Sn-C compound electrode material and preparation method and application thereof

A technology of electrode materials and composites, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as collapsed electrodes, peeling, and sharp drop in battery capacity, and achieve good cycle stability, high energy density, and high reversible capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh SnCl 2 . 2H 2 O 2g, dissolve in 1.8g deionized water, add trace hydrochloric acid solution, then weigh 0.5g starch, dissolve in 2.5g deionized water, mix the two solutions and place them in an ultrasonic disperser for ultrasonic dispersion for 30min until the two solutions are uniform mix.

Embodiment 2

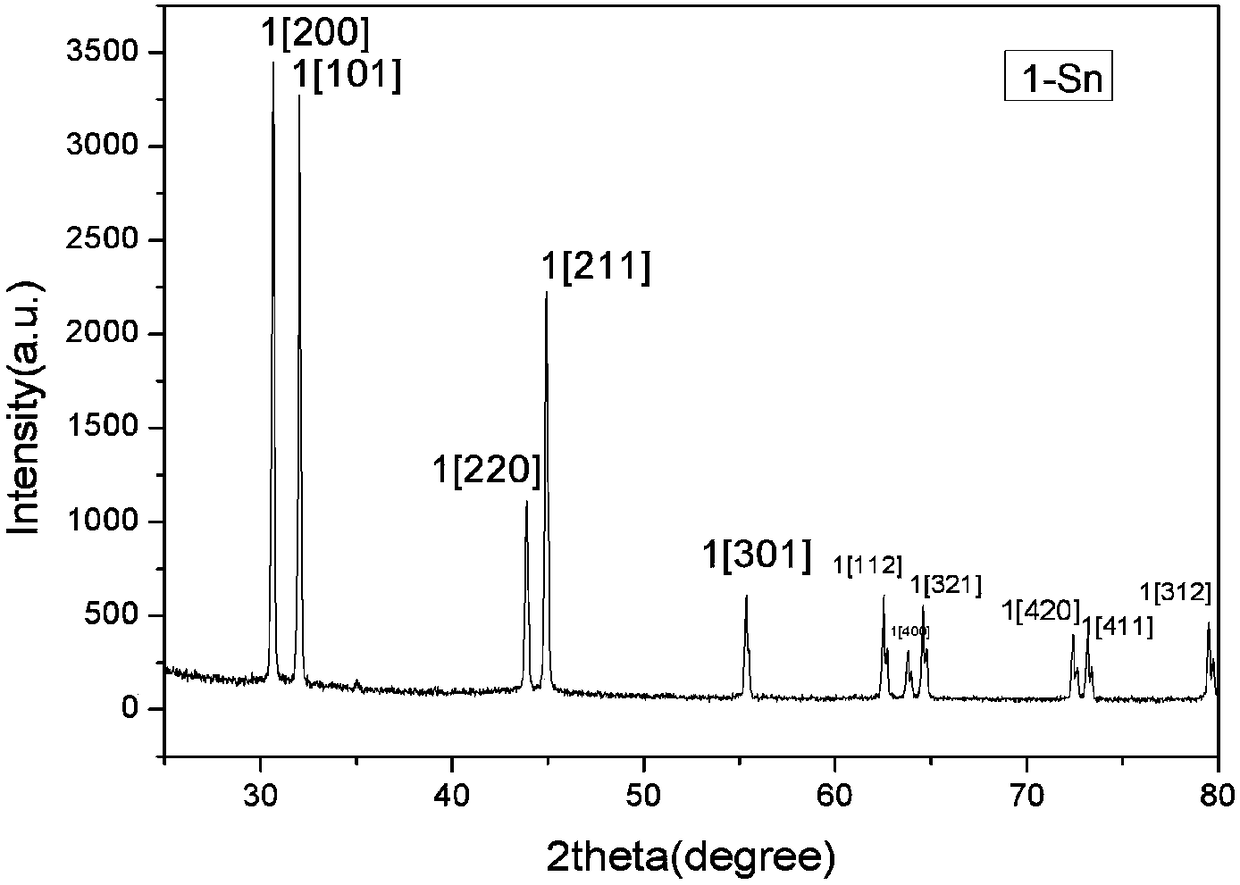

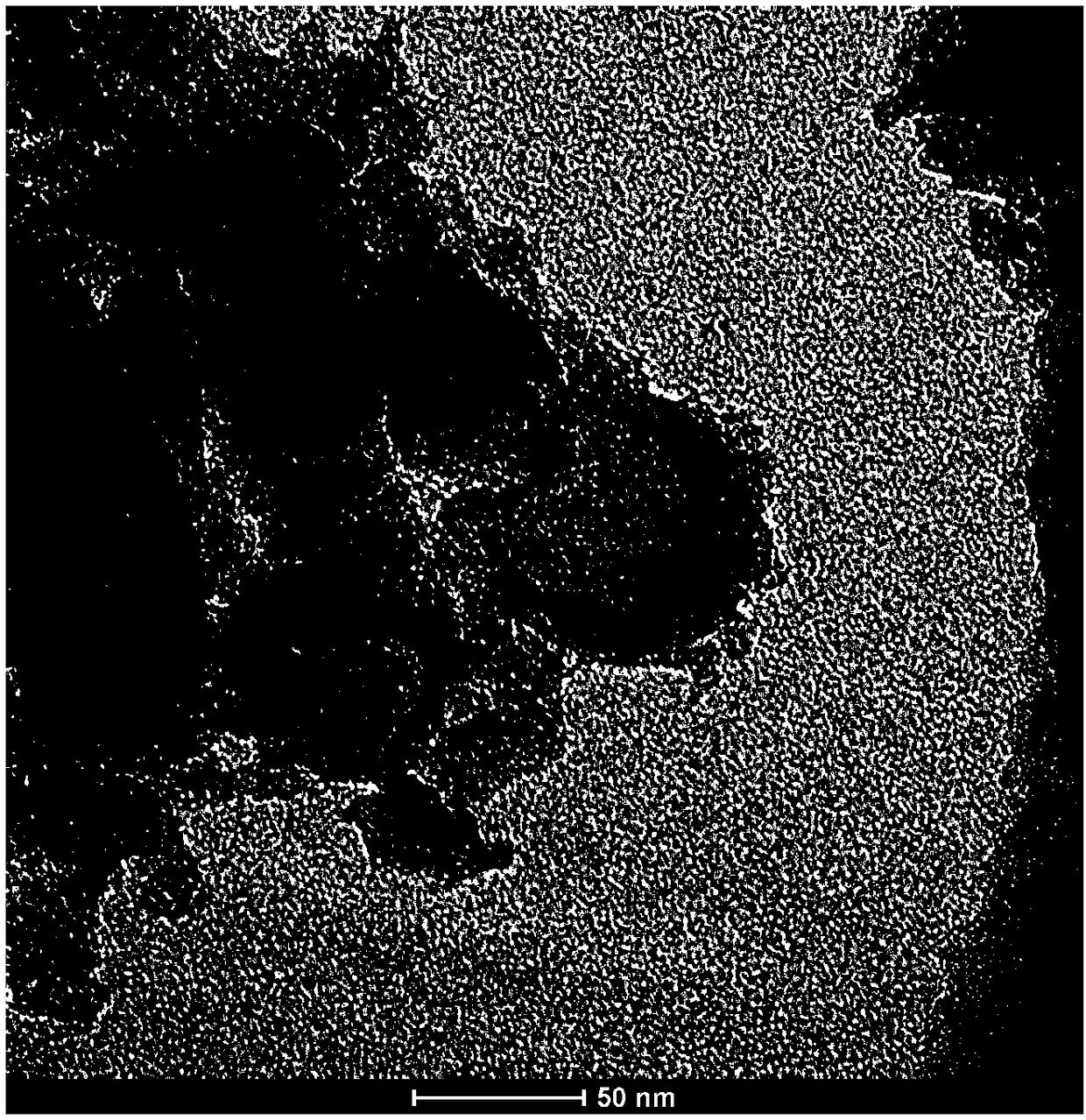

[0024] Put the uniformly mixed solution into a vacuum drying oven after suction filtration, and dry it at 100°C for 8-10 hours. After drying, put it into a tubular calciner for carbonization and reduction. o C / min heating up to 900 o C, and keep warm for 6 hours, flow Ar gas into the whole process, and naturally cool to room temperature after the end, to obtain the Sn-C composite (see figure 1 , figure 2 and image 3 ).

[0025] Take out the obtained Sn-C composite powder, conductive carbon black super P and binder PVDF and mix them in a mass ratio of 8:1:1, add an appropriate amount of organic solvent NMP to make a uniform slurry, and coat (thickness about 5 μm) On the current collector copper foil. The copper foil coated with the sample was put into a vacuum drying oven and dried in a vacuum environment for 10 hours. Take out the dried sample, punch the electrode sheet, the diameter of the electrode sheet is 13mm.

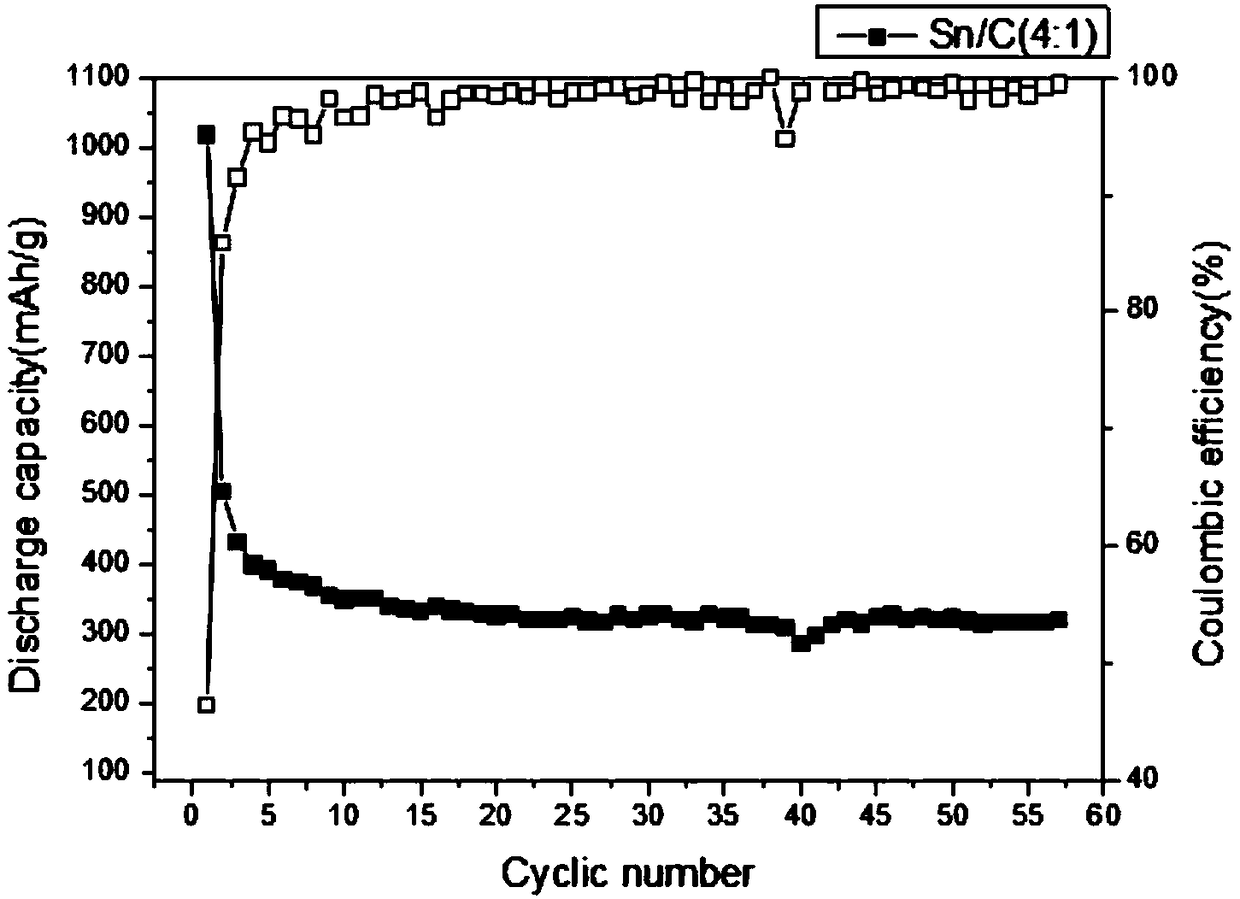

[0026] The charging and discharging performance of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com