High-pressure-resistant and impermeable heat-preservation composite pipeline and preparation method thereof

A thermal insulation composite, anti-penetration technology, applied in the field of pipelines, can solve problems such as low pressure resistance, achieve the effects of improving strength, enhancing interface bonding, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

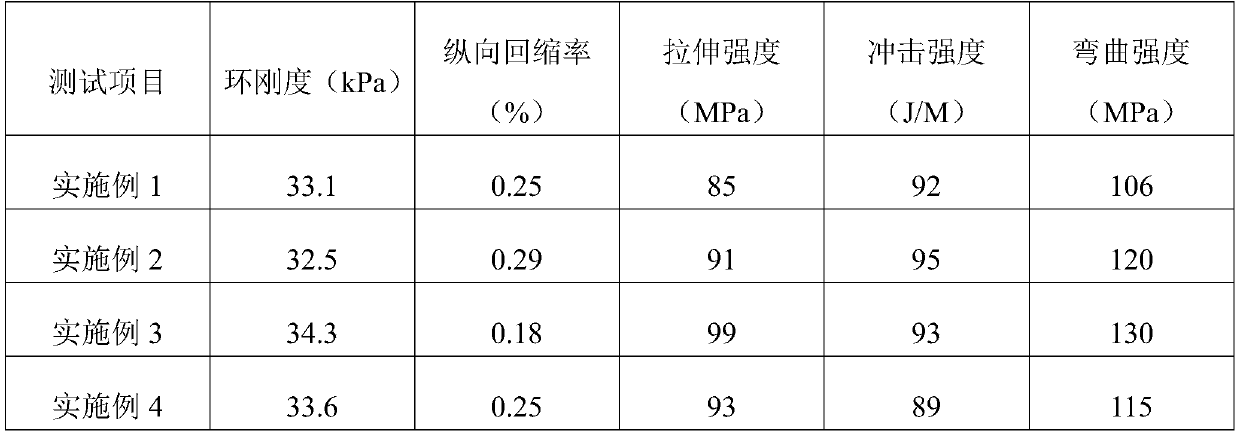

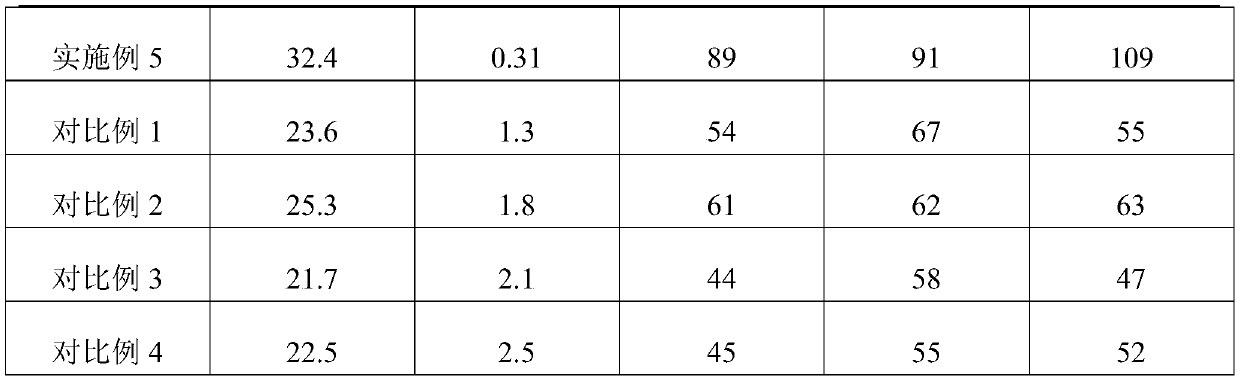

Examples

Embodiment 1

[0046] A high-pressure-resistant and anti-seepage thermal insulation composite pipeline, comprising an inner working layer, a middle insulating layer, and an outer protective layer arranged sequentially from the inside to the outside, and the inner working layer includes an anti-penetration barrier layer arranged sequentially from the inside to the outside, Polyethylene material layer, modified reinforcement layer, heat-sensitive micro-foaming adhesive layer, prepreg tape wrapping layer, polyethylene material layer is PERT-Ⅱ type high-density polyethylene material layer, anti-permeation barrier layer is made of nylon MXD6 or vinyl / vinyl alcohol copolymer, the modified reinforcement layer is glass fiber reinforced nylon MXD6 layer, the prepreg tape winding layer is glass fiber reinforced polyethylene prepreg tape layer, the middle insulation layer is polyurethane foam insulation layer, and the outer protective layer Made of high density polyethylene,

[0047] A method for prep...

Embodiment 2

[0059] A high-pressure-resistant and anti-penetration thermal insulation composite pipe, the structure of which is the same as in Example 1, and its preparation method comprises the following steps:

[0060] S1. Weigh the raw materials according to the following components by weight: 40 parts of nylon MXD6, 20 parts of glass fiber, 0.3 parts of silane coupling agent KH550, 1.2 parts of antioxidant 1010, 0.6 parts of fatty acid amide, and 7 parts of polyolefin elastomer ;

[0061] S2. Immerse the glass fibers in an aqueous solution of silane coupling agent KH550 with a mass ratio concentration of 1%, soak for 9 minutes, dry the soaked glass fibers at 80°C for 30 minutes, and then raise the temperature to 125°C for 30 minutes. , to obtain surface-treated glass fibers;

[0062] S3, mixing nylon MXD6 with antioxidant 1010, fatty acid amide, and polyolefin elastomer at the speed of high mixer 200r / min for 10min, then adding the surface-treated glass fiber obtained in step S2 throu...

Embodiment 3

[0071] A high-pressure-resistant and anti-penetration thermal insulation composite pipe, the structure of which is the same as in Example 1, and its preparation method comprises the following steps:

[0072] S1. Weigh the raw materials according to the following components by weight: 43 parts of nylon MXD6, 33 parts of glass fiber, 0.6 part of silane coupling agent KH550, 1.5 parts of antioxidant 1010, 0.7 part of fatty acid amide, and 10 parts of polyolefin elastomer ;

[0073] S2. Immerse the glass fibers in an aqueous solution of silane coupling agent KH550 with a mass ratio concentration of 1.5%, soak for 10 minutes, dry the soaked glass fibers at a temperature of 85°C for 30 minutes, and then raise the temperature to 130°C for 30 minutes. , to obtain surface-treated glass fibers;

[0074] S3, mixing nylon MXD6 with antioxidant 1010, fatty acid amide, and polyolefin elastomer at the speed of high mixer 200r / min for 10min, then adding the surface-treated glass fiber obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com