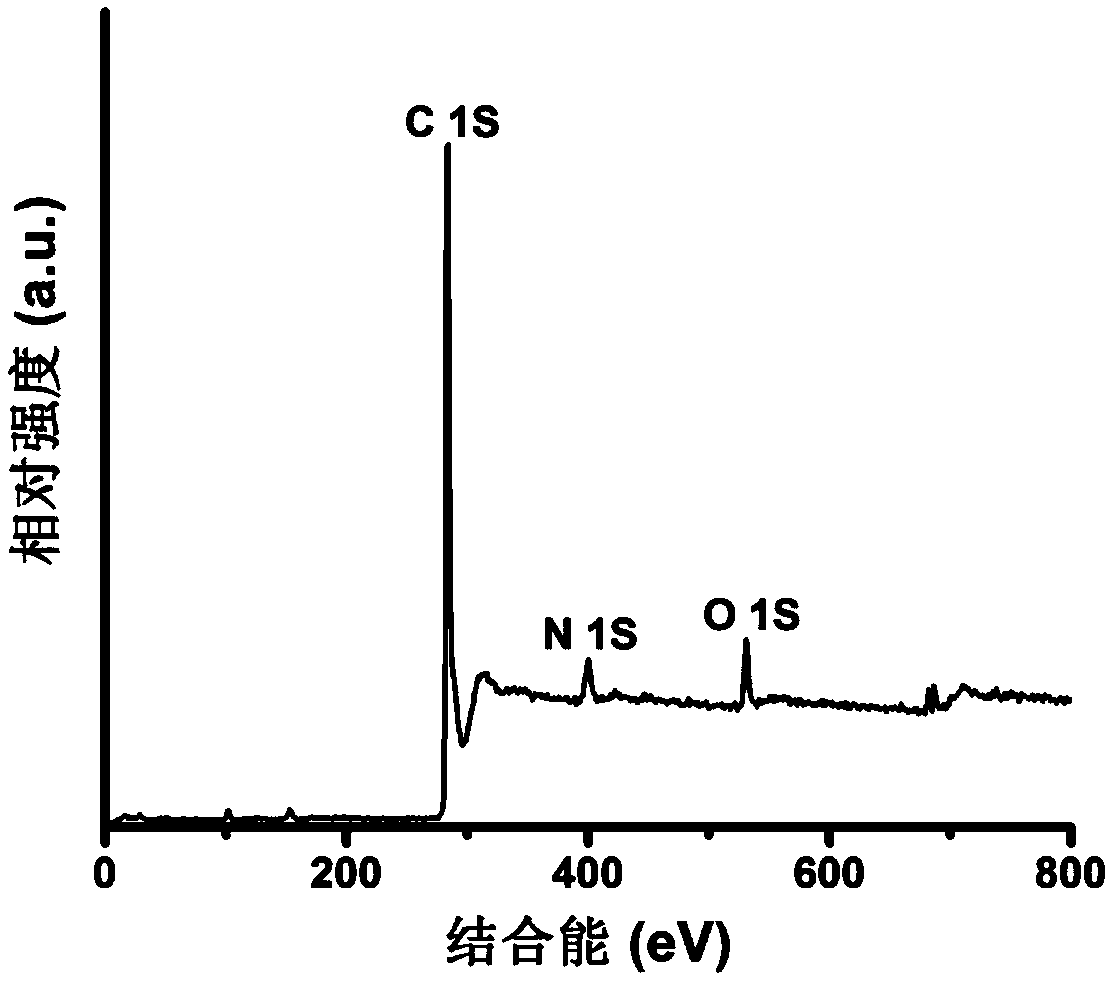

A method for preparing a high-performance nitrogen-doped porous carbon-supported PtNi alloy particle methanol fuel cell catalyst

ActiveCN109103474ADifferent structureLow costMaterial nanotechnologyCell electrodesPtru catalystFuel cells

The invention relates to a method for preparing a high-performance nitrogen-doped porous carbon supported PtNi alloy particle methanol fuel cell catalyst. The method uses waste cigarette end filter core as carbon source and nitrogen source to generate nitrogen-doped porous carbon material in one step; Non-noble metal Ni and noble metal Pt alloy particles are supported on nitrogen-doped porous carbon materials to form catalysts. The invention provides a simple preparation method of nitrogen-doped porous carbon-supported PtNi binary alloy (PtNi / N-HPC) catalyst, which improves the CO poisoning disadvantage of a single Pt-based catalyst.

Owner:HEBEI UNIV OF TECH

Terylene leisure sport fabric with elastic weft and warp

The invention discloses terylene sports fabric with elastic warp yarns and weft yarns. The fabric is characterized in that: at least one of the warp yarn and weft yarn is high-elasticity yarn prepared by the combination of polyethylene terephthalate(PET) and polypropylene terephthalate(PTT), the denier of the warp yarn and weft yarn is between 50 and 300D, and the denier per filament is between 0.5 and 3.2D. The fabric has the characteristics of loose texture, soft touch, good elasticity and drapability, good size stability, easy washing, no need of ironing, water resistance, stain resistant and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Andalusite fiber size and preparation method thereof

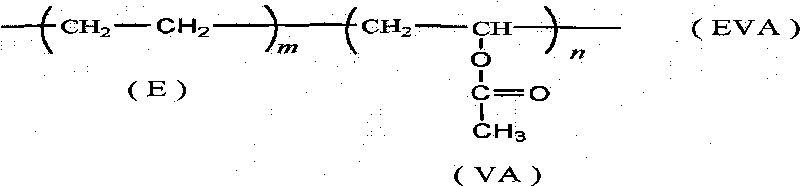

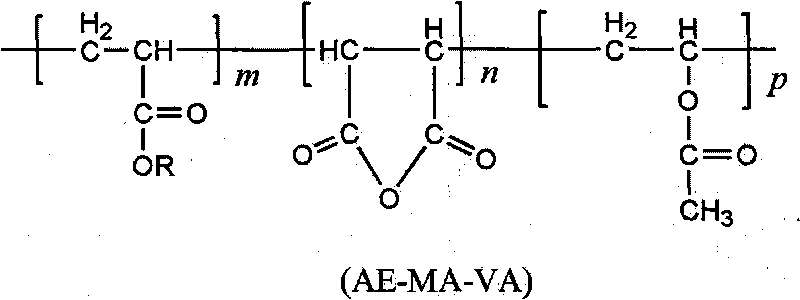

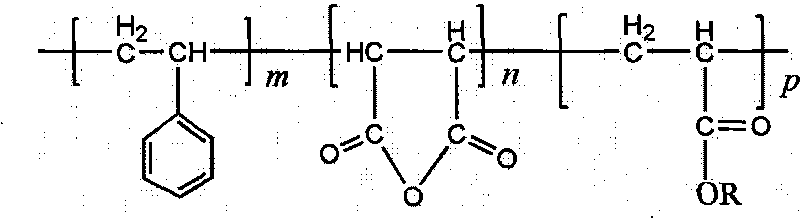

The invention provides a multifunctional size for andalusite fibers, which uses an organic compound containing flexible chains in molecules as a main body and compounds a plurality of auxiliary agents. The size comprises the following components in percentage by weight: 0.5-1.5 percent of film forming agent, 1-10 percent of softening agent (penetrating agent), 0.05-0.3 percent of antistatic agent(antiseptic), 0.01-0.2 percent of dispersant, 0.01-0.07 percent of coupling agent, 0.05-0.1 percent of catalyst and the balance of tap water. The size has good convergence, lubricating property, filmforming property, antistatic property and antiseptic characteristic. Not only fibers processed through the size have flexible, anti-bending and anti-stretching characteristics, but also the fibers sprayed with the size have good dispersive property in water and can be used for the surface soakage treatment of multiple silicate fibers.

Owner:甘肃紫鑫矿业煤化工有限公司

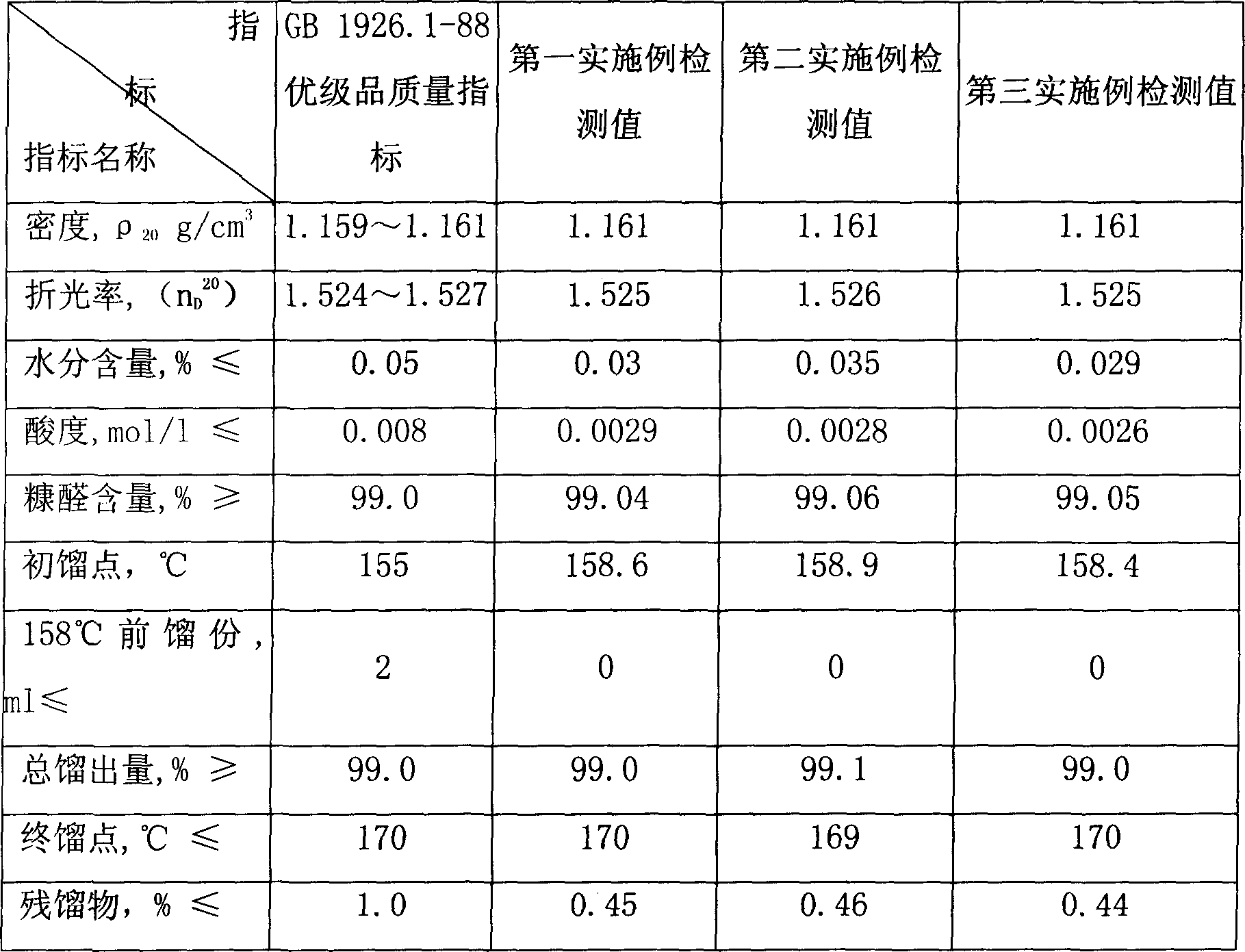

Method for preparing furfural by utilizing cotton stalk

The preparation method for furfural with cotton stalk comprises: cutting the cotton stalk into small bars of 2-5cm; further crushing and rolling to obtain the cotton stalk particles of 1-3cm as well as the corn core particle of 1-1.5cm; mixing the cotton stalk and corn core to stir with acid by great liquid and solid ratio in machine; then, loading into the hydrolysis kettle with filling density as 160-240kg / m3; leading vapor into the kettle, keeping the hydrolysis temperature as 145-180Deg for 2-5h as the hydrolysis period; leading the furfural primary liquid into post-process to extract, refine and obtain the final product. This invention improves yield, ensures product quality, and benefit to environmental protection.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Preparation method of wuta-tsai dedicated organic matrix

The invention discloses a preparation method of a wuta-tsai dedicated organic matrix. The preparation method includes organic matrix fermentation treatment, air drying, crushing treatment, screening, cleaning selection and winnowing, granulation process treatment and other steps. The prepared organic matrix has the total nitrogen content of 10-12%, the carbon content of 65-72%, the total sugar content of 12-16%, the reducing sugar content of 4-8%, and the humic acid content of 10-13%; and the prepared organic matrix can greatly improve the yield of wuta-tsai, improves the quality, and also can effectively reduce the occurrence of diseases.

Owner:陈凯

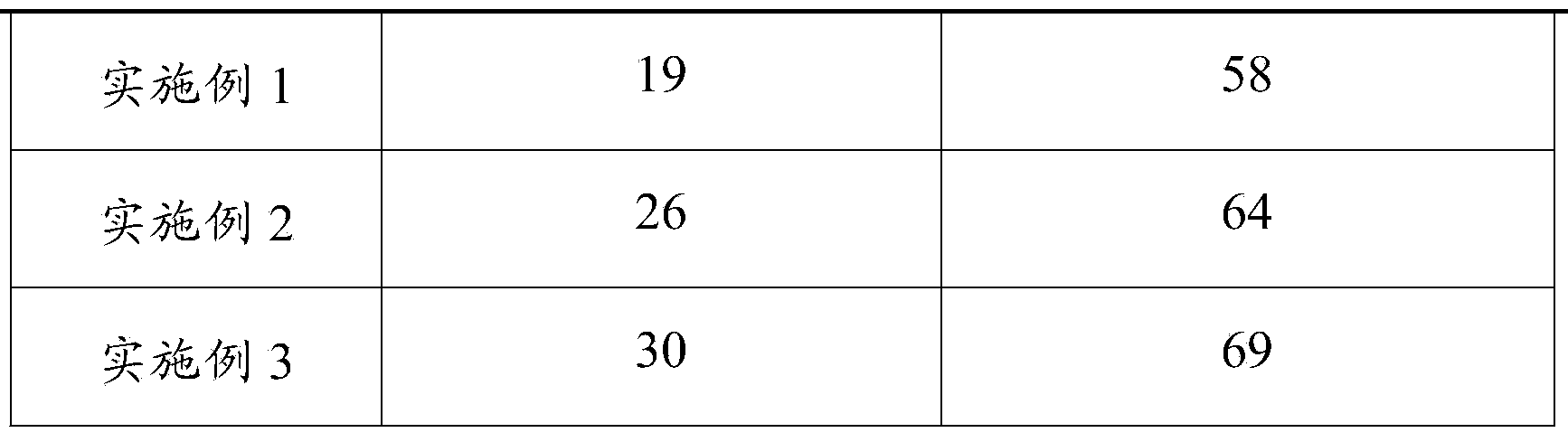

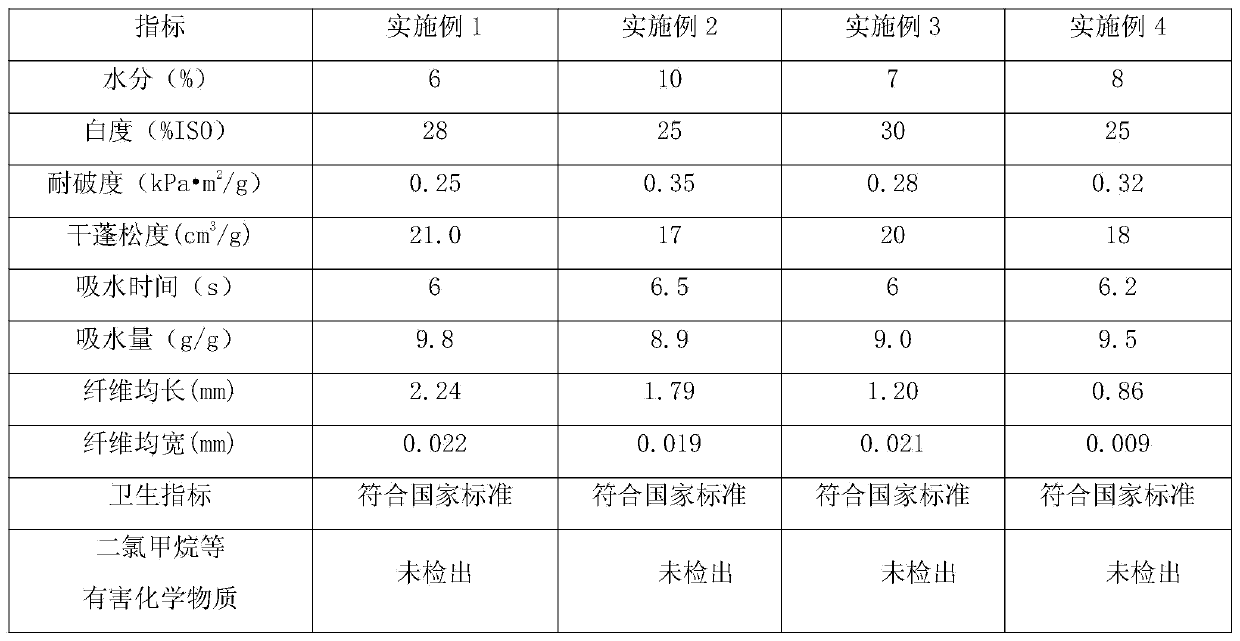

Inflatable fermented milk and preparation method thereof

The invention discloses inflatable fermented milk and a preparation method thereof. The fermented milk contains the following raw materials in percentage by weight: 8%-12% of saccharose, 0-15% of watery cream, 0-0.15% of an emulsifying agent, 0-0.25% of pectin, 0.5%-2% of gelatin, 0.7%-1.5% of starch, 0.004%-0.008% of a fermenting agent and the balance of raw material milk; and fermented milk is further inflated with nitrogen, and the inflation amount of the nitrogen is 75%-85% of the volume of the fermented milk. The inflatable fermented milk is prepared by the steps of mixing all raw materials except the fermenting agent, carrying out homogenization and sterilization, cooling, inoculating the fermenting agent for fermentation, and carrying out encapsulation. The fermented milk is inflated with nitrogen, and the proportion of the raw materials is optimized, so that the inflatable fermented milk with a fluffy, silky and soft texture is obtained; and the obtained inflatable fermented milk has a relatively high viable count, has the stable tissue state in a guarantee period and simultaneously has the sour and sweet flavors of the fermented milk and the taste of a soft mousse cake, and the overflowing of gas is avoided.

Owner:BRIGHT DAIRY & FOOD

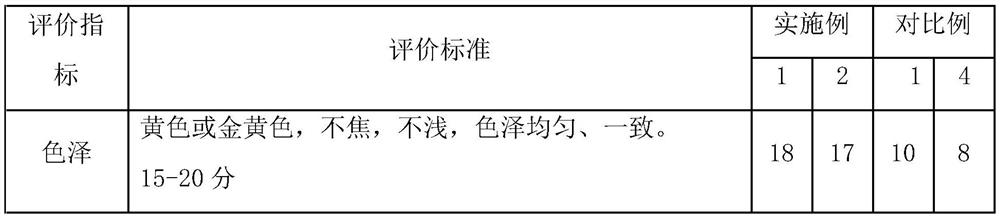

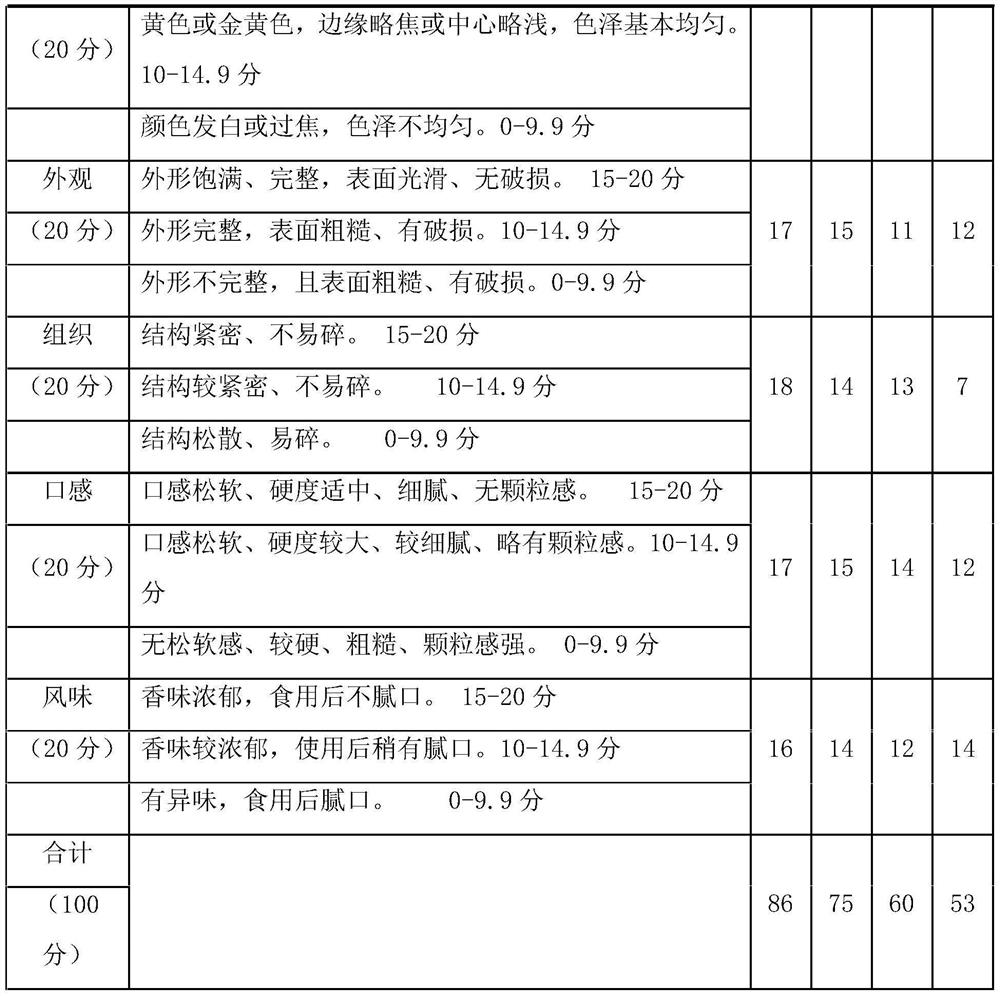

Chenopodium quinoa soda biscuits and making method thereof

InactiveCN109090185ACrispy tasteUnique flavorDough treatmentModified nutritive productsCooking & bakingFlavor

The invention discloses Chenopodium quinoa soda biscuits and a making method thereof. The Chenopodium quinoa soda biscuits comprise, by weight, 30-40 parts of Chenopodium quinoa flour, 30-40 parts ofhigh-gluten wheat flour, 30-40 parts of water, 8-10 parts of vegetable oil, 6-8 parts of butter, 5-8 parts of white granulated sugar, 1-2 parts of active dry yeast and 1 parts of salt. The Chenopodiumquinoa soda biscuits are mainly made by raw materials such as the Chenopodium quinoa flour, the high-gluten wheat flour, the water, the vegetable oil, the butter, the white granulated sugar, the active dry yeast and the salt through procedures such as raw material preparation, primary mixing and fermentation, secondary mixing and fermentation, crisping, rolling and forming, baking and cooling. The making method has the advantages that high proportion of the Chenopodium quinoa flour is kept, the processability deficiency of the Chenopodium quinoa flour is overcome, and the made Chenopodium quinoa soda biscuits are rich in nutrition, crispy in taste and capable of satisfying consumers' requirements on different flavors.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

Indoor foliage plant soilless culture substrate and preparation method thereof

InactiveCN108207545AImprove breathabilityImprove antibacterial propertiesGrowth substratesCulture mediaAntibacterial propertyChemistry

The invention discloses an indoor foliage plant soilless culture substrate and a preparation method thereof, and relates to the technical field of soilless culture substrates. The soilless culture substrate is prepared from 65-75 parts of perlite, 45-50 parts of medical stone, 25-35 parts of sustained release particles, 15-20 parts of antibacterial component and 70-75 parts of water. The soillessculture substrate has good gas permeability, antibacterial properties, and strong water retention and fertilizer retention ability, and is not easy to harden.

Owner:HEFEI SHENWO HORTICULTURE CO LTD

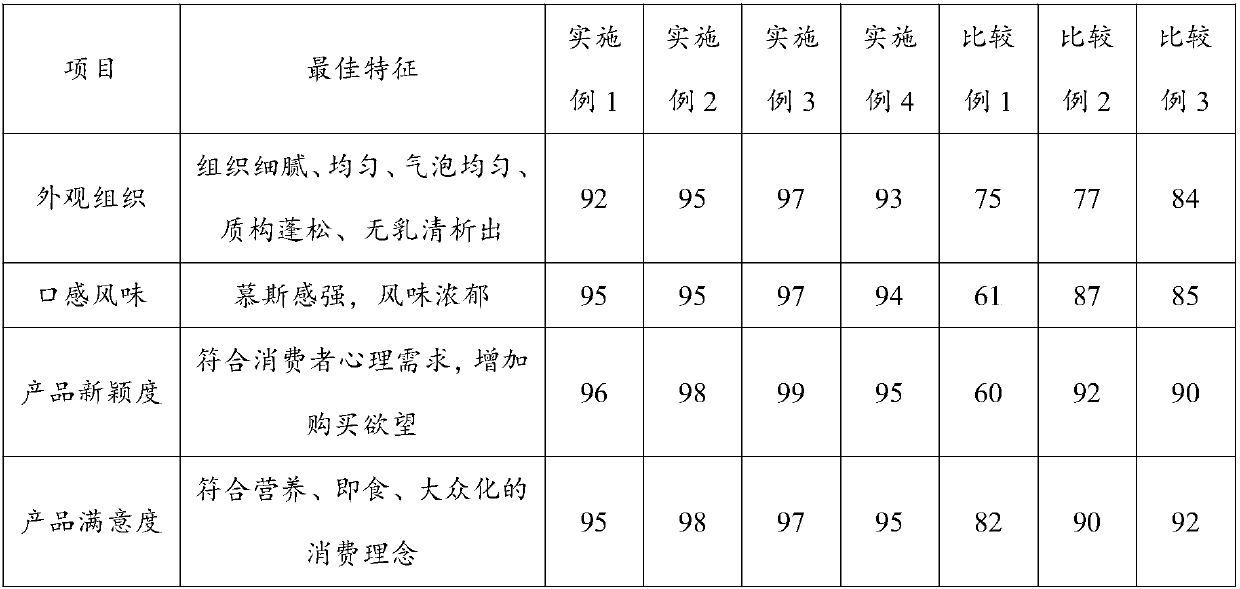

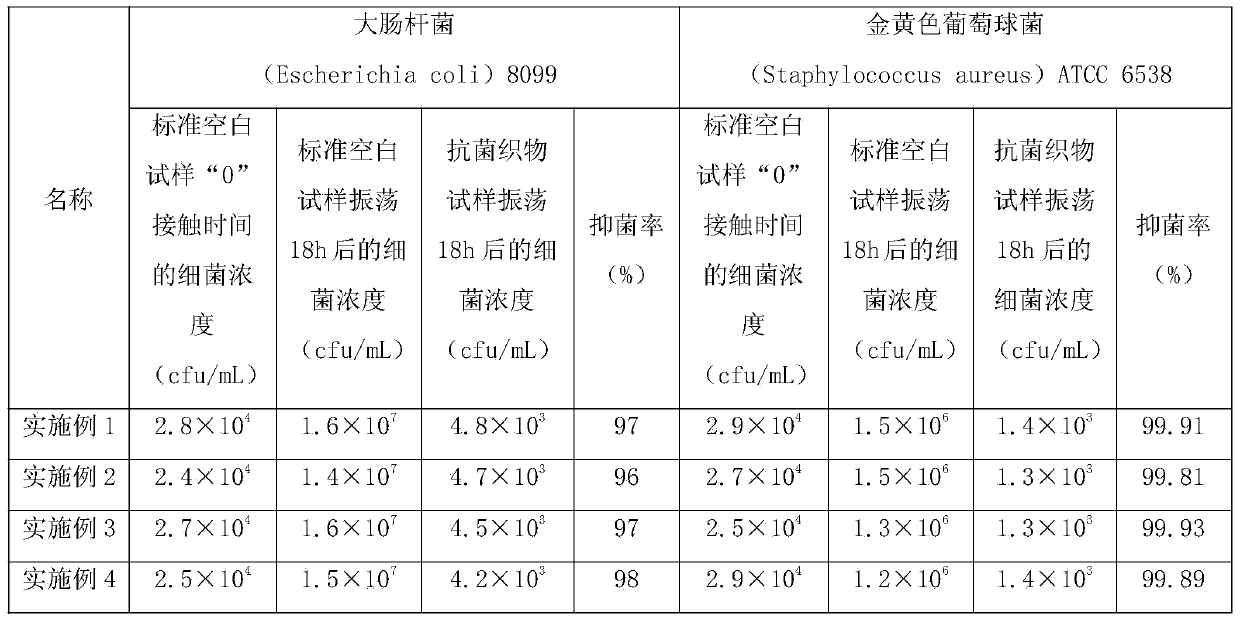

Natural-color fuzzy bamboo pulp with high bacteriostatic activity and preparation method thereof

ActiveCN104195868AReduce usageAvoid residual contaminationPaper/cardboardPulping with inorganic basesBursting strengthFiber

The invention discloses natural-color fuzzy bamboo pulp with high bacteriostatic activity. The natural-color fuzzy bamboo pulp is 25-30%ISO (International Standardization Organization) in whiteness degree, is 0.25-0.35kPa m<2> / g in bursting strength, is 17-21cm<3> / g in dry filling power, is 6-6.5s in water absorption time, is 8.9-9.8g / g in water absorption capacity, is 0.86-3.79mm in average fiber length and is 0.009-0.022mm in average fiber width. A preparation method of the natural-color fuzzy bamboo pulp comprises the steps of pulping raw materials, cooking, washing, modifying and drying, wherein the washing step comprises coarse selection by a vibrating screen, black liquid extraction by a vacuum pulp washer, fine selection by a pressure screen, dedusting by a residue removal and pulp washing by a vacuum pulp washing machine. The natural-color fuzzy bamboo pulp has long fiber length, high flexibility and good water-absorbing ability and water-retaining property, has soft and fluffy texture and strong antibacterial property, can keep the 100% natural color of the bamboo fiber and can remarkably improve the quality of the down-stream products; and the preparation method has the characteristics of simplicity in operation, convenience in production, low cost and environment protection.

Owner:SICHUAN HUANLONG NEW MATERIAL

Method for preparing special organic substrate for cucumbers

InactiveCN104446706ALow densityFluffy textureBio-organic fraction processingBioloigcal waste fertilisersCorn stoverSaw dust

The invention discloses a method for preparing a special organic substrate for cucumbers. The method comprises the following main steps: compounding 12-16 parts of mushroom residue, 20-24 parts of cottonseed hulls, 5-10 parts of crushed corn stalks, 4-8 parts of straw, 12-18 parts of saw dust and 10-12 parts of turf, and then putting the mixture into a fermenting tank made of cement; adding 1-3 percent of organic manure fermentation bacteria for fermentation treatment, then air-drying, crushing, continuing to air-dry and continuing to crush the fermented substrate, finally sieving, cleaning and winnowing, and thus obtaining particles with the grain sizes smaller than 6mm. the substrate can greatly increase the yield of cucumbers, and the fruiting time can be advanced.

Owner:陈凯

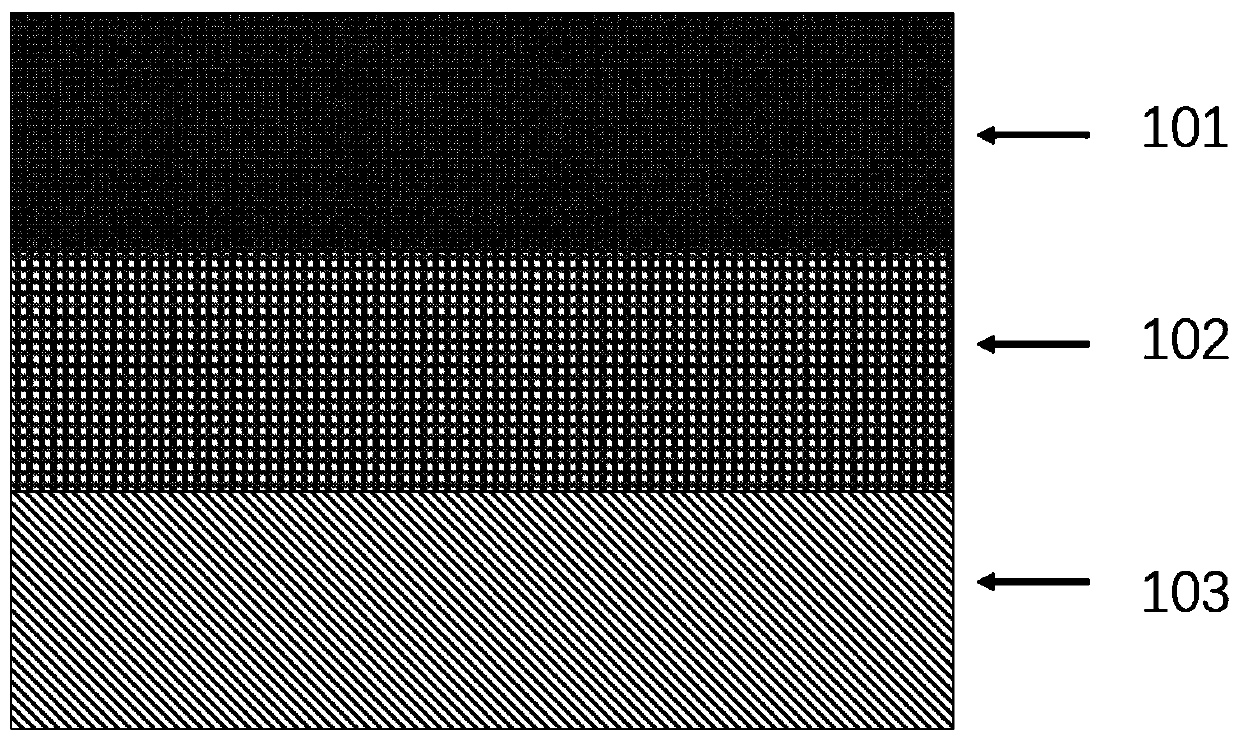

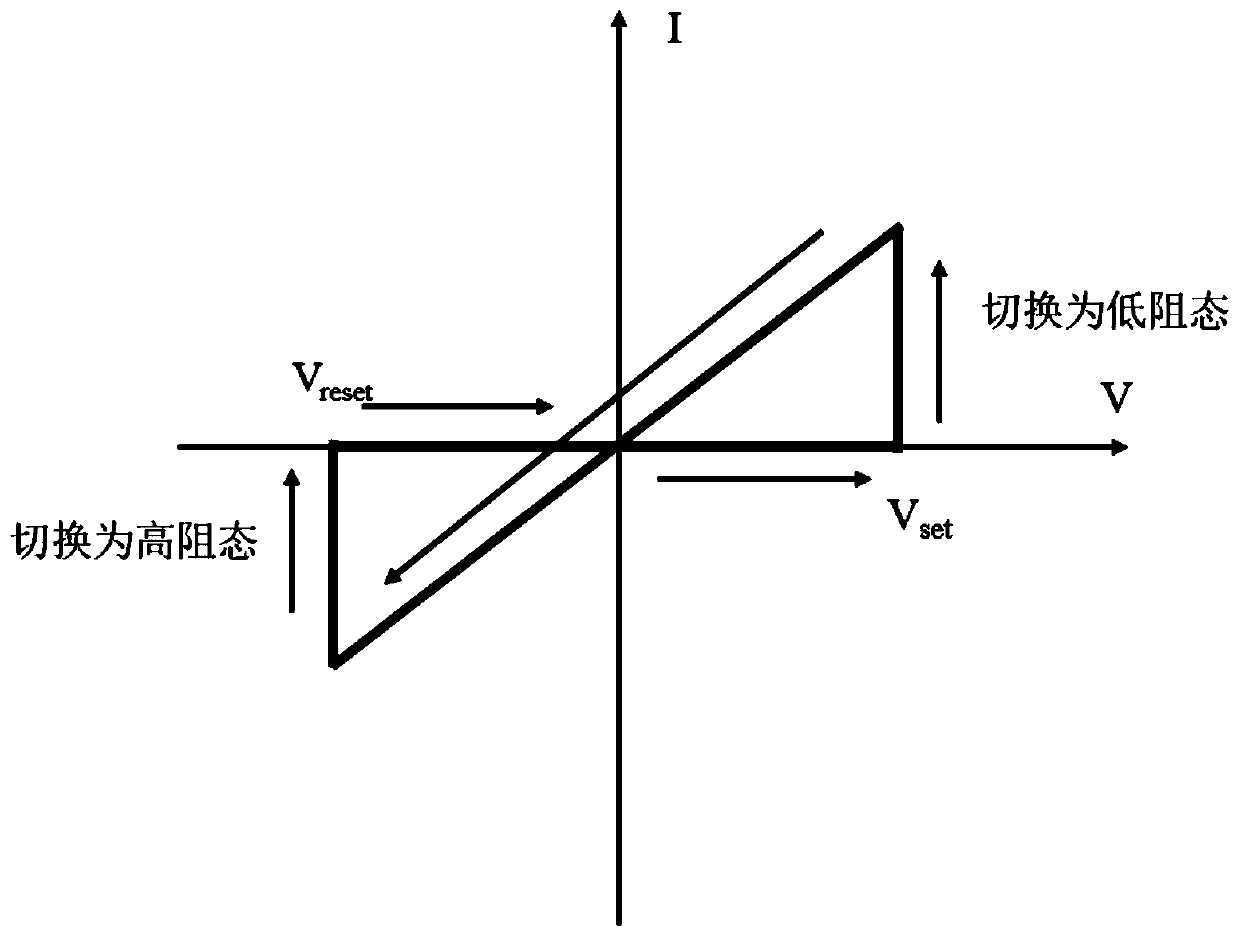

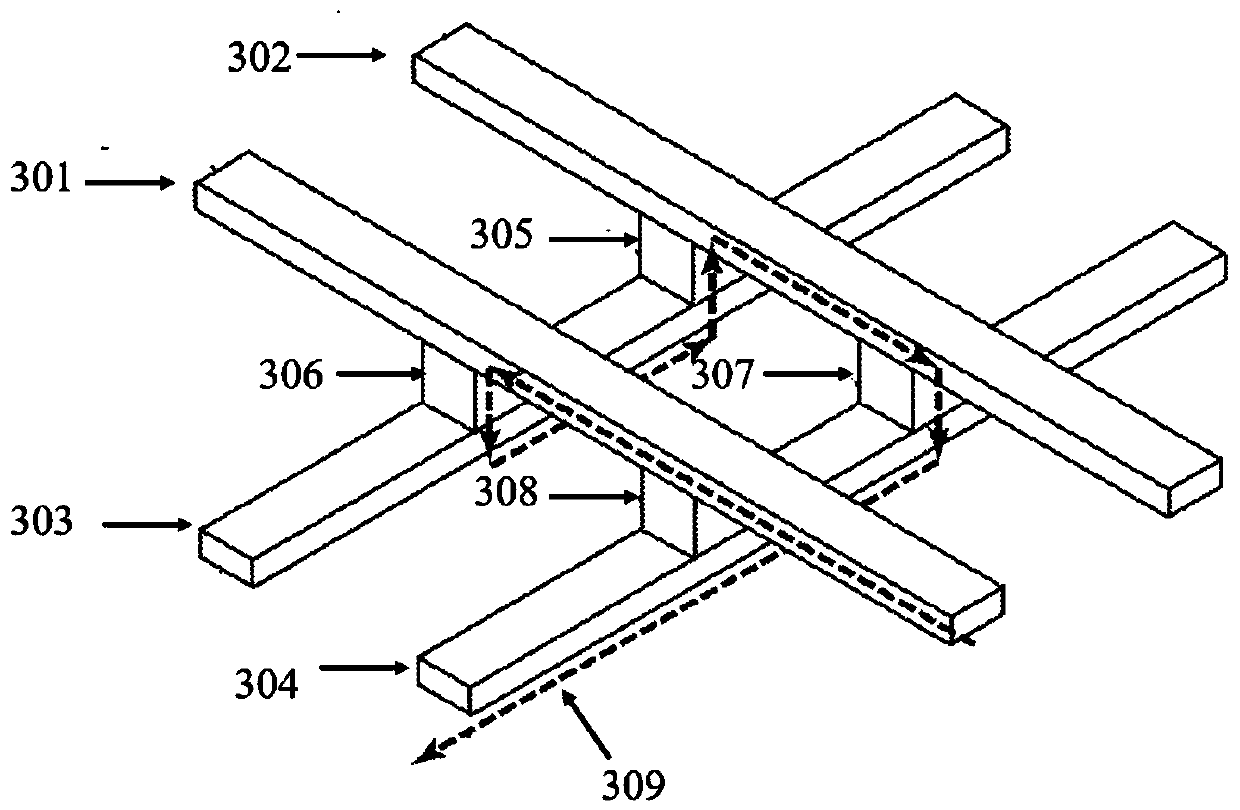

Threshold switch device based on organic and inorganic hybrid perovskite and preparation method of threshold switch device

ActiveCN109755391ASimple preparation processReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceElectrical resistance and conductance

The invention relates to a threshold switch device based on organic and inorganic hybrid perovskite and a preparation method of the threshold switch device, belongs to the field of data storage; the threshold switch device comprises a bottom electrode, a dielectric layer and a top electrode, wherein the top electrode is a silver electrode, the bottom electrode is FTO conductive glass, and the dielectric layer adopts (CsxFAyMA1-x-y)Pb(IzBr1-z)3. The threshold switch device has a high resistance state and a low resistance state. The method comprises the following steps of firstly, dropwise adding a (CsxFAyMA1-x-y)Pb(IzBr1-z)3 solution on the conductive surface of the bottom electrode, starting a glue mixing machine for spin coating, and then dropwise adding anti-solvent chlorobenzene beforethe spin coating is finished, so that the perovskite is rapidly crystallized; secondly, carrying out annealing to obtain a perovskite thin film on the conductive surface; finally, depositing the top electrode on the perovskite thin film, and applying continuous electric pulse stimulation to the silver electrode, so that silver is diffused into the perovskite layer to obtain the threshold switch device. Compared with a traditional threshold switch device, the method disclosed by the invention is carried out in dry air by adopting a low-temperature solution spin-coating process, and a high-temperature process or a high-vacuum or inert environment is not needed, so that the production cost is low, the process is simple, and the method is suitable for large-scale manufacturing.

Owner:DALIAN UNIV OF TECH

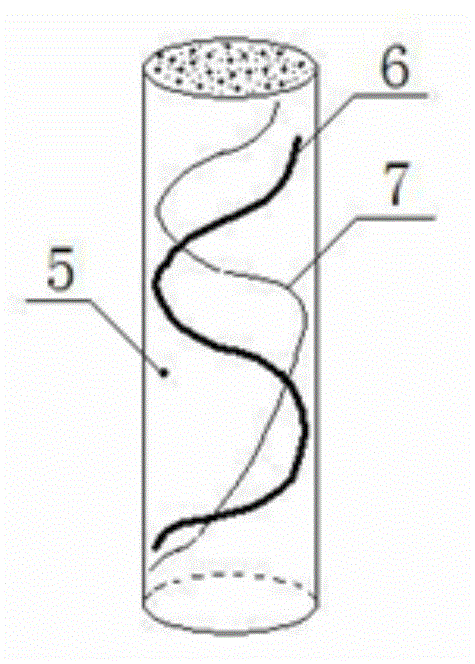

Preparation method of self-colored bamboo fiber filter tip

ActiveCN104138031AEliminate residual pollutionReduce raw material consumptionTobacco smoke filtersPaper sheetPotassium permanganate

The invention discloses a preparation method of a self-colored bamboo fiber filter tip. The method comprises the first step of disintegrating raw materials, that is, disintegrating the bamboo fiber raw materials into sheets through a dry method, the second step of digesting, that is, mixing the sheets and digesting liquor evenly and then digesting the mixture to obtain high-hardness bamboo pulp with a potassium permanganate value ranging from 26 to 38, the third step of washing, that is, washing and screening the high-hardness bamboo pulp through a pressure screen and a vacuum washing and starching machine to obtain clean bamboo pulp with the concentration ranging from 3% to 8%, the fourth step of manufacturing paper with the pulp, that is, manufacturing thin paper sheets with the quantification of 25-40 g / cm3 with the clean bamboo pulp on a paper machine, the fifth step of dividing the thin paper sheets into rolls, that is, slitting the thin paper sheets into the paper rolls with the width ranging from 20 cm to 28 cm, and the sixth step of preparing filter sticks, that is, feeding the paper rolls into a horn mouth of a filter stick forming machine and machining the paper rolls into the circular filter sticks with the diameter ranging from 7.5 mm to 8.0 mm. The preparation method has the advantages that the raw materials are convenient to get, the preparation process is simple, harm to operators is small, the cost is low, and the environment is protected.

Owner:SICHUAN HUANLONG NEW MATERIAL

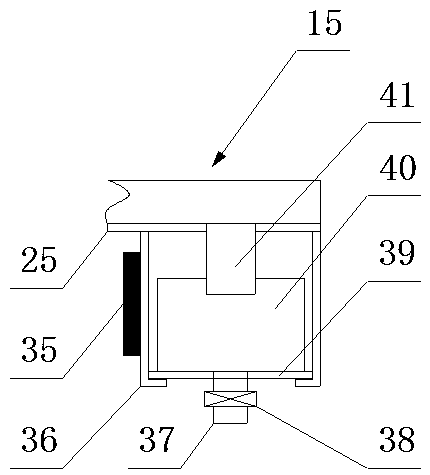

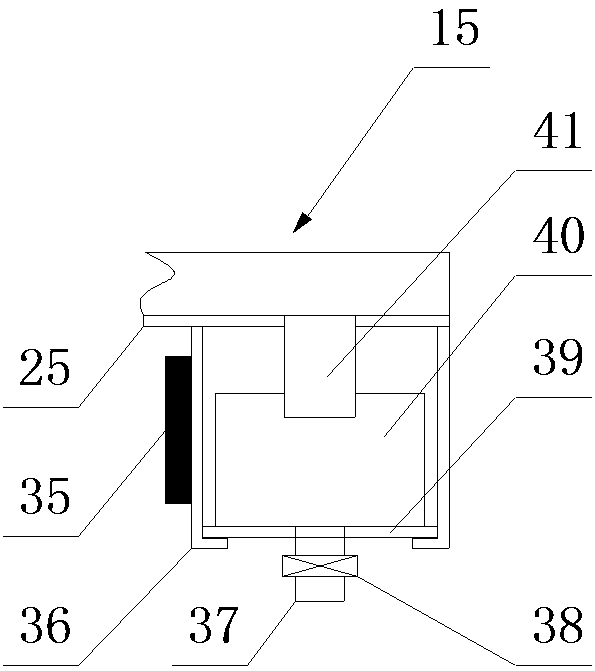

Feeding box capable of compressing traditional Chinese medicine and traditional Chinese medicine decoction pieces

The invention discloses a feeding box capable of compressing traditional Chinese medicine and traditional Chinese medicine decoction pieces. The feeding box comprises a compression rack. The upper endof the compression rack is connected with a plurality of springs, the upper ends of the springs are fixedly connected with nuts, the interiors of the nuts are connected with adjusting rods through threads, and the lower ends of the adjusting rods are fixedly connected with core shafts. The lower ends of the core shafts are connected with upper compressing shaft rollers, a first conveying belt isarranged at the lower ends of the upper compressing shaft rollers, and the upper compressing shaft rollers and lower compressing shaft rollers are kept aligned. The left ends of the lower compressingshaft rollers are connected with shaft rollers, and the shaft rollers are connected with a first speed reducer through a first belt. The left end of the compression rack is fixedly connected with a first vacuum transparent cover, a vacuum pumping mechanism is arranged at the upper end of the first vacuum transparent cover, and the right end of the compression rack is connected with a second vacuumtransparent cover and a third vacuum transparent cover. According to the feeding box, the sizes of the traditional Chinese medicine and the traditional Chinese medicine decoction pieces are effectively decreased through compression, air is isolated, the product quality is improved, meanwhile, automatic metering feeding can be achieved, and thus the working efficiency is improved.

Owner:金寨县真自然农场

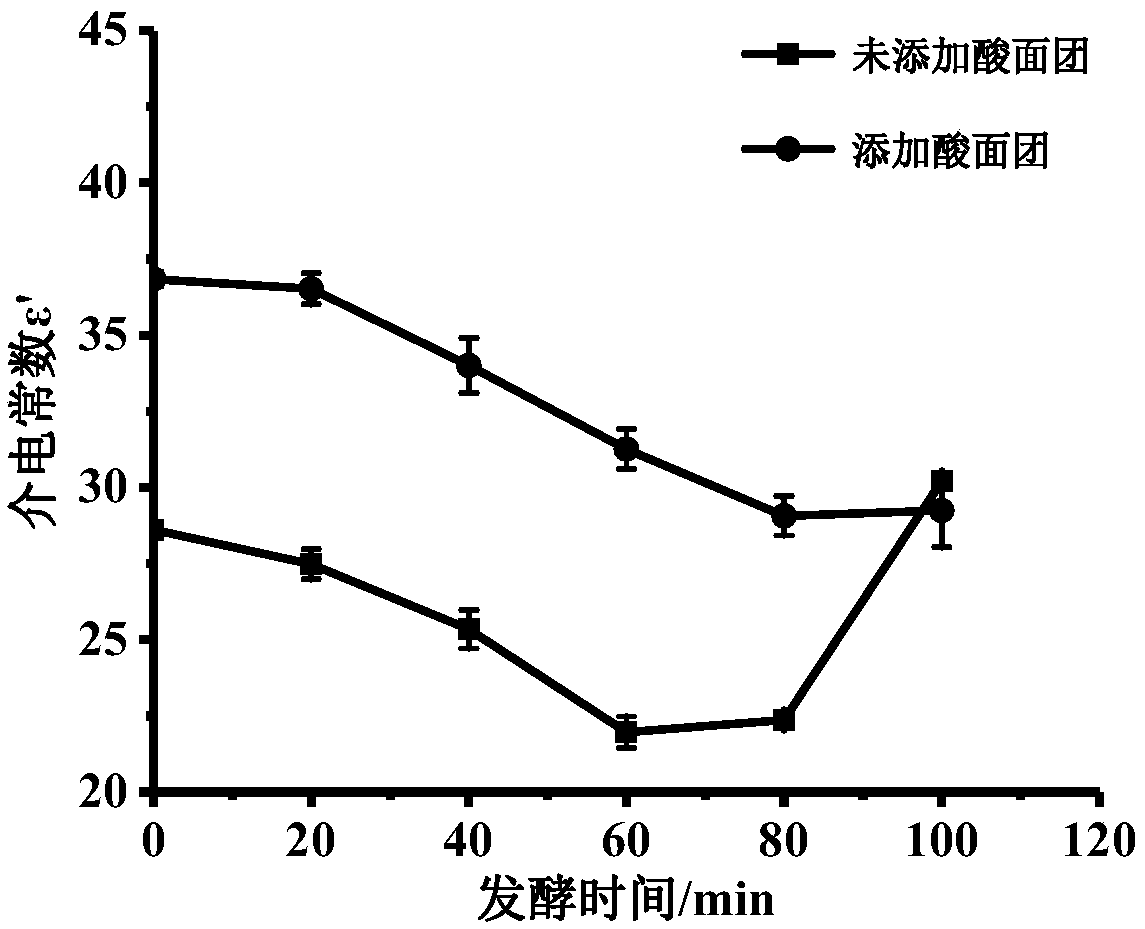

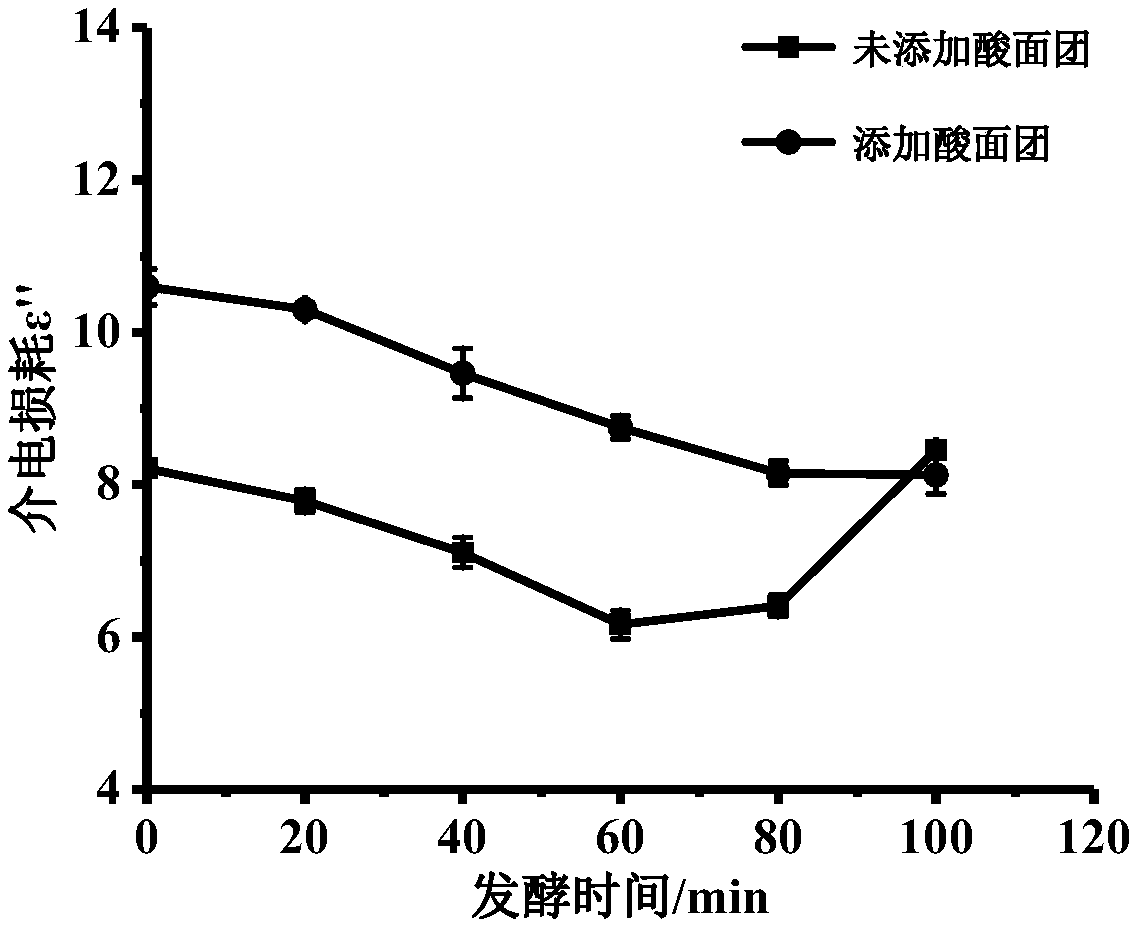

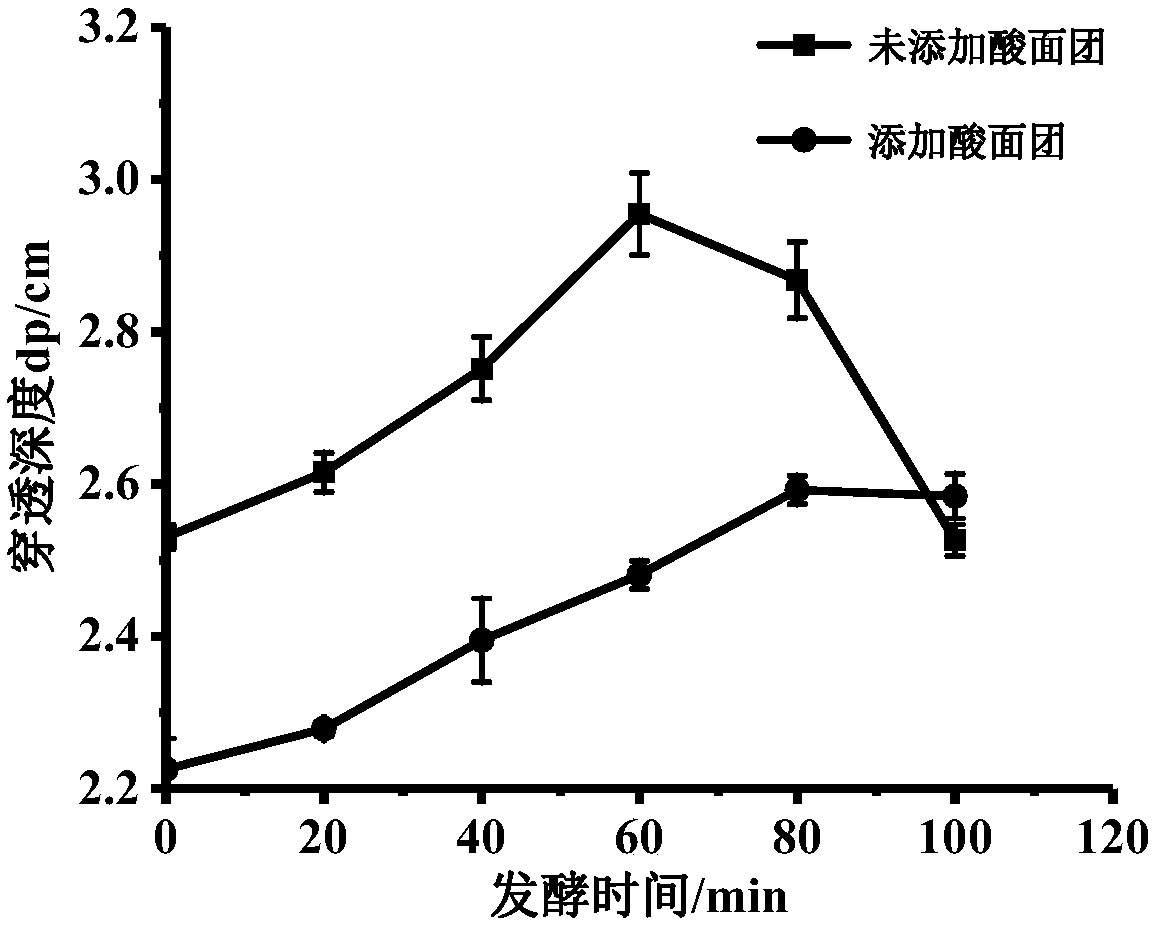

Microwave processing method for sour dough fermented rice flour food

ActiveCN109527377AFluffy textureDelicate tasteDough treatmentYeast food ingredientsFood additiveSlurry

The invention discloses a microwave processing method for a sour dough fermented rice flour food, and belongs to the technical field of food processing. The method comprises the following steps: adding a sour dough to steamed sponge cake raw materials, preparing a steamed sponge cake slurry, fermenting the steamed sponge cake slurry until the dielectric constant is 20-34, the dielectric loss is 6.3-9.0, the water content is 45-55% and the water activity is 0.920-0.980, and carrying out microwave heating to prepare the steamed sponge cake food. The sour dough is added to the steamed sponge cakeraw materials, and the regulation effect of the dielectric properties of the material system in the microbial fermentation process is used, so the problems of hard center, rough and dry surface and poor flavor of the product, caused by too fast and non-uniform heating in microwave heating, are solved without adding a food additive; and the microwave cooking process can be easily instantaneously controlled, has a high heating efficiency, is selective, and can achieve sterilization during heating, so the method has the advantages of simplicity, low energy consumption, energy saving and environmental protection.

Owner:JIANGNAN UNIV +3

Raw white knitted underwear fabric and processing technique thereof

InactiveCN104413576AEnhanced suede effectFluffy and soft structureWeft knittingBiochemical fibre treatmentEnzymeYarn

The invention discloses a raw white knitted underwear fabric and a processing technique. The raw white knitted underwear fabric consists of a double-surface weft-knitted fabric, wherein the double-surface weft-knitted fabric comprises outer side surface loops and inner side surface loops; and short down is arranged on surfaces of at least one of the outer side surface loops and the inner side surface loops. The processing technique of the raw white knitted underwear fabric comprises the following steps of firstly, knitting the double-surface weft-knitted fabric comprising the outer surface loops and the inner side surface loops by using raw white yarns; secondly, treating the fabric by using biological enzyme; thirdly, brushing the surface of the fabric which is treated by the biological enzyme by using a brush; and finally, drying the knitted fabric by using cold, hot, dry and wet air flow and with the aid of up-down vibration and front-back vibration. The double-surface weft-knitted fabric is fluffy, feels soft, does not have dyeing residues or chemical treatment residues, and is beneficial to health of human bodies; a processing procedure is low-carbon and energy-saving; and products are degradable.

Owner:江苏AB集团股份有限公司

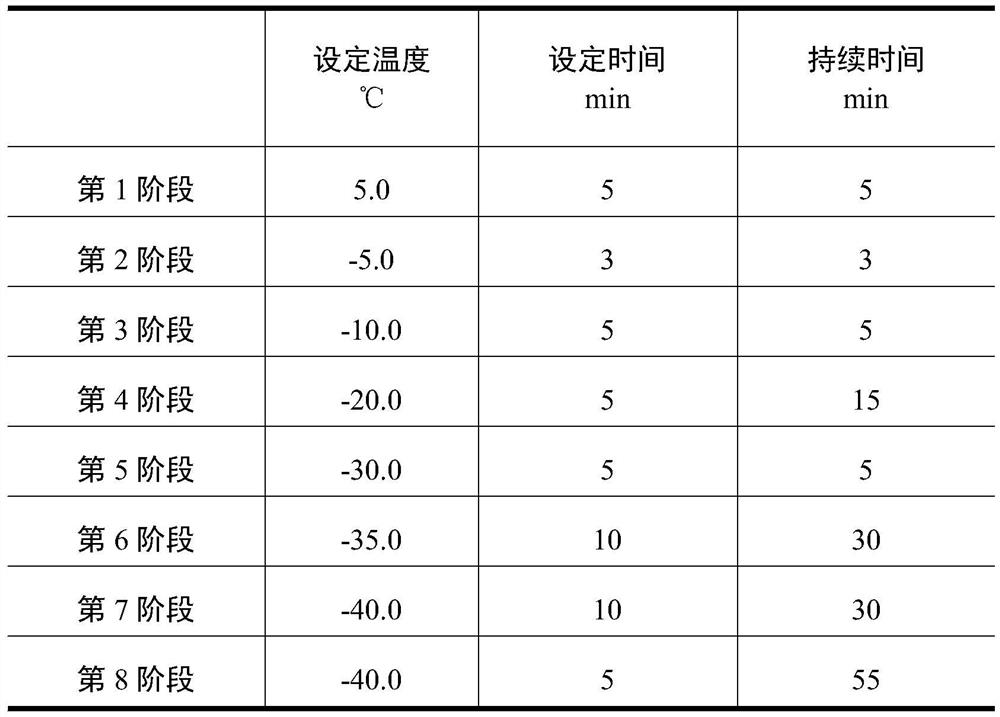

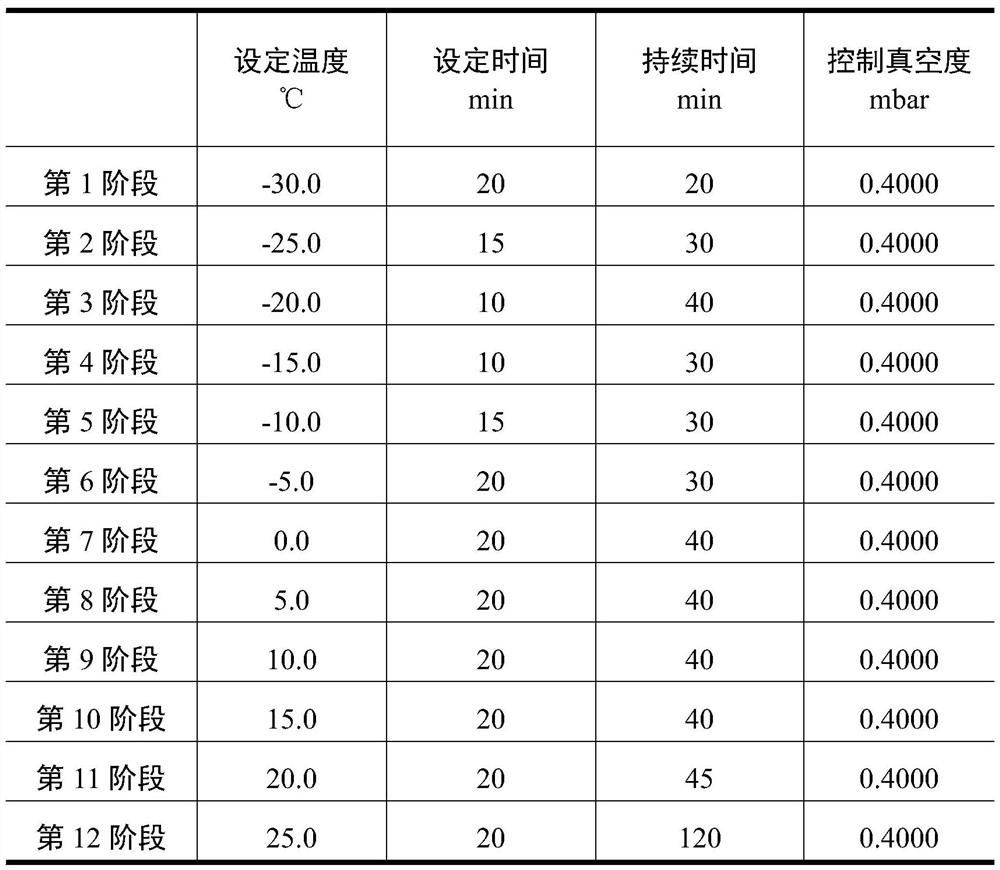

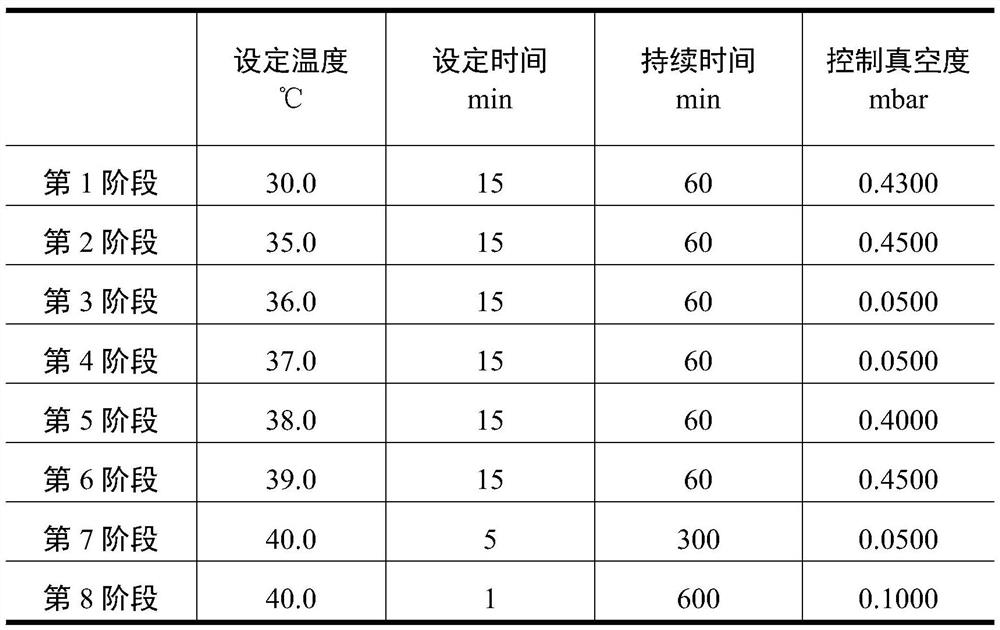

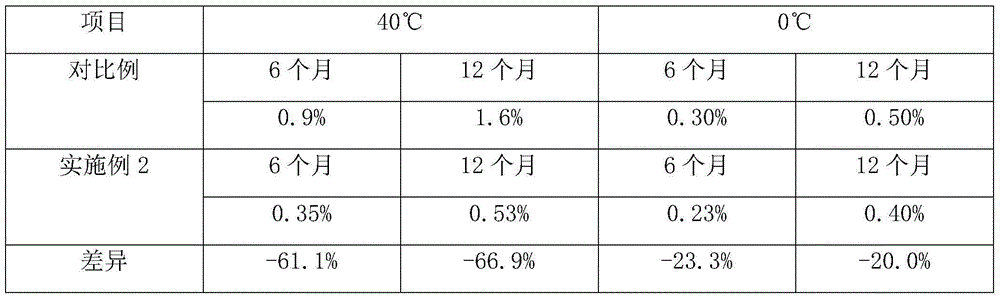

Freeze-drying protective agent for protease K as well as preparation method and application of freeze-drying protective agent

ActiveCN112972662ASimple componentsLow costPowder deliveryPeptide/protein ingredientsSucroseMannitol

The invention provides a freeze-drying protective agent for protease K as well as preparation method and application of the freeze-drying protective agent. The freeze-drying protective agent comprises 0.1 to 0.4 w / v% of beta-alanine, 0.2 to 0.5 w / v% of sucrose, 0.1 to 0.4 w / v% of trehalose, 0.05 to 0.2 w / v% of PVP, 0.05 to 0.2 w / v% of albumin, 0.1 to 0.5 w / v% of mannitol, 0.04 to 0.2 w / v% of sorbitol, 0.05 to 0.2 w / v% of polysaccharides, 0.01 to 0.1 v / v% of Tween-80, 0.5 to 1 v / v% of tertiary butanol and the balance of ultrapure water, and addition mass ratios of the sucrose to the trehalose and the mannitol to the sorbitol are (1-2): 1 and (2-4): 1. A proteinase K freeze-dried powder containing about 30% of the freeze-drying protective agent of the invention has a specific activity of more than 30 U / mg, can be stored at 4 DEG C for more than 2 years, and can maintain stable specific activity when heated at 37 DEG C for 3 months.

Owner:WUHAN AIBO TAIKE BIOTECH CO LTD

Gamma-aminobutyric acid enriched mung bean biscuits and processing method thereof

InactiveCN107751303APromote conversionIncrease contentDough treatmentBakery productsCooking & bakingFlavor

The present invention discloses gamma-aminobutyric acid enriched mung bean biscuits and a processing method thereof. The mung bean biscuits consist mainly of wheat flour, mung bean flour, butter, eggwhite liquid, milk powder, edible salt, highly active yeasts and edible baking soda. The processing method is as follows: dry mung beans are subjected to a heat-moisture treatment at a temperature of45-75 DEG C and a humidity of 90-98% to enrich gamma-aminobutyric acid, then the mung beans are dried and the dried mung beans are crushed to prepare mung bean powder for a standby application; the wheat flour is mixed with a yeast solution, water is added into a mixture, the mixture is kneaded into dough in a dough kneading machine, and the dough is fermented for a standby application; a mixtureof the other wheat flour and pre-treated mung bean powder (at a ratio of 1:1 to 2:1) is added into the fermented dough, then the butter, egg white liquid, milk powder, edible salt and baking soda areadded, then mixture is mixed evenly in the dough kneading machine, and a second fermentation is performed; the fermented dough is roll-pressed, and bakery shortening, shaping, baking and annealing areconducted to obtain the gamma-aminobutyric acid enriched mung bean biscuits. The mung bean biscuits processed by using the technology are crisp in mouthfeel and unique in flavor. At the same time, the dry mung beans are subjected to the heat-moisture treatment to promote a significant increase of the gamma-aminobutyric acid content in the mung beans, and the gamma-aminobutyric acid enriched mungbean biscuits can satisfy consumers' demands for nutritiousness and deliciousness of healthy snack food.

Owner:佛山煜新科技有限公司

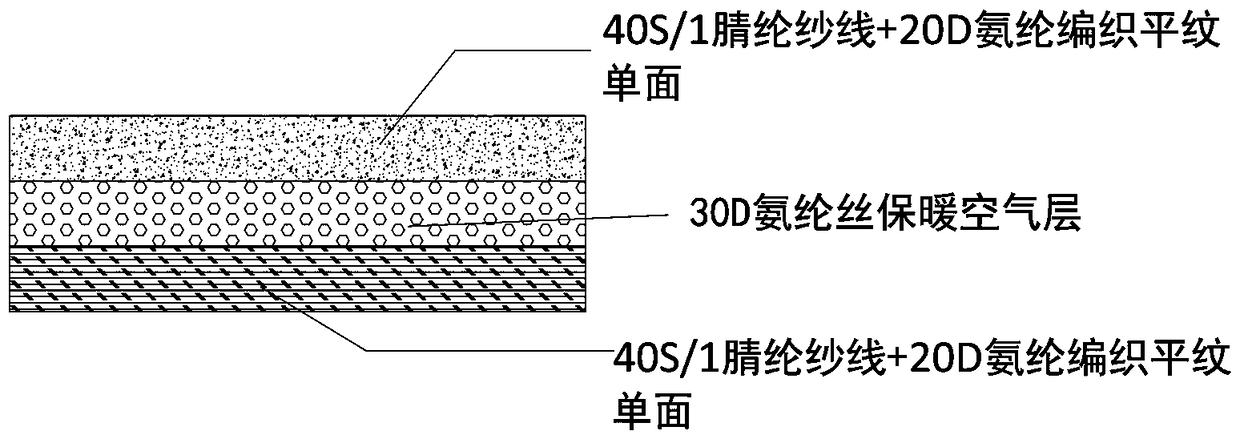

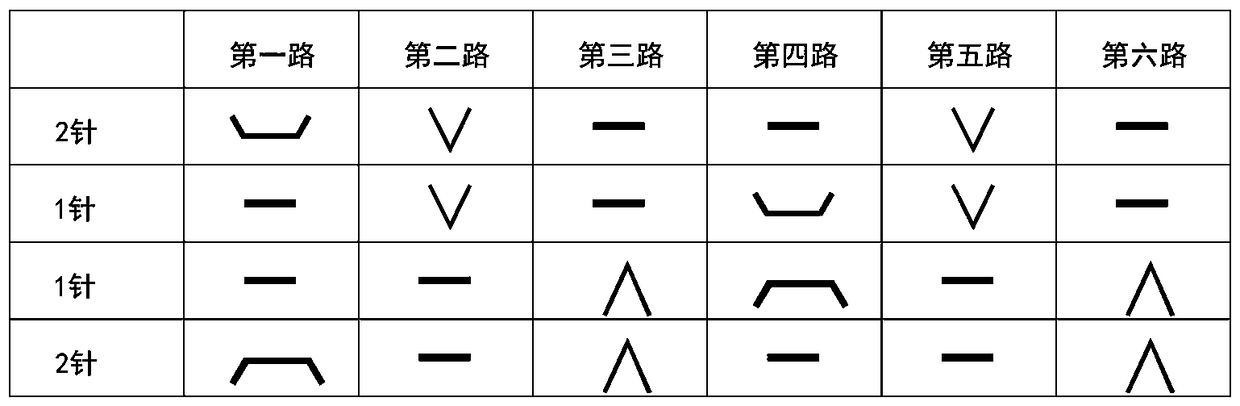

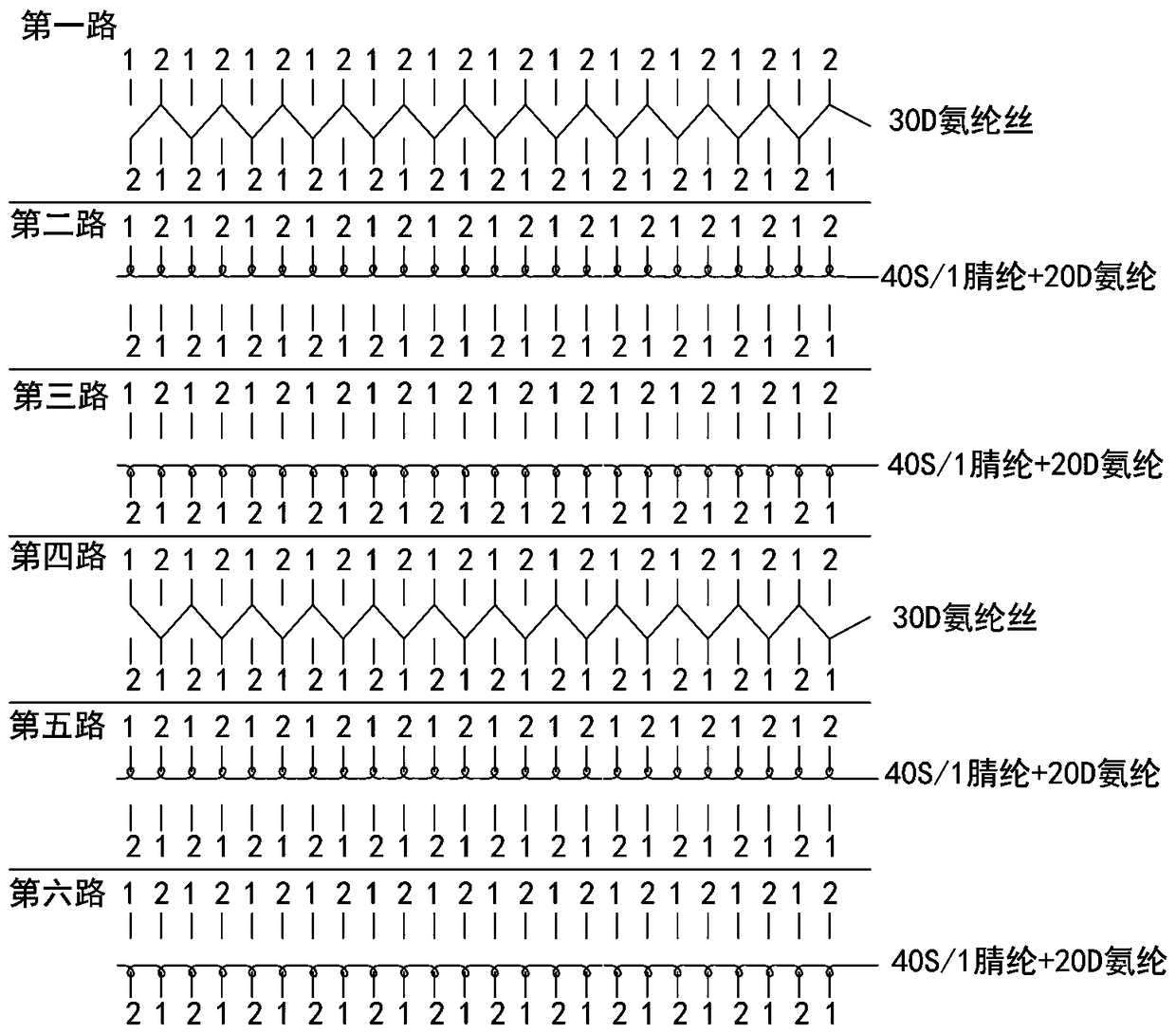

Double-layer air layer pure separation shell fabric capable of being tailored at will

The invention relates to the technical field of shell fabric weaving and specifically relates to a double-layer air layer pure separation shell fabric capable of being tailored at will. The double-layer air layer pure separation shell fabric an upper-layer plain single face and a lower-layer plain single face, wherein the upper-layer plain single face and the lower-layer plain single face are woven from 20 D asahi kasei spandex and 40 S / 1 toyobo acrylic fiber yarns, the upper-layer plain single face and the lower-layer plain single face are woven and connected together through spandex betweenthe upper-layer plain single face and the lower-layer plain single face, an a thermal-insulation air layer is formed between the upper-layer plain single face and the lower-layer plain single face, the spandex is chosen from asahi kasei 30 D spandex, and the double-layer air layer pure separation shell fabric capable of being tailored at will is woven by a six-way circular weaving method. The double-layer air layer pure separation shell fabric disclosed by the invention has the advantages that upper-layer gray cloth and lower-layer gray cloth are connected through the spandex, no chemical adhesion aid is utilized, and environmental friendliness and hygiene are achieved; the double-layer air layer pure separation shell fabric disclosed by the invention is of a unique lock structure, so thatthe shell fabric can be tailored at will, and the problem of hemming of the shell fabric after being tailored is solved; the thermal-insulation air layer is formed between the two layers of cloth, sothat the fabric has more thermal insulation and good breathability.

Owner:广东易通纺织科技有限公司

Additive-free bread crumbs for fried foods and preparation method of additive-free bread crumbs

InactiveCN107801755AHigh nutritional valueCrispy tasteDough treatmentModified nutritive productsWater bathsWater Chestnuts

The invention discloses additive-free bread crumbs for fried foods. The additive-free bread crumbs comprise the following raw materials in parts by weight: 100-140 parts of high gluten flour, 20-40 parts of corn starch, 0.5-0.8 part of yeast powder, 1-4 parts of salt, 1-3 parts of malt sugar, 5-10 parts of modified corn protein powder, 1-5 parts of water chestnut starch, 2-5 parts of mung bean starch, 1-6 parts of small red beans, 2-8 parts of oat, 1-4 parts of honey, 2-4 parts of Chinese wolfberry fruits, 5-10 parts of eggs, 1-2 parts of an emulsifying agent and 10-20 parts of water, whereinthe modified corn protein powder is prepared through the following technologies: uniformly mixing zein with a phosphate buffer solution, adding protein transglutaminase, performing stirring, adding skimmed whey protein and water, regulating the pH value of a system to 7.2-7.6, performing water-bath vibration, then adding alkali protease, performing enzymolysis, performing boiling-water-bath enzymedeactivation, regulating the system to be neutral, performing micro-thinning treatment, adding dry yeast, performing fermentation, performing sterilization, and performing spray drying so as to obtain the modified corn protein powder.

Owner:WUHU FEIYUE FOOD

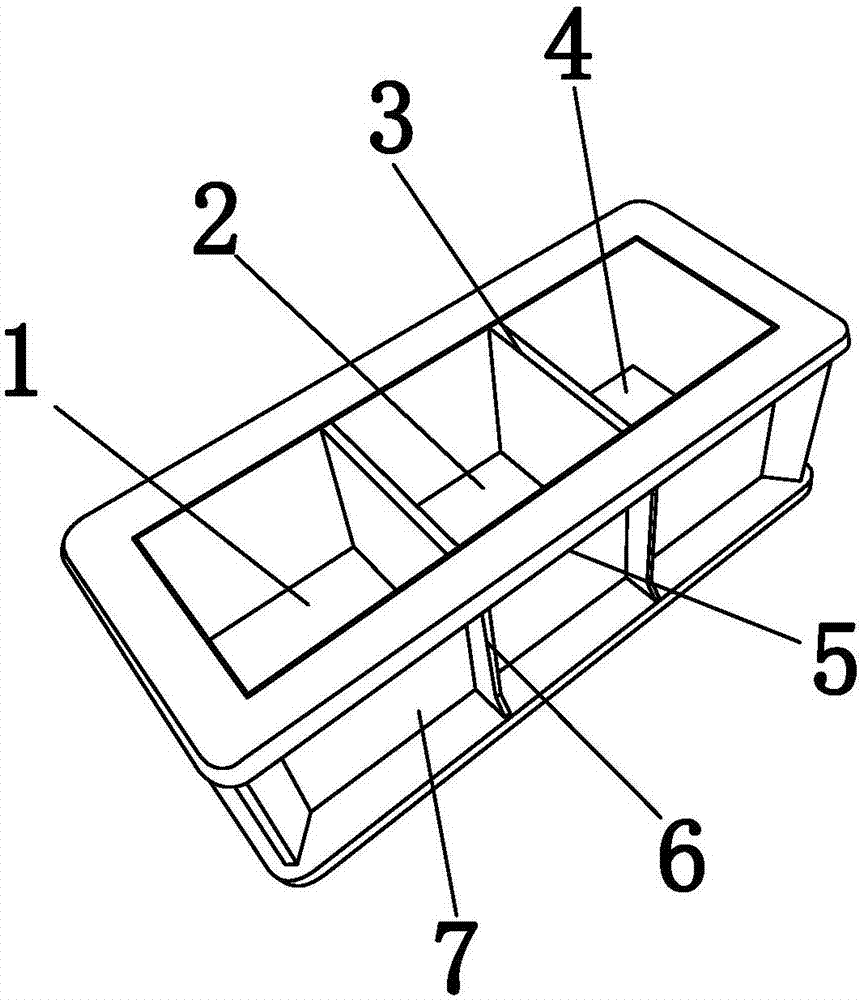

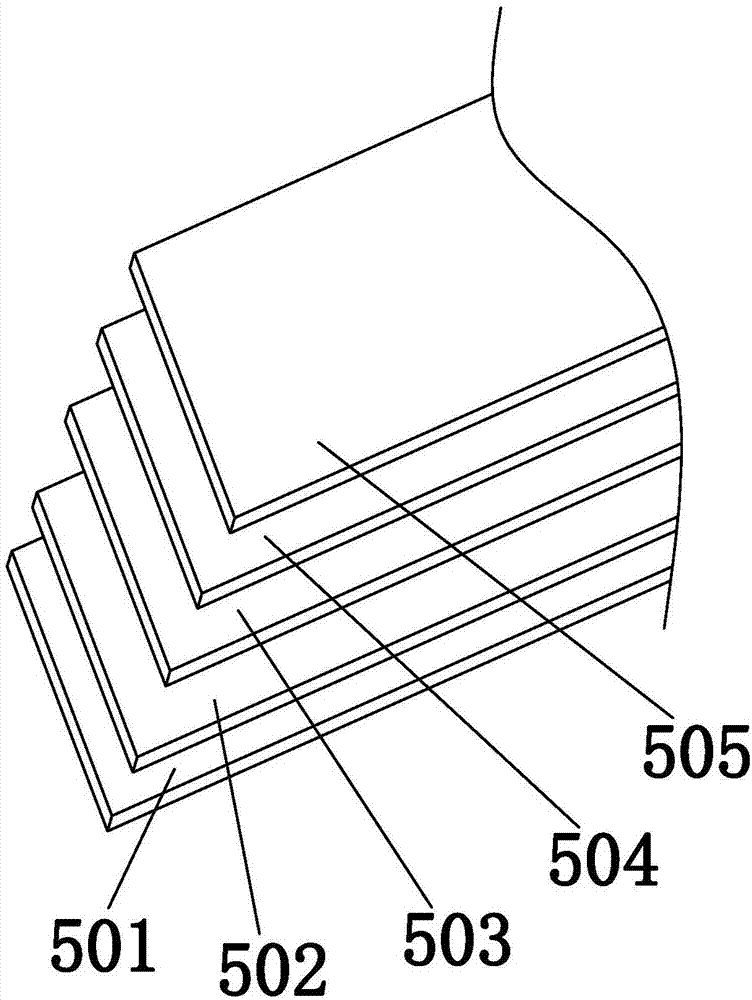

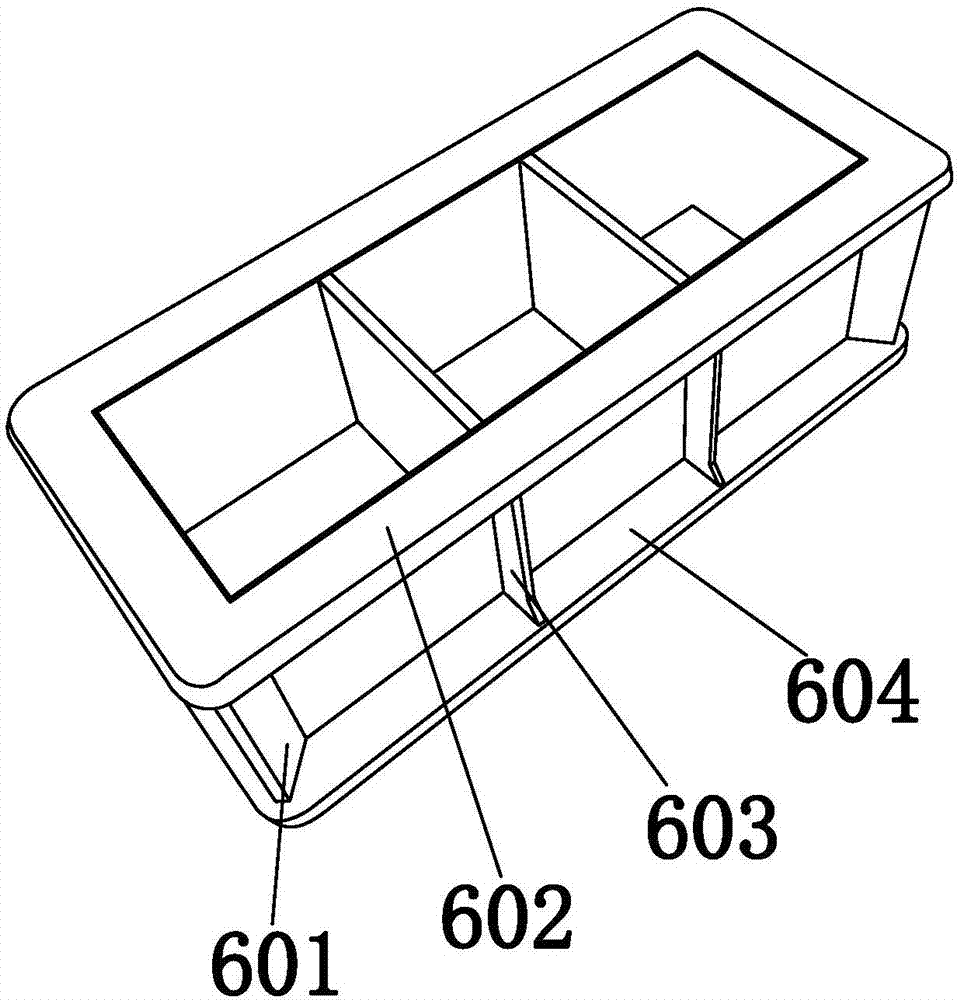

Concrete mould

InactiveCN107379225APrevent burstIntegrity guaranteedCeramic shaping apparatusMetal layered productsDetonationCoating

The invention discloses a concrete mold, the structure of which comprises a first mold cavity, a second mold cavity, a partition, a third mold cavity, a shell, a bursting device, and an explosion-proof panel. In the inner cavity of the shell, the partition plate divides the inner cavity of the shell into the first cavity, the second cavity, and the third cavity respectively, and the first cavity, the second cavity, and the third cavity are connected to prevent bursting The device is set on the side of the shell, and the explosion-proof panels are provided with four pieces and are perpendicular to each other. The explosion-proof panels are fixed on the side of the shell and form an integrated structure with the shell. , Reinforcement panel, rectangular reinforcement block, L-shaped reinforcement block, which can avoid the fluffy texture of the formed mold blank, which is easy to adhere to the inner wall of the mold or even slag when it is taken out, effectively ensuring the integrity of the mold. Rectangular reinforcement block , The L-shaped reinforcement block can prevent the shell from bursting due to excessive pressure in the inner cavity, and has high practicability.

Owner:广州市鹭江远科技有限公司

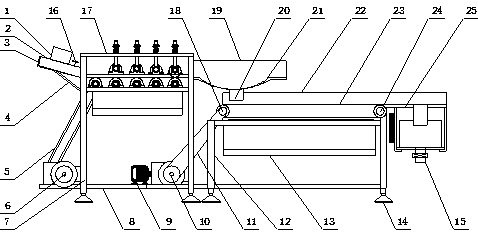

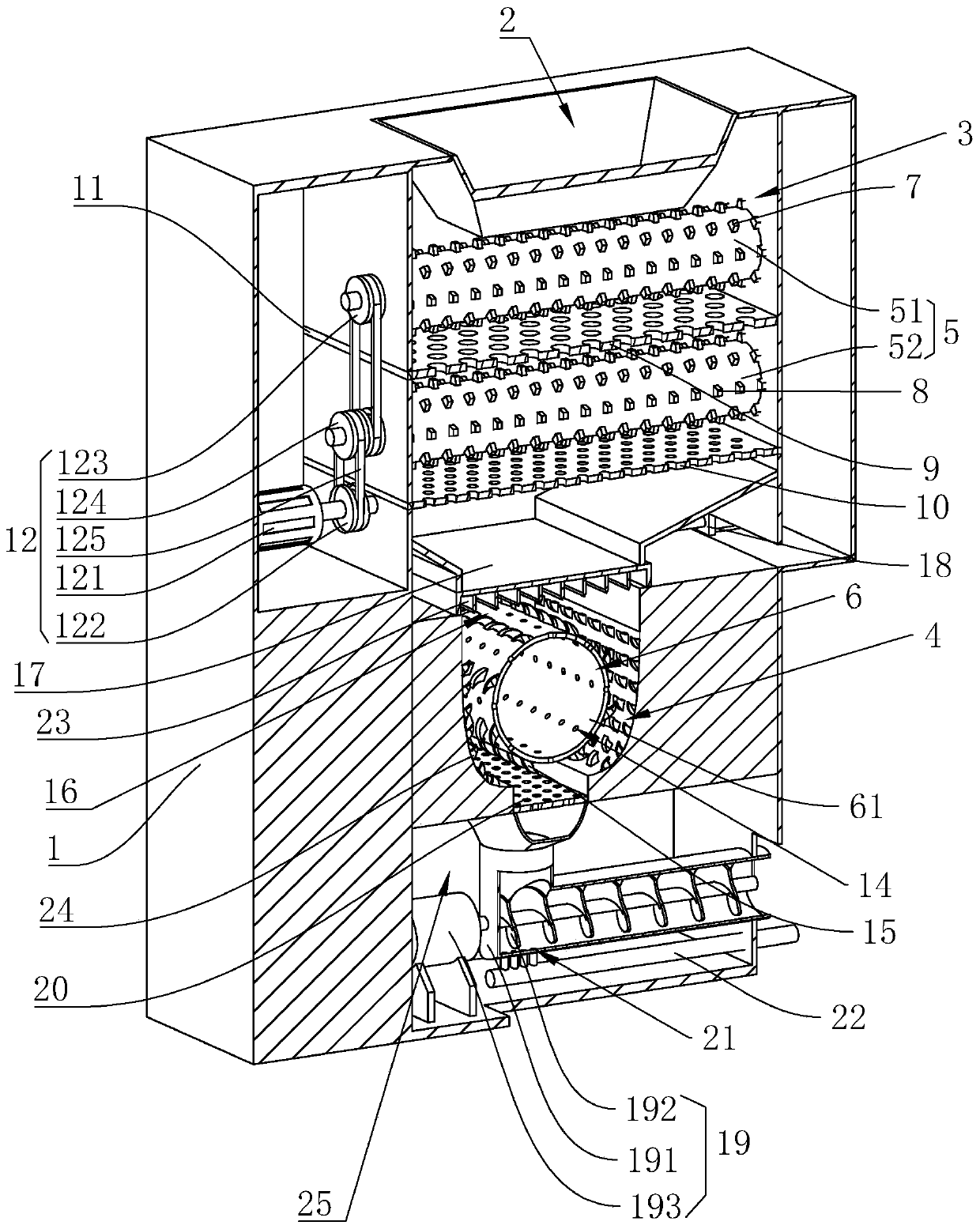

Wood pulp crushing device and hygienic product production equipment using same

ActiveCN111254731AEffective isolationFluffy textureRaw material divisionElectric machineryEquipment use

The invention relates to a wood pulp crushing device, which comprises a machine body, wherein a feeding hole is formed in the machine body; a first cavity and a second cavity are formed in the machinebody. A first crushing group is arranged in the first cavity; a second crushing group is arranged in the second cavity; the second crushing group comprises a hollow cylinder and a crushing motor; thecrushing motor is fixedly mounted on the machine body; the hollow cylinder is rotationally mounted in the second cavity; an air inlet pipe is mounted at one end of the hollow cylinder; a plurality ofair outlet holes are formed in the peripheral side wall of the hollow cylinder; third crushing teeth are arranged on the peripheral side wall of the hollow cylinder; the first crushing group and thesecond crushing group are communicated through a transition opening, a baffle plate used for opening and closing the transition opening is installed in the machine body, a driving air cylinder used for driving the baffle plate to move is installed in the machine body, a discharging mechanism is arranged in the machine body, and the discharging mechanism and the second cavity are separated througha third screen. The invention further discloses hygienic product production equipment using the device. The wood pulp crushing device is good in pulverizing effect, not prone to knotting and more complete in pulverizing.

Owner:上海舒晓实业有限公司

Application of bamboo powder culture medium to industrial cultivation of white flammulina velutipes

InactiveCN112293156AImprove water absorptionImprove water retentionCultivating equipmentsMushroom cultivationMyceliumSoybean hulls

The invention discloses an application of a bamboo powder culture medium to industrial cultivation of white flammulina velutipes. The white flammulina velutipes is cultured by the bamboo powder ediblefungus culture medium, and the bamboo powder edible fungus culture medium is composed of the following raw materials in percentage by weight of 5-10% of bamboo powder, 30-40% of corncob, 30-35% of rice bran, 10-20% of bran, 2-3% of dry bean dregs, 5-8 brewer's grains, 5-6% of soybean hulls, 1-3% of shell powder and 0-1% of light calcium carbonate. The application of the bamboo powder edible fungus culture medium to cultivation of the white flammulina velutipes comprises the following steps of 1) putting the bamboo powder edible fungus culture medium into a culture bottle; 2) inoculating a liquid strain into the culture bottle; 3) after hyphae cultured in the step (2) overgrow the culture bottle, performing mycelium stimulation treatment; 4) after bud pressing is finished, performing lightinhibition and wind inhibition on mushroom buds; 5) increasing the concentration of CO2 to 10000 ppm or above, and promoting growth of stipes of the flammulina velutipes; and 6) performing harvestingwhen the harvesting height is achieved. The application has the advantages of being low in cost, good in mushroom fruiting effect and the like.

Owner:江苏华绿生物科技股份有限公司

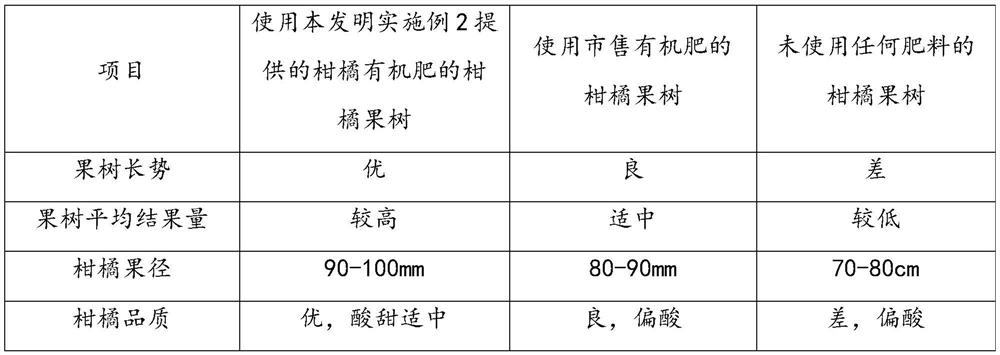

Special fertilizer for citrus and production method of special fertilizer

PendingCN112159265AImprove qualityGreat tasteSuperphosphatesBio-organic fraction processingFruit treeCitrus tree

The invention provides a special fertilizer for citrus and a production method of the special fertilizer, and belongs to the technical field of agricultural fruit tree planting. The special fertilizerfor citrus comprises the following components in parts by weight: 3-5 parts of ammonium phosphate, 2-3 parts of potassium chloride, 2-3 parts of magnesium sulfate, 1-2 parts of borax, 1-2 parts of zinc nitrate, 0.1-1 part of calcium superphosphate, 10-50 parts of a biological organic fertilizer and 0.1-1 part of a fermentation inoculant. The invention also provides a production method of the special fertilizer for citrus. The special fertilizer for citrus can guarantee high yield and high quality of citrus and stable growth of citrus trees, improves the soil environment, and provides sustainable development for planting of a citrus orchard.

Owner:HUAZHONG AGRI UNIV

Calcium-rich instant egg white powder and preparation method thereof

The invention belongs to the technical field of functional food and relates to calcium-rich instant egg white powder and a preparation method thereof. The preparation method comprises technical processes of preparation of main materials, preparation of egg white peptide calcium chelate, blending of main and auxiliary materials, low-temperature superfine grinding and high-temperature sterilization. The auxiliary material components in the calcium-rich instant egg white powder comprise, in percentage by weight of the main materials, 4%-6% of the egg white peptide calcium chelate, 3%-5% of maltodextrin, 0.5%-5% of sucralose and 0.2%-0.5% of perfume. The calcium-rich instant egg white powder which can supplement calcium and high-quality amino acid, is instant when made, has light yellow color, tastes fine and mellow and is easy to digest by the human body is prepared while the problem of lower calcium absorption rate is solved.

Owner:DALIAN POLYTECHNIC UNIVERSITY

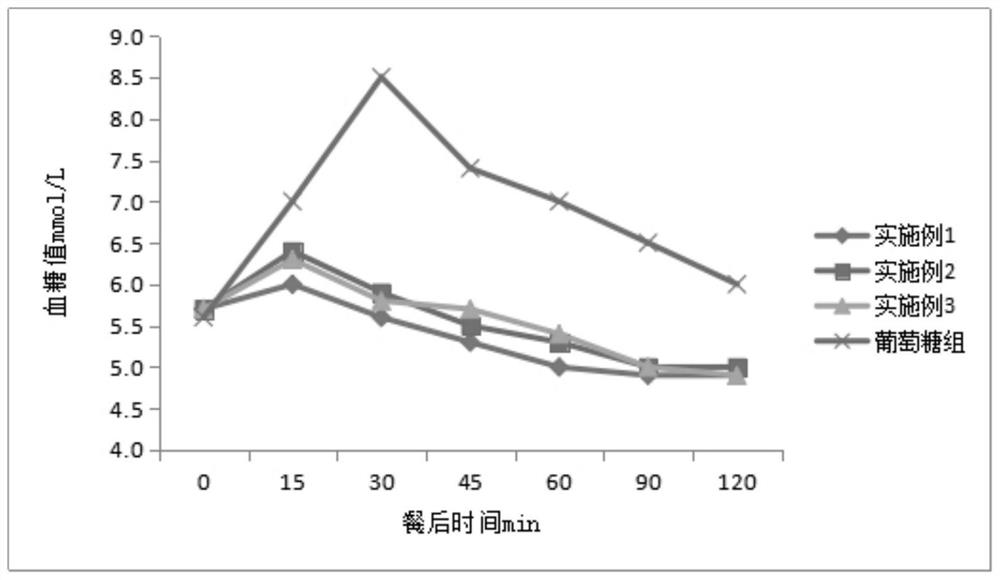

High-protein high-dietary-fiber granular nutrition bar and preparation method thereof

PendingCN112352805ABalanced compositionImprove water absorptionModified nutritive productsBiotechnologyGlycaemic index

The invention discloses a high-protein high-dietary-fiber granular nutrition bar and a preparation method thereof. The nutrition bar comprises the components in parts by mass: 26-32 parts of protein powder, 20-28 parts of dietary fibers, 8-12 parts of sugar alcohol, 6-10 parts of edible oil and 5-8 parts of protein particles. The formula disclosed by the invention is soft and non-sticky in taste,low in sugar alcohol addition amount, low in glycemic index and strong in satiety, and is suitable for diabetics, weight-reducing people and athletes to eat; and meanwhile, the added oligosaccharide can regulate the gastrointestinal health of a human body, and added chestnut peel extract can effectively control the postprandial blood sugar.

Owner:杭州赛能医药科技有限公司 +1

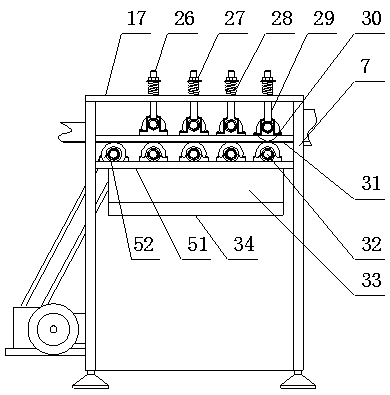

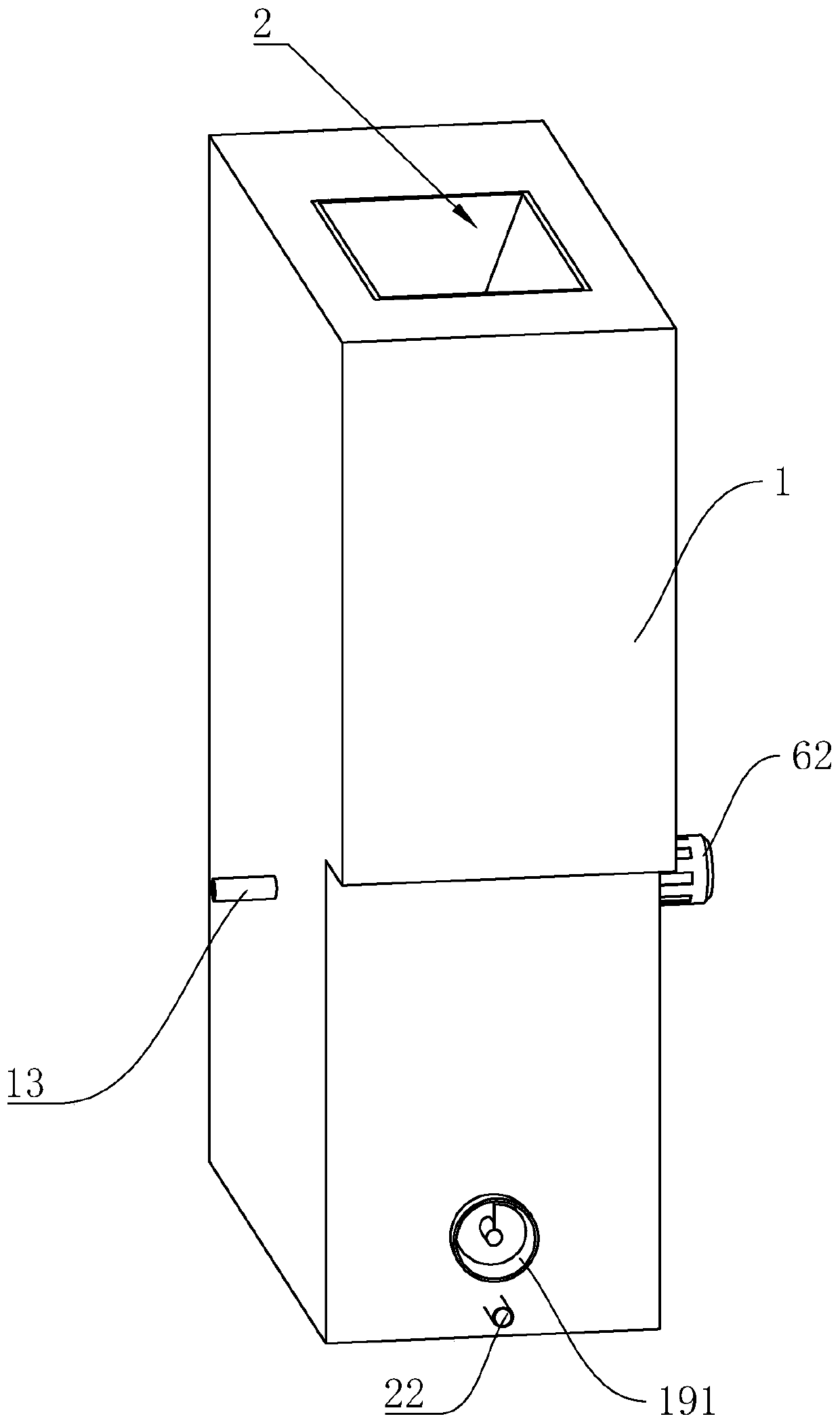

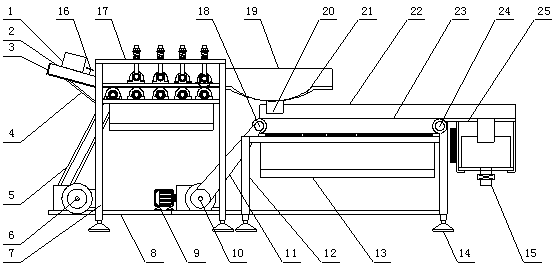

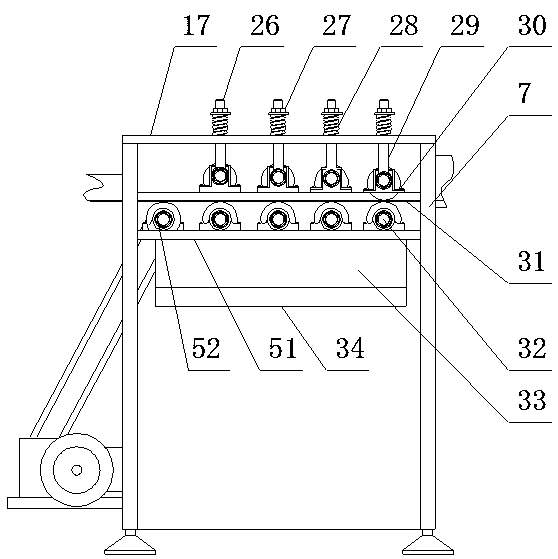

Feeding box for pressing traditional Chinese medicinal materials and traditional Chinese medicine decoction pieces

InactiveCN109353055AFluffy textureAvoid situations such as incomplete compressionPressesVacuum pumpingEngineering

The invention discloses a feeding box for pressing traditional Chinese medicinal materials and traditional Chinese medicine decoction pieces. The feeding box comprises a compressing rack; the upper end of the compressing rack is connected with a plurality of springs, and the upper ends of the springs are fixedly connected with nuts; the nuts are internally connected with adjusting rods through threads, and the lower ends of the adjusting rods are fixedly connected with core shafts; the lower ends of the core shafts are connected with upward pressing shaft rolls, and the lower ends of the upward pressing shaft rolls are provided with first conveyor belts; the upward pressing shaft rolls and downward pressing shaft rolls are aligned, and the left ends of the downward pressing shaft rolls areconnected with shaft rolls; the shaft rolls are connected with a first reducer through a first belt, and the left end of the compressing rack is fixedly connected with a first vacuum transparent hood; and a vacuum pumping mechanism is arranged at the upper end of the first vacuum transparent hood, and the right end of the compressing rack is connected with a second vacuum transparent hood and a third vacuum transparent hood. The sizes of the traditional Chinese medicinal materials and the traditional Chinese medicine decoction pieces are effectively compressed, air is isolated, the product quality is improved, meanwhile feeding can be automatically metered, and thus the working efficiency is improved.

Owner:胡成兵

Washing composite enzyme containing fungus alpha-amylase and preparation method of washing composite enzyme

ActiveCN104479909AWith dustproofGood storage stabilityNon-ionic surface-active compoundsDetergent compounding agentsAntioxidantEnzyme system

The invention discloses a washing composite enzyme containing fungus alpha-amylase and a preparation method of the washing composite enzyme, and belongs to the technical field of preparation of a washing enzyme. A washing composite enzyme, which is high in storage stability, high in enzyme activity and efficacy, comprehensive in enzyme system and excellent in decontaminating effect, and has dustproof, antibacterial, cross-color resistant and essence-flavored effects is prepared from sawdust serving as a carrier and heat-resistant fungus alpha-amylase serving as a main raw material, as well as a plant extract, a nonionic surfactant, alkaline protease, alkaline lipase, alkaline glucanase, an activator, a protective agent, an antioxidant and the like which are scientifically compounded. Compared with commercially available special composite enzyme for washing, the enzymatic laundry powder produced by using the washing composite enzyme containing fungus alpha-amylase has the advantages that the detersive power is strong; the detersive power for carbon black dirt, protein dirt and sebum dirt is respectively improved by 88%, 107% and 129%; the deposition ash content ratio is reduced by 36%; the residual bacterial count on the clothes surfaces is reduced by 71%; skin and clothes are not damaged, cross-color resistant ability is high, fragrance lasts for a long time and no dust is generated in a use process.

Owner:湖南新鸿鹰生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com