Patents

Literature

31results about How to "Counteract internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-seepage, anti-freeze-thaw self-compacting concrete and preparation method thereof

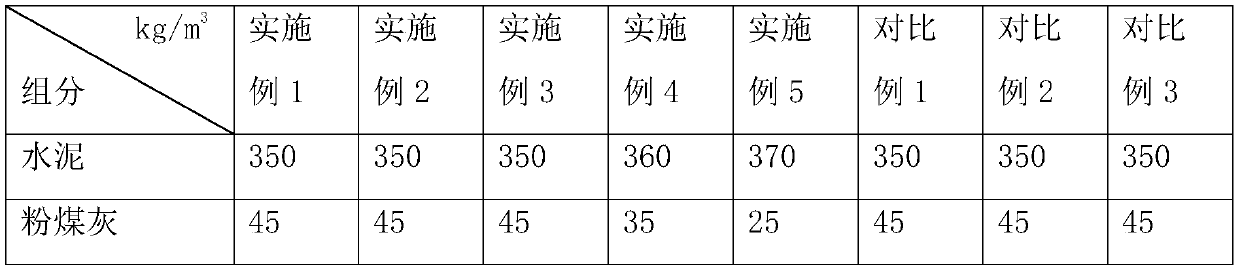

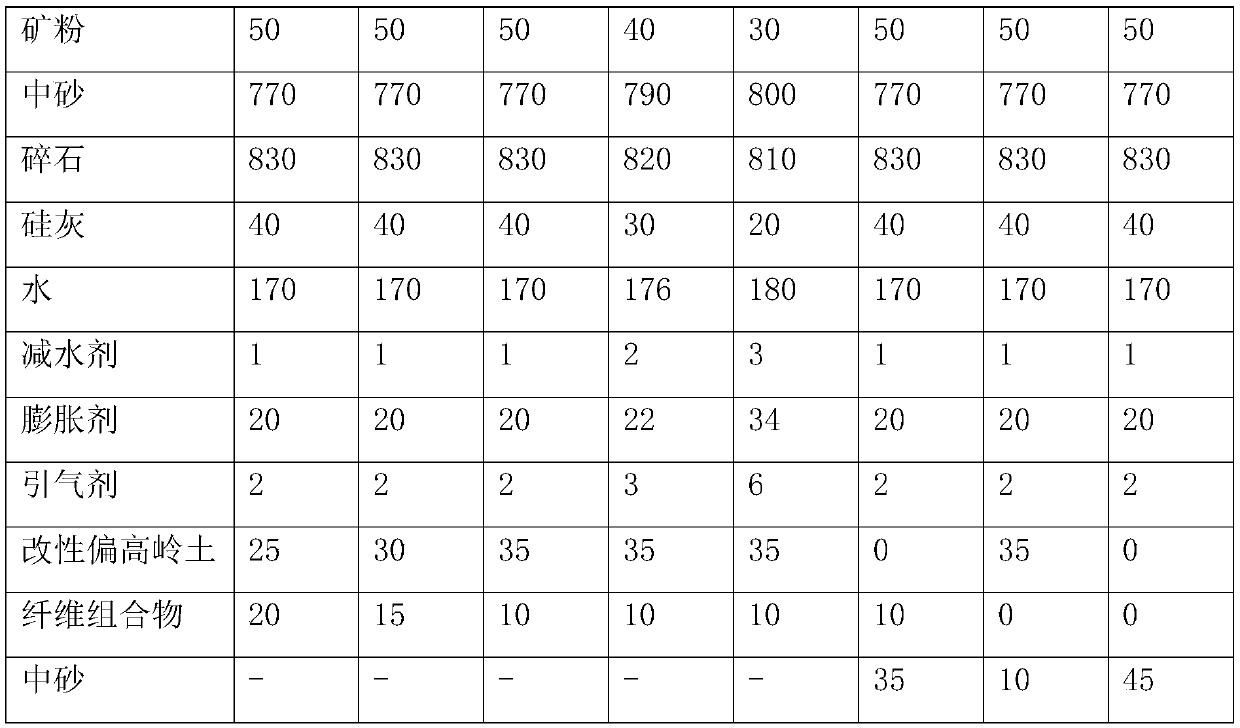

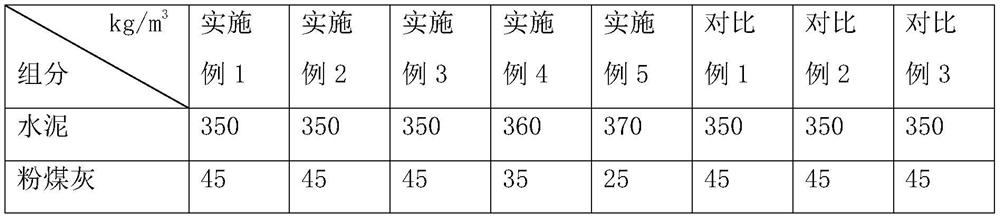

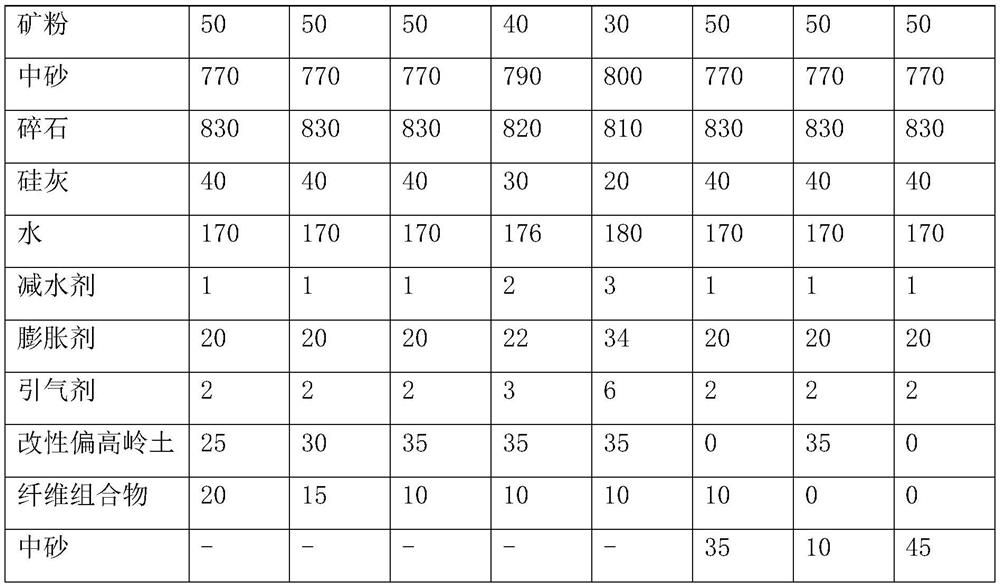

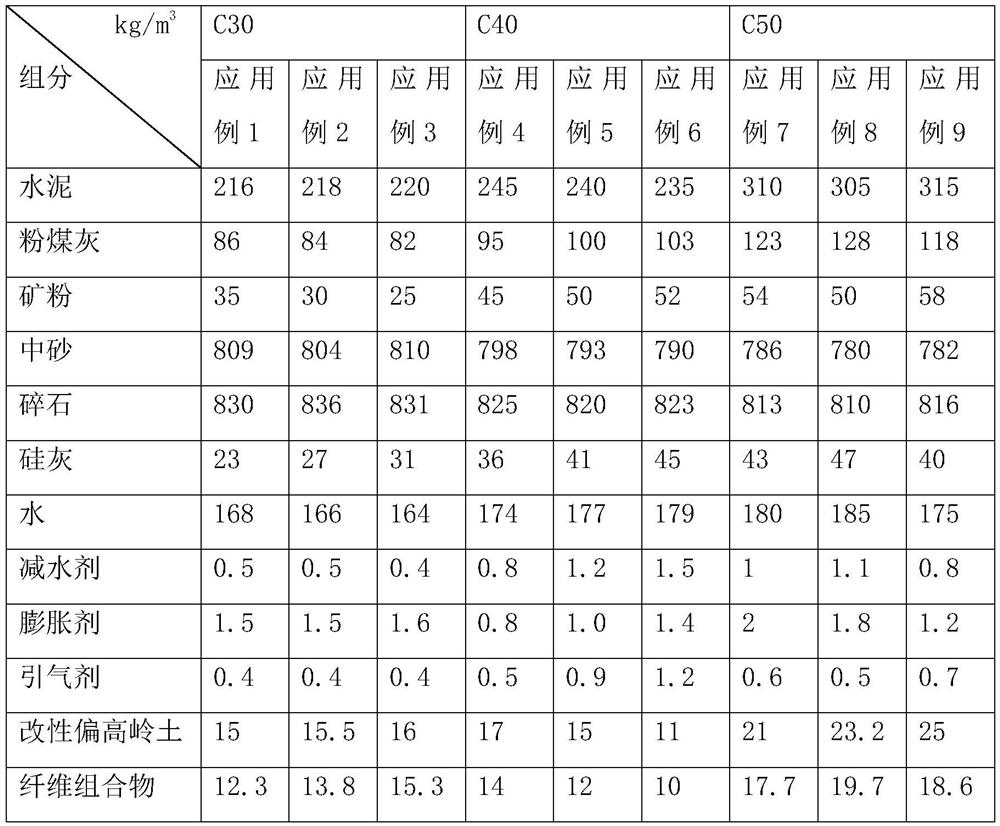

The invention discloses anti-seepage, anti-freeze-thaw self-compacting concrete and a preparation method thereof. The anti-seepage, anti-freeze-thaw self-compacting concrete comprises the following components in parts by weight: 350-370 parts of cement, 25-45 parts of fly ash, 25-35 parts of modified metakaolin, 30-50 parts of mineral powder, 770-800 parts of medium sand, 810-830 parts of crushedstone, 20-40 parts of silica fume, 170-180 parts of water, 1-3 parts of a water reducing agent, 20-34 parts of an expansion agent, 2-6 parts of an air entraining agent, and 10-20 parts of a fiber composition, wherein the fiber composition is prepared by mixing a modified polyester fiber, a basalt fiber and a polyacrylonitrile fiber in a mass ratio of 1:0.6-0.9:0.3-0.6. The anti-seepage, anti-freeze-thaw self-compacting concrete has the advantages of good workability and fluidity, and excellent anti-seepage performance and anti-freezing performance.

Owner:西安新意达建筑制品有限公司

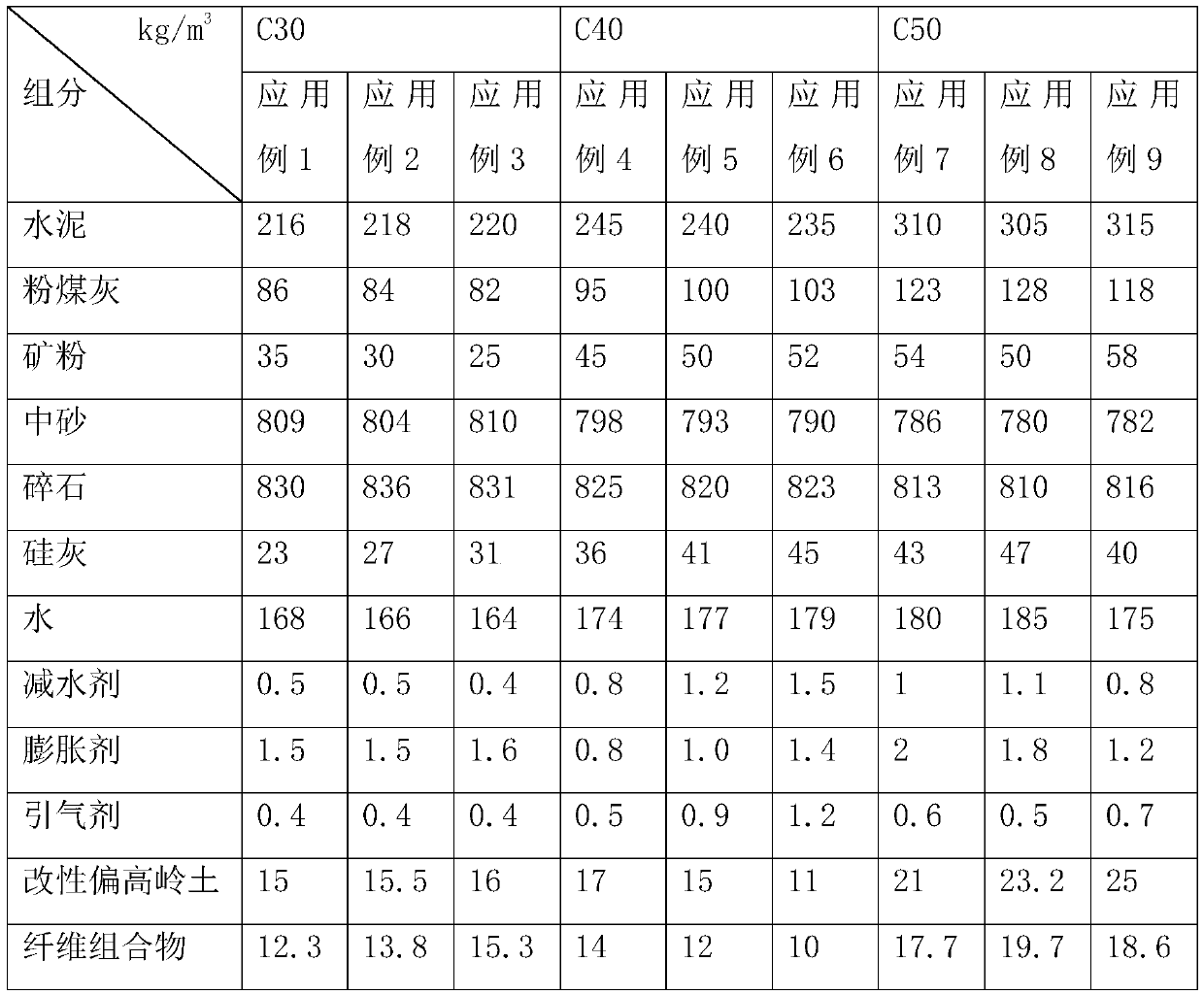

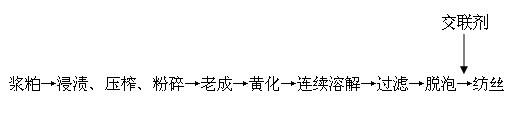

Modification method of regenerated cellulose fibre

InactiveCN102080270AReduce water swellingImproved boiling water shrinkageArtificial filaments from viscoseViscose fiberChemistry

The invention provides a modification method of a regenerated cellulose fibre, comprising: pulping, dipping, squeezing, crushing, maturation, etiolation, continuous dissolving, filtering, deaeration and spinning, wherein functional additives are added in a continuous dissolving step or before a spinning step; and the functional additives are added with cross-linking agents which take 1 to 3 percent of a gross weight of the functional additives. The invention can increase fixation rates of additives and reduce water swelling properties of the regenerated fibres, therefore having a great significance for viscose glue continuous spinning products, specifically, a shrinkage in boiling water of continuous spinning rayon products can be improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Magnetic nano composite film and its method for preparing sol-gel

InactiveCN1588593ACounteract internal stressNo microcracksNanostructure manufactureMagnetic film to substrate applicationComposite filmElectromagnetic shielding

The invention is a nano complex film and its sol-gel preparing method, firstly making a TiO2 sol and a barium ferrite precursor sol, respectively, then mixing them to make stable mixed sols in different mass proportions, adopting a rotating method to coat a substrate (like a quartz glass plate), making drying and thermal treatment to obtain a microcrack-free complex film. It belongs to a nano complex film and a crystal particle size less than 100 nm; it also belongs to an inorganic film and has a wide range of use temperature. It has higher magnetic property and has a wide application prospect in the fields of magnetic recording, electromagnetic screening, wave absorption coating, etc.

Owner:SHANGHAI JIAO TONG UNIV

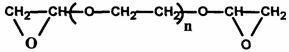

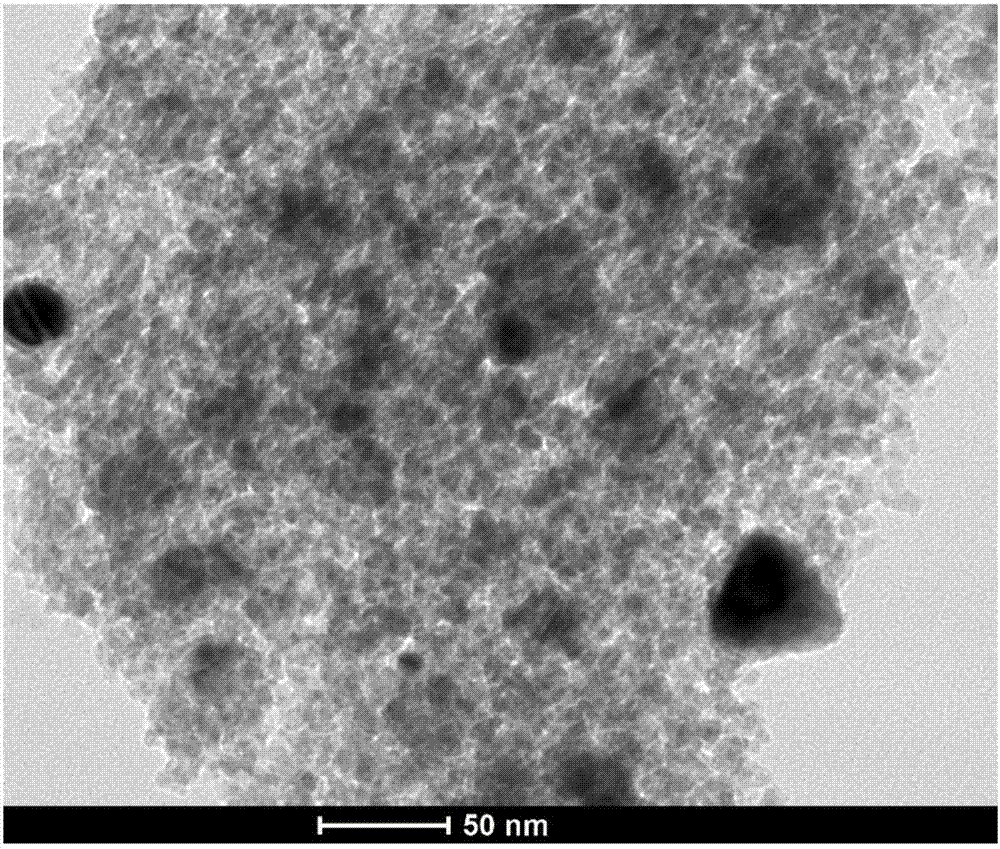

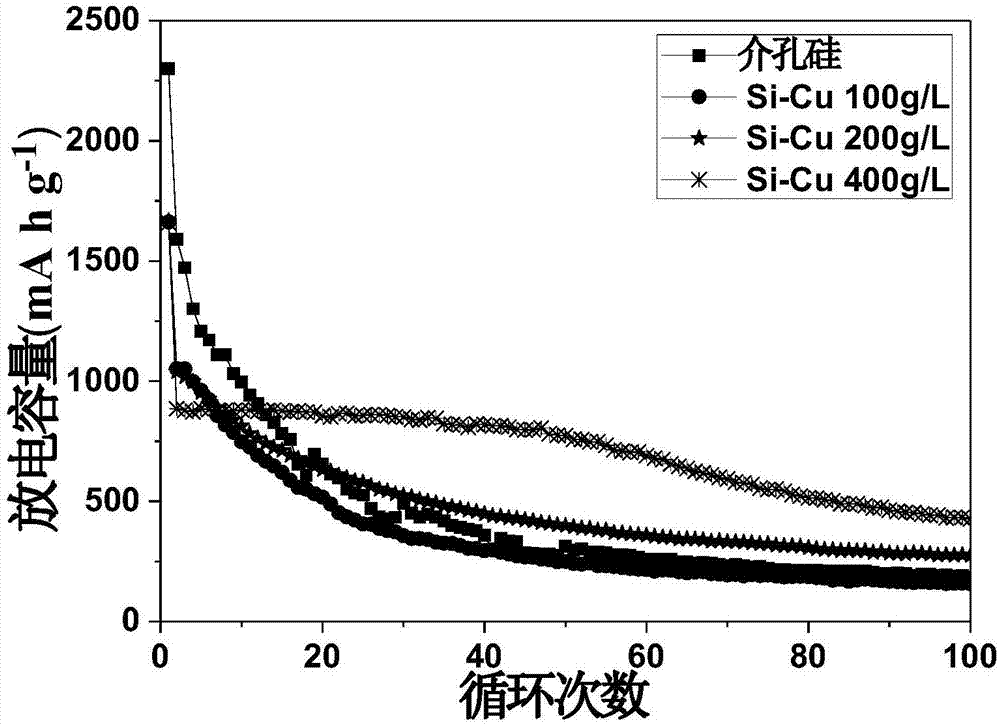

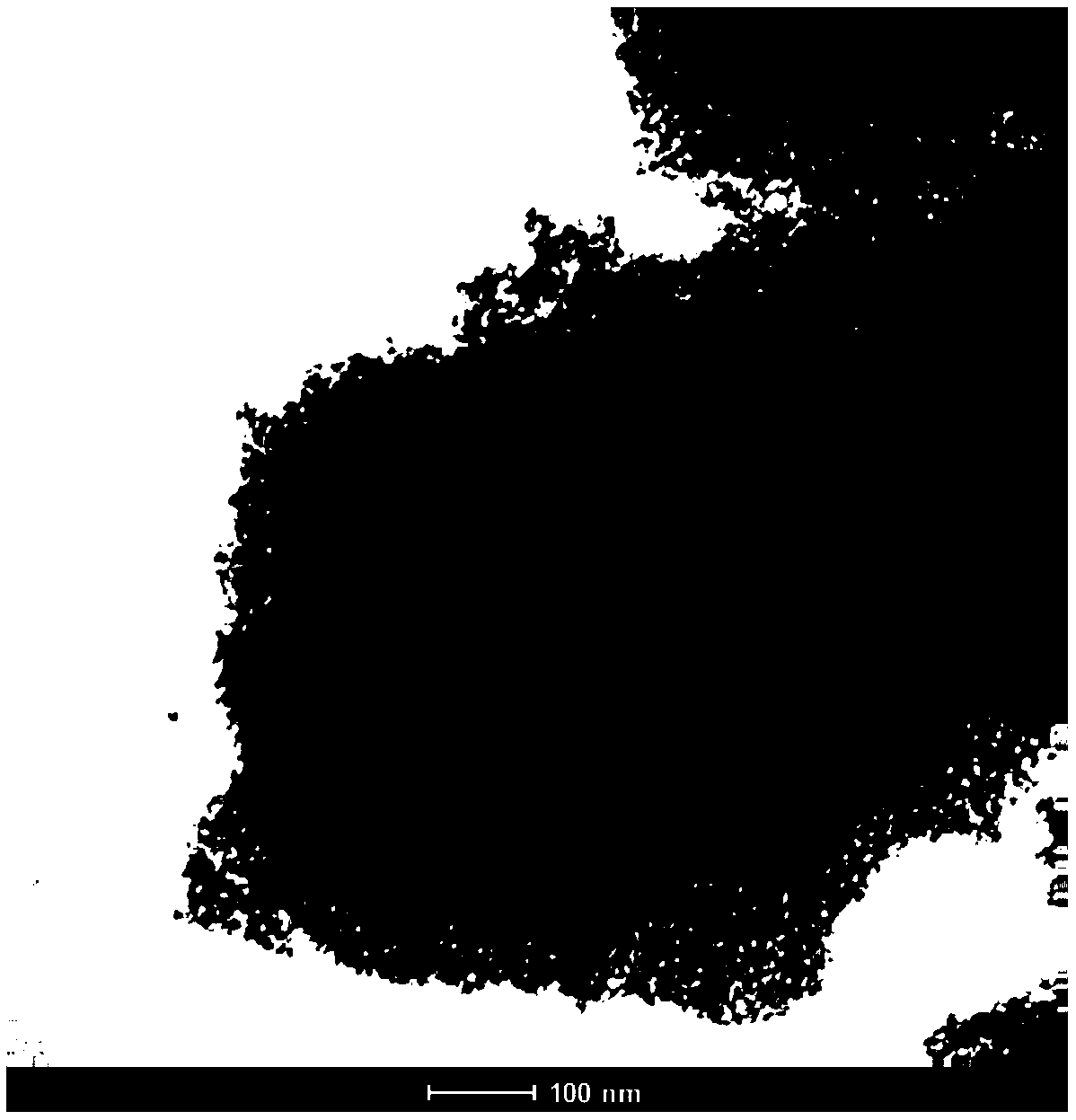

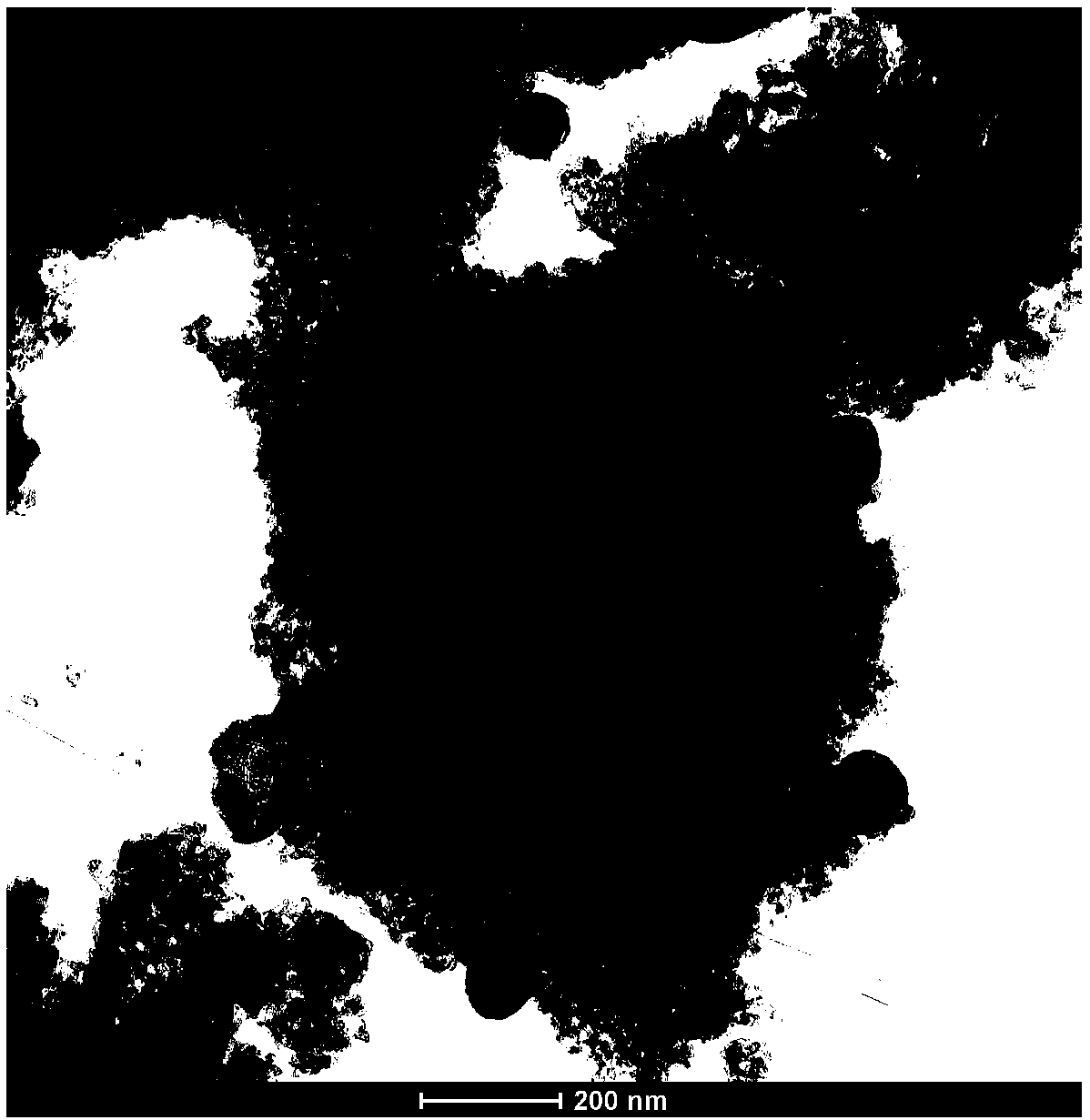

Meso-porous silicon-copper compound electrode material, and preparation method and application thereof

InactiveCN107394150AIncrease energy densityHigh reversible capacityMaterial nanotechnologyCell electrodesMesoporous silicaSilicon dioxide

The invention discloses a meso-porous silicon-copper compound electrode material, and a preparation method and an application thereof. The meso-porous silicon-copper compound electrode material has a 10-100nm porous structure, the specific surface is 60-300m<2> / g and the mass fraction of copper accounts for 15-75%. The preparation method comprises the following steps: performing a magnesium thermal reaction on the mixture of magnesium powder and mesoporous silica to prepare meso-porous silicon; and preparing the meso-porous silicon-copper compound by using a dipping-hydrogen reduction method. The invention further provides an application of the meso-porous silicon-copper compound electrode material in the preparation of lithium ion battery cathodes. The meso-porous silicon-copper compound electrode material provided by the invention has the advantages of high reversible capacity, good circulation stability, high multiplying performance and large scale production, etc.

Owner:SOUTHEAST UNIV

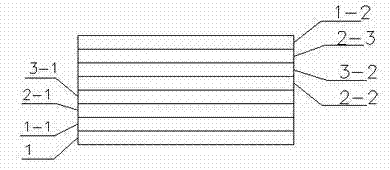

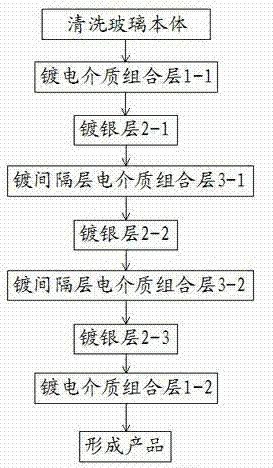

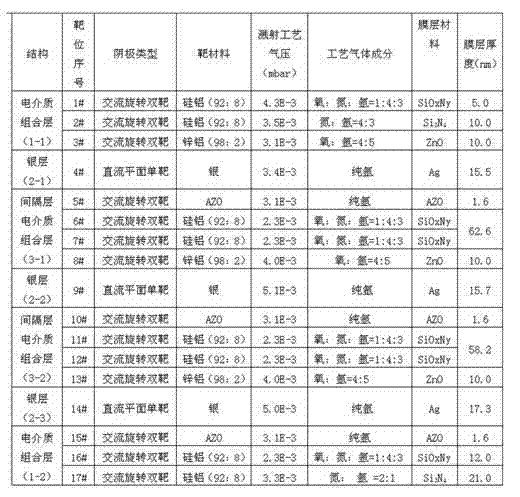

Triple-silver low-emissivity coated glass and preparation method thereof

The invention relates to a triple-silver low-emissivity coated glass, which comprises a glass body and a coating film coated on the glass body. The coating film comprises two dielectric combination layers, three silver layers and two spacing layer dielectric combination layers. The two dielectric combination layers are respectively arranged at the upper layer and the lower layer of a coating layer. The three silver layers and the two spacing layer dielectric combination layers are alternately arranged between the two dielectric combination layers in order. The dielectric combination layers and the spacing layer dielectric combination layers are all composed of one or more film layers of SSTOx, CrNx, CdO, MnO2, InSbOx, TxO, SnO2, ZnO, ZnSnOx, ZnSnPbOx, ZrO2, AZO, Si3N4, SiO2, SiOxNy, BiO2, Al2O3, Nb2O5, Ta2O5, In2O3 and MoO3. The triple-silver low-emissivity coated glass disclosed in the invention abolishes a metal barrier layer in a traditional film layer structure, and employs novel material dielectric combination layers to conduct silver layer protection, so that the influence of film layers on visible light transmittance can be effectively reduced, and consequently, high visible light transmittance, low emissivity, and a good photothermal ratio can be obtained. Besides, with diverse color options, the triple-silver low-emissivity coated glass has a wide range of application.

Owner:林嘉宏

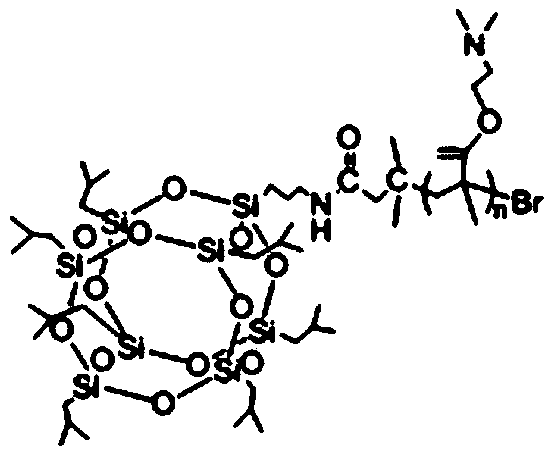

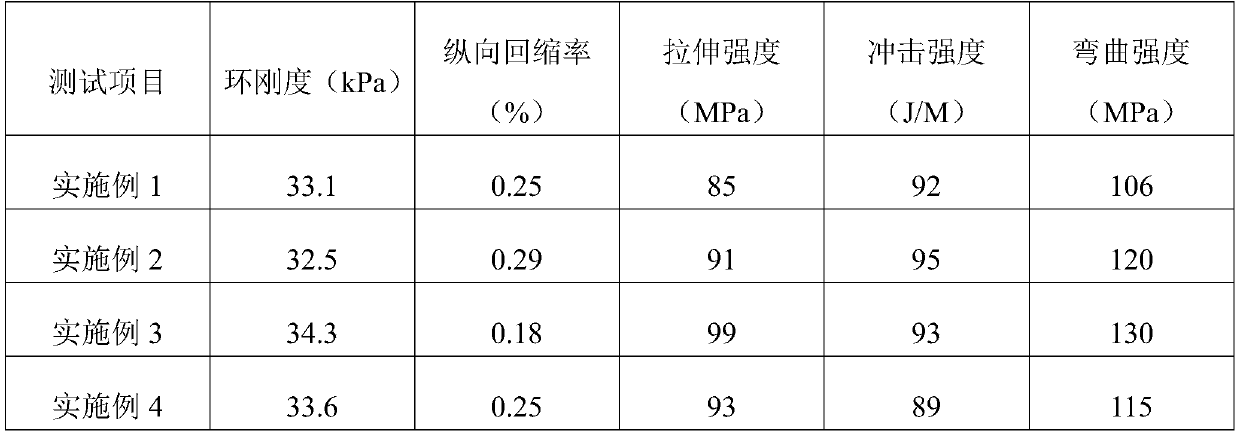

High-pressure-resistant and impermeable heat-preservation composite pipeline and preparation method thereof

InactiveCN110594496ASolve the problem of low withstand voltageGood overall performanceNon-macromolecular adhesive additivesThermal insulationAntioxidantPressure resistance

The invention belongs to the technical field of pipelines, and provides a high-pressure-resistant and impermeable heat-preservation composite pipeline and a preparation method thereof. The heat-preservation composite pipeline comprises an inner-layer working layer, a middle-layer insulating layer and an outer-layer protective layer which are sequentially arranged from inside to outside, wherein the inner-layer working layer comprises an impermeable barrier layer, a polyethylene material layer, a modified reinforcing layer, a heat-sensitive micro-foaming adhesive layer and a prepreg tape winding layer which are sequentially arranged from inside to outside, wherein the polyethylene material layer is a PERT-II type high-density polyethylene material layer, the impermeable barrier layer is made of nylon MXD6 or ethylene / vinyl alcohol copolymers, the modified reinforcing layer is a glass fiber reinforced nylon MXD6 layer, the prepreg tape winding layer is a glass fiber reinforced polyethylene prepreg tape layer, and the modified reinforcing layer is composed of the following components of, in parts by weight, 35-50 parts of nylon MXD6, 15-50 parts of glass fiber, 0.2-1 part of a silanecoupling agent, 1-2 parts of an antioxidant, 0.5-1 part of a lubricant and 5-15 parts of a toughening agent. The heat-preservation composite pipeline and the preparation method solve the problem thatthe high-density polyethylene composite heat preservation pipeline is low in pressure resistance.

Owner:河北汇锐管业有限公司

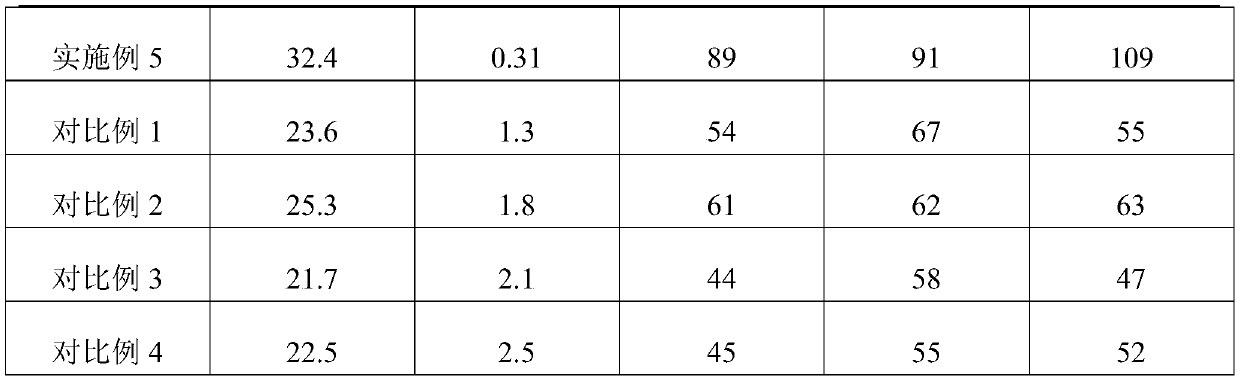

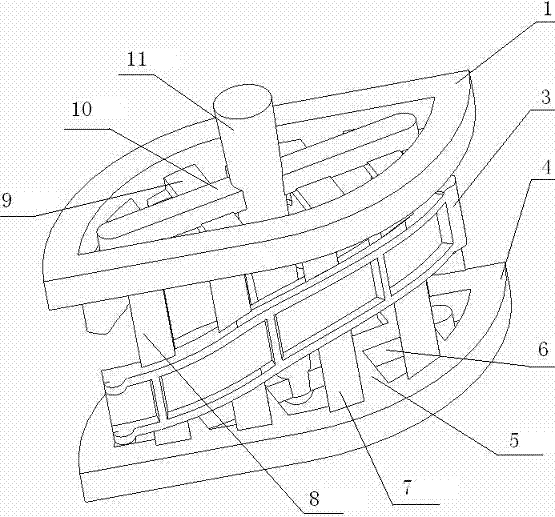

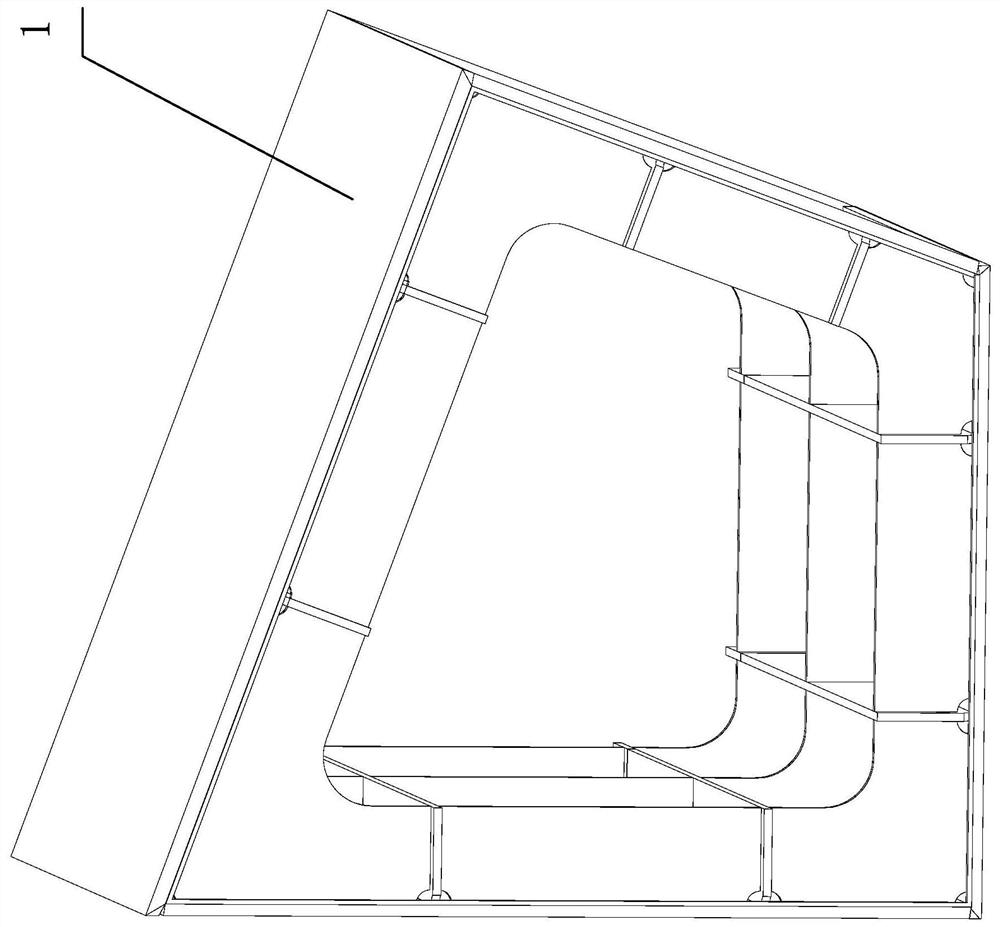

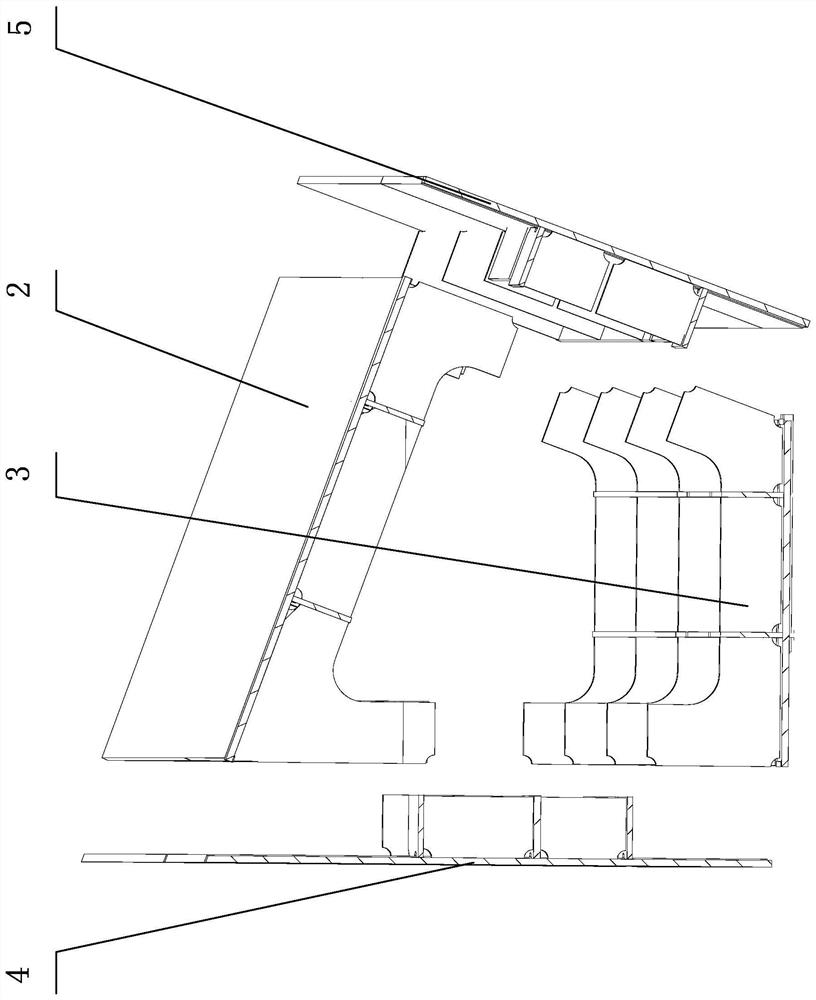

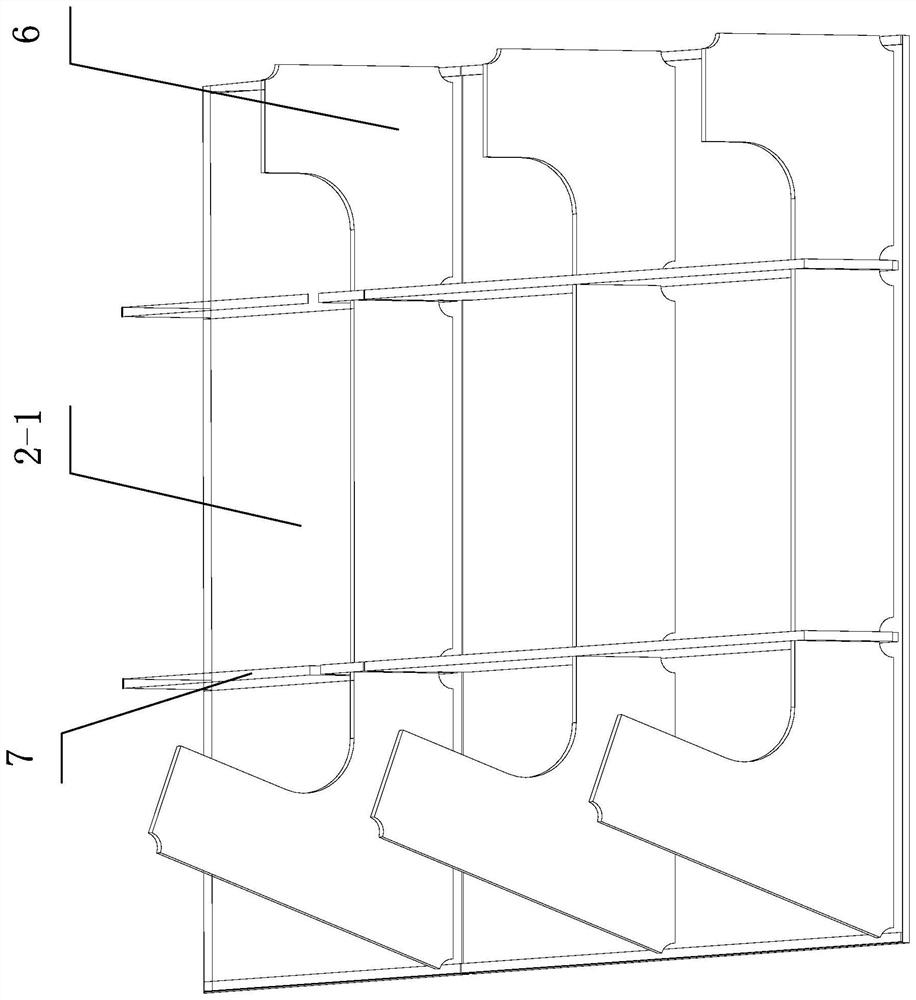

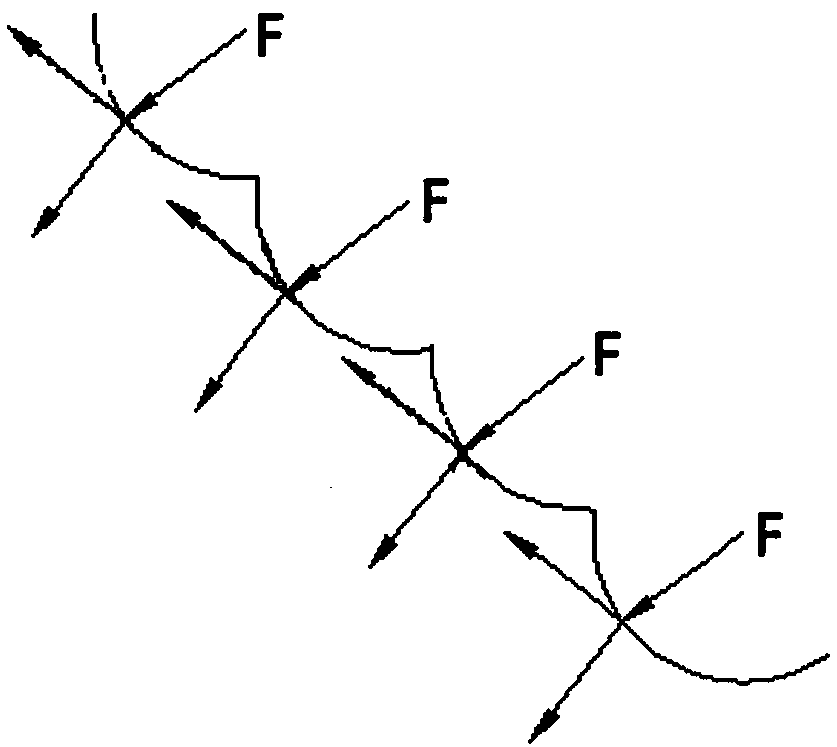

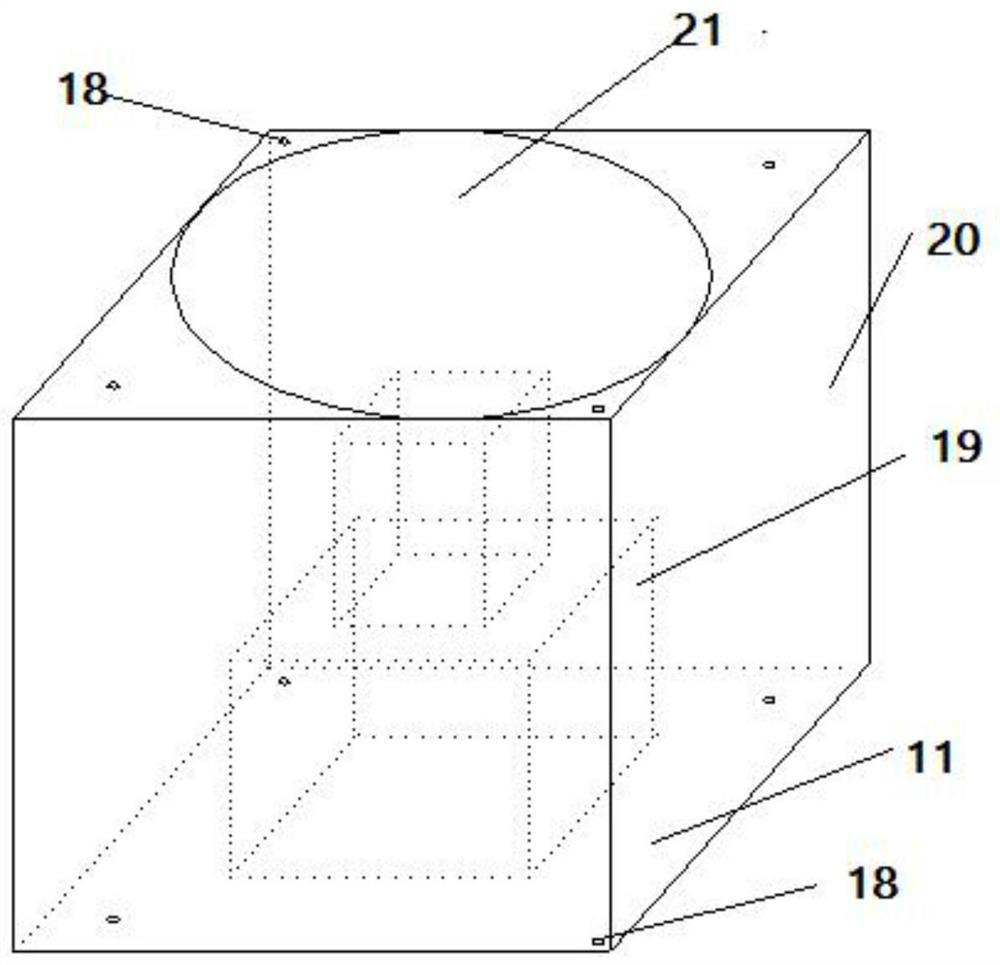

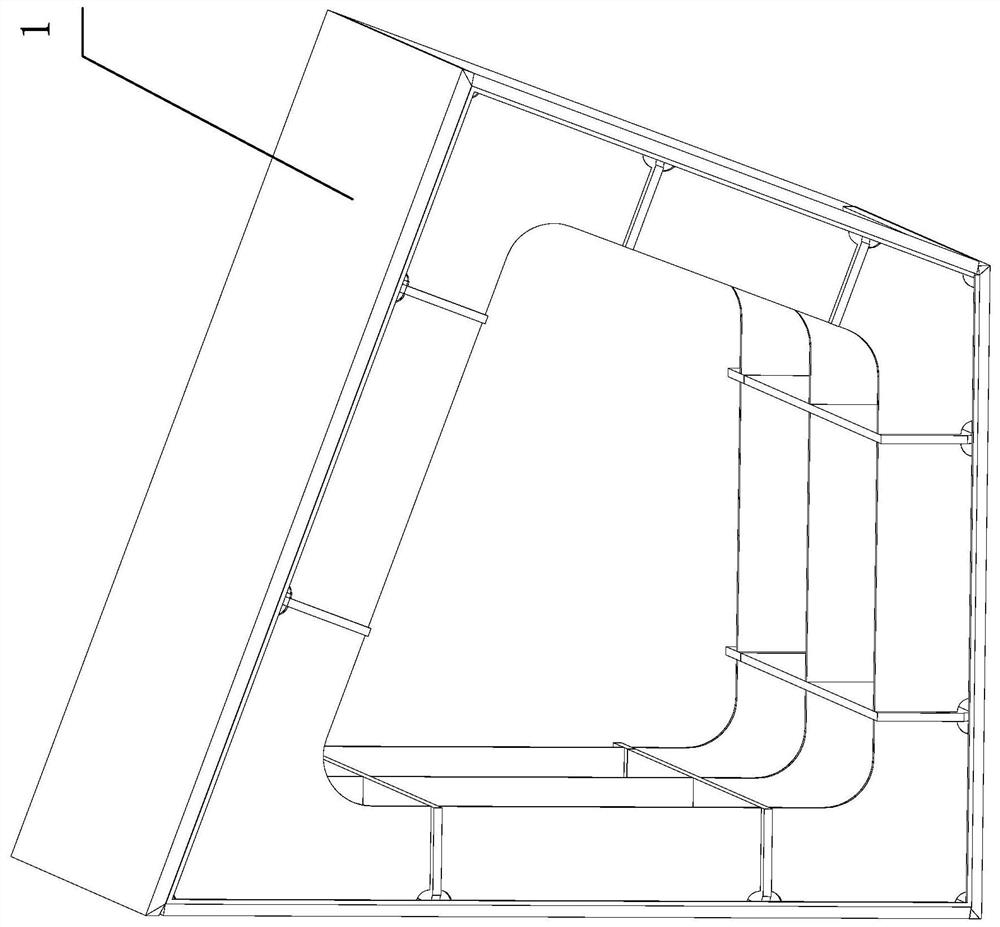

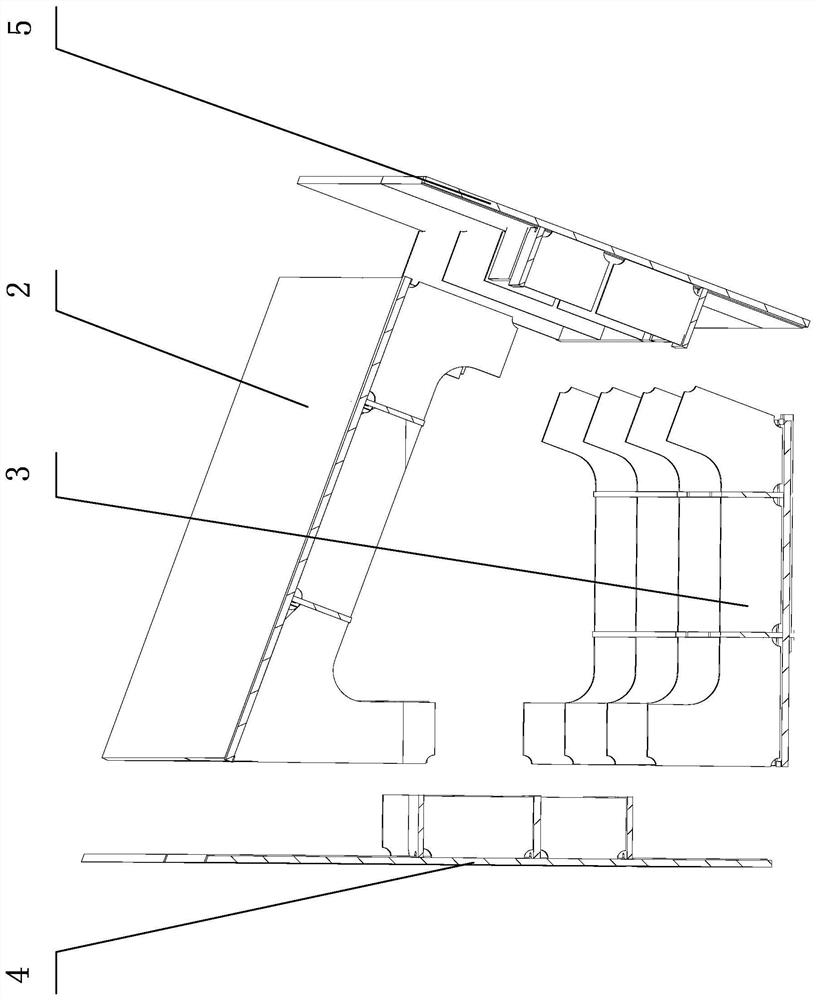

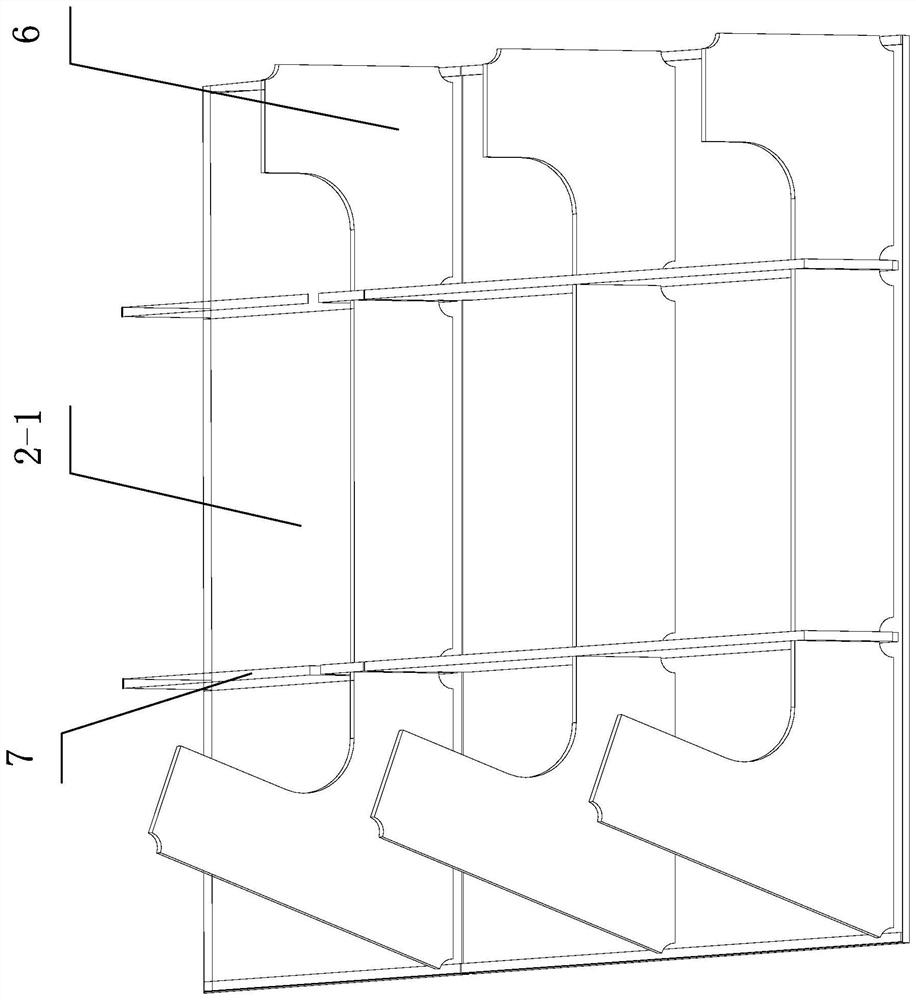

Space curve type casting anti-deformation box cage structure and machining method

InactiveCN105436419APrevent excessive deformationCounteract internal stressFoundry mouldsFoundry coresMachine buildingEngineering

The invention relates to a process method with the space curve type casting anti-deformation function, and belongs to the field of machine manufacturing. By means of a casting method for changing an upper guide rail casting and a lower guide rail casting, an upper annular cavity type tie bar, a lower annular cavity type tie bar, upper follow-up cavity type tie bars and lower follow-up cavity type tie bars are communicated with a straight sprue, transverse sprues and inner sprues to form a box cage structure. The number of times of deformation in the casting forming process is controlled, and the deformation is controlled within 0.5 mm. In the pouring and heat treatment process, under the alternating stress action of heating and cooling, the castings bear irresistible residual stress which cannot be fully offset in the shell expansion and casting shrinkage process, and irregular and disordered permanent plastic deformation is generated. For deformation, a one-mold two-piece process is adopted, the heads and tails are oppositely arranged, the box cage structure is designed, and the deformation of the castings is reduced. The residual stress of the castings is removed through subsequent heat treatment, and it is guaranteed that no excessive deformation is generated after casting cleaning.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

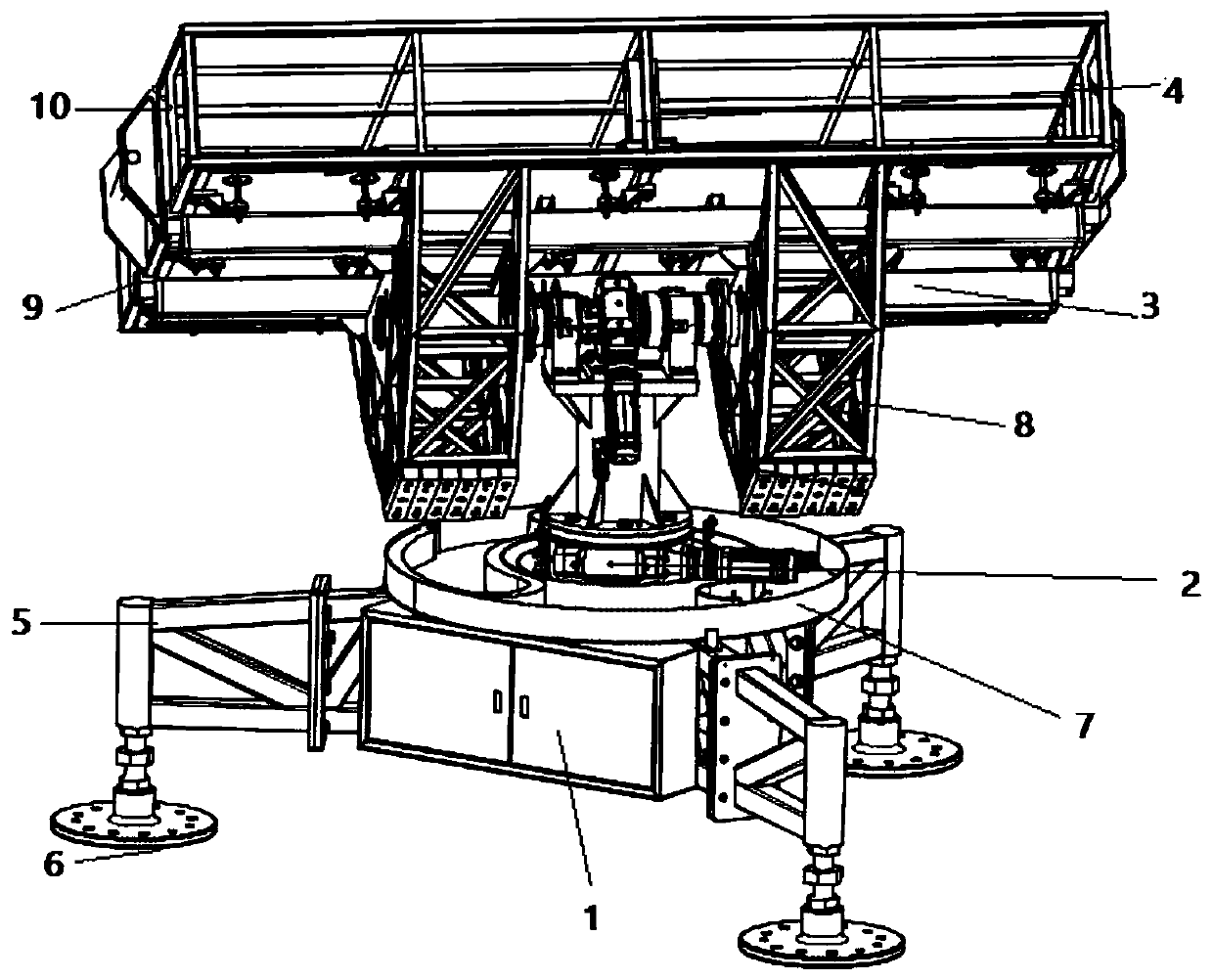

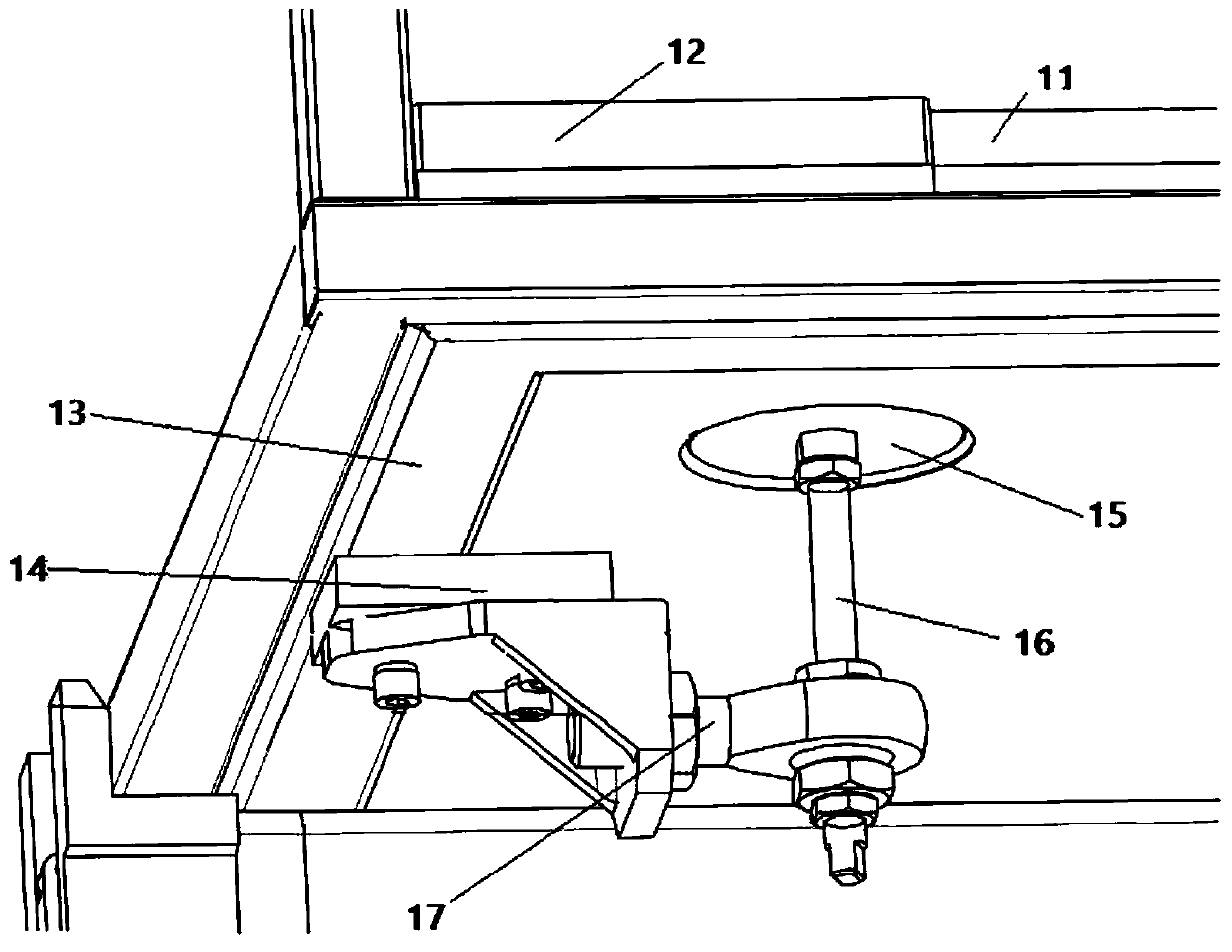

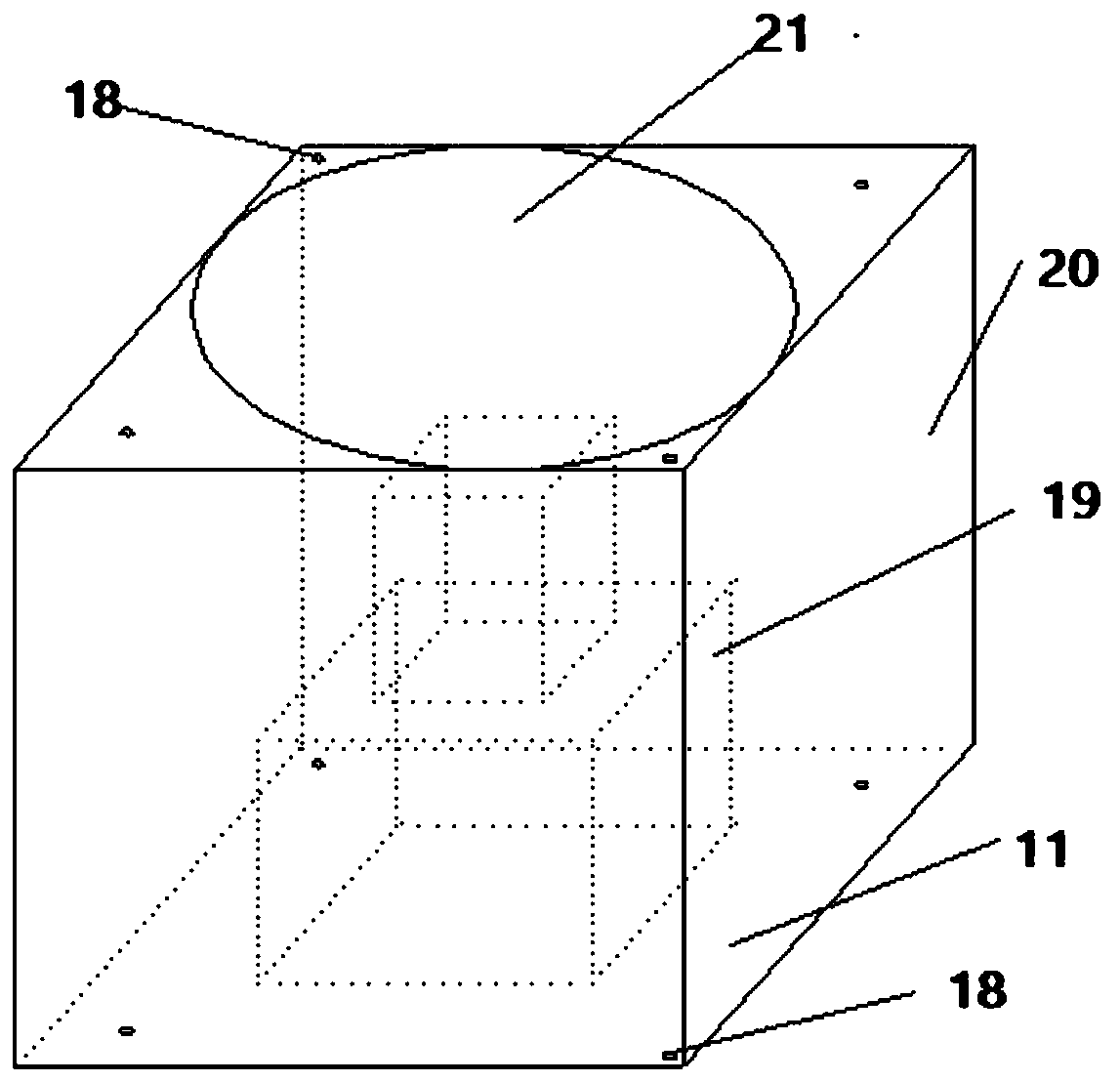

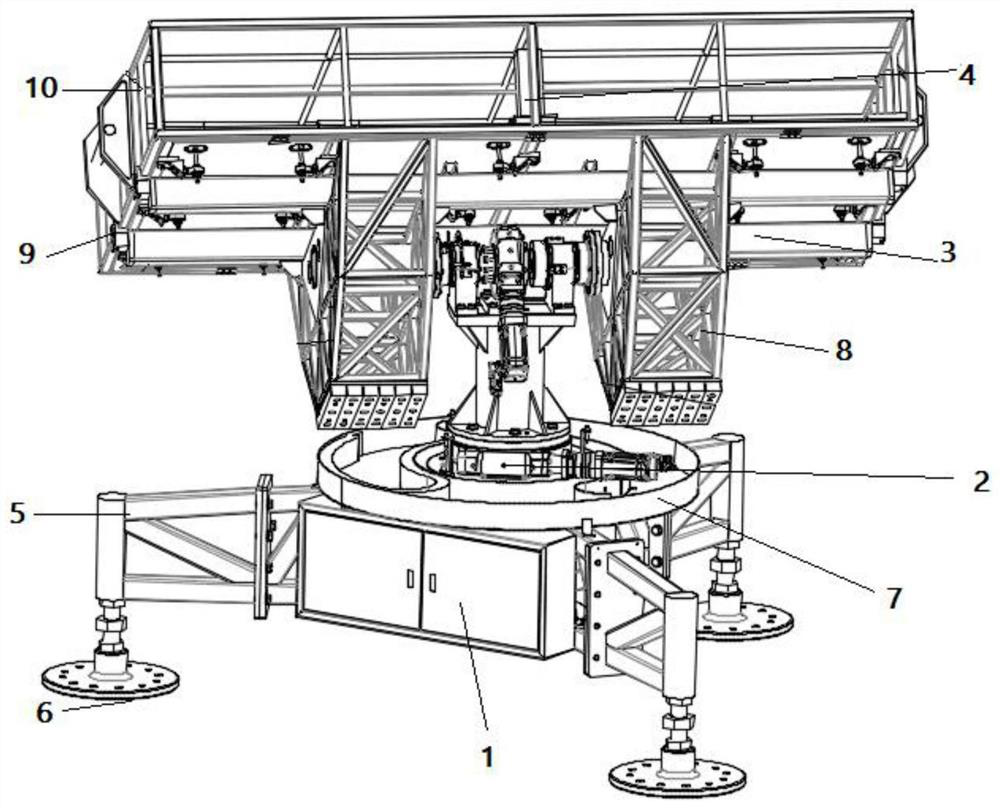

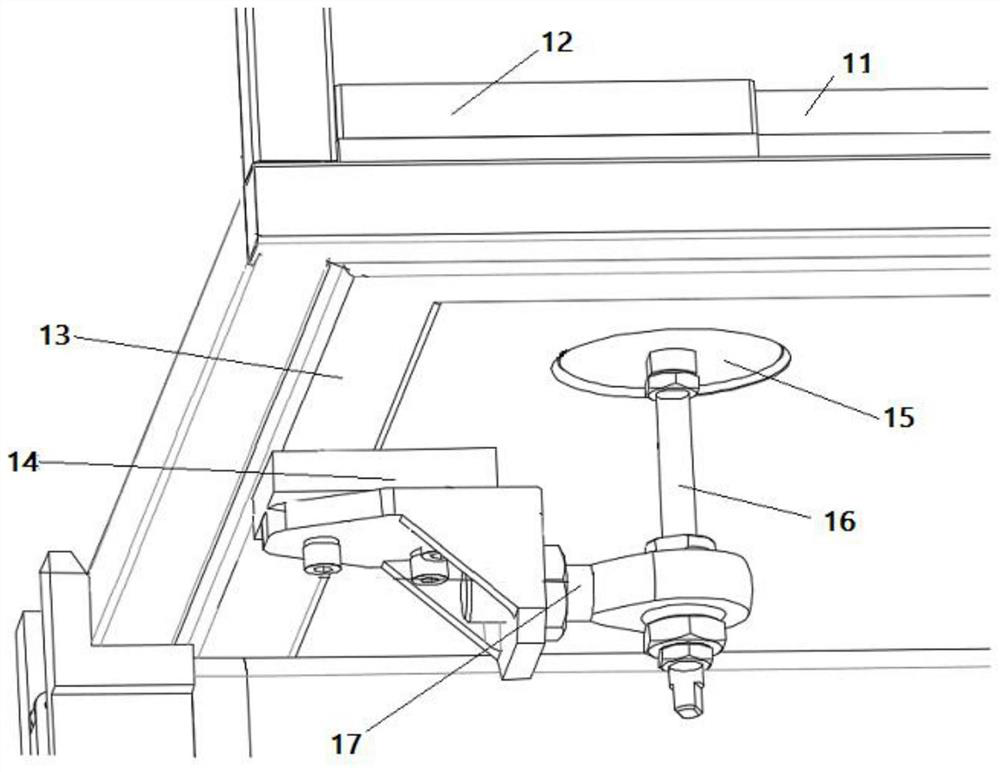

Novel automatic full-spectrum radiometric calibration reference target device

ActiveCN110243393AGuaranteed surface flatnessGuaranteed Surface AccuracyRadiation pyrometrySpectrum investigationMiddle infraredImaging quality

The invention discloses a novel automatic full-spectrum radiometric calibration reference target device, and relates to the technical field of the aerial remote sensing. The device comprises a reflector module, a sun sensor module, an attitude regulation and control module and an electric control system; the attitude regulation and control module is connected with the reflector module and used for driving the reflector module to rotate; the sun sensor module is arranged on the reflector module, and an optical axis of the sun sensor module is parallel to a reflector normal of the reflector module; and the sun sensor module and the attitude regulation and control module are connected with electric control system. The device disclosed by the invention is suitable for the full-spectrum radiometric calibration of high-orbit and low-orbit optical remote sensing satellites, thereby realizing the absolute radiometric calibration and image quality assessment of satellite loads at different orbits at the sun reflection waveband, the middle infrared waveband and the hot infrared waveband (0.35 micron to 12.5 micron).

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

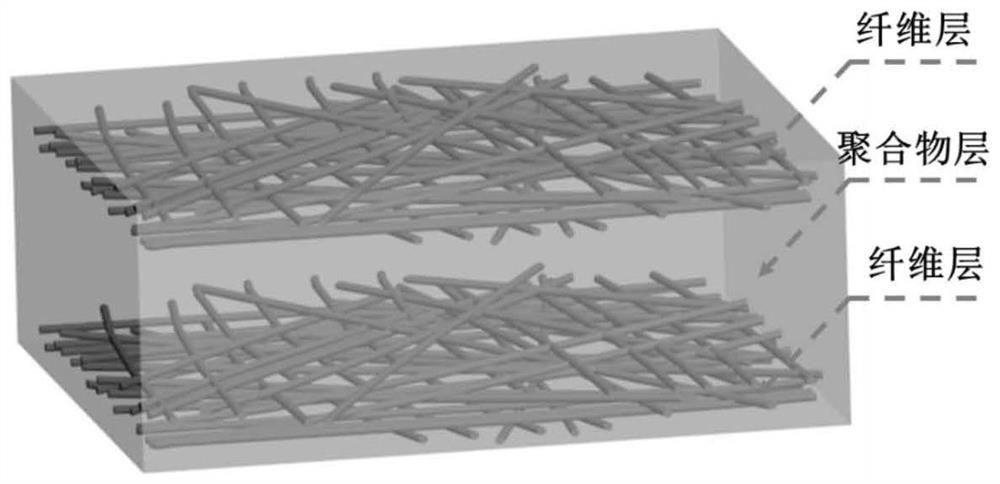

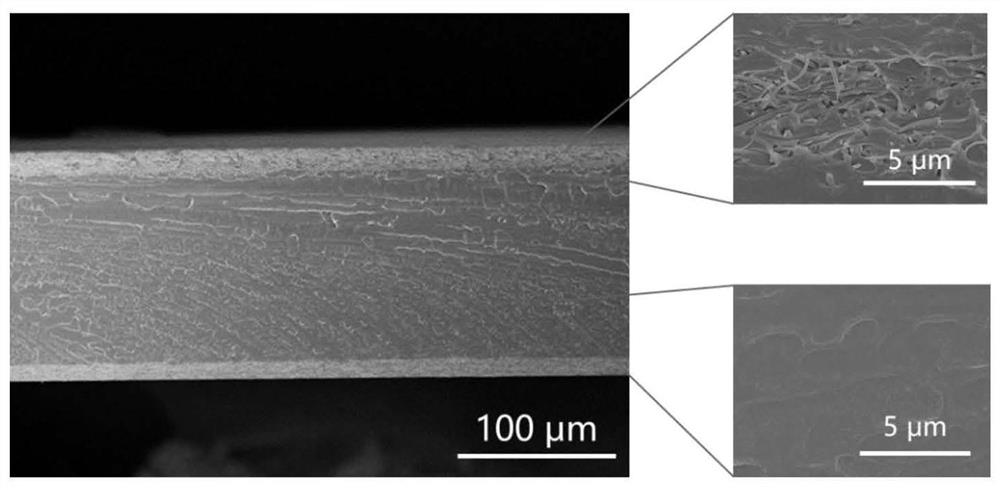

Polymer-based double-layer nanofiber composite proton exchange membrane and preparation method thereof

InactiveCN113270622AImprove transmission efficiencyImprove proton conductivityMonocomponent synthetic polymer artificial filamentNon-woven fabricsPolymer electrolytesFiber

The invention provides a polymer-based double-layer nanofiber composite proton exchange membrane, and the proton exchange membrane comprises a polymer layer and two fiber layers compounded with the polymer layer, wherein the polymer layer is located between the two fiber layers; and the polymer layer comprises a polymer electrolyte, and the fiber layer comprises nanofibers. The polymer-based double-layer nanofiber composite proton exchange membrane provided by the invention has good proton conductivity, structural stability and other properties.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

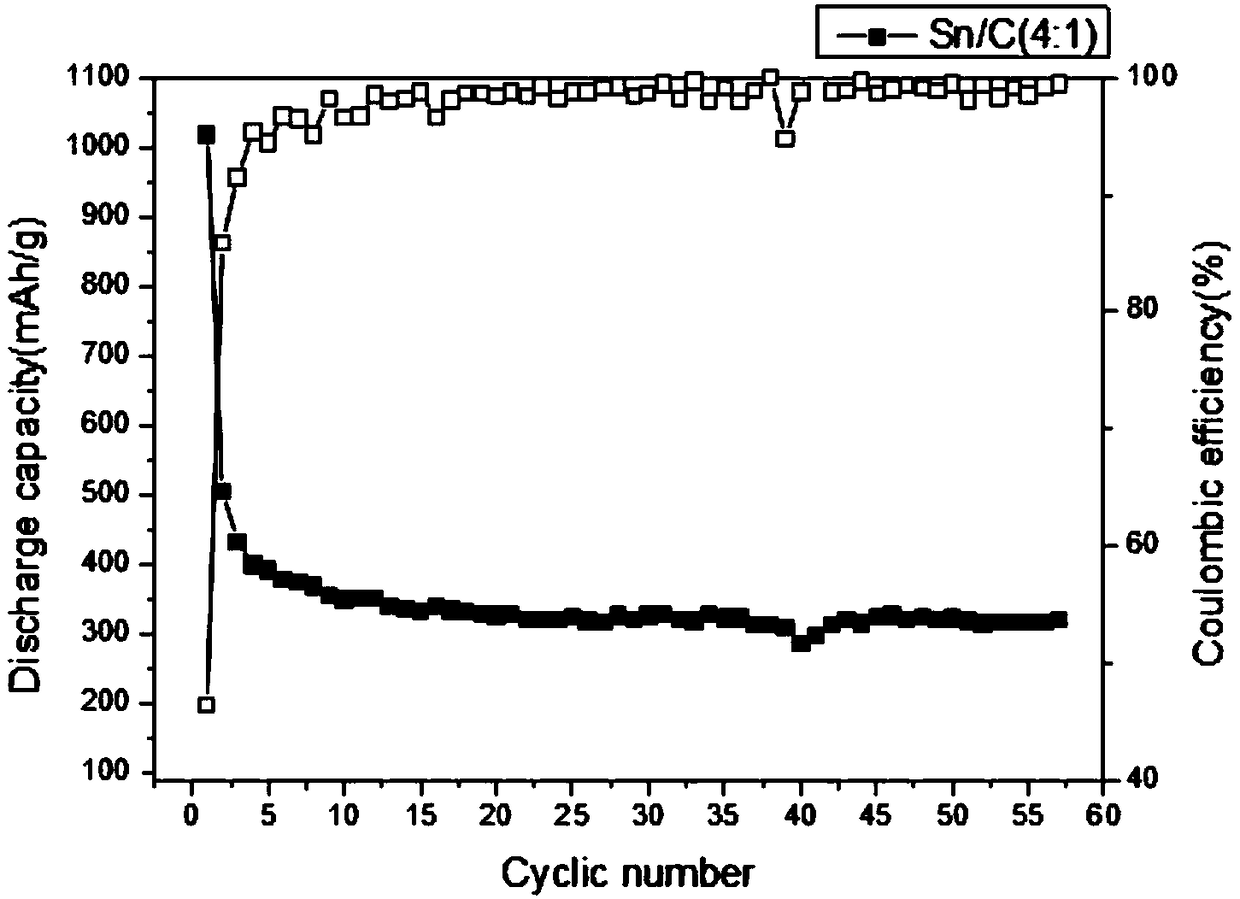

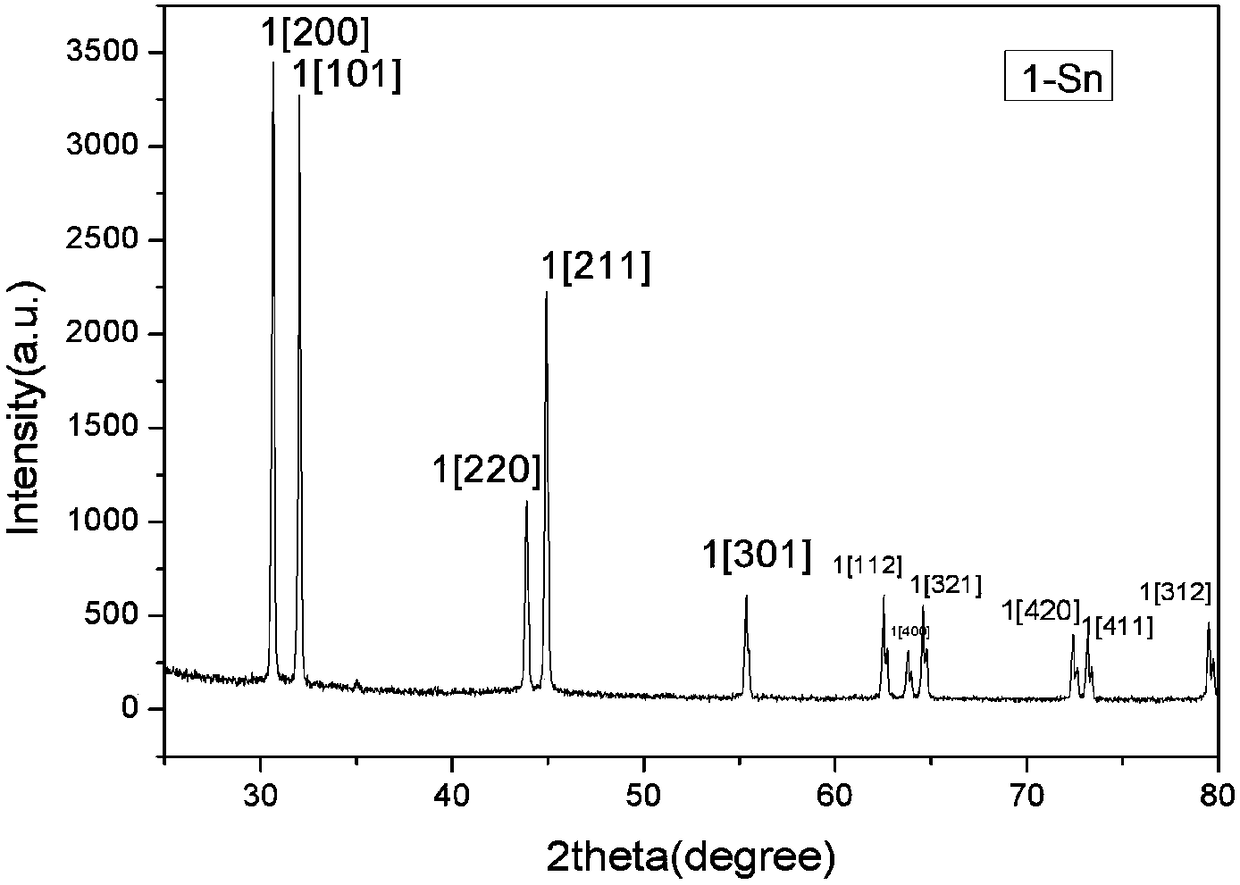

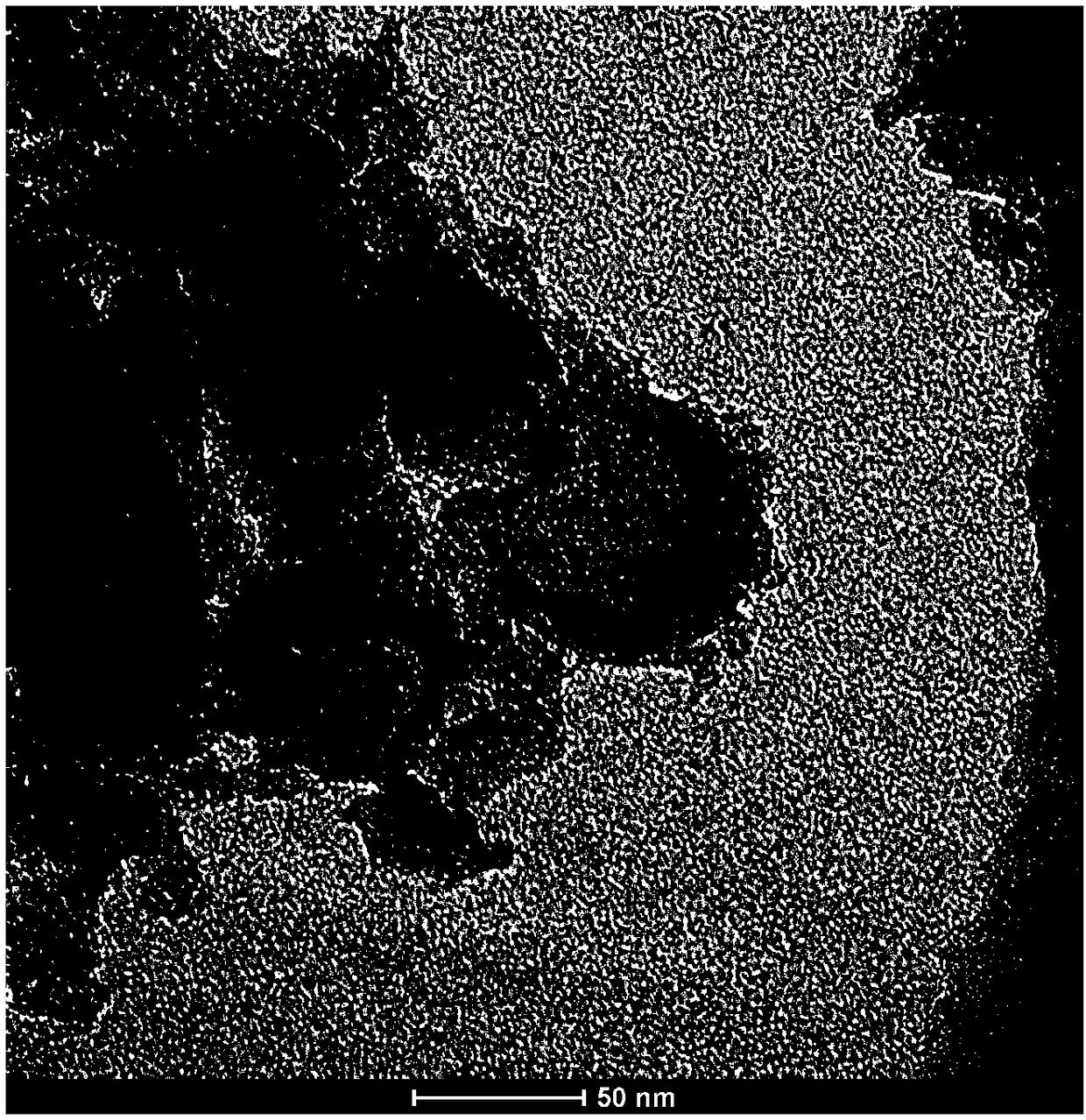

Mesoporous silicon-tin composite electrode material and preparation method thereof, and application thereof

InactiveCN109585834AHigh reversible capacityImprove cycle stabilityCell electrodesSecondary cellsMesoporous silicaSilicon dioxide

The invention discloses a mesoporous silicon-tin composite electrode material and a preparation method thereof, and application thereof. The mesoporous silicon-tin composite electrode material has a pore structure of 5 to 40 nm, and the mass fraction of tin accounts for 5 to 20%. The preparation method comprises the steps of: preparing a mesoporous silicon by a magnesium thermal reaction of a mixture of magnesium powder and mesoporous silica; and preparing a mesoporous silicon-tin composite by employing a dipping hydrogen reduction method. The invention also provides the application of the mesoporous silicon-tin composite electrode material in the preparation of the lithium ion battery negative electrode. The mesoporous silicon-tin composite electrode material is high in reversible capacity, good in cycle stability and good in rate performance and can perform large-scale production.

Owner:包头市石墨烯材料研究院有限责任公司

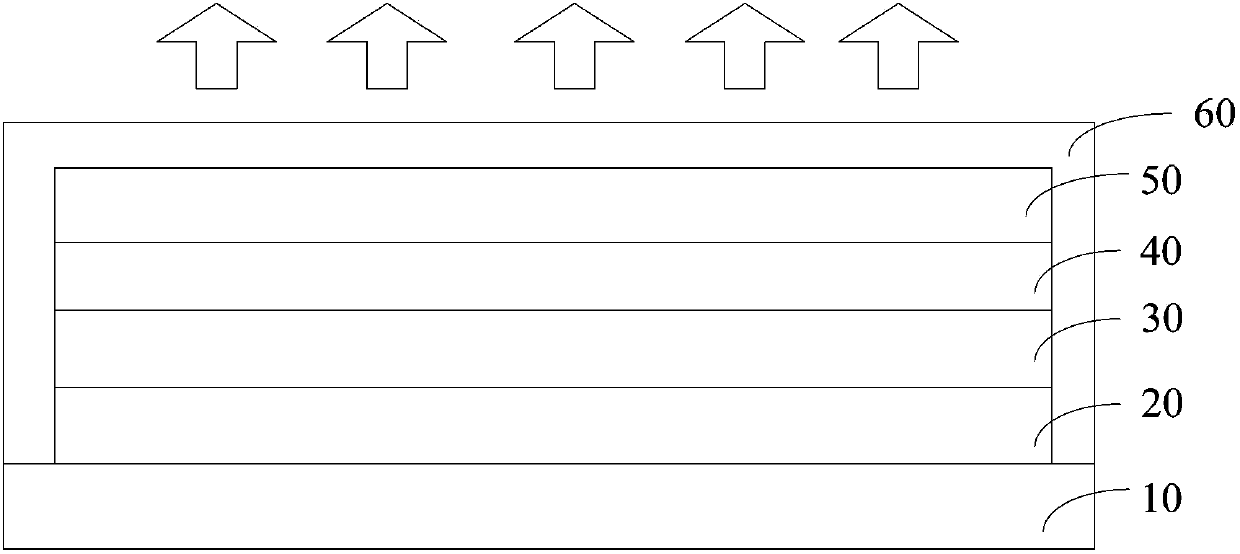

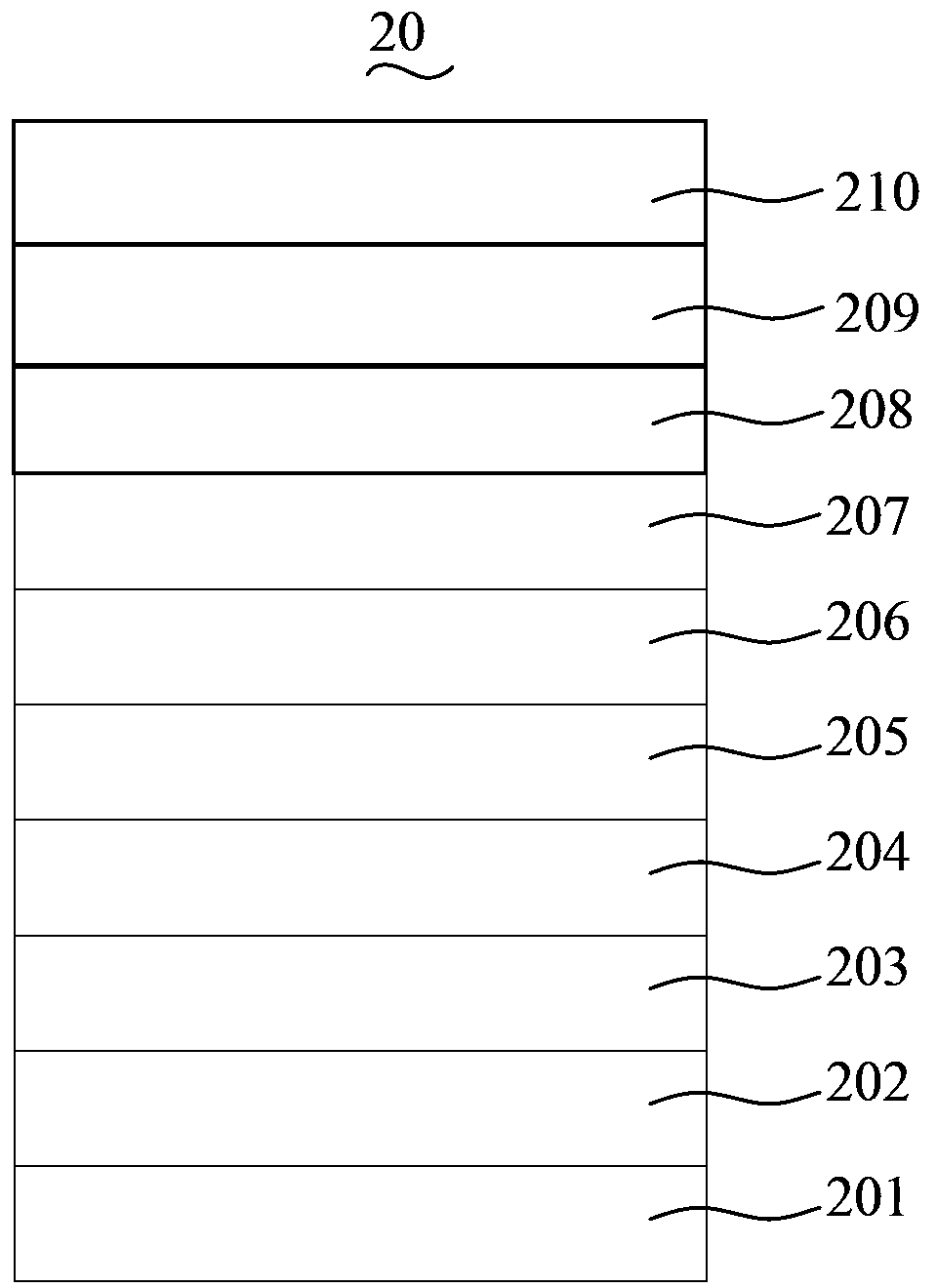

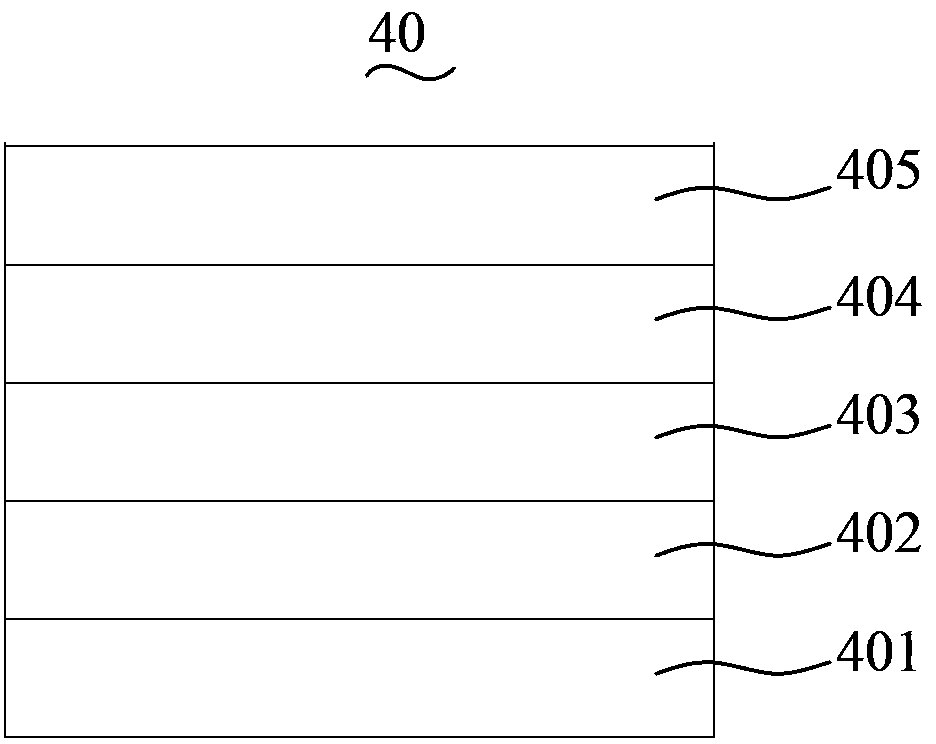

Organic light-emitting device and preparation method thereof

InactiveCN104183709AImprove integrityCounteract internal stressOrganic semiconductor materialsSolid-state devicesXylyleneParylene

The invention provides an organic light-emitting device and a preparation method thereof. The invention discloses the organic light-emitting device which is characterized in that a buffer layer is arranged between a substrate and an anode, wherein the buffer layer includes poly-p-xylylene thin films and inorganic thin films, which are laminated alternatively, and the inorganic thin films in the buffer layer are silicon dioxide, silicon nitride or aluminum oxide. The package layer includes poly-p-xylylene thin films and inorganic thin films, which are alternatively laminated, wherein the inorganic thin films in the package layer are silicon dioxide, silicon nitride or aluminum oxide. The preparation method for the organic light-emitting device is simple in preparation process, wide in material source and low in cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

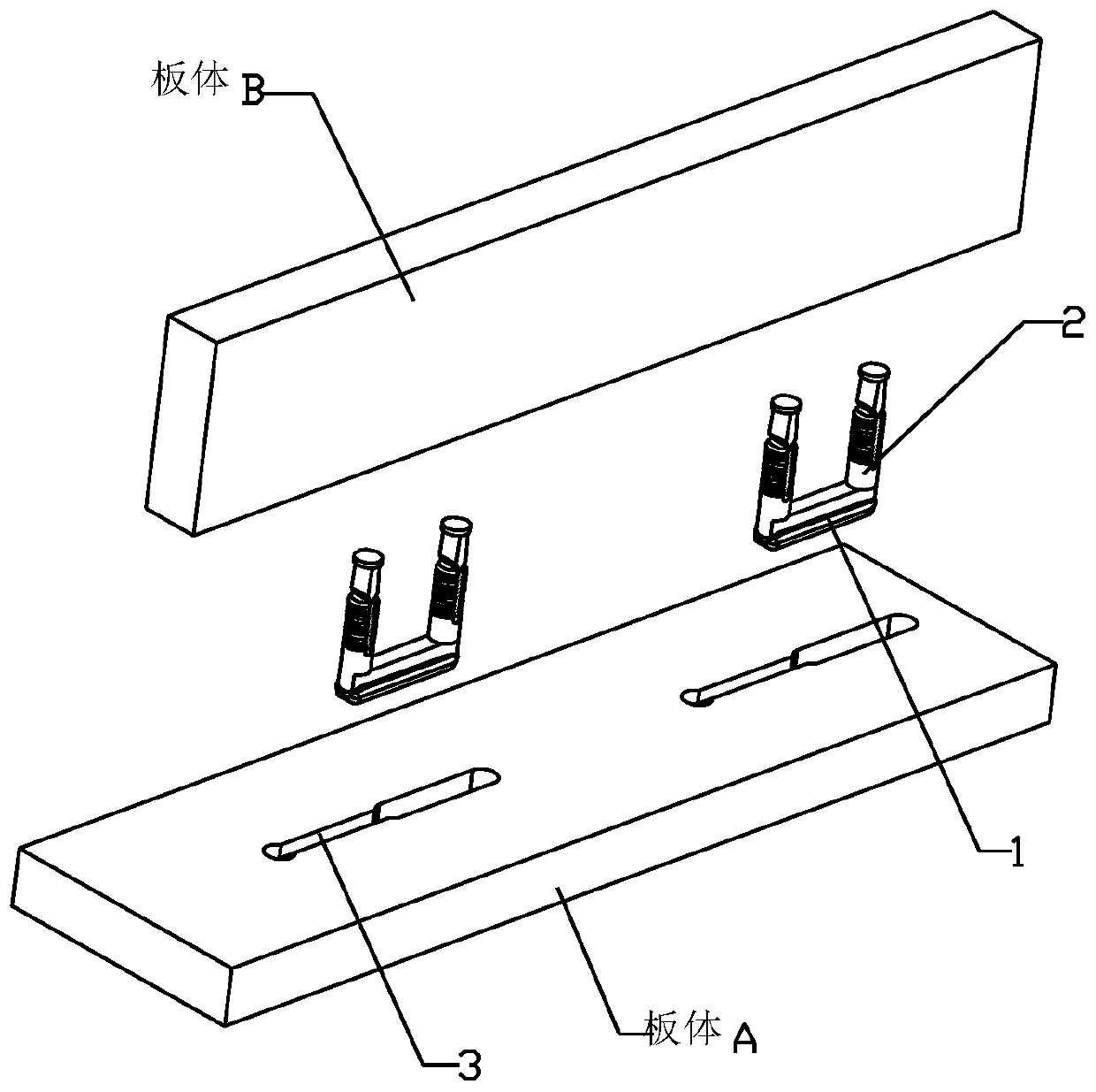

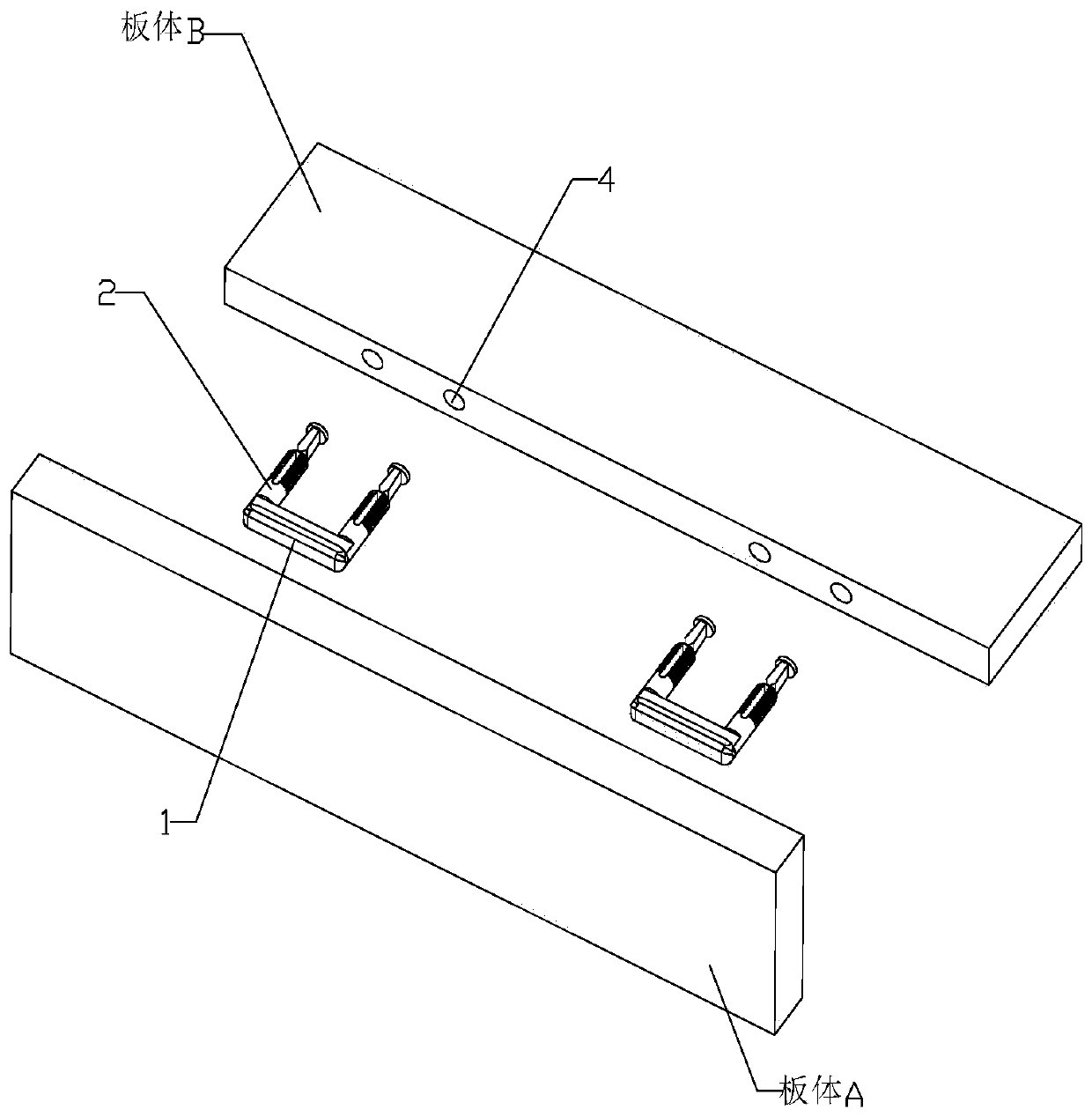

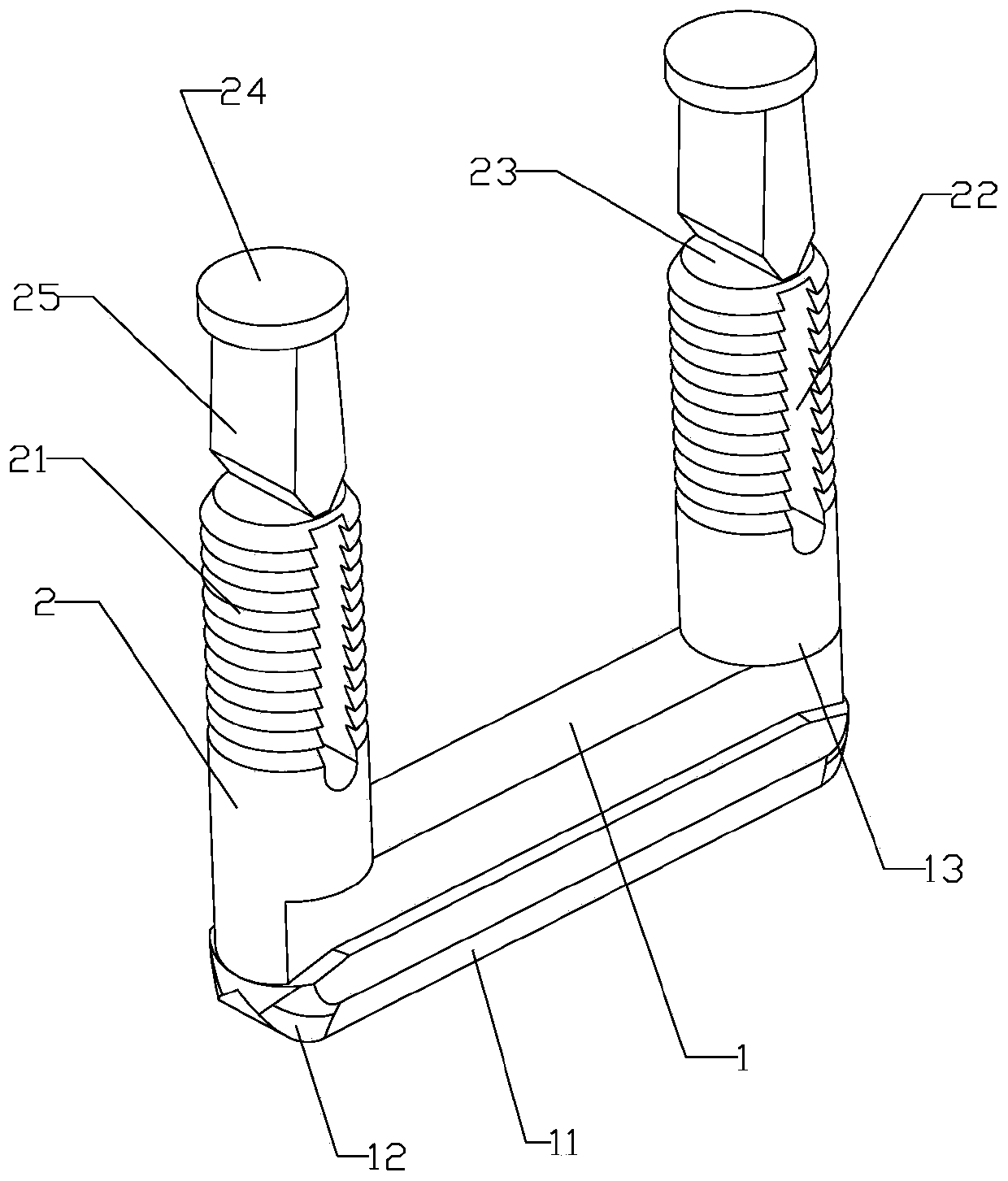

Fully-hidden sliding locking furniture plate body connecting piece

PendingCN110645241AReduce internal stressImprove stabilitySheet joiningDowelsEngineeringStructural engineering

The invention discloses a fully-hidden sliding locking furniture plate body connecting piece. The fully-hidden sliding locking furniture plate body connecting piece comprises a connecting block arranged in a plate body A and connecting rods arranged in a plate body B, and is characterized in that the two or more connecting rods integrally formed with the connecting block are arranged on the connecting block, the connecting block is connected with a sliding groove with a reverse buckle in the plate body A in a matched mode, the connecting rods are connected with connecting holes in the plate body B in a matched mode, and expansive locking parts are arranged on the sides, connected with the plate body B, of the connecting rods. The fully-hidden sliding locking furniture plate body connectingpiece is good in fixing property, and all accessories are not exposed.

Owner:GUANGDONG ANDISI INTELLIGENT FURNITURE COMPONENT

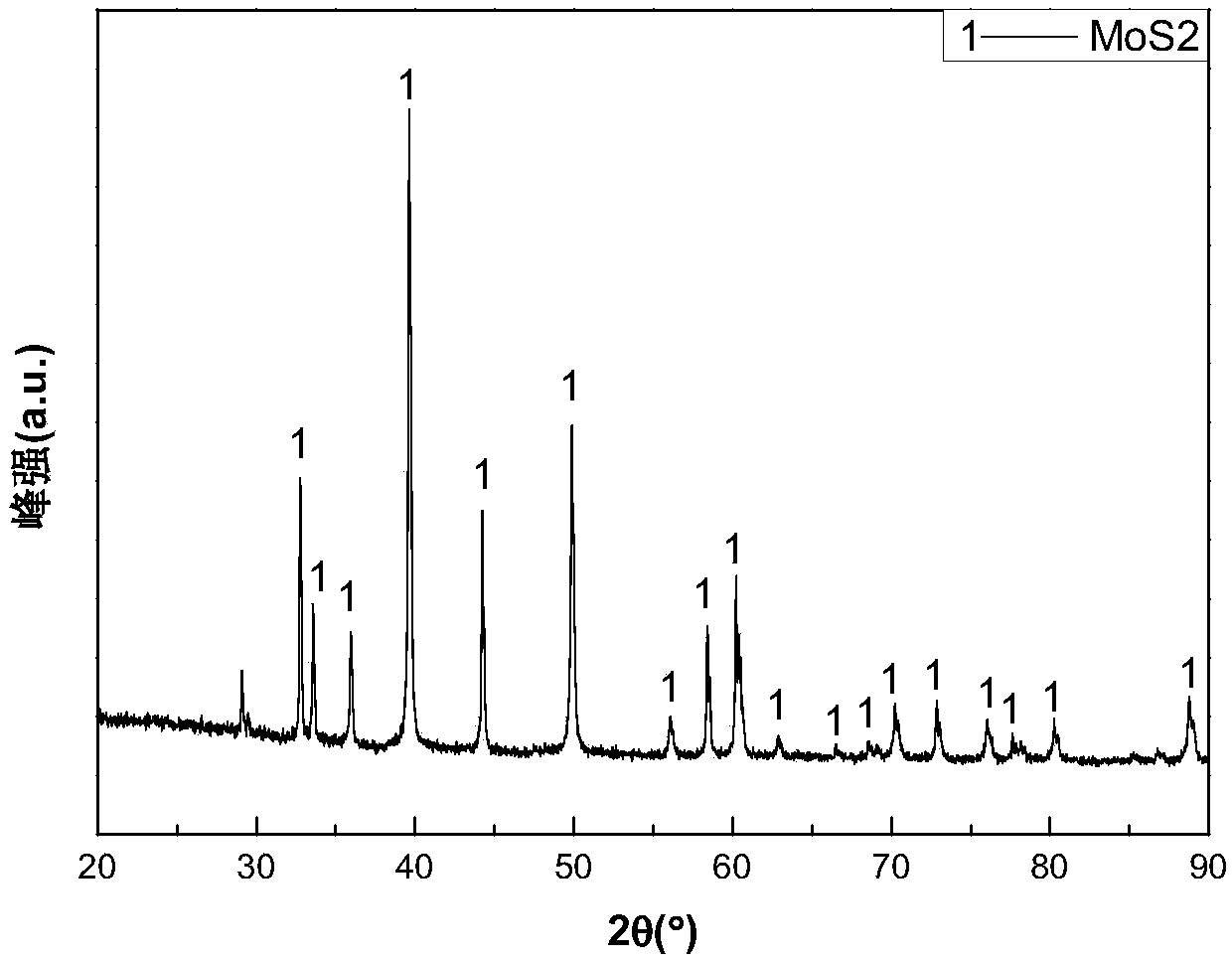

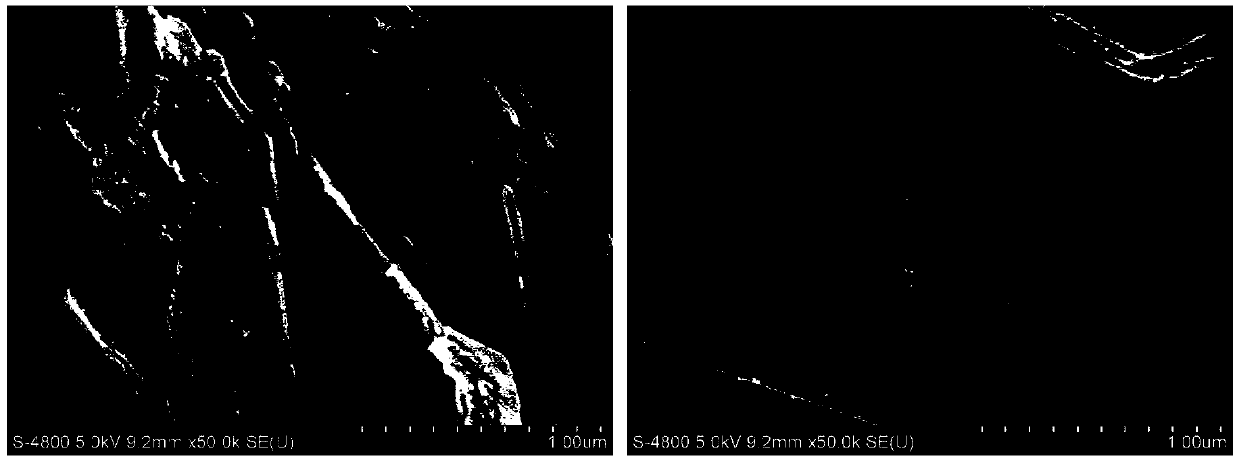

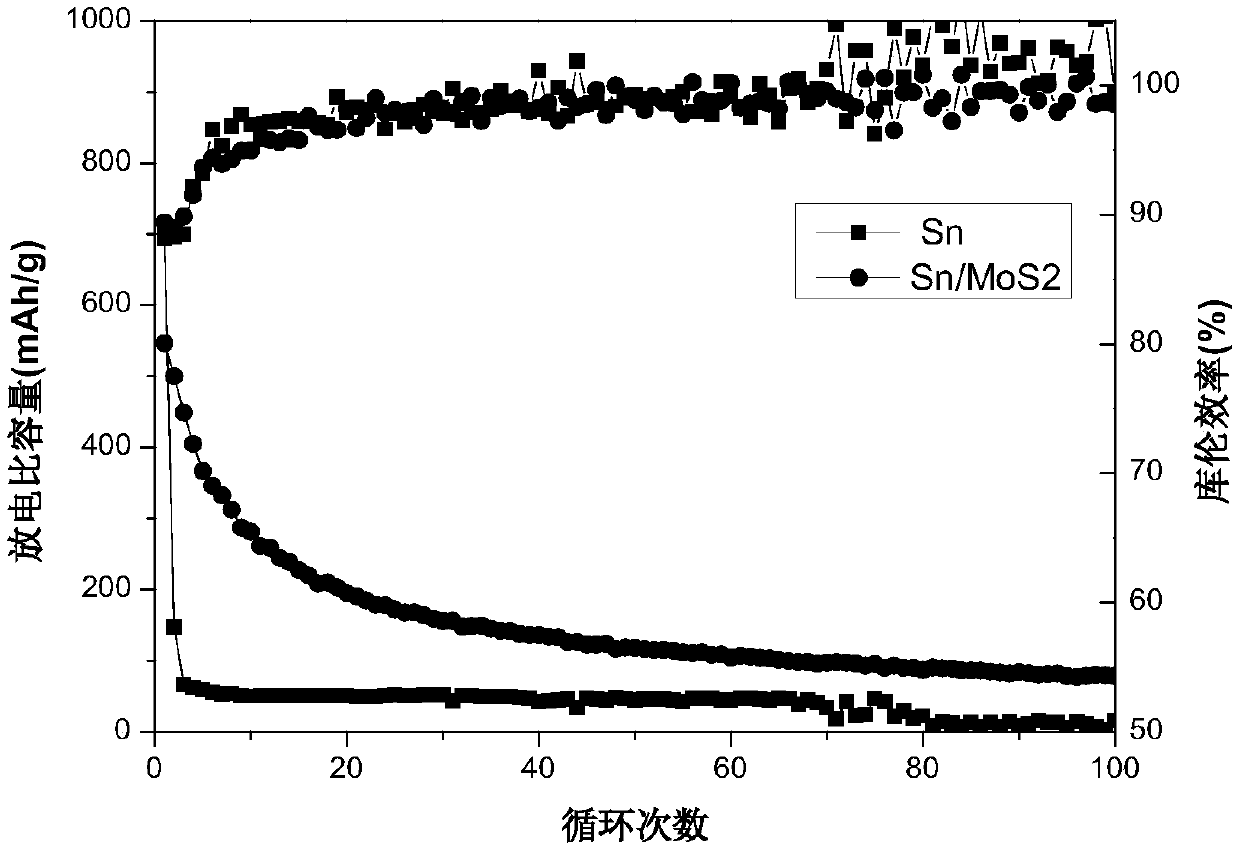

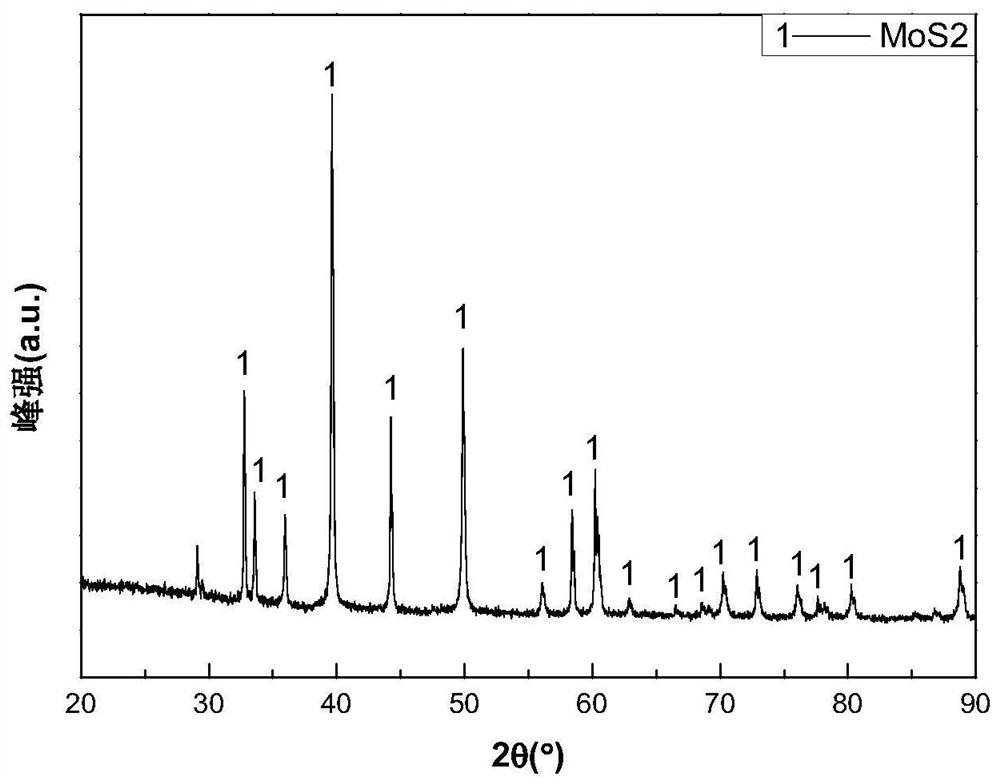

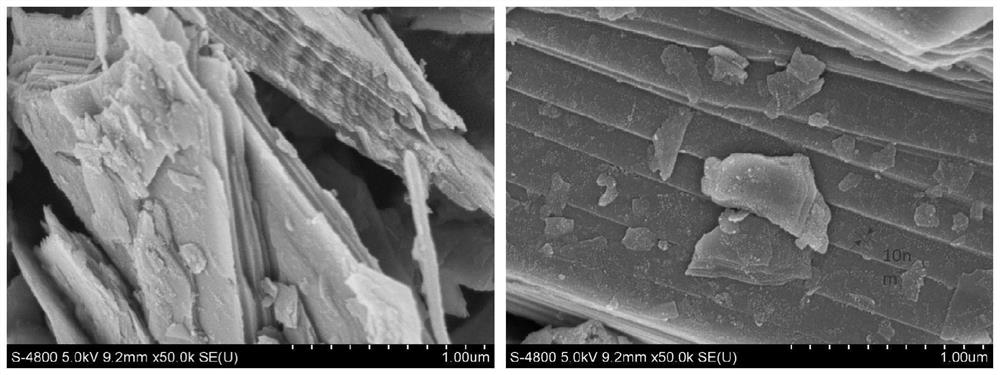

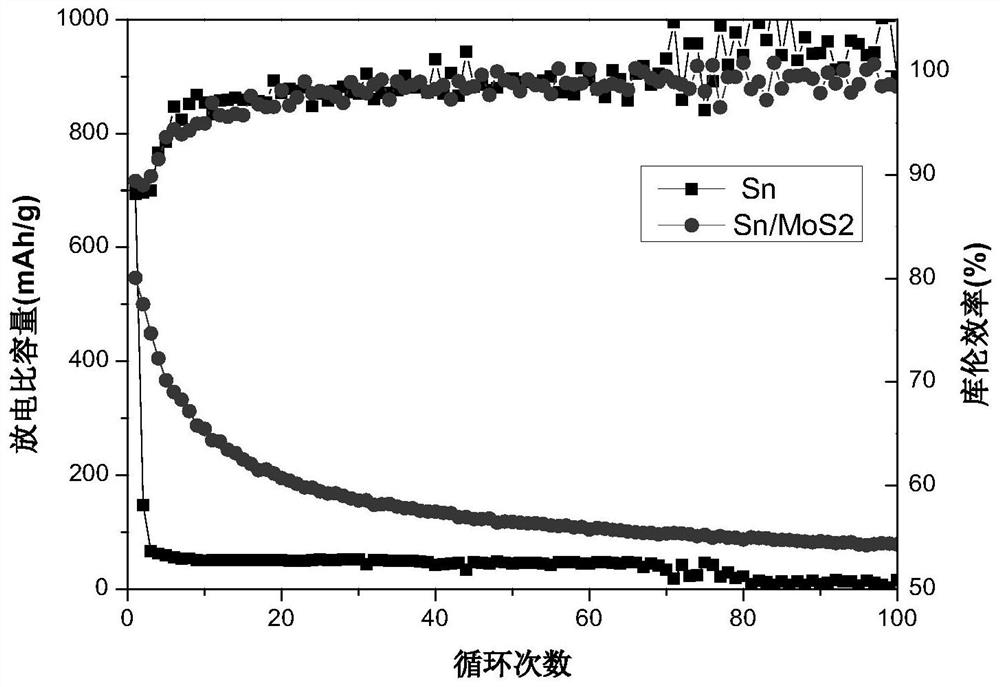

Nanometer tin-molybdenum disulfide compound negative electrode material as well as preparation method and application thereof

ActiveCN109560280AIncrease energy densityHigh reversible capacityNegative electrodesSecondary cellsLithium intercalationMaterials science

The invention discloses a nanometer tin-molybdenum disulfide compound negative electrode material as well as a preparation method and an application thereof. According to the prepared material, molybdenum disulfide is of a laminated structure, and tin is dispersedly distributed on a molybdenum disulfide sheet in a particle form, wherein the particle size of the tin particles is 8 -15 nm. The preparation method comprises the following steps of dipping molybdenum disulfide by using a SnCl4 solution, and preparing and obtaining the tin-molybdenum disulfide compound negative electrode material trough a hydrogenation reduction method. The layered structure of molybdenum disulfide is utilized, so that the volume change of the tin material in the lithium intercalation process is buffered, a partof internal stress is counteracted, and the cycling stability of a tin-based electrode is improved. The cycling capacity retention rate of the prepared tin-molybdenum disulfide compound electrode is obviously improved compared with that of commercial tin powder, the capacity reduction is relatively small when the large-current discharge is carried out, the platform effect is not obvious, and the capacity loss rate after the rate discharge is ended is low.

Owner:包头市石墨烯材料研究院有限责任公司

Welding method of steel structure tetrahedron huge column

ActiveCN112427832AAvoid deformationAvoid stressWelding/soldering/cutting articlesWorkpiece edge portionsEngineeringWeld seam

The invention discloses a welding method of a steel structure tetrahedron huge column. The method is used for assembling and welding front, back, left and right parts forming the tetrahedron huge column and comprises the following welding steps that (1) spot welding between main plates of the front and back parts and corresponding longitudinal and transverse rib plates is performed; (2) main plates of the left part and the right part are assembled with the main plates of the front part and the back part in a spot welding mode respectively, the assembling and welding angle between the main plate of the front part and the main plate of the right part and the assembling and welding angle between the main plate of the back part and the main plate of the left part are both 90 degrees, the assembling and welding angle between the main plate of the front part and the main plate of the left part is smaller than 90 degrees, and the assembling and welding angle between the main plate of the backpart and the main plate of the right part is greater than 90 degrees; (3) the corresponding longitudinal and transverse rib plates is spot-welded on the main plates of the left part and the right part; (4) the spot-welded longitudinal and transverse rib plates are welded on the main plates of the corresponding parts; (5) the alignment rib plates between the main plates of the adjacent parts are welded into a whole; and (6) an inner side main welding seam and an outer side main welding seam between the main plates of the adjacent parts are welded.

Owner:FANGCHENGGANG ZHONGYI HEAVY IND

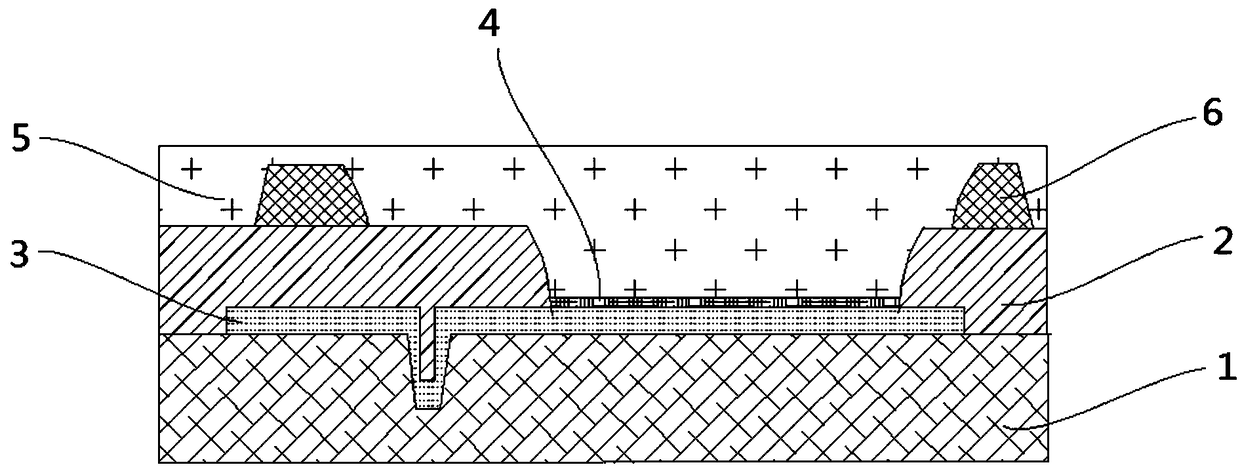

Display panel and display device having the same

InactiveCN109166884AIncrease contact areaGood dispersionSolid-state devicesSemiconductor devicesDisplay deviceLight-emitting diode

The present invention relates to a display panel, include an array substrate, A light emitting unit provided on the array substrate and a pixel defining layer provided between adjacent light emittingunits, The light emitting unit comprises a first electrode layer (3), a light emitting layer (4) and a second electrode layer (5) arranged in a stacked order, the pixel defining layer and at least part of the surface of the light emitting unit being in a smooth curved surface, and the light emitting unit has a surface matching the smooth curved surface of the pixel defining layer. A display panelof the present invention and a display device having the same, A surface of a portion of a plurality of film layer including a pixel-defining lay and a corresponding light emitting unit is designed with a smooth curved surface, The contact area between the film layers can be enlarged, the adhesion effect between the film layers can be enhanced, and the external force can be better dispersed when the film layers are impacted by the external force, and the internal stress can be partially offset, so that the impact resistance of the panel and the device can be greatly enhanced.

Owner:YUNGU GUAN TECH CO LTD

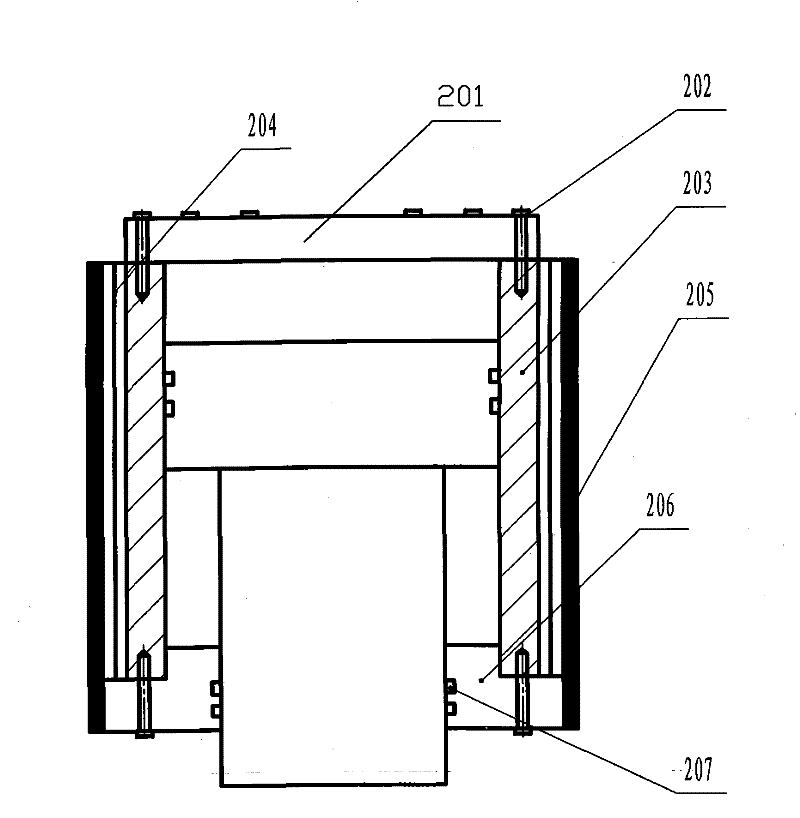

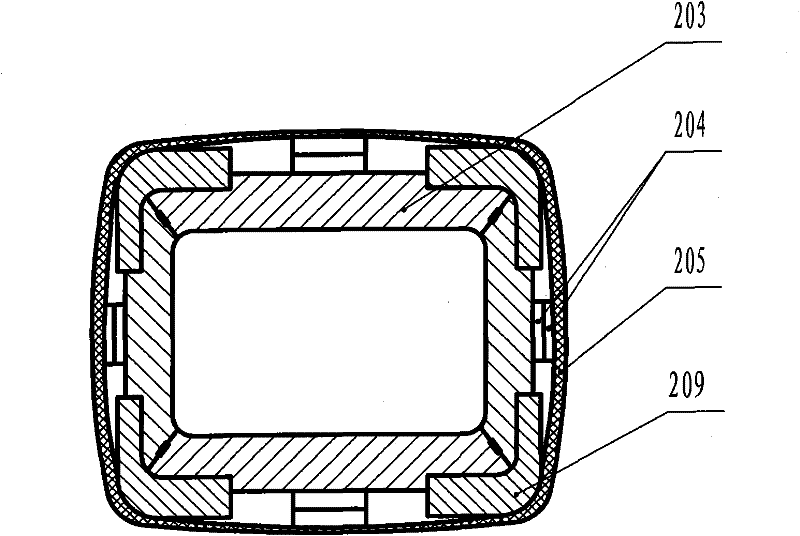

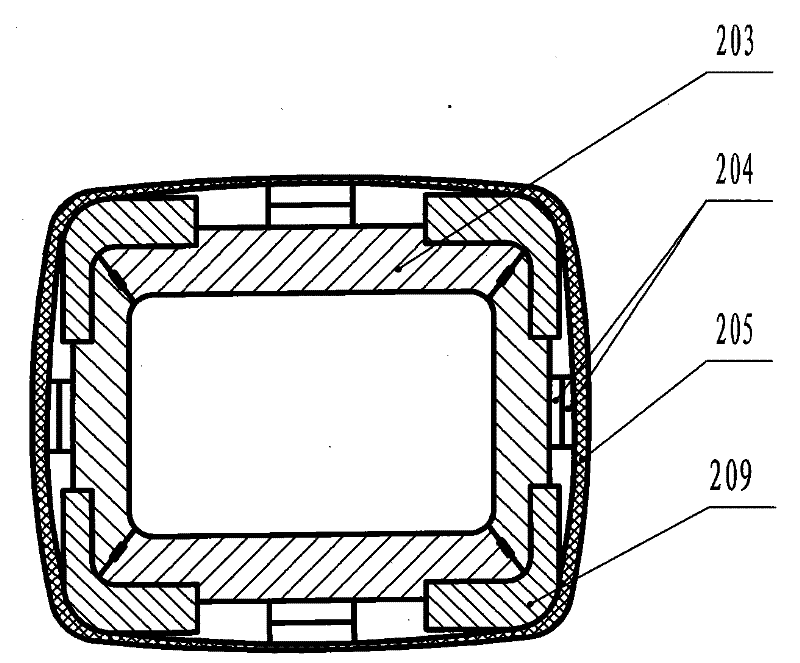

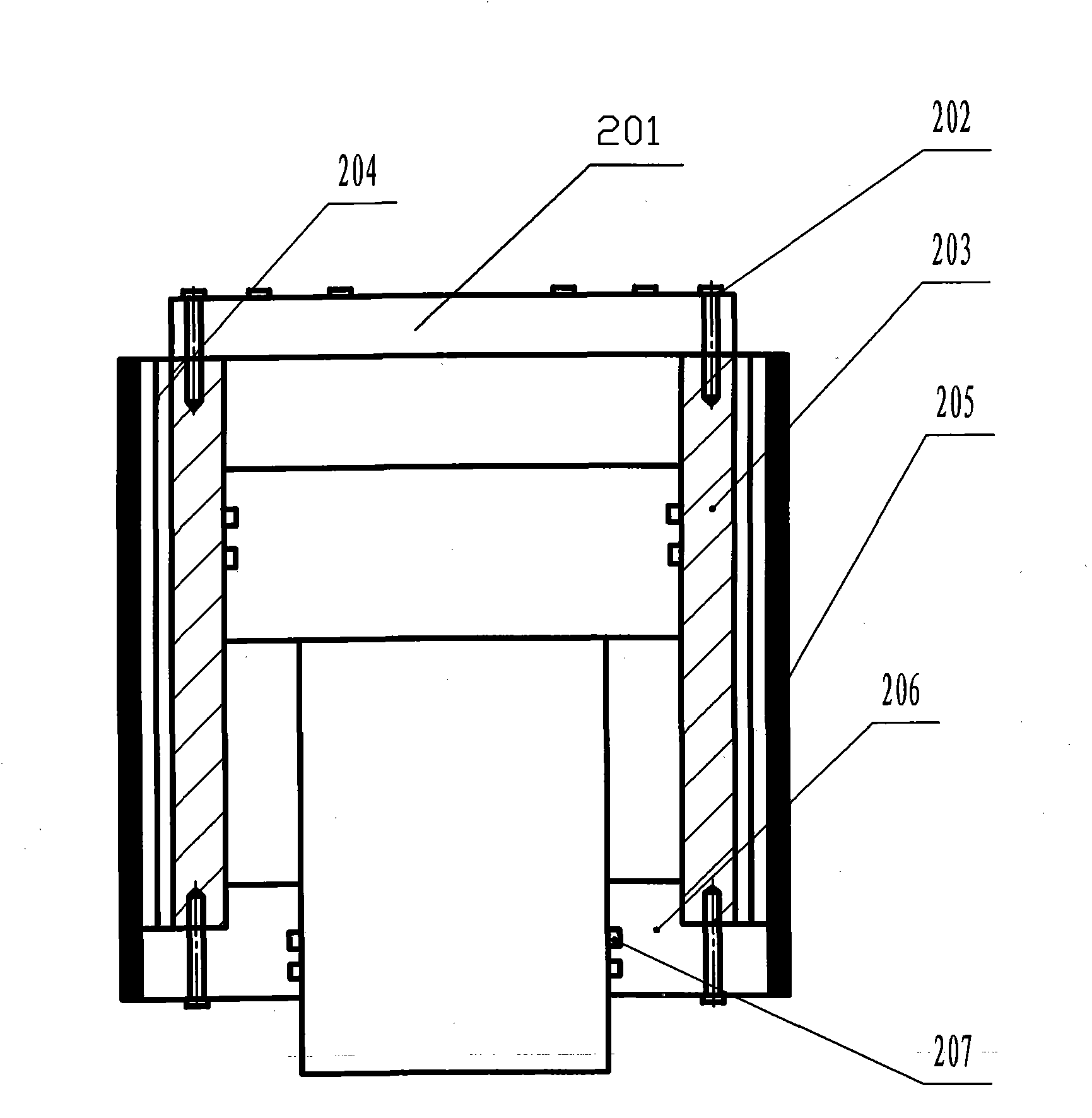

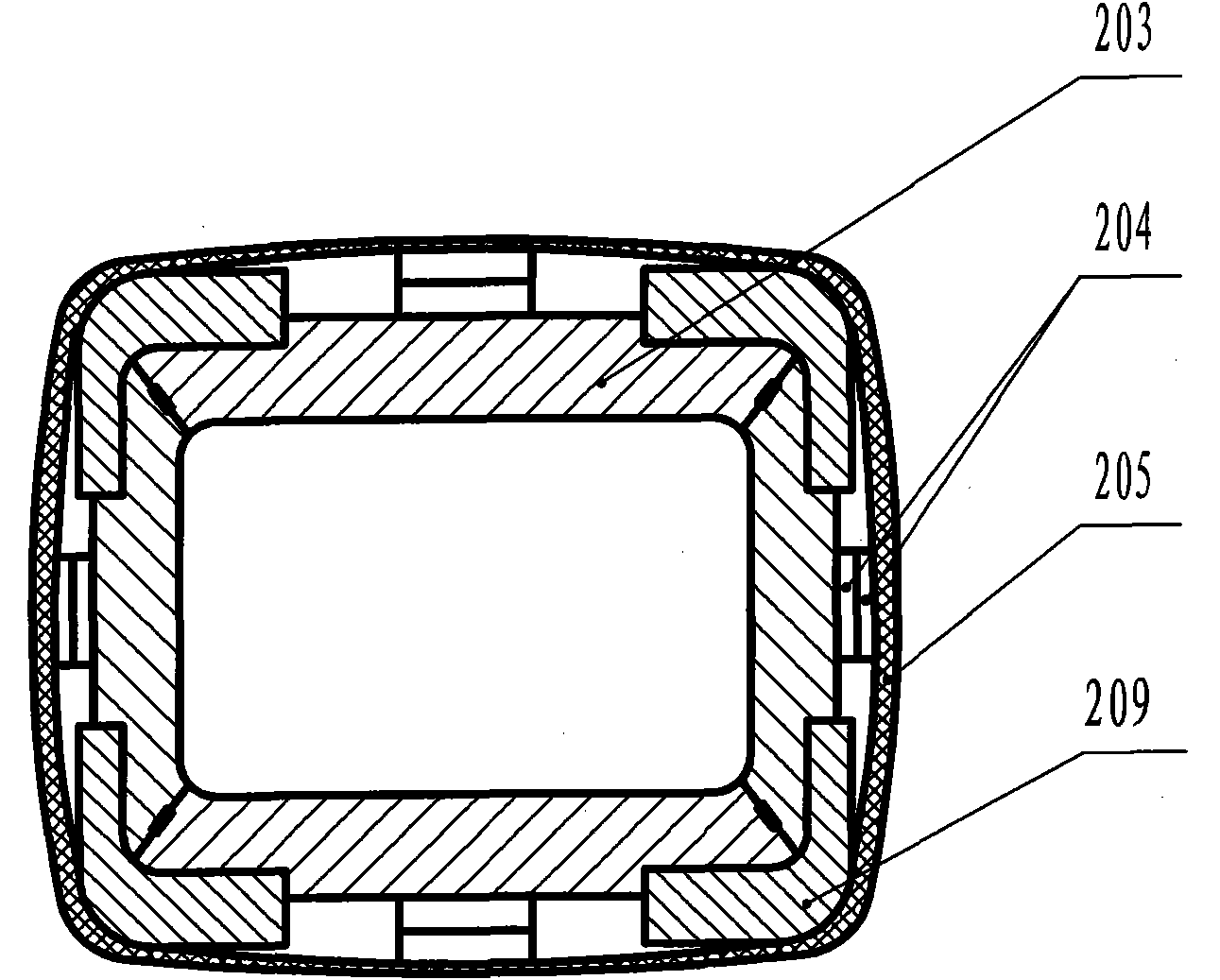

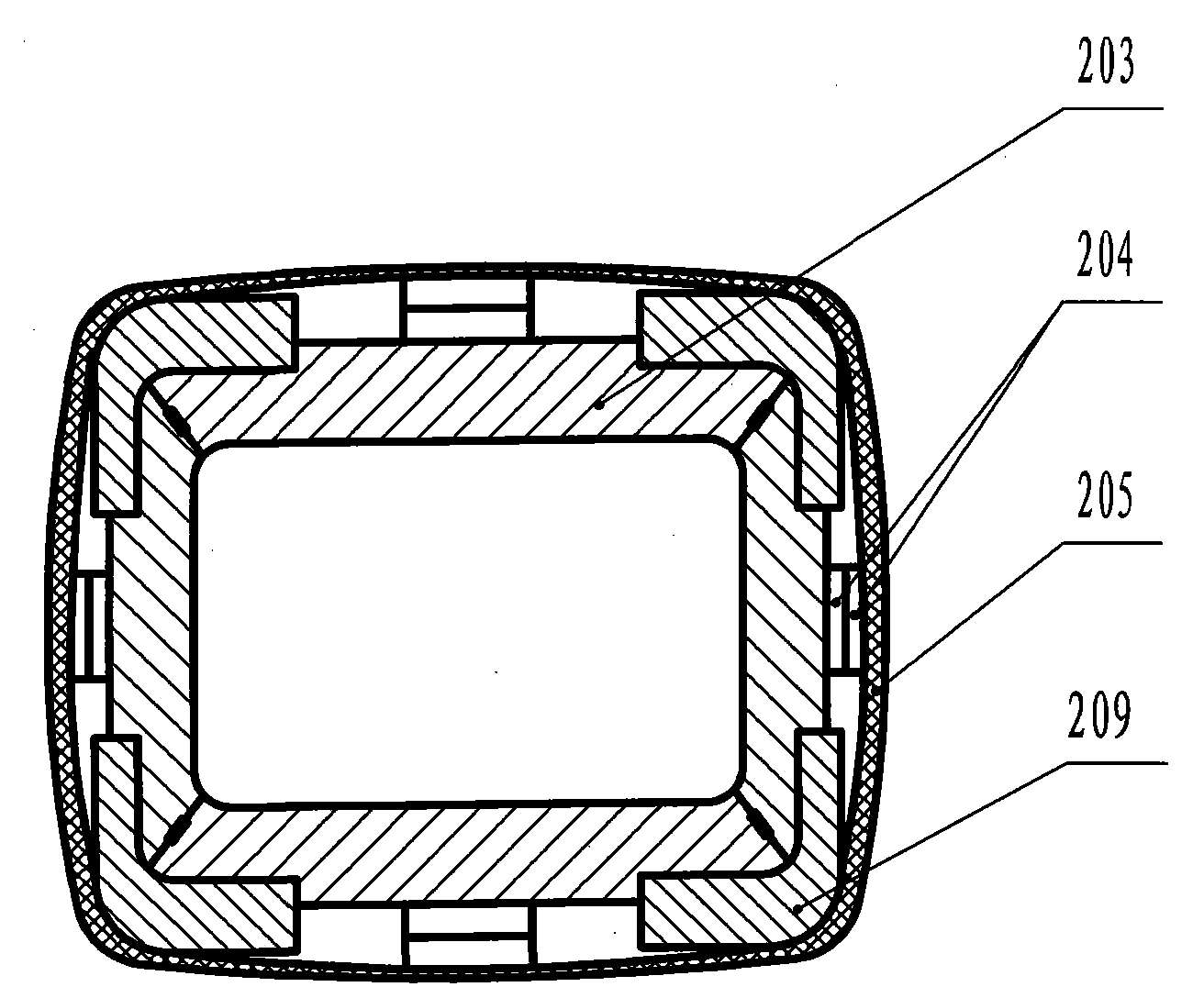

Combined rectangular oil cylinder

InactiveCN101893088BStrong resistance to stress and deformationEasy to processCylindersInternal pressureInternal stress

The invention discloses a combined rectangular oil cylinder. The oil cylinder is formed by combining a plurality of components of a cylinder body, wherein the components of the cylinder body consist of four cylinder wall structural blocks and four corner fixing blocks in the longitudinal direction of an oil cylinder body; four corners of every two adjacent cylinder wall structural blocks are obliquely joined at 45 degrees and sealed in the middle; the outsides of the four corners are fixed by the four corner fixing blocks; a wire winding layer is tightly wound around the corner fixing blocks;and a wedging block group is tightly wedged between the winding layer and the cylinder wall structural blocks to further tighten the wire so as to reach a larger pre-tightening force. An upper end cover and a lower end cover are fixed at two ends by bolts. The wire winding layer of the oil cylinder makes the cylinder body generate an internal stress in advance, and the wire presses wedging blocksto generate a pre-stressed force to the cylinder wall so as to eliminate the internal pressure to the cylinder wall in the use of the oil cylinder. The corner fixing block generates a pre-stressed force to four corners of the cylinder wall to eliminate an internal stress to the corners of the cylinder wall. The combined rectangular oil cylinder solves the stress deformation and other processing problems in the use of the oil cylinder in the prior art.

Owner:DALIAN POLYTECHNIC UNIVERSITY

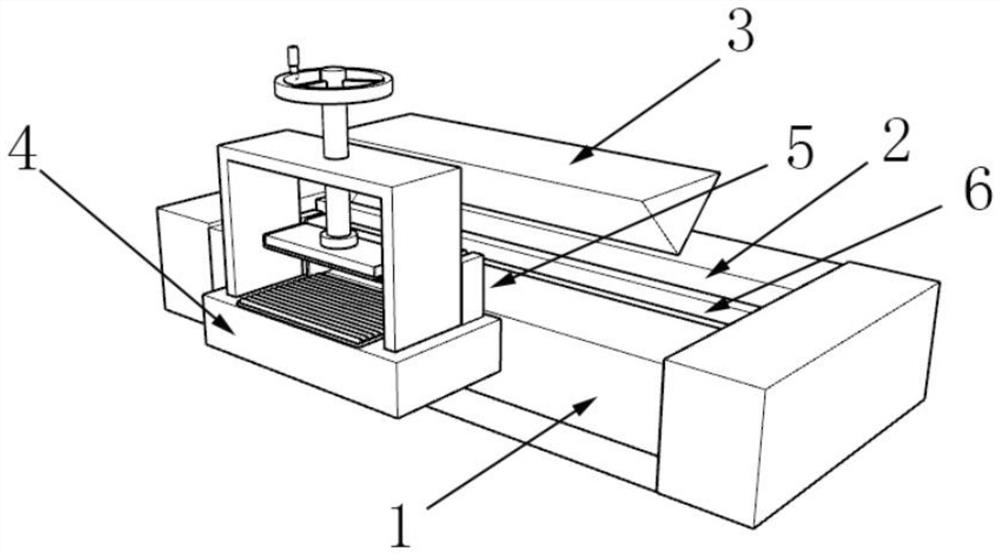

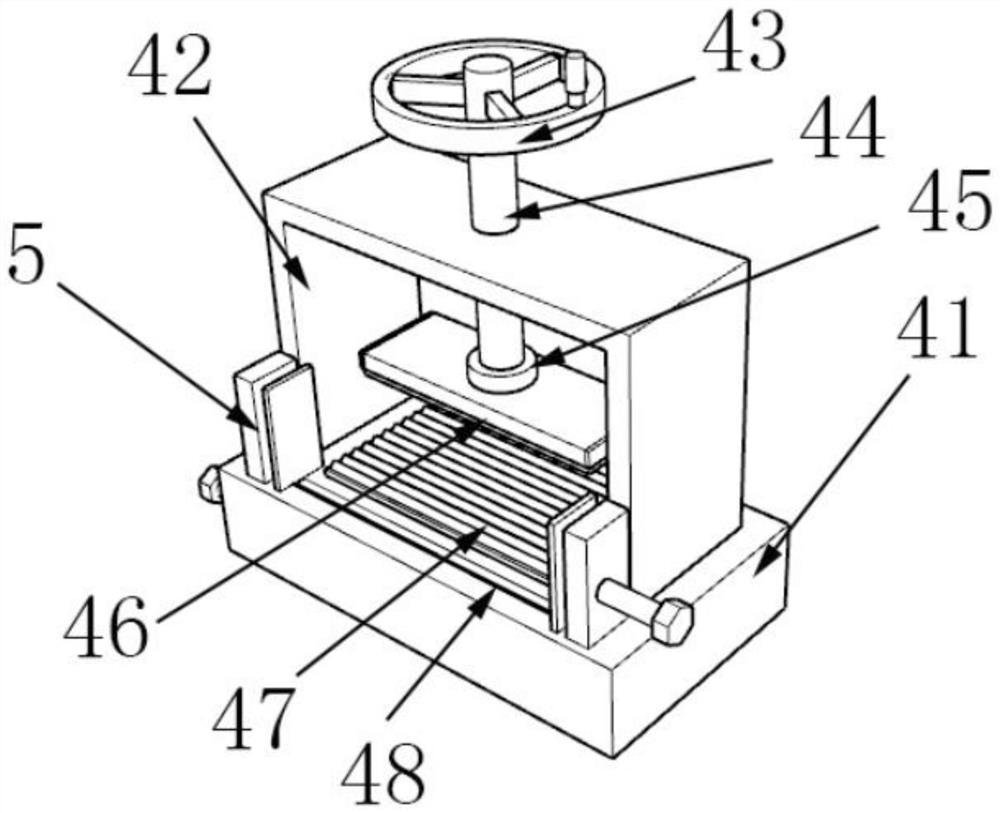

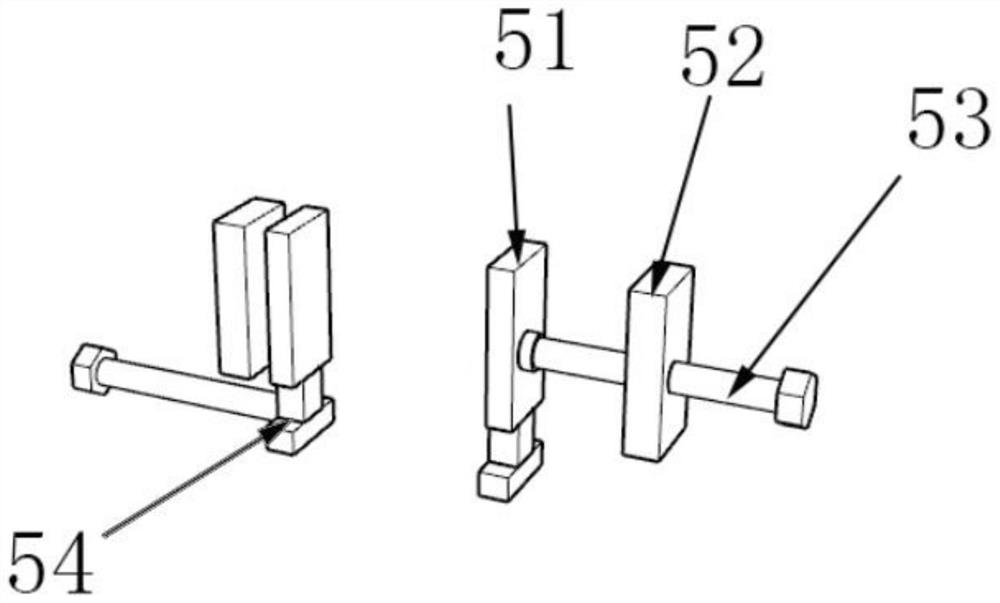

High-stability fixing clamp capable of counteracting machining internal stress

PendingCN114309312AAvoid offsetCounteract internal stressShaping toolsMetal-working feeding devicesEngineeringMachine

The invention discloses a high-stability fixing clamp capable of counteracting machining internal stress, and relates to the technical field of fixing clamps, the high-stability fixing clamp comprises a lower die base, bending machine bodies are fixedly installed at the two ends of the lower die base, upper dies are movably installed at the tops of the bending machine bodies, and clamping clamps are fixedly installed on the side edges of the bending machine bodies; and a guide positioning device is fixedly mounted on the clamping fixture. According to the scheme, the clamping fixture is fixedly installed on the side edge of the bending machine body, the heating block is movably installed in the lifting groove, the buffering device is fixedly installed at the bottom of the heating block, in the working process of the device, a workpiece is fixed left and right through the guide plate, the workpiece is fixed through the pressing plate through the fixing bolts, and a certain part of the workpiece is heated through the heating device; the upper die is pressed downwards, the heating block descends through the buffer device, the workpiece is heated, the internal stress of the workpiece is offset, the workpiece is more stable, manpower and time are saved, the product quality is improved, and the product production effect is more ideal.

Owner:苏州彪炳机械有限公司

A kind of nano tin-molybdenum disulfide composite negative electrode material and its preparation method and application

ActiveCN109560280BIncrease energy densityHigh reversible capacitySecondary cellsNegative electrodesCapacity lossComposite electrode

The invention discloses a nano tin-molybdenum disulfide composite negative electrode material, a preparation method and an application thereof. In the material prepared by the invention, the molybdenum disulfide has a lamellar structure, and the tin is dispersed and distributed on the molybdenum disulfide sheet in the form of particles, and the particle diameter of the tin particles is 8-15nm. The preparation method includes: using SnCl 4 After impregnating the molybdenum disulfide with the solution, the tin-molybdenum disulfide composite negative electrode material is prepared by hydrogenation reduction. The invention utilizes the layered structure of the molybdenum disulfide to buffer the volume change of the tin material during the lithium intercalation process, offset part of the internal stress, and improve the cycle stability of the tin-based electrode. Compared with commercial tin powder, the cycle capacity retention rate of the tin-molybdenum disulfide composite electrode prepared in the present invention is significantly improved, and the capacity drop is small during high-current discharge, the plateau effect is not obvious, and the capacity loss rate is small after rate discharge. .

Owner:包头市石墨烯材料研究院有限责任公司

An automatic full-spectrum radiation calibration reference target device

ActiveCN110243393BGuaranteed surface flatnessGuaranteed Surface AccuracyRadiation pyrometrySpectrum investigationMiddle infraredImaging quality

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A kind of anti-seepage and anti-freezing and thawing self-compacting concrete and its preparation method

The invention discloses an anti-seepage anti-freezing and thawing self-compacting concrete and a preparation method thereof. The anti-seepage and anti-freezing and thawing self-compacting concrete includes the following components by weight: 350-370 parts of cement, 25-45 parts of fly ash, 25-35 parts of modified metakaolin, 30-50 parts of mineral powder, 770-800 parts Medium sand, 810-830 parts of gravel, 20-40 parts of silica fume, 170-180 parts of water, 1-3 parts of water reducing agent, 20-34 parts of expansion agent, 2-6 parts of air-entraining agent, 10-20 parts Fiber composition; the fiber composition is composed of modified polyester fiber, basalt fiber and polyacrylonitrile fiber with a mass ratio of 1:0.6-0.9:0.3-0.6. The anti-seepage and anti-freeze-thaw self-compacting concrete of the invention has the advantages of good workability and fluidity, and excellent anti-seepage performance and antifreeze performance.

Owner:西安新意达建筑制品有限公司

A high-pressure-resistant and anti-penetration thermal insulation composite pipe and its preparation method

InactiveCN110594496BSolve technical problems with low withstand voltageHigh strengthNon-macromolecular adhesive additivesThermal insulationGlass fiberPolymer science

The invention belongs to the technical field of pipelines, and provides a high-pressure-resistant and impermeable heat-preservation composite pipeline and a preparation method thereof. The heat-preservation composite pipeline comprises an inner-layer working layer, a middle-layer insulating layer and an outer-layer protective layer which are sequentially arranged from inside to outside, wherein the inner-layer working layer comprises an impermeable barrier layer, a polyethylene material layer, a modified reinforcing layer, a heat-sensitive micro-foaming adhesive layer and a prepreg tape winding layer which are sequentially arranged from inside to outside, wherein the polyethylene material layer is a PERT-II type high-density polyethylene material layer, the impermeable barrier layer is made of nylon MXD6 or ethylene / vinyl alcohol copolymers, the modified reinforcing layer is a glass fiber reinforced nylon MXD6 layer, the prepreg tape winding layer is a glass fiber reinforced polyethylene prepreg tape layer, and the modified reinforcing layer is composed of the following components of, in parts by weight, 35-50 parts of nylon MXD6, 15-50 parts of glass fiber, 0.2-1 part of a silanecoupling agent, 1-2 parts of an antioxidant, 0.5-1 part of a lubricant and 5-15 parts of a toughening agent. The heat-preservation composite pipeline and the preparation method solve the problem thatthe high-density polyethylene composite heat preservation pipeline is low in pressure resistance.

Owner:河北汇锐管业有限公司

Sn-C compound electrode material and preparation method and application thereof

InactiveCN108565411AIncrease energy densityHigh reversible capacityCell electrodesArgon atmosphereUltrasonic dispersion

The invention discloses an Sn-C compound electrode material and a preparation method and application thereof. The Sn-C compound electrode material has a complete C coating structure, the preparation method comprises the steps that SnCl2.2H2O and starch are fully dissolved in deionized water according to a certain ratio, then ultrasonic dispersion is carried out, after dispersing evenly is carriedout, vacuum drying is carried out, and lastly heat treatment is carried out in a tube furnace (argon atmosphere, 900 DEG C) to obtain an Sn-C compound. The invention further provides the application of the Sn-C compound electrode material in preparing a lithium ion battery negative electrode, the Sn-C compound electrode material has the advantages that the reversible capacity is high, the cyclingstability is good, the rate performance is good, and the scale production can be achieved.

Owner:无锡新锂耀辉能源科技有限公司

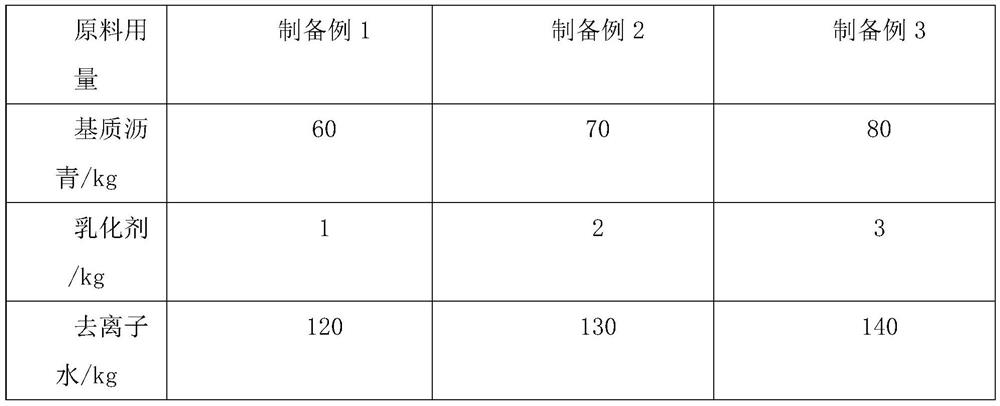

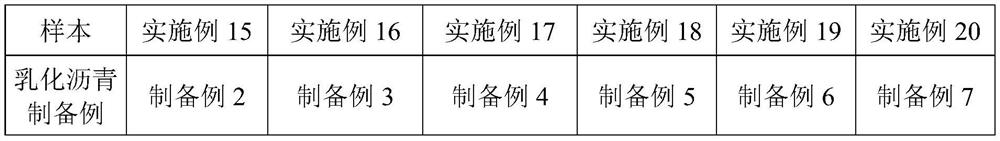

A kind of PVC sole and preparation technology thereof

ActiveCN113214575BImprove flexibilityReduce brittlenessSolesBuilding insulationsPolymer scienceBitumen emulsion

The application relates to the field of plastic products, and specifically discloses a PVC shoe sole and a preparation process thereof. The PVC sole is made of the following components by weight: 35-60 parts of PVC, 20-45 parts of reinforcing filler, 15-25 parts of emulsified asphalt, 5-10 parts of water-based epoxy resin, and 4-8 parts of curing agent; its preparation The process is: first emulsify the base asphalt to obtain emulsified asphalt, then mix the emulsified asphalt with water-based epoxy resin to obtain epoxy emulsified asphalt, then mix the epoxy emulsified asphalt with curing agent to obtain epoxy asphalt, and finally mix the epoxy asphalt , reinforcing filler and PVC are kneaded together to obtain PVC soles. In this application, by adding emulsified asphalt to PVC, the brittleness of the PVC sole is reduced, and the PVC sole is not easy to crack when bent, thereby improving the bending strength and fracture toughness of the PVC sole.

Owner:温州市剑利鞋业有限公司

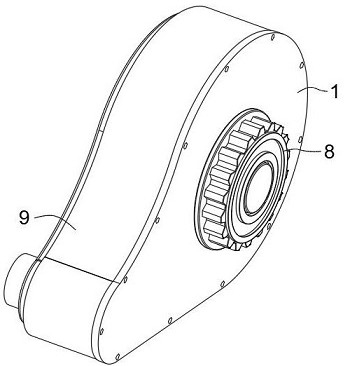

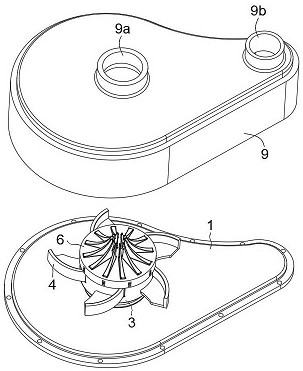

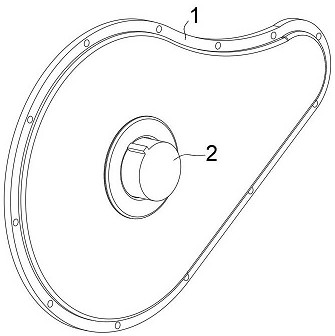

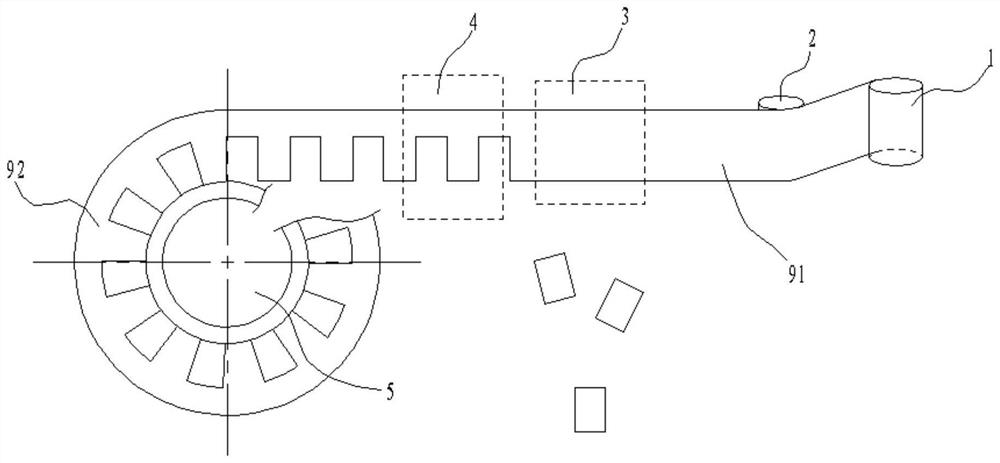

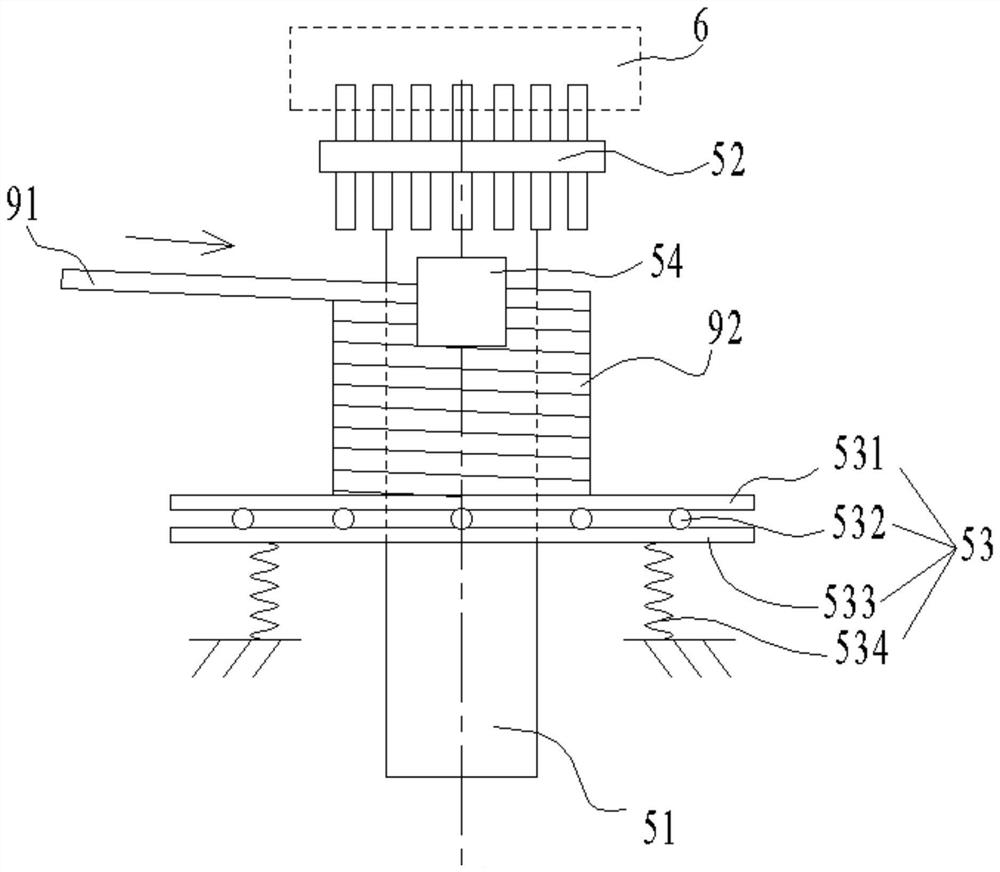

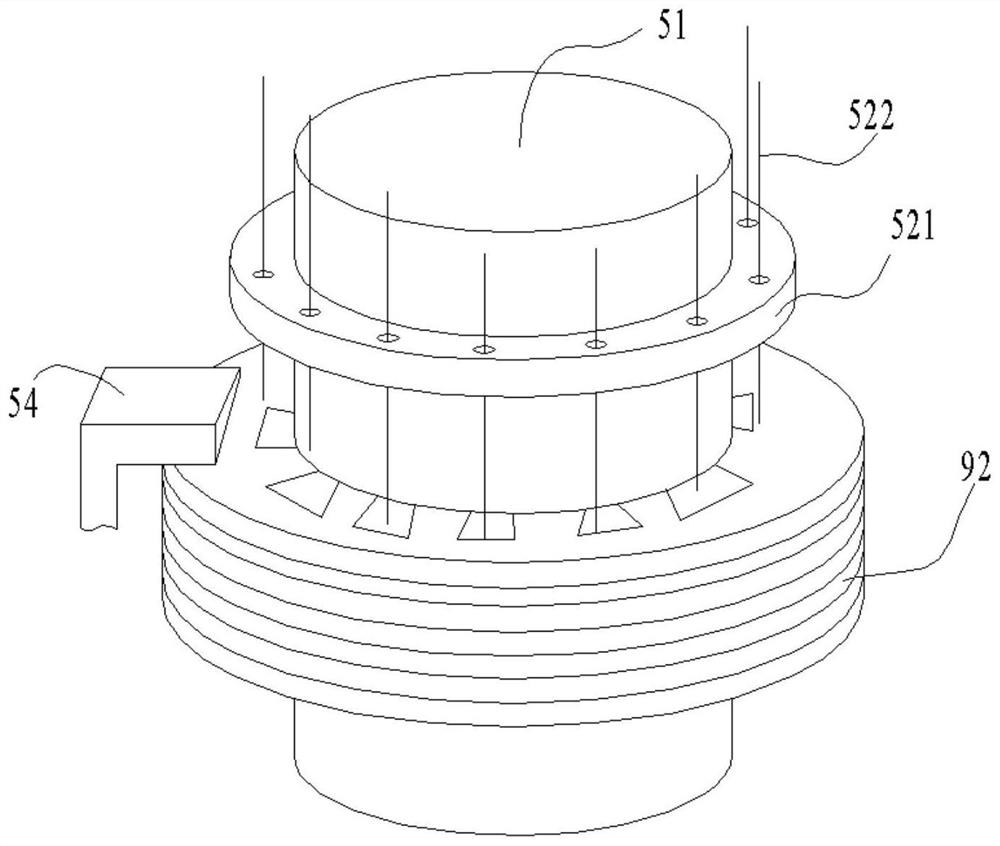

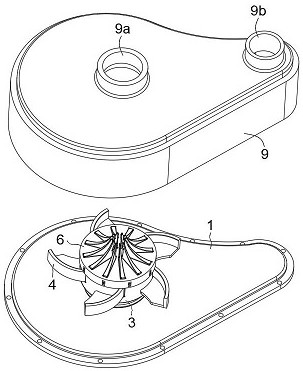

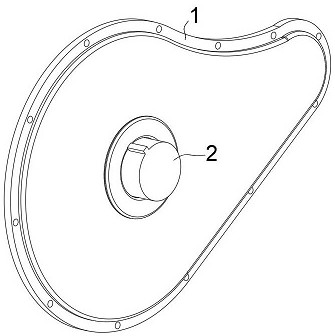

A new energy vehicle battery cooling water circulation pump

ActiveCN114033707BCounteract internal stressEffective protectionPump componentsSecondary cellsImpellerNew energy

The invention relates to the field of circulation pumps, in particular to a new energy vehicle battery cooling water circulation pump. The new energy vehicle battery cooling water circulating pump includes a pump body, and a rotating shaft is installed away from the axis, and one end of the rotating shaft extends out of the pump body and is provided with a fixedly connected pulley flange; the pump cover is closed On the pump body, the water inlet pipe and the water outlet pipe are installed on the pump cover; the assembly part is located on the rotating shaft in the pump body, and the impeller blade is installed through the assembly part, the assembly part includes a shaft cylinder, and the shaft The cylinder is fixedly installed on the rotating shaft through a coupling, and a sleeve is installed in the shaft cylinder. The new energy vehicle battery cooling water circulation pump provided by the present invention has impeller blades compared with the traditional integral impeller structure, which reduces the difficulty of the preparation process, and can be replaced independently after a single impeller blade is damaged, without abandoning the entire impeller structure , more economical and practical advantages.

Owner:HANGZHOU SAIQI MACHINERY CO LTD

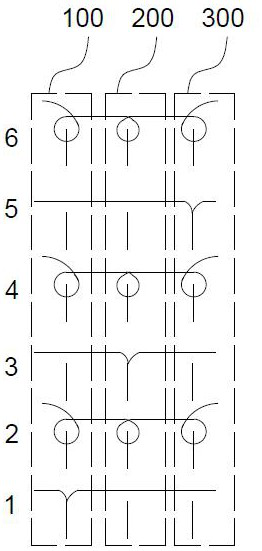

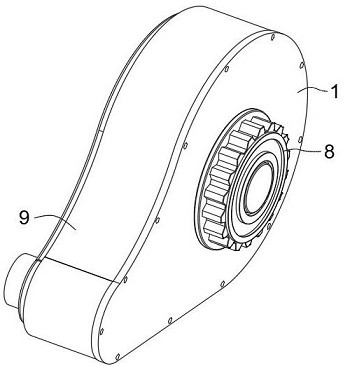

Motor iron core winding equipment

PendingCN112383197AEasy to moveFully contactedManufacturing dynamo-electric machinesElectric machineryStructural engineering

The invention discloses motor iron core winding equipment. A steel belt is wound into an iron core, and the winding equipment comprises a silicon steel winding drum, a guide wheel, a stamping assemblyand a winding assembly, wherein the coiled steel belt is arranged on the silicon steel winding drum, and one end of the steel belt is pulled out, bypasses the guide wheel, penetrates through the stamping assembly and then reaches the winding assembly; the winding assembly is used for winding a steel belt into a sheet spiral iron core, the guide wheel plays a role in guiding and supporting, and the stamping assembly is used for stamping a wire embedding groove in the steel belt. The winding assembly comprises a winding drum, a driving pin wheel, a tray and an extrusion inclined plane, the winding drum is vertically arranged, a rotary driver is arranged at the bottom of the winding drum, an iron core is wound around the outer cylindrical surface of the winding drum, and the driving pin wheel is detachably installed at the upper end of the winding drum, provided with a plug pin capable of extending downwards and inserted into an iron core wire embedding groove downwards; the bottom of the iron core is borne on the tray, the tray can be pressed downwards, and the extrusion slope is located at the position where the steel belt is wound into the iron core and extrudes the steel belt downwards by the distance of the thickness of the steel belt.

Owner:张莉

Magnetic nano composite film and its method for preparing sol-gel

InactiveCN1271652CCounteract internal stressNo microcracksNanostructure manufactureMagnetic film to substrate applicationComposite filmElectromagnetic shielding

The invention is a nano complex film and its sol-gel preparing method, firstly making a TiO2 sol and a barium ferrite precursor sol, respectively, then mixing them to make stable mixed sols in different mass proportions, adopting a rotating method to coat a substrate (like a quartz glass plate), making drying and thermal treatment to obtain a microcrack-free complex film. It belongs to a nano complex film and a crystal particle size less than 100 nm; it also belongs to an inorganic film and has a wide range of use temperature. It has higher magnetic property and has a wide application prospect in the fields of magnetic recording, electromagnetic screening, wave absorption coating, etc.

Owner:SHANGHAI JIAO TONG UNIV

A kind of knitted fabric and its preparation method

ActiveCN111501174BCounteract internal stressRoll resistantWeft knittingHeating/cooling textile fabricsYarnFiber

Owner:GUANGDONG FORWARD DENIM

Cooling water circulating pump for storage battery of new energy automobile

ActiveCN114033707ACounteract internal stressEffective protectionPump componentsSecondary cellsImpellerNew energy

The invention relates to the field of circulating pumps, in particular to a cooling water circulating pump for a storage battery of a new energy automobile. The cooling water circulating pump comprises: a pump body, wherein a rotating shaft is rotationally connected to the position deviating from the axis, and one end of the rotating shaft extends out of the pump body and is sleeved with a fixedly-connected belt wheel flange; a pump cover covering the pump body, wherein a water inlet pipe and a water outlet pipe are mounted on the pump cover; and an assembly part which is located on the rotating shaft in the pump body, wherein impeller blades are installed through the assembly part, the assembly part comprises a shaft barrel, the shaft barrel is fixedly installed on the rotating shaft through a coupling, and a sleeve is installed in the shaft barrel. Compared with a traditional integral impeller structure, the cooling water circulating pump for the storage battery of the new energy automobile has the advantages that the difficulty of a preparation process is reduced, the single impeller blade can be independently replaced after being damaged, the whole impeller structure does not need to be abandoned, and the cooling water circulating pump is more economical and practical.

Owner:HANGZHOU SAIQI MACHINERY CO LTD

Combined rectangular oil cylinder

InactiveCN101893088AStrong resistance to stress and deformationEasy to processCylindersInternal pressureCylinder block

The invention discloses a combined rectangular oil cylinder. The oil cylinder is formed by combining a plurality of components of a cylinder body, wherein the components of the cylinder body consist of four cylinder wall structural blocks and four corner fixing blocks in the longitudinal direction of an oil cylinder body; four corners of every two adjacent cylinder wall structural blocks are obliquely joined at 45 degrees and sealed in the middle; the outsides of the four corners are fixed by the four corner fixing blocks; a wire winding layer is tightly wound around the corner fixing blocks; and a wedging block group is tightly wedged between the winding layer and the cylinder wall structural blocks to further tighten the wire so as to reach a larger pre-tightening force. An upper end cover and a lower end cover are fixed at two ends by bolts. The wire winding layer of the oil cylinder makes the cylinder body generate an internal stress in advance, and the wire presses wedging blocks to generate a pre-stressed force to the cylinder wall so as to eliminate the internal pressure to the cylinder wall in the use of the oil cylinder. The corner fixing block generates a pre-stressed force to four corners of the cylinder wall to eliminate an internal stress to the corners of the cylinder wall. The combined rectangular oil cylinder solves the stress deformation and other processing problems in the use of the oil cylinder in the prior art.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Welding method of tetrahedron giant column in steel structure

ActiveCN112427832BAvoid deformationAvoid stressWelding/soldering/cutting articlesWorkpiece edge portionsWeld seamSpot welding

The invention discloses a welding method for a tetrahedral giant column of a steel structure, which is to assemble and weld the front, rear, left and right parts constituting the tetrahedral giant column. Spot welding with the corresponding longitudinal and transverse ribs; ② The main boards of the left and right parts are respectively assembled with the main boards of the front and rear parts by spot welding, and the welding angle between the main boards of the front parts and the main boards of the right parts , The assembly welding angle between the main board of the rear part and the main board of the left part is 90°; the welding angle between the main board of the front part and the main board of the left part is <90°; The assembly welding angle between the main boards of the right parts is >90°; ③ spot-weld the corresponding longitudinal and transverse ribs on the main boards of the left and right parts; ④ weld the spot-welded longitudinal and transverse ribs to the main boards of the corresponding parts ⑤ Weld the alignment ribs between the main boards of adjacent parts into one; ⑥ Weld the inner main weld and outer main weld between the main boards of adjacent parts.

Owner:FANGCHENGGANG ZHONGYI HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com