Method for preparing furfural by utilizing cotton stalk

A cotton stalk and furfural technology is applied in the field of producing furfural by using cotton stalks, which can solve the problems of inability to fully contact cotton stalk raw materials for slag discharge, inability to mix acid with dilute acid solution, and difficult to break cotton stalks, thereby shortening the hydrolysis reaction time. , Guarantee the quality of furfural and the effect of complete crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The raw material is cotton stalks air-dried in spring, and its water content is 22.5%. The cotton stalks are first cut into 4cm long segments with a grass cutter, and dust is removed with a three-roller dust collector during the cutting process. The cut cotton stalks are sent to the cutting and crushing equipment for further cutting and crushing of cotton stalk particles with a final length of about 1-1.5cm. Corncob particles, corncob particles and cotton stalk particles are fully mixed according to the mass ratio of 0.5 to 1:1 in the process of conveying to the bucket elevator, and then transported by the elevator to the acid mixing truck for acid mixing. The catalyst is sulfuric acid. The acid concentration is 5-10%, the amount of acid used is kept at a specific ratio of liquid to solid, and it is sent to the hydrolysis kettle through a belt conveyor. The volume of the hydrolysis kettle is 10 cubic meters, and the double kettles are operated in series. At 160~240kg / m...

Embodiment 2

[0018] The raw material is corncobs air-dried in spring, and its water content is 27%. After the corncob is dedusted by a vibrating screen, it is crushed into 1-1.5cm corncob particles by a hammer mill, and then transported by the elevator to the acid mixing truck for acid mixing. The acid concentration is 5-10%, and the amount of acid used is kept at With a specific solid-to-liquid ratio, it is sent to the hydrolysis kettle through a belt conveyor. The volume of the hydrolysis kettle is 10 cubic meters. It is operated in series with two kettles. The packing density of corncobs is 160-240kg / m 3 , After filling the hydrolysis kettle, feed water vapor with a pressure of 0.45-0.75MPa, the hydrolysis temperature is 145-180°C, and the hydrolysis takes 2 hours, 45 minutes to 5 hours. The furfural stock solution obtained by hydrolysis is introduced into the subsequent process, and the gross aldehyde is extracted, and the furfural is continuously refined to obtain commercial furfural....

Embodiment 3

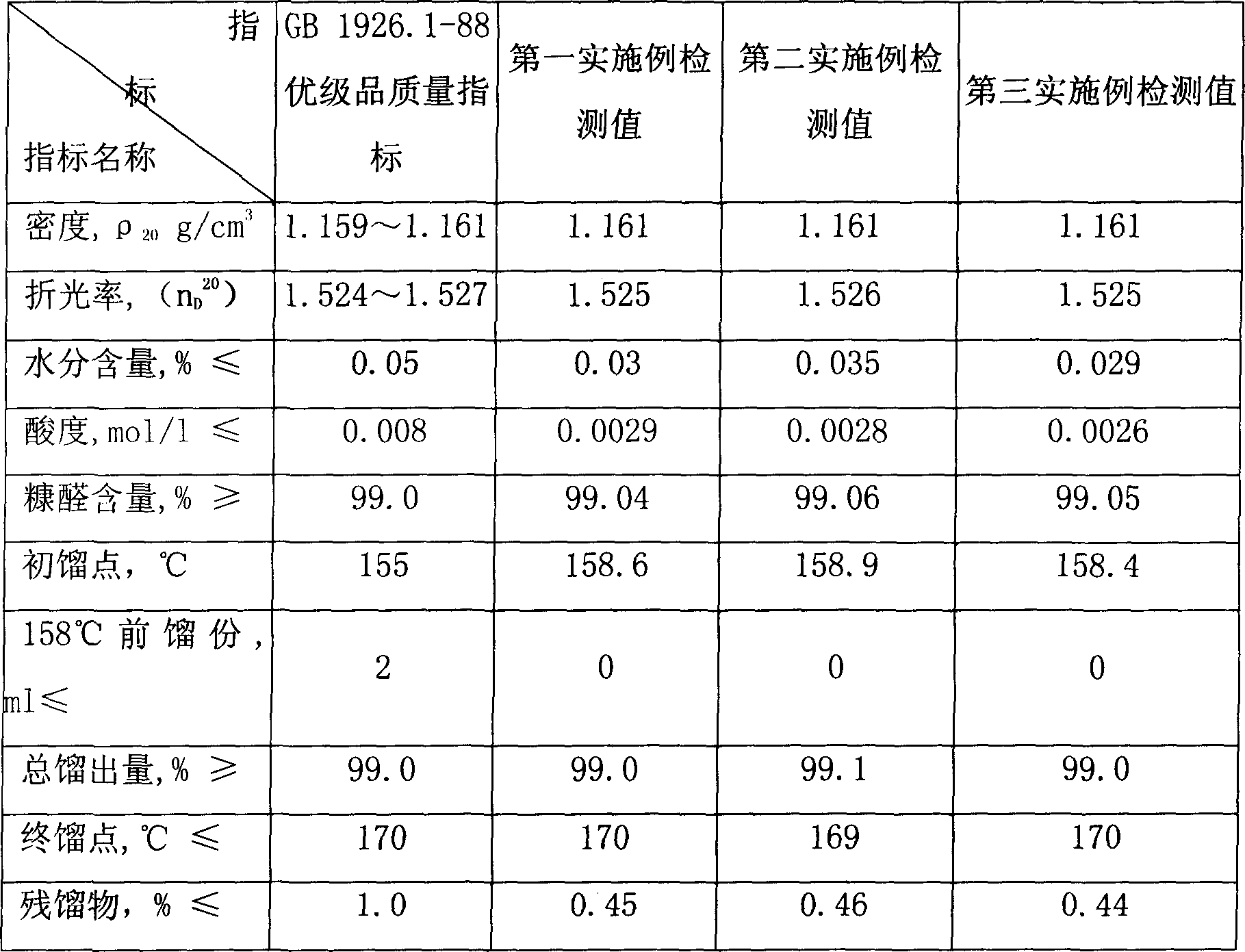

[0020] The raw materials used in this example, equipment and operation flow are identical with embodiment 1. The technological condition is changed to: the mass ratio of cotton stalk and corncob is 0.4:1. This example furfural yield is 8~8.5%. The quality has also reached the national premium product index. The quality inspection indicators are shown in Table 1, and the consumption details are shown in Table 2.

[0021] Table 1: Comparison list of the results of furfural quality inspection in the examples and the indicators specified in GB 1926.1-88

[0022]

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com