Patents

Literature

33results about How to "Solve curling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

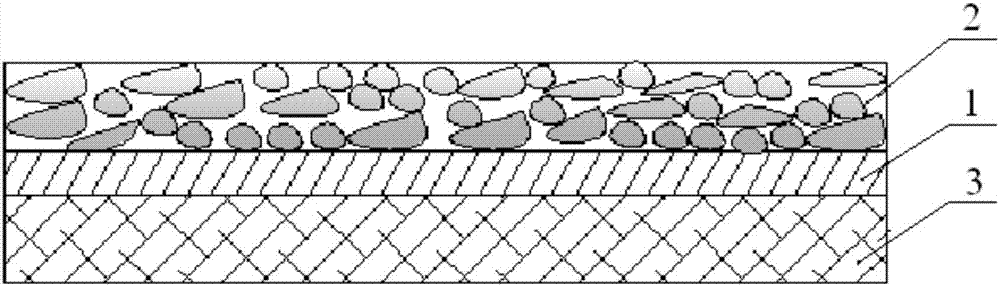

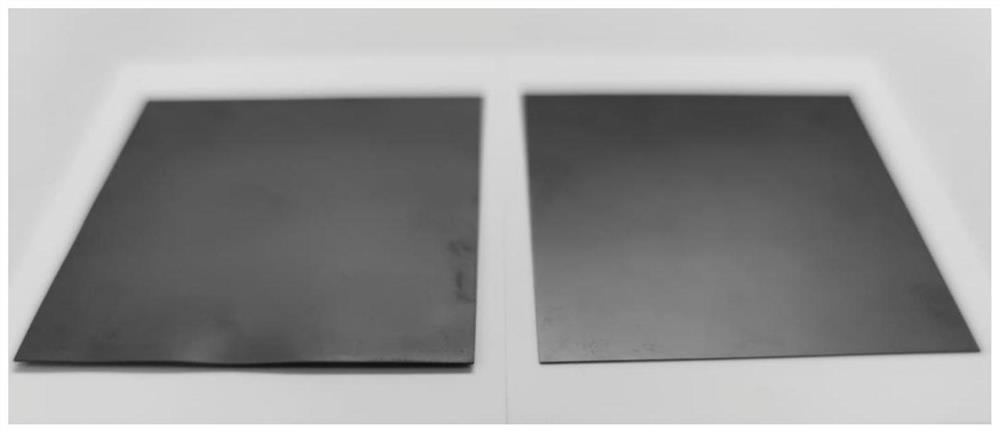

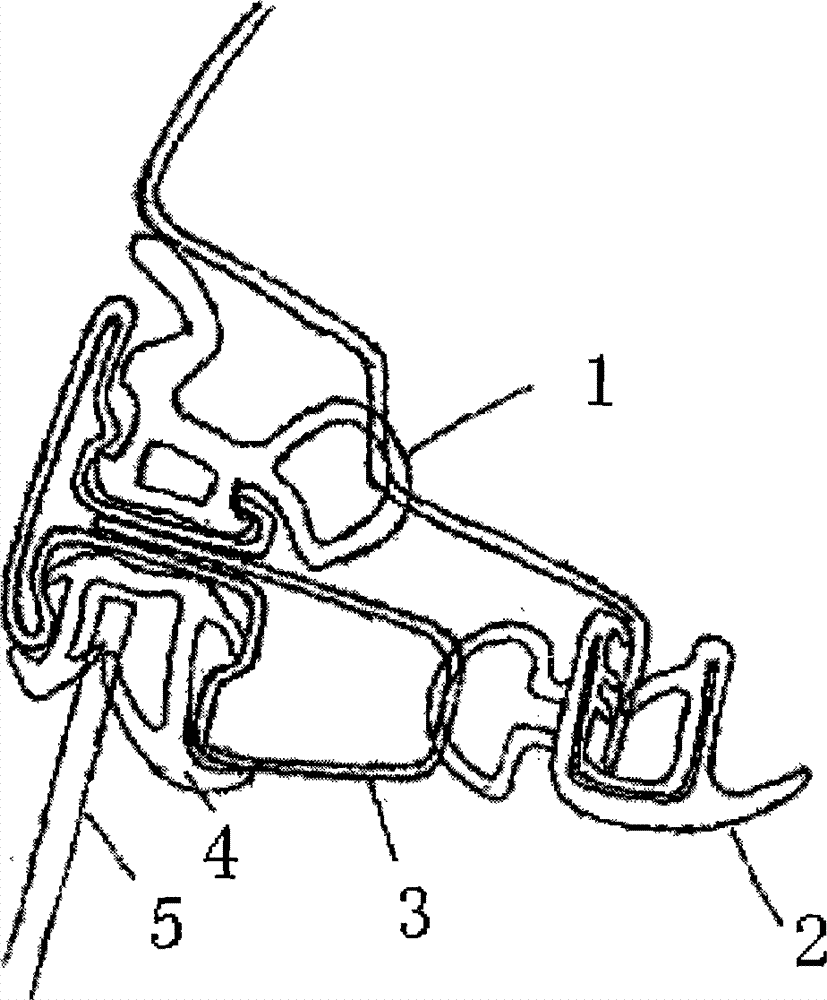

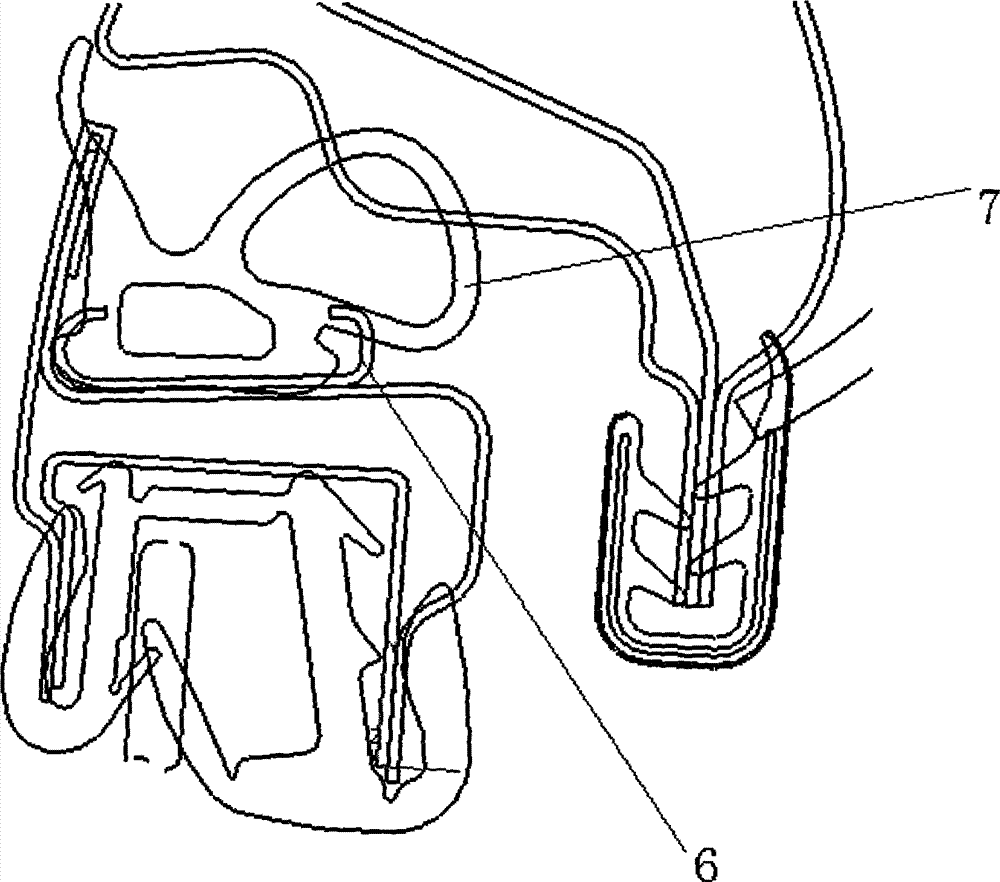

Battery pole piece and method for preventing battery pole piece from being curled

ActiveCN107134561AReduce material dropHigh strengthElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesEngineeringPole piece

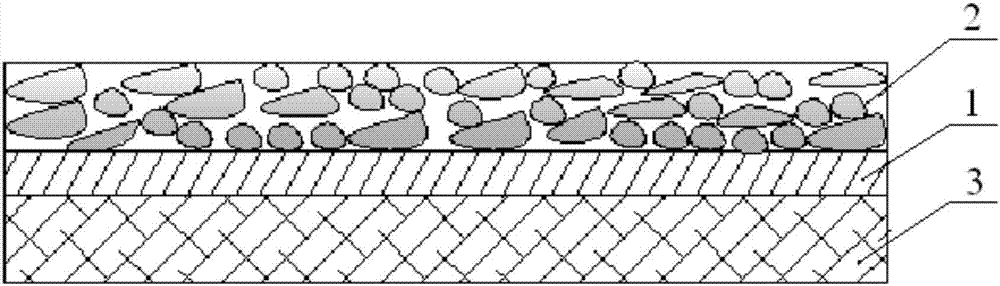

The invention discloses a battery pole piece and a method for preventing the battery pole piece from being curled. The battery pole piece comprises a metal current collector, wherein an active material layer is arranged on side of the metal current collector; and a high polymer material layer is arranged on the other side of the metal current collector. According to the battery pole piece disclosed by the invention, the high polymer material layer is arranged on one side, on which the active material layer does not need to be arranged, of the metal current collector, and stress caused by extension of the active material after rolling can be offset or partially offset, so that the pole piece curling problem caused by single-sided coating and rolling of the pole piece can be solved.

Owner:HANGZHOU FUTURE POWER TECH

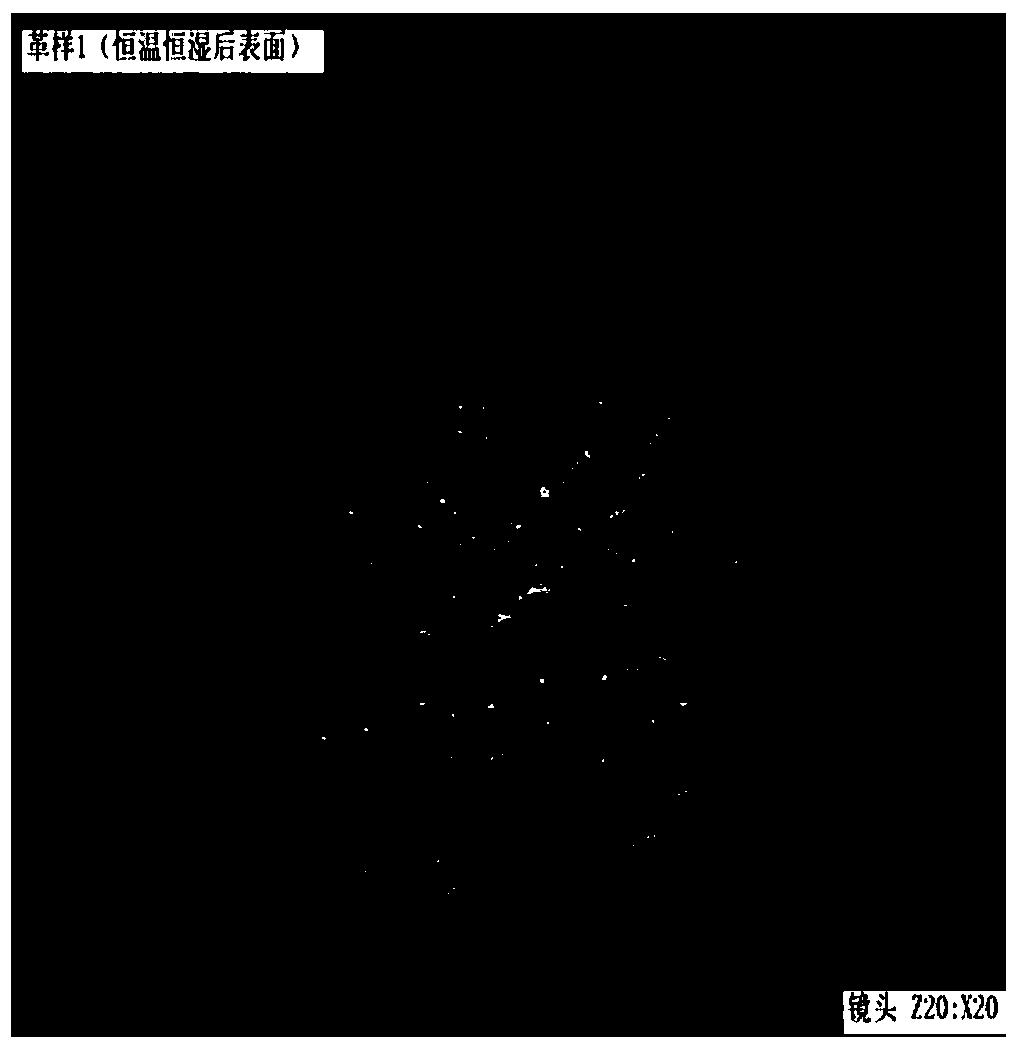

Soft sheepskin-imitating polyurethane resin, preparation method thereof, and method of producing sheepskin-imitating artificial leather therewith

ActiveCN105671989AImprove immersionMuch infiltrationGlovesPolyurea/polyurethane coatingsN dimethylformamideWear resistance

The invention relates to soft sheepskin-imitating polyurethane resin which includes the following components: wet-method polyurethane resin, N,N-dimethylformamide, paper pulp powder, a hand feeling agent, a permeation agent, an anti-crimping agent and an oily color material. The invention also relates to a method of producing sheepskin-imitating artificial leather with the soft sheepskin-imitating polyurethane resin, wherein the method includes the following steps: 1) impregnating a base cloth in a soft sheepskin-imitating polyurethane resin mixture liquid; 2) regulating sizing quantity through extrusion, and performing solidification, water washing, drying and polishing to prepare wet-method base; and 3) performing veneering and vacuum grain suction to the wet-method base to prepare the sheepskin-imitating artificial leather. The sheepskin-imitating artificial leather has a soft and light feel, has fine and elastic hand feeling, is high in tear strength and good in weather and wear resistance, has a soft and natural surface color, has full grains and has strong stereoscopic sense.

Owner:SHANGHAI HUIDE TECH CO LTD

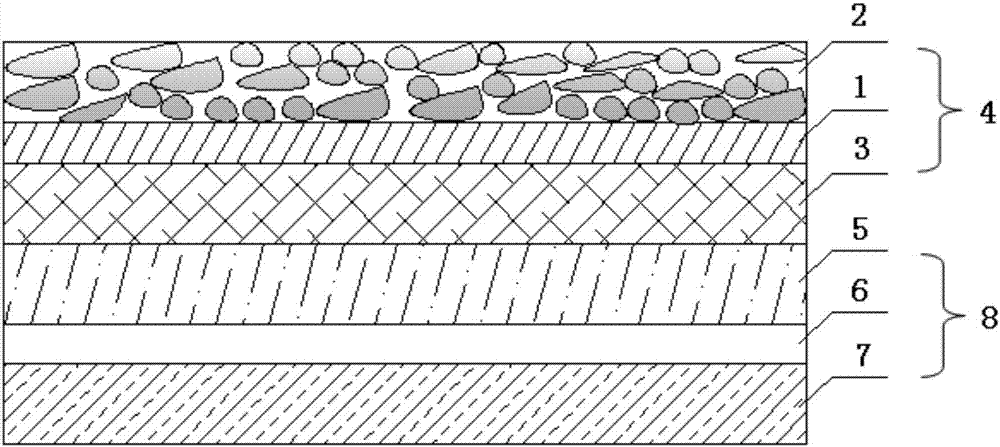

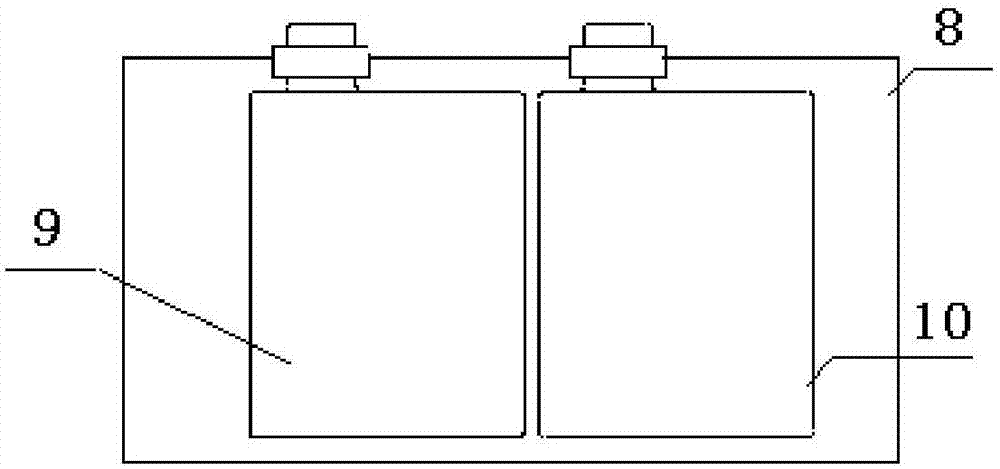

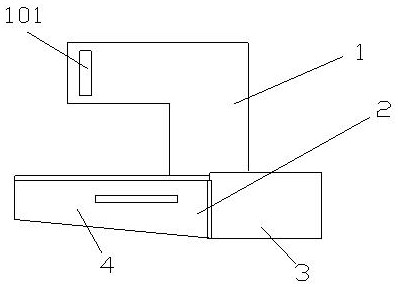

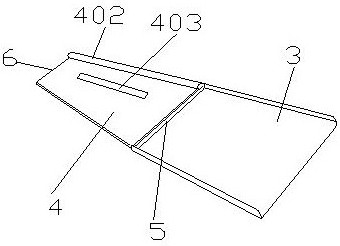

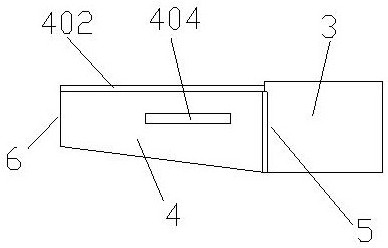

Thin type secondary battery and preparation method therefor

PendingCN106960976AReduce material dropHigh strengthFinal product manufactureSmall-sized flat cells/batteriesElectrical batteryEngineering

The invention discloses a thin type secondary battery and a preparation method therefor. The thin type secondary battery comprises at least one positive electrode plate and at least one negative electrode plate; the positive electrode plate and the negative electrode plate are arranged at intervals in sequence; each electrode plate comprises a metal current collector; the thin type secondary battery is characterized in that an active material layer is arranged on one surface, facing to other electrode plates, of the metal current collector in the electrode plate on the outermost side, while a high polymer material layer is arranged on the other surface; and when the number of the electrode plates is greater than or equal to three, the two surfaces of the metal current collector of the middle electrode plate are both provided with the active material layer. According to the thin type secondary battery, only one surface of the electrode plate on the outermost side needs to be provided with the hot melt adhesive active material layer; one surface, which does not need the active material layer, of the metal current collector is provided with the high polymer material layer, so that stress caused by extension of the active material after rolling can be counteracted or partially counteracted, so that the problem of electrode plate rolling caused after the single surface of the electrode plate is coated and rolled can be solved; and in addition, the thin type secondary battery also can be subjected to thermal compounding with an aluminum plastic composite packaging film used for external packaging to form an integrated electrode.

Owner:HANGZHOU FUTURE POWER TECH

Low-shrinkage treatment method and afterfinishing method of high-elastic fabric and high-elastic fabric

ActiveCN106988072ASmall shrinkageSolve curlingShrinkingSucessive textile treatmentsEnvironmental engineeringLow shrinkage

The invention discloses a low-shrinkage treatment method and afterfinishing method of high-elastic fabric and high-elastic fabric; the low-shrinkage treatment method of the high-elastic fabric comprises: washing the high-elastic fabric; dewatering the treated high-elastic fabric; scotching the high-elastic fabric; drying the high-elastic fabric. The low-shrinkage treatment method of the high-elastic fabric provided herein has an additional treatment step in the original fabric afterfinishing method; low-shrinkage treatment is arranged before pre-shrinkage treatment. The high-elastic fabric treated by the low-shrinkage treatment method gains high elasticity and low shrinkage, the difficulty in manufacturing high-elasticity ready-made apparel and washing the ready-made apparel is reduced greatly.

Owner:GUANGDONG FORWARD DENIM

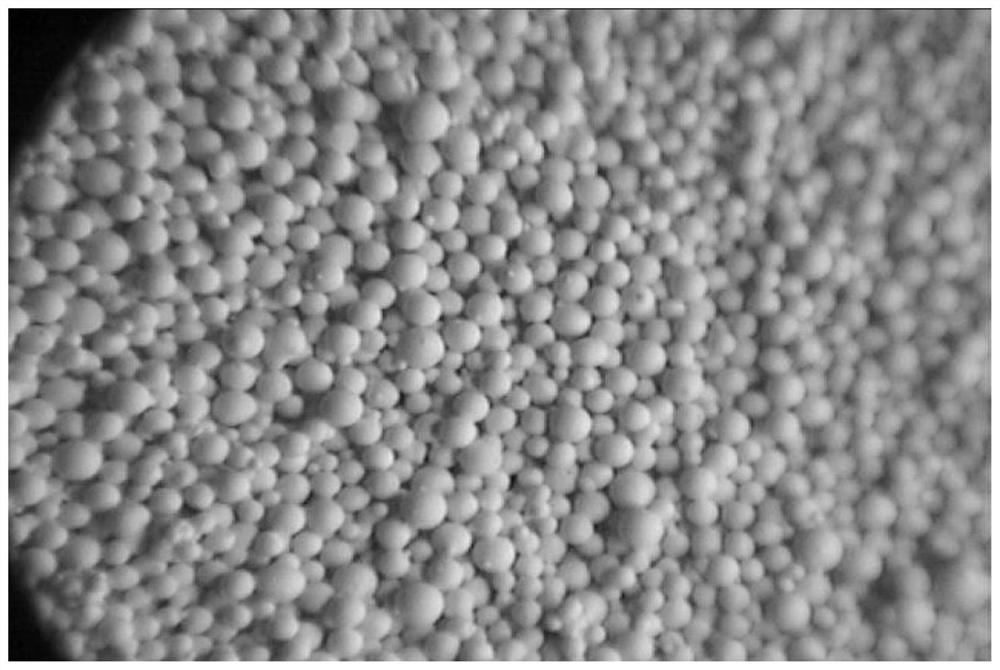

Preparation method of ultra-thin large-size LTCC (Low Temperature Co-Fired Ceramic) substrate

The invention relates to a preparation method of an ultra-thin large-size LTCC (Low Temperature Co-Fired Ceramic) substrate. The preparation method comprises the following steps: mixing ZnO and Nb2O5 according to a molar ratio, pre-sintering and synthesizing to obtain a ZnNb2O6 system as a basic system; adjusting the dielectric constant of the material system by compounding a high-dielectric-constant TiO2 material; reducing the sintering temperature of the system by adding a sintering aid; reducing the particle size of the powder by introducing a sanding process, so that the specific surface area of the powder is increased, and the reaction activity of the powder is improved; adding a solvent, a dispersing agent and a defoaming agent into the powder obtained by sanding, carrying out primary ball milling to prepare slurry, supplementing a binder and a solvent, and carrying out secondary ball milling to prepare a casting material; and performing casting, laminating, isostatic pressing and cutting, and sintering and molding according to an LTCC (Low Temperature Co-Fired Ceramic) process. The problems of warping, edge curling, breaking and the like of an existing ultra-thin large-size ceramic substrate in the sintering process are solved. The ratio of the size to the thickness size of the prepared substrate can reach 5000: 1, and the method can be widely applied to the field of miniaturization of electronic components.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Pretreatment method for all-cotton high-density poplin

InactiveCN105568497AGood hair effectGood desizing rateMercerising of indefinite length fabricsSolvent-treatmentHigh densityPretreatment method

The invention relates to a pretreatment method for all-cotton high-density poplin. The method comprises the steps of (1) singeing; (2) padding, rolling and cold-batching; (3) tight continuous padding alkali-oxygen liquid short steaming; (4) mercerizing; and (5) drying. The all-cotton high-density poplin is treated with the method, so that the efficiency can be improved and the pollution can be alleviated.

Owner:SUNTEX

Pretreatment method for all-cotton single-yarn drill

The invention relates to a pretreatment method for all-cotton single-yarn drill. The method includes the steps of singeing; padding, rolling and cold batching; compact continuous padding alkali oxygen liquid short steaming; mercerizing; drying. The method is adopted to treat the all-cotton single-yarn drill, efficiency can be improved, and pollution can be reduced.

Owner:SUNTEX

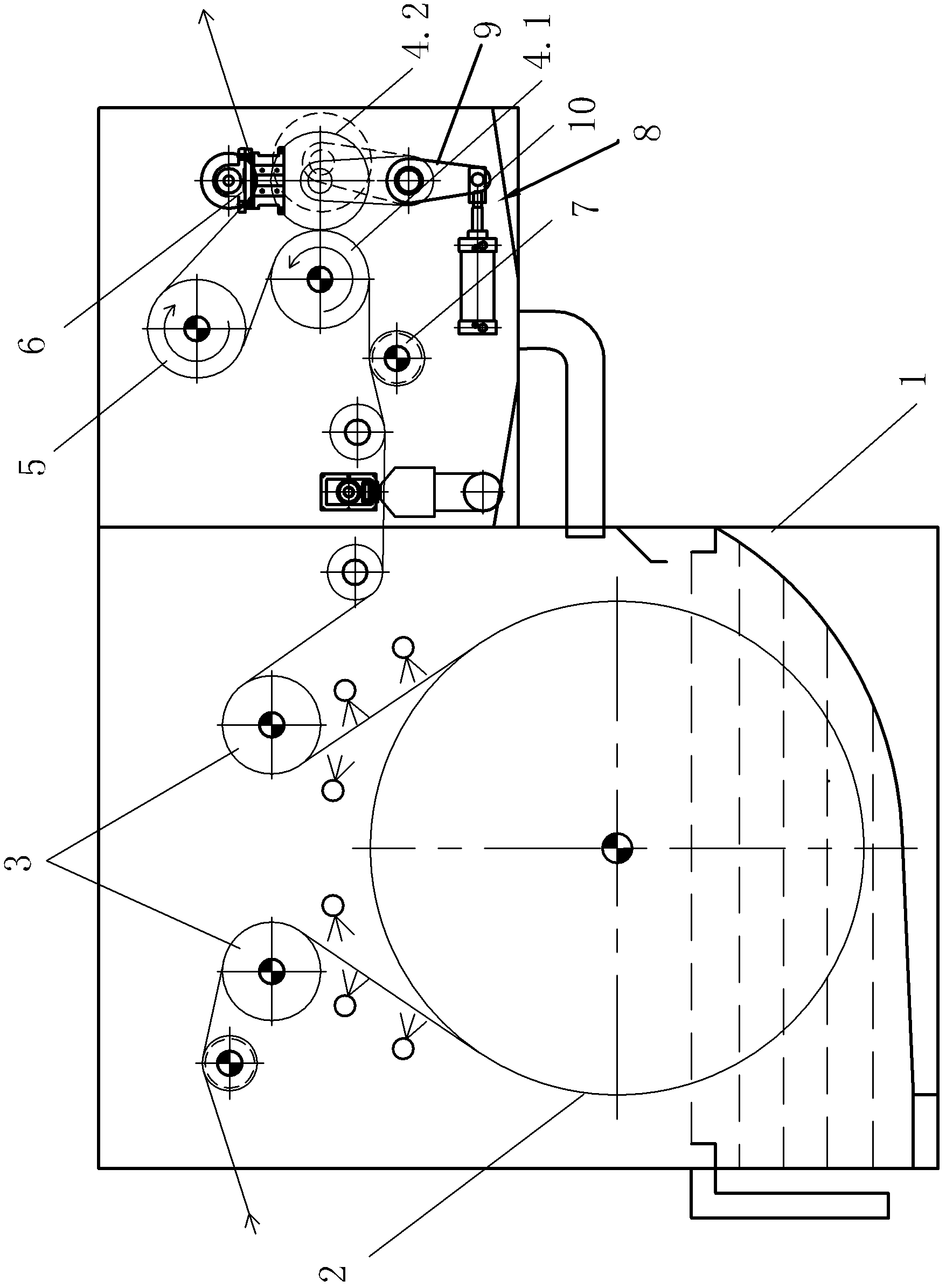

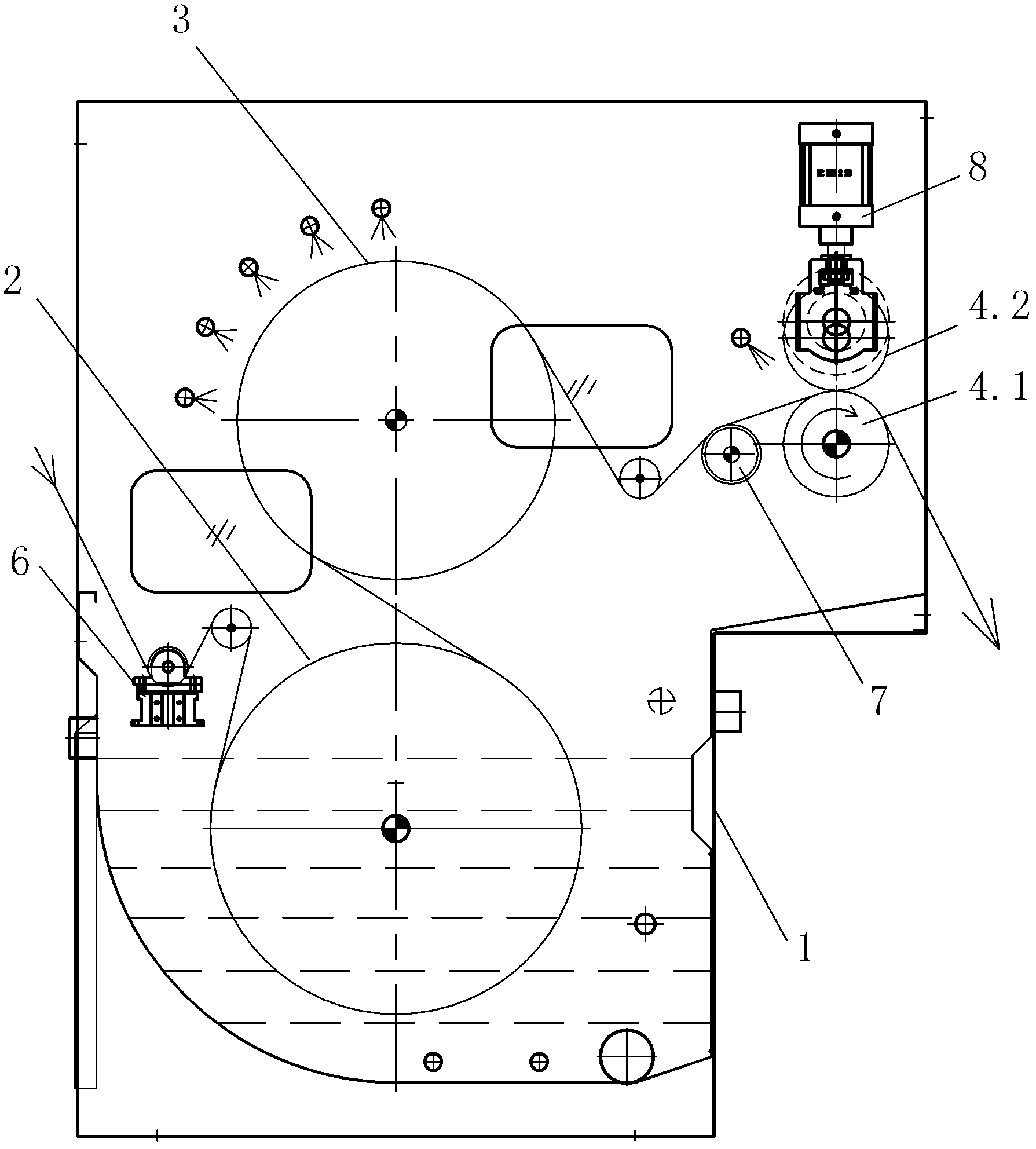

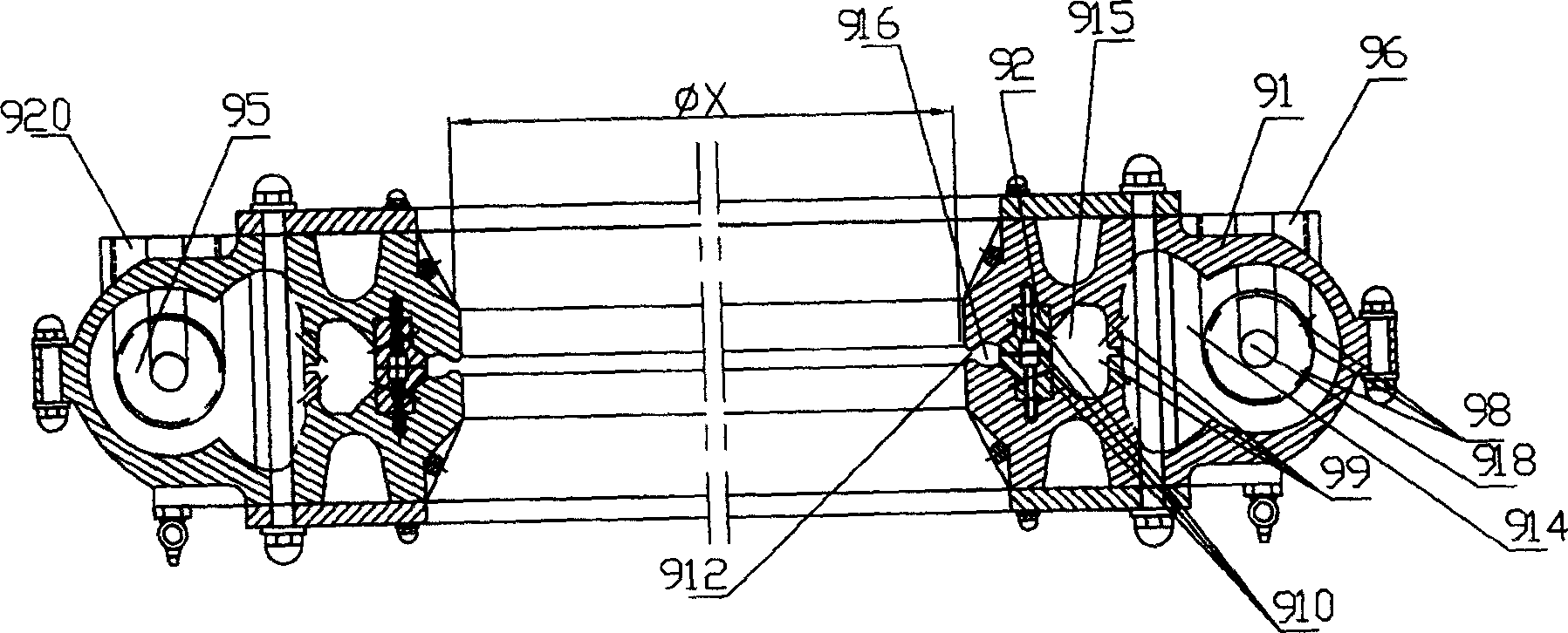

Automatic fabric tension control system suitable for knitting open-width wet processing unit

ActiveCN102517827AAvoid Stretch DeformationGuaranteed qualityTextile treatment carriersTextile treatment rollersControl systemStructural engineering

The invention relates to an automatic fabric tension control system suitable for a knitting open-width wet processing unit. The system comprises at least more than two groups of wet processing units, wherein adjacent wet processing units are in station connection to form the open-width wet processing unit; drum / roller group stations and roller groups which are matched with the drum / roller groups are arranged in box bodies of the wet processing units; and the system is characterized in that: the drum / roller groups are main driving components; and the roller groups comprise driving rollers and driven rollers which are matched with each other. The invention has outstanding characteristics that: the drums / rollers, rollers and traction rollers in each wet processing unit are main driving components; numerical values of various driving mechanisms can be directly set according to differences of fabric composition and technical requirements of fabrics machined by the unit, so that the fabrics do not have tension, the fabrics are prevented from being subjected to tensile deformation in each wet processing unit, and the quality of the fabrics is guaranteed.

Owner:绍兴东升数码科技有限公司

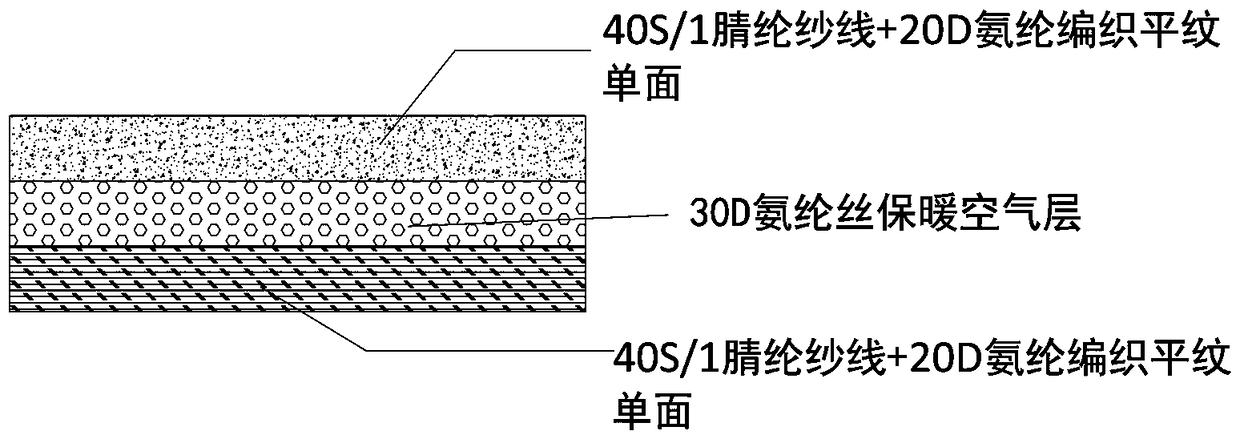

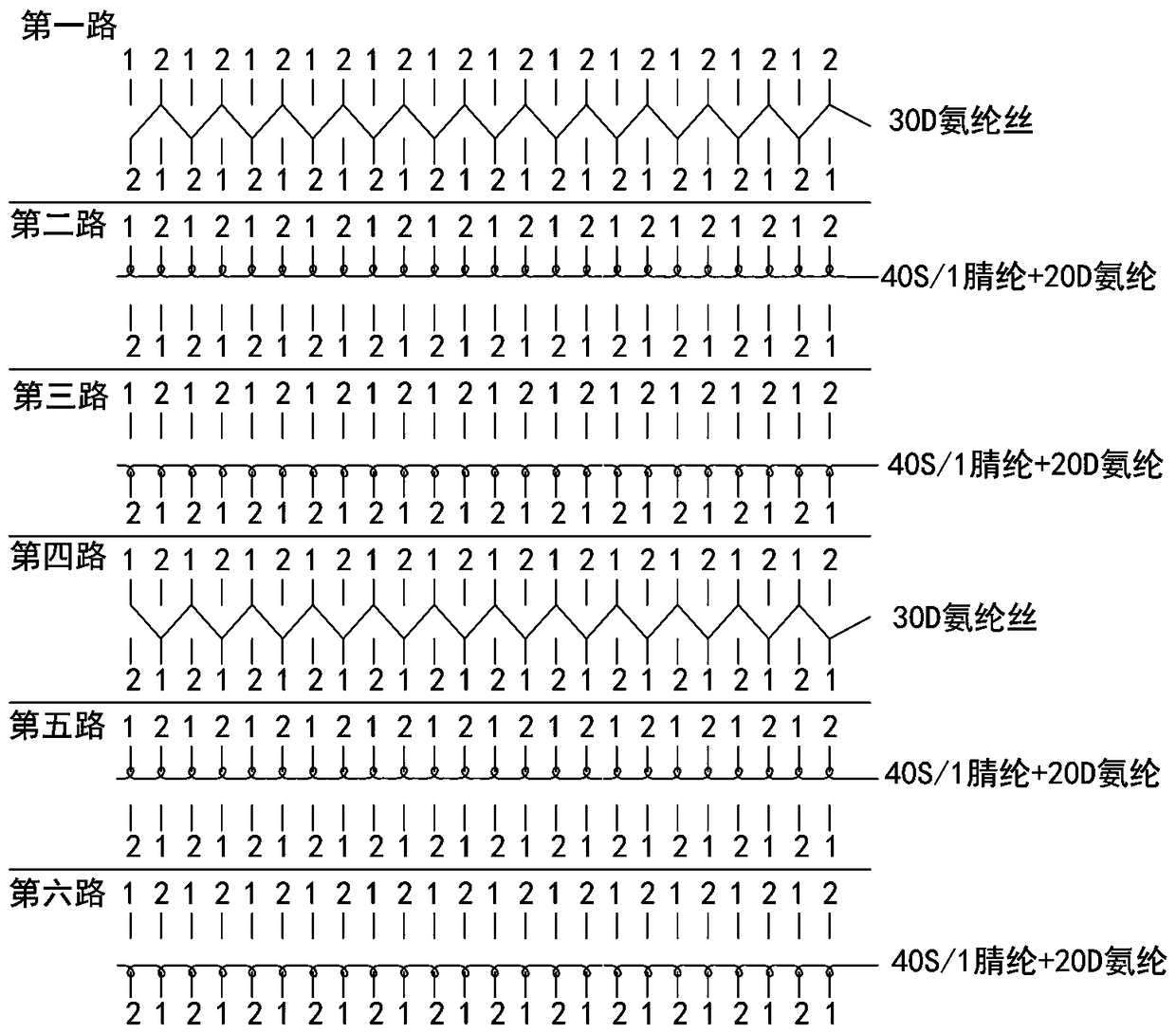

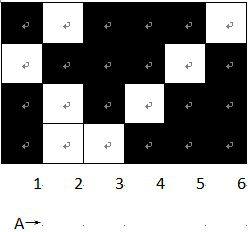

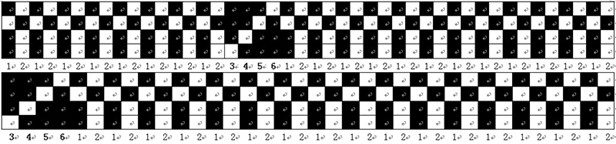

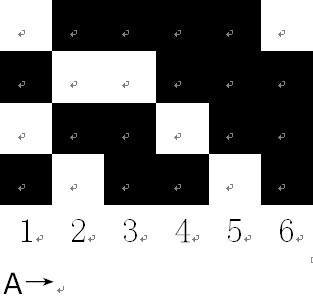

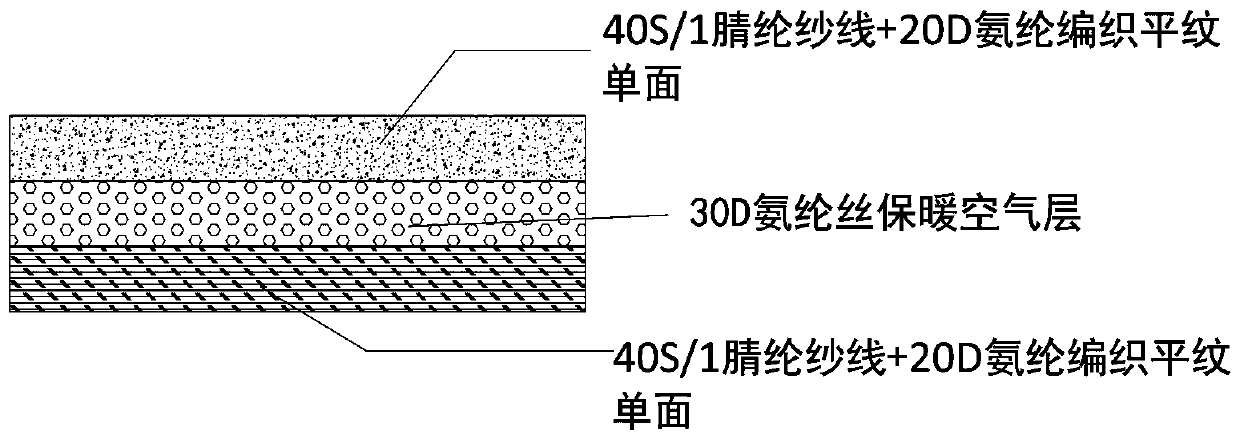

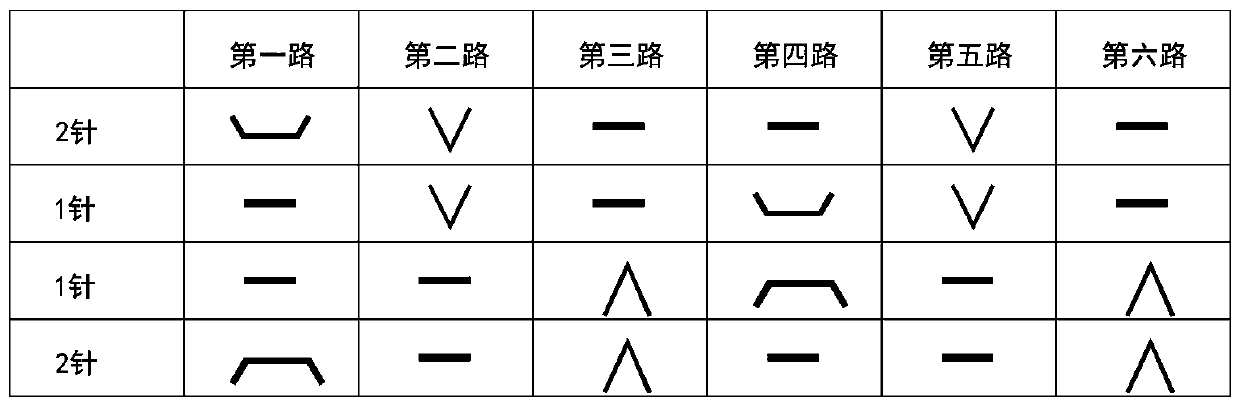

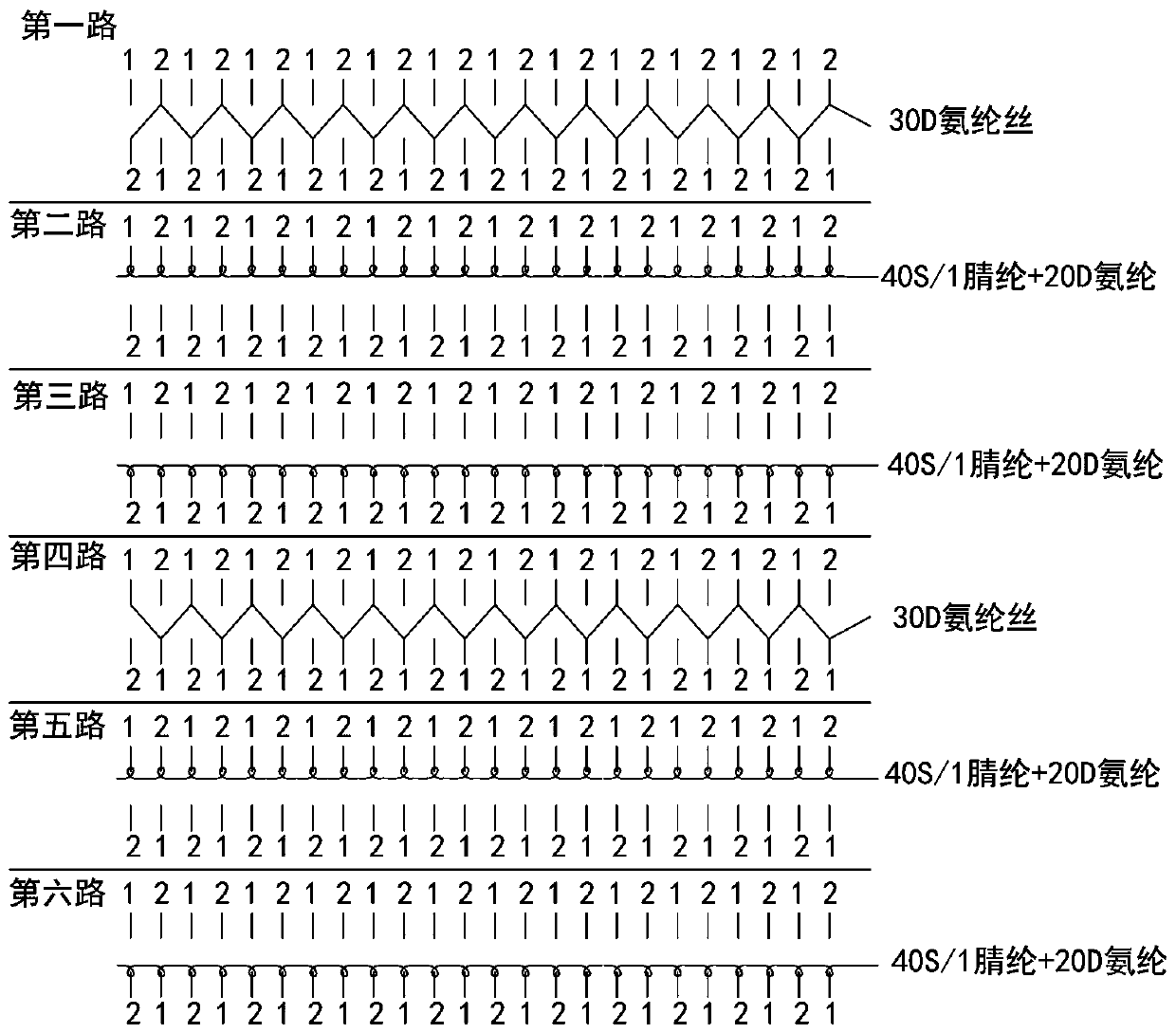

Double-layer air layer pure separation shell fabric capable of being tailored at will

The invention relates to the technical field of shell fabric weaving and specifically relates to a double-layer air layer pure separation shell fabric capable of being tailored at will. The double-layer air layer pure separation shell fabric an upper-layer plain single face and a lower-layer plain single face, wherein the upper-layer plain single face and the lower-layer plain single face are woven from 20 D asahi kasei spandex and 40 S / 1 toyobo acrylic fiber yarns, the upper-layer plain single face and the lower-layer plain single face are woven and connected together through spandex betweenthe upper-layer plain single face and the lower-layer plain single face, an a thermal-insulation air layer is formed between the upper-layer plain single face and the lower-layer plain single face, the spandex is chosen from asahi kasei 30 D spandex, and the double-layer air layer pure separation shell fabric capable of being tailored at will is woven by a six-way circular weaving method. The double-layer air layer pure separation shell fabric disclosed by the invention has the advantages that upper-layer gray cloth and lower-layer gray cloth are connected through the spandex, no chemical adhesion aid is utilized, and environmental friendliness and hygiene are achieved; the double-layer air layer pure separation shell fabric disclosed by the invention is of a unique lock structure, so thatthe shell fabric can be tailored at will, and the problem of hemming of the shell fabric after being tailored is solved; the thermal-insulation air layer is formed between the two layers of cloth, sothat the fabric has more thermal insulation and good breathability.

Owner:广东易通纺织科技有限公司

Super-elastic non-hemming denim fabric and preparation method thereof

The invention discloses a super-elastic non-hemming denim fabric and a preparation method thereof, and belongs to the technical field of denim fabric weaving. The fabric comprises a ground weave and two edge weaves, wherein the ground weave is a twill weave; the fabric is characterized in that the two edge weaves are distributed on the left and right outer sides of the ground weave in a mirror symmetry manner; each edge weave comprises two circulating units, namely a plain weave unit and a twill weave unit; and the weave structure of each edge weave sequentially comprises the plain weave unit circulated for 6-12 times, the twill weave unit circulated for 1 time, the plain weave unit circulated for 12-16 times, the twill weave unit circulated for 1 time and the plain weave unit circulated for 14-20 times from the ground weave to the outside in the weft direction. The preparation method comprises the steps of drawing-in and weaving. According to the super-elastic non-hemming denim fabric, the hemming problem of a weft elastic denim fabric can be solved, and the elastic elongation rate and the elastic recovery rate of the denim fabric obtained through the preparation method are relatively high.

Owner:山东兰雁纺织服装有限公司

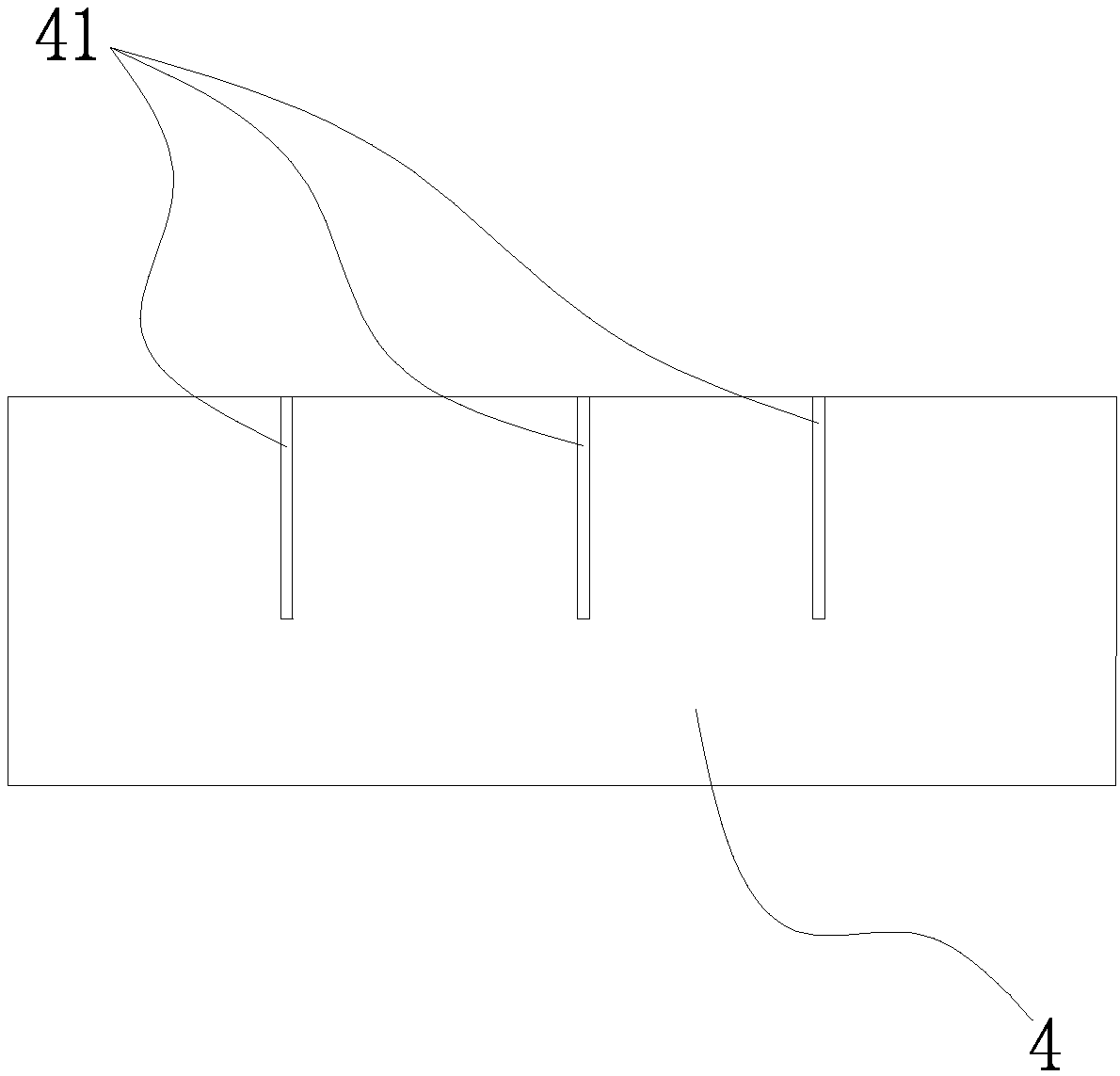

Edge aligning device for hot melting compound machine

The invention relates to an edge aligning device for a hot melting compound machine. The edge aligning device comprises a bottom plate. A left connecting plate is integrally arranged on the left end of the bottom plate and a right connecting plate is integrally arranged on the right end of the bottom plate; a guide plate is integrally arranged on the upper end surface of the bottom plate, and a stainless steel surface layer is fixedly arranged on the upper surface of the guide plate; a limiting plate is fixedly arranged on the back end surface of the bottom plate, and a crimping adjusting device, a first edge fixing device, a second edge fixing device and a third edge fixing device are successively arranged right above the stainless steel surface layer from middle to left; a first lightinglamp device, a second lighting lamp device, a third lighting lamp device and a monitoring device are successively arranged on the limiting plate from left to right. By adopting the technical scheme,the edge aligning device is reasonable in structure set, simple in structure and convenient to use, can solve the problem of crimping a material, reduces the labor intensity and the production cost, and is high in production efficiency.

Owner:平湖市新保纺织科技有限公司

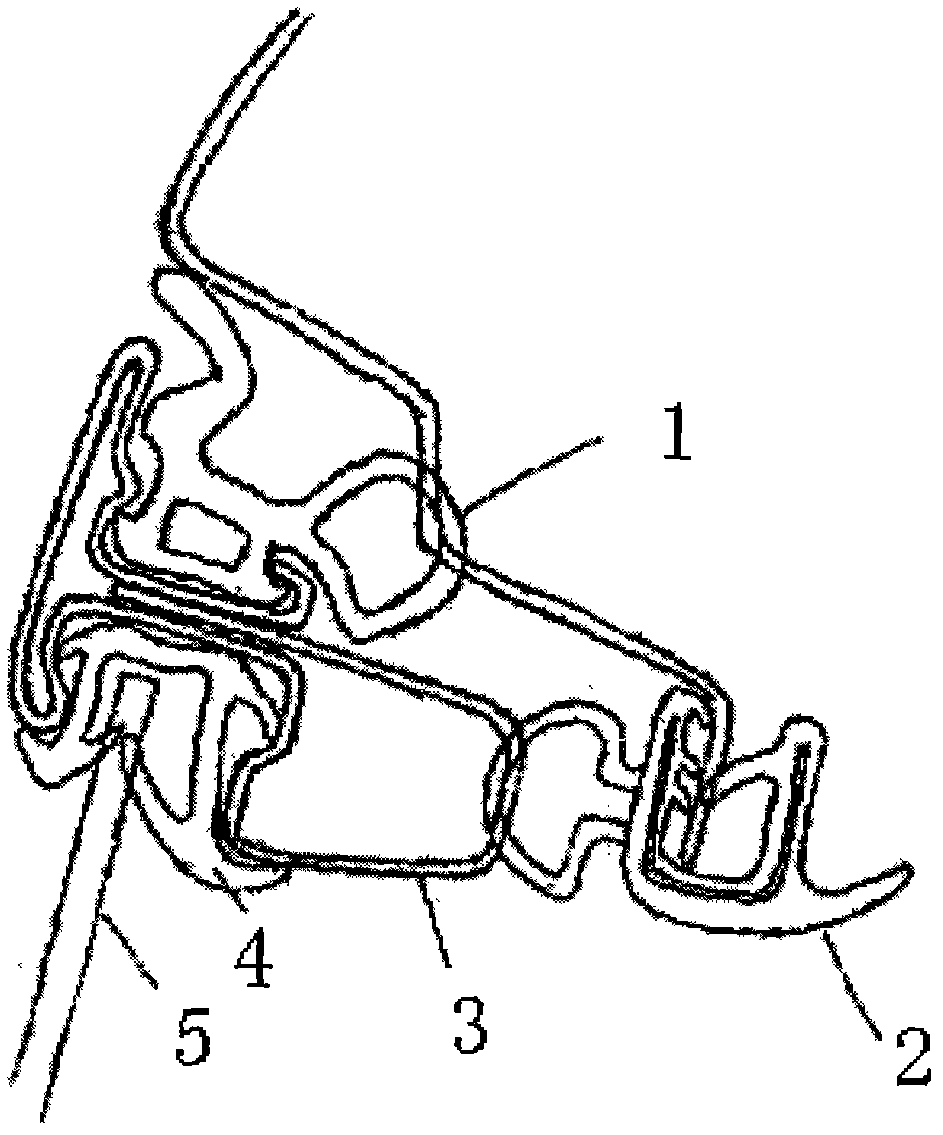

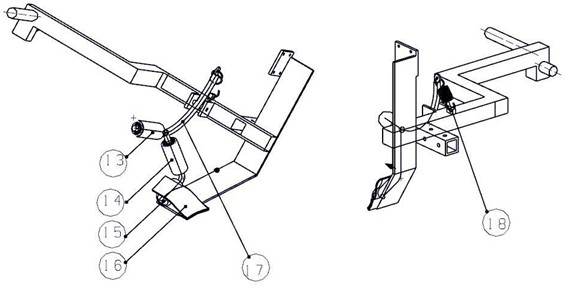

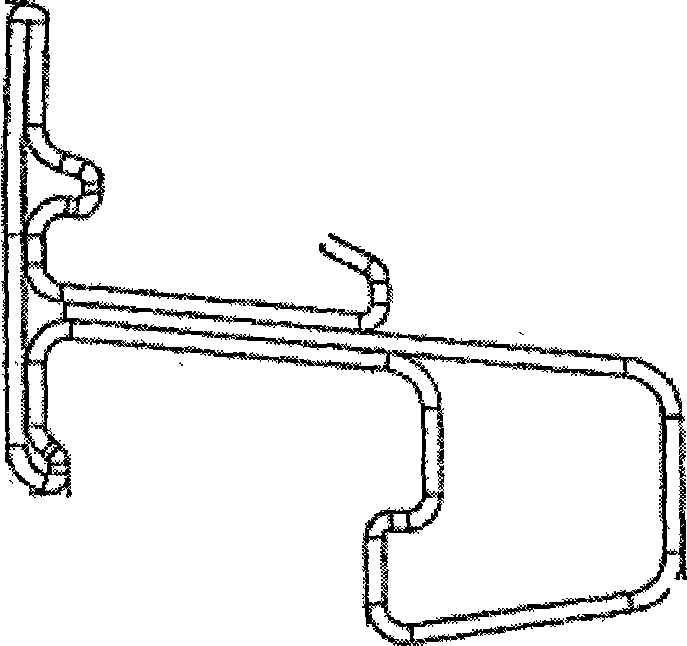

Method and device for fastening joint corner position of sealing strip of front door of automobile

InactiveCN102848891AAvoid water and dust leakageImprove reliabilityEngine sealsVehicle sealing arrangementsCar doorHinge angle

The invention provides a method and a device for fastening a joint corner position of a sealing strip of a front door of an automobile. The problems of deformation and failure are mainly caused by the fact that bottom section barbs of the sealing strip of a ROOF section at the top of the sealing strip of the front door of the automobile are mainly clamped through a section of a guide rail, and an installation and fastening purpose and good waterproof and dustproof sealing performance are achieved; however, near the position of a hinge of the front door, the space is narrow, an adhesive tape is not installed in place and is easy to separate from the guide rail, the sealing strip is pressed and deformed when the door is opened or closed, and an existing sealing effect disappears completely. The technical scheme includes that an inserting sheet is added at the position which is 30mm away from the edge of the guide rail of the ROOF section of the sealing strip of the front door, the inserting sheet is attached to the bottom section of the sealing strip, during assembly, the guide rail is slide in firstly, and then the sealing strip is installed and fastened, and looseness is avoided.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

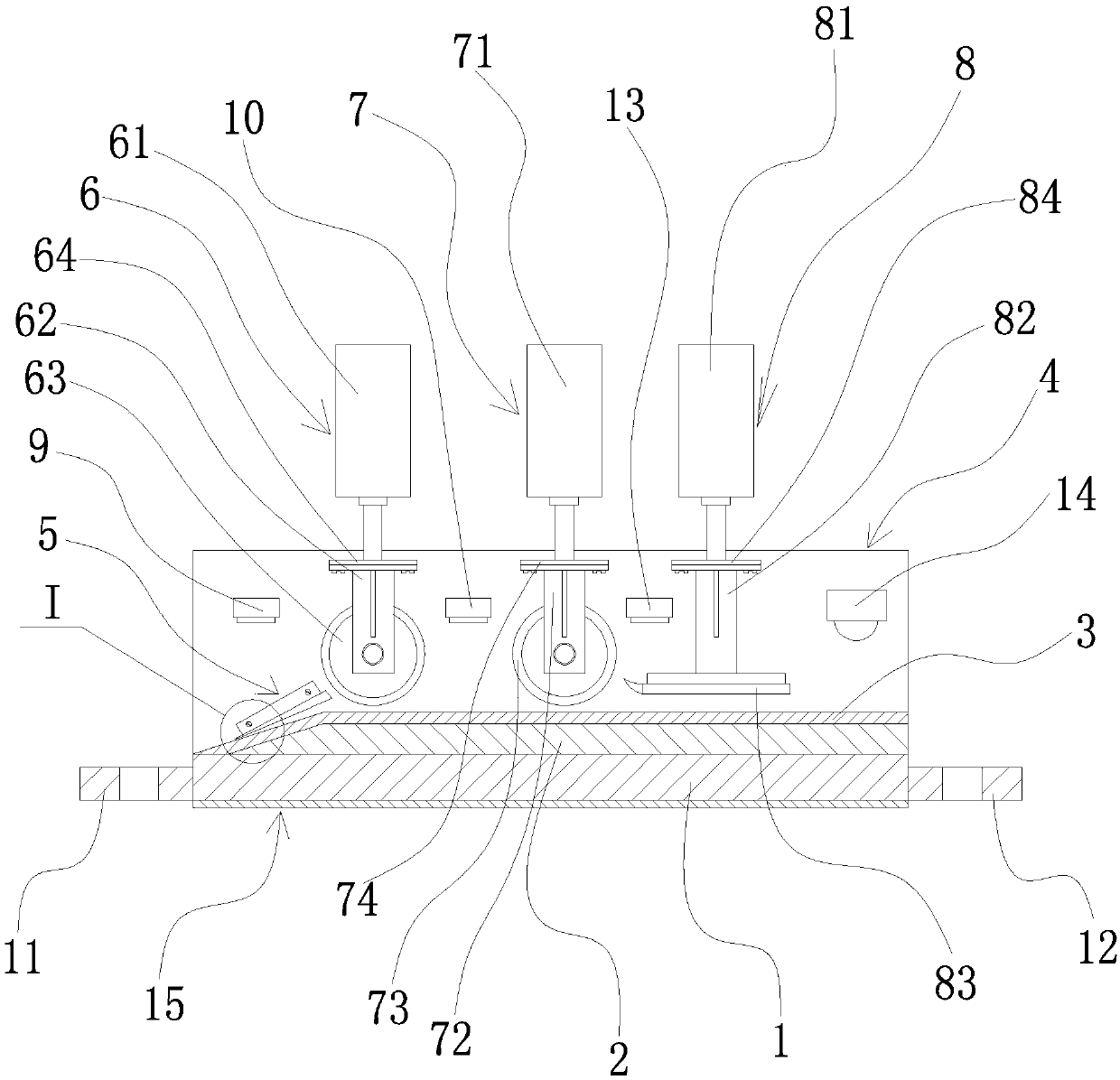

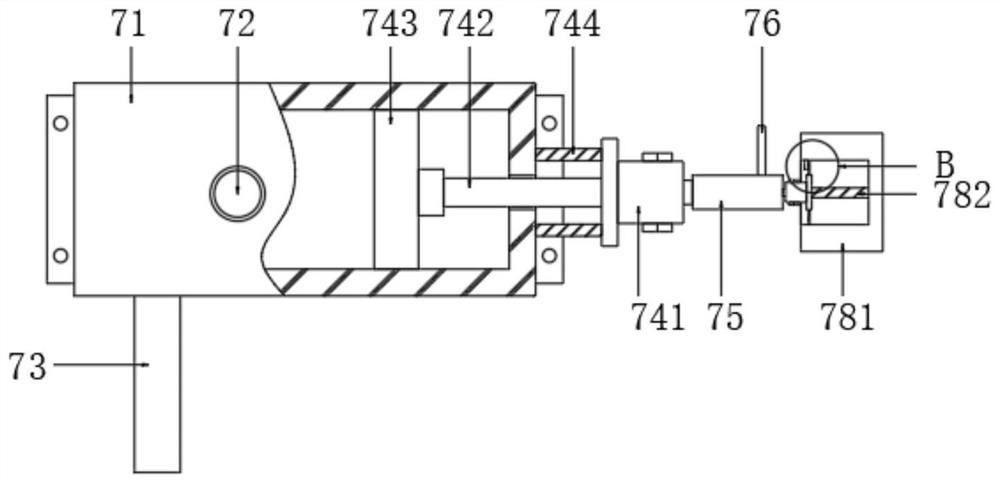

Expressway surface concrete layer leveling equipment and method for avoiding curl of curing film

The invention discloses expressway surface concrete layer leveling equipment and method for avoiding curl of a curing film in the technical field of expressway construction, and the equipment comprises a fixing plate, vertical plates are arranged on the front side and the rear side of the top of the fixing plate, and a fixing groove is formed in the left side of the fixing plate; the opposite sides of the two sets of vertical plates are rotationally connected with rotating rollers through bearings, one end of each rotating roller is connected with the power end of a motor, the motors are fixedly connected to the vertical plates, curing films are wound around the outer walls of the rotating rollers, glue solidifies to enable pressing blocks and the curing films to be bonded together, and it can be effectively guaranteed that the pressing blocks press the curing films. The pressing block is arranged, so that the pressing block cannot be moved by external factors, the maintenance film can be pressed after the maintenance film is laid, the edge curling problem of the maintenance film is solved, a subsequent heavy object placing mode is not needed, and the equipment is extremely suitable for being used on a long-distance expressway.

Owner:中国铁建昆仑投资集团有限公司

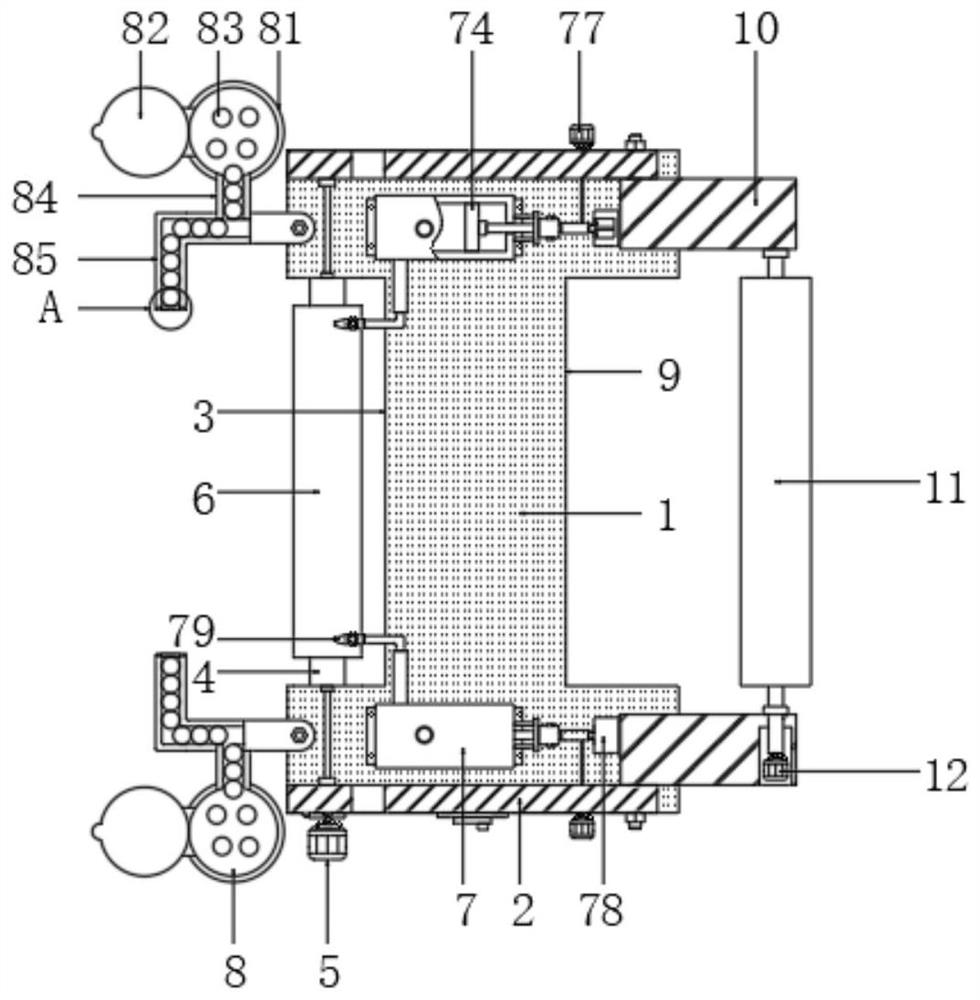

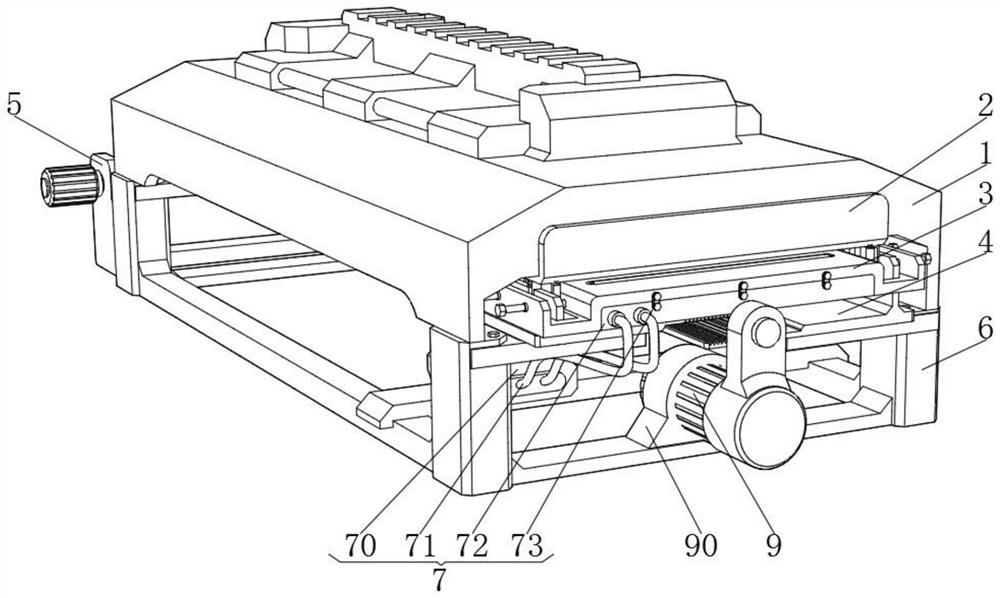

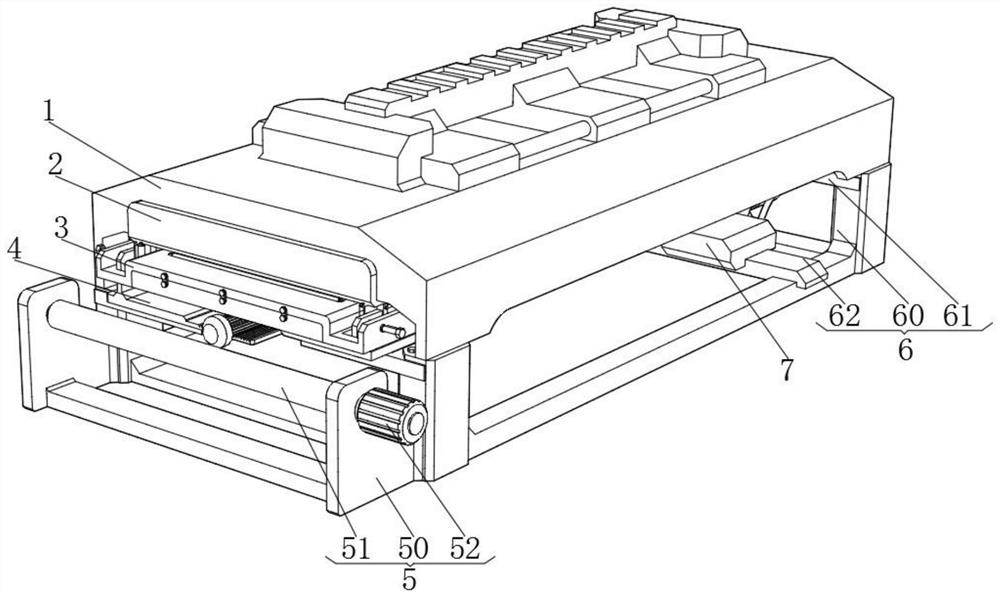

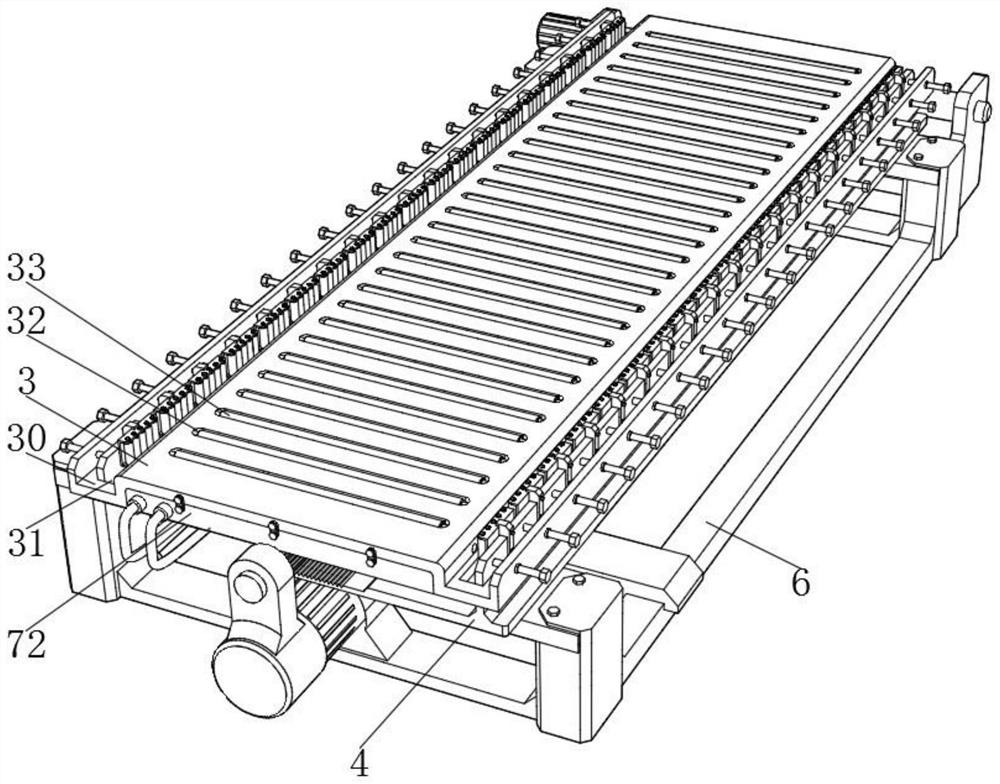

Cloth drying device capable of preventing edge curling and used for dance garment processing

ActiveCN113983767ADry thoroughlyHeating fastDrying solid materials with heatDrying machines with progressive movementsMechanical engineeringMaterials science

The invention discloses cloth drying device capable of preventing edge curling and used for dance garment processing. The device comprises a top cover, a microwave dryer, a cloth drying plate, a cloth edge pressing mechanism, a winding mechanism, a supporting frame and a suction mechanism, and is characterized in that the bottom of the inner side of the top cover and the top of the microwave dryer are fixedly mounted, and the front end of the supporting frame and the rear end of the winding mechanism are fixedly installed. According to the invention, cloth needing to be dried can be placed on the upper surface of a cloth drying plate, the edges of the cloth are placed in grooves in the two sides of the cloth drying plate, after a motor drives a tooth face rod to rotate, a movable pressing plate a and a movable pressing plate b on the upper side and the lower side of the tooth face rod carry edge pressing pieces on the tops of the movable pressing plate a and the movable pressing plate b to get close to the side of the cloth drying plate, the edge pressing pieces tightly extrude the edge of the cloth on the inner side surfaces of grooves for limiting and leveling, and when the cloth is conveyed and dried on the cloth drying plate, the edges of the cloth is always extruded by the edge pressing pieces to be in close contact with the inner walls of the grooves, so that the edge curling phenomenon is avoided when the edges of the cloth are dried.

Owner:江西炫舞文化发展有限公司

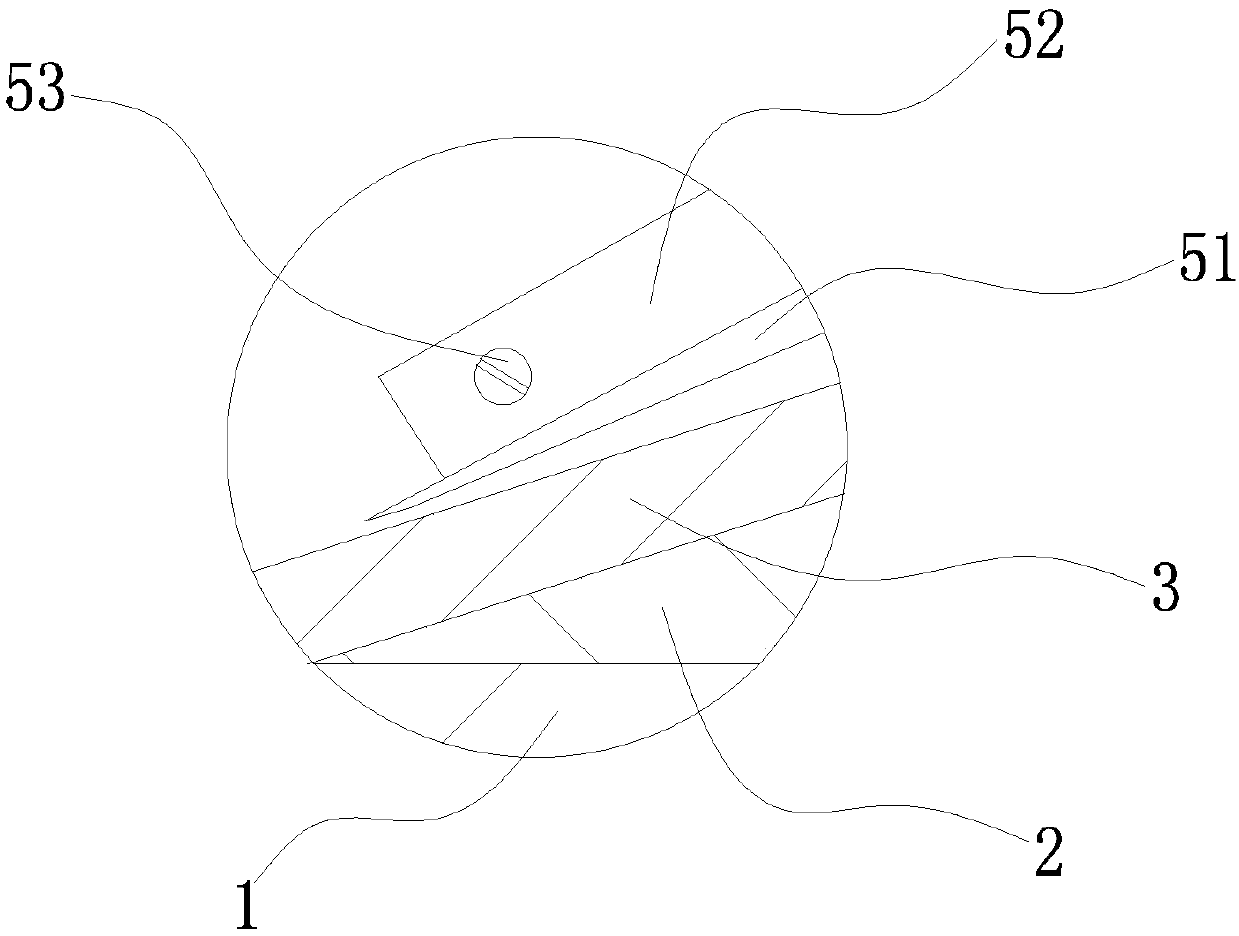

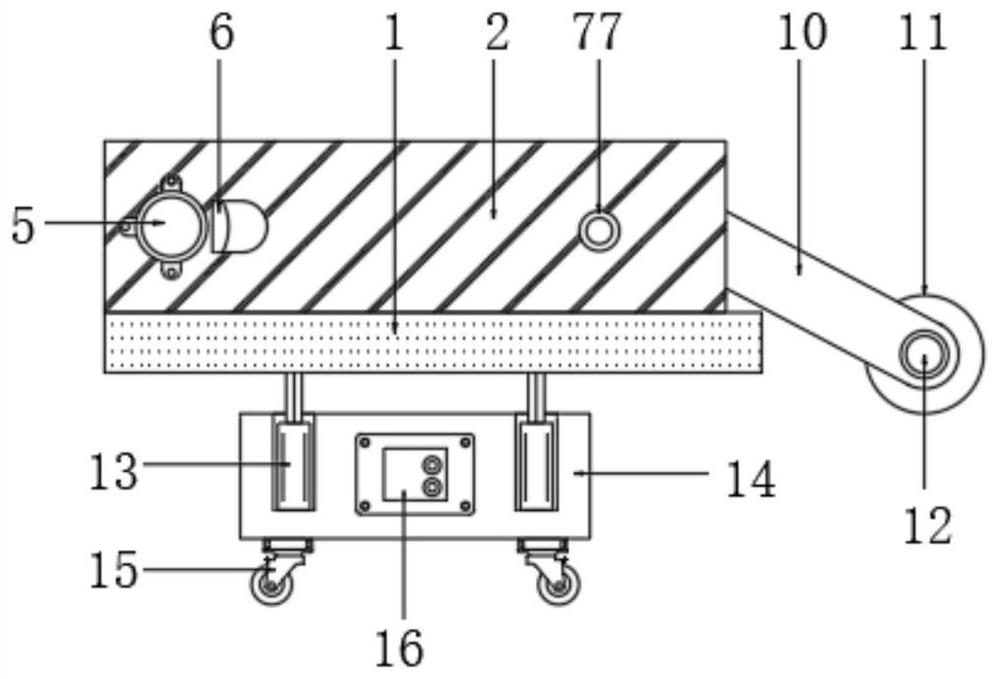

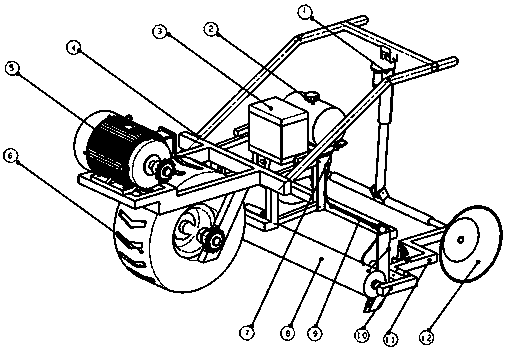

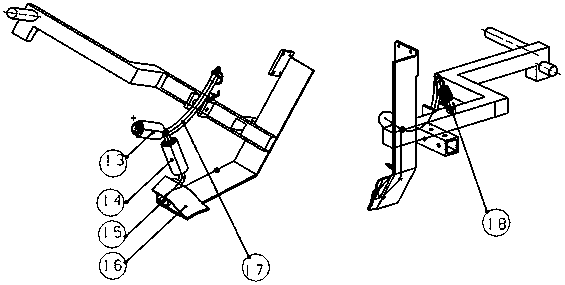

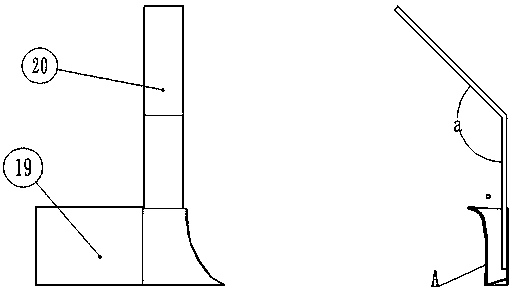

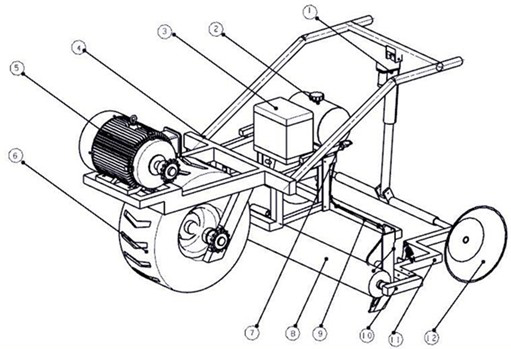

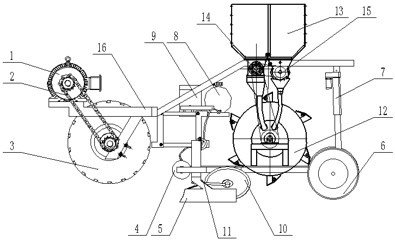

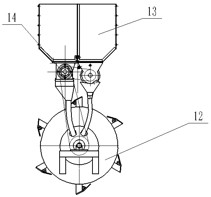

Liquid-spray embedded roller mulching film laying device

ActiveCN107047154ACompact structureWork reliablyPlant protective coveringsMonitoring systemAgricultural engineering

The invention relates to a liquid-spray embedded roller mulching film laying device which is suitable for field and shed film laying, and belongs to the field of agricultural machinery. The device is composed of a driving system, a liquid spray system, a furrowing and film laying system, an intelligent control system and a rack, each group serves as a monomer and is installed on the rack, the device is driven by the driving system to work, the intelligent control system reasonably controls the film pressing strength and furrowing depth, reasonable film pressing is achieved, and film laying operation of the ridge width being 400-1,500 mm can be completed. An opener stand column is installed on the adjustable rack, an opener is installed on the opener stand column by forming an angle of 45 degrees with the opener stand column, and three small film pressing rollers with different angles cooperate with the opener to complete film laying. A liquid box is installed on the rear end rack, a thin tube is installed at the bottom of a box body, and the thin tube is led to the position, inclining inwards, of the edge of the two ends of mulching film. A truncated conical-shaped press wheel is installed at the rear end of the rack, and intelligent adjustment can be conducted on pressure through a monitoring system according to the agricultural requirements.

Owner:SHANDONG UNIV OF TECH

Soft sheepskin-like polyurethane resin, preparation method and method for preparing sheepskin-like synthetic leather with the soft sheepskin-like polyurethane resin

ActiveCN105671989BImprove immersionMuch infiltrationGlovesPolyurea/polyurethane coatingsN dimethylformamideWear resistance

The invention relates to soft sheepskin-imitating polyurethane resin which includes the following components: wet-method polyurethane resin, N,N-dimethylformamide, paper pulp powder, a hand feeling agent, a permeation agent, an anti-crimping agent and an oily color material. The invention also relates to a method of producing sheepskin-imitating artificial leather with the soft sheepskin-imitating polyurethane resin, wherein the method includes the following steps: 1) impregnating a base cloth in a soft sheepskin-imitating polyurethane resin mixture liquid; 2) regulating sizing quantity through extrusion, and performing solidification, water washing, drying and polishing to prepare wet-method base; and 3) performing veneering and vacuum grain suction to the wet-method base to prepare the sheepskin-imitating artificial leather. The sheepskin-imitating artificial leather has a soft and light feel, has fine and elastic hand feeling, is high in tear strength and good in weather and wear resistance, has a soft and natural surface color, has full grains and has strong stereoscopic sense.

Owner:SHANGHAI HUIDE TECH CO LTD

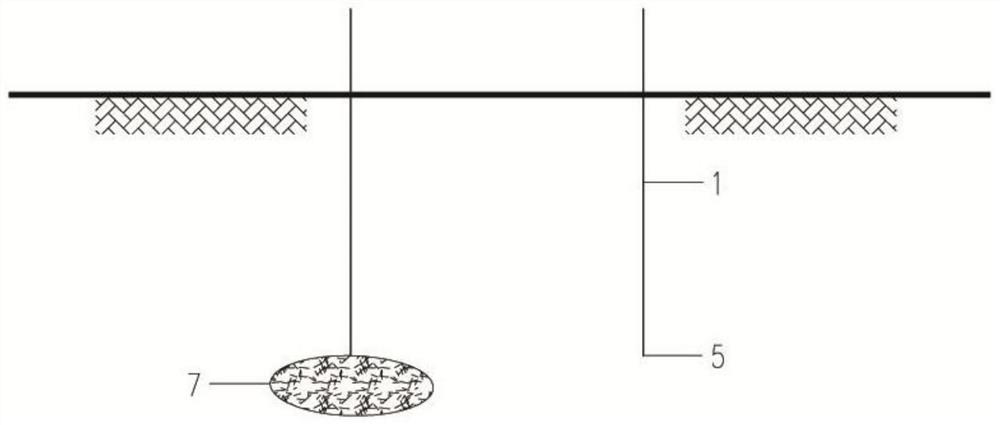

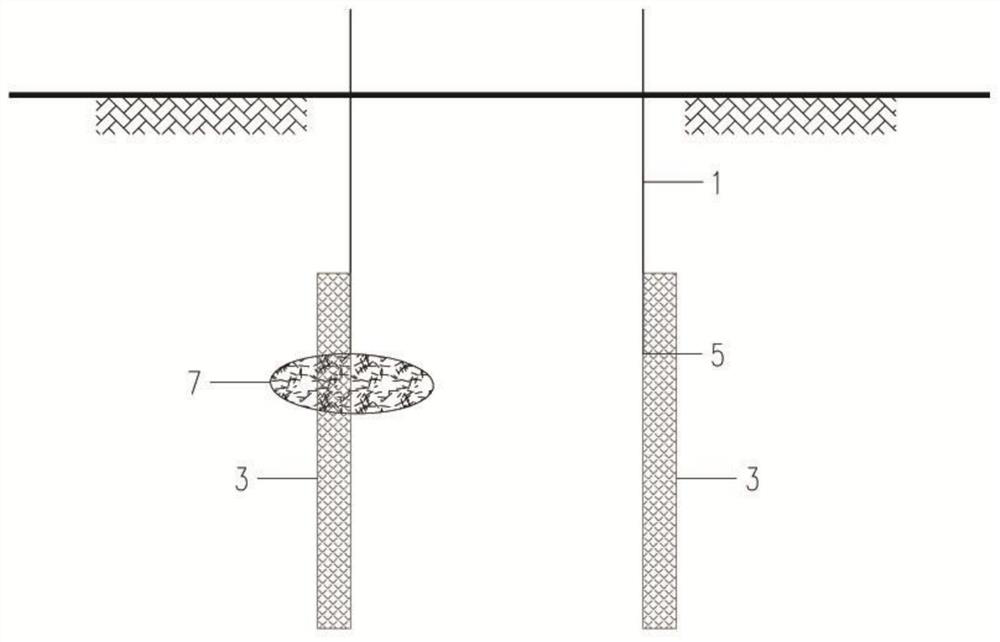

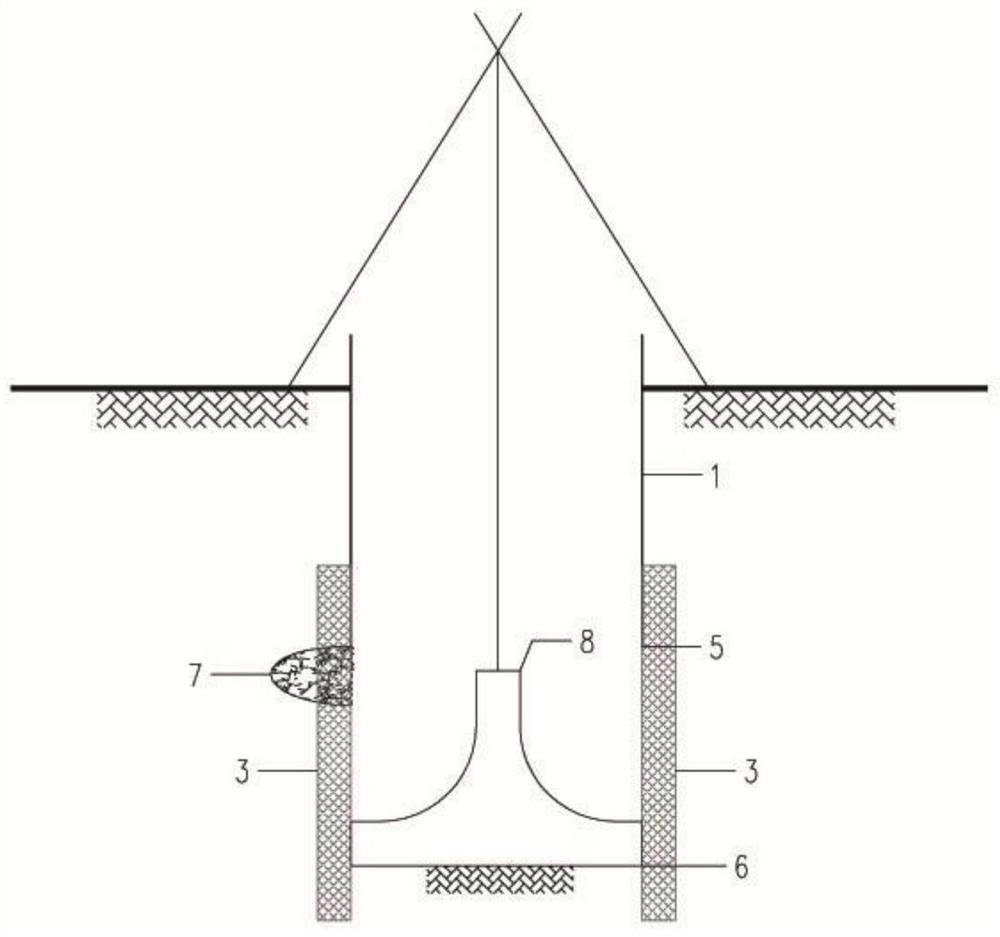

The treatment method of the steel casing sinking and meeting the boulder, the structure of the steel casing and the bored pile

The invention discloses a treatment method for sinking a steel casing to encounter a boulder, a steel casing structure and a drilled pile, and relates to the technical field of steel casing construction. The treatment method includes the following steps that S1, a first steel casing is inserted at a designed pile location until the bottom of the first steel casing encounters the boulder, and the diameter of the first steel casing is larger than that of a designed pile hole; S2, sweep hole operation is carried out along the inner wall of the first steel casing, the boulder at the hole wall is broken and the pile hole is excavated until the bottom of the pile hole reaches the elevation of a bottom port of the steel casing required by design; S3, a bottom port of a second steel casing is lowered to the elevation of a bottom port of the steel casing, and the diameter of the second steel casing is larger than the diameter of the designed pile hole; and S4, a gap in the first steel casing and the second steel casing is filled with concrete. According to the treatment method for sinking the steel casing to encounter the boulder, the steel casing can be lowered into the designed elevationin the pile hole, and the problem of rolled edge or stuck at the bottom port of the steel casing under the condition of steel casing sinking to encounter the boulder is solved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

A liquid spray embedded roller mulching device

ActiveCN107047154BCompact structureWork reliablyPlant protective coveringsAgricultural engineeringPlastic mulch

The invention relates to a liquid-spraying embedded roller mulching device, which is suitable for film-laying in fields and sheds, and belongs to the field of agricultural machinery. It consists of a drive system, a liquid spray system, a ditching film system, an intelligent control system, and a frame. Each group is installed on the frame as a single unit, driven by the drive system. The intelligent control system reasonably controls the strength and opening of the film. The depth of the ditch can achieve reasonable lamination, and it can complete the film laying operation with a ridge width of 400-1500mm. The opener column is installed on the adjustable frame, and the opener and the opener column are installed on the opener column at a 45° angle. Three small lamination rollers with different angles cooperate with the opener to complete the film laying . Install a fluid tank on the rear rack. A thin tube is installed at the bottom of the box, and the thin tube is led to the inner position of the edges of the two ends of the mulching film. A truncated conical pressure wheel is installed at the rear end of the frame, and the pressure can be intelligently adjusted according to agricultural requirements with a monitoring system.

Owner:SHANDONG UNIV OF TECH

Method and device for fastening joint corner position of sealing strip of front door of automobile

InactiveCN102848891BImprove satisfactionSolve curlingEngine sealsVehicle sealing arrangementsEngineeringCar door

The invention provides a method and a device for fastening a joint corner position of a sealing strip of a front door of an automobile. The problems of deformation and failure are mainly caused by the fact that bottom section barbs of the sealing strip of a ROOF section at the top of the sealing strip of the front door of the automobile are mainly clamped through a section of a guide rail, and an installation and fastening purpose and good waterproof and dustproof sealing performance are achieved; however, near the position of a hinge of the front door, the space is narrow, an adhesive tape is not installed in place and is easy to separate from the guide rail, the sealing strip is pressed and deformed when the door is opened or closed, and an existing sealing effect disappears completely. The technical scheme includes that an inserting sheet is added at the position which is 30mm away from the edge of the guide rail of the ROOF section of the sealing strip of the front door, the inserting sheet is attached to the bottom section of the sealing strip, during assembly, the guide rail is slide in firstly, and then the sealing strip is installed and fastened, and looseness is avoided.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Battery pole piece and method for preventing battery pole piece from curling

ActiveCN107134561BSolve curlingReduce material dropElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesPole pieceMetal

The invention discloses a battery pole piece and a method for preventing the battery pole piece from being curled. The battery pole piece comprises a metal current collector, wherein an active material layer is arranged on side of the metal current collector; and a high polymer material layer is arranged on the other side of the metal current collector. According to the battery pole piece disclosed by the invention, the high polymer material layer is arranged on one side, on which the active material layer does not need to be arranged, of the metal current collector, and stress caused by extension of the active material after rolling can be offset or partially offset, so that the pole piece curling problem caused by single-sided coating and rolling of the pole piece can be solved.

Owner:HANGZHOU FUTURE POWER TECH

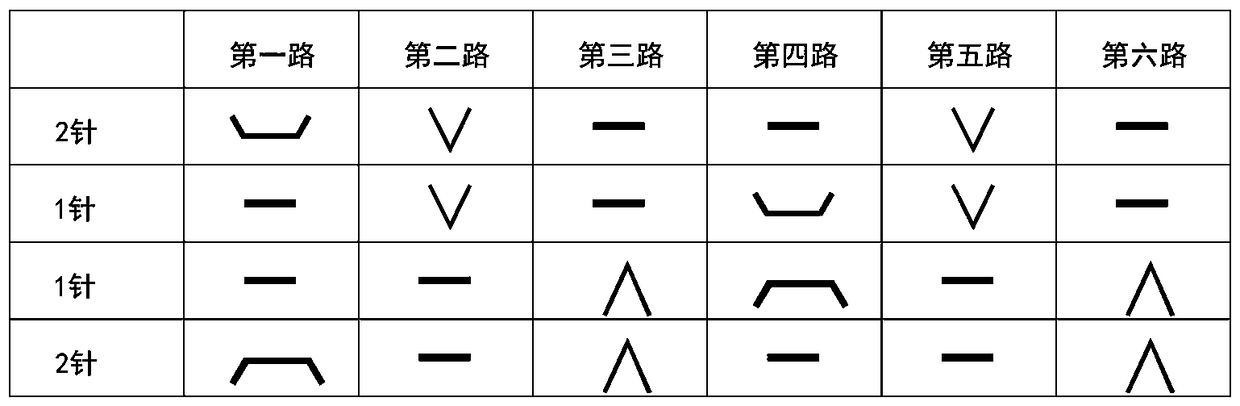

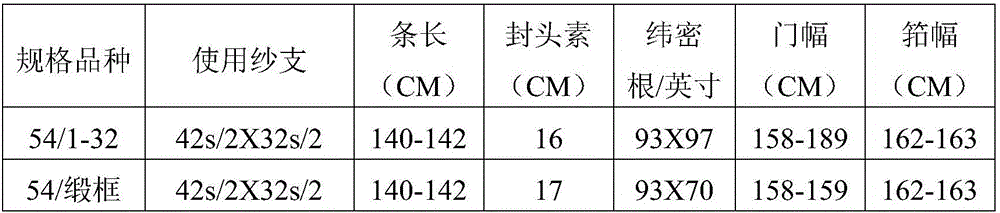

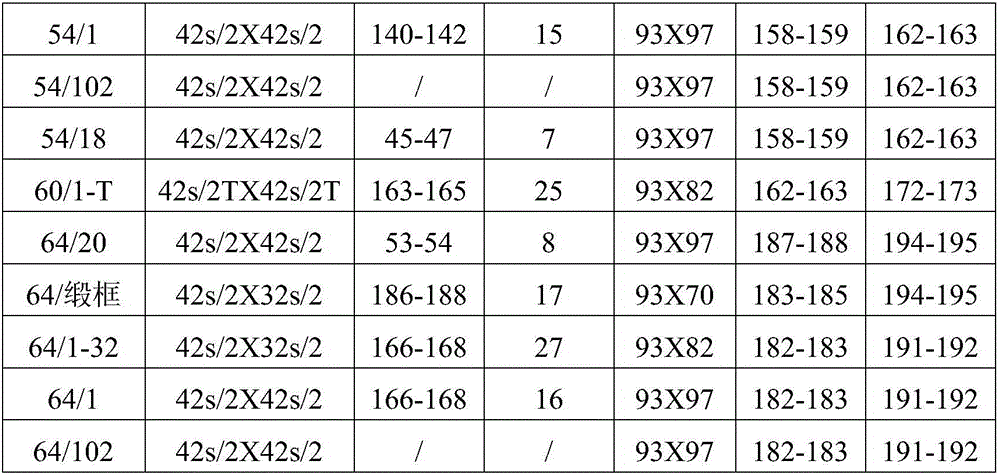

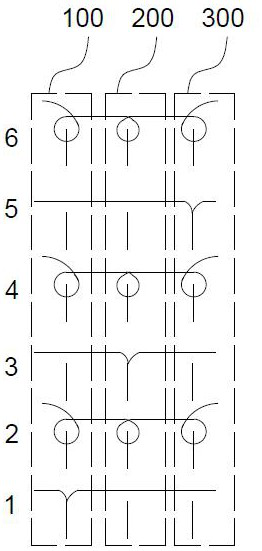

Anti-curl satin drill elastic fabric and weaving process thereof

ActiveCN103437040BSolve curlingChange the threading processFibre treatmentResilient fabricsPolymer scienceEngineering

The invention discloses a weaving process of an anti-curl elastic fabric and an anti-curl elastic fabric obtained by the process. The process steps include raw material preparation, twisting, warping, sizing, reeding, and weaving , finishing, the warp yarn is 100% cotton yarn, and the weft yarn is cotton-wrapped spandex yarn, wherein the weight percentage of cotton yarn is 92.38-94.94%, and the corresponding spandex yarn weight percentage is 7.62-5.06%; the warp yarn count is 21-, and the corresponding weft yarn count 16—, the fineness of the covered spandex yarn is 70—40D; the reeding process adopts 6 pages of healds, the threading sequence is ground weave: 2.3.4.5.6, side weave: 2.2.1.1 from the left 7 times Gradually reduce to 2 times. The threading method on the right is opposite to that on the left. 2.2.1.1 The number of cycles from the cloth body to the edge is gradually increased. Change the threading sequence to change the threading process of the selvage weave, thereby effectively eliminating the dyeing and finishing process. curling phenomenon.

Owner:ANHUI YUHUA TEXTILE

Novel cloth hemming device and cloth hemming treatment method

PendingCN112575457ASolve curlingIncrease productivityWork-feeding meansIndustrial engineeringElectrical and Electronics engineering

The invention provides a novel cloth hemming device and a cloth hemming treatment method thereof. The cloth hemming device comprises a support and a hemmer, wherein the hemmer is fixedly connected with the support, a fixing hole is formed in the support, the support is fixed to a workbench of a sewing machine through screws, the hemmer comprises a hemming barrel and a cloth guide rail, the hemmingbarrel comprises a cloth channel, an inlet end and an outlet end, the inlet end is connected with the cloth guide rail, the cloth channel is a cavity defined by all faces of the hemming barrel, one side of the bottom face of the hemming barrel spirally curls inwards by 360 degrees to form a hemming channel and is finally connected with the upper surface of the hemming barrel, the hemming channelis parallel to the cloth guide rail, and the width of the hemming barrel is gradually reduced from the inlet end to the outlet end. According to the hemming device, the hemming problem that the hemming width of cloth is 3 mm or below is effectively solved, double-layer hemming is achieved, output is stable, the efficiency is high, and the hemming device is suitable for application and popularization.

Owner:江苏茂源服饰有限公司

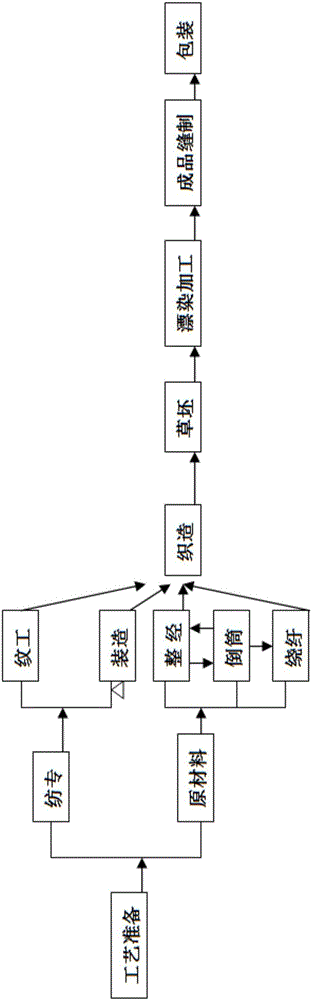

Spinning method of spinning machine

InactiveCN106835421AImprove production and maintenance efficiencyImprove product qualityJacquardsWarping machinesState of artRaw material

The invention discloses a weaving method for a weaving machine, which belongs to the field of weaving. Aiming at the problems of low production and maintenance efficiency, low product quality and insufficient precision existing in the prior art, the present invention provides a jacquard tablecloth weaving method, 1) the textile machine needs to be disassembled and prepared, and the required work The disassembly and assembly of the textile machine includes the following steps: A, dismantling: remove the original loom parts, retain the wall panels and frame, disassemble the loom parts in turn, and repair the worn shafts after disassembly; B, loading: Install the loom components that need to be installed on the frame in turn; C. Calibration: Correct each component after installation to ensure that it is installed at the required position; D. Test run: Conduct a test run of the newly installed loom. 2) Textile machine preparation: Texture preparation and textile machine assembly; 3) Raw material preparation: Warping, rewinding and winding preparation. It can achieve the effects of high production and maintenance efficiency, high product quality and high precision.

Owner:MAANSHAN JINZI TEXTILE OMAMENT

An embedded mulch bedding drilling and seeding machine

Owner:SHANDONG UNIV OF TECH

A low-shrinkage treatment method and finishing method for high-elastic fabrics

ActiveCN106988072BSmall shrinkageSolve curlingShrinkingSucessive textile treatmentsEnvironmental engineeringLow shrinkage

The invention discloses a low-shrinkage treatment method and afterfinishing method of high-elastic fabric and high-elastic fabric; the low-shrinkage treatment method of the high-elastic fabric comprises: washing the high-elastic fabric; dewatering the treated high-elastic fabric; scotching the high-elastic fabric; drying the high-elastic fabric. The low-shrinkage treatment method of the high-elastic fabric provided herein has an additional treatment step in the original fabric afterfinishing method; low-shrinkage treatment is arranged before pre-shrinkage treatment. The high-elastic fabric treated by the low-shrinkage treatment method gains high elasticity and low shrinkage, the difficulty in manufacturing high-elasticity ready-made apparel and washing the ready-made apparel is reduced greatly.

Owner:GUANGDONG FORWARD DENIM

A kind of knitted fabric and its preparation method

ActiveCN111501174BCounteract internal stressRoll resistantWeft knittingHeating/cooling textile fabricsYarnFiber

Owner:GUANGDONG FORWARD DENIM

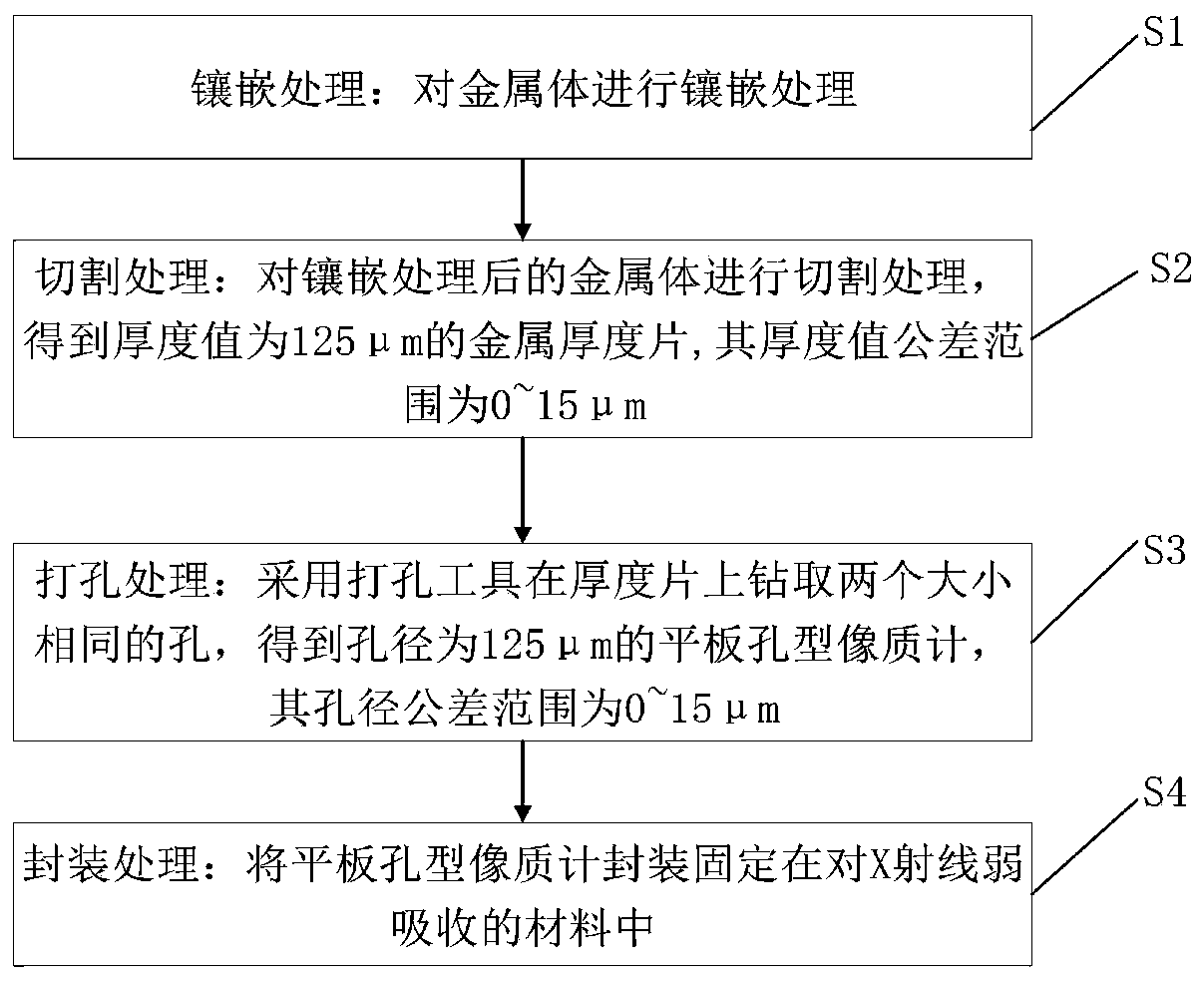

Preparation method of flat plate hole pattern image quality indicator

PendingCN111307839AMeet the standardsEasy to manufacturePreparing sample for investigationMaterial analysis by transmitting radiationImaging qualityImage quality

The invention relates to the field of medical instruments, in particular to a preparation method of a flat plate hole pattern image quality indicator, which comprises the following steps: S1, inlayingtreatment: inlaying a metal body; S2, conducting cutting treatment, specifically, acquiring the metal body obtained after inlaying treatment is cut, a metal thickness piece with the thickness value being 125 micrometers, wherein the tolerance range of the thickness value is 0-15 micrometers; S3, punching treatment: drilling two holes with the same size in the thickness sheet by adopting a punching tool to obtain a flat plate hole pattern image quality indicator with the hole diameter of 125 microns and the hole diameter tolerance range of 0-15 microns; and S4, packaging treatment: packaging and fixing the flat plate hole pattern image quality indicator in a material weakly absorbing X-rays. The preparation method of the flat plate hole pattern image quality indicator provided by the invention meets the requirements on the image quality indicator in radiographic detection, and is simple in process, easy to realize, efficient in production and low in cost.

Owner:广东省医疗器械质量监督检验所

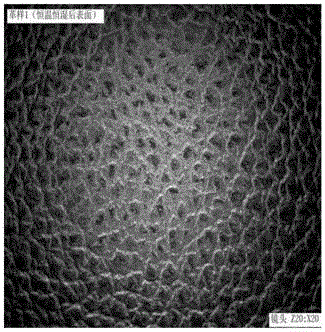

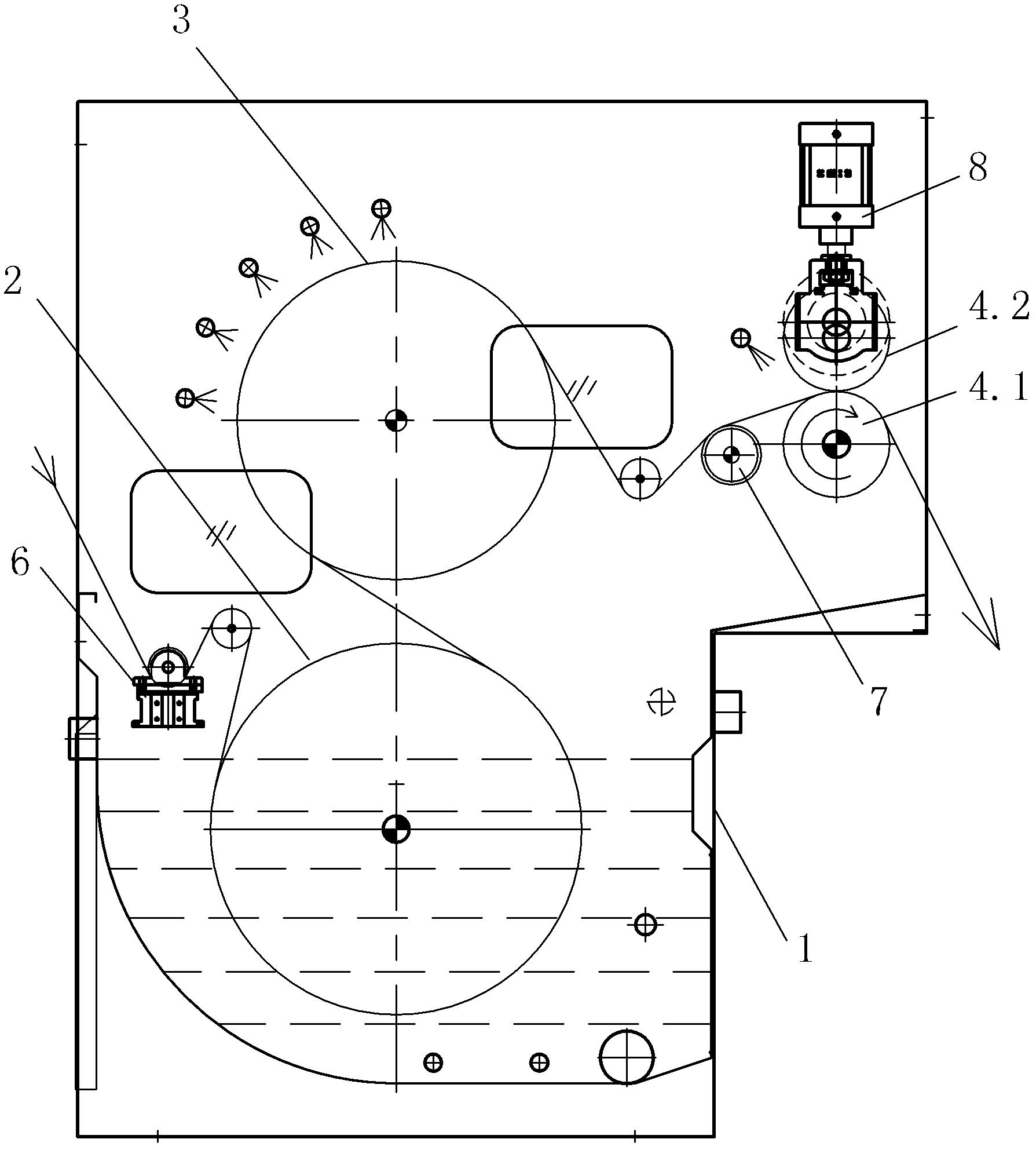

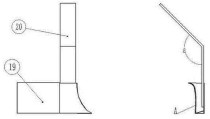

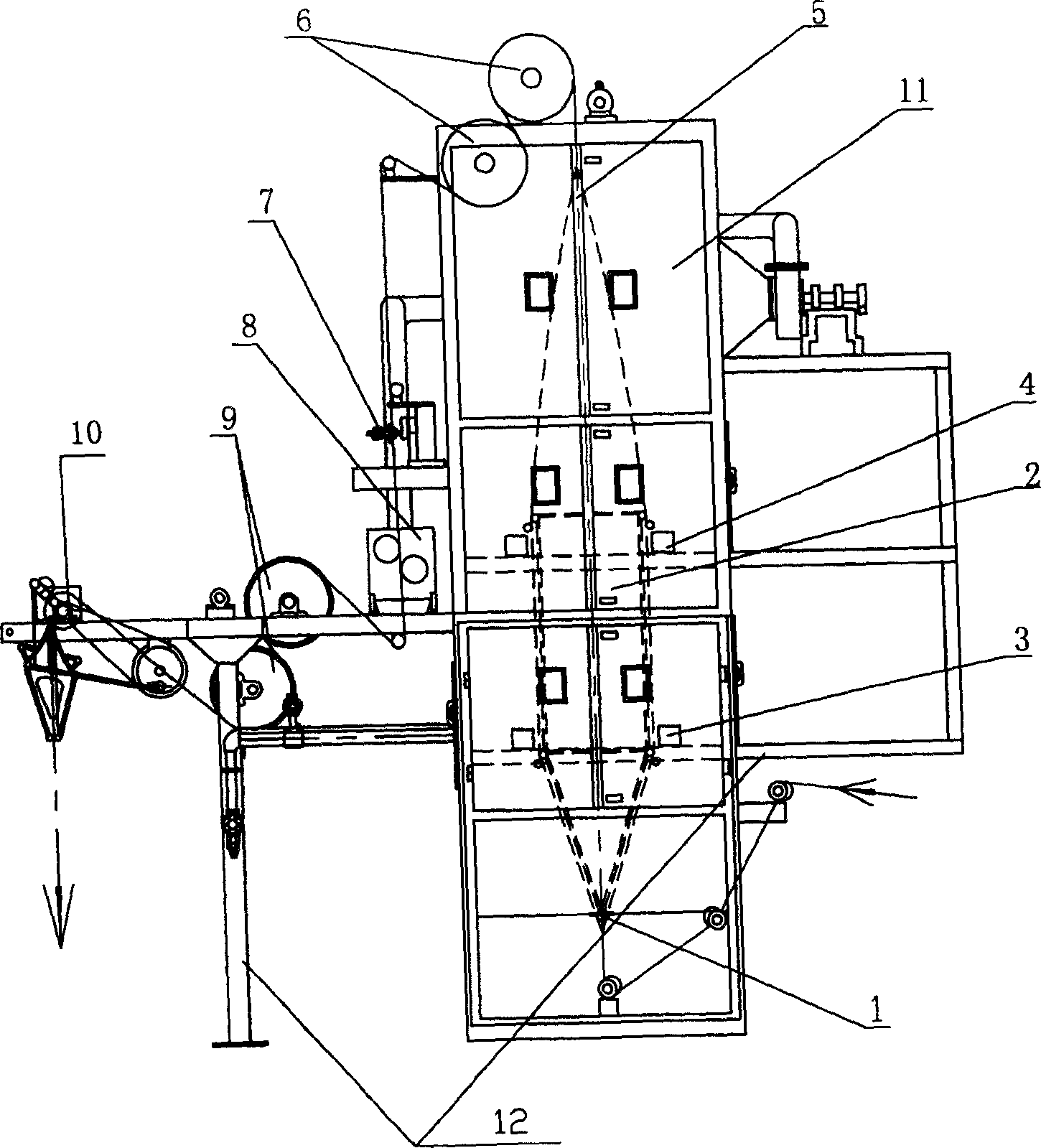

Singeing defold setting machine for non-cutting circular knit

InactiveCN1283874CSolve the difficult problem of knitting fabric curlingSolve curlingSingeingEngineeringTextile

The invention relates to a non-cutting type circular knitted fabric singeing wrinkle-removing and setting machine, which belongs to the field of textile printing and dyeing machinery. It includes frame, cloth feeding device, singeing chamber and cloth falling device. Expansion device, above the inner support sleeve-shaped expansion device, there is a cylindrical flattening expansion device, and an annular singeing burner is arranged around the inner support sleeve-shaped expansion device. The invention solves the curling problem of knitted fabric which is difficult to be solved by the shearing type singeing device. The process is simple, the efficiency is high, and the phenomenon of oblique pulling will not occur. It is prone to the disadvantages of stripes and singeing marks.

Owner:QINGDAO JINDING MACHINERY

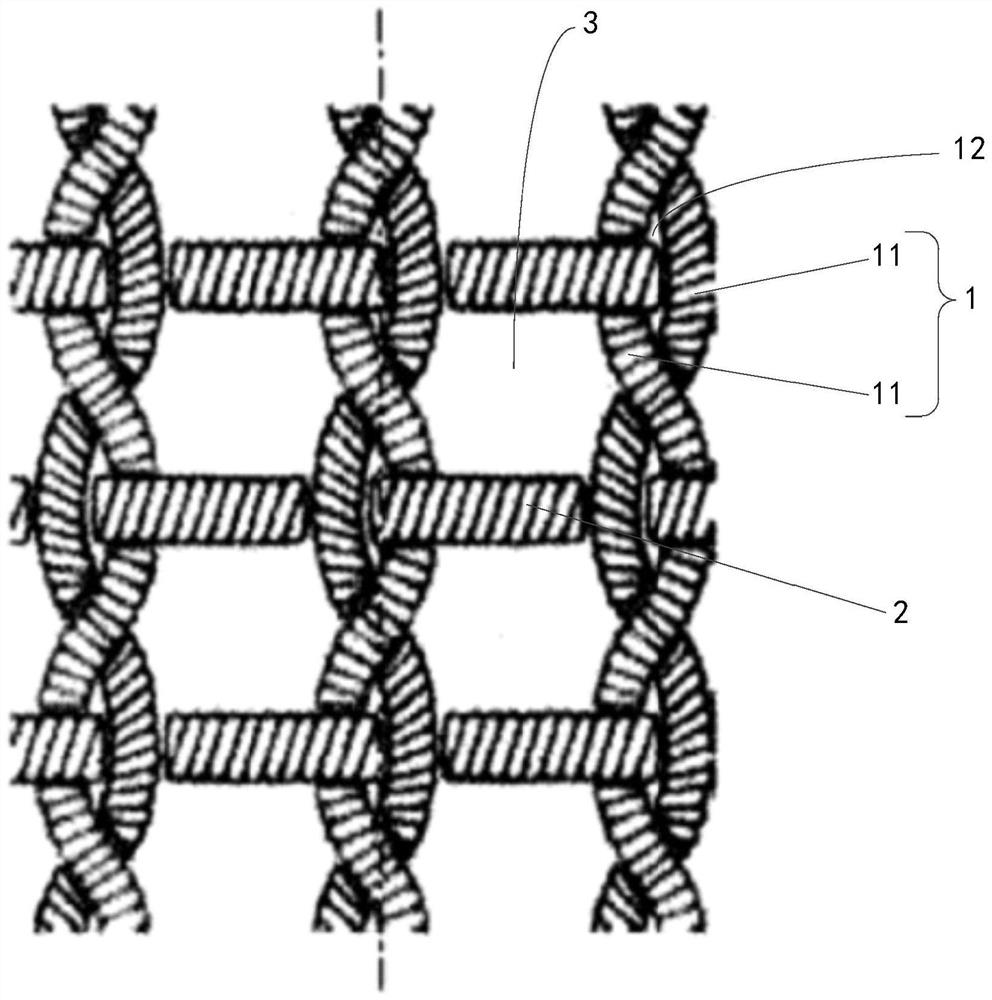

Warp-knitting-like high-performance woven mesh fabric and weaving method thereof

PendingCN114753042AHigh tensile strengthLarge design spaceOpen work fabricsFiberMechanical engineering

The invention provides a warp-knitting-like high-performance woven mesh fabric and a weaving method thereof, and relates to the technical field of weaving. The warp-knitting-like high-performance woven mesh fabric comprises a plurality of warp units arranged side by side, each warp unit comprises two pieces of warp, the two pieces of warp are twisted together to form the warp unit, and a plurality of through holes are continuously formed in the length direction of the warp units; the plurality of wefts are arranged side by side in the length direction of the warp units, and the wefts sequentially penetrate through one through hole of each warp unit to connect the plurality of warp units; wherein every two adjacent warp units and every two adjacent weft units are enclosed to form meshes. According to the structure provided by the warp-knitting-like high-performance woven mesh fabric, high-performance fibers can be used for weaving in a weaving mode, the problems of broken holes and curled edges generated by the high-performance fiber woven mesh fabric are solved, meanwhile, the tensile strength is improved, and the gram weight of the fabric is reduced.

Owner:SHANGHAI LABON TECHNICAL FIBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com