Leather fabric for leatherware and preparation process of leather fabric

A leather and fabric technology, applied in the field of artificial leather, can solve the problems of non-environmental protection, high cost, and lack of softness of PVC artificial leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Using PVC artificial leather instead of natural leather can not only greatly save costs, but also achieve an effect similar to genuine leather in appearance. The formula of PVC artificial leather is usually composed of PVC resin, plasticizer, stabilizer, flame retardant, foaming agent, surface treatment agent and base fabric. The base fabric usually includes knitted fabric, non-woven fabric or microfiber fabric, etc. The production process is generally There are coating method and calendering method. Existing PVC artificial leather has the problem of lack of softness. Research hotspots in this field mainly focus on the formulation optimization of the material itself, such as the improvement of plasticizers in the prior art, composite PU polymer materials, etc. However, the existing technology has problems such as cost and environmental protection, and it is not a good way to improve.

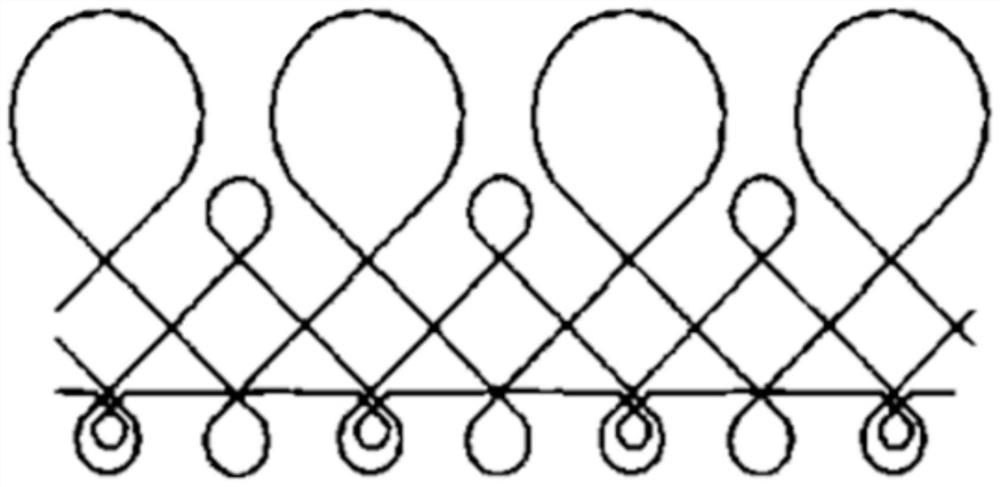

[0045] The applicant's research has found that the softness of PVC artificial leathe...

example 1

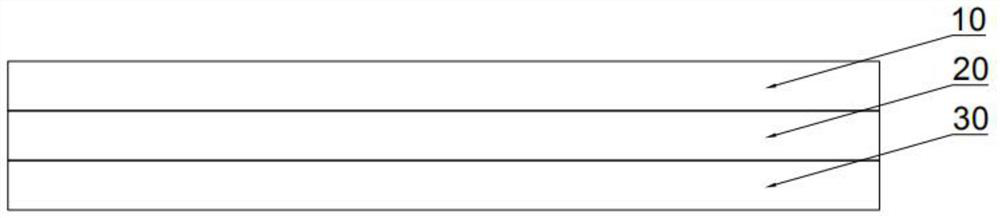

[0077] Example 1: The leather goods and leather fabric described in Example 1 includes a surface layer, a foam layer and a base cloth that are sequentially compounded from top to bottom. The base fabric is a basic fabric described in the embodiment.

[0078] The present invention also provides a preparation process for the above-mentioned leather goods leather fabric, comprising the following steps:

[0079] (1) Prepare the base cloth and release paper, and configure the surface layer slurry and foam layer slurry according to the following formula:

[0080] The surface layer is made of the following raw materials in proportion by weight: 100 parts of PVC resin powder, 70 parts of plasticizer, 5 parts of stabilizer, 10 parts of color paste and appropriate amount of nano-silica filler, wherein, Adding a mass fraction of 5% nano-silica filler in the layer slurry;

[0081] The foam layer is made of the following raw materials in proportion by weight: 100 parts of PVC resin powde...

Embodiment 2

[0118] In a preferred implementation of the present invention, the outer surface of the surface layer is also coated with a silicone-modified polyurethane resin coating.

[0119] Polyurethane resin is grafted and modified by using silicone to achieve soft and slippery effect on artificial leather. Because the main body of polyurethane is also polyester ether, it can be modified with polyether-containing silicone, which has the advantage of good compatibility. Silicone modification, there is a 100% modulus and a decrease in the coefficient of sliding friction at the same time, but it can endow the artificial leather with soft and slippery, or soft but not sticky.

[0120] In one implementation, the modified silicone can be SF-8427 (DOW CORNING), which is a polyether-modified silicone with two hydroxyl groups, with a relative molecular mass of 2000.

[0121] For other structures of the leather fabric and its preparation process described in this embodiment, refer to the prior a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loft | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com