High-Mn and high-Nb anti-crack-defect nickel-based welding wire and welding method

A welding method and anti-crack technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve problems such as defects, easy cracks, high Mn, high Nb anti-cracks, etc., and achieve good forming, good wire feeding performance, and no floating Slag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

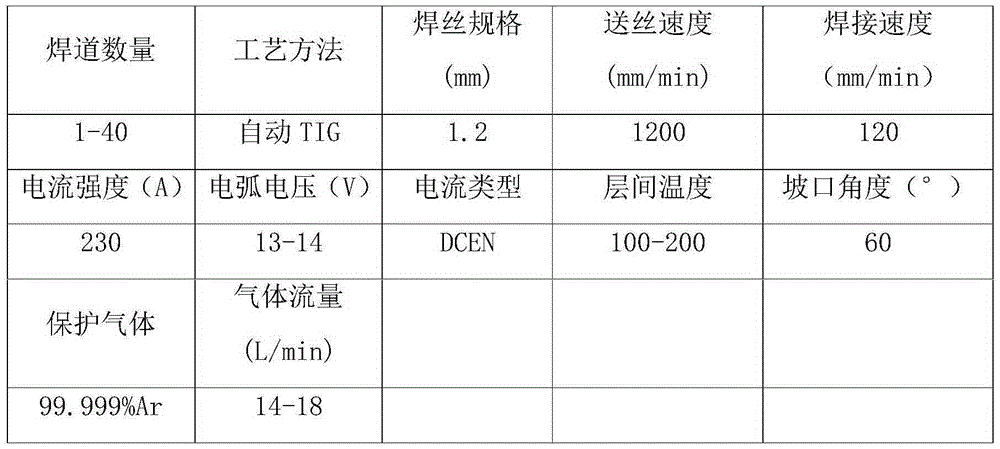

[0016] In Example 1, the master alloy steel ingot was forged and rolled, and then subjected to multiple passes of cold drawing and on-line annealing. After cleaning, a welding wire was finally formed, and the chemical composition of the welding wire was finally C: 0.024%, Si: 0.18%. Mn: 3.96%, S: <0.003%, P: <0.003%, Cr: 29.75%, Mo: 0.03%, Cu: <0.05%, Nb: 2.37%, Mn+Nb: 6.2-6.6%, Ti: 0.55%, Al: 0.18%, Fe: 9.00%, Ca: <0.005%, Mg: <0.005%, O: <0.005%, N: 0.29%, B: <0.001%, Zr: <0.005%, Ta: <0.02%, Ni is the balance.

Embodiment 2

[0017] In Example 2, the master alloy steel ingot was forged and rolled, and then subjected to multiple passes of cold drawing and on-line annealing. After cleaning, a welding wire was finally formed, and the chemical composition of the welding wire was finally C: 0.02, 3%, Si: 0.16 %, Mn: 4.01%, S: <0.003%, P: <0.003%, Cr: 29.62%, Mo: 0.03%, Cu: <0.05%, Nb: 2.40%, Ti: 0.50%, Al: 0.19%, Fe: 8.36%, Ca: <0.005%, Mg: <0.005%, O: <0.005%, N: 0.28%, B: <0.001%, Zr: <0.005%, Ta: <0.02%, Ni is the balance.

[0018] In the present invention, the welding wire can be smelted and produced in a vacuum induction furnace, or can be smelted and produced in an electric furnace plus an out-of-furnace refining method, as long as the final chemical composition of the welding wire can meet the requirements of the above invention.

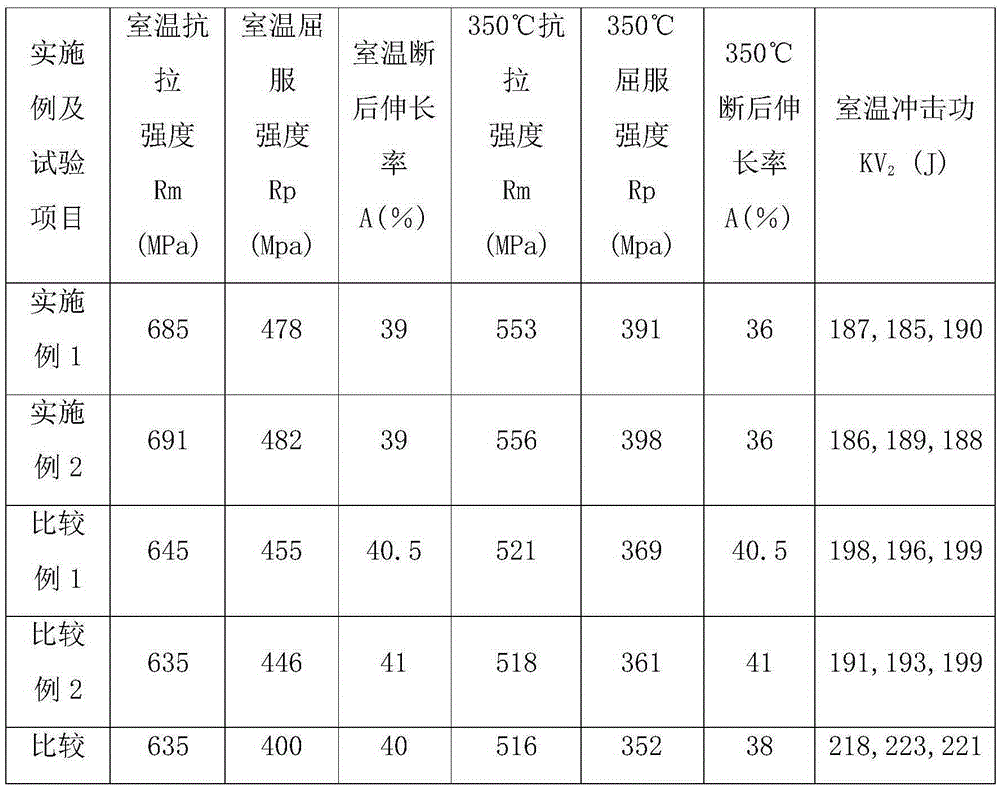

[0019] In order to verify the effect of the present invention, the following two embodiments are compared with three comparative examples.

[0020] Table 1 shows the basic ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com