Warp-knitting-like high-performance woven mesh fabric and weaving method thereof

A high-performance woven, mesh fabric technology, used in fabrics, through-hole fabrics, textiles and papermaking, etc., can solve the problems affecting the normal use of fabrics, low tensile strength of base fabrics, and poor surface density uniformity. Wide application range, lower fabric weight, good areal density uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

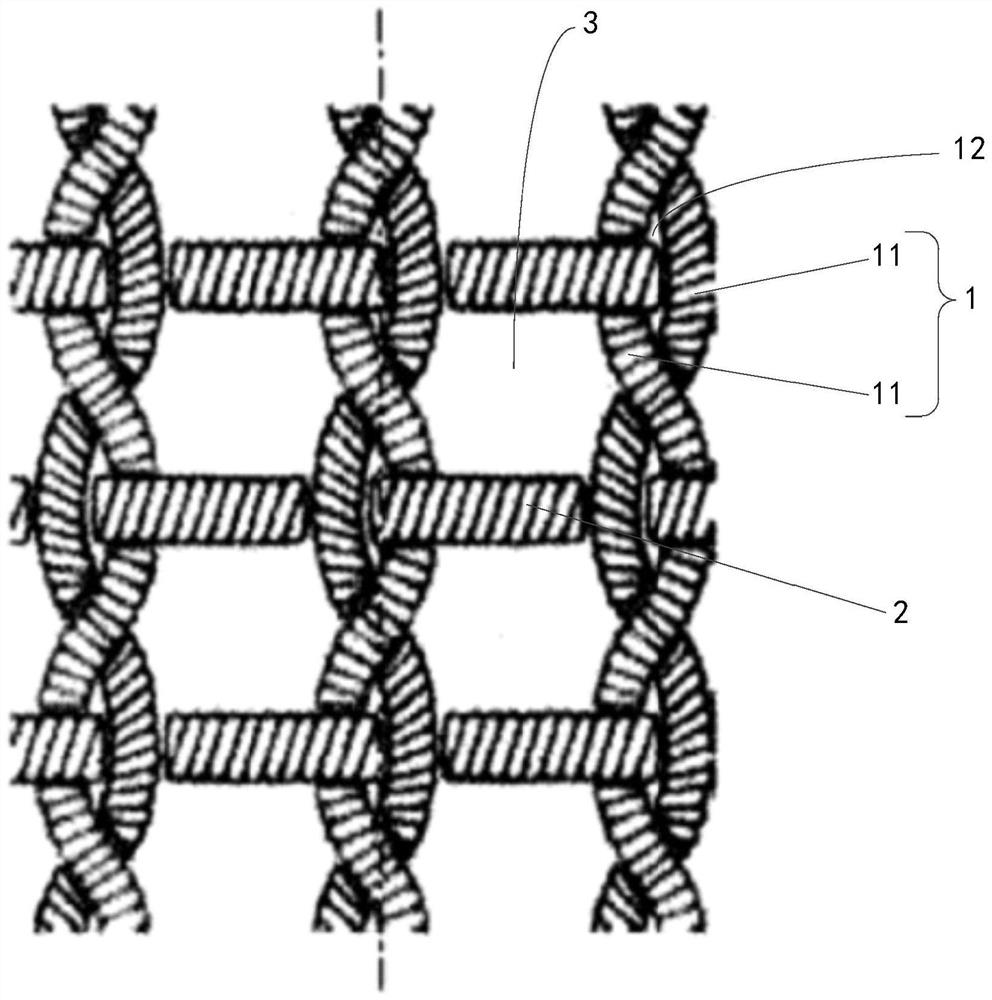

[0040] like figure 1 As shown, the warp-knitted high-performance woven mesh fabric proposed in Embodiment 1 of the present invention includes: several warp thread units 1 and several weft threads 2;

[0041] A number of warp units 1 are arranged side by side, the warp unit 1 includes two warp yarns 11, the two warp yarns 11 are twisted together to form the warp unit 1, and the warp unit 1 continuously forms a plurality of Perforations 12; a plurality of the weft threads 2 are arranged side by side along the length direction of the warp thread unit 1, and the weft threads 2 pass through one of the through holes 12 of each of the warp thread units 1 in turn to connect the several warp thread units 1; wherein, Two adjacent warp units 1 and two adjacent wefts 2 are enclosed to form a mesh 3 .

[0042] Specifically, the warp-like high-performance woven mesh fabric provided by the embodiment of the present invention is woven by several warp units 1 and several weft threads 2 interw...

Embodiment 2

[0056] A weaving method for a warp-knitted high-performance woven mesh fabric proposed in Embodiment 2 of the present invention is used for weaving the warp-knitted high-performance woven mesh fabric described in the above Embodiment 1. The method includes:

[0057] Two systems are used for warp yarns, and the warp yarns of the two systems each form a group and are twisted to form a warp unit;

[0058] The whole half harness is twisted, and the upper half harness and the lower half harness are combined to carry out the harnessing; wherein, the harnessing method is grouped.

[0059] Specifically, the main process of the weaving method provided by the embodiment of the present invention is the same as that of the current weaving method, but it should be noted that in the weaving process of this method, two warp yarns of two systems need to be used to form a group and twisted to form a group. Warp yarn unit, and the warp yarns of both systems are twisted instead of a single twist...

Embodiment 3a

[0065] Raw material: 30S / 2 meta-aramid yarn, the breaking strength is 2.4cN / dtex, the breaking elongation is 15.8%, and the 3mm hairiness index is 11.2;

[0066] The warping method adopts the slit warping method, and for the convenience of description, the subsequent warp units formed by twisting two warp yarns are called warp yarns;

[0067] Heddle weaving: The whole half-heddle is used for twisting, and the upper half-heddle and the lower half-heddle are combined. The first warp yarn first passes through the middle of the second pair of twisted heddles and the two base heddles, and then penetrates into the first pair of twisted heddles. The half heald of the silk, the second warp yarn first passes through the half heald of the second pair of twisted heddles, and then passes through the middle of the two base healds of the first pair of twisted healds, the first group (the first and the second) is the right Threading method; the 3rd and 4th warp yarns are the same as the 1st ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com