PVC fiber composition for simulated wig and preparation method of PVC fiber composition

A fiber composition, PVC resin technology, applied in wigs, fiber chemical characteristics, applications, etc., can solve problems such as differences in human hair, achieve soft light, increase water absorption and antistatic properties, and feel soft and smooth.

Active Publication Date: 2021-04-20

CHINA PETROLEUM & CHEM CORP +1

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009]

The PVC-based fibers for wigs produced by the prior art are significantly different from human hair in terms of gloss, flexibility, bulkiness, and smoothness, both in appearance and feel.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

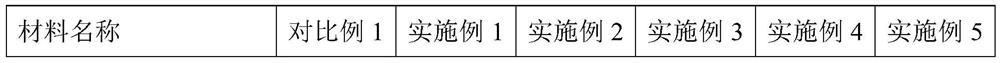

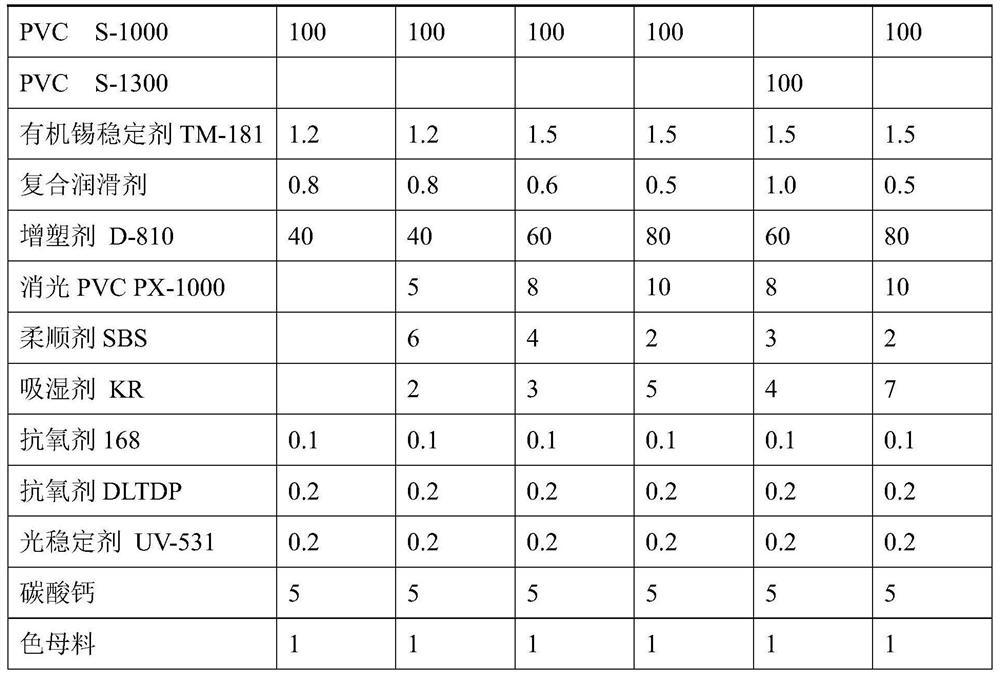

Embodiment 1-5 and comparative example 1

[0031] See Table 1 for the ingredients of the PVC fiber composition for artificial wigs.

[0032] The composite lubricant used in Table 1 is PE wax / calcium stearate with a mass ratio of 2:1.

[0033] The hygroscopic agent used in Table 1 is KR from Kuraray, Japan.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of processing and application of polyvinyl chloride resin, and particularly relates to a PVC fiber composition for a simulated wig and a preparation method of the PVC fiber composition. The PVC fiber composition for the simulated wig is prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 0.8-5 part of a heat stabilizer, 0.5-2 part of a composite lubricant, 40-80 parts of a plasticizer, 5-10 parts of a delustering agent, 2-6 parts of a softener, 2-5 parts of a moisture absorbent, 0.2-0.5 part of an antioxidant, 0.1-0.3 part of a light stabilizer, 2-10 parts of filler and 0.5-2 part of color masterbatch. The PVC fiber composition for the simulated wig is soft in gloss, soft, smooth and fine in hand feeling, and high in similarity with human hair; and the preparation method is scientific, reasonable, simple and feasible.

Description

technical field [0001] The invention belongs to the field of processing and application of polyvinyl chloride resin, and in particular relates to a PVC fiber composition for artificial wigs and a preparation method thereof. Background technique [0002] Synthetic fibers commonly used in hair products include polyvinyl chloride (PVC)-based fibers, polyacrylonitrile (PAN)-based fibers, polyester (mainly PET)-based fibers, polypropylene (PP)-based fibers and protein-based fibers. Among them, the PVC-based fiber made of PVC resin spinning is close to human hair in terms of strength, elongation at break, density, etc. Naturally, therefore, PVC-based fibers became the material of choice for making artificial wigs. However, PVC-based fibers also have some disadvantages, such as narrow molding processing temperature range, poor processing fluidity, low heat-resistant deformation temperature, migration and precipitation of plasticizers, and the like. [0003] Existing literature pa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01F6/48D01F1/10A41G3/00

Inventor 袁辉志张学明王晶张新华孔秀丽贾小波肖恩琳李长春孙丽朋张强许永森

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com