Wound dressing and method for manufacturing the same

A technology for wound dressings and mixtures, applied in dressings, viscous dressings, thin material processing, etc., can solve the problems of silicone gel coating surface roughness dependence and inability to produce silicone layers, etc., and achieve maximum absorption consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

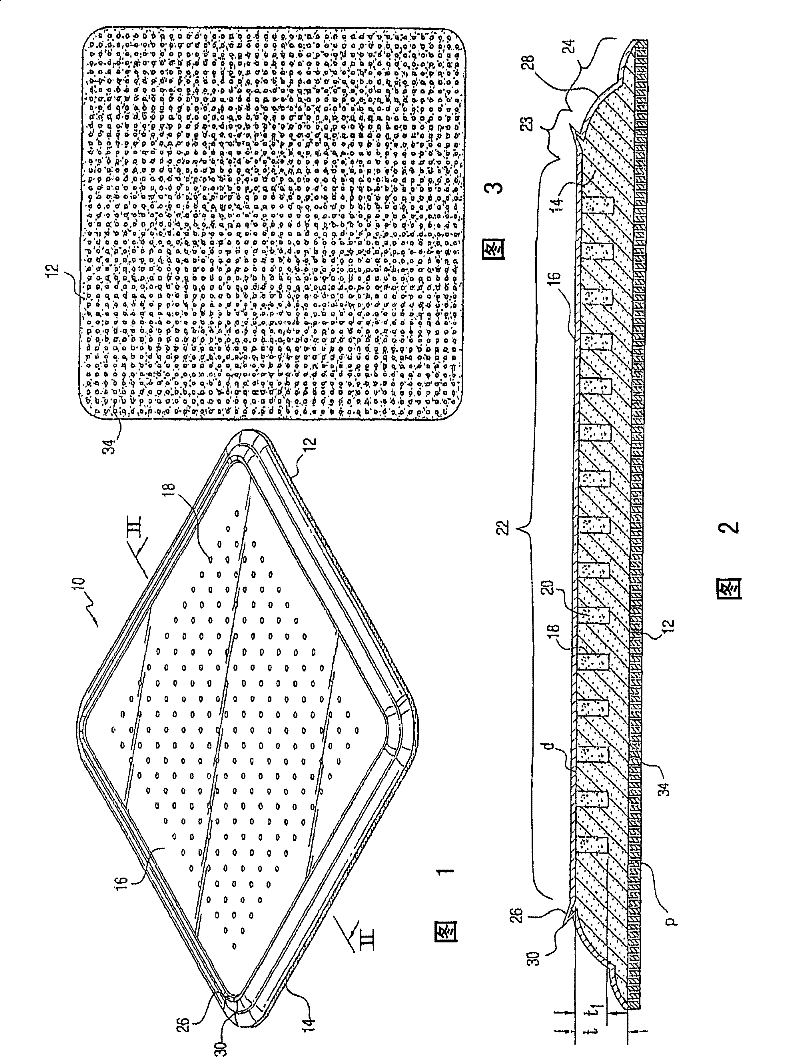

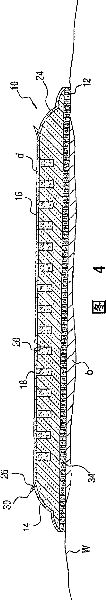

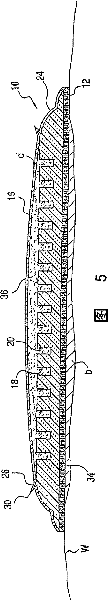

[0088] According to one embodiment, the capsule holders are arranged in a rectangular pattern, with individual capsule holders being generally 5 mm apart (measured from the central axis of each capsule holder). The depth of each capsule support is generally 4-5mm, at least 0.5mm away from the surface layer. The pattern can be tailored to include more pocket receptacles in certain dressing areas than in other areas.

[0089] The density of the receptacle can be modified according to the desired fluid absorption properties of the dressing. For example, more pockets may be arranged at a higher density in the central portion of the absorbent core than near the border portions of the dressing. The number of pocket holders at any given area of the absorbent core may depend on the sensing area where a greater amount of fluid is locally present, for example, at the central portion, to maximize fluid absorption while also limiting certain absorbent core areas, For example, in the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com