Wet spinning method of low-proportion high-spun flax macrofiber

A technology of flax fiber and long fiber, which is applied in wet spinning of flax fiber and wet spinning of flax long fiber with low configuration and high spinning. Ease of production and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

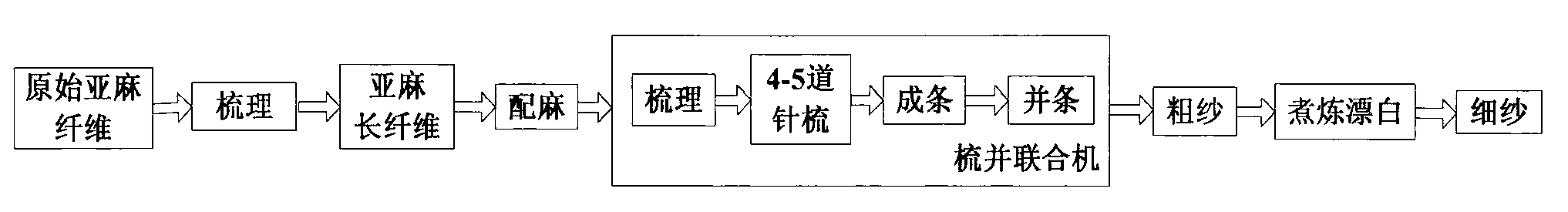

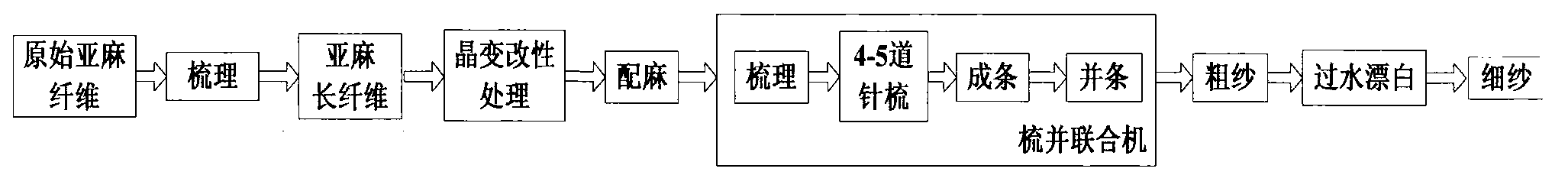

[0028] Such as figure 2 Shown, a kind of low profile high spinning flax long fiber wet spinning method provided by the invention, its steps are:

[0029] The first step is to comb the original flax fiber to obtain 60-80mm long flax fiber;

[0030] The second step is to carry out crystal modification treatment on the long flax fiber. During the crystal transformation modification process, the long flax fiber will swell and the cellulose will be degummed, thereby improving the splitting degree of the long flax fiber and making the spinnable fiber thinner ;

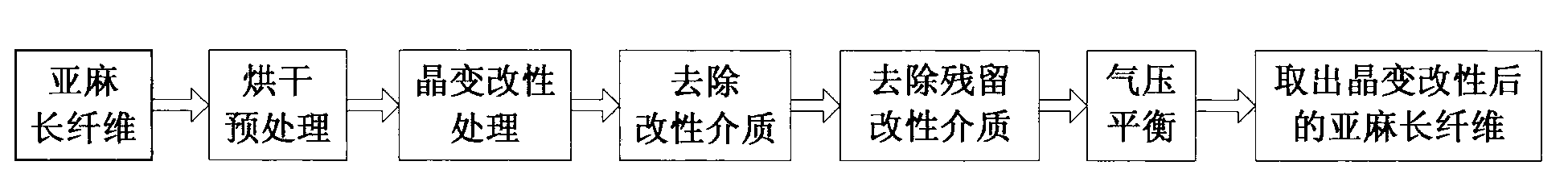

[0031] combine image 3 , the steps of crystal transformation modification treatment are as follows: dry and pretreat flax long fibers to make them dry and free of moisture, then put them into a closed modified kettle, and then fill the modified kettle with ammonia gas after vacuuming Make the internal pressure of the modified kettle greater than 3MPa, and then fill in liquid ammonia to make it immerse all the flax long ...

Embodiment 2

[0038] Such as figure 2 Shown, a kind of low profile high spinning flax long fiber wet spinning method provided by the invention, its steps are:

[0039] The first step is to comb the original flax fiber to obtain 60-80mm long flax fiber;

[0040] The second step is to carry out crystal modification treatment on the long flax fiber. During the crystal transformation modification process, the long flax fiber will swell and the cellulose will be degummed, thereby improving the splitting degree of the long flax fiber and making the spinnable fiber thinner ;

[0041] combine image 3 , the steps of crystal transformation modification treatment are as follows: dry and pretreat flax long fibers to make them dry and free of moisture, then put them into a closed modified kettle, and then fill the modified kettle with ammonia gas after vacuuming Make the internal pressure of the modified kettle greater than 3MPa, and then fill in liquid ammonia to make it immerse all the flax long ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com