Blended yarn deeply developed from silkworms and spinning process

A blended yarn, depth technology, applied in the direction of yarn, textiles and paper making, can solve the problems of high cost of silk yarn and unsatisfactory comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

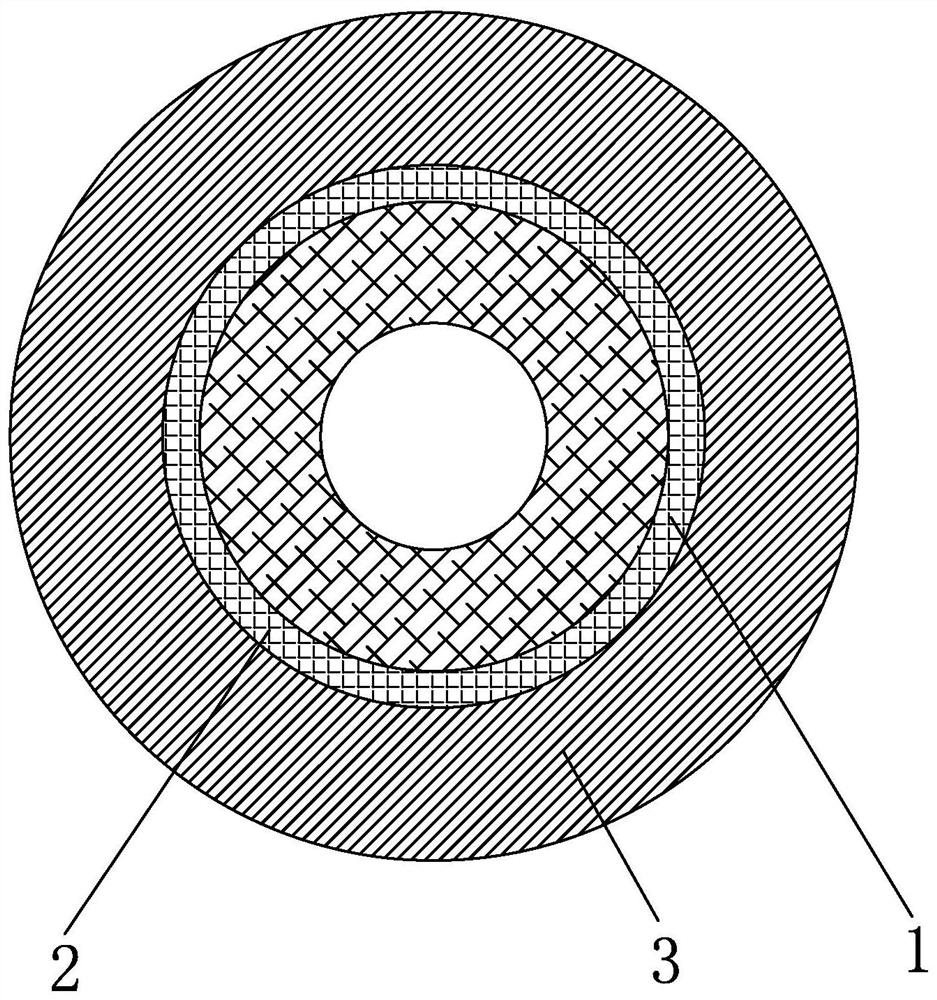

[0024] combine figure 1 , the invention discloses a blended yarn deeply developed for sericulture, including a yarn body. The yarn body is a hollow yarn, including a hollow inner core layer 1, a sericin film layer 2 and a wrapping skin layer 3 arranged sequentially from inside to outside. The hollow inner core layer 1 adopts mulberry fiber; the mulberry fiber is spirally wrapped outside the hollow core hole of the yarn body. The length of the mulberry fiber is 14-20mm; the mulberry fiber is 2-3.5dtex. The sericin film layer 2 is coated on the outside of the hollow inner core layer 1 by sericin to form a film layer structure. The winding cortex 3 adopts winding filaments, and the winding filaments are spirally wound outside the sericin film layer 2 to form an outsourcing structure. The winding filament can be pupal protein viscose filament or spun silk. Preferably, the wound filaments are pupal protein viscose filaments.

[0025] The yarn body is 18.5-55.5tex. Specificall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com