A liquid spray embedded roller mulching device

An embedded and roller technology, which is applied in the field of liquid spray embedded roller mulch covering device, can solve the problems of large mulch covering area, insufficient sunlight utilization rate, and poor mulch fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] The present invention will be described in further detail below in conjunction with the embodiments given by the accompanying drawings.

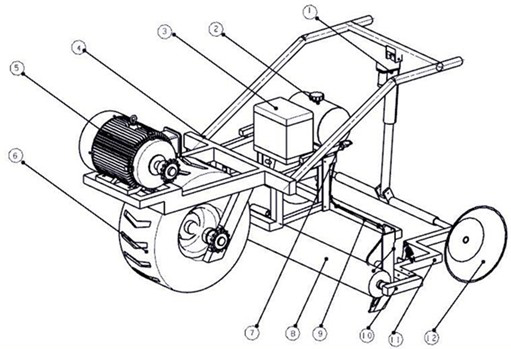

[0016] The present invention works by connecting various parts by the frame, first the traveling wheel (6) and the speed regulating motor (5) are placed on the front end of the frame, and the speed regulating motor is installed at a position partial to the front relative to the traveling wheel main shaft. The control box (3) and the liquid tank (2) are installed in a fixed position below the frame.

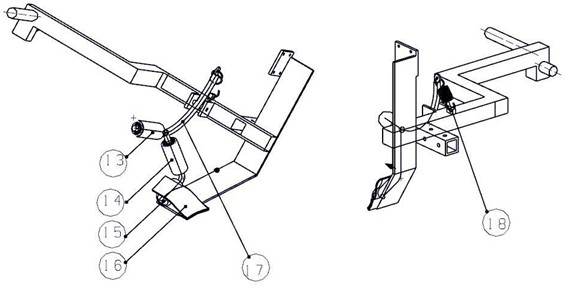

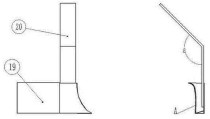

[0017] The openers (16) are installed on the adjustable frame, and the distance between the left and right openers is 400mm-1500mm. Install the acute-angle shovel type ditch opener on the shovel handle at an angle of 0°-90°, the opener curve analysis formula: y = 0.3468x 2 - 3.2457x + 36.111. The traveling wheel (6) (20-100r / min) is installed on the front end of the adjustable frame, and the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com