Singeing defold setting machine for non-cutting circular knit

A technology for knitted fabrics and setting machines, which is applied in singeing, fabric surface trimming, textile and papermaking, etc., can solve the problems of difficulty, knitted fabric curling, complicated processes, etc., and achieves high efficiency, good consistency, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

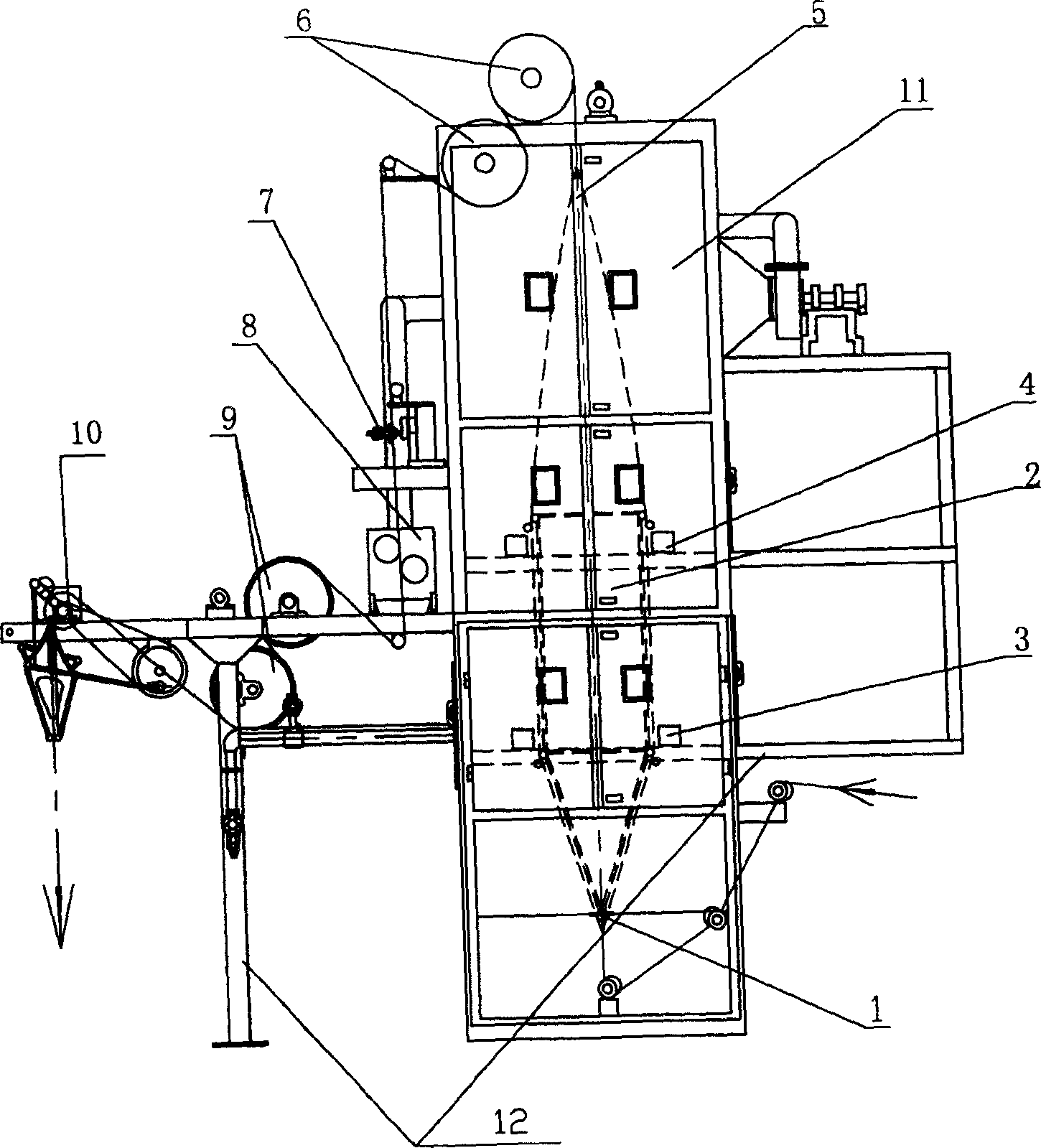

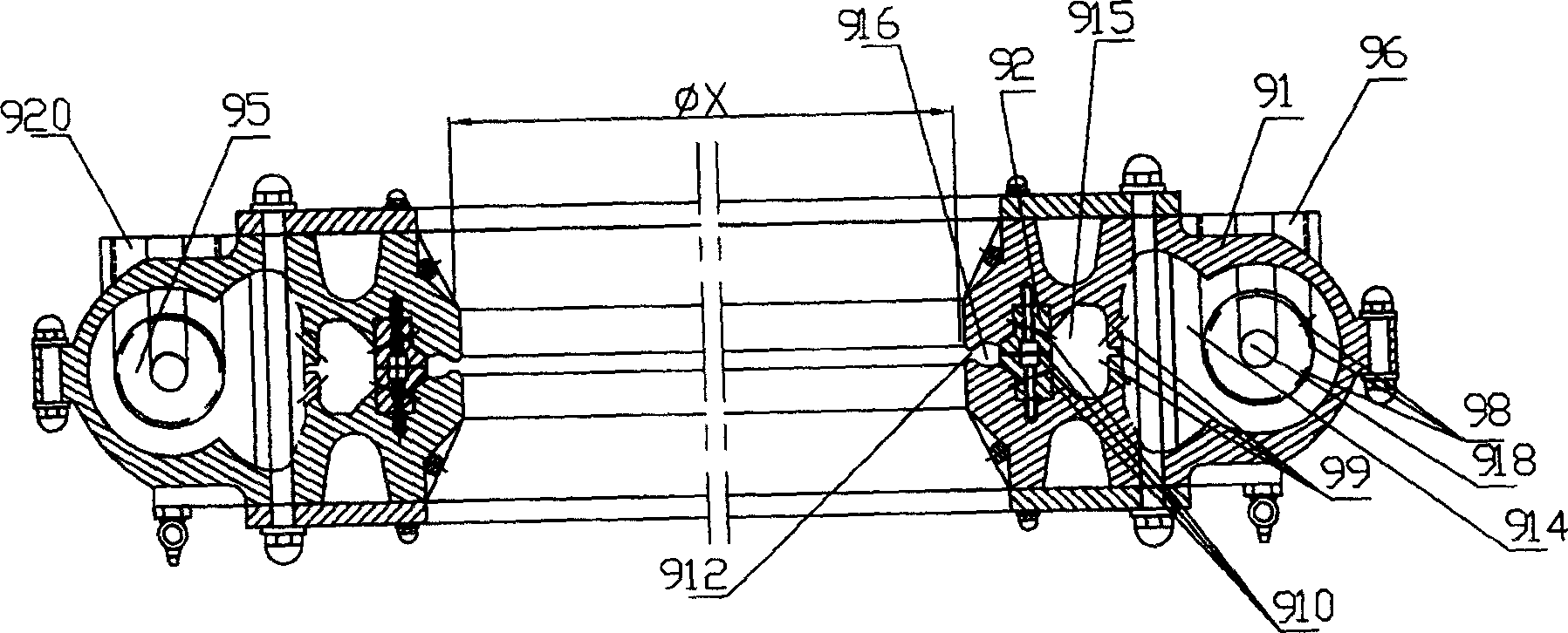

[0012] Such as figure 1 As shown, the non-cutting type circular knitted fabric singeing wrinkle-removing sizing machine of the present invention includes a frame 12, a cloth feeding device, a singeing chamber and a cloth doffing device, and the singeing chamber is arranged in the frame 12, The cloth feeding device and the cloth dropping device are respectively located on both sides of the frame 12, and the inner support sleeve-shaped expanding device 2 is arranged in the singeing chamber, and the top of the inner supporting sleeve-shaped expanding device 2 is provided with a cylinder flattening device. The expanding device 5 is provided with two ring-shaped singeing burners 3 and 4 around the simple expanding device 2 of the inner support sleeve. Such as figure 2 As shown, the annular singeing burners 3, 4 include a housing 91, an air inlet 96, 920 on the housing 91, an expansion chamber 914 and a compression chamber 915 communicated with the air inlet 96, 920, and the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com