Preparation method of flat plate hole pattern image quality indicator

A hole type image quality meter and flat plate technology, applied in the field of medical devices, can solve problems such as non-compliance, complicated manufacturing process, long cycle, etc., achieve the effect of solving curling and eccentricity problems, simple and easy to implement method, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

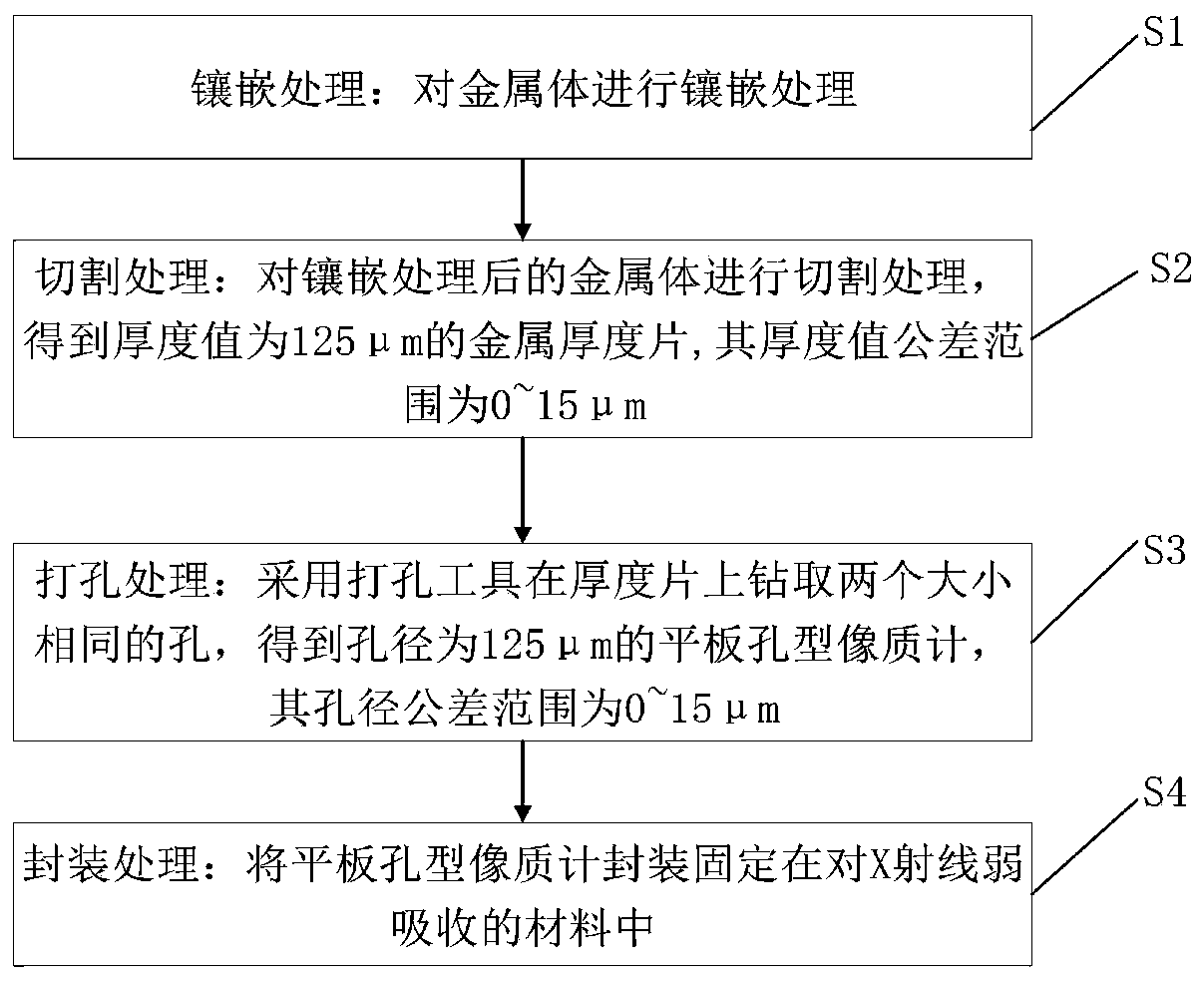

[0043] Such as figure 1 Shown, a kind of preparation method of plate hole type image quality meter, described preparation method comprises the following steps:

[0044] S1. Mosaic treatment: perform mosaic treatment on the metal body;

[0045] Specifically, the material of the metal body in the embodiment of the present invention is the same as that of the material to be detected, which can ensure the consistency of material absorption of the image quality meter in radiography. The source of the metal body material selected can be dental metal raw materials, The casting process is the same as the casting process in the production of the detected material in the prior art, and the sprue waste produced in the process of casting dentures.

[0046] Preferably, the step S1 in the embodiment of the present invention specifically includes: performing hot embedding treatment on the metal body according to the selected inlay body.

[0047] Preferably, the thermal embedding treatment ...

Embodiment 2

[0061] A preparation method of a flat hole type image quality meter, said preparation method comprising the following steps:

[0062] S1. Mosaic treatment: perform mosaic treatment on the metal body;

[0063] S2. Cutting treatment: cutting the metal body after the mosaic treatment to obtain a metal thickness sheet with a thickness value of 125 μm, and the tolerance range of the thickness value is 0-15 μm;

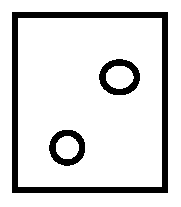

[0064] S3, punching treatment: use a punching tool to drill two holes of the same size on the thickness sheet, the hole size is 125 μm, to obtain a flat hole type image quality meter, and the hole diameter tolerance range is 0 to 15 μm;

[0065] S4. Encapsulation treatment: Encapsulate and fix the flat hole type image quality meter in a material that has weak absorption of X-rays.

[0066] Preferably, the step S1 in the embodiment of the present invention specifically includes: performing cold mounting treatment on the metal body according to the selected mosaic body.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com