Portland cement foamed lightweight partition board and preparation method thereof

A technology of Portland cement and lightweight partition wall panels, which is applied in the field of building materials, can solve the problems of high surface density, poor compressive strength, and high production costs of cement-polystyrene particle-mixed partition wall panels, and achieve scientific and reasonable production methods. Excellent durability and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

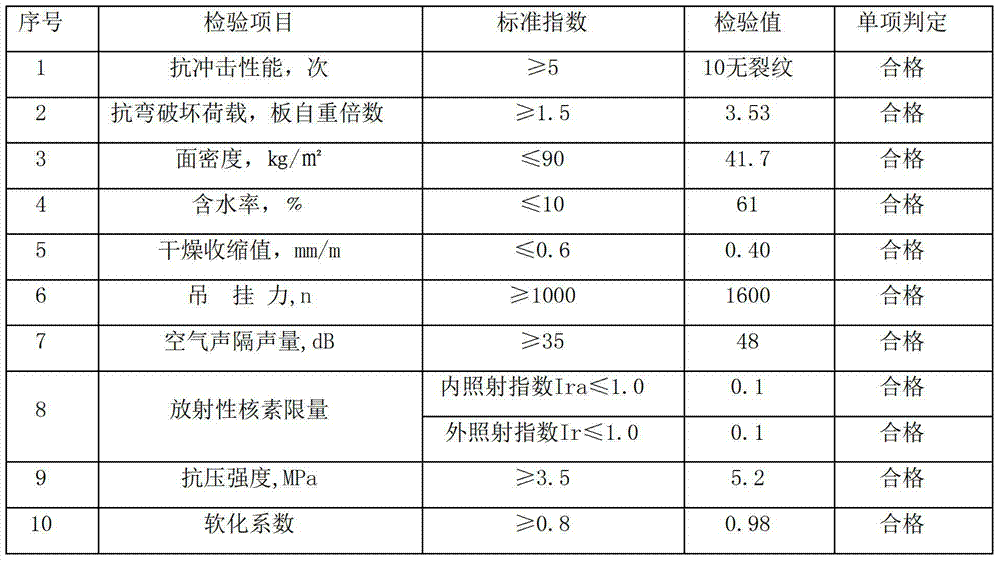

Examples

Embodiment 1

[0020] Embodiment 1: the Portland cement foamed lightweight partition wall board of embodiment 1 comprises: by 10 Portland cement foamed lightweight partition wall boards, the length of the Portland cement foamed lightweight partition wall board × Width × thickness is 2900mm × 600mm × 90mm, and the following weight units are composed of raw materials: 200kg of water, 500kg of 425 Portland cement, 30kg of calcium carbonate, 30kg of calcium oxide, 5kg of waterproof toughening agent, 2kg of quick-setting enhancer, 10kg of 30-60mm anti-crack fiber and appropriate amount of foaming foam.

Embodiment 2

[0021] Embodiment 2: the Portland cement foamed lightweight partition wall board of embodiment 2 comprises: by 10 Portland cement foamed lightweight partition wall boards, the length of the Portland cement foamed lightweight partition wall board × Width × thickness is 2900mm × 600mm × 90mm, the following weight units are composed of raw materials: water 230kg, 425 Portland cement 525kg, calcium carbonate 40kg, calcium oxide 40kg, waterproof toughening agent 5.5kg, quick-setting enhancer 3.5 kg, 30-60mm anti-crack fiber 10kg and appropriate amount of foaming foam.

Embodiment 3

[0022] Embodiment 3: the Portland cement foamed lightweight partition wall board of embodiment 3 comprises: according to 10 lightweight Portland cement lightweight partition wall strips, the length of the Portland cement foamed lightweight partition wall board ×Width×Thickness is 2900mm×600mm×90mm, and the raw materials in the following weight units are: 260kg of water, 550kg of 425 Portland cement, 50kg of calcium carbonate, 50kg of calcium oxide, 6kg of waterproof toughening agent, and 5kg of quick-setting strengthening agent , 30 ~ 60mm anti-crack fiber 10kg and appropriate amount of foaming foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com