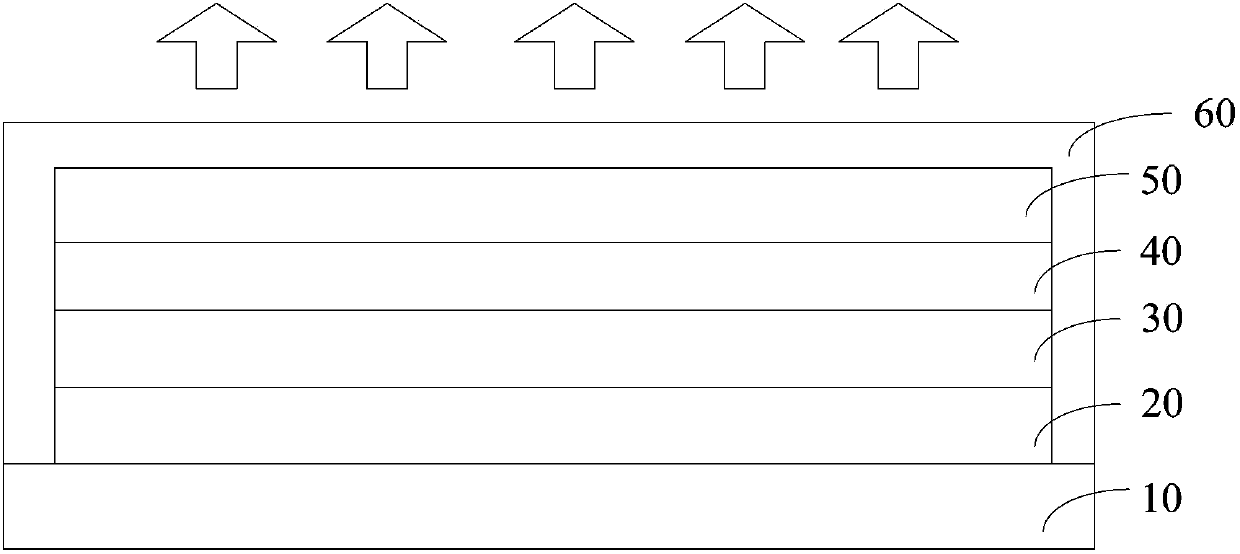

Organic light-emitting device and preparation method thereof

An electroluminescence device and electroluminescence technology, which are applied in the directions of organic semiconductor devices, materials of organic semiconductor devices, and electric solid devices, etc., and can solve the problems of no bending, fragile glass, poor mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

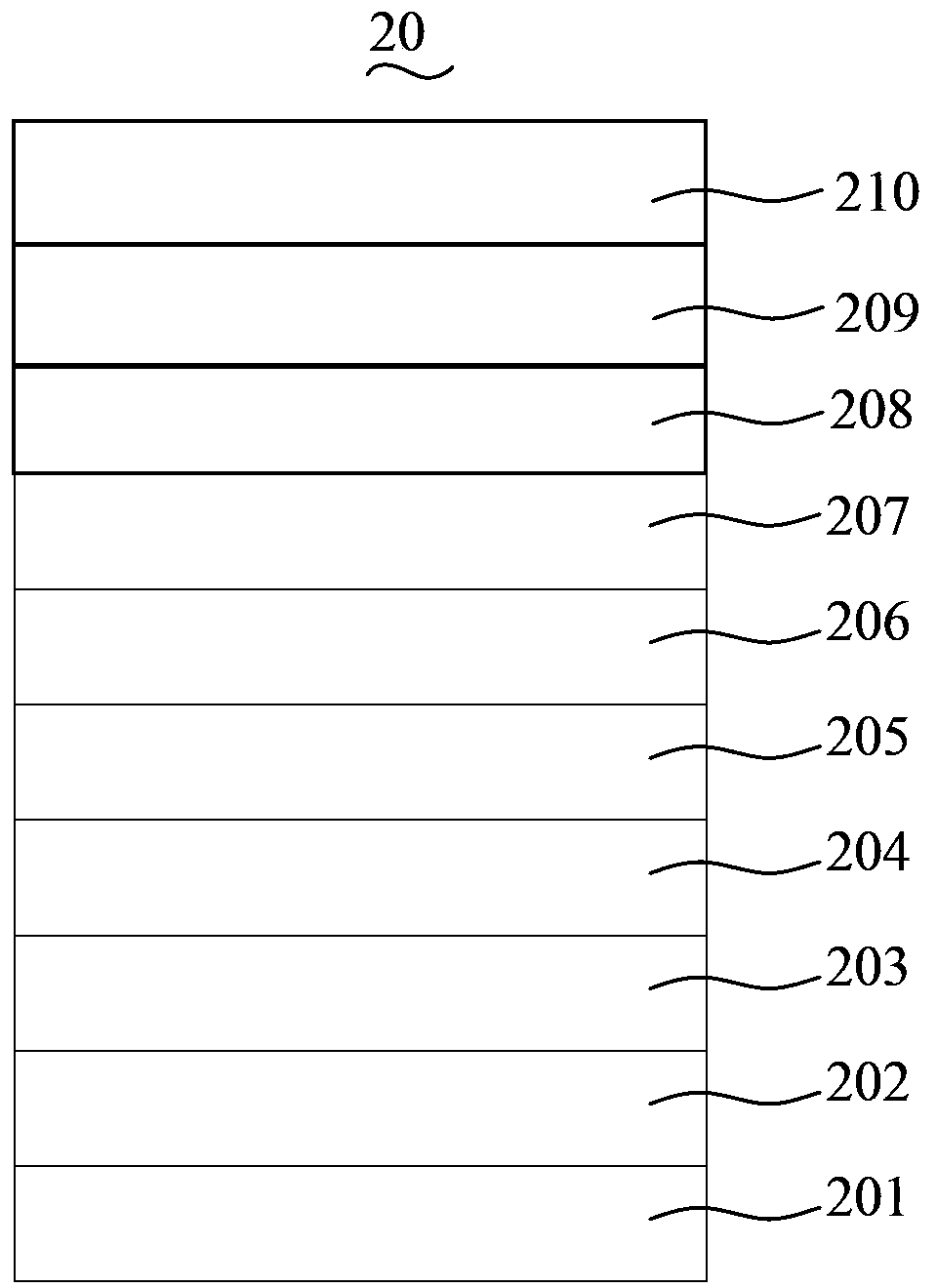

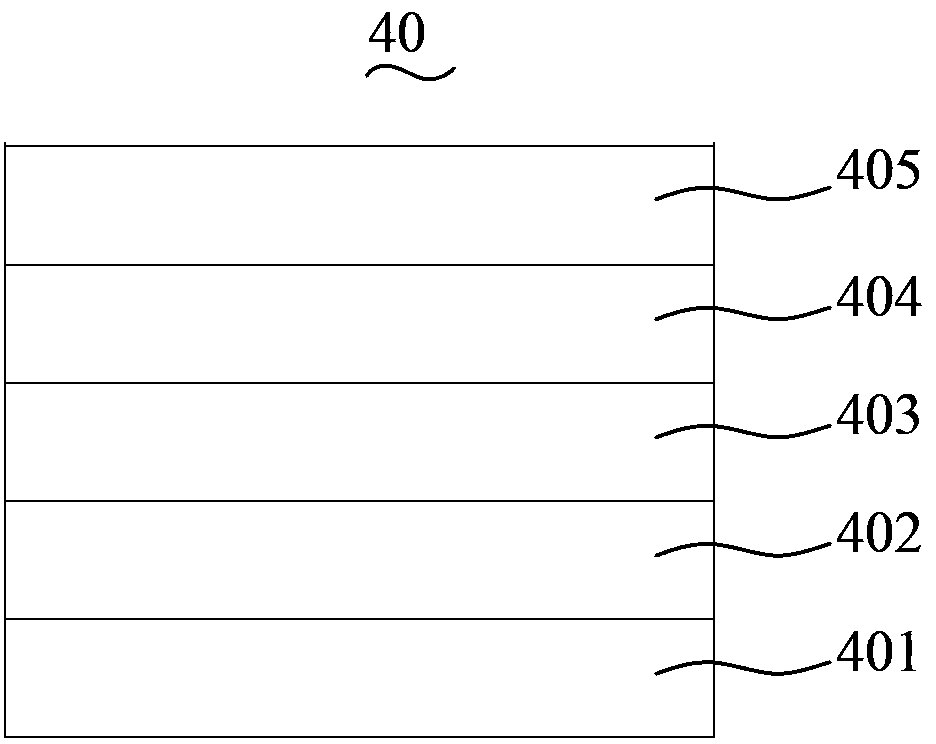

[0101] A method for preparing an organic electroluminescent device, comprising the following steps:

[0102] (1) Provide a stainless steel sheet with a thickness of 0.05mm as the substrate;

[0103] (2) Prepare a buffer layer on the substrate:

[0104] a. Get the solid p-xylene ring dimer, sublimate to gaseous state at 170°C, then crack at 690°C to obtain the gaseous monomer molecules of p-xylene with free radicals;

[0105] b. The substrate is placed in a vacuum deposition chamber, gaseous monomer molecules are introduced, and the gaseous monomer molecules are polymerized on the substrate to form a parylene film;

[0106] c. At a vacuum of 5×10 -4 In the sputter coating chamber of Pa, silicon dioxide film was prepared by sputtering on the parylene film, the sputtering conditions were acceleration voltage 500V, magnetic field 100G, power density 20W / cm 2 ;

[0107] Repeat steps a to c for a total of 5 times to prepare a buffer layer;

[0108] (3) In a vacuum of 5×10 -4 I...

Embodiment 2

[0120] A method for preparing an organic electroluminescent device, comprising the following steps:

[0121] (1) Provide a stainless steel sheet with a thickness of 0.1mm as the substrate;

[0122] (2) Prepare a buffer layer on the substrate:

[0123] a. Get the solid p-xylene ring dimer, sublimate to gaseous state at 170°C, then crack at 690°C to obtain the gaseous monomer molecules of p-xylene with free radicals;

[0124] b. The substrate is placed in a vacuum deposition chamber, gaseous monomer molecules are introduced, and the gaseous monomer molecules are polymerized on the substrate to form a parylene film;

[0125] c. At a vacuum of 1×10 -5 In the sputter coating chamber of Pa, silicon dioxide film was prepared by sputtering on the parylene film, the sputtering conditions were acceleration voltage 300V, magnetic field 50G, power density 1W / cm 2 ;

[0126] Repeat steps a to c for a total of 6 times to prepare a buffer layer;

[0127] (3) In a vacuum of 1×10 -5 In t...

Embodiment 3

[0136] A method for preparing an organic electroluminescent device, comprising the following steps:

[0137] (1) Provide a stainless steel sheet with a thickness of 0.05mm as the substrate;

[0138] (2) Prepare a buffer layer on the substrate:

[0139] a. Get the solid p-xylene ring dimer, sublimate to gaseous state at 170°C, then crack at 690°C to obtain the gaseous monomer molecules of p-xylene with free radicals;

[0140] b. The substrate is placed in a vacuum deposition chamber, gaseous monomer molecules are introduced, and the gaseous monomer molecules are polymerized on the substrate to form a parylene film;

[0141] c. At a vacuum of 1×10 -3 In the sputtering coating chamber of Pa, aluminum oxide film was prepared by sputtering on the parylene film, the sputtering conditions were acceleration voltage 800V, magnetic field 200G, power density 40W / cm 2 ;

[0142] Repeat steps a to c for a total of 3 times to prepare a buffer layer;

[0143] (3) In a vacuum of 1×10 -3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com