Raw white knitted underwear fabric and processing technique thereof

A technology of underwear fabric and processing technology, applied in knitting, underwear, weft knitting, etc., can solve the problem of not meeting the skin-friendly requirements of the original knitted underwear fabric, affecting the softness of underwear, and not considering the technological progress of regenerated natural cellulose fiber, etc. problems, to achieve the effect of low carbon and energy saving in the processing process, fluffy and soft structure, and improved processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

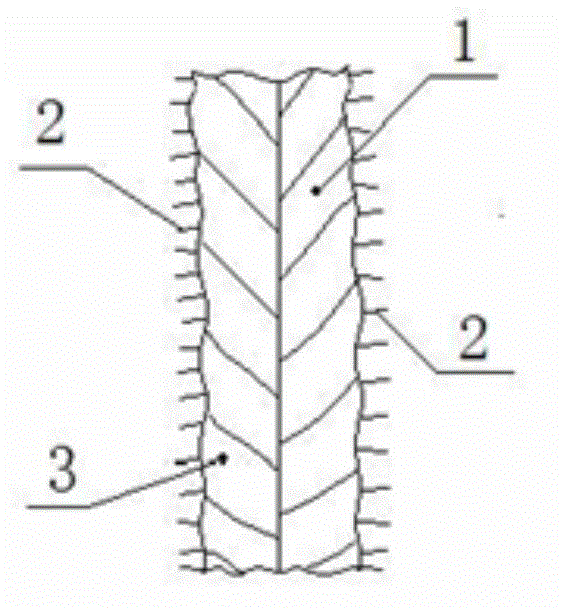

[0025] Embodiment: a kind of white knitted underwear fabric, which is made of double-sided weft knitted fabric, and the double-sided weft knitted fabric includes outer surface loop 1 and inner surface loop 3, at least one surface of the outer surface loop and inner surface loop Has short hair2.

[0026] A process for processing raw white knitted underwear fabrics, the specific steps are as follows:

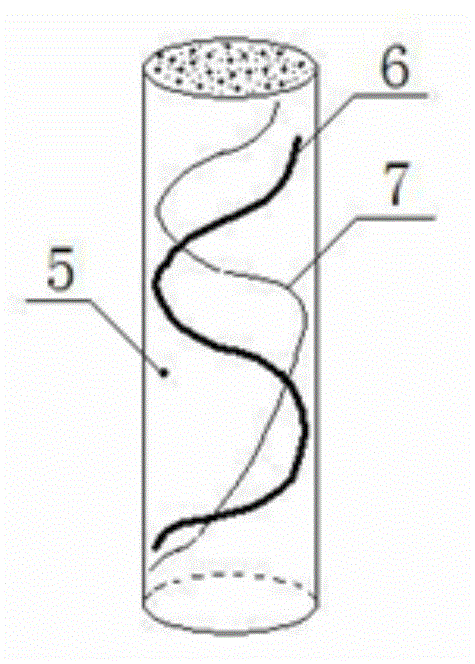

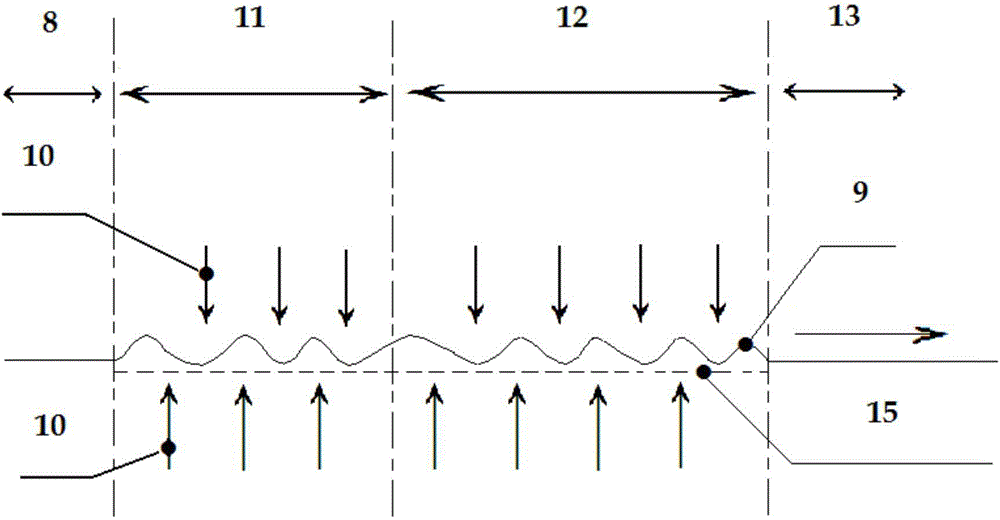

[0027] Step 1: Select this white yarn to weave a double-sided weft knitted fabric including outer surface loop 1 and inner surface loop 3; this white yarn is a blended yarn 5 of long-staple cotton fiber 6 and regenerated cellulose fiber 7, select 32 British long-staple cotton and Modal blended yarn, the blending ratio is 80:20, the fiber length of long-staple cotton is 38-39mm, the fiber length of Modal is 44mm, and the single fiber fineness is 0.9D. For spinning, the twist is 252-324. (The twist is 10% lower than the conventional one, (the actual twist coefficient control range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com